Waste Glass as Partial Cement Replacement in Sustainable Concrete: Mechanical and Fresh Properties Review

Abstract

:1. Introduction

2. Pozzolanic Materials: Composition and Characteristics

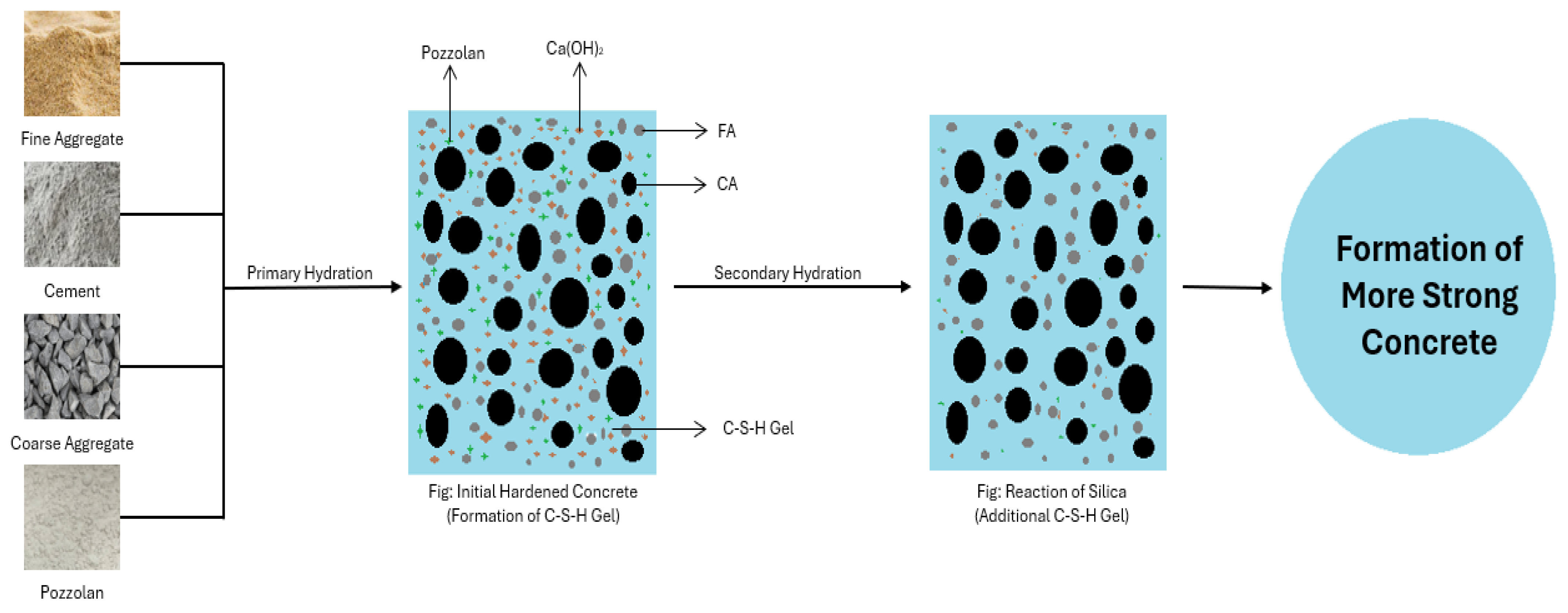

2.1. Types of Pozzolans and Reaction Mechanism

2.2. Chemical Composition of Pozzolans

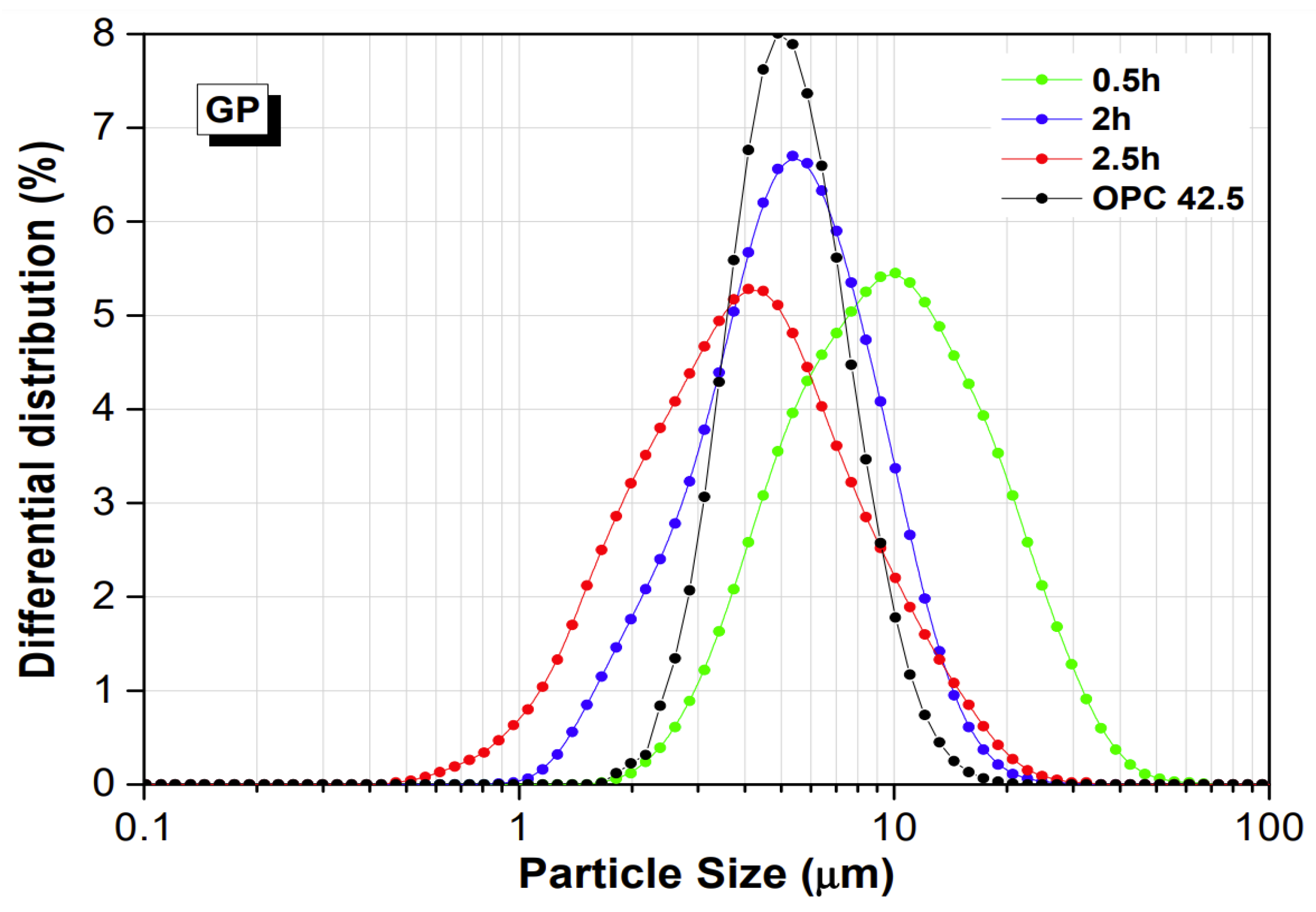

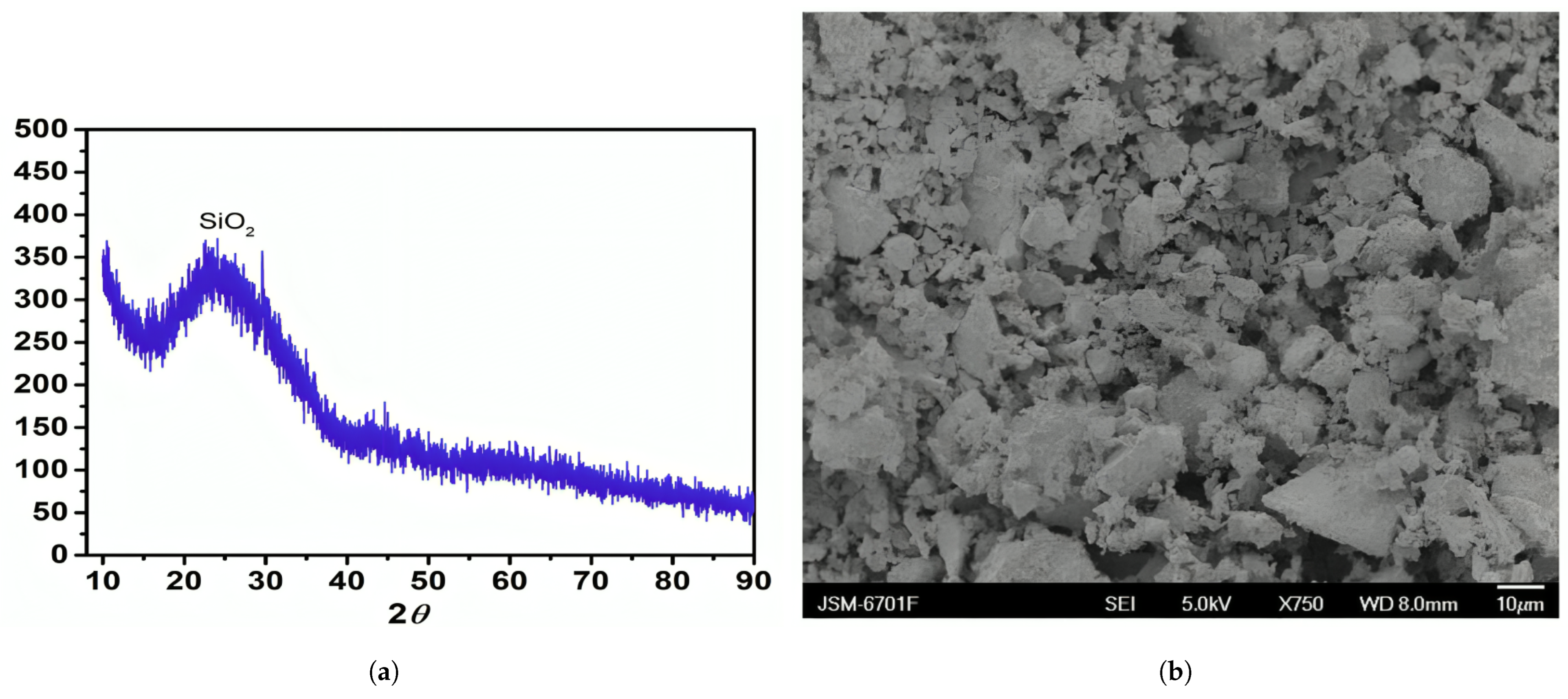

2.3. Ground Glass Pozzolan (GGP)

2.3.1. Types of Glass

2.3.2. Glass Color

3. Fresh Concrete Properties

3.1. Rheological Behavior

3.2. Slump

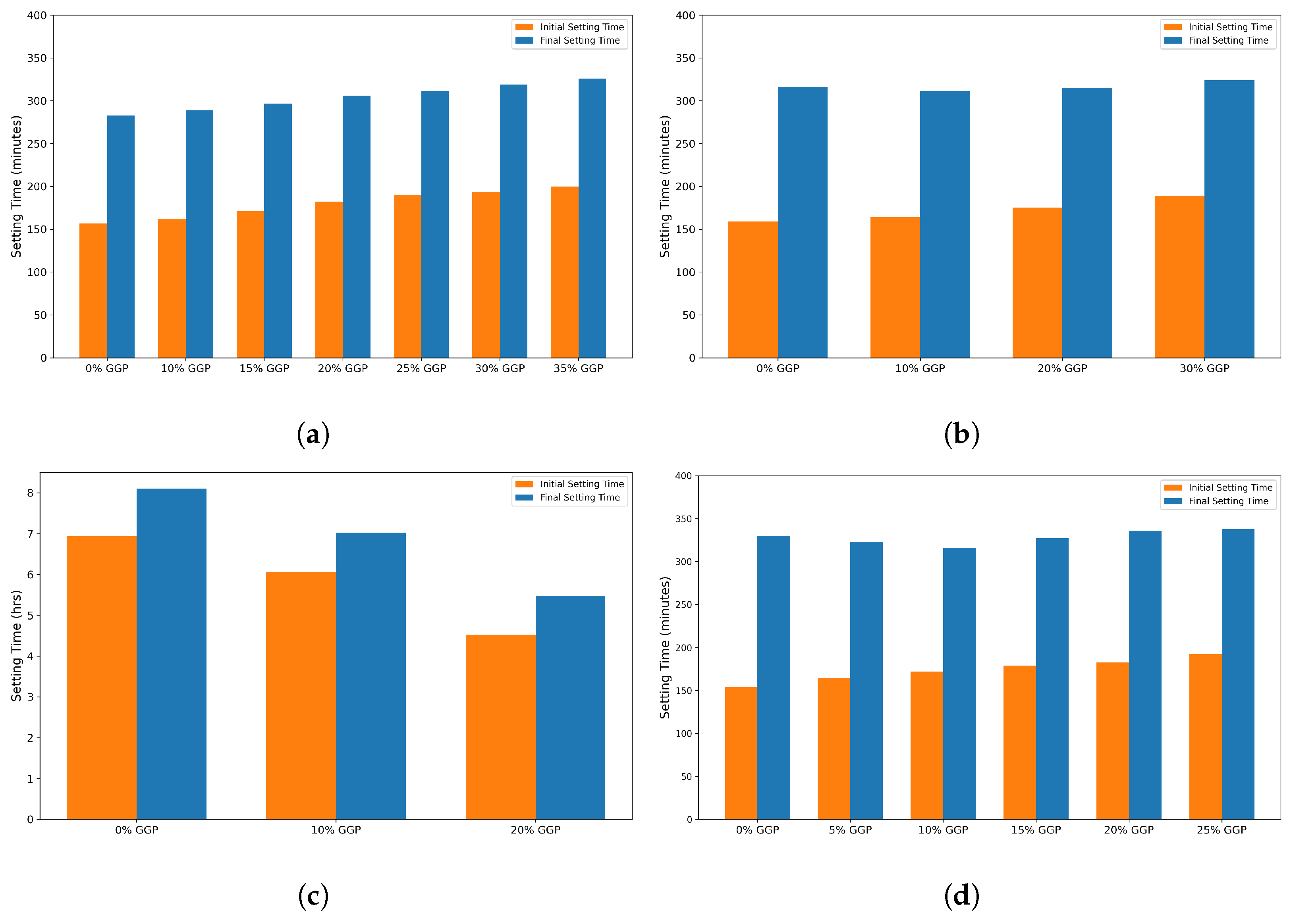

3.3. Setting Time

4. Physical Properties

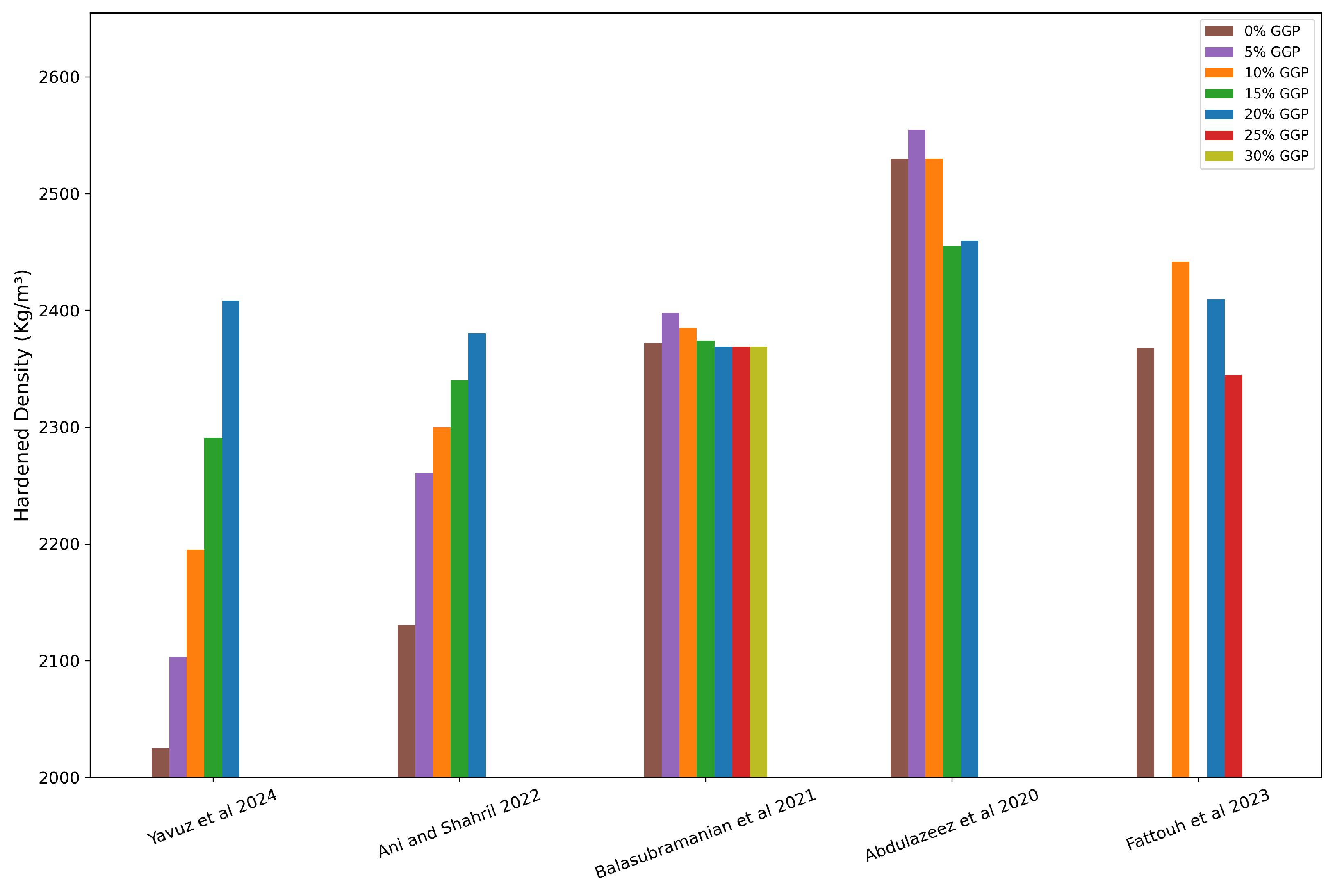

Density

5. Mechanical Properties

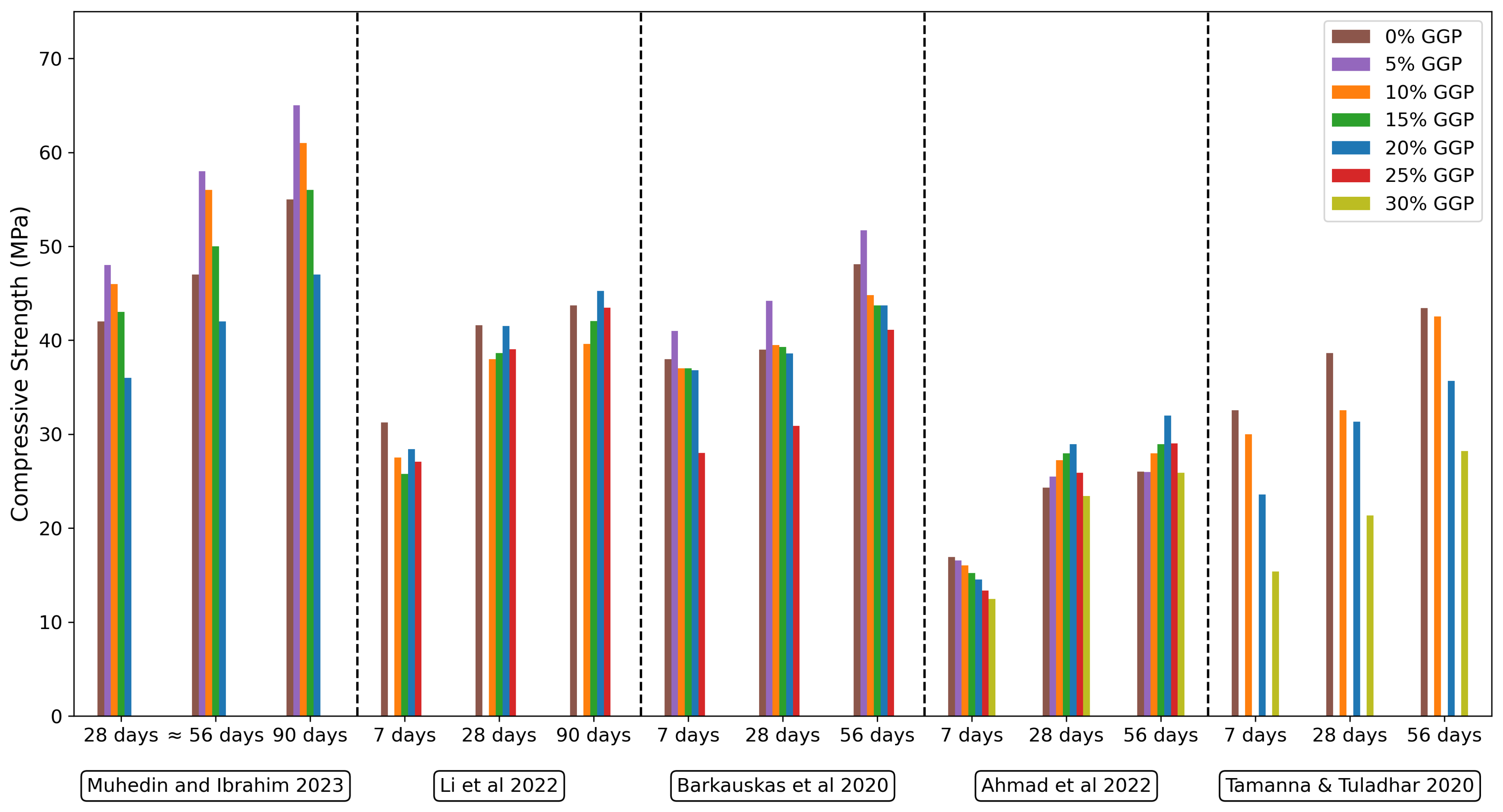

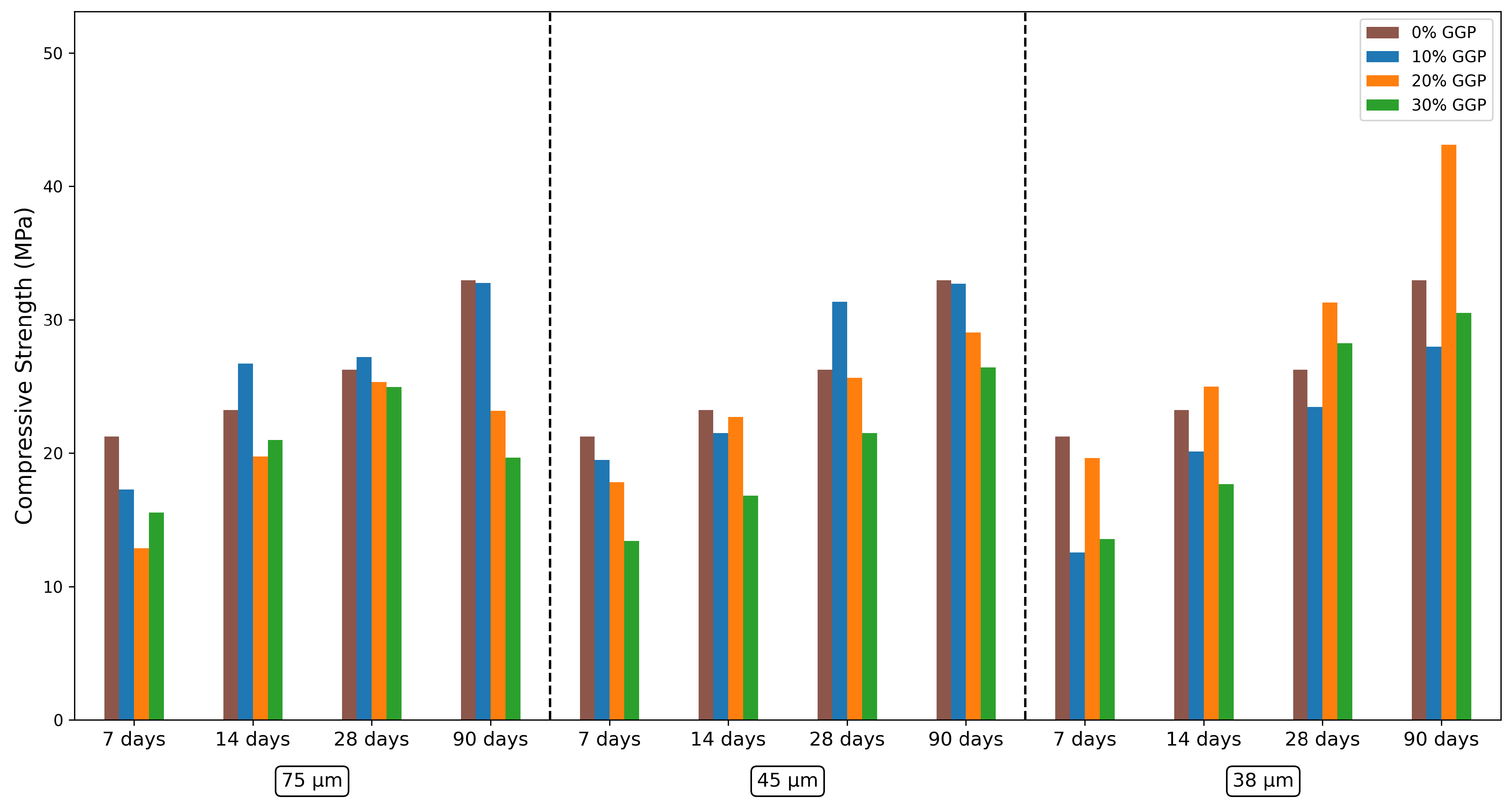

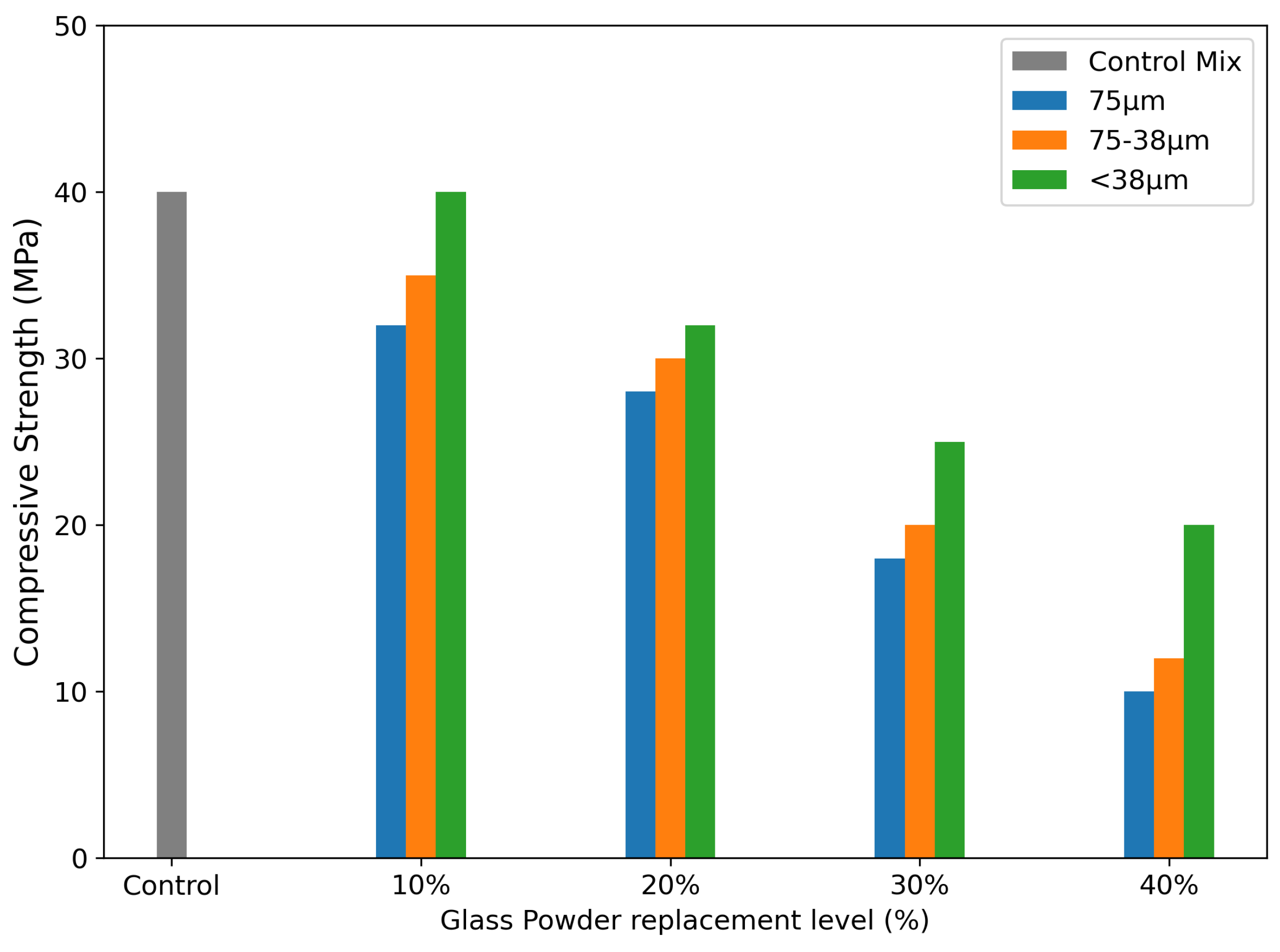

5.1. Compressive Strength

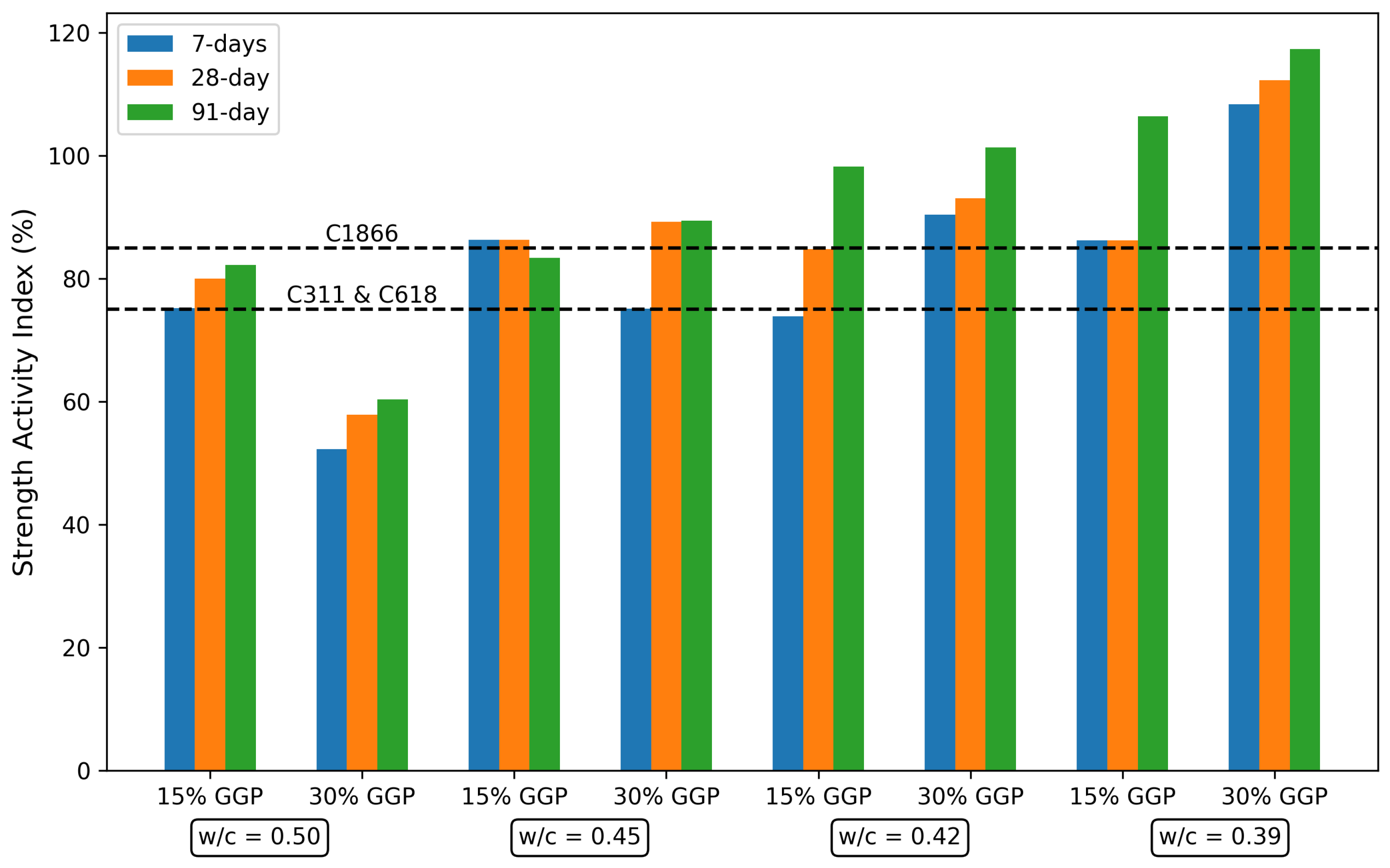

5.2. Strength Activity Index (SAI)

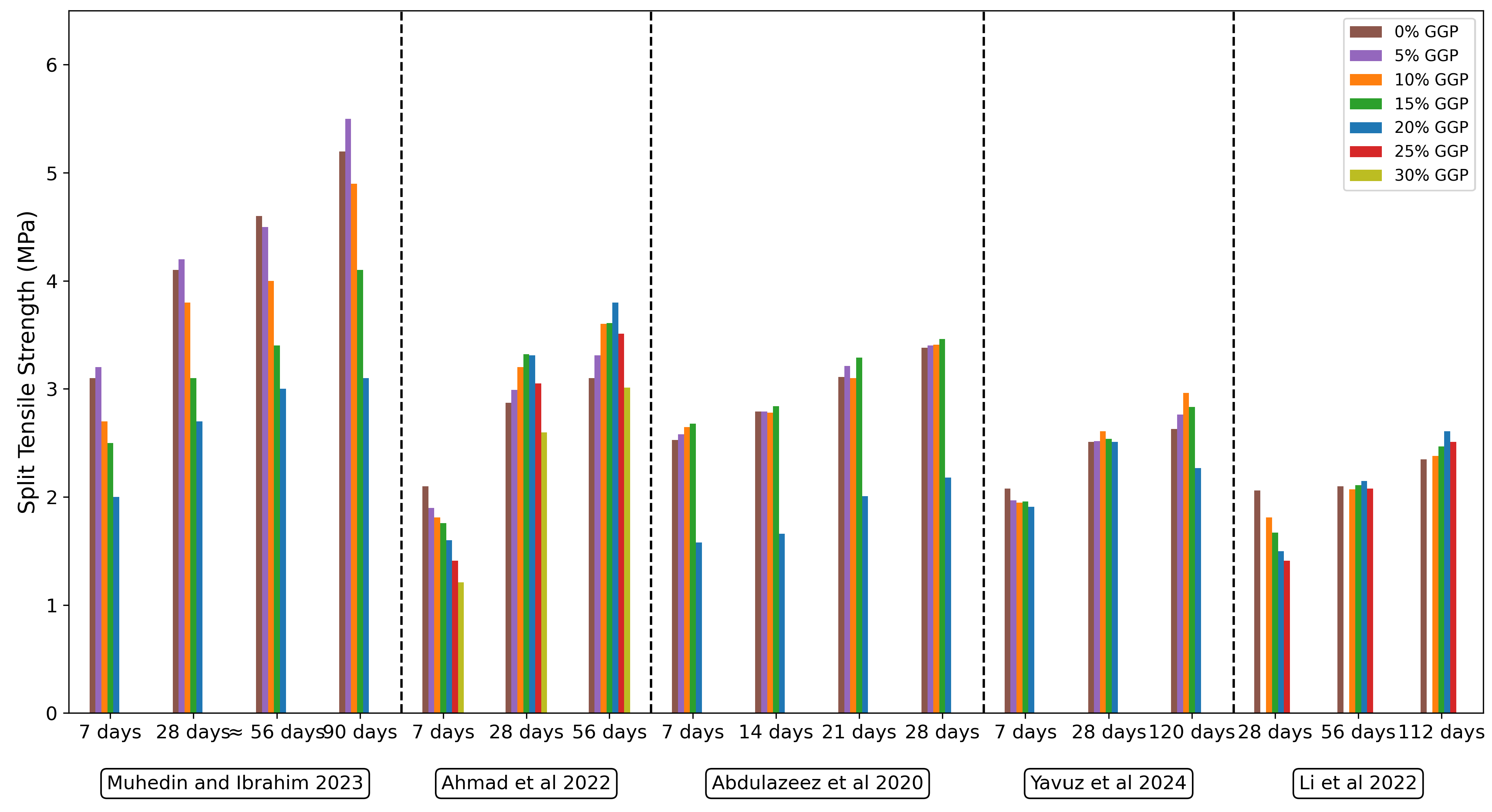

5.3. Tensile Strength

5.4. Flexural Strength

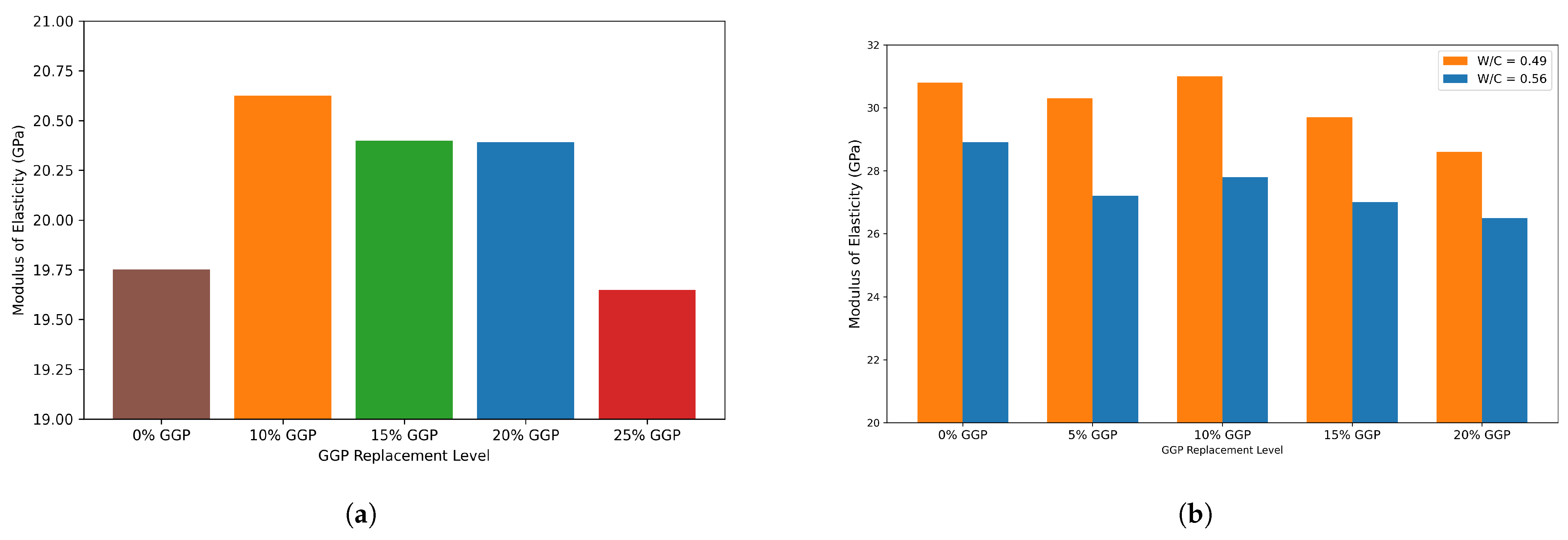

5.5. Modulus of Elasticity

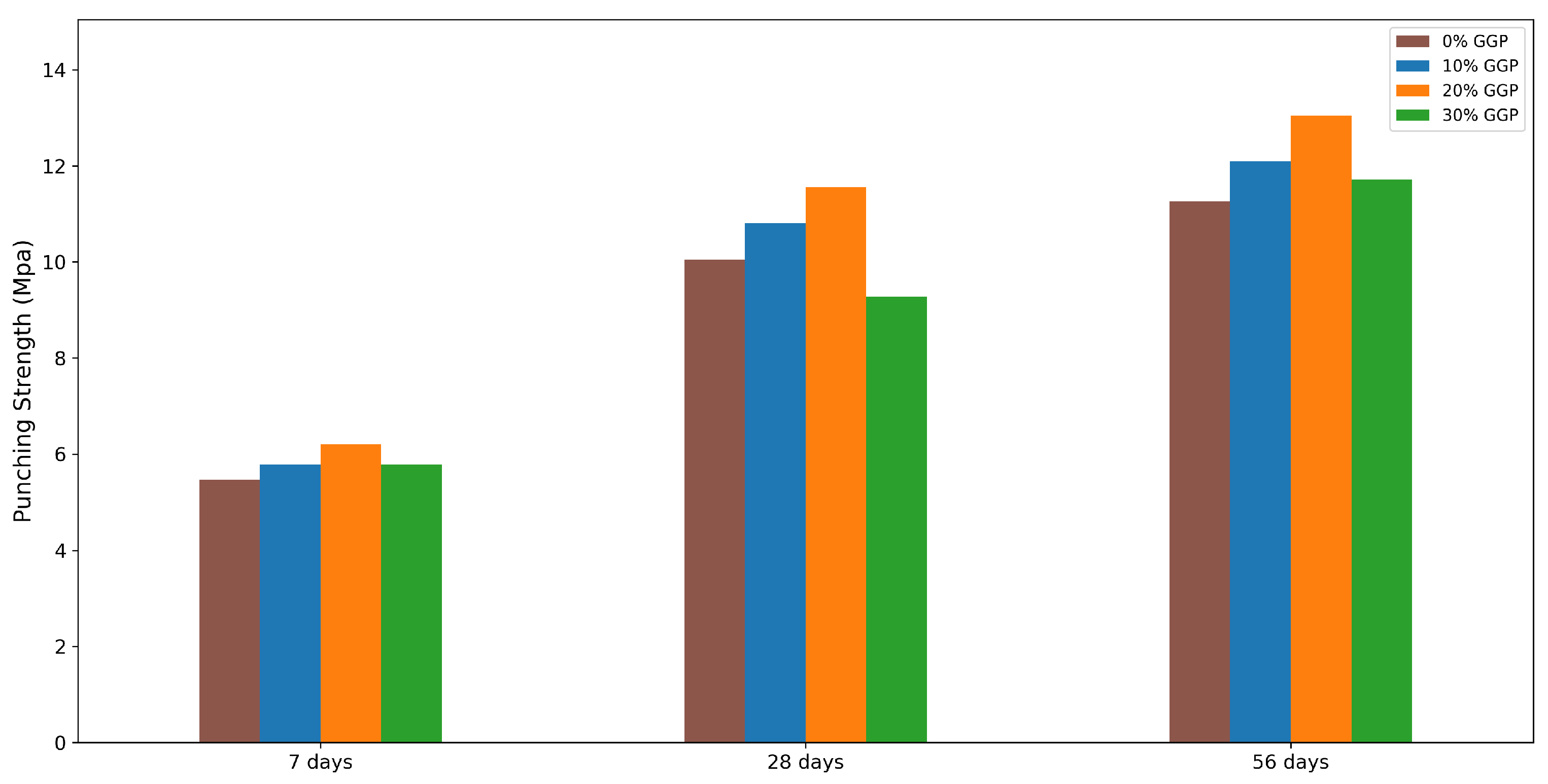

5.6. Punching Strength of Concrete

6. Life Cycle Assessment (LCA)

7. Field Application of GGP

8. Conclusions

- The concrete rheological properties change with GGP incorporation as a partial cement replacement, enhancing the flowability and viscosity while reducing segregation.

- The slump value increases with a higher amount of GGP in some cases, while in other cases the slump value decreases. The increase in the slump occurs as a result of lower water absorption and reduced internal friction from the presence of GGP. However, the decrease in slump results from the angular shape of GGP particles with a high surface area, which requires more cement paste for coating. Further research is recommended to clarify these varying effects on the slump.

- An increase in the GGP content decreases the concrete density. This occurs due to the low specific gravity of GGP and incomplete pozzolanic reactions. However, other findings show an increase in concrete density due to the densification of the matrix by filling ITZ with an additional C-S-H gel. Further research is recommended to gain a deeper understanding of these contrasting results.

- The addition of GGP in concrete increases the initial setting time. This occurs because the glass particles of GGP reduce water absorption, increasing the amount of free water in the mix and delaying the initial setting time. However, some studies reported a decrease in the final setting time while others reported an increase. Further research can be performed to better understand these differences in results in a final setting time.

- The addition of GGP improves the compressive strength at later curing ages due to the pozzolanic reaction forming an additional C-S-H gel, while at early curing stages, the compressive strength remains lower compared to the control mix. Furthermore, a finer GGP particle size results in a higher compressive strength.

- The tensile strength and flexural strength of GGP-incorporated concrete improve at later curing days due to additional pozzolanic reactions and the formation of a denser concrete matrix. However, ductility decreases with an increase in the amount of GGP.

- The punching strength is enhanced due to the addition of GGP because of microfillings from secondary hydration in the concrete matrix.

- The variation in the modulus of elasticity of the GGP-incorporated concrete is minimal at lower replacement levels (≤15%). However, due to the formation of less C-S-H gel, stiffness decreases at higher replacement levels (≥20%).

- The optimum dosage of GGP depends upon different factors such as mix design; particle size; specific surface area; and glass chemical composition, type, and color.

- LCA studies demonstrate a significant reduction in global warming potential and associated energy consumption, contributing to the sustainability of GGP incorporation in concrete.

- Field application in pavements, buildings, and bridges confirms the feasibility of GGP incorporation as a partial cement replacement in the construction industry.

9. Future Research Prospects

- Further research should be focused on a detailed investigation of the key parameters such as W/C ratio and GGP particle size, type, color, chemical composition, and replacement percentage to quantify their inter-dependencies. Through experimental research, a strong correlation between these parameters could be established, allowing for the optimization of GGP-incorporated concrete.

- The application of GGP-incorporated concrete in load-bearing components including beams, columns, and foundations should be studied. Such studies provide insights into the field application of GGP-incorporated concrete and contribute to sustainable building practices.

- The thermal response of GGP-incorporated concrete should be studied to better understand the behavior of glass pozzolan under high-temperature conditions.

- The application of machine learning models could be utilized to optimize the mix design based on the currently available experimental data. This could significantly reduce the utilization of raw materials and the need for prolonged curing periods, enhancing resource-efficient concrete production.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bueno, E.T.; Paris, J.M.; Clavier, K.A.; Spreadbury, C.; Ferraro, C.C.; Townsend, T.G. A review of ground waste glass as a supplementary cementitious material: A focus on alkali-silica reaction. J. Clean. Prod. 2020, 257, 120180. [Google Scholar] [CrossRef]

- Kalakada, Z.; Doh, J.; Zi, G. Utilisation of coarse glass powder as pozzolanic cement—A mix design investigation. Constr. Build. Mater. 2020, 240, 117916. [Google Scholar] [CrossRef]

- Jani, Y.; Hogland, W. Waste glass in the production of cement and concrete—A review. J. Environ. Chem. Eng. 2014, 2, 1767–1775. [Google Scholar] [CrossRef]

- Krstic, M.; Davalos, J. Field Application of Recycled Glass Pozzolan for Concrete. ACI Mater. J. 2019, 116, 123–131. [Google Scholar] [CrossRef]

- Li, C.; Gong, X.Z.; Cui, S.P.; Wang, Z.H.; Zheng, Y.; Chi, B.C. CO2 emissions due to cement manufacture. Mater. Sci. Forum Trans. Tech. Publ. 2011, 685, 181–187. [Google Scholar] [CrossRef]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Ahmad, J.; Martinez-Garcia, R.; Algarni, S.; de Prado-Gil, J.; Alqahtani, T.; Irshad, K. Characteristics of sustainable concrete with partial substitutions of glass waste as a binder material. Int. J. Concr. Struct. Mater. 2022, 16, 21. [Google Scholar] [CrossRef]

- Statista. Major Countries in Worldwide Cement Production in 2023. 2023. Available online: https://www.statista.com/statistics/267364/world-cement-production-by-country/ (accessed on 4 March 2025).

- U.S. Environmental Protection Agency (EPA). Advancing Sustainable Materials Management: 2018 Fact Sheet. Available online: https://www.epa.gov/sites/default/files/2020-11/documents/2018_ff_fact_sheet.pdf (accessed on 4 March 2025).

- Mohajerani, A.; Vajna, J.; Cheung, T.H.H.; Kurmus, H.; Arulrajah, A.; Horpibulsuk, S. Practical recycling applications of crushed waste glass in construction materials: A review. Constr. Build. Mater. 2017, 156, 443–467. [Google Scholar] [CrossRef]

- Container Recycling Institute. Glass Recycling Rates by Country 1996/1998 vs. 2010. 2012. Available online: https://www.container-recycling.org/index.php/glass-containers/ (accessed on 4 March 2025).

- Adesina, A.; Das, S. Influence of glass powder on the durability properties of engineered cementitious composites. Constr. Build. Mater. 2020, 242, 118199. [Google Scholar] [CrossRef]

- Kasaniya, M.; Thomas, M.D.; Moffatt, E.G. Pozzolanic reactivity of natural pozzolans, ground glasses and coal bottom ashes and implication of their incorporation on the chloride permeability of concrete. Cem. Concr. Res. 2021, 139, 106259. [Google Scholar] [CrossRef]

- Nassar, R.U.D.; Soroushian, P. Strength and durability of recycled aggregate concrete containing milled glass as partial replacement for cement. Constr. Build. Mater. 2012, 29, 368–377. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z.; Usanova, K.I.; Vatin, N.I.; El-Shorbagy, M.A. A step towards concrete with partial substitution of waste glass (WG) in concrete: A review. Materials 2022, 15, 2525. [Google Scholar] [CrossRef] [PubMed]

- Matos, A.M.; Sousa-Coutinho, J. Durability of mortar using waste glass powder as cement replacement. Constr. Build. Mater. 2012, 36, 205–215. [Google Scholar] [CrossRef]

- Raju, A.S.; Anand, K.; Rakesh, P. Partial replacement of Ordinary Portland cement by LCD glass powder in concrete. Mater. Today Proc. 2021, 46, 5131–5137. [Google Scholar] [CrossRef]

- Taha, B.; Nounu, G. Properties of concrete contains mixed colour waste recycled glass as sand and cement replacement. Constr. Build. Mater. 2008, 22, 713–720. [Google Scholar] [CrossRef]

- Shayan, A.; Xu, A. Performance of glass powder as a pozzolanic material in concrete: A field trial on concrete slabs. Cem. Concr. Res. 2006, 36, 457–468. [Google Scholar] [CrossRef]

- Shayan, A.; Xu, A. Value-added utilisation of waste glass in concrete. Cem. Concr. Res. 2004, 34, 81–89. [Google Scholar] [CrossRef]

- Zidol, A.; Tognonvi, M.T.; Tagnit-Hamou, A. Effect of glass powder on concrete sustainability. New J. Glass Ceram. 2017, 7, 34–47. [Google Scholar] [CrossRef]

- Idir, R.; Cyr, M.; Tagnit-Hamou, A. Pozzolanic properties of fine and coarse color-mixed glass cullet. Cem. Concr. Compos. 2011, 33, 19–29. [Google Scholar] [CrossRef]

- Idir, R.; Cyr, M.; Tagnit-Hamou, A. Use of waste glass in cement-based materials. Environ. Ing. Dév. 2010, 57, 10. [Google Scholar] [CrossRef]

- Lu, J.X.; Duan, Z.H.; Poon, C.S. Fresh properties of cement pastes or mortars incorporating waste glass powder and cullet. Constr. Build. Mater. 2017, 131, 793–799. [Google Scholar] [CrossRef]

- Schwarz, N.; Cam, H.; Neithalath, N. Influence of a fine glass powder on the durability characteristics of concrete and its comparison to fly ash. Cem. Concr. Compos. 2008, 30, 486–496. [Google Scholar] [CrossRef]

- Rashidian-Dezfouli, H.; Afshinnia, K.; Rangaraju, P.R. Efficiency of Ground Glass Fiber as a cementitious material, in mitigation of alkali-silica reaction of glass aggregates in mortars and concrete. J. Build. Eng. 2018, 15, 171–180. [Google Scholar]

- Omran, A.F.; Etienne, D.; Harbec, D.; Tagnit-Hamou, A. Long-term performance of glass-powder concrete in large-scale field applications. Constr. Build. Mater. 2017, 135, 43–58. [Google Scholar] [CrossRef]

- Frigione, G.; Marra, S. Relationship between particle size distribution and compressive strength in Portland cement. Cem. Concr. Res. 1976, 6, 113–127. [Google Scholar] [CrossRef]

- Lee, H.; Hanif, A.; Usman, M.; Sim, J.; Oh, H. Performance evaluation of concrete incorporating glass powder and glass sludge wastes as supplementary cementing material. J. Clean. Prod. 2018, 170, 683–693. [Google Scholar] [CrossRef]

- Anwar, A. The influence of waste glass powder as a pozzolanic material in concrete. Int. J. Civ. Eng. Technol 2016, 7, 131–148. [Google Scholar]

- Sahmenko, G.; Korjakins, A.; Bumanis, G. Bore-silicate glass waste of lamp as a micro-filler for concrete. Rigas Teh. Univ. Zinat. Raksti 2009, 10, 131. [Google Scholar]

- Okeke, K.; Adedeji, A. A review on the properties of concrete incorporated with waste glass as a substitute for cement. Epistem. Sci. Eng. Technol. 2016, 5, 396–407. [Google Scholar]

- Rahma, A.; El Naber, N.; Issa Ismail, S. Effect of glass powder on the compression strength and the workability of concrete. Cogent Eng. 2017, 4, 1373415. [Google Scholar] [CrossRef]

- Khmiri, A.; Samet, B.; Chaabouni, M. A cross mixture design to optimise the formulation of a ground waste glass blended cement. Constr. Build. Mater. 2012, 28, 680–686. [Google Scholar] [CrossRef]

- Nodehi, M.; Ren, J.; Shi, X.; Debbarma, S.; Ozbakkaloglu, T. Experimental evaluation of alkali-activated and portland cement-based mortars prepared using waste glass powder in replacement of fly ash. Constr. Build. Mater. 2023, 394, 132124. [Google Scholar] [CrossRef]

- Tucker, E.L.; Ferraro, C.C.; Laux, S.J.; Townsend, T.G. Economic and life cycle assessment of recycling municipal glass as a pozzolan in portland cement concrete production. Resour. Conserv. Recycl. 2018, 129, 240–247. [Google Scholar] [CrossRef]

- Guignone, G.; Calmon, J.L.; Vieira, G.; Zulcão, R.; Rebello, T.A. Life cycle assessment of waste glass powder incorporation on concrete: A bridge retrofit study case. Appl. Sci. 2022, 12, 3353. [Google Scholar] [CrossRef]

- Gebremichael, N.N.; Jadidi, K.; Karakouzian, M. Waste glass recycling: The combined effect of particle size and proportion in concrete manufactured with waste recycled glass. Constr. Build. Mater. 2023, 392, 132044. [Google Scholar] [CrossRef]

- Kaminsky, A.; Krstic, M.; Rangaraju, P.; Tagnit-Hamou, A.; Thomas, M.D. Ground-glass pozzolan for use in concrete. Concr. Int 2020, 42, 24–32. [Google Scholar]

- Gowtham, R.; Prabhu, S.M.; Gowtham, M.; Ramasubramani, R. A review on utilization of waste glass in construction field. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1130, 012010. [Google Scholar] [CrossRef]

- Yao, Z.; Qin, B.; Huang, Z.; Ruan, J.; Xu, Z. Green combined resource recycling system for the recycling of waste glass. ACS Sustain. Chem. Eng. 2021, 9, 7361–7368. [Google Scholar] [CrossRef]

- Bouchikhi, A.; Benzerzour, M.; Abriak, N.E.; Maherzi, W.; Mamindy-Pajany, Y. Study of the impact of waste glasses types on pozzolanic activity of cementitious matrix. Constr. Build. Mater. 2019, 197, 626–640. [Google Scholar] [CrossRef]

- Serelis, E.; Vaitkevicius, V. Utilization of glass shards from municipal solid waste in aluminium-based ultra-lightweight concrete. Constr. Build. Mater. 2022, 350, 128396. [Google Scholar] [CrossRef]

- AL-Zubaid, A.B.; Shabeeb, K.M.; Ali, A.I. Study the effect of recycled glass on the mechanical properties of green concrete. Energy Procedia 2017, 119, 680–692. [Google Scholar] [CrossRef]

- ASTM-C125; Standard Terminology Relating to Concrete and Concrete Aggregates. Standard, American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- Kasaniya, M. Pozzolans: Reactivity Test Method Development and Durability Performance. Ph.D. Thesis, The University of New Brunswick, Fredericton and Saint John, NB, Canada, 2014. [Google Scholar]

- Massazza, F. Pozzolana and pozzolanic cements. In Lea’s Chemistry of Cement and Concrete; Hewlett, P.C., Ed.; Butterworth-Heinemann: Oxford, UK, 1998; Chapter 10; pp. 471–631. [Google Scholar]

- Kasaniya, M.; Thomas, M.D. Role of the alkalis of supplementary cementing materials in controlling pore solution chemistry and alkali-silica reaction. Cem. Concr. Res. 2022, 162, 107007. [Google Scholar] [CrossRef]

- Suda, Y.; Saeki, T.; Saito, T. Relation between chemical composition and physical properties of CSH generated from cementitious materials. J. Adv. Concr. Technol. 2015, 13, 275–290. [Google Scholar] [CrossRef]

- Ramanathan, S.; Kasaniya, M.; Tuen, M.; Thomas, M.D.; Suraneni, P. Linking reactivity test outputs to properties of cementitious pastes made with supplementary cementitious materials. Cem. Concr. Compos. 2020, 114, 103742. [Google Scholar] [CrossRef]

- Becerra-Duitama, J.A.; Rojas-Avellaneda, D. Pozzolans: A review. Eng. Appl. Sci. Res. 2022, 49, 495–504. [Google Scholar]

- Burhan, L.; Ghafor, K.; Mohammed, A. Modeling the effect of silica fume on the compressive, tensile strengths and durability of NSC and HSC in various strength ranges. J. Build. Pathol. Rehabil. 2019, 4, 19. [Google Scholar] [CrossRef]

- Hamada, H.M.; Abed, F.; Katman, H.Y.B.; Humada, A.M.; Al Jawahery, M.S.; Majdi, A.; Yousif, S.T.; Thomas, B.S. Effect of silica fume on the properties of sustainable cement concrete. J. Mater. Res. Technol. 2023, 24, 8887–8908. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Y.; Zhang, P.; Ma, Y. Effective utilization of waste glass as cementitious powder and construction sand in mortar. Materials 2020, 13, 707. [Google Scholar] [CrossRef]

- Du, J.; Meng, W.; Khayat, K.H.; Bao, Y.; Guo, P.; Lyu, Z.; Abu-Obeidah, A.; Nassif, H.; Wang, H. New development of ultra-high-performance concrete (UHPC). Compos. Part B Eng. 2021, 224, 109220. [Google Scholar] [CrossRef]

- Shao, Y.; Lefort, T.; Moras, S.; Rodriguez, D. Studies on concrete containing ground waste glass. Cem. Concr. Res. 2000, 30, 91–100. [Google Scholar] [CrossRef]

- Mirzahosseini, M.; Riding, K.A. Effect of curing temperature and glass type on the pozzolanic reactivity of glass powder. Cem. Concr. Res. 2014, 58, 103–111. [Google Scholar] [CrossRef]

- Maraghechi, H.; Maraghechi, M.; Rajabipour, F.; Pantano, C.G. Pozzolanic reactivity of recycled glass powder at elevated temperatures: Reaction stoichiometry, reaction products and effect of alkali activation. Cem. Concr. Compos. 2014, 53, 105–114. [Google Scholar] [CrossRef]

- Vaitkevičius, V.; Šerelis, E.; Hilbig, H. The effect of glass powder on the microstructure of ultra high performance concrete. Constr. Build. Mater. 2014, 68, 102–109. [Google Scholar] [CrossRef]

- Tural, H.; Ozarisoy, B.; Derogar, S.; Ince, C. Investigating the governing factors influencing the pozzolanic activity through a database approach for the development of sustainable cementitious materials. Constr. Build. Mater. 2024, 411, 134253. [Google Scholar] [CrossRef]

- Zier, M.; Stenzel, P.; Kotzur, L.; Stolten, D. A review of decarbonization options for the glass industry. Energy Convers. Manag. X 2021, 10, 100083. [Google Scholar] [CrossRef]

- Guo, P.; Meng, W.; Nassif, H.; Gou, H.; Bao, Y. New perspectives on recycling waste glass in manufacturing concrete for sustainable civil infrastructure. Constr. Build. Mater. 2020, 257, 119579. [Google Scholar] [CrossRef]

- Balasubramanian, B.; Krishna, G.G.; Saraswathy, V.; Srinivasan, K. Experimental investigation on concrete partially replaced with waste glass powder and waste E-plastic. Constr. Build. Mater. 2021, 278, 122400. [Google Scholar] [CrossRef]

- Li, Q.; Qiao, H.; Li, A.; Li, G. Performance of waste glass powder as a pozzolanic material in blended cement mortar. Constr. Build. Mater. 2022, 324, 126531. [Google Scholar] [CrossRef]

- Christiansen, M.U.; Dymond, B.Z. Effect of composition on performance of ground glass pozzolan. ACI Mater. J. 2019, 116, 89–98. [Google Scholar] [CrossRef]

- Karazi, S.; Ahad, I.; Benyounis, K. Laser Micromachining for Transparent Materials. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Yue, Y.; Tuheen, M.I.; Du, J. Borosilicate glasses. In Encyclopedia of Materials: Technical Ceramics and Glasses; Elsevier: Amsterdam, The Netherlands, 2021; pp. 519–539. [Google Scholar]

- Sheikh, M.Z.; Atif, M.; Raza, M.A.; Suo, T.; Li, Y.; Zhou, F.; Dar, U.A. Damage propagation and dynamic material properties of aluminosilicate glass. J. Non-Cryst. Solids 2020, 547, 120313. [Google Scholar] [CrossRef]

- Chen, C.; Huang, R.; Wu, J.; Yang, C.C. Waste E-glass particles used in cementitious mixtures. Cem. Concr. Res. 2006, 36, 449–456. [Google Scholar] [CrossRef]

- Zhang, M.; Matinlinna, J.P. E-glass fiber reinforced composites in dental applications. Silicon 2012, 4, 73–78. [Google Scholar] [CrossRef]

- ASTM-C1866; Standard Specification for Ground-Glass Pozzolan for Use in Concrete. Standard, American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- Lecanuet, G.; Rocca, E.; Hee, P.; Skaper, M.A.; Rapin, C. Mechanism of alteration of the surface of lead crystal glass in contact with food: A chemical study of the surface layer. Appl. Surf. Sci. 2022, 580, 152281. [Google Scholar] [CrossRef]

- Ashby, M.F. Chapter 15—Material profiles. In Materials and the Environment (Second Edition), 2nd ed.; Ashby, M.F., Ed.; Butterworth-Heinemann: Boston, MA, USA, 2013; pp. 459–595. [Google Scholar] [CrossRef]

- Jin, W.; Meyer, C.; Baxter, S. “Glascrete”-concrete with glass aggregate. ACI Mater. J. 2000, 97, 208–213. [Google Scholar]

- Du, H.; Tan, K.H. Use of waste glass as sand in mortar: Part II–Alkali–silica reaction and mitigation methods. Cem. Concr. Compos. 2013, 35, 118–126. [Google Scholar] [CrossRef]

- Park, S.B.; Lee, B.C.; Kim, J.H. Studies on mechanical properties of concrete containing waste glass aggregate. Cem. Concr. Res. 2004, 34, 2181–2189. [Google Scholar] [CrossRef]

- Laveglia, A.; Trezza, M.A.; Rahhal, V.F. Does the colour of the waste glass affect their efficiency as supplementary cementitious material? Int. J. Constr. Manag. 2022, 22, 3098–3108. [Google Scholar] [CrossRef]

- Islam, G.S.; Rahman, M.; Kazi, N. Waste glass powder as partial replacement of cement for sustainable concrete practice. Int. J. Sustain. Built Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef]

- Li, G.; Shao, Y.; Fang, Y.; Li, W.; Lin, Y.; Yan, D. Effect of Waste Glass on Slurry Rheological Properties of Cement and Concrete. J. Phys. Conf. Ser. 2021, 2044, 012015. [Google Scholar] [CrossRef]

- younis Khudair, A.; Mohammed, M.K.; Hama, S.M. Optimization of glass powder content in self-compacting concrete as partial replacement of cement. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Thi-Qar, Iraq, 15–16 July 2020; IOP Publishing: Bristol, UK, 2020; Volume 928, p. 022140. [Google Scholar]

- Bouty, A.; Homsi, F. The effects of partially replacing cement by glass waste powder on concrete properties. Építoanyag J. Silic. Based Compos. Mater. 2021, 73, 40. [Google Scholar] [CrossRef]

- Abdulazeez, A.S.; Idi, M.A.; Kolawole, M.A.; Hamza, B. Effect of waste glass powder as a pozzolanic material in concrete production. Int. J. Eng. Res. 2020, 9, 589–594. [Google Scholar]

- Ibrahim, K. Recycled waste glass powder as a partial replacement of cement in concrete containing silica fume and fly ash. Case Stud. Constr. Mater. 2021, 15, e00630. [Google Scholar] [CrossRef]

- Fattouh, M.S.; Elsayed, E.K. Influence of utilizing glass powder with silica fume on mechanical properties and microstructure of concrete. Delta Univ. Sci. J. 2023, 6, 111–122. [Google Scholar] [CrossRef]

- Khan, F.A.; Shahzada, K.; Ullah, Q.S.; Fahim, M.; Khan, S.W.; Badrashi, Y.I. Development of environment-friendly concrete through partial addition of waste glass powder (WGP) as cement replacement. Civ. Eng. J. 2020, 6, 2332–2343. [Google Scholar] [CrossRef]

- Ani, F.M.; Hossain, M.A.; Shahril, R.N. Recycling of Glass Waste on the Concrete Properties as a Partial Binding Material Substitute. Eur. J. Eng. Technol. Res. 2022, 7, 138–142. [Google Scholar] [CrossRef]

- Sayeeduddin, M.S.; Chavan, M.F. Use of waste glass powder as a partial replacement of cement in fibre reinforced concrete. J. Mech. Civ. Eng. 2016, 13, 16–21. [Google Scholar] [CrossRef]

- Gupta, J.; Jethoo, A.; Lata, N. Assessment of mechanical properties by using powder waste glass with cement in concrete mix. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Tamil Nadu, India, 9–10 April 2020; IOP Publishing: Bristol, UK, 2020; Volume 872, p. 012122. [Google Scholar]

- Ahmad, J.; Martínez-García, R.; de Prado-Gil, J.; Irshad, K.; El-Shorbagy, M.A.; Fediuk, R.; Vatin, N.I. Concrete with partial substitution of waste glass and recycled concrete aggregate. Materials 2022, 15, 430. [Google Scholar] [CrossRef]

- Jiang, X.; Xiao, R.; Bai, Y.; Huang, B.; Ma, Y. Influence of waste glass powder as a supplementary cementitious material (SCM) on physical and mechanical properties of cement paste under high temperatures. J. Clean. Prod. 2022, 340, 130778. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, M.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Wattanapornprom, R.; Stitmannaithum, B. Comparison of properties of fresh and hardened concrete containing finely ground glass powder, fly ash, or silica fume. Eng. J. 2015, 19, 35–48. [Google Scholar] [CrossRef]

- Bansal, M.; Bansal, M.; Bahrami, A.; Krishan, B.; Garg, R.; Özkılıç, Y.O.; Althaqafi, E. Influence of pozzolanic addition on strength and microstructure of metakaolin-based concrete. PLoS ONE 2024, 19, e0298761. [Google Scholar] [CrossRef] [PubMed]

- Garg, R.; Garg, R.; Bansal, M.; Aggarwal, Y. Experimental study on strength and microstructure of mortar in presence of micro and nano-silica. Mater. Today Proc. 2021, 43, 769–777. [Google Scholar] [CrossRef]

- Liu, H.; Li, Q.; Su, D.; Yue, G.; Wang, L. Study on the influence of nanosilica sol on the hydration process of different kinds of cement and mortar properties. Materials 2021, 14, 3653. [Google Scholar] [CrossRef] [PubMed]

- Tamanna, N.; Tuladhar, R. Sustainable use of recycled glass powder as cement replacement in concrete. Open Waste Manag. J. 2020, 13, 1–13. [Google Scholar] [CrossRef]

- Yavuz, D.; Akbulut, Z.F.; Guler, S. An experimental investigation of hydraulic and early and later-age mechanical properties of eco-friendly porous concrete containing waste glass powder and fly ash. Constr. Build. Mater. 2024, 418, 135312. [Google Scholar] [CrossRef]

- Muhedin, D.A.; Ibrahim, R.K. Effect of waste glass powder as partial replacement of cement & sand in concrete. Case Stud. Constr. Mater. 2023, 19, e02512. [Google Scholar]

- Barkauskas, K.; Nagrockienė, D.; Norkus, A. The effect of ground glass waste on properties of hardened cement paste and mortar. Ceramics-Silikaty 2020, 64, 478–487. [Google Scholar] [CrossRef]

- Letelier, V.; Henríquez-Jara, B.I.; Manosalva, M.; Parodi, C.; Ortega, J.M. Use of waste glass as a replacement for raw materials in mortars with a lower environmental impact. Energies 2019, 12, 1974. [Google Scholar] [CrossRef]

- Tamanna, N.; Sutan, N.M.; Yakub, I.; Lee, D. Strength Characteristics of Mortar Containing Different Sizes Glass Powder. J. Civ. Eng. Sci. Technol. 2014, 5, 11–16. [Google Scholar] [CrossRef]

- Banerji, S.; Poudel, S.; Thomas, R.J. Performance of Concrete with Ground Glass Pozzolan as Partial Cement Replacement. In Proceedings of the 10th International Conference on CONcrete Under SEvere Conditions—Environment and Loading 2024, Chennai, India, 25–27 September 2024. [Google Scholar]

- Ikotun, B.; Senatsi, K.; Abdulwahab, R.; Nkala, M. Effects of Waste Glass Powder as Partial Replacement of Cement on the Structural Performance of Concrete. Civ. Eng. Archit. 2024, 12, 2547–2556. [Google Scholar]

- Qasem, O.A.M.A. The Utilization of Glass Powder as Partial Replacement Material for the Mechanical Properties of Concrete. Ph.D. Thesis, Universitas Islam Indonesia, Yogyakarta, Indonesia, 2024. [Google Scholar]

- Herki, B.M. Strength and Absorption Study on Eco-Efficient Concrete Using Recycled Powders as Mineral Admixtures under Various Curing Conditions. Recycling 2024, 9, 99. [Google Scholar] [CrossRef]

- Baikerikar, A.; Mudalgi, S.; Ram, V.V. Utilization of waste glass powder and waste glass sand in the production of Eco-Friendly concrete. Constr. Build. Mater. 2023, 377, 131078. [Google Scholar] [CrossRef]

- Zhu, J.; Meng, X.; Wang, B.; Tong, Q. Experimental Study on Long-Term Mechanical Properties and Durability of Waste Glass Added to OPC Concrete. Materials 2023, 16, 5921. [Google Scholar] [CrossRef] [PubMed]

- Naaamandadin, N.A.; Abdul Aziz, I.S.; Mustafa, W.A.; Santiagoo, R. Mechanical properties of the utilisation glass powder as partial replacement of cement in concrete. In Intelligent Manufacturing and Mechatronics, Proceedings of the 2nd Symposium on Intelligent Manufacturing and Mechatronics–SympoSIMM 2019, Melaka, Malaysia, 8 July 2019; Springer: Berlin/Heidelberg, Germany, 2020; pp. 221–229. [Google Scholar]

- Moreira, O.; Camões, A.; Malheiro, R.; Jesus, C. High Glass Waste Incorporation towards Sustainable High-Performance Concrete. CivilEng 2024, 5, 41–64. [Google Scholar] [CrossRef]

- Paul, D.; Bindhu, K.; Matos, A.M.; Delgado, J. Eco-friendly concrete with waste glass powder: A sustainable and circular solution. Constr. Build. Mater. 2022, 355, 129217. [Google Scholar] [CrossRef]

- Chen, W.; Liu, D.; Liang, Y. Influence of Ultra Fine Glass Powder on the Properties and Microstructure of Mortars. Fluid Dyn. Mater. Process. 2024, 20, 915–938. [Google Scholar] [CrossRef]

- Kim, J.; Yi, C.; Zi, G. Waste glass sludge as a partial cement replacement in mortar. Constr. Build. Mater. 2015, 75, 242–246. [Google Scholar] [CrossRef]

- ASTM-C311; Standard Test Methods for Sampling and Testing Fly Ash or Natural Pozzolans for Use in Portland-Cement Concrete1. Standard, American Society for Testing and Materials: West Conshohocken, PA, USA, 2022.

- ASTM-C618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. Standard, American Society for Testing and Materials: West Conshohocken, PA, USA, 2023.

- Afshinnia, K.; Rangaraju, P.R. Influence of fineness of ground recycled glass on mitigation of alkali–silica reaction in mortars. Constr. Build. Mater. 2015, 81, 257–267. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Y.; Riefler, C.; Wang, H. Characteristics and pozzolanic reactivity of glass powders. Cem. Concr. Res. 2005, 35, 987–993. [Google Scholar] [CrossRef]

- Patel, D.; Shrivastava, R.; Tiwari, R.; Yadav, R. Properties of cement mortar in substitution with waste fine glass powder and environmental impact study. J. Build. Eng. 2020, 27, 100940. [Google Scholar] [CrossRef]

- Poudel, S.; Cibelli, A.; Del Prete, C.; Wan-Wendner, R.; Mazzotti, C.; Buratti, N. Insights on Lattice Discrete Particle Model Calibration and Validation Procedure to Simulate Polypropylene and Steel Fibre-Reinforced Concrete. Fibers 2025, 13, 16. [Google Scholar] [CrossRef]

- Bhetuwal, U.; Shrestha, J.K.; Pradhananga, R. Fatigue life analysis of steel–concrete composite bridge considering road surface conditions. Innov. Infrastruct. Solut. 2022, 7, 124. [Google Scholar] [CrossRef]

- Li, A.; Qiao, H.; Li, Q.; Hakuzweyezu, T.; Chen, B. Study on the performance of pervious concrete mixed with waste glass powder. Constr. Build. Mater. 2021, 300, 123997. [Google Scholar] [CrossRef]

- Yassin, M.M.; Mahmoud, A.S.; Hama, S.M. Effectiveness of glass wastes as powder on some hardened properties of concrete. Al-Nahrain J. Eng. Sci. 2019, 22, 14–17. [Google Scholar] [CrossRef]

- Mohammed, T.K.; Hama, S.M. Mechanical properties, impact resistance and bond strength of green concrete incorporating waste glass powder and waste fine plastic aggregate. Innov. Infrastruct. Solut. 2022, 7, 1–12. [Google Scholar] [CrossRef]

- Omer, B.; Saeed, J. Effect of water to binder ratio and particle size distribution of waste glass powder on the compressive-strength and modulus of elasticity of normal-strength concrete. Eur. J. Environ. Civ. Eng. 2022, 26, 5300–5321. [Google Scholar] [CrossRef]

- Goh, P.G.; Maghfouri, M.; Onn, C.C.; Loo, S.C. Life cycle assessment on recycled e-waste concrete. Case Stud. Constr. Mater. 2022, 17, e01412. [Google Scholar] [CrossRef]

- Deschamps, J.; Simon, B.; Tagnit-Hamou, A.; Amor, B. Is open-loop recycling the lowest preference in a circular economy? Answering through LCA of glass powder in concrete. J. Clean. Prod. 2018, 185, 14–22. [Google Scholar] [CrossRef]

- Jiang, M.; Chen, X.; Rajabipour, F.; Hendrickson, C.T. Comparative life cycle assessment of conventional, glass powder, and alkali-activated slag concrete and mortar. J. Infrastruct. Syst. 2014, 20, 04014020. [Google Scholar] [CrossRef]

- Nassar, R.U.D.; Soroushian, P. Field investigation of concrete incorporating milled waste glass. J. Solid Waste Technol. Manag. 2011, 37, 307–319. [Google Scholar] [CrossRef]

- Omran, A.; Tagnit-Hamou, A. Performance of glass-powder concrete in field applications. Constr. Build. Mater. 2016, 109, 84–95. [Google Scholar] [CrossRef]

- Roz-Ud-Din, N.; Soroushian, P.; Sufyan-Ud-Din, M. Long-term field performance of concrete produced with powder waste glass as partial replacement of cement. Case Stud. Constr. Mater. 2021, 15, e00745. [Google Scholar]

- Omran, A.; Harbec, D.; Tagnit-Hamou, A.; Gagne, R. Production of roller-compacted concrete using glass powder: Field study. Constr. Build. Mater. 2017, 133, 450–458. [Google Scholar] [CrossRef]

- Soliman, N.A.; Omran, A.F.; Tagnit-Hamou, A. Laboratory Characterization and Field Application of Novel Ultra-High-Performance Glass Concrete. ACI Mater. J. 2016, 113, 307–316. [Google Scholar] [CrossRef]

| Material | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O + K2O | LOI |

|---|---|---|---|---|---|---|---|

| Portland Cement | 19.7–21.4 | 4.7–5.5 | 2.2–3.9 | 63.6–65 | 1.19–1.5 | 0.1–0.97 | 0.16–2.3 |

| Blast Furnace Slag | 32–42 | 6–19.3 | 0–2.5 | 30–48 | 3–14 | 0–1.4 | - |

| Fly Ash—A | 56.7 | 27.6 | 4.4 | 3.6 | 1.2 | 0.5 | 1.8 |

| Fly Ash—B | 73.8 | 17.9 | 3.3 | 1 | 1.2 | 0.4 | 3.25 |

| Glass HA | 71 | 0.8 | 0.3 | 9.4 | 3.1 | 13 | 1.1 |

| Glass LA | 53.6 | 13.7 | 0.4 | 21.9 | 1.1 | 0.5 | 0.6 |

| Ground Glass | 53.6–71.5 | 0.8–13.7 | <0.1–0.4 | 9.4–21.9 | 1.1–3.1 | 0.1–13.3 | 0.2–1.1 |

| Ground Quartz | 98.5 | 0.5 | <0.1 | <0.1 | <0.1 | 0.2 | 0.5 |

| Lassenite | 64.2 | 13.7 | 5.7 | 1.6 | 0.8 | 1.6 | 8.8 |

| Metakaolin | 51.5–51.17 | 40.2–44.5 | 0.45–4.64 | 0.01–2.0 | 0–0.2 | 0–0.2 | 0.4 |

| Perlite | 73.9 | 12.7 | 1.1 | 0.8 | 0.1 | 6 | 3.6 |

| Pumice 1 | 76.3 | 12.1 | 1.7 | 0.4 | - | 0.6 | - |

| Pumice 2 | 69 | 10.9 | 1.3 | 0.8 | 0.46 | 2.4 | 3.4 |

| RHA | 82.13–87.3 | 0.09–24.1 | 0.09–15.7 | 0.5–16.1 | 0.3–8.65 | 0.09–2.1 | - |

| Silica Fume—A | 96.5 | 0.5 | 0.1 | 0.4 | 0.4 | - | 2.89 |

| Silica Fume—B | 89.3 | 0.3 | 1 | 0.7 | - | 0.4 | 1.21 |

| Glass Type | SiO2 (%) | Na2O + K2O (%) | CaO (%) | Al2O3 (%) | MgO (%) | B2O3 (%) |

|---|---|---|---|---|---|---|

| Electric glass | 52.0–56.0 | 0.0–2.0 | 16.0–25.0 | 12.0–16.0 | – | – |

| Borosilicate glass | 70.0–80.0 | 4.0–8.0 | – | 7.0 | – | 11.0–15.0 |

| Lead glass | 54.0–65.0 | 13.0–15.0 | – | – | – | – |

| Soda–lime glass | 71.0–75.0 | 12.0–16.0 | 10.0–15.0 | – | 0.1–4.0 | – |

| E-glass | 59.9–61.3 | 0.77–0.81 | 21.4–21.9 | 12.5–12.64 | 2.69 | – |

| Barium glass | 36.0–35.0 | 7.0 | 2.0 | 2.0–4.0 | 9.0 | 10.0 |

| Aluminosilicate glasses | 57.0–64.5 | 0.5–1 | 8.0–10.0 | 17.0–24.5 | 7.0–10.5 | 5 |

| Type | SiO2 | Al2O3 | CaO | Fe2O3 | SO3 | Na2Oeq | Moisture | LOI |

|---|---|---|---|---|---|---|---|---|

| GS | ≥60.0 | ≤5.0 | ≤15.0 | ≤1.0 | ≤1.0 | ≤15.0 | ≤0.5 | ≤0.5 |

| GE | ≥55.0 | ≤15.0 | ≤25.0 | ≤1.0 | ≤1.0 | ≤4.0 | ≤0.5 | ≤0.5 |

| Component | SiO2 (%) | CaO (%) | Na2O (%) | Al2O3 (%) | Fe2O3 (%) | MgO (%) | Cr2O3 |

|---|---|---|---|---|---|---|---|

| Clear Glass | 73.2–73.5 | - | 13.6–14.1 | 1.7–1.9 | 0.04–0.05 | - | - |

| Amber Glass | 70.66 | 9.12 | 8.32 | 6.53 | 2.52 | 1.45 | 0.01 |

| Green Glass | 72.25 | 12.35 | 10.54 | 2.54 | - | 1.18 | 0.43–0.44 |

| Brown Glass | 72.1 | - | - | 1.74 | 0.31 | - | 0.01 |

| White Glass | 69.82 | 8.76 | 8.42 | 1.02 | 0.55 | 3.43 | - |

| Author | Mean Size | W/C Ratio | Replacement | Compressive Strength (MPa) | Optimum Replacement | ||||

|---|---|---|---|---|---|---|---|---|---|

| (µm) | Level (%) | 7 D | 14 D | 28 D | 56 D | 90 D | Level and Curing Days | ||

| Gupta et al. [88] | ≈75 | 0.45 | 5 | ↑ | - | ↓ | - | - | 35% at 28 days |

| 10 | ↑ | - | ↑ | - | - | ||||

| 15 | ↑ | - | ↑ | - | - | ||||

| 20 | ↑ | - | ↑ | - | - | ||||

| 25 | ↑ | - | ↑ | - | - | ||||

| 30 | ↑ | - | ↑ | - | - | ||||

| 35 | ↑ | - | ↓ | - | - | ||||

| Ikotun et al. [103] | ≈75 | 0.47 | 5 | ↑ | - | ↓ | ↓ | - | 5% at 56 days |

| 15 | ↓ | - | ↓ | ↓ | - | ||||

| 25 | ↓ | - | ↓ | ↓ | - | ||||

| OAMA Qasem [104] | ≈75 | 0.45 | 10 | - | - | ↓ | - | - | 25% at 28 days |

| 15 | - | - | ↑ | - | - | ||||

| 20 | - | - | ↑ | - | - | ||||

| 25 | - | - | ↑ | - | - | ||||

| 30 | - | - | ↑ | - | - | ||||

| Herki. B MA [105] | ≈75 | 0.50 | 10 | ↓ | - | ↓ | - | - | 10% at 28 days |

| 20 | ↓ | - | ↓ | - | - | ||||

| Baikerikar et al. [106] | ≈50 | 0.42 | 5 | ↑ | - | ↑ | - | - | 25% at 28 days |

| 10 | ↓ | - | ↓ | - | - | ||||

| 15 | ↓ | - | ↓ | - | - | ||||

| 20 | ↓ | - | ↓ | - | - | ||||

| 25 | ↓ | - | ↓ | - | - | ||||

| Zhu et al. [107] | ≈40 | 0.46 | 10 | ↓ | ↓ | ↓ | ↓ | ↓ | 10% at 56 days |

| 20 | ↓ | ↓ | ↓ | ↓ | ↓ | ||||

| 30 | ↓ | ↓ | ↓ | ↓ | ↓ | ||||

| Naaamandadin et al. [108] | ≈30 | 0.45 | 4 | ↑ | - | ↑ | - | - | 8% at 28 days |

| 8 | ↑ | - | ↑ | - | - | ||||

| 12 | ↓ | - | ↓ | - | - | ||||

| Moreira et al. [109] | 0.40 | 50 | ↑ | ↑ | ↑ | - | - | 50% at 28 days | |

| 0.35 | 50 | ↑ | ↑ | ↑ | - | - | W/C = 0.4 | ||

| Paul et al. [110] | ≈20 | 0.40 | 10 | ↓ | - | ↓ | - | ↑ | 40% at 90 days |

| 20 | ↓ | - | ↓ | - | ↑ | ||||

| 30 | ↑ | - | ↑ | - | ↑ | ||||

| 40 | ↓ | - | ↓ | - | ↓ | ||||

| Chen et al. [111] | ≈20 | 0.50 | 5 | ↓ | ↓ | ↓ | - | ↓ | 10% at 56 days |

| 10 | ↓ | ↓ | ↓ | - | ↓ | ||||

| 15 | ↓ | ↓ | ↓ | - | ↓ | ||||

| Paul et al. [110] | ≈8 | 0.48 | 10 | ↓ | - | ↓ | - | ↑ | 30% at 90 days |

| 20 | ↑ | - | ↑ | - | ↑ | ||||

| 30 | ↑ | - | ↑ | - | ↑ | ||||

| 40 | ↑ | - | ↓ | - | ↑ | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poudel, S.; Bhetuwal, U.; Kharel, P.; Khatiwada, S.; KC, D.; Dhital, S.; Lamichhane, B.; Yadav, S.K.; Suman, S. Waste Glass as Partial Cement Replacement in Sustainable Concrete: Mechanical and Fresh Properties Review. Buildings 2025, 15, 857. https://doi.org/10.3390/buildings15060857

Poudel S, Bhetuwal U, Kharel P, Khatiwada S, KC D, Dhital S, Lamichhane B, Yadav SK, Suman S. Waste Glass as Partial Cement Replacement in Sustainable Concrete: Mechanical and Fresh Properties Review. Buildings. 2025; 15(6):857. https://doi.org/10.3390/buildings15060857

Chicago/Turabian StylePoudel, Sushant, Utkarsha Bhetuwal, Prabin Kharel, Sudip Khatiwada, Diwakar KC, Subash Dhital, Bipin Lamichhane, Sachin Kumar Yadav, and Saurabh Suman. 2025. "Waste Glass as Partial Cement Replacement in Sustainable Concrete: Mechanical and Fresh Properties Review" Buildings 15, no. 6: 857. https://doi.org/10.3390/buildings15060857

APA StylePoudel, S., Bhetuwal, U., Kharel, P., Khatiwada, S., KC, D., Dhital, S., Lamichhane, B., Yadav, S. K., & Suman, S. (2025). Waste Glass as Partial Cement Replacement in Sustainable Concrete: Mechanical and Fresh Properties Review. Buildings, 15(6), 857. https://doi.org/10.3390/buildings15060857