Abstract

Periodic wet–dry processes are a significant weathering mechanism that can quickly alter a soil’s mechanical characteristics, reducing its resilience and durability. This study investigates the physical and microstructural characterization of stabilized soils through experimental analysis. While the conventional approach to ground improvement involves the application of ordinary Portland cement (OPC) and lime for treating unstable soil, this research explores calcium sulfoaluminate (CSA) cement as an eco-friendly alternative with comparable efficacy and fewer adverse environmental effects. The primary objective is to evaluate the impact of cyclic wet–dry (W–D) events on the durability and stability of CSA cement-treated sand using comprehensive laboratory testing. Various samples were prepared with cement contents of 3%, 5%, 7%, and 10%, corresponding to the optimum moisture content. Stabilized soil specimens underwent testing for unconfined compressive strength (UCS) and ultrasonic pulse velocity (UPV) after curing for 3, 7, 14, and 28 days. Subsequently, these specimens were exposed to zero, one, three, five, and seven W–D cycles. The outcomes show a decrease in the strength and durability index of the soil with a rising number of W–D cycles. However, the decline in the strength and durability of CSA-treated soil samples is significantly mitigated as the CSA content increases from 3% to 10%. The findings indicate that after seven W–D cycles, the UCS value of 10% cemented samples dropped by 14% after 28 days of curing, whereas 3% specimens experienced a 28% loss in strength. Similarly, UCS values for 5% and 7% cement content reduced from 666 kPa to 509 kPa and from 1587 kPa to 1331 kPa, respectively, indicating improved resilience with higher CSA content. The durability index was less affected during the first three cycles, but showed a more pronounced decline after five and seven cycles. For 3% cemented soil, the durability index dropped from 0.95 to 0.71, whereas for 10% cemented soil, it decreased from 0.97 to 0.82 after seven W–D cycles. The scanning electron microscope (SEM) also determines the cement–soil interaction before and after W–D, and it was noted that the pores and cracks increased after each cycle. Based on the findings, it is established that subgrade materials treated with CSA cement demonstrate durability, environmental sustainability, and suitability for integration into road construction projects.

1. Introduction

Numerous studies have highlighted the occurrence of desiccation cracks in soil structures subjected to repeated wetting–drying (W–D) cycles, leading to increased water flow [1,2,3]. W–D cycles result from rapid exposure to extreme weather variations that erode the pavement structures and cause cracks [4,5,6]. These cracks influence hydraulic conductivity during the rainy season, affecting water infiltration and subsequently raising hydraulic conductivity. Consequently, this elevation in pore water pressure within the cracked zone may lead to structural instability, including landslides [7,8,9,10]. W–D cycles deform civil engineering structures by causing volume changes, fractures, and strength losses due to differences in moisture content, which emphasizes how vulnerable structures are to environmental stress [11,12,13,14]. Human-induced climate change has resulted in long-term alterations to typical weather patterns, leading to extreme weather conditions such as intense droughts or heavy rains in certain regions [15,16,17]. These climate variations intricately affect numerous geotechnical infrastructure systems [18].

The mechanical behavior of soil, influenced by the W–D cycle, can significantly impact the performance of geotechnical structures [19]. Over the past few decades, several studies have investigated the adverse effects of W–D cycles on soil properties, including liquid limit, shear strength parameters, void ratio, and moisture content, all of which play a role in determining structural stability substantial and irreversible formations of swelling or shrinking, coupled with notable alterations in soil structure, have been observed during W–D cycles [20]. The periodic W–D cycles induced by precipitation and evaporation significantly modify soil parameters, influencing its application in geotechnical engineering [21]. Consequently, adaptation and mitigation techniques are crucial to managing the challenges posed by these weather patterns and their impacts on structure strength and stability.

Soil stabilization is a fundamental aspect of civil engineering, involving the modification of soil’s physical properties to enhance engineering characteristics like strength, stability, and workability, which are crucial for civil engineering projects, particularly in road construction and infrastructure development and maintenance. Several stabilizing techniques, employing various methods, have been utilized to address soil challenges arising from climatic variations. The chemical stabilization of soil stands out due to numerous advantages, including improved strength, durability, physical properties, control over shrinkage behavior, and reduction in the toxicity and mobility of pollutants [22,23,24,25,26]. Chemical stabilization involves introducing different chemical additives, such as lime, ordinary Portland cement (OPC), fly ash, sawdust ash, quicklime, lime–rice husk ash, lignosulfonate, basic oxygen furnace (BOF) slag, and ground granulated blast furnace slag (GGBFS), to enhance soil performance [27,28,29,30,31,32,33,34,35].

Traditionally, conventional stabilizers like OPC have significantly influenced soil stabilization, enhancing soil engineering properties. However, environmental concerns related to OPC production, particularly carbon dioxide (CO2) emissions, have led to a quest for more sustainable alternatives [36].

Recent studies have explored the use of calcium sulfoaluminate (CSA) cement as a sustainable binder alternative in the construction sector. CSA cement has a smaller carbon footprint, producing 34% less carbon emissions during production than OPC [36,37,38,39]. The advantages of CSA cement include long-term and rapid strength development, reduced shrinkage, and resilience to chemical and weather-related deterioration [40,41,42,43,44]. For example, it has been demonstrated that heightened cement content and a prolonged time enhance soil strength against freeze–thaw cycles [45,46]. Also, Ocheme et al. [47] explored the influence of CSA cement and high confining stress on the shear strength and mechanical behavior of cemented sand, highlighting the significant impact of the degree of cementation and confining pressure on soil strength. Figure 1 illustrates the advantages of employing CSA cement in soil stabilization.

Figure 1.

Advantages of using CSA cement.

Despite extensive research on soil stabilization, there remains a significant gap in the literature regarding the effects of W–D cycles on soils treated with environmentally friendly binders. This study provides a novel perspective on sustainable soil stabilization, addressing critical challenges in an era of climate change. By examining the influence of repeated W–D cycles on the properties of soil treated with CSA cement, it makes substantial contributions to the advancement of eco-friendly construction practices.

This study specifically explores whether CSA cement-treated soil can mitigate the adverse effects of W–D cycles. To answer this, various proportions of CSA cement were tested to identify optimal ratios, and the strength development behavior under W–D cycles was evaluated using multiple testing methods. Ultrasonic pulse velocity (UPV) and unconfined compressive strength (UCS) tests were employed to provide reliable, direct measures of the stabilized soil’s strength, which are critical for assessing its performance. Additionally, scanning electron microscopy (SEM) was used to analyze the impact of W–D cycles on the microstructure of the treated soil, offering deeper insights into the material’s durability and integrity.

Building on the findings of existing studies and considering the data in Table 1, this experimental investigation adopts specific curing conditions and tailored parameters to perform a comprehensive analysis. This research is anchored in the foundational work of Sagidullina et al. [45], which introduced critical concepts in soil stabilization using cementitious materials. This previous study provided a significant baseline for understanding the interactions between stabilizing agents and soil under varying environmental conditions. Expanding upon these foundational principles, the present study explores the application of CSA cement to enhance soil resilience under repetitive wet–dry (W–D) cycles, specifically within the context of fluctuating environmental conditions. By modifying key variables such as curing periods and cement content, this research aims to address critical gaps in existing knowledge related to the microstructural behavior and mechanical performance of CSA-treated soil exposed to W–D cycles. The findings from this investigation are intended to provide valuable insights into the durability and adaptability of CSA cement in geotechnical engineering applications, supporting the development of sustainable and climate-resilient infrastructure.

Table 1.

Comparing and analyzing the experimental parameters.

2. Materials and Methods

2.1. Materials

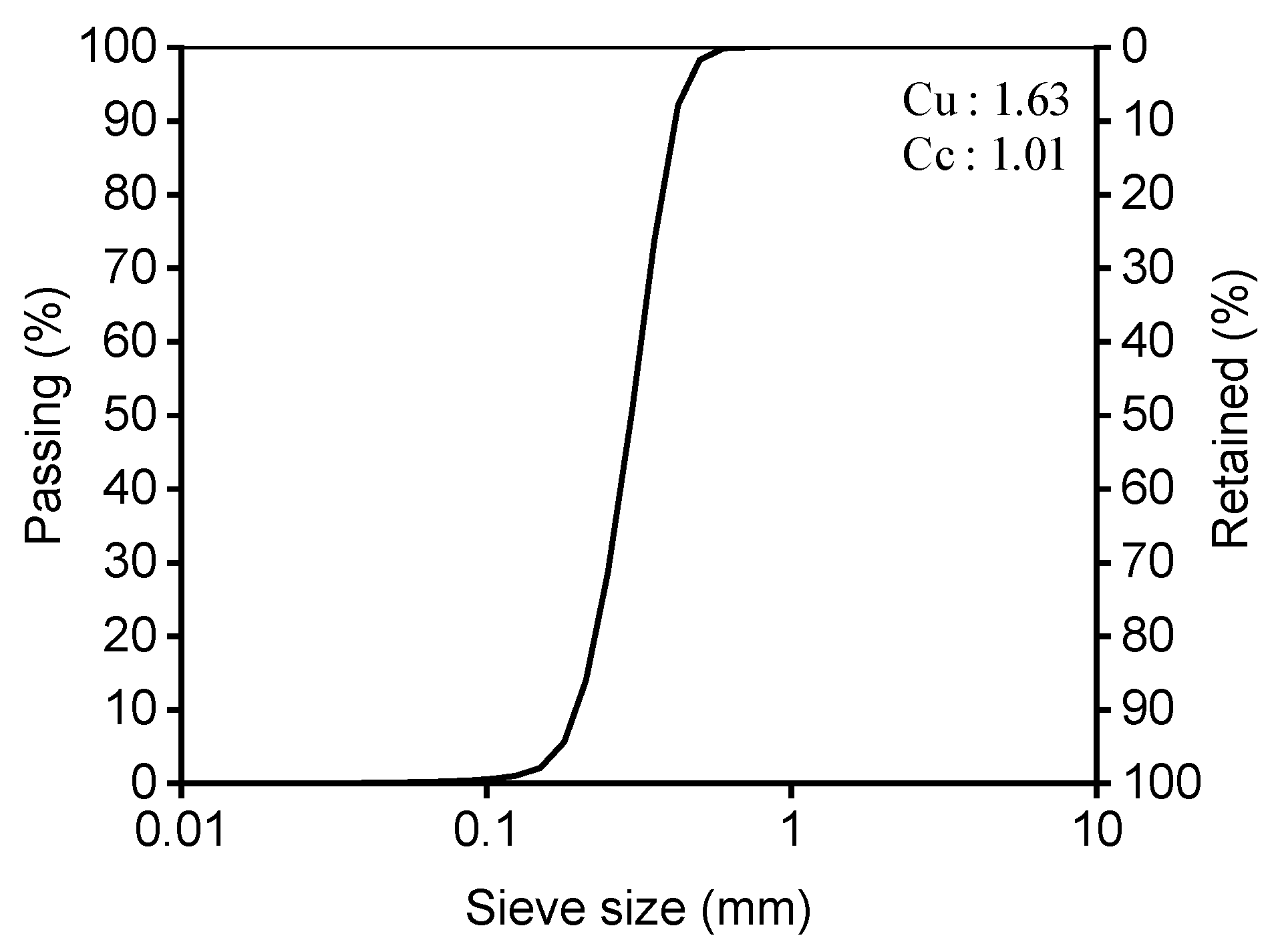

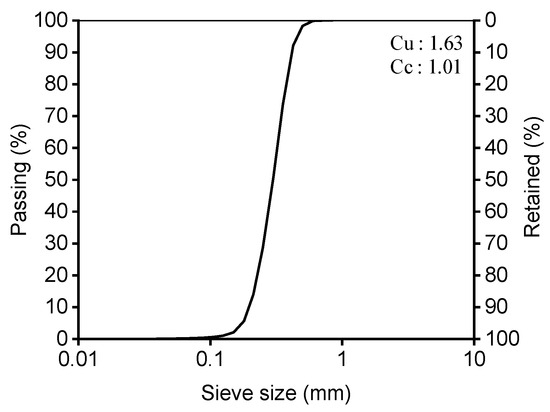

In this experimental investigation, quartz sand served as the primary material. The Qicpic Particle Size Analyzer was used to examine the distribution of soil particle sizes, following the guidelines outlined in ASTM D1921-18 [54] to ensure consistency and reliability in characterizing the soil’s properties. Figure 2 illustrates the particle size distribution with the curvature coefficient (Cc) and uniformity coefficient (Cu), providing a detailed analysis of the sand’s gradation, which plays an integral role in its performance during stabilization processes.

Figure 2.

Grain-size distribution of the studied sand.

A comprehensive overview of the physical characteristics of the sand is provided in Table 2. As per the unified soil classification system (USCS), the soil was categorized as “Poorly graded soil (SP)”.

Table 2.

Physical properties of the soil.

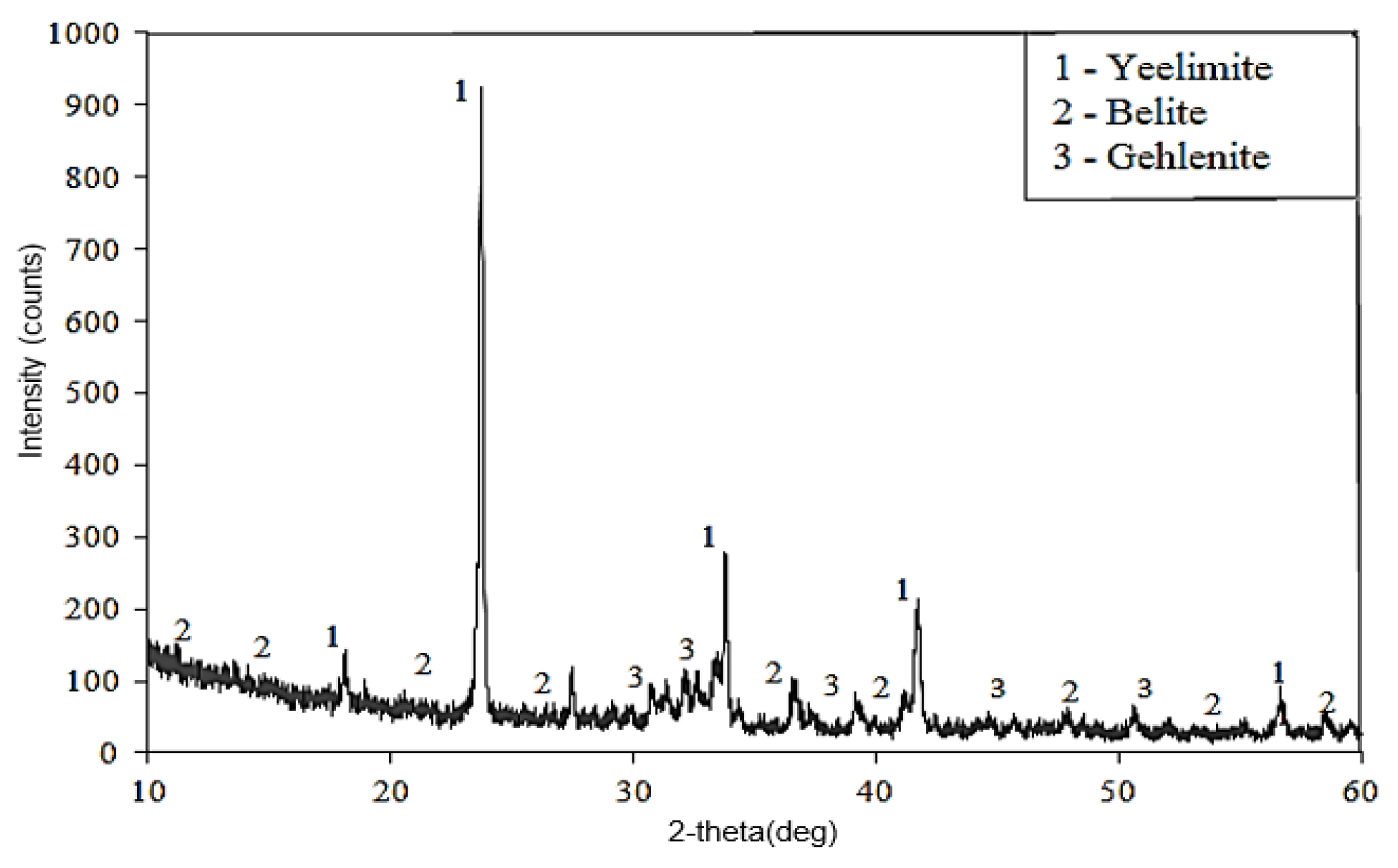

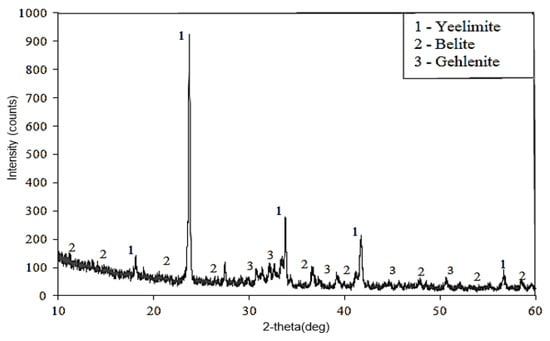

Calcium sulfoaluminate (CSA) cement was employed as the stabilizing agent in this study. The mineral compositions of the CSA cement were determined through XRD analysis, as shown in Figure 3. A detailed account of XRD analysis results has been provided in a prior study [46]. The analysis revealed that CSA cement primarily comprises Ye’elimite, belite, and gehlenite. Ye’elimite contributes to rapid early strength development, while belite () is responsible for long-term strength enhancement.

Figure 3.

XRD analysis of CSA cement [46].

Table 3 describes the chemical composition of CSA cement [55]. The key chemical constituents essential for CSA cement’s performance include AlO3 and SO3, which facilitate the formation of ye’elimite and ettringite, leading to quick setting and high early strength, whereas SiO2 promotes the formation of belite, which ensures long-term stability. MgO and FeO3 contribute to enhanced durability, whereas CaO is crucial for hydration processes, supporting the overall development of strength [37,56,57,58]. Building on findings from previous research, the optimal gypsum proportion for CSA-treated sand was identified as 30%, as this ratio has been shown to significantly enhance both early strength and long-term strength improvement [59]. Consequently, this study incorporated a 30% gypsum content as a partial replacement for the CSA component to maximize the stabilization efficiency.

Table 3.

Chemical composition of CSA cement.

2.2. Sample Preparation

Various CSA cement contents, specifically 3%, 5%, 7%, and 10% (dry weight of soil) were utilized in this study. For sample preparation, the dry materials were meticulously mixed to achieve a uniform blend before adding water. The soil specimens were processed using a cylindrical mold with dimensions of 50 mm × 100 mm with the optimum moisture content (OMC) obtained from the standard proctor test (ASTM D698) [60]. Each layer was compacted twenty-five times to prepare the samples by manually compacting the soil into three levels. Upon proper extrusion, each sample was covered with a polythene sheet to avoid moisture content loss. The specimens were then cured at room temperature for 3, 7, 14, and 28 days.

2.3. Testing Methods

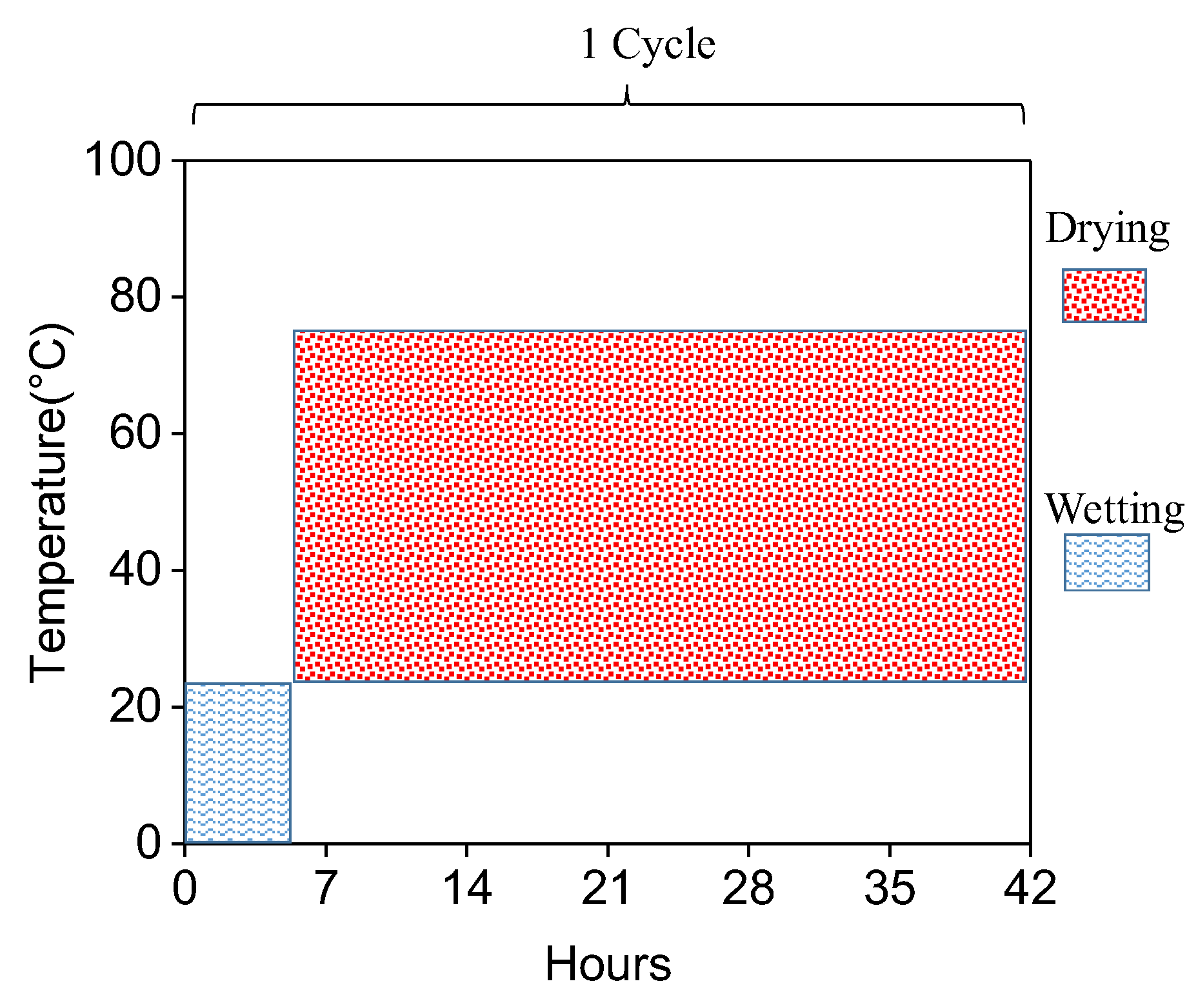

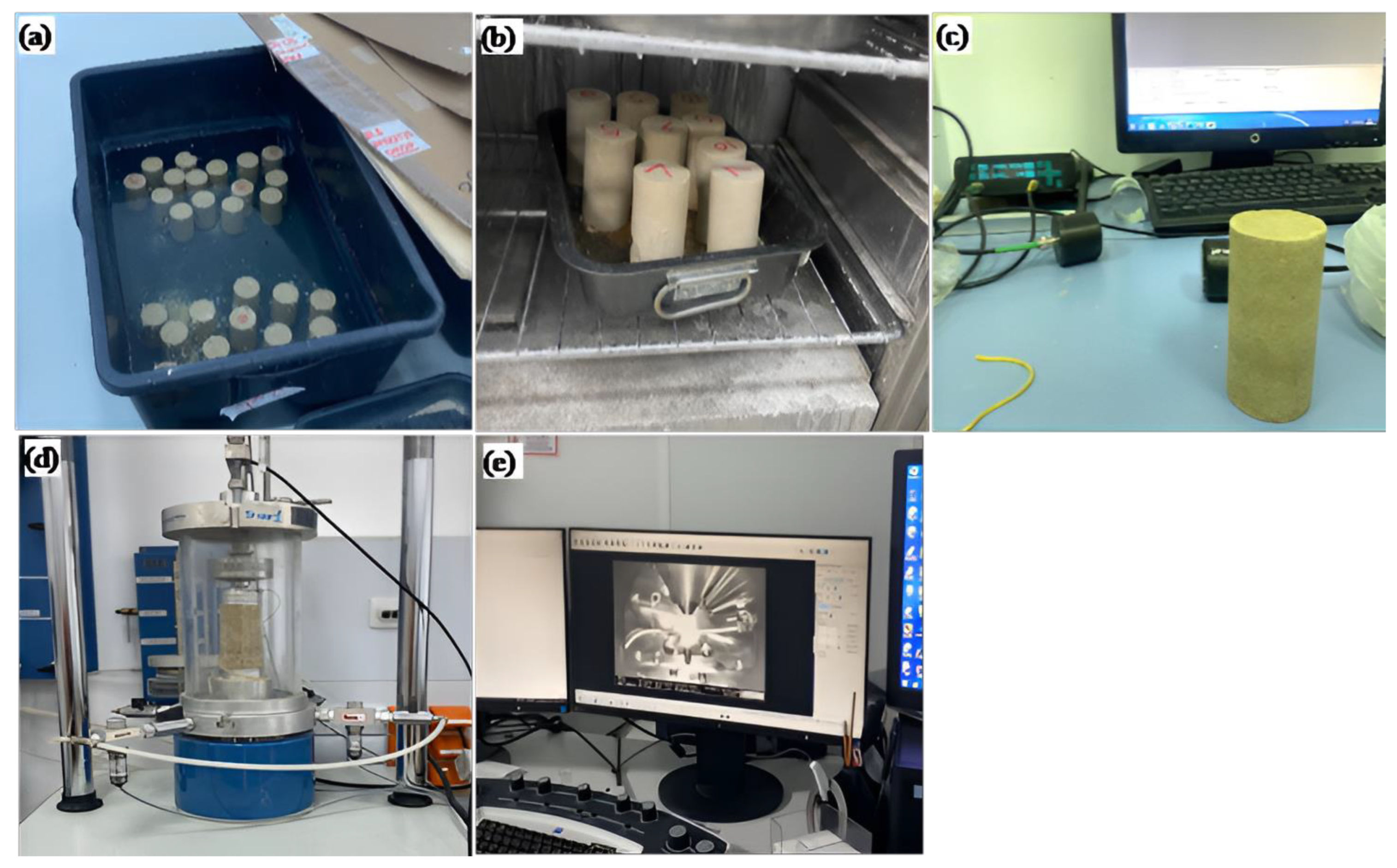

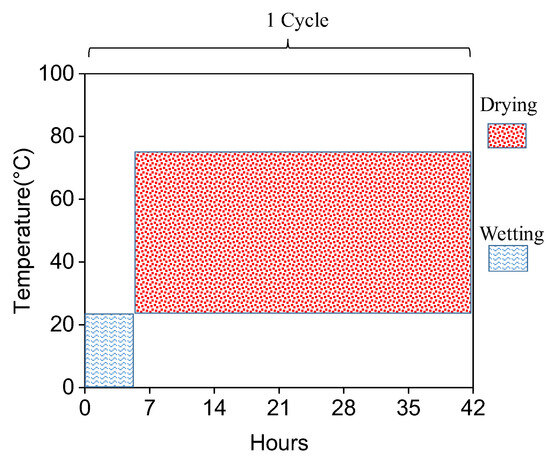

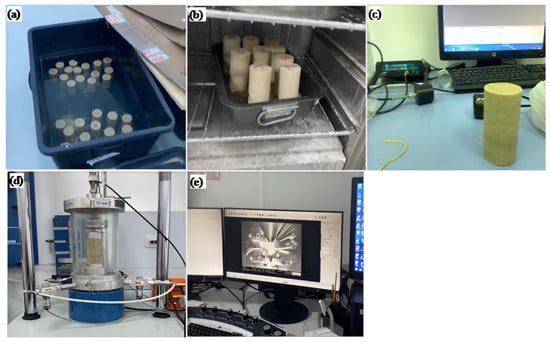

The investigation examined the impact of CSA cement content on stabilized soil strength through UCS testing. Figure 4 provides a thorough illustration of each W–D cycle, highlighting the temperature variation in relation to the sample location. Figure 5a,b show the experimental process in which soil samples underwent 0, 1, 3, 5, and 7 W–D cycles, with wet cycles at room temperature for 5 h and dry cycles at 71 ± 3 °C for 42 h, adhering to ASTM-D559/D559M standards [61].

Figure 4.

Temperature change during each W–D cycle.

Figure 5.

Schematic of experimental work (a) wetting; (b) drying; (c) UPV; (d) UCS; (e) SEM.

UPV tests were conducted to evaluate the effects of W–D cycles on CSA cement-stabilized soil. The apparatus was first calibrated using a cylindrical block to ensure accuracy. This study employed the PUNDIT apparatus to perform UPV measurements, correlating the results with unconfined compressive strength (UCS) values to monitor sample degradation over repeated W–D cycles (Figure 5c). Then, UCS tests were carried out in accordance with D2166/D2166M [62] at curing intervals of 3, 7, 14, and 28 days to assess the strength of the samples after each W–D cycle. The test involved applying a continuous axial load at a rate of 1 mm/min until the specimen failed. The results from three replicate samples were averaged for each test condition, ensuring reliable and consistent observations. SEM imaging was performed using a Zeiss Crossbeam 540 to assess microstructural changes before and after W–D cycles (Figure 5e). High-resolution images obtained through SEM provided detailed insights into the formation of pores and cracks, allowing for a better understanding of the degradation mechanisms in CSA-treated soil. The analysis highlighted changes in the material’s microstructure, including increases in porosity and the development of microcracks due to repeated W–D cycles.

3. Results and Discussion

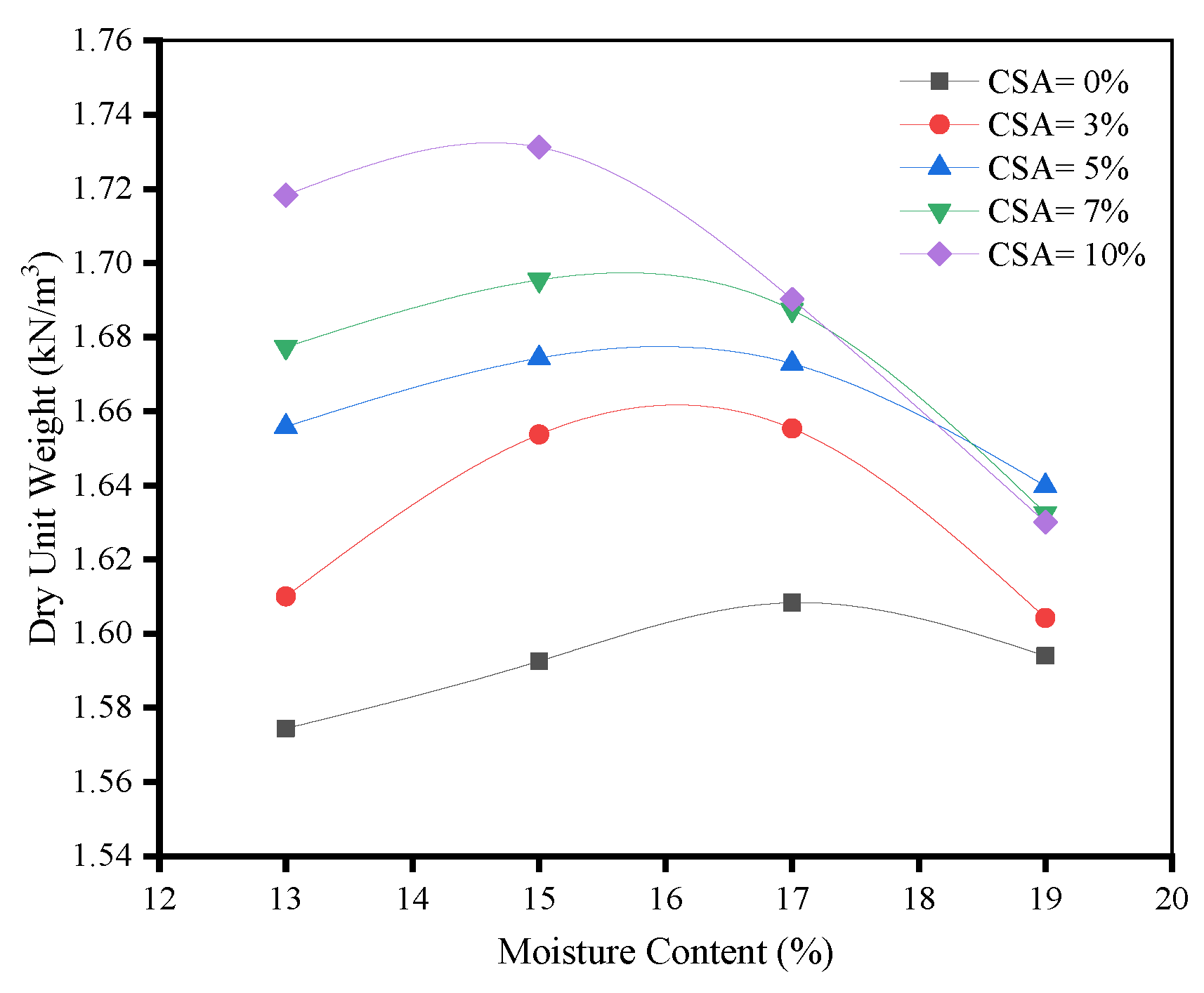

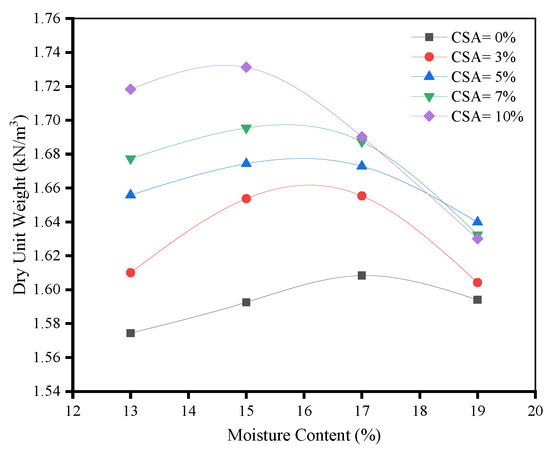

3.1. Compaction Characteristics

The initial OMC and maximum dry density (MDD) values for the sand were 17% and 1.60 kN/m3, respectively. However, as depicted in Figure 6, a higher cement content increases MDD values, accompanied by a decrease in OMC. The finer particles of CSA cement fill voids more efficiently, thereby increasing compaction densities. Additionally, the water requirement decreases with increasing CSA cement content due to the rapid hydration of CSA cement, which reduces the volume of water needed to reach the OMC. The OMC and MDD values corresponding to 3%, 5%, 7%, and 10% cement content were observed as follows: 16.4%, 16%, 15.6%, 14.7% for OMC and 1.66, 1.67, 1.69, and 1.73 kN/m3 for MDD. This trend aligns with prior research, illustrating a decreasing OMC with an increasing concentration of cement [63].

Figure 6.

Standard proctor test results.

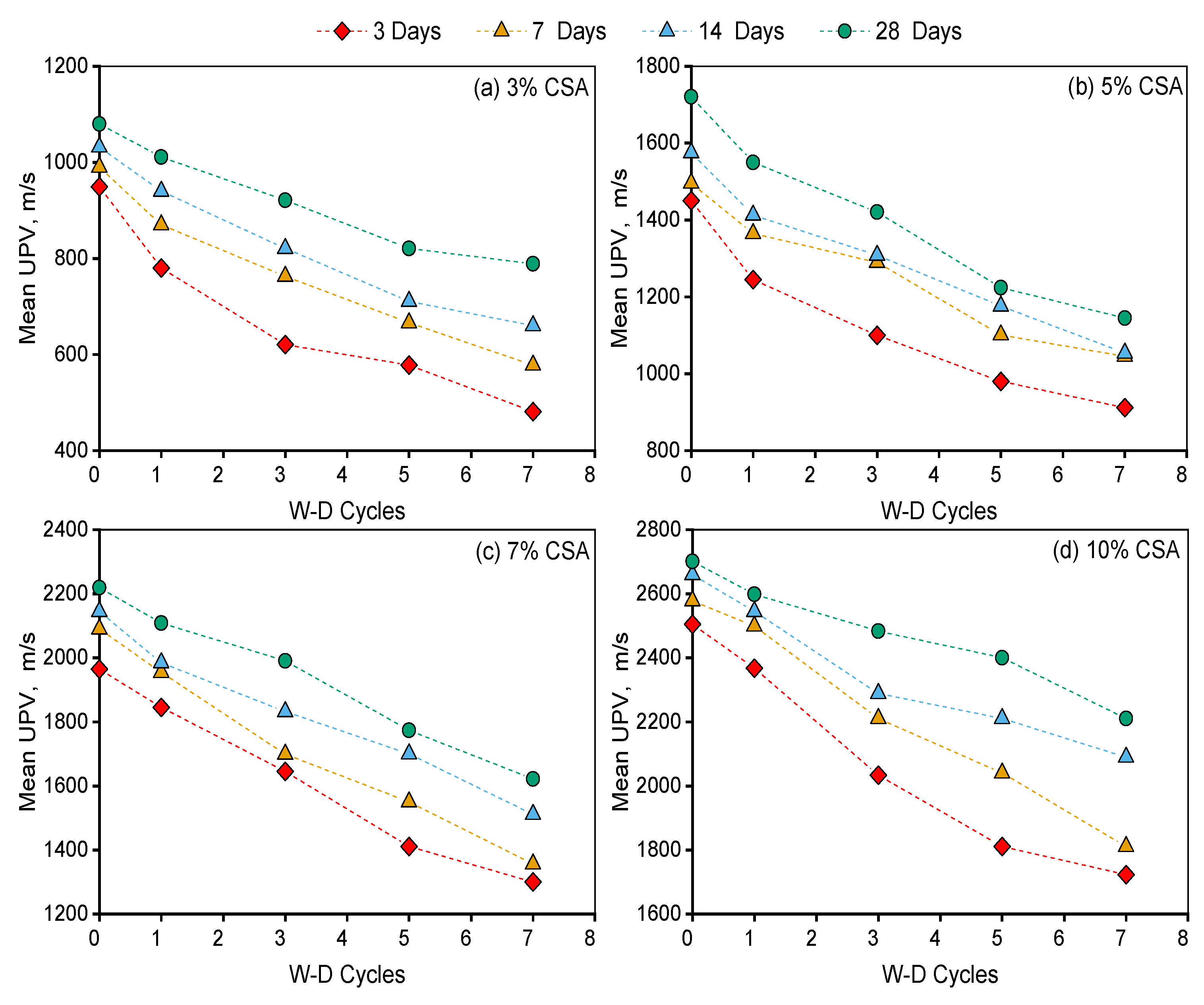

3.2. Ultrasonic Pulse Velocity (UPV)

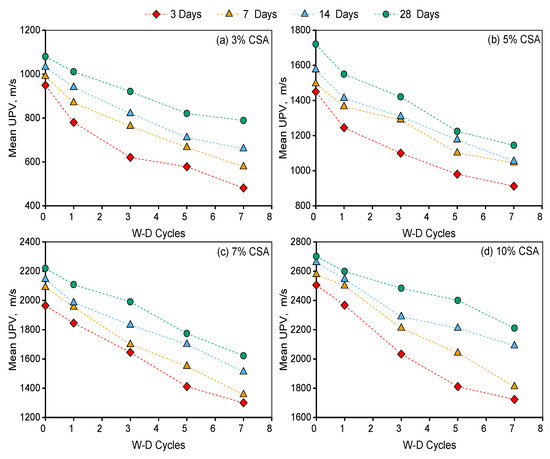

Figure 7 illustrates the effect of W–D cycles on the UPV values of various CSA cement-treated samples. The UPV results illustrate the outcomes for samples with varying cement contents (3%, 5%, 7%, and 10%) after 3, 7, 14, and 28 days of curing. The data reveal that W–D cycles reduce UPV values in the CSA-treated soil samples. The increase in curing time enhances the UPV value of stabilized soil. For instance, the UPV values for 10% stabilized soil increase from 2505 m/s to 2701 m/s as the curing time extends from 3 to 28 days. This improvement in UPV values is attributed to the cementation phenomenon, signifying enhanced strength with higher cement content. These findings align with previous studies indicating that elevated wet–dry cycles diminish UPV results in stabilized soil [64]. However, a decrease in UPV values was observed from 2701 to 2211 after seven W–D cycles. The occurrence of wet–dry cycles induces the expansion of microcracks and a rise in void volume, contributing to diminished UPV outcomes.

Figure 7.

The UPV test results for 3%, 5%, 7%, and 10% CSA cement-treated sand.

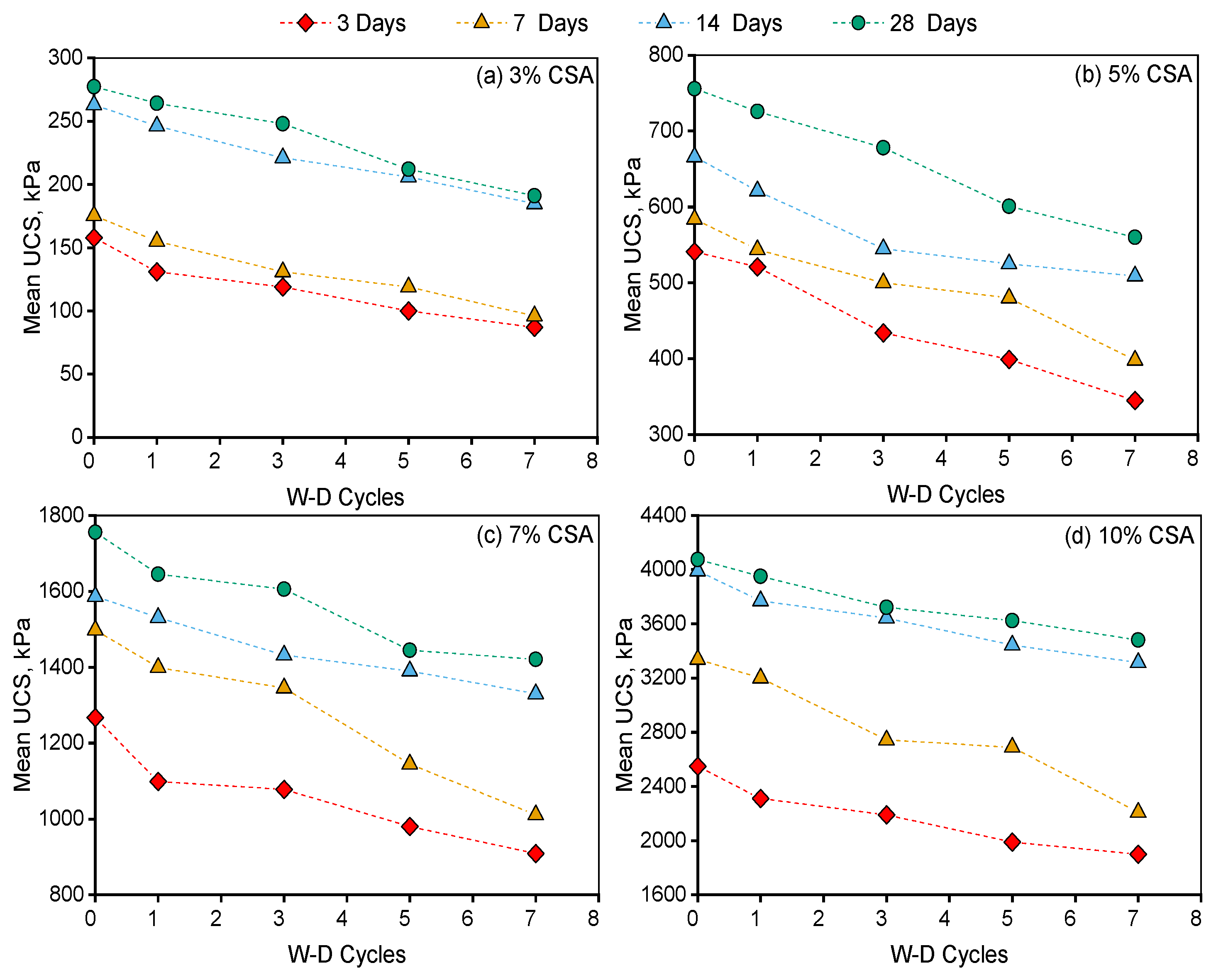

3.3. UCS Performance

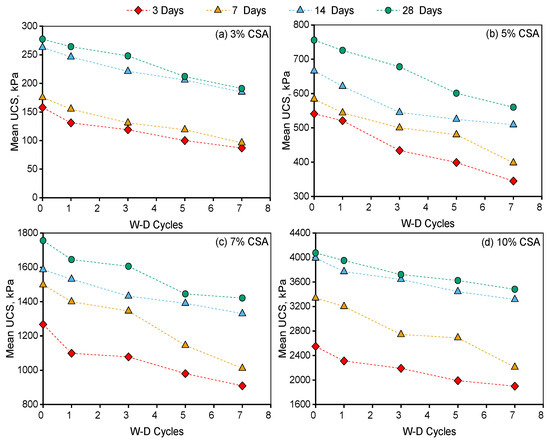

Figure 8 shows that increased cement content (3%, 5%, 7%, and 10%) and longer curing periods (3, 7, 14, and 28 days) improved the strength of CSA cement-treated soil. On the completion of each W–D cycle, the sample was removed from the oven and kept at room temperature before performing the UCS test to avoid any errors in the results. For 3% cement, the UCS improved from 158 kPa to 278 kPa with an increase in curing time from 3 days to 28 days. Similarly, for 10% cement content, the strength rose from 2549 kPa to 4075 kPa. This substantial increase in strength is attributed to the cementation process occurring between soil particles. Additionally, it depicts the impact of various numbers of W–D cycles (zero, one, three, five, and seven) on the properties of CSA-treated soils, demonstrating a reduction in strength with each cycle. As the total number of W–D cycles rose from 0 to 7, the stress value decreased for specimens containing 3% cement from 263 kPa to 185 kPa, for 5% cement it decreased from 666 kPa to 509 kPa, for 7% cement it decreased from 1587 kPa to 1331 kPa, and for 10% cement it decreased from 3990 kPa to 3314 kPa.

Figure 8.

UCS test results for 3%, 5%, 7%, and 10% CSA cement-treated sand.

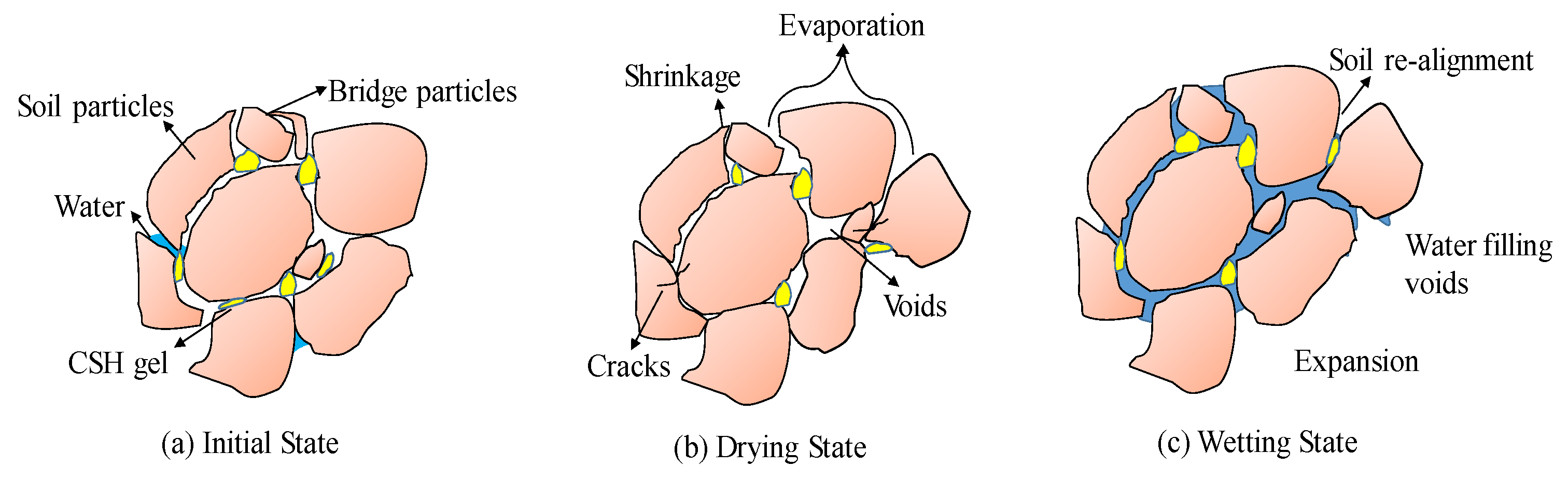

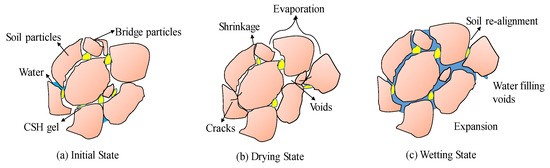

During the wet cycle, the sample was submerged in water, causing an increase in sample volume due to water infiltrating the soil voids. This infiltration negatively impacts soil properties by weakening the interparticle bonds. Conversely, during the dry cycle, the sample was placed in an oven at a controlled temperature, resulting in water evaporation. This drying process further weakens the connections between soil particles, as the loss of moisture reduces cohesion. Repeated cycles of swelling during wetting and shrinkage during drying lead to the development of microcracks within the soil matrix. Over time, leaching caused by successive wet–dry (W–D) cycles enlarges voids, increases pore sizes, and diminishes interparticle bonding, as shown in Figure 9. These findings align with prior studies on soil stabilization against W–D cycles through the adoption of various additives [29,48,64,65].

Figure 9.

Demonstration of the impact of W–D cycles on soil.

It was observed that the initial W–D cycle had a relatively minor impact on UCS values of the soil. However, as the number of W–D cycles increased, UCS values declined significantly. This trend is attributed to the reduction in the soil’s water-holding capacity after repeated W–D cycles [66]. Several studies have demonstrated that repeated W–D cycles induce irreversible volume changes in the soil, leading to a decrease in total density and structural integrity [67,68,69]. Cracking is another critical outcome of W–D cycles. Tang et al. [70] examined the effects of W–D cycles on the cracking behavior of clay slurry and observed that both the surface crack ratio and crack width increased with the number of cycles. Similarly, [71] reported that the continuous restructuring of soil occurred in parallel with W–D cycles, resulting in increased pore diameter and volume over time. These phenomena—cracks, enlarged pores, and volume changes—are the primary factors contributing to the progressive reduction in soil strength. The cumulative impact of W–D cycles is characterized by diminished cohesion, loss of interparticle bonding, and structural deterioration, all of which underscore the need for effective stabilization strategies to mitigate these effects. The observed results highlight the critical role of understanding W–D cycle behavior in designing durable and resilient soil structures, especially in regions with fluctuating moisture conditions.

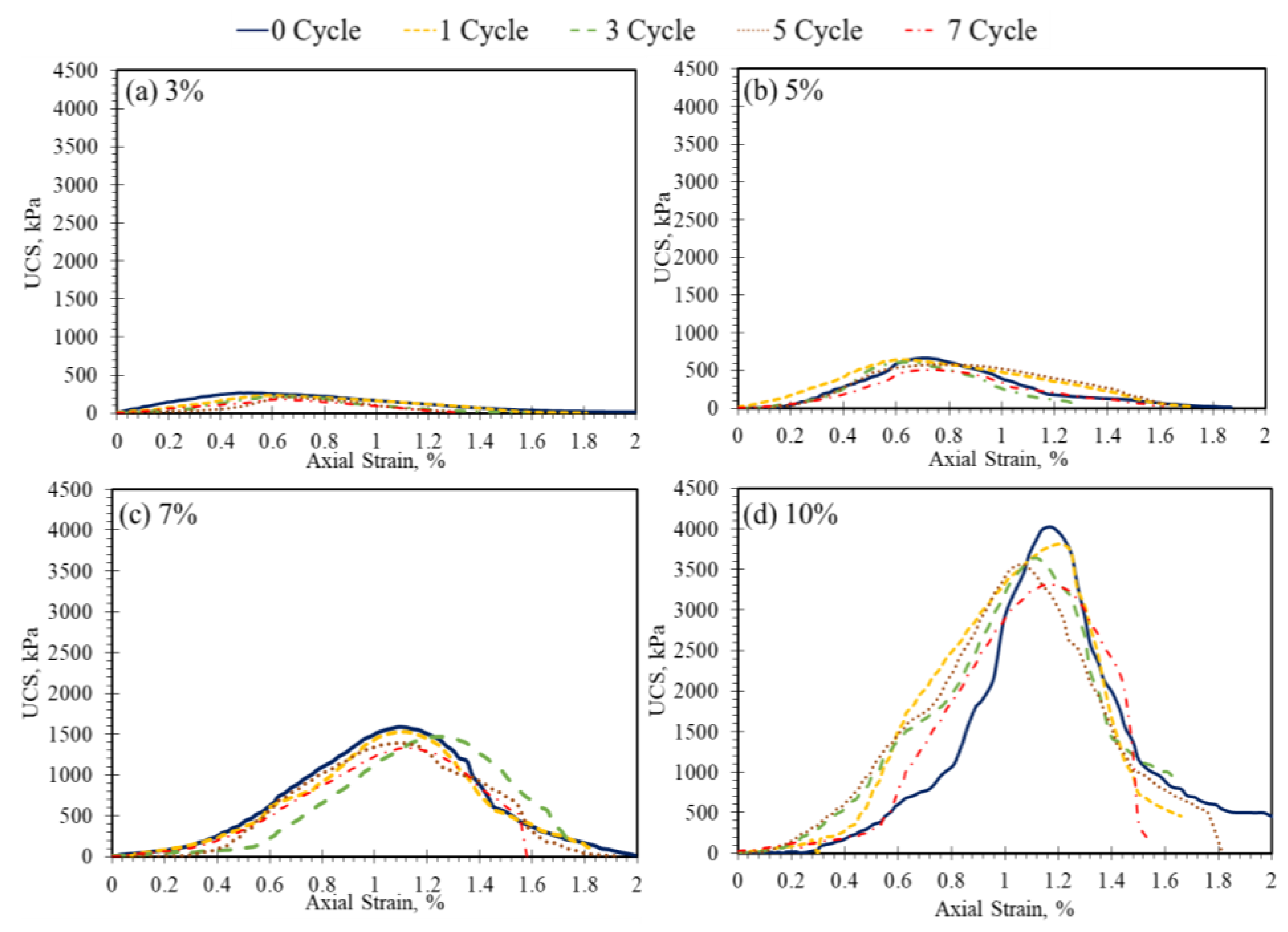

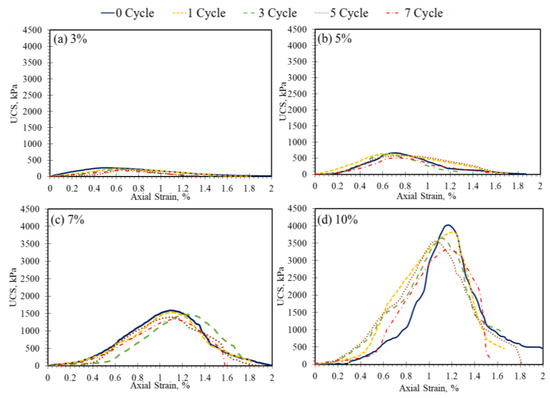

3.4. Stress–Strain Performance

Stress–strain curves of CSA cement-treated soil were analyzed to evaluate its mechanical behavior, including its strength, strain hardening, brittleness, and ductility. This analysis focused on 14-day cured samples subjected to varying wet–dry (W–D) cycles to understand the impact of these cycles and cement content on soil behavior. As shown in Figure 10, the stress–strain curves demonstrate a consistent reduction in peak stress as the number of W–D cycles increases. This decline highlights the cumulative damage inflicted by W–D cycles, including microcrack formation, loss of cohesion, and increased porosity, which collectively degrade the structural integrity of the soil matrix.

Figure 10.

Stress–strain response of 3%, 5%, 7%, and 10% CSA-treated samples at 14 days.

The shift in the stress–strain curve peaks is notable with increasing CSA cement content, ranging from 3% to 10%. As cement content rises, the graph’s peak moves to the right, reflecting enhanced strength due to improved hydration processes. These processes lead to the development of denser microstructures and stronger interparticle bonding. The resulting matrix exhibits reduced porosity and increased stiffness, contributing to greater resistance against deformation.

Sagidullina et al. [45] demonstrated that an increasing CSA cement content significantly enhances stress values, reflecting an improvement in the energy absorption capacity of the soil-cement specimens. The present study corroborates these findings, showing that higher cement ratios result in increased strength and stiffness of the soil–cement matrix. Experimental results indicated a notable shift in soil failure patterns with increasing cement content, as depicted in Figure 11. The higher cement content promotes the formation of ettringite, a mineral that contributes to a denser microstructure. This densification strengthens interparticle bonding and reduces porosity, thereby enhancing the overall stiffness and strength of the treated soil. The improved microstructure also facilitates hydration, further increasing stiffness and reducing susceptibility to large plastic deformations under loading conditions.

Figure 11.

Failure pattern of treated samples at different cement ratios.

As the cement content increases, the failure pattern transitions from progressive deformation to more abrupt failure, characterized by sudden cracking. This shift indicates that the material becomes more brittle at higher cement concentrations, with reduced ductility but increased load-bearing capacity. The abrupt cracking observed at higher cement ratios aligns with the stiffer, less deformable nature of the soil–cement matrix, which is less able to accommodate strain before failure.

These findings highlight the dual effect of increased CSA cement content: enhancing strength and stiffness while simultaneously altering the failure mechanism toward a brittle response. This behavior underscores the need for the careful consideration of cement content when designing soil stabilization strategies, particularly for applications requiring a balance between strength and ductility.

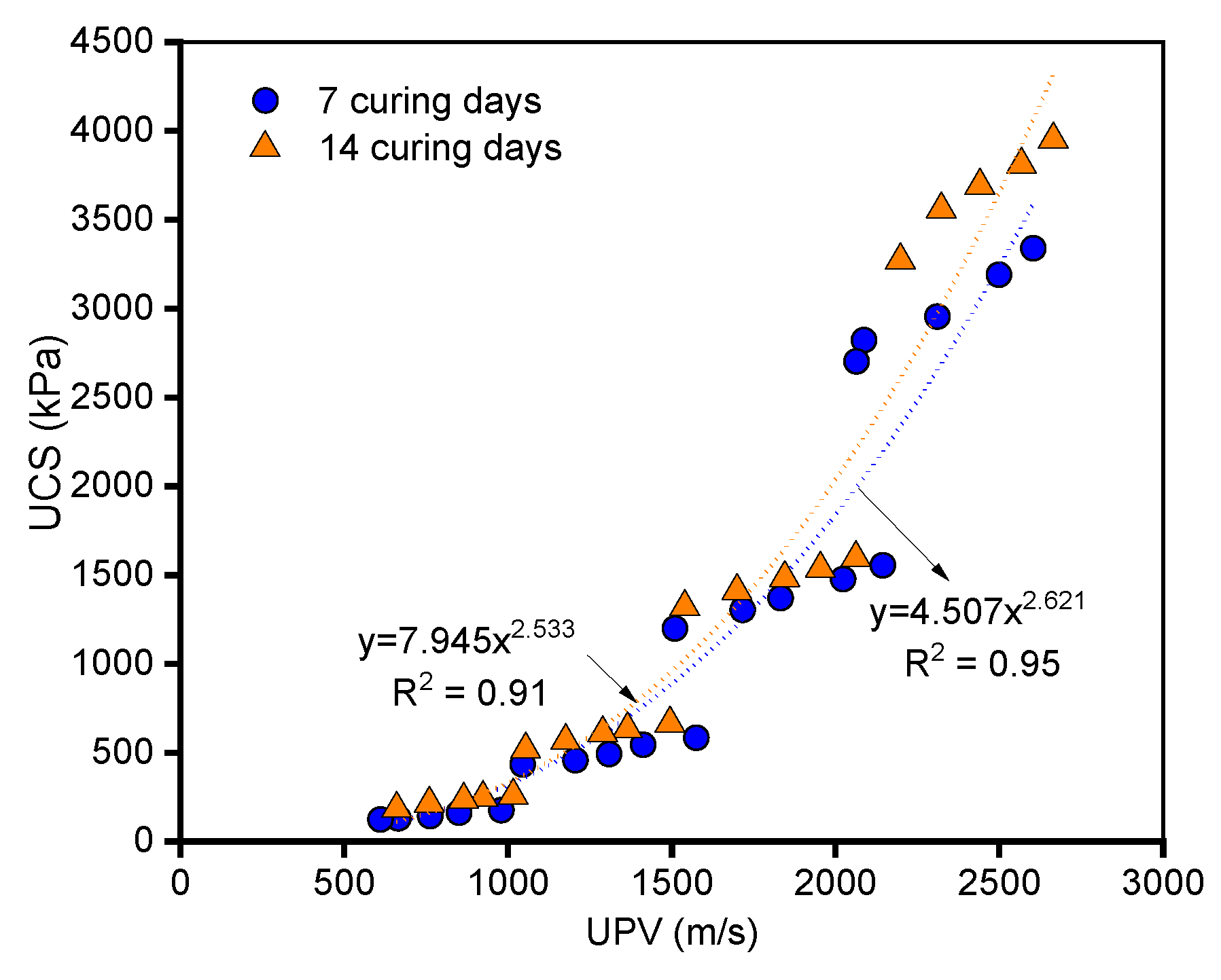

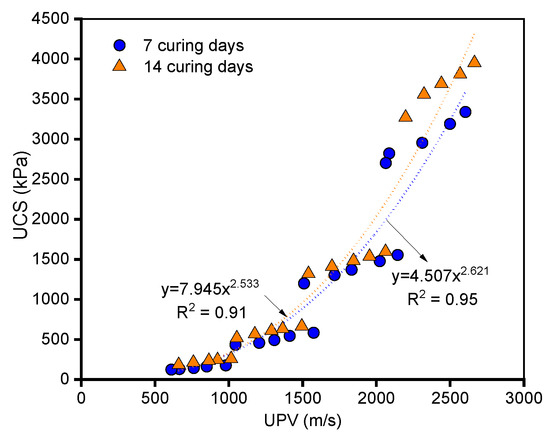

3.5. UCS and UPV Correlation

A robust correlation is essential to ensure that the predicted UCS trend derived from UPV values closely aligns with actual outcomes obtained through UCS testing, accounting for various variables such as curing interval and cement content. To determine the relationship between the UCS and UPV values, a correlation plot was used, as shown in Figure 12. The investigational outcomes of specimens exposed to W–D cycles were evaluated, as these cycles can induce internal cracks in soil samples, potentially causing signal distortions during the UPV test. To mitigate potential signal variations caused by W–D cycles, the UPV test was conducted multiple times on the sample. The correlation for both 7- and 14-day curing periods exhibited a strong fit, with R-square values of 0.95 and 0.91, respectively, indicating a high level of agreement between the two datasets [72].

Figure 12.

Relationship between UPV and UCS.

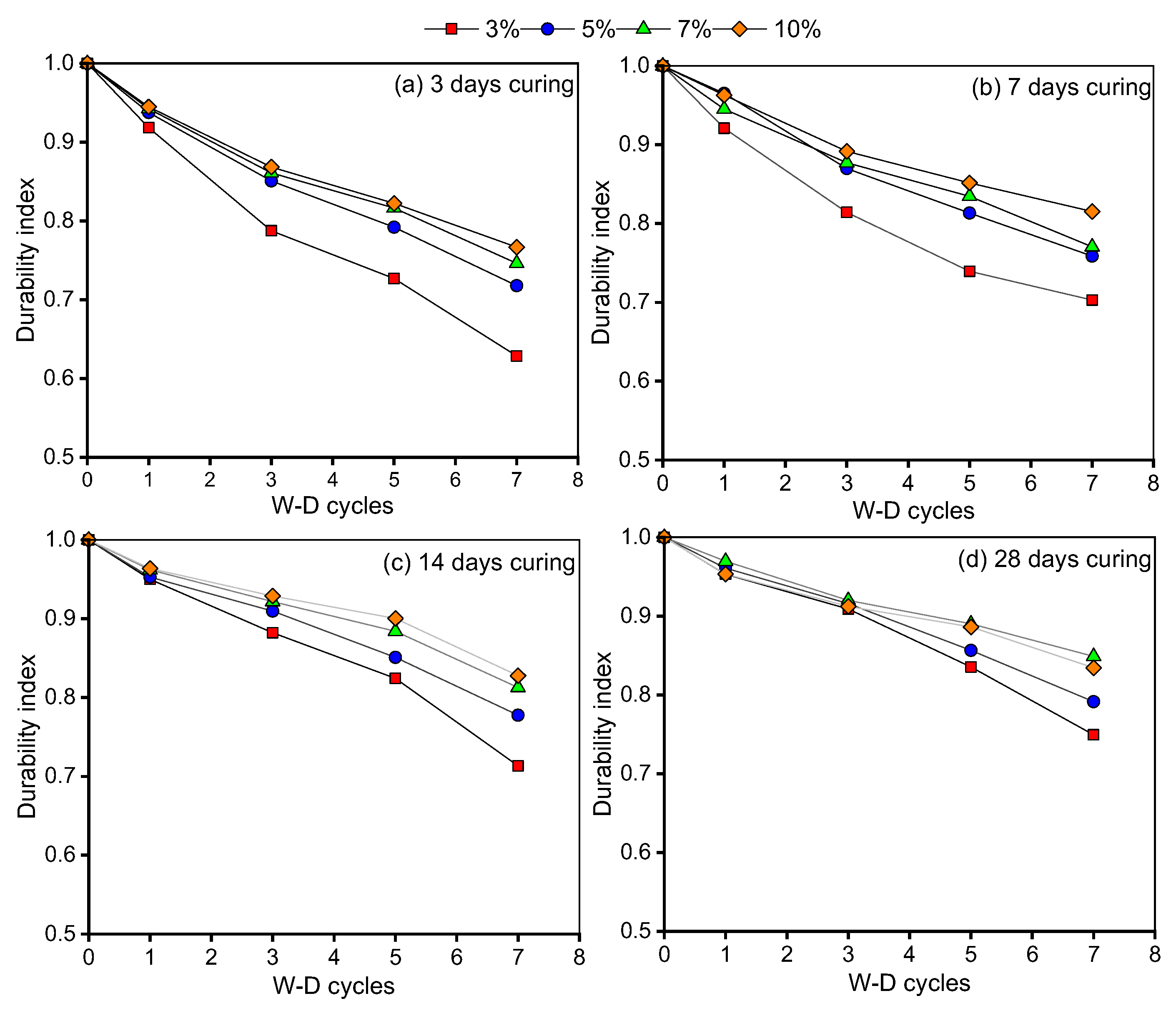

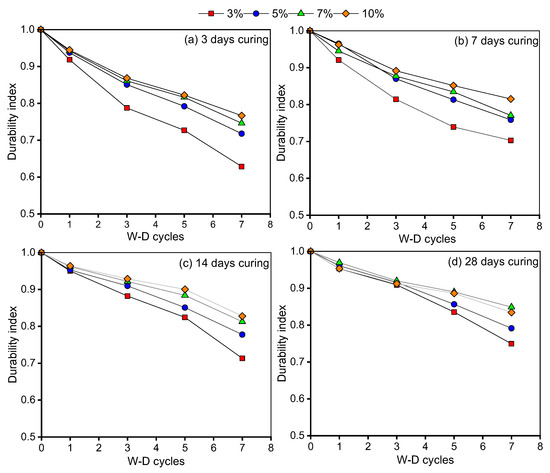

3.6. Durability Index (DI)

Figure 13 illustrates the correlation between the DI and W–D cycle events, considering varied cement content and curing durations. The durability index, a metric utilized to evaluate the influence of W–D cycles on the durability of CSA-treated sand, was calculated using Equation (1):

where is the UCS value after different numbers of W–D cycles and is the UCS value after zero W–D cycles. The DI experiences minimal reduction after the initial W–D cycle, with significant durability loss observed after five W–D cycles. CSA-stabilized specimens exhibit fewer adverse effects after one and three W–D cycles compared to after five and seven W–D cycles. The repetitive expansion and contraction caused by W–D cycles lead to particle breakage and a weakening of the soil structure. The emergence of more pores and cracks results in the deterioration of bonds within the soil structure, compromising the specimens’ ability to withstand loads. Consequently, the long-term resilience of the stabilized soils diminishes due to decreased stiffness and increased deformation. This reduction in the soil durability index indicates decreased cohesion and heightened susceptibility to erosion. These findings align with those of previous studies, reinforcing the consistency of our results and highlighting that an increase in cement content enhances soil durability, as depicted in Figure 13.

Figure 13.

Influence of W–D cycles on the durability index of CSA-treated samples: (a) 3 days of curing, (b) 7 days of curing, (c) 14 days of curing, (d) 28 days of curing.

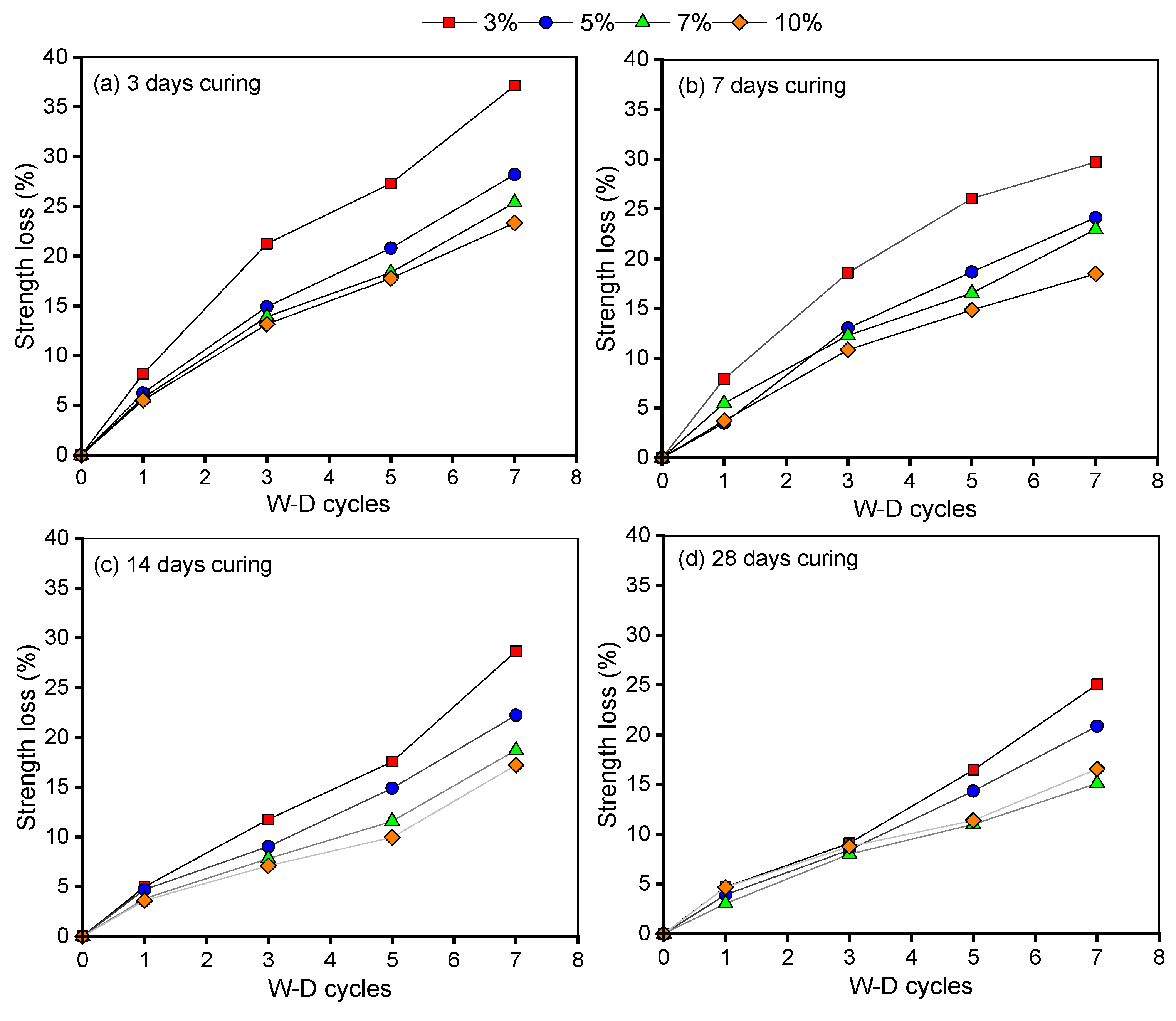

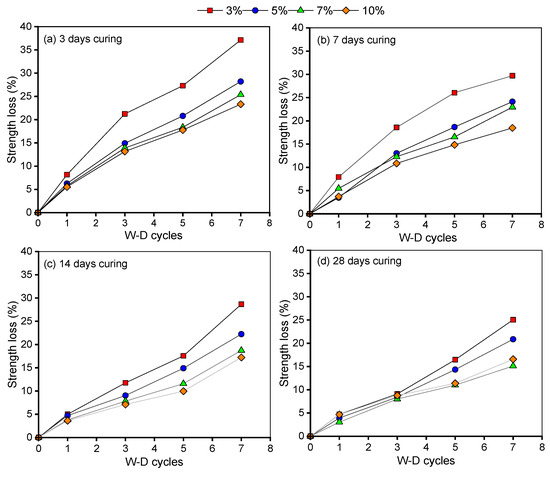

3.7. Strength Loss

The strength gain/loss values of cement-treated soil exposed to W–D cycles across various samples were assessed using Equation (2). Figure 14 portrays the correlation between the UCS values of stabilized soil and the strength variation following different W–D cycles and curing durations.

where is the UCS value without W–D cycles and is the UCS value after the number of W–D cycles. The findings reveal that soil samples cured for 3 days exhibit a substantial strength loss of up to 38% after undergoing seven W–D cycles. However, this strength reduction diminishes with a rise in the percentage of cement used and curing time. This phenomenon can be attributed to the hydration process of soil particles, contributing to an overall enhancement in the characteristics of the reinforced soil. Notably, it is observed that the impact of strength reduction becomes more pronounced after five and seven W–D cycles, signifying alterations in the mechanical characteristics of the stabilized soil following the W–D cycles.

Figure 14.

Strength loss of CSA-treated samples after different numbers of W–D cycles: (a) 3 days of curing, (b) 7 days of curing, (c) 14 days of curing, (d) 28 days of curing.

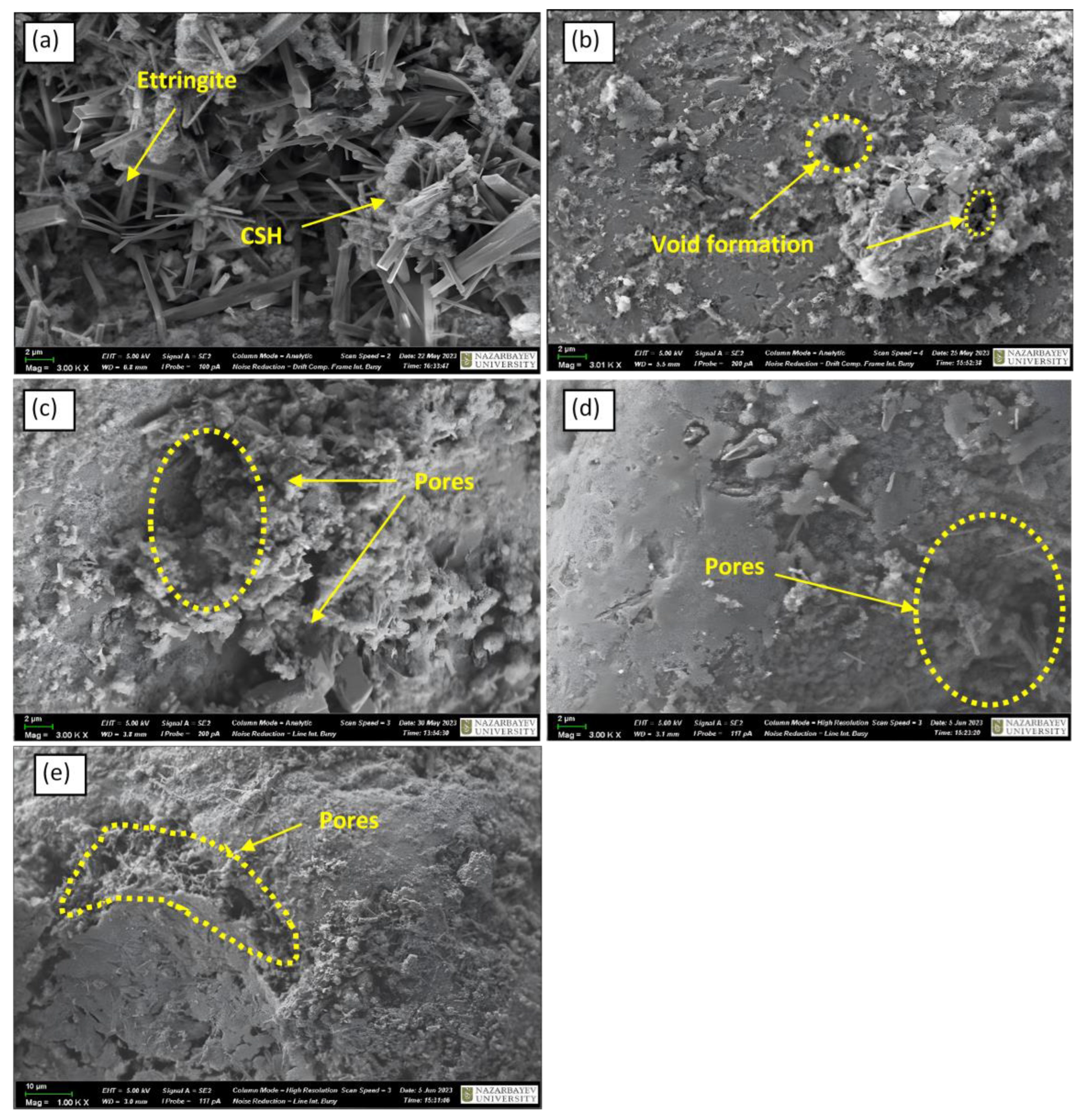

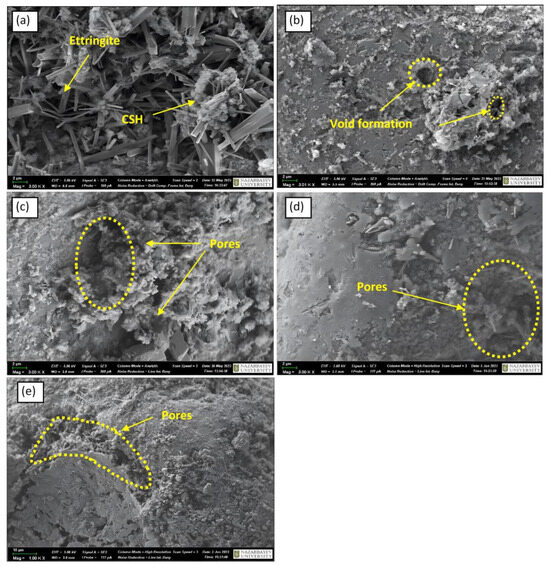

3.8. SEM

The microstructural properties of soil samples were meticulously examined through SEM images, specifically focusing on detecting microstructure alterations following W–D cycles. The microstructure of 10% CSA-treated soil after 14 days of curing was analyzed to evaluate the impact of W–D cycles.

Prior to SEM imaging, the samples were carefully dried and coated with a thin layer of gold powder to ensure electrical conductivity and enhance image resolution, as recommended in prior studies [46,73].

Figure 15 illustrates the presence of needle-shaped structures in the CSA-treated soil, which are characteristic of ettringite formation. These ettringite needles play a pivotal role in improving soil properties by increasing density and reducing porosity. Their formation contributes significantly to early strength development and a faster setting time. The needle-like structures bind soil particles together by filling interstitial spaces within the soil matrix, thereby improving the compactness and mechanical properties of the material. The enhancement in strength observed during UCS testing is attributed to the hydration of CSA cement in the soil mixture, which facilitates the formation of ettringite and other hydration products. These microstructural changes highlight the effectiveness of CSA cement in mitigating the adverse effects of repeated W–D cycles.

Figure 15.

SEM images of 10% cement-treated samples treated after different numbers of W–D cycles: (a) 0 W–D cycles, (b) 1 W–D cycles, (c) 3 W–D cycles, (d) 5 W–D cycles, and (e) 7 W–D cycles.

SEM images provide a detailed illustration of the effects of wet–dry (W–D) cycles on the microscopic structure of the soil. Following multiple W–D cycles, the void ratio increased steadily, while the aggregation of soil particles significantly diminished. The previously dense soil matrix became disrupted, and the development of pores caused by cyclic W–D cycles resulted in a looser soil structure. This disruption is consistent with the findings of Zhao-tian et al. [74], who used mercury intrusion porosimetry (MIP) to confirm similar morphological changes in the soil caused by W–D cycles.

The results also align with the observations of Li et al. [75], who demonstrated that structural variation within soil profiles is primarily influenced by factors such as profile depth and the duration of evaporation or infiltration during W–D cycles. However, traditional soil structure testing techniques (i.e., SEM, ESEM, and MIP) have limitations in capturing the cyclic variations in internal soil structures and profiles under wetting and drying conditions.

The structural changes induced by W–D cycles have significant implications for soil strength. The repeated shrinkage and expansion of soil particles during wetting and drying weakens the interparticle bonds, thereby reducing the overall strength of the material. Capillary forces, which play a crucial role in particle cohesion, undergo fluctuations during W–D cycles, further weakening interparticle connections and lowering the soil’s strength. The cumulative effects of these cycles ultimately result in a substantial reduction in soil strength. Another critical consequence of W–D cycles is the loss of soil mass, which induces the formation of voids and increases soil porosity. The dissolution of minerals such as ettringite and gypsum during these cycles contributes to this porosity increase, leading to a decline in soil strength. These findings align with Roshan et al. [64], who emphasized that the number of voids and the porosity of soil samples consistently increase with repeated W–D cycles. Moreover, continued exposure to W–D cycles causes gradual soil mass erosion, resulting in the formation of void spaces and a significant reduction in structural integrity and strength.

4. Conclusions

This research investigates the impact of CSA cement with variable dosages and curing durations on the mechanical strength and the microscopic structure of treated soils exposed to W–D cycles. The results from the investigation indicate the following conclusions:

- Increasing the CSA cement content in soil results in increased UPV values by reducing porosity and enhancing homogeneity and soil stiffness; however, the rise in the number of W–D cycles results in a considerable decline in UPV value

- As the dosage of CSA cement in the soil mixture rises, it helps to boost the strength of the soil by minimizing the negative influence of W–D cycles. However, the decrease in strength for 3% and 10% cement-treated samples with 14 days of curing after seven W–D cycles was 29% and 16%.

- The strength and durability of soils are significantly improved against W–D cycles by accelerating CSA cement ratios and curing durations. The findings for the durability index indicate that early W–D cycles have a lower impact on soil specimens; however, an increase in the number of these cycles increases the negative influence.

- The strength/loss results indicate that soil strength is impacted by cement content and curing time. However, an increase in the number of W–D cycles decreases soil strength, which is more significant in soil with a lower cement content.

- SEM examination of the soil treated with CSA cement shows the formation of hydration products, such as space-filling ettringite needles, which improve soil strength. However, a rise in the number of W–D events results in an increase in porosity, which reduces the soil strength.

This study highlights the effectiveness of calcium sulfoaluminate (CSA) cement as a stabilizing agent for soils in regions experiencing periodic climatic changes. The findings demonstrate that increasing the concentration of CSA cement in soil significantly enhances strength by filling pore spaces and increasing the contact area, thereby improving the mechanical properties of cement-treated soils. The eco-friendliness, rapid early strength development, and durability of CSA cement make it a highly suitable choice for applications in earthworks and road construction.

However, the generalizability of these findings may be limited to specific soil types and environmental conditions, as the outcomes are influenced by the cement concentration and soil characteristics. To evaluate the broader applicability of CSA cement stabilization, further research is necessary to investigate its performance across a range of soil types, cement contents, and environmental conditions. This research contributes to advancing the use of CSA cement in subsurface engineering and infrastructure projects, promoting sustainable construction practices. Future studies will focus on comparing the performance of CSA cement stabilization with other additive types to assess long-term durability and effectiveness under varied geotechnical conditions.

Author Contributions

Conceptualization, methodology, investigation, A.R. and S.-W.M.; data curation, visualization, A.R. and S.-W.M.; writing—original draft preparation, A.R. and S.-W.M.; writing—review and editing, J.K. and A.S.; supervision, project administration, funding acquisition, S.-W.M. All authors have read and agreed to the published version of the manuscript.

Funding

This exploration was funded by the Ministry of Education and Science (MES) Grant No. AP19675456 and Nazarbayev University, Collaborative Research Project (CRP) Grant No. 111024CRP2011 and Faculty Development Competitive Research Grant Program (FDCRGP) Grant No. 20122022FD4115. The ideas, results, accomplishments, and suggestions included in this material belong to the author(s) and may not necessarily represent the viewpoints of Nazarbayev University.

Data Availability Statement

The data demonstrated in this research are available upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Louati, F.; Trabelsi, H.; Jamei, M.; Taibi, S. Impact of wetting-drying cycles and cracks on the permeability of compacted clayey soil. Eur. J. Environ. Civ. Eng. 2021, 25, 696–721. [Google Scholar] [CrossRef]

- Tang, C.-S.; Cheng, Q.; Leng, T.; Shi, B.; Zeng, H.; Inyang, H.I. Effects of wetting-drying cycles and desiccation cracks on mechanical behavior of an unsaturated soil. Catena 2020, 194, 104721. [Google Scholar] [CrossRef]

- Rabot, E.; Wiesmeier, M.; Schlüter, S.; Vogel, H.-J. Soil structure as an indicator of soil functions: A review. Geoderma 2018, 314, 122–137. [Google Scholar] [CrossRef]

- Hoy, M.; Nhieu, D.V.; Horpibulsuk, S.; Suddeepong, A.; Chinkulkijniwat, A.; Buritatum, A.; Arulrajah, A. Effect of wetting and drying cycles on mechanical strength of cement-natural rubber latex stabilized recycled concrete aggregate. Constr. Build. Mater. 2023, 394, 132301. [Google Scholar] [CrossRef]

- Khoury, N.; Zaman, M.M. Durability of stabilized base courses subjected to wet–dry cycles. Int. J. Pavement Eng. 2007, 8, 265–276. [Google Scholar] [CrossRef]

- Suddeepong, A.; Intra, A.; Horpibulsuk, S.; Suksiripattanapong, C.; Arulrajah, A.; Shen, J.S. Durability against wetting-drying cycles for cement-stabilized reclaimed asphalt pavement blended with crushed rock. Soils Found. 2018, 58, 333–343. [Google Scholar] [CrossRef]

- McDonnell, J. The influence of macropores on debris flow initiation. Q. J. Eng. Geol. Hydrogeol. 1990, 23, 325–331. [Google Scholar] [CrossRef]

- Louati, F.; Houcem, T.; Jamei, M. Unsaturated permeability prediction using natural evaporation method in cracked clay. In Proceedings of the 7th International Conference on Unsaturated Soils (2018), Hong Kong, China, 3–5 August 2018. [Google Scholar]

- Clarke, D.; Smethurst, J. Effects of climate change on cycles of wetting and drying in engineered clay slopes in England. Q. J. Eng. Geol. Hydrogeol. 2010, 43, 473–486. [Google Scholar] [CrossRef] [PubMed]

- Rajabian, A. Effect of initial failure geometry on the progress of a retrogressive seepage-induced landslide. Int. J. Geo-Eng. 2023, 14, 11. [Google Scholar] [CrossRef]

- Marushchak, U.; Sydor, N.; Braichenko, S.; Hohol, M. Effect of Dry–Wet Cycles on Properties of High Strength Fiber-Reinforced Concrete. In Proceedings of the International Conference Current Issues of Civil and Environmental Engineering Lviv-Košice–Rzeszów, Rzeszów, Poland, 6–8 September 2023; pp. 265–272. [Google Scholar]

- Wang, C.; Yang, W.; Zhang, N.; Wang, S.; Ma, C.; Wang, M.; Zhang, Z. Effect of Moisture Content and Wet–Dry Cycles on the Strength Properties of Unsaturated Clayey Sand. Buildings 2024, 14, 1375. [Google Scholar] [CrossRef]

- Consoli, N.; Scheuermann Filho, H.; Segadães, L.; Cristelo, N. Effect of wet-dry cycles on the durability, strength and stiffness of granite residual soil stabilised with portland cement. In Proceedings of the 17th European Conference on Soil Mechanics and Geotechnical Engineering (ECSMGE), Reykjavik, Iceland, 1–6 September 2019; pp. 1–7. [Google Scholar]

- Liang, H.; Li, S.; Lu, Y.; Yang, T. The combined effects of wet–dry cycles and sustained load on the bond behavior of FRP–concrete interface. Polym. Compos. 2019, 40, 1006–1017. [Google Scholar] [CrossRef]

- Trenberth, K.E. Climate change caused by human activities is happening and it already has major consequences. J. Energy Nat. Resour. Law 2018, 36, 463–481. [Google Scholar] [CrossRef]

- Dagbegnon, C.; Djebou, S.; Singh, V.P. Impact of climate change on the hydrologic cycle and implications for society. Environ. Soc. Psychol. 2016, 1, 16. [Google Scholar] [CrossRef]

- Trenberth, K.E. The impact of climate change and variability on heavy precipitation, floods, and droughts. Encycl. Hydrol. Sci. 2005, 17, 1–11. [Google Scholar] [CrossRef]

- Vardon, P.J. Climatic influence on geotechnical infrastructure: A review. Environ. Geotech. 2015, 2, 166–174. [Google Scholar] [CrossRef]

- Rasul, J.M.; Ghataora, G.S.; Burrow, M.P. The effect of wetting and drying on the performance of stabilized subgrade soils. Transp. Geotech. 2018, 14, 1–7. [Google Scholar] [CrossRef]

- Alonso, E.; Romero, E.; Hoffmann, C.; García-Escudero, E. Expansive bentonite–sand mixtures in cyclic controlled-suction drying and wetting. Eng. Geol. 2005, 81, 213–226. [Google Scholar] [CrossRef]

- Tang, C.-S.; Wang, D.-Y.; Shi, B.; Li, J.J.C. Effect of wetting–drying cycles on profile mechanical behavior of soils with different initial conditions. CATENA 2016, 139, 105–116. [Google Scholar] [CrossRef]

- Prusinski, J.R.; Bhattacharja, S. Effectiveness of Portland cement and lime in stabilizing clay soils. Transp. Res. Rec. 1999, 1652, 215–227. [Google Scholar] [CrossRef]

- Batchelor, B. Overview of waste stabilization with cement. Waste Manag. 2006, 26, 689–698. [Google Scholar] [CrossRef]

- Buritatum, A.; Horpibulsuk, S.; Udomchai, A.; Suddeepong, A.; Takaikaew, T.; Vichitcholchai, N.; Horpibulsuk, J.; Arulrajah, A. Durability improvement of cement stabilized pavement base using natural rubber latex. Transp. Geotech. 2021, 28, 100518. [Google Scholar] [CrossRef]

- Mekonnen, E.; Amdie, Y.; Etefa, H.; Tefera, N.; Tafesse, M. Stabilization of expansive black cotton soil using bioenzymes produced by ureolytic bacteria. Int. J. Geo-Eng. 2022, 13, 10. [Google Scholar] [CrossRef]

- Ahmadullah, T.; Chrysochoou, M. Relationship between strength development and pozzolanic reactions in lime stabilized kaolinite. Int. J. Geo-Eng. 2024, 15, 11. [Google Scholar] [CrossRef]

- James, J.; Saraswathy, R. Performance of fly ash-lime stabilized lateritic soil blocks subjected to alternate cycles of wetting and drying. Civ. Environ. Eng. 2020, 16, 30–38. [Google Scholar] [CrossRef]

- Abdalla, T.A.; Salih, N.B. Wetting and Drying Cycles Influences on Geotechnical Properties of Lime-Stabilized Clayey Soil. In Proceedings of the International Conference on Geotechnical Engineering-IRAQ, Baghdad, Iraq, 17–19 May 2022; pp. 278–289. [Google Scholar]

- Abbey, S.J.; Amakye, S.Y.; Eyo, E.U.; Booth, C.A.; Jeremiah, J.J. Wet–Dry Cycles and Microstructural Characteristics of Expansive Subgrade Treated with Sustainable Cementitious Waste Materials. Materials 2023, 16, 3124. [Google Scholar] [CrossRef] [PubMed]

- Maaitah, O.N. Soil stabilization by chemical agent. Geotech. Geol. Eng. 2012, 30, 1345–1356. [Google Scholar] [CrossRef]

- Mustafayeva, A.; Bimykova, A.; Olagunju, S.O.; Kim, J.; Satyanaga, A.; Moon, S.-W. Mechanical Properties and Microscopic Mechanism of Basic Oxygen Furnace (BOF) Slag-Treated Clay Subgrades. Buildings 2023, 13, 2962. [Google Scholar] [CrossRef]

- Ale, T.O. Improving the geotechnical properties of a Nigerian termite reworked soil using pretest drying conditions and sawdust ash. Int. J. Geo-Eng. 2023, 14, 1. [Google Scholar] [CrossRef]

- Regasa, H.; Jothimani, M.; Oyda, Y. Subgrade soil stabilization using the Quicklime: A case study from Modjo-Hawassa highway, Central Ethiopia. Int. J. Geo-Eng. 2023, 14, 17. [Google Scholar] [CrossRef]

- Zivari, A.; Siavoshnia, M.; Rezaei, H. Effect of lime-rice husk ash on geotechnical properties of loess soil in Golestan province, Iran. Int. J. Geo-Eng. 2023, 14, 20. [Google Scholar] [CrossRef]

- Chavali, R.V.P.; Reshmarani, B. Characterization of expansive soils treated with lignosulfonate. Int. J. Geo-Eng. 2020, 11, 17. [Google Scholar] [CrossRef]

- Nie, S.; Zhou, J.; Yang, F.; Lan, M.; Li, J.; Zhang, Z.; Chen, Z.; Xu, M.; Li, H.; Sanjayan, J.G. Analysis of theoretical carbon dioxide emissions from cement production: Methodology and application. J. Clean. Prod. 2022, 334, 130270. [Google Scholar] [CrossRef]

- Chaunsali, P.; Mondal, P. Influence of calcium sulfoaluminate (CSA) cement content on expansion and hydration behavior of various ordinary portland cement-CSA blends. J. Am. Ceram. Soc. 2015, 98, 2617–2624. [Google Scholar] [CrossRef]

- Hanein, T.; Imbabi, M.S.; Glasser, F.P.; Bannerman, M.N. Lowering the carbon footprint and energy consumption of cement production: A novel Calcium SulfoAluminate cement production process. In Proceedings of the 1st International Conference on Grand Challenges in Construction Materials, Los Angeles, CA, USA, 17–18 March 2016. [Google Scholar]

- Nie, S.; Zhang, Q.; Lan, M.; Zhou, J.; Xu, M.; Li, H.; Wang, J. Fundamental design of low-carbon ordinary Portland cement-calcium sulfoaluminate clinker-anhydrite blended system. Cem. Concr. Compos. 2023, 139, 105053. [Google Scholar] [CrossRef]

- Subramanian, S.; Moon, S.-W.; Moon, J.; Ku, T. CSA-treated sand for geotechnical application: Microstructure analysis and rapid strength development. J. Mater. Civ. Eng. 2018, 30, 04018313. [Google Scholar] [CrossRef]

- Guan, Y.; Gao, Y.; Sun, R.; Won, M.C.; Ge, Z. Experimental study and field application of calcium sulfoaluminate cement for rapid repair of concrete pavements. Front. Struct. Civ. Eng. 2017, 11, 338–345. [Google Scholar] [CrossRef]

- Bertola, F.; Gastaldi, D.; Irico, S.; Paul, G.; Canonico, F. Behavior of blends of CSA and Portland cements in high chloride environment. Constr. Build. Mater. 2020, 262, 120852. [Google Scholar] [CrossRef]

- Moon, S.-W.; Vinoth, G.; Subramanian, S.; Kim, J.; Ku, T. Effect of fine particles on strength and stiffness of cement treated sand. Granul. Matter 2020, 22, 9. [Google Scholar] [CrossRef]

- Sagidullina, N.; Muratova, A.; Kim, J.; Satyanaga, A.; Moon, S.-W. Stabilization of organic soil with CSA cement. In Smart Geotechnics for Smart Societies; CRC Press: Boca Raton, FL, USA, 2023; pp. 578–582. [Google Scholar]

- Sagidullina, N.; Abdialim, S.; Kim, J.; Satyanaga, A.; Moon, S.-W. Influence of freeze–thaw cycles on physical and mechanical properties of cement-treated silty sand. Sustainability 2022, 14, 7000. [Google Scholar] [CrossRef]

- Rauf, A.; Moon, S.-W.; Lim, C.-K.; Satyanaga, A.; Kim, J. Mechanical characteristics of CSA-treated sand reinforced with fiber under freeze-thaw cycles. Case Stud. Constr. Mater. 2024, 21, e03875. [Google Scholar] [CrossRef]

- Ocheme, J.I.; Olagunju, S.O.; Khamitov, R.; Satyanaga, A.; Kim, J.; Moon, S.-W. Triaxial shear behavior of calcium sulfoaluminate (CSA)-treated sand under high confining pressures. Geomech. Eng 2023, 33, 41–51. [Google Scholar] [CrossRef]

- Nabil, M.; Mustapha, A.; Rios, S. Impact of wetting—Drying cycles on the mechanical properties of lime-stabilized soils. Int. J. Pavement Res. Technol. 2020, 13, 83–92. [Google Scholar] [CrossRef]

- Wassermann, A.; Abdallah, A.; Cuisinier, O. Impact of wetting and drying cycles on the mechanical behaviour of a cement-treated soil. Transp. Geotech. 2022, 36, 100804. [Google Scholar] [CrossRef]

- Das, G.; Razakamanantsoa, A.; Herrier, G.; Deneele, D. Influence of wetting fluids on the compressive strength, physicochemical, and pore-structure evolution in lime-treated silty soil subjected to wetting and drying cycles. Transp. Geotech. 2022, 35, 100798. [Google Scholar] [CrossRef]

- Xu, X.-T.; Liu, D.-Q.; Xian, Z.-X.; Yang, F.; Jian, W.-B.; Xu, X.; Huang, J.-B. Influence of Drying–Wetting Cycles on the Water Retention and Microstructure of Residual Soil. Geofluids 2022, 2022, 9948658. [Google Scholar] [CrossRef]

- Chu, C.; Zhan, M.; Feng, Q.; Li, D.; Xu, L.; Zha, F.; Deng, Y. Effect of Drying-Wetting Cycles on Engineering Properties of Expansive Soils Modified by Industrial Wastes. Adv. Mater. Sci. Eng. 2020, 2020, 5602163. [Google Scholar] [CrossRef]

- Aldaood, A.; Bouasker, M.; Al-Mukhtar, M. Impact of wetting–drying cycles on the microstructure and mechanical properties of lime-stabilized gypseous soils. Eng. Geol. 2014, 174, 11–21. [Google Scholar] [CrossRef]

- ASTM D1921-18; Standard Test Methods for Particle Size (Sieve Analysis) of Plastic Materials. ASTM: West Conshohocken, PA, USA, 2018.

- Tangshan Polar Bear Building Materials Co., L. Calcium Sulfo Aluminate Cement Type 3. Available online: https://tspolarbear.en.made-in-china.com/product/eZhaovWbXETG/China-Polar-Bear-CSA-Cement-Pure-Clinker-Type-3.html (accessed on 20 January 2023).

- Lan, W.; Glasser, F. Hydration of calcium sulphoaluminate cements. Adv. Cem. Res. 1996, 8, 127–134. [Google Scholar] [CrossRef]

- Tao, Y.; Rahul, A.; Mohan, M.K.; De Schutter, G.; Van Tittelboom, K. Recent progress and technical challenges in using calcium sulfoaluminate (CSA) cement. Cem. Concr. Compos. 2023, 137, 104908. [Google Scholar] [CrossRef]

- Park, S.; Jeong, Y.; Moon, J.; Lee, N. Hydration characteristics of calcium sulfoaluminate (CSA) cement/portland cement blended pastes. J. Build. Eng. 2021, 34, 101880. [Google Scholar] [CrossRef]

- Subramanian, S.; Khan, Q.; Ku, T. Strength development and prediction of calcium sulfoaluminate treated sand with optimized gypsum for replacing OPC in ground improvement. Constr. Build. Mater. 2019, 202, 308–318. [Google Scholar] [CrossRef]

- ASTM D698-12; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft3 (600 kN-m/m3)). ASTM: West Conshohocken, PA, USA, 2021.

- ASTM D559/D559M-15; Standard Test Methods for Wetting and Drying Compacted Soil–Cement Mixtures. ASTM: West Conshohocken, PA, USA, 2023.

- D2166/D2166M; Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM: West Conshohocken, PA, USA, 2007.

- Jumassultan, A.; Sagidullina, N.; Kim, J.; Sung-Woo, M. Effect of cyclic freezing-thawing on strength and durability of sand stabilized with CSA cement. In Proceedings of the 2020 World Congress on the 2020 World Congress on Advances in Civil, Environmental, & Materials Research, Seoul, Republic of Korea, 25–28 August 2020; pp. 25–28. [Google Scholar]

- Roshan, K.; Choobbasti, A.J.; Kutanaei, S.S. Evaluation of the impact of fiber reinforcement on the durability of lignosulfonate stabilized clayey sand under wet-dry condition. Transp. Geotech. 2020, 23, 100359. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, J.; Wang, Y.; Qi, C.; Ma, X.; Che, W.; Ma, K. Wetting–drying effects on the mechanical performance of xanthan gum biopolymer-stabilized soil. Environ. Earth Sci. 2024, 83, 197. [Google Scholar] [CrossRef]

- Goh, S.; Rahardjo, H.; Leong, E. Shear strength of unsaturated soils under multiple drying-wetting cycles. J. Geotech. Geoenviron. Eng. 2014, 140, 06013001. [Google Scholar] [CrossRef]

- Basma, A.A.; Al-Homoud, A.S.; Malkawi, A.I.H.; Al-Bashabsheh, M.A. Swelling-shrinkage behavior of natural expansive clays. Appl. Clay Sci. 1996, 11, 211–227. [Google Scholar] [CrossRef]

- Chen, R.; Ng, C.W.W. Impact of wetting–drying cycles on hydro-mechanical behavior of an unsaturated compacted clay. Appl. Clay Sci. 2013, 86, 38–46. [Google Scholar] [CrossRef]

- Nowamooz, H.; Masrouri, F. Density-dependent hydromechanical behaviour of a compacted expansive soil. Eng. Geol. 2009, 106, 105–115. [Google Scholar] [CrossRef]

- Tang, C.-S.; Cui, Y.-J.; Shi, B.; Tang, A.-M.; Liu, C. Desiccation and cracking behaviour of clay layer from slurry state under wetting–drying cycles. Geoderma 2011, 166, 111–118. [Google Scholar] [CrossRef]

- Zemenu, G.; Martine, A.; Roger, C. Analysis of the behavior of a clayey soil under cyclic water stresses. Bull. Eng. Geol. Environ. 2009, 68, 421–436. [Google Scholar] [CrossRef]

- Asif, U.; Memon, S.A.; Javed, M.F.; Kim, J. Predictive Modeling and Experimental Validation for Assessing the Mechanical Properties of Cementitious Composites Made with Silica Fume and Ground Granulated Blast Furnace Slag. Buildings 2024, 14, 1091. [Google Scholar] [CrossRef]

- Chaduvula, U.; Desai, A.K.; Solanki, C. Application of triangular polypropylene fibres on soil subjected to freeze–thaw cycles. Indian Geotech. J. 2014, 44, 351–356. [Google Scholar] [CrossRef]

- Zhao-tian, Z.; Hai-bo, L.; Yan-lin, Z. Study of pore size distribution of expansive soil during wetting-drying cycle and its application. Rock Soil Mech. 2013, 34, 322–328. [Google Scholar]

- Li, D.; Velde, B.; Zhang, T. Observations of pores and aggregates during aggregation in some clay-rich agricultural soils as seen in 2D image analysis. Geoderma 2004, 118, 191–207. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).