Comprehensive Review of Binder Matrices in 3D Printing Construction: Rheological Perspectives

Abstract

:1. Introduction

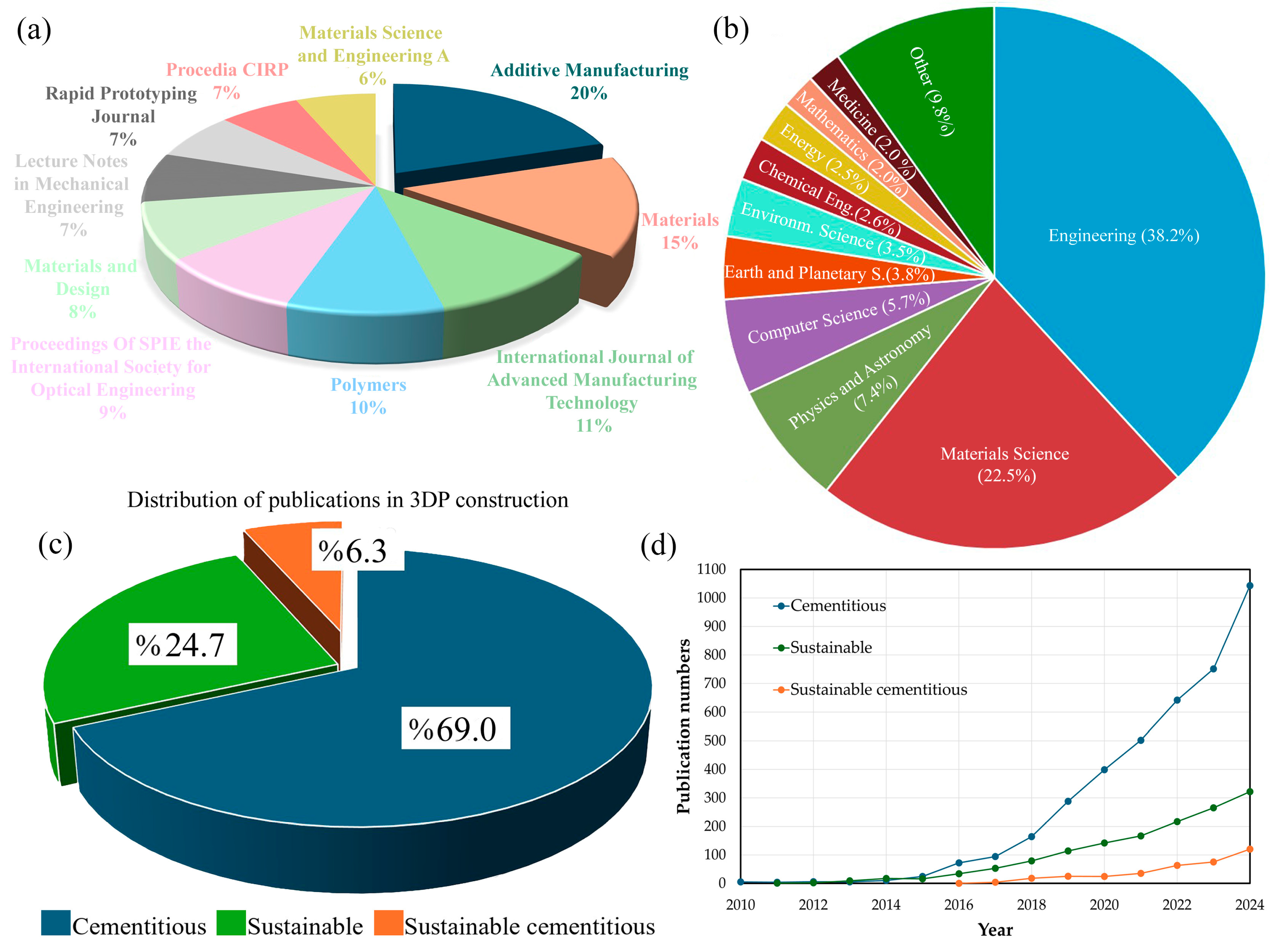

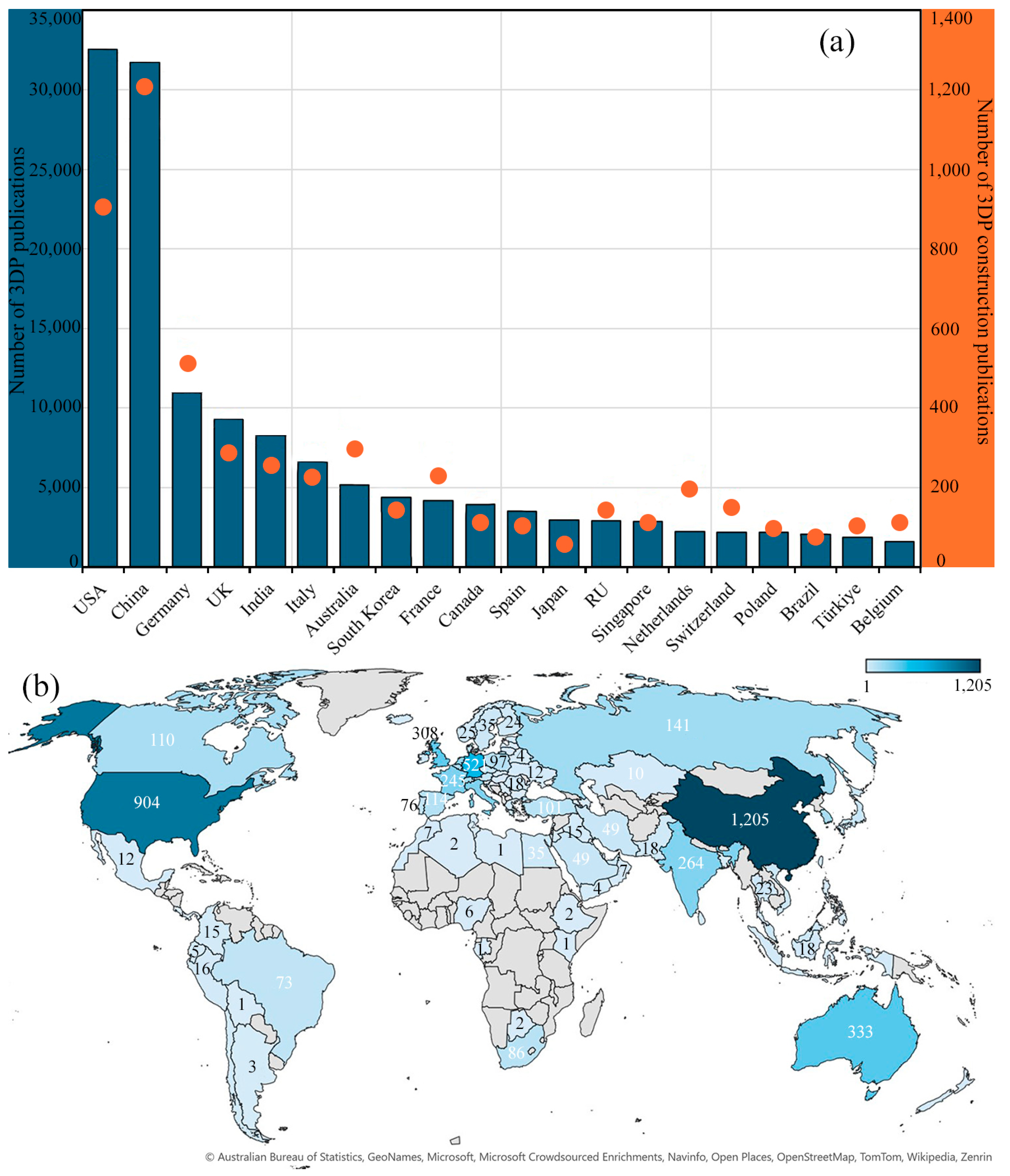

2. Review Methodology

3. Enhancing the Benefits of 3D Printing in Construction

3.1. Cement Matrix Inks

3.2. Sustainable Binders

3.2.1. Geopolymer Inks

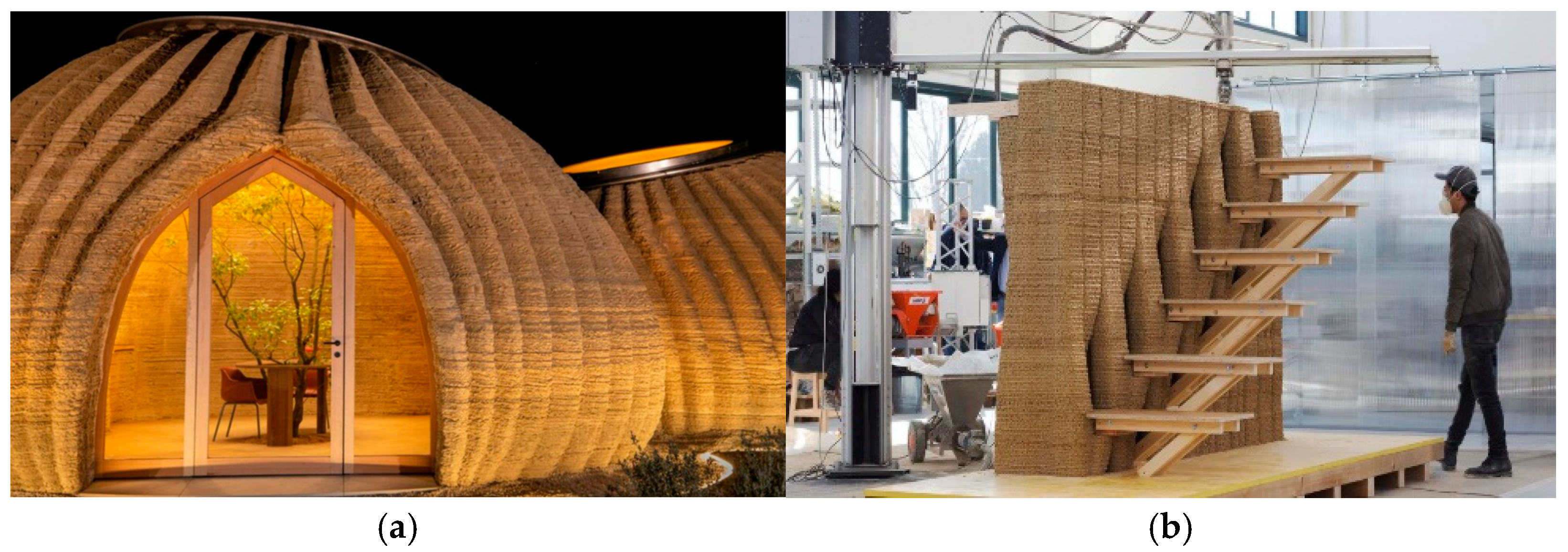

3.2.2. Earth-Based Inks

3.3. Sustainable Cementitious (Including SCMs) Binders

3.4. Foam Concrete

4. Research Findings

4.1. Yield Stress and Structural Stability

4.2. Viscosity and Flow Behavior

4.3. Thixotropy and Material Recovery

5. Future Work

5.1. Advancing Sustainability in Materials and Design

5.2. Enhancing Durability, Reinforcement, and Technological Frontiers

6. Conclusions

- Material innovation: Developing new binder materials with lower environmental impact, improved mechanical properties, and enhanced printability is crucial. This includes exploring the use of natural fibers, optimizing the mix design of sustainable binders, and investigating new polymers for reinforcement.

- Lifecycle assessment: Conducting comprehensive lifecycle assessments of 3D-printed structures will provide valuable insights into their long-term sustainability and environmental impact. This will help identify areas for improvement and promote the adoption of green materials and processes.

- Design and simulation tools: Enhancing computer-aided design (CAD) systems and simulation tools tailored for additive manufacturing will streamline the design process and improve the accuracy and efficiency of 3D printing in construction.

- Automation and reinforcement: Integrating reinforcement strategies into automated printing systems will address the structural demands of 3D-printed buildings. Research should focus on optimizing the placement and type of reinforcements to ensure the structural integrity of printed structures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Y.; Zhang, H.; Zhang, Z.; Li, Y.; Fang, H.; Yuan, J.; Tang, S. The Early-Age Cracking Sensitivity, Shrinkage, Hydration Process, Pore Structure and Micromechanics of Cement-Based Materials Containing Alkalis with Different Metal Ions. Dev. Built Environ. 2024, 18, 100454. [Google Scholar] [CrossRef]

- Feng, W.; Li, Z.; Long, Q.; Tang, S.; Zhao, Y. Study on the Properties of Autoclaved Aerated Concrete with High Content Concrete Slurry Waste. Dev. Built Environ. 2024, 17, 100338. [Google Scholar] [CrossRef]

- Wangler, T.; Lloret, E.; Reiter, L.; Hack, N.; Gramazio, F.; Kohler, M.; Bernhard, M.; Dillenburger, B.; Buchli, J.; Roussel, N.; et al. Digital Concrete: Opportunities and Challenges. RILEM Tech. Lett. 2016, 1, 67–75. [Google Scholar] [CrossRef]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and Hardened Properties of 3D Printable Cementitious Materials for Building and Construction. Arch. Civil. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- Wi, K.; Suresh, V.; Wang, K.; Li, B.; Qin, H. Quantifying Quality of 3D Printed Clay Objects Using a 3D Structured Light Scanning System. Addit. Manuf. 2020, 32, 100987. [Google Scholar] [CrossRef]

- Bock, T. The Future of Construction Automation: Technological Disruption and the Upcoming Ubiquity of Robotics. Autom. Constr. 2015, 59, 113–121. [Google Scholar] [CrossRef]

- Alaloul, W.S.; Liew, M.S.; Zawawi, N.A.W.A.; Mohammed, B.S. Industry Revolution IR 4.0: Future Opportunities and Challenges in Construction Industry. MATEC Web Conf. 2018, 203, 02010. [Google Scholar] [CrossRef]

- Craveiro, F.; Duarte, J.P.; Bartolo, H.; Bartolo, P.J. Additive Manufacturing as an Enabling Technology for Digital Construction: A Perspective on Construction 4.0. Autom. Constr. 2019, 103, 251–267. [Google Scholar] [CrossRef]

- Zhang, Z.; Demir, K.G.; Gu, G.X. Developments in 4D-Printing: A Review on Current Smart Materials, Technologies, and Applications. Int. J. Smart Nano Mater. 2019, 10, 205–224. [Google Scholar] [CrossRef]

- Craveiro, F.; Duarte, J.P.; Bártolo, H.; Bártolo, P. Moving Forward to 3D/4D Printed Building Facades. In Progress in Digital and Physical Manufacturing; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2020; pp. 277–282. [Google Scholar] [CrossRef]

- Mogale, S.P. 3D Concrete Printing Technology: Enhancing Productivity in the South African Construction Industry-Exploring the Benefits, Barriers, and Improvement Strategies. Master’s Thesis, Stellenbosch University, Stellenbosch, South Africa, 2023. [Google Scholar]

- Jadhav, A.; Jadhav, V.S. A Review on 3D Printing: An Additive Manufacturing Technology. Mater. Today Proc. 2022, 62, 2094–2099. [Google Scholar] [CrossRef]

- Tu, H.; Wei, Z.; Bahrami, A.; Ben Kahla, N.; Ahmad, A.; Özkılıç, Y.O. Recent Advancements and Future Trends in 3D Concrete Printing Using Waste Materials. Dev. Built Environ. 2023, 16, 100187. [Google Scholar] [CrossRef]

- Nodehi, M.; Aguayo, F.; Nodehi, S.E.; Gholampour, A.; Ozbakkaloglu, T.; Gencel, O. Durability Properties of 3D Printed Concrete (3DPC). Autom. Constr. 2022, 142, 104479. [Google Scholar] [CrossRef]

- Akman, A.; Sadhu, A. Recent Development of 3D-Printing Technology in Construction Engineering. Pract. Period. Struct. Des. Constr. 2023, 29, 03123005. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Rehman, A.U.; Kim, J.H. 3D Concrete Printing: A Systematic Review of Rheology, Mix Designs, Mechanical, Microstructural, and Durability Characteristics. Materials 2021, 14, 3800. [Google Scholar] [CrossRef] [PubMed]

- El-Sayegh, S.; Romdhane, L.; Manjikian, S. A Critical Review of 3D Printing in Construction: Benefits, Challenges, and Risks. Arch. Civil. Mech. Eng. 2020, 20, 34. [Google Scholar] [CrossRef]

- Praveena, B.A.; Lokesh, N.; Buradi, A.; Santhosh, N.; Praveena, B.L.; Vignesh, R. A Comprehensive Review of Emerging Additive Manufacturing (3D Printing Technology): Methods, Materials, Applications, Challenges, Trends and Future Potential. Mater. Today Proc. 2022, 52, 1309–1313. [Google Scholar] [CrossRef]

- Tarhan, Y.; Şahin, R. Fresh and Rheological Performances of Air-Entrained 3D Printable Mortars. Materials 2021, 14, 2409. [Google Scholar] [CrossRef] [PubMed]

- Takagishi, K.; Umezu, S. Development of the Improving Process for the 3D Printed Structure. Sci. Rep. 2017, 7, 39852. [Google Scholar] [CrossRef] [PubMed]

- Shah, J.; Snider, B.; Clarke, T.; Kozutsky, S.; Lacki, M.; Hosseini, A. Large-Scale 3D Printers for Additive Manufacturing: Design Considerations and Challenges. Int. J. Adv. Manuf. Technol. 2019, 104, 3679–3693. [Google Scholar] [CrossRef]

- Žujović, M.; Obradović, R.; Rakonjac, I.; Milošević, J. 3D Printing Technologies in Architectural Design and Construction: A Systematic Literature Review. Buildings 2022, 12, 1319. [Google Scholar] [CrossRef]

- Tarhan, Y.; Craveiro, F.; Bartolo, H. An Overview of Binder Materials’ Sustainability for 3D Printing in Construction. In Progress in Digital and Physical Manufacturing; Springer: Cham, Switzerland, 2023; pp. 291–302. [Google Scholar] [CrossRef]

- Lu, B.; Zhu, W.; Weng, Y.; Liu, Z.; Yang, E.H.; Leong, K.F.; Tan, M.J.; Wong, T.N.; Qian, S. Study of MgO-Activated Slag as a Cementless Material for Sustainable Spray-Based 3D Printing. J. Clean. Prod. 2020, 258, 120671. [Google Scholar] [CrossRef]

- Singh, N.; Colangelo, F.; Farina, I. Sustainable Non-Conventional Concrete 3D Printing—A Review. Sustainability 2023, 15, 10121. [Google Scholar] [CrossRef]

- Rudziewicz, M.; Maroszek, M.; Góra, M.; Dziura, P.; Mróz, K.; Hager, I.; Hebda, M. Feasibility Review of Aerated Materials Application in 3D Concrete Printing. Materials 2023, 16, 6032. [Google Scholar] [CrossRef]

- Al-Tamimi, A.K.; Alqamish, H.H.; Khaldoune, A.; Alhaidary, H.; Shirvanimoghaddam, K. Framework of 3D Concrete Printing Potential and Challenges. Buildings 2023, 13, 827. [Google Scholar] [CrossRef]

- Motalebi, A.; Khondoker, M.A.H.; Kabir, G. A Systematic Review of Life Cycle Assessments of 3D Concrete Printing. Sustain. Oper. Comput. 2024, 5, 41–50. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Tetik, M.; Mohite, A.; Peltokorpi, A.; Li, M.; Weng, Y.; Holmström, J. Additive Manufacturing in the Construction Industry: The Comparative Competitiveness of 3D Concrete Printing. Appl. Sci. 2021, 11, 3865. [Google Scholar] [CrossRef]

- Batikha, M.; Jotangia, R.; Baaj, M.Y.; Mousleh, I. 3D Concrete Printing for Sustainable and Economical Construction: A Comparative Study. Autom. Constr. 2022, 134, 104087. [Google Scholar] [CrossRef]

- Bhattacherjee, S.; Basavaraj, A.S.; Rahul, A.V.; Santhanam, M.; Gettu, R.; Panda, B.; Schlangen, E.; Chen, Y.; Copuroglu, O.; Ma, G.; et al. Sustainable Materials for 3D Concrete Printing. Cem. Concr. Compos. 2021, 122, 104156. [Google Scholar] [CrossRef]

- Anonymous. THE 17 GOALS | Sustainable Development. Available online: https://sdgs.un.org/goals (accessed on 15 May 2024).

- De Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti-Juan, I. Vision of 3D Printing with Concrete—Technical, Economic and Environmental Potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Markin, V.; Nerella, V.N.; Schröfl, C.; Guseynova, G.; Mechtcherine, V. Material Design and Performance Evaluation of Foam Concrete for Digital Fabrication. Materials 2019, 12, 2433. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Law, R.; Gibb, A.G.F.; Thorpe, T. Hardened Properties of High-Performance Printing Concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef]

- Rückrich, S.; Agranati, G.; Grobman, Y.J. Earth-Based Additive Manufacturing: A Field-Oriented Methodology for Evaluating Material Printability. Archit. Sci. Rev. 2023, 66, 133–143. [Google Scholar] [CrossRef]

- Ahmed, G.H.; Askandar, N.H.; Jumaa, G.B. A Review of Largescale 3DCP: Material Characteristics, Mix Design, Printing Process, and Reinforcement Strategies. Structures 2022, 43, 508–532. [Google Scholar] [CrossRef]

- Nair, A.; Aditya, S.D.; Adarsh, R.N.; Nandan, M.; Dharek, M.S.; Sreedhara, B.M.; Prashant, S.C.; Sreekeshava, K.S. Additive Manufacturing of Concrete: Challenges and Opportunities. IOP Conf. Ser. Mater. Sci. Eng. 2020, 814, 012022. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; She, W.; Yang, L.; Liu, G.; Yang, Y. Rheological and Harden Properties of the High-Thixotropy 3D Printing Concrete. Constr. Build. Mater. 2019, 201, 278–285. [Google Scholar] [CrossRef]

- Dilawar Riaz, R.; Usman, M.; Ali, A.; Majid, U.; Faizan, M.; Jalil Malik, U. Inclusive Characterization of 3D Printed Concrete (3DPC) in Additive Manufacturing: A Detailed Review. Constr. Build. Mater. 2023, 394, 132229. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.F.; Thorpe, T. Mix Design and Fresh Properties for High-Performance Printing Concrete. Mater. Struct. /Mater. et Constr. 2012, 45, 1221–1232. [Google Scholar] [CrossRef]

- Tarhan, Y.; Şahin, R. Developments of 3D concrete printing process. In Proceedings of the International Civil Engineering & Architecture Conference, Trabzon, Turkey, 17–20 April 2019; pp. 2394–2404. [Google Scholar]

- Weng, Y.; Lu, B.; Li, M.; Liu, Z.; Tan, M.J.; Qian, S. Empirical Models to Predict Rheological Properties of Fiber Reinforced Cementitious Composites for 3D Printing. Constr. Build. Mater. 2018, 189, 676–685. [Google Scholar] [CrossRef]

- Roussel, N. Rheological Requirements for Printable Concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Yang, E.-H.; Sahmaran, M.; Yang, Y.; Li, V.C. Rheological Control in Production of Engineered Cementitious Composites. ACI Mater. J. 2009, 106, 357. [Google Scholar] [CrossRef]

- Wi, K.; Wang, K.; Taylor, P.C.; Laflamme, S.; Sritharan, S.; Qin, H. Properties and Microstructure of Extrusion-Based 3D Printing Mortar Containing a Highly Flowable, Rapid Set Grout. Cem. Concr. Compos. 2021, 124, 104243. [Google Scholar] [CrossRef]

- Antoni, A.; Adi, N.; Kurniawan, M.E.; Agraputra, A.; Teopilus, D.; Pudjisuryadi, P.; Chandra, J.; Hardjito, D. The Influence of Viscosity-Modifying Agent and Calcium Carbonate on 3D Printing Mortar Characteristics. IOP Conf. Ser. Earth Environ. Sci. 2023, 1195, 012021. [Google Scholar] [CrossRef]

- Zaid, O.; El Ouni, M.H. Advancements in 3D Printing of Cementitious Materials: A Review of Mineral Additives, Properties, and Systematic Developments. Constr. Build. Mater. 2024, 427, 136254. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L. Printable Properties of Cementitious Material Containing Copper Tailings for Extrusion Based 3D Printing. Constr. Build. Mater. 2018, 162, 613–627. [Google Scholar] [CrossRef]

- Moeini, M.A.; Hosseinpoor, M.; Yahia, A. Use of the Chemical and Mineral Admixtures to Tailor the Rheology and the Green Strength of 3D Printing Cementitious Mixtures. RILEM Bookseries 2020, 28, 73–82. [Google Scholar] [CrossRef]

- Said, F.; Eldwib, D.; Zaytoun, M.; Abd Elsalam, A.; Bakhoum, M.; Elshehemy, O.; Abou Ali, R.; El-Gamal, S.; Abou-Zeid, M. 3D Printing Concrete Incoroprating Environmentally Friendly Materials. Lect. Notes Civil. Eng. 2023, 248, 627–639. [Google Scholar] [CrossRef]

- Volpe, S.; Sangiorgio, V.; Petrella, A.; Coppola, A.; Notarnicola, M.; Fiorito, F. Building Envelope Prefabricated with 3D Printing Technology. Sustainability 2021, 13, 8923. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Liu, G.; Yang, Y.; Wu, M.; Pang, B. Fresh Properties of a Novel 3D Printing Concrete Ink. Constr. Build. Mater. 2018, 174, 263–271. [Google Scholar] [CrossRef]

- Papachristoforou, M.; Mitsopoulos, V.; Stefanidou, M. Evaluation of Workability Parameters in 3D Printing Concrete. Procedia Struct. Integr. 2018, 10, 155–162. [Google Scholar] [CrossRef]

- Dai, P.; Lyu, Q.; Zong, M.; Zhu, P. Effect of Waste Plastic Fibers on the Printability and Mechanical Properties of 3D-Printed Cement Mortar. J. Build. Eng. 2024, 83, 108439. [Google Scholar] [CrossRef]

- Statkauskas, M.; Grinys, A.; Vaičiukynienė, D. Investigation of Concrete Shrinkage Reducing Additives. Materials 2022, 15, 3407. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Q.; Liu, Q.; Wu, S.; Zheng, H.; Sun, W. Modification Effect of Nanosilica and Polypropylene Fiber for Extrusion-Based 3D Printing Concrete: Printability and Mechanical Anisotropy. Addit. Manuf. 2022, 56, 102944. [Google Scholar] [CrossRef]

- Chao, Y.; Zhang, H.; Li, J.; Duong, T.Q.; Korolev, E.; Inozemtcev, A. Selection of Reinforcing Fiber for High-Strength Lightweight Concrete for 3D-Printing. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1030, 012007. [Google Scholar] [CrossRef]

- Marczyk, J.; Ziejewska, C.; Gadek, S.; Korniejenko, K.; Łach, M.; Góra, M.; Kurek, I.; Dogan-Saglamtimur, N.; Hebda, M.; Szechynska-Hebda, M. Hybrid Materials Based on Fly Ash, Metakaolin, and Cement for 3d Printing. Materials 2021, 14, 6874. [Google Scholar] [CrossRef]

- Chougan, M.; Hamidreza Ghaffar, S.; Nematollahi, B.; Sikora, P.; Dorn, T.; Stephan, D.; Albar, A.; Al-Kheetan, M.J. Effect of Natural and Calcined Halloysite Clay Minerals as Low-Cost Additives on the Performance of 3D-Printed Alkali-Activated Materials. Mater. Des. 2022, 223, 111183. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Zou, S.; Wang, Y. Hardened Properties of Layered 3D Printed Concrete with Recycled Sand. Cem. Concr. Compos. 2020, 113, 103724. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Kua, H.W.; Yu, L.N.; Chung, J.K.H. Fresh Properties of Cementitious Materials Containing Rice Husk Ash for Construction 3D Printing. J. Mater. Civil. Eng. 2020, 32, 04020195. [Google Scholar] [CrossRef]

- Bos, F.P.; Kruger, P.J.; Lucas, S.S.; van Zijl, G.P.A.G. Juxtaposing Fresh Material Characterisation Methods for Buildability Assessment of 3D Printable Cementitious Mortars. Cem. Concr. Compos. 2021, 120, 104024. [Google Scholar] [CrossRef]

- Rahul, A.V.; Sharma, A.; Santhanam, M. A Desorptivity-Based Approach for the Assessment of Phase Separation during Extrusion of Cementitious Materials. Cem. Concr. Compos. 2020, 108, 103546. [Google Scholar] [CrossRef]

- Kazemian, A.; Yuan, X.; Meier, R.; Khoshnevis, B. Performance-Based Testing of Portland Cement Concrete for Construction-Scale 3D Printing. 3d Concr. Print. Technol. Constr. Build. Appl. 2019, 13–35. [Google Scholar] [CrossRef]

- Hambach, M.; Rutzen, M.; Volkmer, D. Properties of 3D-Printed Fiber-Reinforced Portland Cement Paste. 3d Concr. Print. Technol. Constr. Build. Appl. 2019, 73–113. [Google Scholar] [CrossRef]

- Perrot, A.; Rangeard, D.; Pierre, A. Structural Built-up of Cement-Based Materials Used for 3D-Printing Extrusion Techniques. Mater. Struct./Mater. et Constr. 2016, 49, 1213–1220. [Google Scholar] [CrossRef]

- Ibrahim, K.A.; Van Zijl, G.P.A.G.; Babafemi, A.J. Influence of Limestone Calcined Clay Cement on Properties of 3D Printed Concrete for Sustainable Construction. J. Build. Eng. 2023, 69, 2352–7102. [Google Scholar] [CrossRef]

- Qiu, M.; Sun, Y.; Qian, Y. Interfacial Bonding Performance of 3D-Printed Ultra-High Performance Strain-Hardening Cementitious Composites (UHP-SHCC) and Cast Normal Concrete. J. Build. Eng. 2024, 82, 108268. [Google Scholar] [CrossRef]

- Singh, A.; Wang, Y.; Zhou, Y.; Sun, J.; Xu, X.; Li, Y.; Liu, Z.; Chen, J.; Wang, X. Utilization of Antimony Tailings in Fiber-Reinforced 3D Printed Concrete: A Sustainable Approach for Construction Materials. Constr. Build. Mater. 2023, 408, 133689. [Google Scholar] [CrossRef]

- Lucen, H.; Long, L.; Shipeng, Z.; Huanghua, Z.; Jianzhuang, X.; Chi Sun, P. The Synergistic Effect of Greenhouse Gas CO2 and Silica Fume on the Properties of 3D Printed Mortar. Compos. B Eng. 2024, 271, 111188. [Google Scholar] [CrossRef]

- Teh, S.H.; Wiedmann, T.; Castel, A.; de Burgh, J. Hybrid Life Cycle Assessment of Greenhouse Gas Emissions from Cement, Concrete and Geopolymer Concrete in Australia. J. Clean. Prod. 2017, 152, 312–320. [Google Scholar] [CrossRef]

- Zhang, C.; Nerella, V.N.; Krishna, A.; Wang, S.; Zhang, Y.; Mechtcherine, V.; Banthia, N. Mix Design Concepts for 3D Printable Concrete: A Review. Cem. Concr. Compos. 2021, 122, 104155. [Google Scholar] [CrossRef]

- Zhang, X.; Heeren, N.; Bauer, C.; Burgherr, P.; McKenna, R.; Habert, G. The Impacts of Future Sectoral Change on the Greenhouse Gas Emissions of Construction Materials for Swiss Residential Buildings. Energy Build. 2024, 303, 113824. [Google Scholar] [CrossRef]

- Mohamad, N.; Muthusamy, K.; Embong, R.; Kusbiantoro, A.; Hashim, M.H. Environmental Impact of Cement Production and Solutions: A Review. Mater. Today Proc. 2022, 48, 741–746. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Bhusan Das, B.; Adak, D. Roadmap to a Net-Zero Carbon Cement Sector: Strategies, Innovations and Policy Imperatives. J. Environ. Manag. 2024, 359, 121052. [Google Scholar] [CrossRef]

- Cavalett, O.; Watanabe, M.D.B.; Voldsund, M.; Roussanaly, S.; Cherubini, F. Paving the Way for Sustainable Decarbonization of the European Cement Industry. Nat. Sustain. 2024, 7, 568–580. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Kanavaris, F.; Das, B.B.; Idrees, M. Decarbonising Cement and Concrete Production: Strategies, Challenges and Pathways for Sustainable Development. J. Build. Eng. 2024, 86, 108861. [Google Scholar] [CrossRef]

- Griffiths, S.; Sovacool, B.K.; Furszyfer Del Rio, D.D.; Foley, A.M.; Bazilian, M.D.; Kim, J.; Uratani, J.M. Decarbonizing the Cement and Concrete Industry: A Systematic Review of Socio-Technical Systems, Technological Innovations, and Policy Options. Renew. Sustain. Energy Rev. 2023, 180, 113291. [Google Scholar] [CrossRef]

- Jotangia, R.; Batikha, M. Heriot-Watt University’s Centre of Excellence in Smart Construction Research Bulletin. Heriot-Watt University: Edinburgh, UK, 2021; pp. 31–35. [Google Scholar]

- Tonelli, M.; Faralli, A.; Ridi, F.; Bonini, M. 3D Printable Magnesium-Based Cements towards the Preparation of Bioceramics. J. Colloid. Interface Sci. 2021, 598, 24–35. [Google Scholar] [CrossRef] [PubMed]

- Panda, B.; Sonat, C.; Yang, E.H.; Tan, M.J.; Unluer, C. Use of Magnesium-Silicate-Hydrate (M-S-H) Cement Mixes in 3D Printing Applications. Cem. Concr. Compos. 2021, 117, 103901. [Google Scholar] [CrossRef]

- Tayyab, A.; Kienzle, A.; Thomas, R.J. Engineering Properties and Setting Time of Belitic Calcium Sulfoaluminate (BCSA) Cement Concrete. Constr. Build. Mater. 2022, 352, 128979. [Google Scholar] [CrossRef]

- Olajire, A.A. A Review of Mineral Carbonation Technology in Sequestration of CO2. J. Pet. Sci. Eng. 2013, 109, 364–392. [Google Scholar] [CrossRef]

- Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. 3D Concrete Printing of Eco-Friendly Geopolymer Containing Brick Waste. Cem. Concr. Compos. 2023, 138, 104943. [Google Scholar] [CrossRef]

- Reddy, M.S.; Dinakar, P.; Rao, B.H. Mix Design Development of Fly Ash and Ground Granulated Blast Furnace Slag Based Geopolymer Concrete. J. Build. Eng. 2018, 20, 712–722. [Google Scholar] [CrossRef]

- Khalil, N.; Aouad, G.; El Cheikh, K.; Rémond, S. Use of Calcium Sulfoaluminate Cements for Setting Control of 3D-Printing Mortars. Constr. Build. Mater. 2017, 157, 382–391. [Google Scholar] [CrossRef]

- Abu-Ennab, L.; Dixit, M.K.; Birgisson, B.; Pradeep Kumar, P. Comparative Life Cycle Assessment of Large-Scale 3D Printing Utilizing Kaolinite-Based Calcium Sulfoaluminate Cement Concrete and Conventional Construction. Clean. Environ. Syst. 2022, 5, 100078. [Google Scholar] [CrossRef]

- de Matos, P.R.; Zat, T.; Lima, M.M.; Andrade Neto, J.d.S.; Souza, M.T.; Rodríguez, E.D. Effect of the Superplasticizer Addition Time on the Fresh Properties of 3D Printed Limestone Calcined Clay Cement (LC3) Concrete. Case Stud. Constr. Mater. 2023, 19, e02419. [Google Scholar] [CrossRef]

- Wang, X.; Krishnan, P.; Celik, K. Enhancing Carbonation and Thermal Insulation of Reactive Magnesium Oxide Cement (RMC)-Based 3D Printable Pastes with Cenospheres. Cem. Concr. Compos. 2024, 150, 105559. [Google Scholar] [CrossRef]

- Khalil, A.; Wang, X.; Celik, K. 3D Printable Magnesium Oxide Concrete: Towards Sustainable Modern Architecture. Addit. Manuf. 2020, 33, 101145. [Google Scholar] [CrossRef]

- Liao, Y.; Cai, Z.; Deng, F.; Ye, J.; Wang, K.; Tang, S. Hydration Behavior and Thermodynamic Modelling of Ferroaluminate Cement Blended with Steel Slag. J. Build. Eng. 2024, 97, 110833. [Google Scholar] [CrossRef]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-Efficient Cements: Potential Economically Viable Solutions for a Low-CO2 Cement-Based Materials Industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Chaunsali, P.; Mondal, P. Influence of Calcium Sulfoaluminate (CSA) Cement Content on Expansion and Hydration Behavior of Various Ordinary Portland Cement-CSA Blends. J. Am. Ceram. Soc. 2015, 98, 2617–2624. [Google Scholar] [CrossRef]

- Chaunsali, P.; Ardeshirilajimi, A.; Mondal, P. On the Interaction of Class C Fly Ash with Portland Cement–Calcium Sulfoaluminate Cement Binder. Mater. Struct./Mater. et Constr. 2018, 51, 1–9. [Google Scholar] [CrossRef]

- Mohan, M.K.; Rahul, A.V.; De Schutter, G.; Van Tittelboom, K. Early Age Hydration, Rheology and Pumping Characteristics of CSA Cement-Based 3D Printable Concrete. Constr. Build. Mater. 2021, 275, 122136. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Monteiro, P.J.M.; Gastaldi, M.M. Investigation of the Mechanical and Durability Properties of Sustainable High Performance Concrete Based on Calcium Sulfoaluminate Cement. J. Build. Eng. 2021, 43, 102656. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, T.; Faried, M.; Chen, W. 3D Printing Cement Based Ink, and It’s Application within the Construction Industry. MATEC Web Conf. 2017, 120, 02003. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, D.; Li, H.; Sun, X.; Zhao, K.; Wang, Y. Effect of FA and GGBFS on Compressive Strength, Rheology, and Printing Properties of Cement-Based 3D Printing Material. Constr. Build. Mater. 2022, 339, 127685. [Google Scholar] [CrossRef]

- Rubio, M.; Sonebi, M.; Amziane, S. 3D Printing of Fibre Cement-Based Materials: Fresh and Rheological Performances. Acad. J. Civil. Eng. 2017, 35, 480–488. [Google Scholar] [CrossRef]

- Yuan, Q.; Li, Z.; Zhou, D.; Huang, T.; Huang, H.; Jiao, D.; Shi, C. A Feasible Method for Measuring the Buildability of Fresh 3D Printing Mortar. Constr. Build. Mater. 2019, 227, 116600. [Google Scholar] [CrossRef]

- Kruger, J.; Zeranka, S.; van Zijl, G. A Rheology-Based Quasi-Static Shape Retention Model for Digitally Fabricated Concrete. Constr. Build. Mater. 2020, 254, 119241. [Google Scholar] [CrossRef]

- Kruger, J.; Zeranka, S.; van Zijl, G. An Ab Initio Approach for Thixotropy Characterisation of (Nanoparticle-Infused) 3D Printable Concrete. Constr. Build. Mater. 2019, 224, 372–386. [Google Scholar] [CrossRef]

- Lee, K.-W.; Lee, H.-J.; Choi, M.-S. Correlation between Thixotropic Behavior and Buildability for 3D Concrete Printing. Constr. Build. Mater. 2022, 347, 128498. [Google Scholar] [CrossRef]

- Weng, Y.; Li, M.; Tan, M.J.; Qian, S. Design 3D Printing Cementitious Materials via Fuller Thompson Theory and Marson-Percy Model. Constr. Build. Mater. 2018, 163, 600–610. [Google Scholar] [CrossRef]

- Zhang, C.; Hou, Z.; Chen, C.; Zhang, Y.; Mechtcherine, V.; Sun, Z. Design of 3D Printable Concrete Based on the Relationship between Flowability of Cement Paste and Optimum Aggregate Content. Cem. Concr. Compos. 2019, 104, 103406. [Google Scholar] [CrossRef]

- Moeini, M.A.; Hosseinpoor, M.; Yahia, A. Effectiveness of the Rheometric Methods to Evaluate the Build-up of Cementitious Mortars Used for 3D Printing. Constr. Build. Mater. 2020, 257, 119551. [Google Scholar] [CrossRef]

- Qian, Y.; De Schutter, G. Enhancing Thixotropy of Fresh Cement Pastes with Nanoclay in Presence of Polycarboxylate Ether Superplasticizer (PCE). Cem. Concr. Res. 2018, 111, 15–22. [Google Scholar] [CrossRef]

- Panda, B.; Lim, J.H.; Tan, M.J. Mechanical Properties and Deformation Behaviour of Early Age Concrete in the Context of Digital Construction. Compos. B Eng. 2019, 165, 563–571. [Google Scholar] [CrossRef]

- Harbouz, I.; Roziere, E.; Yahia, A.; Loukili, A. Printability Assessment of Cement-Based Materials Based on Rheology, Hydration Kinetics, and Viscoelastic Properties. Constr. Build. Mater. 2022, 325, 126810. [Google Scholar] [CrossRef]

- Mohan, M.K.; Rahul, A.V.; Van Tittelboom, K.; De Schutter, G. Rheological and Pumping Behaviour of 3D Printable Cementitious Materials with Varying Aggregate Content. Cem. Concr. Res. 2021, 139, 106258. [Google Scholar] [CrossRef]

- Chen, M.; Liu, B.; Li, L.; Cao, L.; Huang, Y.; Wang, S.; Zhao, P.; Lu, L.; Cheng, X. Rheological Parameters, Thixotropy and Creep of 3D-Printed Calcium Sulfoaluminate Cement Composites Modified by Bentonite. Compos. B Eng. 2020, 186, 107821. [Google Scholar] [CrossRef]

- Long, W.-J.; Tao, J.-L.; Lin, C.; Gu, Y.; Mei, L.; Duan, H.-B.; Xing, F. Rheology and Buildability of Sustainable Cement-Based Composites Containing Micro-Crystalline Cellulose for 3D-Printing. J. Clean. Prod. 2019, 239, 118054. [Google Scholar] [CrossRef]

- Tran, M.V.; Cu, Y.T.H.; Le, C.V.H. Rheology and Shrinkage of Concrete Using Polypropylene Fiber for 3D Concrete Printing. J. Build. Eng. 2021, 44, 103400. [Google Scholar] [CrossRef]

- Tramontin Souza, M.; Maia Ferreira, I.; Guzi de Moraes, E.; Senff, L.; Arcaro, S.; Castro Pessôa, J.R.; J. Ribeiro, M.; Novaes de Oliveira, A.P. Role of Chemical Admixtures on 3D Printed Portland Cement: Assessing Rheology and Buildability. Constr. Build. Mater. 2022, 314, 125666. [Google Scholar] [CrossRef]

- Nerella, V.N.; Beigh, M.A.B.; Fataei, S.; Mechtcherine, V. Strain-Based Approach for Measuring Structural Build-up of Cement Pastes in the Context of Digital Construction. Cem. Concr. Res. 2019, 115, 530–544. [Google Scholar] [CrossRef]

- Prevedello Rubin, A.; Hasse, J.A.; Longuini Repette, W. The Evaluation of Rheological Parameters of 3D Printable Concretes and the Effect of Accelerating Admixture. Constr. Build. Mater. 2021, 276, 122221. [Google Scholar] [CrossRef]

- Chen, M.; Yang, L.; Zheng, Y.; Huang, Y.; Li, L.; Zhao, P.; Wang, S.; Lu, L.; Cheng, X. Yield Stress and Thixotropy Control of 3D-Printed Calcium Sulfoaluminate Cement Composites with Metakaolin Related to Structural Build-Up. Constr. Build. Mater. 2020, 252, 119090. [Google Scholar] [CrossRef]

- Jayathilakage, R.; Rajeev, P.; Sanjayan, J.G. Yield Stress Criteria to Assess the Buildability of 3D Concrete Printing. Constr. Build. Mater. 2020, 240, 117989. [Google Scholar] [CrossRef]

- Singh, N.B.; Middendorf, B. Geopolymers as an Alternative to Portland Cement: An Overview. Constr. Build. Mater. 2020, 237, 117455. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Hui, L.J.; Tay, Y.W.D.; Tan, M.J. Additive Manufacturing of Geopolymer for Sustainable Built Environment. J. Clean. Prod. 2017, 167, 281–288. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers: Inorganic Polymeric New Materials. J. Therm. Anal. Calorim. 2005, 37, 1633–1656. [Google Scholar] [CrossRef]

- Zhao, J.; Tong, L.; Li, B.; Chen, T.; Wang, C.; Yang, G.; Zheng, Y. Eco-Friendly Geopolymer Materials: A Review of Performance Improvement, Potential Application and Sustainability Assessment. J. Clean. Prod. 2021, 307, 127085. [Google Scholar] [CrossRef]

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S.K. Geopolymer Concrete: A Review of Some Recent Developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. A Review of Properties and Behaviour of Reinforced Geopolymer Concrete Structural Elements- A Clean Technology Option for Sustainable Development. J. Clean. Prod. 2020, 245, 118762. [Google Scholar] [CrossRef]

- Kumar, M.L.; Revathi, V. Microstructural Properties of Alkali-Activated Metakaolin and Bottom Ash Geopolymer. Arab. J. Sci. Eng. 2020, 45, 4235–4246. [Google Scholar] [CrossRef]

- Nagalia, G.; Park, Y.; Abolmaali, A.; Aswath, P. Compressive Strength and Microstructural Properties of Fly Ash–Based Geopolymer Concrete. J. Mater. Civil. Eng. 2016, 28, 04016144. [Google Scholar] [CrossRef]

- Badrawi, H.A.; Makahleh, H.Y.; Haweileh, R.A. Compressive Strength and Durability of Geopolymer Concrete. In Proceedings of the 2022 Advances in Science and Engineering Technology International Conferences, ASET 2022, Dubai, United Arab Emirates, 21–24 February 2022. [Google Scholar] [CrossRef]

- Pilehvar, S.; Szczotok, A.M.; Rodríguez, J.F.; Valentini, L.; Lanzón, M.; Pamies, R.; Kjøniksen, A.L. Effect of Freeze-Thaw Cycles on the Mechanical Behavior of Geopolymer Concrete and Portland Cement Concrete Containing Micro-Encapsulated Phase Change Materials. Constr. Build. Mater. 2019, 200, 94–103. [Google Scholar] [CrossRef]

- Neupane, K.; Chalmers, D.; Kidd, P. High-Strength Geopolymer Concrete- Properties, Advantages and Challenges. Adv. Mater. 2018, 7, 15–25. [Google Scholar] [CrossRef]

- Antoni, A.; Purwantoro, A.A.T.; Suyanto, W.S.P.D.; Hardjito, D. Fresh and Hardened Properties of High Calcium Fly Ash-Based Geopolymer Matrix with High Dosage of Borax. Iran. J. Sci. Technol.—Trans. Civil. Eng. 2020, 44, 535–543. [Google Scholar] [CrossRef]

- Olivia, M.; Nikraz, H. Properties of Fly Ash Geopolymer Concrete Designed by Taguchi Method. Mater. Des. (1980–2015) 2012, 36, 191–198. [Google Scholar] [CrossRef]

- Kleshchevnikova, V.; Belyaeva, S.; Baranov, A. Optimization of Mix Designs and Experimental Study of the Properties of Concrete Mix for 3D Printing. In Proceedings of the EECE 2020; Lecture Notes in Civil Engineering. Springer: Cham, Switzerland, 2021; Volume 150, pp. 151–160. [Google Scholar] [CrossRef]

- Kurtoglu, A.E.; Alzeebaree, R.; Aljumaili, O.; Nis, A.; Gulsan, M.E.; Humur, G.; Cevik, A.; Kurtoglu, A.E.; Alzeebaree, R.; Aljumaili, O.; et al. Advances in Concrete Construction. Adv. Concr. Constr. 2018, 6, 345. [Google Scholar] [CrossRef]

- Niveditha, M.; Koniki, S. Effect of Durability Properties on Geopolymer Concrete—A Review. E3S Web Conf. 2020, 184, 01092. [Google Scholar] [CrossRef]

- Zhang, B. Durability of Low-Carbon Geopolymer Concrete: A Critical Review. Sustain. Mater. Technol. 2024, 40, e00882. [Google Scholar] [CrossRef]

- Marczyk, J.; Ziejewska, C.; Korniejenko, K.; Łach, M.; Marzec, W.; Góra, M.; Dziura, P.; Sprince, A.; Szechyńska-Hebda, M.; Hebda, M. Properties of 3D Printed Concrete–Geopolymer Hybrids Reinforced with Aramid Roving. Materials 2022, 15, 6132. [Google Scholar] [CrossRef]

- Jiang, X.; Xiao, R.; Zhang, M.; Hu, W.; Bai, Y.; Huang, B. A Laboratory Investigation of Steel to Fly Ash-Based Geopolymer Paste Bonding Behavior after Exposure to Elevated Temperatures. Constr. Build. Mater. 2020, 254, 119267. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I.; Gupta, R. Durability Performance Evaluation of Green Geopolymer Concrete. Eur. J. Environ. Civil. Eng. 2022, 26, 4297–4345. [Google Scholar] [CrossRef]

- Noushini, A.; Castel, A. The Effect of Heat-Curing on Transport Properties of Low-Calcium Fly Ash-Based Geopolymer Concrete. Constr. Build. Mater. 2016, 112, 464–477. [Google Scholar] [CrossRef]

- Castel, A.; Foster, S.J.; Ng, T.; Sanjayan, J.G.; Gilbert, R.I. Creep and Drying Shrinkage of a Blended Slag and Low Calcium Fly Ash Geopolymer Concrete. Mater. Struct./Mater. et Constr. 2016, 49, 1619–1628. [Google Scholar] [CrossRef]

- Farooq, F.; Jin, X.; Faisal Javed, M.; Akbar, A.; Izhar Shah, M.; Aslam, F.; Alyousef, R. Geopolymer Concrete as Sustainable Material: A State of the Art Review. Constr. Build. Mater. 2021, 306, 124762. [Google Scholar] [CrossRef]

- Assi, L.N.; Carter, K.; Deaver, E.; Ziehl, P. Review of Availability of Source Materials for Geopolymer/Sustainable Concrete. J. Clean. Prod. 2020, 263, 121477. [Google Scholar] [CrossRef]

- Salas, D.A.; Ramirez, A.D.; Ulloa, N.; Baykara, H.; Boero, A.J. Life Cycle Assessment of Geopolymer Concrete. Constr. Build. Mater. 2018, 190, 170–177. [Google Scholar] [CrossRef]

- Meng, Q.; Wu, C.; Hao, H.; Li, J.; Wu, P.; Yang, Y.; Wang, Z. Steel Fibre Reinforced Alkali-Activated Geopolymer Concrete Slabs Subjected to Natural Gas Explosion in Buried Utility Tunnel. Constr. Build. Mater. 2020, 246, 118447. [Google Scholar] [CrossRef]

- Senff, L.; Novais, R.M.; Carvalheiras, J.; Labrincha, J.A. Eco-Friendly Approach to Enhance the Mechanical Performance of Geopolymer Foams: Using Glass Fibre Waste Coming from Wind Blade Production. Constr. Build. Mater. 2020, 239, 117805. [Google Scholar] [CrossRef]

- Wongsa, A.; Kunthawatwong, R.; Naenudon, S.; Sata, V.; Chindaprasirt, P. Natural Fiber Reinforced High Calcium Fly Ash Geopolymer Mortar. Constr. Build. Mater. 2020, 241, 118143. [Google Scholar] [CrossRef]

- Aygörmez, Y.; Canpolat, O.; Al-mashhadani, M.M.; Uysal, M. Elevated Temperature, Freezing-Thawing and Wetting-Drying Effects on Polypropylene Fiber Reinforced Metakaolin Based Geopolymer Composites. Constr. Build. Mater. 2020, 235, 117502. [Google Scholar] [CrossRef]

- Anonymous. (Webpage RENCA). RENCA Makes History with World’s First Geopolymer House—3Dnatives. Available online: https://www.3dnatives.com/en/renca-makes-history-with-worlds-first-geopolymer-house/ (accessed on 16 May 2024).

- Panda, B.; Singh, G.B.; Unluer, C.; Tan, M.J. Synthesis and Characterization of One-Part Geopolymers for Extrusion Based 3D Concrete Printing. J. Clean. Prod. 2019, 220, 610–619. [Google Scholar] [CrossRef]

- Xia, M.; Sanjayan, J. Method of Formulating Geopolymer for 3D Printing for Construction Applications. Mater. Des. 2016, 110, 382–390. [Google Scholar] [CrossRef]

- Aldin, Z. 3D Printing of Geopolymer Concrete 2019; Delft University of Technology: Delft, The Netherlands, 2019. [Google Scholar]

- Lim, J.H.; Panda, B.; Pham, Q.C. Improving Flexural Characteristics of 3D Printed Geopolymer Composites with In-Process Steel Cable Reinforcement. Constr. Build. Mater. 2018, 178, 32–41. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L.; Bai, G. Micro-Cable Reinforced Geopolymer Composite for Extrusion-Based 3D Printing. Mater. Lett. 2019, 235, 144–147. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Ma, G. Mechanical Improvement of Continuous Steel Microcable Reinforced Geopolymer Composites for 3D Printing Subjected to Different Loading Conditions. Compos. B Eng. 2020, 187, 107796. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Ramakrishnan, S.; Sanjayan, J. Effect of Alkali Reactions on the Rheology of One-Part 3D Printable Geopolymer Concrete. Cem. Concr. Compos. 2021, 116, 103899. [Google Scholar] [CrossRef]

- Hojati, M.; Nazarian, S.; Duarte, J.; Ashrafi, N.; Duarte, J.P.; Radlińska, A.; Craveiro, F.; Bilén, S. 3D Printing of Concrete: A Continuous Exploration of Mix Design and Printing Process. In Proceedings of the 42nd IAHS World Congress on Housing, Naples, Italy, 10–13 April 2018. [Google Scholar]

- Panda, B.; Ruan, S.; Unluer, C.; Tan, M.J. Investigation of the Properties of Alkali-Activated Slag Mixes Involving the Use of Nanoclay and Nucleation Seeds for 3D Printing. Compos. B Eng. 2020, 186, 107826. [Google Scholar] [CrossRef]

- Santana, H.A.; Neto, J.S.A.; Ribeiro, D.V.; Cilla, M.S.; Dias, C.M.R. Accelerated Alkaline Attack of 3D Printing Polymers to Assess Their Durability in Geopolymer-Based Matrices. J. Mater. Civil. Eng. 2021, 33, 04021327. [Google Scholar] [CrossRef]

- Jipa, A.; Reiter, L.; Flatt, R.J.; Dillenburger, B. Environmental Stress Cracking of 3D-Printed Polymers Exposed to Concrete. Addit. Manuf. 2022, 58, 103026. [Google Scholar] [CrossRef]

- Panda, B.; Unluer, C.; Tan, M.J. Extrusion and Rheology Characterization of Geopolymer Nanocomposites Used in 3D Printing. Compos. B Eng. 2019, 176, 107290. [Google Scholar] [CrossRef]

- Zhang, D.-W.; Wang, D.; Lin, X.-Q.; Zhang, T. The Study of the Structure Rebuilding and Yield Stress of 3D Printing Geopolymer Pastes. Constr. Build. Mater. 2018, 184, 575–580. [Google Scholar] [CrossRef]

- Zhou, Z.; Geng, J.; Jin, C.; Liu, G.; Xia, Z. Influence of Residue Soil on the Properties of Fly Ash–Slag-Based Geopolymer Materials for 3D Printing. Materials 2024, 17, 2992. [Google Scholar] [CrossRef] [PubMed]

- Paiva, M.D.M.; Fonseca Rocha, L.D.; Castrillon Fernandez, L.I.; Toledo Filho, R.D.; Silva, E.C.C.M.; Neumann, R.; Mendoza Reales, O.A. Rheological Properties of Metakaolin-Based Geopolymers for Three-Dimensional Printing of Structures. Mater. J. 2021, 118, 177–187. [Google Scholar] [CrossRef]

- Panda, B.; Unluer, C.; Tan, M.J. Investigation of the Rheology and Strength of Geopolymer Mixtures for Extrusion-Based 3D Printing. Cem. Concr. Compos. 2018, 94, 307–314. [Google Scholar] [CrossRef]

- Sando, M.; Stephan, D. The Development of a Fly Ash-Based Geopolymer for Extrusion-Based 3D Printing, along with a Printability Prediction Method. Case Stud. Constr. Mater. 2024, 21, e03407. [Google Scholar] [CrossRef]

- Guo, X.; Yang, J.; Xiong, G. Influence of Supplementary Cementitious Materials on Rheological Properties of 3D Printed Fly Ash Based Geopolymer. Cem. Concr. Compos. 2020, 114, 103820. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, J.; Yang, M.; Xiao, J.; Zhang, Y.; Gilabert, F.A. Performance Modulation and Optimization of PE Fiber Reinforced 3D-Printed Geopolymer. Constr. Build. Mater. 2024, 429, 136449. [Google Scholar] [CrossRef]

- Brandvold, A.S.; Kriven, W.M. Influence of Temperature on Rheological Properties during Early-stage Geopolymerization. J. Am. Ceram. Soc. 2024, 107, 748–759. [Google Scholar] [CrossRef]

- Kashani, A.; Ngo, T.D. Optimisation of Mixture Properties for 3D Printing of Geopolymer Concrete. In Proceedings of the 35th International Symposium on Automation and Robotics in Construction (ISARC 2018), Berlin, Germany, 22–25 July 2018. [Google Scholar]

- Rezaei Shahmirzadi, M.; Gholampour, A.; Kashani, A.; Ngo, T.D. Geopolymer Mortars for Use in Construction 3D Printing: Effect of LSS, Graphene Oxide and Nanoclay at Different Environmental Conditions. Constr. Build. Mater. 2023, 409, 133967. [Google Scholar] [CrossRef]

- Lv, X.; Qin, Y.; Liang, H.; Cui, X. Effects of Modifying Agent on Rheology and Workability of Alkali-Activated Slag Paste for 3D Extrusion Forming. Constr. Build. Mater. 2021, 302, 124062. [Google Scholar] [CrossRef]

- Sariyev, B.; Konysbekov, A.; Jexembayeva, A.; Konkanov, M. A Comparative Study of the Rheological Properties of a Fly Ash-Based Geopolymer Reinforced with PP Fiber for 3D Printing: An Experimental and Numerical Approach. Buildings 2024, 14, 2068. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, L.; Wei, K.; Gao, H.; Liu, Z.; She, Y.; Chen, F.; Gao, H.; Yu, Q. Rheology Control and Shrinkage Mitigation of 3D Printed Geopolymer Concrete Using Nanocellulose and Magnesium Oxide. Constr. Build. Mater. 2024, 429, 136421. [Google Scholar] [CrossRef]

- Saadati, F.; Kani, E.N. Phosphorous Slag-Based Geopolymer Cement Incorporate with Mullite for 3D Printing Application. Constr. Build. Mater. 2023, 406, 133444. [Google Scholar] [CrossRef]

- Brandvold, A.S.; Trindade, A.C.C.; Kriven, W.M. Rheological Assessment of Metakaolin-based Geopolymer Composites through Squeeze Flow. J. Am. Ceram. Soc. 2023, 106, 4038–4051. [Google Scholar] [CrossRef]

- Brandvold, A.S.; Al-Chaar, G.K.; Kriven, W.M. Isolating the Effects of Thixotropy in Geopolymer Pastes. J. Am. Ceram. Soc. 2023, 106, 2797–2807. [Google Scholar] [CrossRef]

- Tramontin Souza, M.; Simão, L.; Guzi de Moraes, E.; Senff, L.; de Castro Pessôa, J.R.; Ribeiro, M.J.; Novaes de Oliveira, A.P. Role of Temperature in 3D Printed Geopolymers: Evaluating Rheology and Buildability. Mater. Lett. 2021, 293, 129680. [Google Scholar] [CrossRef]

- Ma, S.; Fu, S.; Yang, T.; Li, K.; Chen, G.; Dong, Q.; He, P.; Sun, Z.; Duan, X.; Jia, D.; et al. Unveiling the Critical Role of Rheology Modifiers in Additive Manufacturing of Geopolymers and Their Mechanical Properties. Addit. Manuf. 2023, 78, 103826. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Pasupathy, K.; Mechtcherine, V.; Sanjayan, J. Printhead Mixing of Geopolymer and OPC Slurries for Hybrid Alkali-Activated Cement in 3D Concrete Printing. Constr. Build. Mater. 2024, 430, 136439. [Google Scholar] [CrossRef]

- Rahemipoor, S.; Hasany, M.; Mehrali, M.; Almdal, K.; Ranjbar, N.; Mehrali, M. Phase Change Materials Incorporation into 3D Printed Geopolymer Cement: A Sustainable Approach to Enhance the Comfort and Energy Efficiency of Buildings. J. Clean. Prod. 2023, 417, 138005. [Google Scholar] [CrossRef]

- Ranjbar, N.; Kuenzel, C.; Gundlach, C.; Kempen, P.; Mehrali, M. Halloysite Reinforced 3D-Printable Geopolymers. Cem. Concr. Compos. 2023, 136, 104894. [Google Scholar] [CrossRef]

- Sun, C.; Xiang, J.; Xu, M.; He, Y.; Tong, Z.; Cui, X. 3D Extrusion Free Forming of Geopolymer Composites: Materials Modification and Processing Optimization. J. Clean. Prod. 2020, 258, 120986. [Google Scholar] [CrossRef]

- Nwaki, W.; Eze, E. Rejuvenating the Market for Earth-Based Building Construction Materials in a Developing Economy. Civil. Sustain. Urban. Eng. 2022, 2, 110–127. [Google Scholar] [CrossRef]

- Ventura, A.; Ouellet-Plamondon, C.; Röck, M.; Hecht, T.; Roy, V.; Higuera, P.; Lecompte, T.; Faria, P.; Hamard, E.; Morel, J.C.; et al. Environmental Potential of Earth-Based Building Materials: Key Facts and Issues from a Life Cycle Assessment Perspective. RILEM State—Art. Rep. 2022, 35, 261–296. [Google Scholar] [CrossRef]

- Idrissi Kaitouni, S.; Charai, M.; Es-sakali, N.; Mghazli, M.O.; El Mankibi, M.; Uk-Joo, S.; Ahachad, M.; Brigui, J. Energy and Hygrothermal Performance Investigation and Enhancement of Rammed Earth Buildings in Hot Climates: From Material to Field Measurements. Energy Build. 2024, 315, 114325. [Google Scholar] [CrossRef]

- Tarhan, Y.; Tarhan, İ.H.; Craveiro, F.; Bartolo, H. Building a Sustainable Future: Examining the Impact of Earth-Based Materials on Civil Engineering Development. In Proceedings of the 3rd International Conference on Water Energy Food and Sustainability (ICoWEFS 2023); Springer: Cham, Switzerland, 2024; pp. 581–590. [Google Scholar] [CrossRef]

- Gomes, M.I.; Faria, P.; Gonçalves, T.D. Earth-Based Mortars for Repair and Protection of Rammed Earth Walls. Stabilization with Mineral Binders and Fibers. J. Clean. Prod. 2018, 172, 2401–2414. [Google Scholar] [CrossRef]

- Tarhan, Y.; Tarhan, İ.H.; Craveiro, F.; Bártolo, H. Sustainable Materials for Additive Manufacturing: Earth-Based Concrete. In Proceedings of the 1st International Conference on Water Energy Food and Sustainability (ICoWEFS 2021), Leiria, Portugal, 10–12 May 2021; pp. 708–716. [Google Scholar] [CrossRef]

- Paula Junior, A.C.; Jacinto, C.; Turco, C.; Fernandes, J.; Teixeira, E.; Mateus, R. Analysis of the Effect of Incorporating Construction and Demolition Waste on the Environmental and Mechanical Performance of Earth-Based Mixtures. Constr. Build. Mater. 2022, 330, 127244. [Google Scholar] [CrossRef]

- Tarhan, Y.; Perrot, A. Reinforcement of 3D Printable Earth-Based Mortar with Natural Textile Material. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Anonymous. (Webpage WASP). 3d Printing Architecture | 3D Printers | WASP. Available online: https://www.3dwasp.com/en/3d-printing-architecture/ (accessed on 16 May 2024).

- Anonymous. (Webpage IAAC). IAAC and WASP: New 3D Printing Strategies Towards the Realisation of Load-Bearing Earthen Structures—IAAC. Available online: https://iaac.net/iaac-wasp-new-3d-printing-strategies-towards-realisation-load-bearing-earthen-structures/ (accessed on 16 May 2024).

- Bajpayee, A.; Farahbakhsh, M.; Zakira, U.; Pandey, A.; Ennab, L.A.; Rybkowski, Z.; Dixit, M.K.; Schwab, P.A.; Kalantar, N.; Birgisson, B.; et al. In Situ Resource Utilization and Reconfiguration of Soils Into Construction Materials for the Additive Manufacturing of Buildings. Front. Mater. 2020, 7, 504591. [Google Scholar] [CrossRef]

- Curth, A.; Pearl, N.; Castro-Salazar, A.; Mueller, C.; Sass, L. 3D Printing Earth: Local, Circular Material Processing, Fabrication Methods, and Life Cycle Assessment. Constr. Build. Mater. 2024, 421, 135714. [Google Scholar] [CrossRef]

- Arrieta-Escobar, J.A.; Derrien, D.; Ouvrard, S.; Asadollahi-Yazdi, E.; Hassan, A.; Boly, V.; Tinet, A.J.; Dignac, M.F. 3D Printing: An Emerging Opportunity for Soil Science. Geoderma 2020, 378, 114588. [Google Scholar] [CrossRef]

- Perrot, A.; Rangeard, D.; Courteille, E. 3D Printing of Earth-Based Materials: Processing Aspects. Constr. Build. Mater. 2018, 172, 670–676. [Google Scholar] [CrossRef]

- Gomaa, M.; Jabi, W.; Soebarto, V.; Xie, Y.M. Digital Manufacturing for Earth Construction: A Critical Review. J. Clean. Prod. 2022, 338, 130630. [Google Scholar] [CrossRef]

- Biggerstaff, A.; Lepech, M.; Fuller, G.; Loftus, D. A Shape Stability Model for 3D Printable Biopolymer-Bound Soil Composite. Constr. Build. Mater. 2022, 321, 126337. [Google Scholar] [CrossRef]

- Alqenaee, A.; Memari, A. Experimental Study of 3D Printable Cob Mixtures. Constr. Build. Mater. 2022, 324, 126574. [Google Scholar] [CrossRef]

- Ji, Y.; Poullain, P.; Leklou, N. The Selection and Design of Earthen Materials for 3D Printing. Constr. Build. Mater. 2023, 404, 133114. [Google Scholar] [CrossRef]

- Asaf, O.; Bentur, A.; Larianovsky, P.; Sprecher, A. From Soil to Printed Structures: A Systematic Approach to Designing Clay-Based Materials for 3D Printing in Construction and Architecture. Constr. Build. Mater. 2023, 408, 133783. [Google Scholar] [CrossRef]

- Benzerara, M.; Guihéneuf, S.; Belouettar, R.; Perrot, A. Combined and Synergic Effect of Algerian Natural Fibres and Biopolymers on the Reinforcement of Extruded Raw Earth. Constr. Build. Mater. 2021, 289, 123211. [Google Scholar] [CrossRef]

- Biggerstaff, A.; Fuller, G.; Lepech, M.; Loftus, D. Determining the Yield Stress of a Biopolymer-Bound Soil Composite for Extrusion-Based 3D Printing Applications. Constr. Build. Mater. 2021, 305, 124730. [Google Scholar] [CrossRef]

- Maierdan, Y.; Armistead, S.J.; Mikofsky, R.A.; Huang, Q.; Ben-Alon, L.; Srubar, W.V.; Kawashima, S. Rheology and 3D Printing of Alginate Bio-Stabilized Earth Concrete. Cem. Concr. Res. 2024, 175, 107380. [Google Scholar] [CrossRef]

- Maierdan, Y.; Zhao, D.; Chokshi, P.H.; Garmonina, M.; Kawashima, S. Rheology, 3D Printing, and Particle Interactions of Xanthan Gum-Clay Binder for Earth Concrete. Cem. Concr. Res. 2024, 182, 107551. [Google Scholar] [CrossRef]

- Tarhan, Y.; Tarhan, İ.H.; Jacquet, Y.; Perrot, A. Mechanical Behaviour of 3D Printed and Textile-Reinforced Eco-Friendly Composites. J. Sustain. Cem. Based Mater. 2024, 1–19. [Google Scholar] [CrossRef]

- Varun Raj, P.; Surya Teja, P.; Sai Siddhartha, K.; Kalyana Rama, J.S. Housing with Low-Cost Materials and Techniques for a Sustainable Construction in India-A Review. Mater. Today Proc. 2021, 43, 1850–1855. [Google Scholar] [CrossRef]

- El-Mahdy, D.; Gabr, H.S.; Abdelmohsen, S. SaltBlock as a 3D Printed Sustainable Construction Material in Hot Arid Climates. J. Build. Eng. 2021, 43, 103134. [Google Scholar] [CrossRef]

- Silva, G.; Quispe, L.; Kim, S.; Nakamatsu, J.; Aguilar, R. Development of a Stabilized Natural Fiber-Reinforced Earth Composite for Construction Applications Using 3D Printing. IOP Conf. Ser. Mater. Sci. Eng. 2019, 706, 012015. [Google Scholar] [CrossRef]

- Kruger, J.; Cho, S.; Zeranka, S.; Viljoen, C.; van Zijl, G. 3D Concrete Printer Parameter Optimisation for High Rate Digital Construction Avoiding Plastic Collapse. Compos. B Eng. 2020, 183, 107660. [Google Scholar] [CrossRef]

- Rahul, A.V.; Santhanam, M.; Meena, H.; Ghani, Z. 3D Printable Concrete: Mixture Design and Test Methods. Cem. Concr. Compos. 2019, 97, 13–23. [Google Scholar] [CrossRef]

- Hojati, M.; Li, Z.; Memari, A.M.; Park, K.; Zahabi, M.; Nazarian, S.; Duarte, J.P.; Radlińska, A. 3D-Printable Quaternary Cementitious Materials towards Sustainable Development: Mixture Design and Mechanical Properties. Results Eng. 2022, 13, 100341. [Google Scholar] [CrossRef]

- Chen, Y.; Veer, F.; Copuroglu, O.; Schlangen, E. Feasibility of Using Low CO2 Concrete Alternatives in Extrusion-Based 3D Concrete Printing. RILEM Bookseries 2019, 19, 269–276. [Google Scholar] [CrossRef]

- Boscaro, F.; Quadranti, E.; Wangler, T.; Mantellato, S.; Reiter, L.; Flatt, R.J. Eco-Friendly, Set-on-Demand Digital Concrete. 3D Print. Addit. Manuf. 2022, 9, 3–11. [Google Scholar] [CrossRef] [PubMed]

- Howard, I.L.; Shannon, J.; Cost, V.T.; Stovall, M. Davis Wade Stadium Expansion and Renovation: Performance of Concrete Produced with Portland-Limestone Cement, Fly Ash, and Slag Cement. J. Mater. Civil. Eng. 2015, 27, 04015044. [Google Scholar] [CrossRef]

- Craveiro, F.; Nazarian, S.; Bartolo, H.; Bartolo, P.J.; Pinto Duarte, J. An Automated System for 3D Printing Functionally Graded Concrete-Based Materials. Addit. Manuf. 2020, 33, 101146. [Google Scholar] [CrossRef]

- Chen, Y.; Chaves Figueiredo, S.; Li, Z.; Chang, Z.; Jansen, K.; Çopuroğlu, O.; Schlangen, E. Improving Printability of Limestone-Calcined Clay-Based Cementitious Materials by Using Viscosity-Modifying Admixture. Cem. Concr. Res. 2020, 132, 106040. [Google Scholar] [CrossRef]

- Karl, D.; Duminy, T.; Lima, P.; Kamutzki, F.; Gili, A.; Zocca, A.; Günster, J.; Gurlo, A. Clay in Situ Resource Utilization with Mars Global Simulant Slurries for Additive Manufacturing and Traditional Shaping of Unfired Green Bodies. Acta Astronaut. 2020, 174, 241–253. [Google Scholar] [CrossRef]

- Xiang, J.; Liu, L.; Cui, X.; He, Y.; Zheng, G.; Shi, C. Effect of Limestone on Rheological, Shrinkage and Mechanical Properties of Alkali—Activated Slag/Fly Ash Grouting Materials. Constr. Build. Mater. 2018, 191, 1285–1292. [Google Scholar] [CrossRef]

- Xia, J.; Yu, B.; Wang, H.; Han, B.; Chen, Y.; Xie, C. Study on Properties and Pore Structure Characteristics of Cement-Based Materials with Limestone Powder. J. Phys. Conf. Ser. 2021, 1904, 012022. [Google Scholar] [CrossRef]

- Dai, X.; Aydin, S.; Yücel Yardimci, M.; Qiang, R.E.N.; Lesage, K.; De Schutter, G. Rheology, Early-Age Hydration and Microstructure of Alkali-Activated GGBFS-Fly Ash-Limestone Mixtures. Cem. Concr. Compos. 2021, 124, 104244. [Google Scholar] [CrossRef]

- Chen, G.Y.; Chen, C.T.; Chang, T.P. Improvement on Engineering Properties and Volumetric Stability of Alkali-Activated Slag-Based Composite Cementitious Material with Rice Husk Ash and Magnesium Oxide. J. Chin. Inst. Eng. 2024, 47, 179–191. [Google Scholar] [CrossRef]

- Bedarf, P.; Dutto, A.; Zanini, M.; Dillenburger, B. Foam 3D Printing for Construction: A Review of Applications, Materials, and Processes. Autom. Constr. 2021, 130, 103861. [Google Scholar] [CrossRef]

- Markin, V.; Sahmenko, G.; Nerella, V.N.; Nather, M.; Mechtcherine, V. Investigations on the Foam Concrete Production Techniques Suitable for 3D-Printing with Foam Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2019, 660, 012039. [Google Scholar] [CrossRef]

- Jin, F.L.; Zhao, M.; Park, M.; Park, S.J. Recent Trends of Foaming in Polymer Processing: A Review. Polymers 2019, 11, 953. [Google Scholar] [CrossRef]

- Falliano, D.; Restuccia, L.; Ferro, G.A.; Gugliandolo, E. Strategies to Increase the Compressive Strength of Ultra-Lightweight Foamed Concrete. Procedia Struct. Integr. 2020, 28, 1673–1678. [Google Scholar] [CrossRef]

- Raj, A.; Sathyan, D.; Mini, K.M. Physical and Functional Characteristics of Foam Concrete: A Review. Constr. Build. Mater. 2019, 221, 787–799. [Google Scholar] [CrossRef]

- Shang, X.; Qu, N.; Li, J. Development and Functional Characteristics of Novel Foam Concrete. Constr. Build. Mater. 2022, 324, 126666. [Google Scholar] [CrossRef]

- Hilal, A.A.; Thom, N.H.; Dawson, A.R. The Use of Additives to Enhance Properties of Pre-Formed Foamed Concrete. Int. J. Eng. Technol. 2015, 7, 286–293. [Google Scholar] [CrossRef]

- Rahul Rollakanti, C.; Siva Rama Prasad, C.V.; Professor, S.; Pavan Kumar, M. Experimental Investigations and Cost Effectiveness of Preformed Foam Cellular Concrete Blocks in Construction Industry. J. Xi’an Univ. Arch. Technol. 2020, 12, 5010–5019. [Google Scholar] [CrossRef]

- Falliano, D.; Gugliandolo, E.; De Domenico, D.; Ricciardi, G. Experimental Investigation on the Mechanical Strength and Thermal Conductivity of Extrudable Foamed Concrete and Preliminary Views on Its Potential Application in 3D Printed Multilayer Insulating Panels. RILEM Bookseries 2019, 19, 277–286. [Google Scholar] [CrossRef]

- Lublasser, E.; Adams, T.; Vollpracht, A.; Brell-Cokcan, S. Robotic Application of Foam Concrete onto Bare Wall Elements—Analysis, Concept and Robotic Experiments. Autom. Constr. 2018, 89, 299–306. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Farzadnia, N.; Ali, A.A.A. Properties and Applications of Foamed Concrete; a Review. Constr. Build. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. 3D-Printable Lightweight Foamed Concrete and Comparison with Classical Foamed Concrete in Terms of Fresh State Properties and Mechanical Strength. Constr. Build. Mater. 2020, 254, 119271. [Google Scholar] [CrossRef]

- Cho, S.; van Rooyen, A.; Kearsley, E.; van Zijl, G. Foam Stability of 3D Printable Foamed Concrete. J. Build. Eng. 2022, 47, 103884. [Google Scholar] [CrossRef]

- Liu, C.; Xiong, Y.; Chen, Y.; Jia, L.; Ma, L.; Deng, Z.; Wang, Z.; Chen, C.; Banthia, N.; Zhang, Y. Effect of Sulphoaluminate Cement on Fresh and Hardened Properties of 3D Printing Foamed Concrete. Compos. B Eng. 2022, 232, 109619. [Google Scholar] [CrossRef]

- de Carvalho Bello, C.B.; Cecchi, A. Experiments on Natural Fibers: Durability and Mechanical Properties. Adv. Mater. Process. Technol. 2017, 3, 632–639. [Google Scholar] [CrossRef]

- Varela, H.; Barluenga, G.; Sonebi, M. Rheology Characterization of 3D Printing Mortars with Nanoclays and Basalt Fibers. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Wang, W.; Konstantinidis, N.; Austin, S.A.; Buswell, R.A.; Cavalaro, S.; Cecinia, D. Flexural Behaviour of AR-Glass Textile Reinforced 3D Printed Concrete Beams. RILEM Bookseries 2020, 28, 728–737. [Google Scholar] [CrossRef]

- Dörrie, R.; David, M.; Freund, N.; Lowke, D.; Dröder, K.; Kloft, H. In-Process Integration of Reinforcement for Construction Elements During Shotcrete 3D Printing. Open Conf. Proc. 2023, 3. [Google Scholar] [CrossRef]

- Anonymous. (Webpage 3D Print Industry). ‘Project MOONRISE’ Scientists 3D Print Lunar Regolith-Based Zero Gravity Structures—3D Printing Industry. Available online: https://3dprintingindustry.com/news/project-moonrise-scientists-3d-print-lunar-regolith-based-zero-gravity-structures-182225/ (accessed on 16 May 2024).

| 3D Printable Bases | Search Expression |

|---|---|

| Cementitious | 3D printing OR 3D-printed OR Additive manufacturing AND (concrete OR cement) AND NOT ceramic AND NOT bioceramic |

| Sustainable | 3D printing OR 3D-printed OR Additive manufacturing AND (geopolymer OR earth OR lime) AND NOT ceramic AND NOT bioceramic |

| Sustainable cementitious | 3D printing OR 3D-printed OR Additive manufacturing AND (concrete OR cement) AND supplementary cementitious materials OR SCMs OR fly ash OR slag OR silica fume OR rice husk AND NOT ceramic AND NOT bioceramic |

| Name | Materials | Material Parameters | Test Equipments/Models | Rheological Properties | Key Findings |

|---|---|---|---|---|---|

| Zhang et al. [54] | Type II 52.5 Portland cement (PC), nanoclay, silica fume (SF), fine aggregate, retarder, thickening agent, superplasticizer (SP) | -Water/binder: 0.35, -Nanoclay content: 0–2% cement replacement, -SF content: 0–2% cement replacement | -Brookfield rheometer with vane spindle -Bingham model for rheological analysis | -Yield stress range: 15–200 Pa, -Viscosity range: 3.5–5 Pa.s -Thixotropy range: 4000–16,000 Pa/s | The addition of nanoclay and SF greatly enhanced buildability, thixotropy, and green strength in 3D printable concrete. The optimized mixture containing both showed the best overall performance in rheology and buildability. |

| Xu et al. [100] | Ordinary portland cement (OPC), sulphoaluminate cement (SAC), fly ash (FA), ground granulated blast furnace slag (GGBS), sand, water reducing agent, rubber powder, cellulose ether, defoamer, accelerator, early strength agent. | -FA content: 0–40% replacement of OPC, -GGBS content: 0–40% replacement of OPC -Water-binder ratio: 0.32 | -Mars40 rheometer -Slump test | For Optimal mixture (20% FA): -Slump: 42 mm, -Expansion: 185 mm, -Apparent viscosity: 1.5–4.5 Pa.s, -Shear stress: 38–58 Pa | The addition of 20% FA resulted in optimal rheological properties for 3D printing, with the lowest apparent viscosity and shear stress, and the best extrusion and buildability performance. FA and GGBS can improve rheological properties. |

| Rubio et al. [101] | Cement, FA, SF, sand, Polypropylene (PP) fibers, SP, viscosity modifying agents (VMA) (diutan gum, nanoclay) | -Water/binder: 0.50, Binder/sand: 0.50, PP fibers: 0.2–0.6% by volume, -SP: 0.275–0.55% of binder, -VMA1 (diutan gum): 0.05% of binder, -VMA2 (nanoclay): 0.10% of binder | -Flow table -Penetration -Cylinder slump -Haake VT550 vane viscometer -Modified Bingham model | -Yield stress: 0–1079 Pa -Slump flow: 140–280 mm -Penetration: 19–40 mm | FA and SF increased yield stress and stability in 3D printing. PP fibers improved cohesiveness but hindered extrusion. VMAs enhanced stability but reduced workability. |

| Yuan et al. [102] | Cement, sand, SP, attapulgite (AG) clay, SAC, sodium gluconate (SG) | -w/c: 0.35, -s/b: 1.5, -AG clay: 0–1% of binder, -SAC: 0–10% PC, SG: 0–0.0008% of binder | -Coaxial cylinder rotary rheometer -Bingham model, -Penetration resistance test | -Static yield stress: 500–4000 Pa, -Dynamic yield stress: 250–580 Pa, -Plastic viscosity: 5.5–8.5 Pa.s, -Penetration resistance: 0–35 kPa (over 10 h) | AG clay enhanced thixotropy, while SAC accelerated structural buildup. Optimal printing intervals varied between 2–10 min depending on the mix. Penetration resistance showed strong correlation with static yield stress growth. |

| Kruger et al. [103] | Cement, FA, SF, sand, SP | -Water/cement ratio: 0.45 | -Germann ICAR Plus rheometer -Stress growth test | -Static yield stress: 6020 Pa -Dynamic yield stress: 692 Pa | An analytical shape retention model for 3D-printed concrete, which uses only rheological properties to predict the maximum stable filament layer height, is developed. This model ensures no plastic yielding occurs under self-weight, which is critical for maintaining shape retention and buildability. |

| Kruger et al. [104] | Cement, FA, SF, sand, SP, VMA, nano-silica | -Water/cement: 0.45, -SP: −15% to +15% of reference dosage, -Nano-silica: 0–3% by mass of cement | -Germann ICAR Plus Rheometer -Stress growth test | -Static yield stress: 2108–6483 Pa, -Dynamic yield stress: 420–2803 Pa, -Reflocculation rate (Rthix): 1.36–8.00 Pa/s, -Structuration rate (Athix): 0.61–1.17 Pa/s | A novel bi-linear thixotropy model was developed for 3D printable concrete, distinguishing between Rthix and structuration Athix rates. Rthix was found to be a better indicator of thixotropic behavior for 3D printing than Athix. |

| Lee et al. [105] | OPC, ISO standard sand, water, high water reducing agent | -Water/binder: 0.30, -High water reducing agent: 0.3% -Sand weight: 0.40–0.55 (by total weight) | -Anton Paar rheometer -Hysteresis loop measurements -Buildup ratio measurements | -Hysteresis loop area: 5647–49,242 Pa/s -Buildup ratio: 0.66–0.81 | A close correlation was found between thixotropic behavior (measured by hysteresis loop area and buildup ratio) and 3D printing buildability. The resting time required for stable buildability could be predicted through analysis of thixotropic behavior. |

| Weng et al. [106] | OPC, SF, FA, silica sand, natural river sand, water, SP | -Water/binder: 0.30, -Sand/binder: 0.50, -Sand gradation: Varied based on Fuller Thompson theory, uniform gradation, gap gradation | -Viskomat XL rheometer -Bingham plastic model -Mini-slump test | -Static yield stress: 1874–3350 Pa, -Dynamic yield stress: 208.4–492.7 Pa, -Plastic viscosity: 16.65–33.31 Pa.s | A mixture based on Fuller–Thompson showed the best buildability, with high yield stress, low plastic viscosity, and stable printing of up to 40 layers. |

| Zhang et al. [107] | PC, SF, nano-silica, micro-AG clay, sand, SP | -SP dosage: 0.8–1% by mass of binder, -Water-to-binder ratio: 0.215–0.340, -Sand-to-binder ratio: 1.41–2.24, -Sand maximum particle size: 1.18–4.75 mm | -Mini-slump test for paste flowability -Brookfield rheometer for yield stress, -Cylinder stability test for buildability assessment | -Yield stress: 2300–2730 Pa | A linear relationship was identified between cement paste flowability and optimal sand content for printable mixes. Using this with the excess paste theory helps design 3D printable mixes with varying sand fineness, ensuring suitable rheology by adjusting sand content based on paste flowability. |

| Mohan et al. [97] | CSA cement, PC, limestone powder, sand, SP, VMA, retarders (borax, sodium gluconate) | -Water-to-binder: 0.35, -Aggregate-to-binder: 1.5, -VMA dosage: 0.1% by weight of binder, -Retarder dosage: 0.5% by weight of binder, -Limestone powder substitution: 0–30% replacement of CSA | -Anton Paar MCR 52 rheometer -Tribometer with smooth Couette geometry -Bingham model -Kaplan model for pumping pressure prediction | -Yield stress: 618–742 Pa, -Plastic viscosity: 22.3–62.1 Pa.s, -Lubricating layer yield stress: 241.7–269.7 Pa, -Lubricating layer viscous constant: 6830.2–7364.0 Pa.s/m | Borax can increase the open time of CSA mixtures without compromising early strength. CSA mixtures showed higher pumping pressures due to higher plastic viscosity. Limestone substitution reduced plastic viscosity and pumping pressures. CSA–limestone mixtures showed improved buildability compared to Portland cement mixtures. |

| Moeini et al. [108] | Cement paste (ternary blended cement containing PC, FA, SF), nanoclay (bentonite and halloysite), SP, quartz sand | -Water/binder: 0.35, by the mass of the binder: -Nanoclay content: 0–0.50% -SP content: 0–0.3%, -Sand/binder: 0.75–1.00 | -Anton Paar MCR 302 rheometer with coaxial cylinders and parallel plate geometries -Mini-slump flow test (ASTM C1437) -Bingham model | For optimal paste mixture(H50HR3) -Static yield stress: 27 Pa (at t = 0), -Static yield stress: 140–1100 Pa, -Plastic viscosity (Pa. s) 1.7–4.0 Pa.s, -Dynamic yield stress (Pa) 58.3–76.2 Pa, -Thixotropy coefficient (Athix): 10.1–60 Pa/min, | Different rheometric methods provided insights into different aspects of material build-up. Static yield stress evolution was suitable for assessing sheared material behavior. |

| Qian and De Schutter [109] | PC, nanoclay (purified AG clay), polycarboxylate ether superplasticizer (PCE) | -Water/cement: 0.4 -Nanoclay content: 0–0.5% by mass of cement -PCE content: 0–0.2% by mass of cement | -Anton-Paar MCR 102 rheometer with coaxial cylinder geometry | -Range for mixtures: Dynamic yield stress: 2.5–27.5 mNm Thixotropic index: 1.1–3.3 | Nanoclay increased thixotropy and dynamic yield stress at all PCE dosages. A half-percent of nanoclay maintained high thixotropy even at high PCE dosages. A nanoclay and PCE combination allows for the achievement of low dynamic yield stress yet high thixotropy, which is desirable for applications like 3D printing. |

| Tarhan and Sahin [20] | CEM I 52.5 R white cement, GGBS, calcined kaolin clay, silica sand, PP fibers, SP, VMA, cement hydration control agent, setting accelerator, air-entraining | -Water/binder: 0.35, -GGBS: 20% of cement weight, -PP: 0.2% of mixture volume, -Total aggregate: 1.24 binder amount, -Air-entraining admixture: 0–0.2% of binder | -Anton Paar RheolabQC rotational rheometer, -Bingham model for rheological analysis | -Yield stress range: 50–262 Pa, -Viscosity range: 24,606–47,697 mPa.s, -Thixotropy range: 18,288–25,877 Pa/s | Air-entraining admixture decreased yield stress and viscosity but interestingly increased thixotropy of 3D printable mortar mixes. The rheological properties were found suitable for 3D printing applications. |

| Bos et al. [64] | PC, FA, SF, sand, SP | Water/binder ratio: 0.45 | -Schleibinger Viskomat XL rheometer -Bingham model for rheological analysis | -Static yield stress: 630–3180 Pa, -Dynamic yield stress range: 40–1450 Pa (initial values), -Thixotropy -(Rthix) range: 4.9 to 6.6 Pa/s, -Athix range: 0.6 to 3.1 Pa/s | Different test methods provided varying and sometimes conflicting results for material property development. Shear strength correlations required assuming high friction angles tied to Mohr–Coulomb failure. |

| Panda et al. [110] | OPC, FA, microsilica, sodium sulphate, sand, nanoclay (AG) | -Water/binder: 0.30, -Sand/binder: 0.83, -Time: 0–150 min after mixing, -Nanoclay content: 0–0.5% of binder | -Anton Paar MCR 102 rheometer | -Yield stress range: ~4000 Pa | Nanoclay enhanced early stiffness and green strength, improving buildability. A mathematical model was created to predict layer deformation during printing based on material properties and time. |

| Harbouz et al. [111] | Cement, sand, SP, VMA, supplementary cementitious materials (SCM) (FA, SF, limestone filler, kaolinite) | -Water-to-binder ratio: 0.28, -SP dosage: 0.3–1.2% by weight of cement, -VMA dosage: 0–1.5% by weight of cement, SCM types and combinations | -Discovery hybrid rheometer with vane-in-cup geometry | -Initial static yield stress: 100–500 Pa, -Athix: 4–15 Pa/min, -Rthix: 5–23 Pa/min, -Viscosity recovery rate (R): 0.4–0.95 | The study proposed a new “WEB” (workability, extrudability, buildability) approach for assessing printability. Optimal printability was achieved with 0.006 < W < 0.015, E > 2.5, and B < 2, where W, E, and B are indices derived from rheological parameters. |

| Zhang et al. [40] | Cement, sand, SP (HRWR), nanoclay, SF, thickening agent | -Water-to-cement: 0.35, -Sand-to-cement (S/C): 0.6 to 1.5 | -Rheometer and Bingham Model | -Viscosity: 3.8–4.5 Pa.s, -Yield stress: 178.5–359.8 Pa, Thixotropy: <6284.5 Pa/s | The study identified an optimal S/C ratio range of 1.0–1.2 for 3D printing concrete, balancing pumpability, extrudability, and buildability. |

| Mohan et al. [112] | Cement (CEM I 52.5 N), GGBS, fine aggregate (max 2 mm), SP, VMA | -Water-to-binder: 0.35, -Aggregate-to-binder (a/b): 1.0 to 1.8, -SP dosage: adjusted to maintain flow value of 50–60% | -Anton Paar MCR-52 dynamic shear rheometer -Tribometer tests, -Krieger–Dougherty and Chateau–Ovarlez–Trung models for the analysis of the influence of aggregate content on the rheological behavior | -Plastic viscosity: 15.3–41.2 Pa·s -Yield stress: 627.6–828.4 Pa -Lubrication layer yield stress: 124.7–182.8 Pa -Lubrication layer viscous constant: 4399.5–5781.8 Pa.s/m | Increasing aggregate content significantly increased plastic viscosity and moderately increased yield stress and storage modulus of printable mixtures. The study demonstrated that rheological properties of both bulk concrete and lubrication layer influence on the pumping behavior of high-yield stress printable concretes. |

| Chen et al. [113] | CSA, hydroxypropyl methyl cellulose (HPMC), water reducing agent (WRA), sodium gluconate (SG), ultrafine quartz sand, bentonite | -Water-to-cement ratio: 0.35, -Bentonite content: 0–3% of cement mass | -Rotational rheometer (kinexus lab+, Malvern), -Bingham model | -Dynamic yield stress: 602.53–717.77 Pa, -Plastic viscosity: 2.37–2.97 Pa.s, -Static yield stress: 580–730 Pa, -Thixotropic parameter: 0.267–0.574 | The addition of 2% bentonite achieved optimal 3D printability with plastic viscosity below 2.50 Pa·s and dynamic yield stress below 645.54 Pa. Bentonite improved structural stability and reduced deformation over time. |

| Long et al. [114] | OPC, FA, SF, microcrystalline cellulose (MCC), superplasticizer (HRWRA), lithium carbonate (accelerator), fine aggregate (max 1 mm) | -Water-to-binder ratio: 0.27–0.35, -MCC content: 0–1.5 wt% of binder | -RM 100 touch rheometer, -Bingham model | -Plastic viscosity: 7.41–12.71 Pa.s -Yield stress: 414.14–1201.24 Pa -Thixotropy: 64,220.14–173,463.26 Pa/s | The addition of 1 wt% MCC provided optimal rheological properties and buildability for 3D printing. Compared to the control mix, plastic viscosity and yield stress increased by 20.9% and 190.0%, respectively. |

| Tran et al. [115] | OPC, FA, SF, limestone powder, PP fiber, sand, SP | -Water-to-binder ratio (W/B): 0.22–0.30 -Sand-to-binder ratio (S/B): 0.58–0.94, -PP fiber content: 0–5.4 kg/m3, -SP dosage: 0.58–0.71% of binder | -ICAR rheometer -Bingham model | -Dynamic yield stress: 250–500 Pa -Plastic viscosity: 22–60 Pa.s | Water/binder ratio and PP fiber content significantly affected rheology. Early-age shrinkage was rapid, reaching 96% within 24 h. |

| Souza et al. [116] | OPC, sucrose, commercial setting retarder (CSR), polycarboxylate ether-based superplasticizer (PCE), calcium chloride (CC), setting accelerator | -Water-to-cement ratio: 0.28–0.32, by cement weight: -CSR: 0–0.5%, -Sucrose: 0–0.5%, -PCE: 0–0.3%, -CC: 0–3.0%, -setting accelerator: 0–5.0% | -RheoWin HAAKE Viscotester iQ rheometer -Shear growth test for static yield stress | -Static yield stress: ~500–1800 Pa -Athix: 0.4–8.2 Pa/s | Setting retarders and superplasticizers improved open time but reduced buildability. Accelerators increased the structuration rate, but higher dosages were needed when used with superplasticizers. |

| Nerella et al. [117] | CEM I 52.5 R cement, FA, micro-silica suspension, SP, set accelerator | -Water-to-cement ratio: 0.42, -SP: 0–0.75% -Accelerator: 0–2.5% -Cement replacement with SCMs: 0–45% by volume | -HAAKE MARS II coaxial rheometer -Stress growth test -Bingham model | -Static yield stress: ~0–260 Pa (varying with composition and age) -Athix: 0.07–1.83 Pa/min | A strain-based approach for measuring structural build-up was proposed, prioritizing a constant effective strain ≥1.5 over a constant shear rate. This method better characterizes stiffer printable mixes. |

| Rubin et al. [118] | PC, natural quartz sand, limestone filler, SF, PCE, aluminum sulfate accelerator | -Water-to-cement: 0.35 -Water-to-binder: 0.32 -Accelerator dosage: 0–4% by cement weight -superplasticizer dosage: 0.003–0.007% by cement weight | -Direct shear test -Rotational rheometry (Schleibinger Viskomat XL) | -Static yield stress: ~2000–4000 Pa, -Athix: 0.67–9.66 Pa/s | Rotational rheometry yielded higher stress values than direct shear tests. Accelerators caused an exponential increase in yield stress at early ages. A new model for this exponential yield stress evolution was proposed, and an analytical model for predicting buildability was reviewed. |

| Chen et al. [119] | CSA, metakaolin, HPMC, WRA, tartaric acid, water. | -Water 0.35, -Metakaolin 0–3% | -Rotational rheometer (Kinexus lab+, Malvern) -Bingham and Herschel–Bulkley models | -Static yield stress: 150–675 Pa -Dynamic yield stress: 303–675 Pa -Plastic viscosity: 2.4–2.57 Pa.s | Metakaolin addition improved yielding behaviors and thixotropy of 3D-printed CSA cement composites, leading to decreased structure deformation. The Herschel–Bulkley model was more suitable for analyzing dynamic rheological properties than the Bingham model |

| Jayathilakage et al. [120] | Cement, graded coarse and fine sand, SF, SP, retarder, water | -Water/cement ratio: 0.25, -Variable: Layer width (20 mm and 30 mm nozzle sizes tested) | -Vane shear apparatus | -Initial yield stress: 300–1500 Pa | A Mohr–Coulomb-based buildability criterion was developed and validated, offering greater accuracy in predicting plastic collapse failure height. |

| Name | Materials | Material Parameters | Test Equipments/Models | Rheological Properties | Key Findings |

|---|---|---|---|---|---|

| Panda et al. [162] | FA, GGBS, Potassium Silicate (K2SiO3), nanoclay (attapulgite clay), river sand, | -Activator-to-binder ratio: 0.35, -Water-to-solid ratio: 0.30, -Nanoclay content: 0.5% | -Stress growth test -Viscosity recovery test | -Static yield stress: ~1000 Pa -Viscosity recovery: ~1000 Pa | The study found that adding 0.5% nanoclay improved the yield stress and thixotropy of geopolymer mixes, enhancing their suitability for 3D printing applications. |

| Zhang et al. [163] | GGBS, steel slag, sodium metasilicate, Sodium Hydroxide (NAOH), | -Water/binder ratio: 0.35, -sodium metasilicate (20–40 g), -NAOH (0–20 g), -Si/Na ratio: 0.5–1.0 | -Rheometer -Modified Bingham model | -Initial yield stress: 0.339–3.439 Pa, -Yield stress after 1–20 min rest: 1.71–5.30 Pa | The study found that lower Si/Na ratios led to higher yield stress and better structure-rebuilding ability, which are beneficial for 3D printing applications. |

| Zhou et al. [164] | FA, GGBS, residue soil (RS), river sand, Sodium Silicate (Na2SiO3), NAOH, | -Water/solid ratio: 0.42, -sand/solid ratio: 1.0, -water reducer: 10%, RS content: 0–110% of binder mass | -Rheometer, -Bingham model | -Static yield stress:1496.4–3196.6 Pa, -Dynamic yield stress: 131.9–504.6 Pa, -Plastic viscosity: 5.73–10.49 Pa.s | Increasing RS content led to higher yield stress and viscosity, improving shape retention and buildability for 3D printing, but excessive RS content (>90%) negatively affected extrudability and mechanical properties. |

| Paiva et al. [165] | Metakaolin, Potassium Hydroxide (KOH), K2SiO3, NaOH, Na2SiO3, natural sand | -Water/solids ratio: 0.40–0.50, -sand content: 0% or 40% volume per volume percent | -Rotational rheometer | -Static yield stress: ~400–4000 Pa (depending on composition and resting time) | Sodium-based activators produced geopolymers with higher initial yield stress compared to potassium-based activators. Lower water/solids ratios and sand addition improved rheological properties. |

| Panda et al. [166] | FA, GGBS, SF, Na2SiO3, NaOH, Solution/binder ratio: 0.46 | -FA content: 90–100% -GGBS and SF contents: 0–10% | -MCR 102 rheometer | -Initial yield stress: ~330–660 Pa, -Thixotropy index (λ): 0.24–1.42 (after 1–20 min rest) | SF addition significantly improved yield stress and thixotropic behavior of geopolymer mixes, enhancing shape retention for 3D printing. |

| Sandoand Stephan [167] | FA, GGBS, Na2SiO3 solution, NaOH, fine aggregate (for mortar mixes), | -Activator/binder ratio: 0.20, -Water/binder ratio: 0.16 | -Penetration test with Toni SET Force penetrometer | -Initial yield stress: ~2000–4000 Pa -Yield stress after 60 min: ~20,000–120,000 Pa | They highlight that mixing time significantly influences the printability of geopolymers. Shorter mixing durations lead to a stiffer consistency, which compromises extrudability and makes the material unsuitable for 3D printing applications. |

| Guo et al. [168] | FA, slag powder, SF, anhydrous Na2SiO3 powder, quartz sand, ATTAGEL-50 | -10–30% slag powder -10–30% SF | -RVDV-2 type rotational viscometer -Bingham model, -Herschel–Bulkley model | -Apparent viscosity: ~10–70 Pa.s -Plastic viscosity: 5.5–8.80 Pa.s -Yield stress: 6.74–103.97 Pa | The addition of 10% slag powder and 10% SF improved the apparent viscosity and yield stress of the geopolymer mixture, enhancing its suitability for 3D printing. The Herschel–Bulkley model was found to be more accurate in characterizing the rheological behavior of the geopolymer mixtures compared to the Bingham model. |

| Zhu et al. [169] | FA, GGBS, sand, NaOH, Na2SiO3 solution, polyethylene (PE) fibers | -GGBS content: 100–300 g, -NaOH content: 27–58 g, -sand content: 400–800 g, -PE fiber volume: 0–0.6% | -Anton Paar MCR302 dynamic shear rheometer, -Herschel–Bulkley model | -Yield stress: 7.93–57.86 Pa | Increasing GGBS and sand content improved stacking performance and fluidity while increasing NaOH content improved stacking but reduced fluidity. Adding PE fibers significantly increased yield stress but slightly reduced flowability. |