Static Load Test and Finite Element Analysis of Phosphogypsum Concrete Composite Slabs

Abstract

:1. Introduction

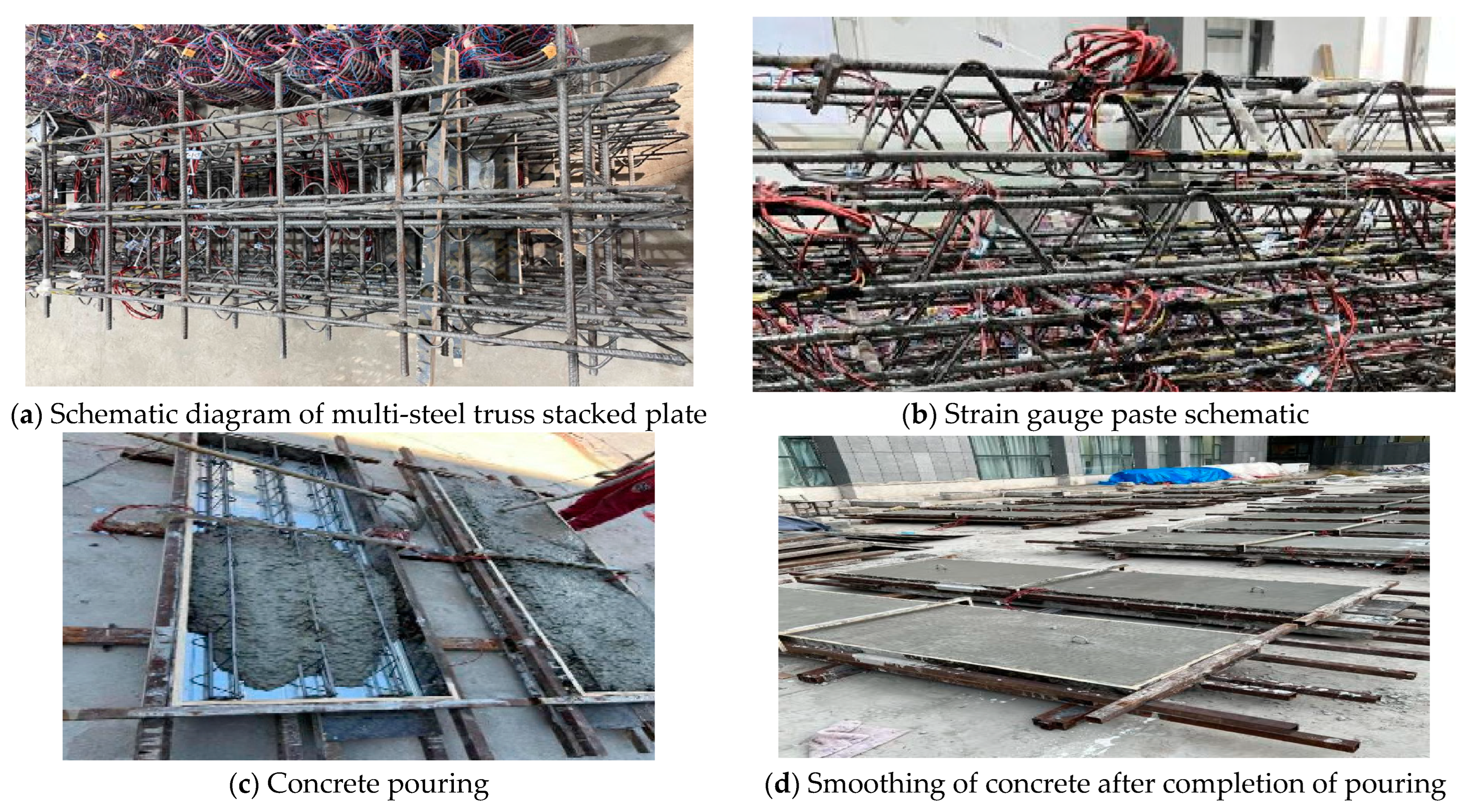

2. Experimental Overview

2.1. Experimental Design

- D1-1 (control): conventional concrete for both slabs;

- D1-2: 2% PG concrete (top) paired with conventional concrete (bottom);

- D1-3: conventional concrete (top) with 2% PG concrete (bottom);

- D1-4: 2% PG concrete for both slabs;

- D1-5: 4% PG concrete for both slabs.

| Serial Number | Board Type | Phosphogypsum Dosage/% | Loading Method |

|---|---|---|---|

| D1-1 | Plain concrete slab | 0 | Monotonic loading |

| D1-2 | Phosphogypsum top plate Bottom plate ordinary concrete | 2 | Monotonic loading |

| D1-3 | Top plate ordinary concrete Phosphogypsum base plate | 2 | Monotonic loading |

| D1-4 | Phosphogypsum mixing for both bottom and top slabs | 2 | Monotonic loading |

| D1-5 | Phosphogypsum mixing for both bottom and top slabs | 4 | Monotonic loading |

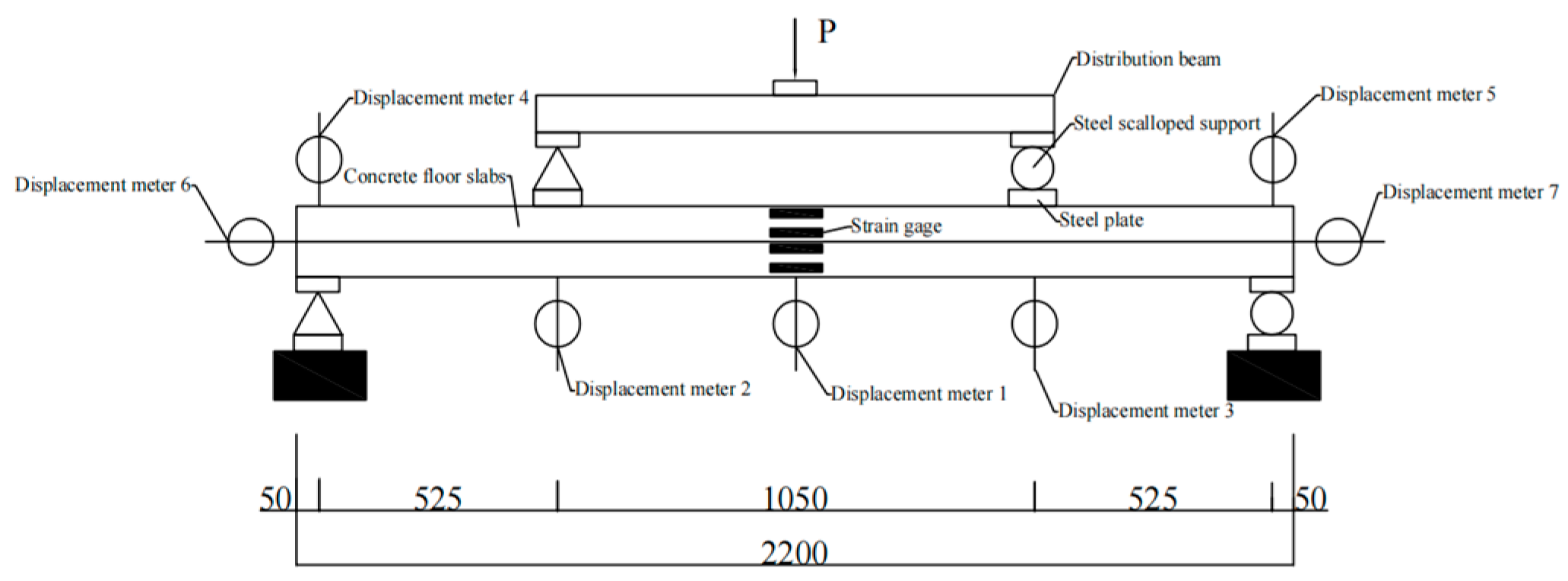

2.2. Measurement Point Arrangement

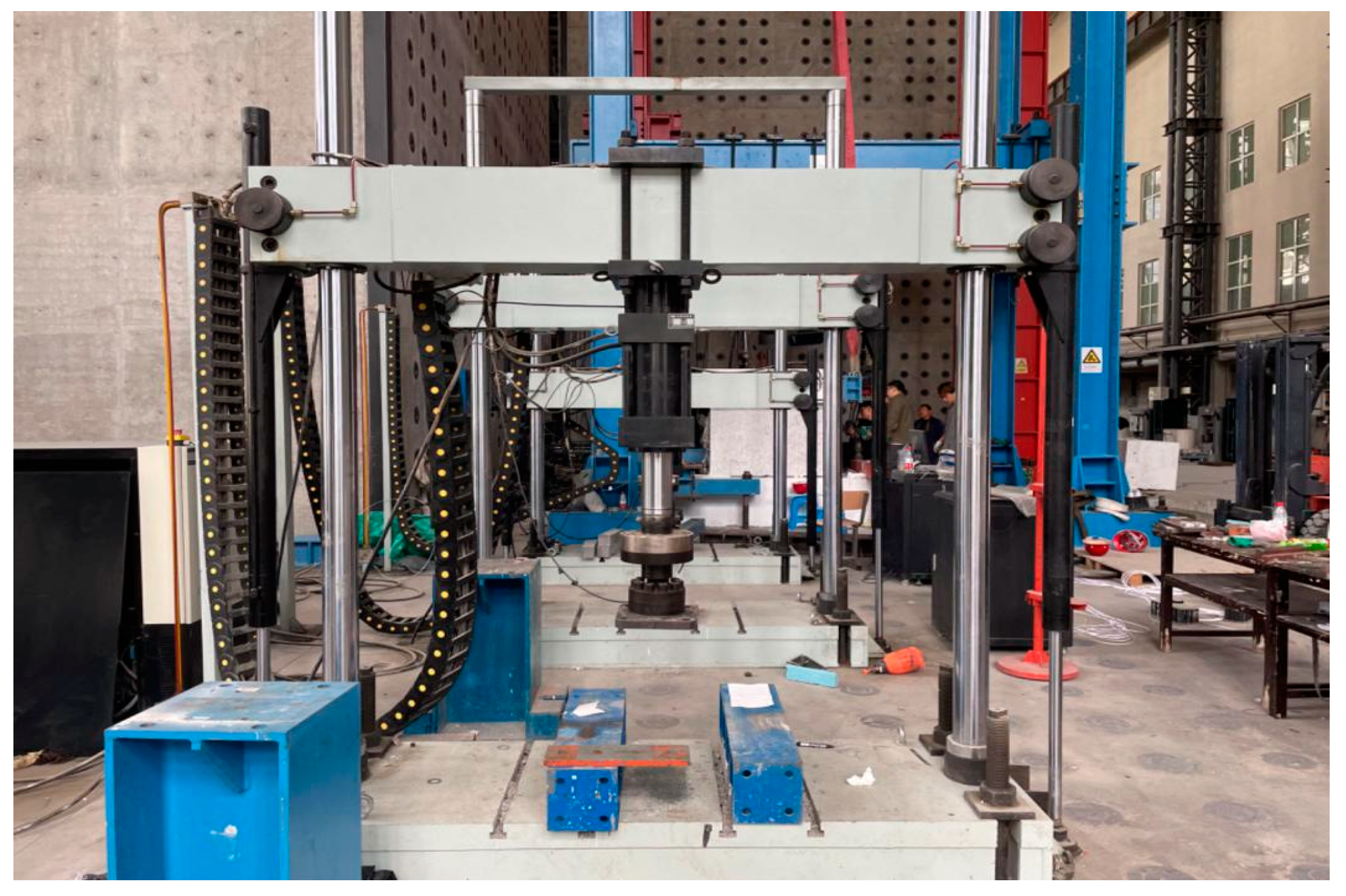

2.3. Experimental Loading Scheme and Measurement Contents

2.4. Material Properties

3. Experimental Observations and Result Analysis

3.1. Experimental Observations

Analysis of Experimental Phenomena

3.2. Comprehensive Result Analysis

- (1)

- According to the results presented in Table 2, none of the composite slabs cracked under the standard load combination during the construction stage. The calculated cracking loads were within an acceptable margin of error when compared to the measured values.

- (2)

- The actual cracking loads of slabs D1-2 and D1-4 were lower than those of the other slabs due to the presence of hollow sections beneath their flanges, which reduced their moment of resistance. This indicates that widening the flanges can significantly enhance the bottom slab’s cracking load capacity.

- (3)

- Overall, the measured cracking load values were 0.97 times the calculated values, indicating that the results are reasonably accurate. This demonstrates that it is feasible to design prefabricated base slabs that meet the non-cracking requirements during the construction stage.

4. Analysis of Experimental Results

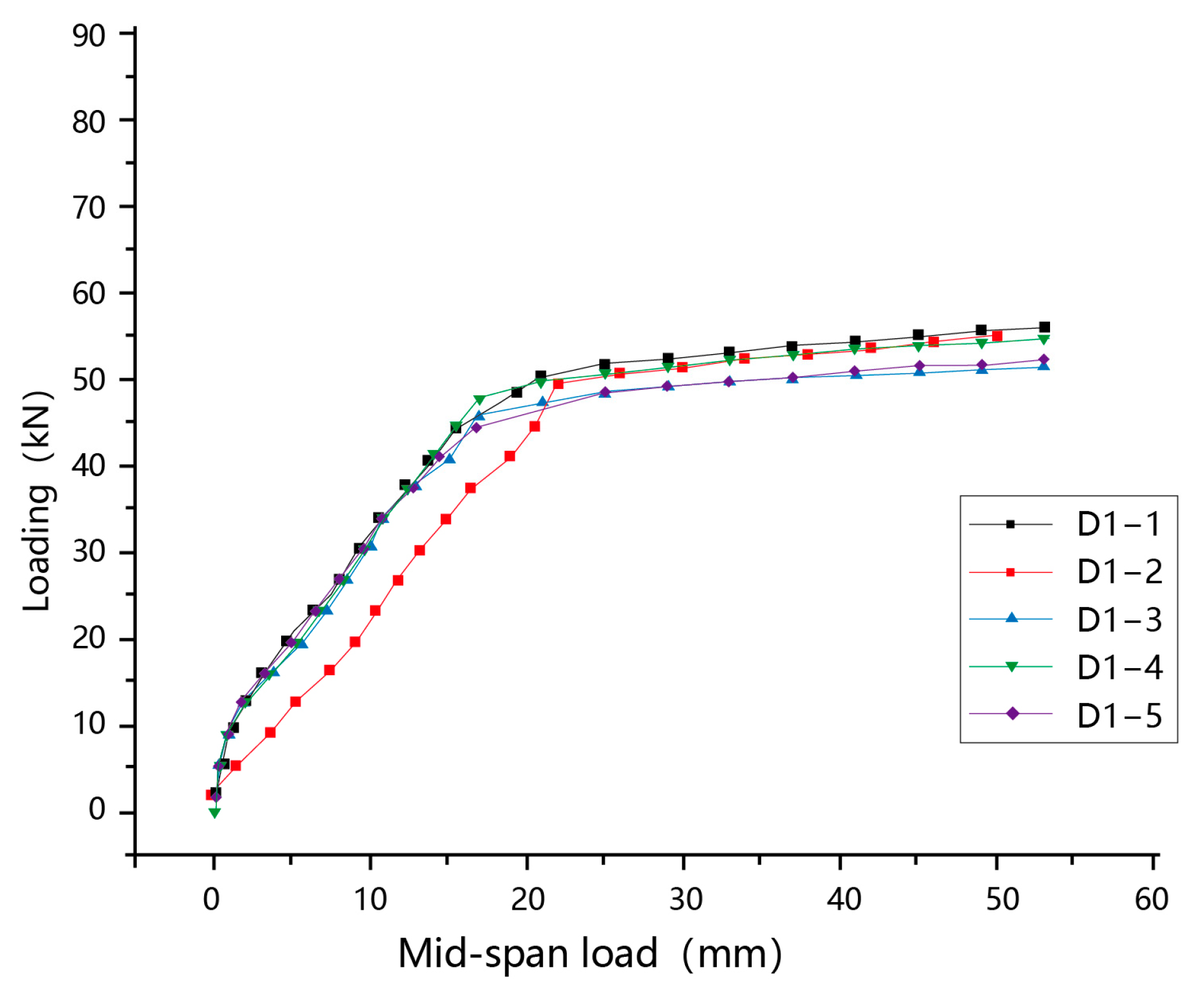

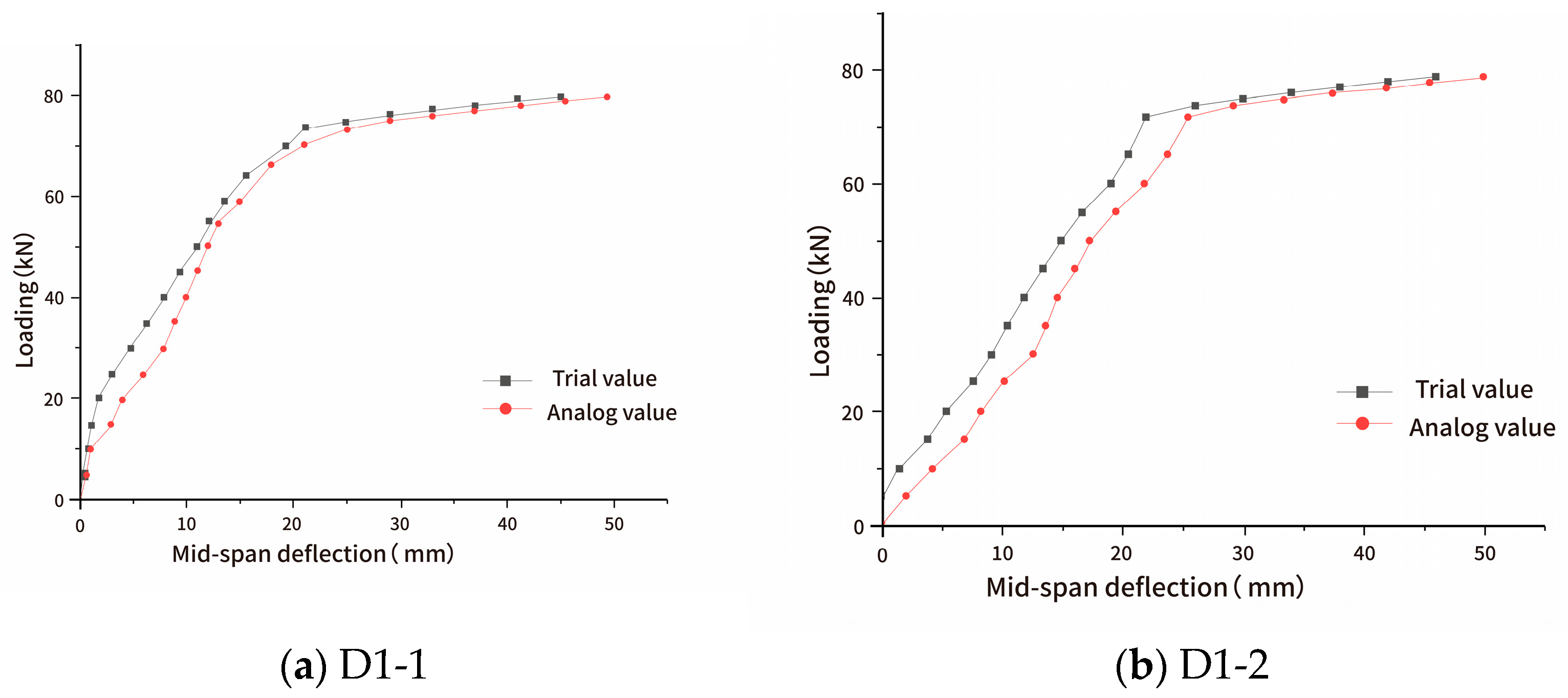

4.1. Analysis of Load–Deflection Relationship

- (1)

- As illustrated in Figure 5, initial cracks parallel to the span direction were ob-served in composite slabs D1-1 to D1-5, located from the slab end to one-third of the span. These cracks did not affect the load-bearing performance, and no longitudinal cracks were observed between the flanges during the loading process.

- (2)

- During the casting of the composite layer, slabs D1-1 and D1-3 were cast normally, while D1-2 and D1-4 had hollow sections beneath the flanges. As a result, D1-2 and D1-4 exhibited lower cracking loads. However, the stiffness of these two slabs remained unchanged before and after cracking, indicating that the hollow sections beneath the flanges did not affect the load-bearing performance of the composite slabs.

- (3)

- Overall, all composite slabs met the requirements for the service stage and were closely aligned with the design specifications.

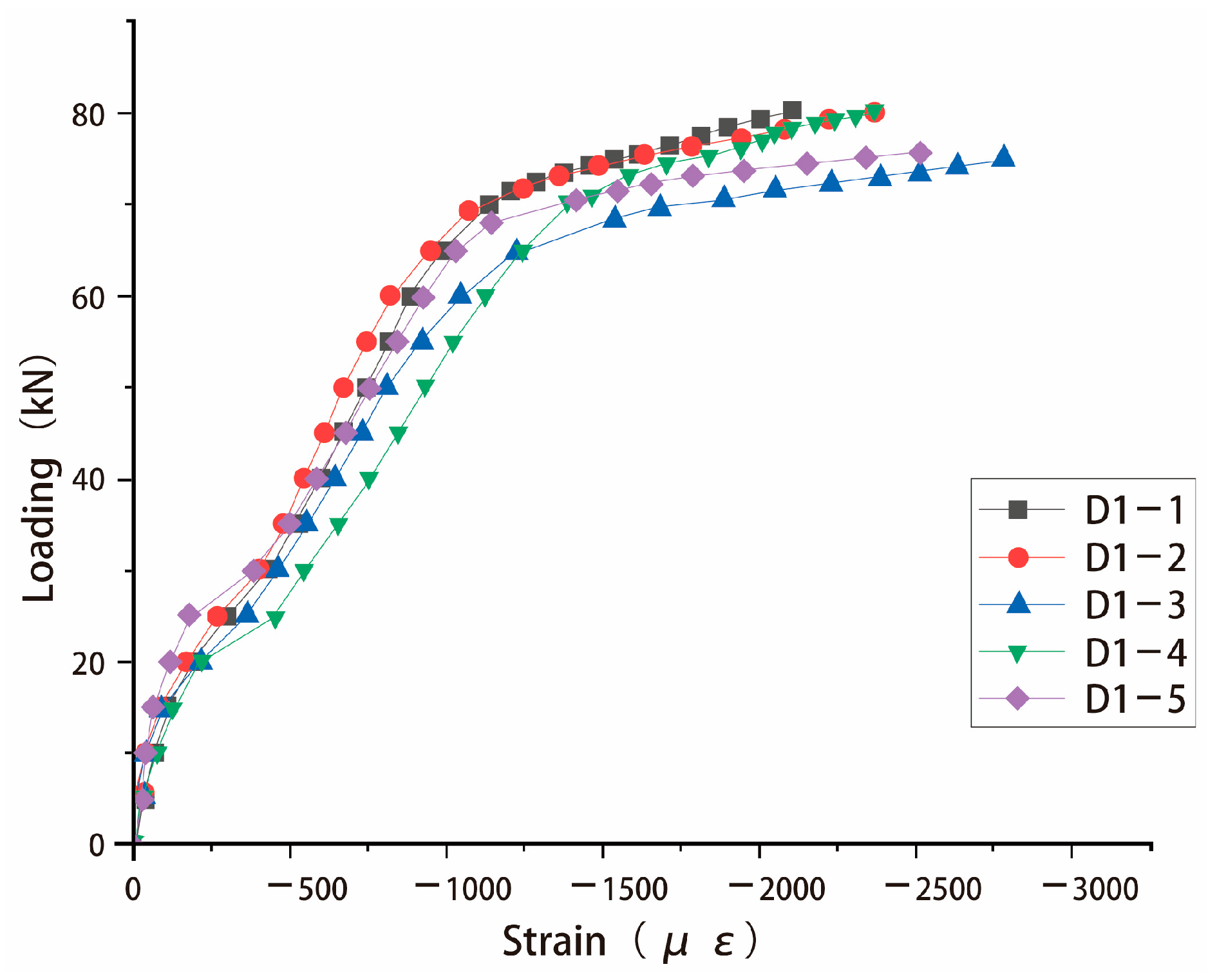

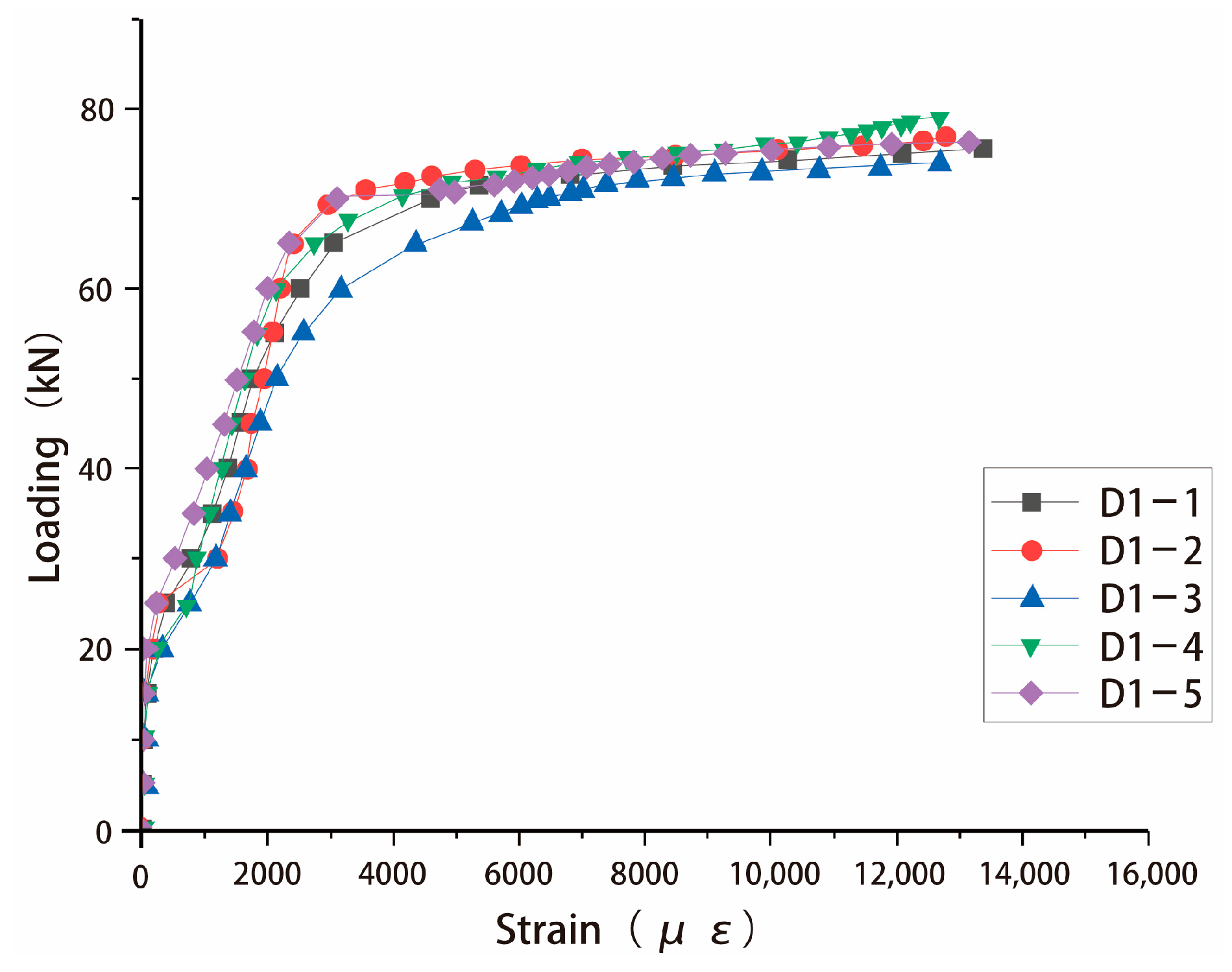

4.2. Concrete Strain Analysis

- (1)

- As depicted in Figure 6, all components experienced compressive strain in the top concrete and tensile strain in the bottom concrete. Before cracking, the strain at the top and bottom of the slabs showed a nearly linear increase. In some components, the strains at the top and bottom were relatively symmetrical, indicating good interaction between the concrete base slab and the flanges of the composite slabs. This suggests efficient interaction between the base slab and the composite layer.

- (2)

- Before cracking, the concrete strain along the height of the composite slabs formed a straight line, aligning with the plane section assumption.

4.3. Web Reinforcement Strain Analysis

- (1)

- As illustrated in Figure 7, the web reinforcement of the composite slab trusses includes both compressive and tensile members, with relatively small strains observed in both types of members.

- (2)

- Before reaching the construction load, the compressive strain in the compressive web members increased almost linearly, indicating that the web reinforcement of the trusses did not experience compressive buckling.

4.4. Analysis of the Load-Bearing Capacity of Composite Slabs

- (1)

- Elastic Stage: In the initial loading stage, the load–strain curve exhibits a linear relationship, indicating that the composite slabs remained in the elastic stage. During this phase, both the concrete and reinforcement behaved elastically, with minimal strain accumulation. The slope of the curve in this region reflects the initial stiffness of the slabs.

- (2)

- Cracking and Post-Cracking Stage: As the load increased, the concrete began to crack, leading to a noticeable change in the slope of the load–strain curve. This transition marks the onset of the post-cracking stage, where the stiffness of the slabs decreases due to the formation of cracks. The strain increased more rapidly with load, indicating a redistribution of stress from the concrete to the reinforcement.

- (3)

- Yield and Hardening Stage: At higher load levels, the reinforcement entered the yield stage, followed by the hardening stage. During this phase, the strain increased significantly with a relatively small increase in load, reflecting the ductile behavior of the slabs. The load–strain curve in this region demonstrates the ability of the slabs to undergo large deformations before failure, which is a key characteristic of ductile failure modes.

- (4)

- Ultimate Load and Failure: The ultimate load-carrying capacity of the slabs can be determined from the peak load in the load–strain curve. Beyond this point, the slabs experienced a rapid increase in strain with a corresponding drop in load, indicating structural failure. The failure mode was primarily governed by the yielding of the reinforcement and the crushing of the concrete.

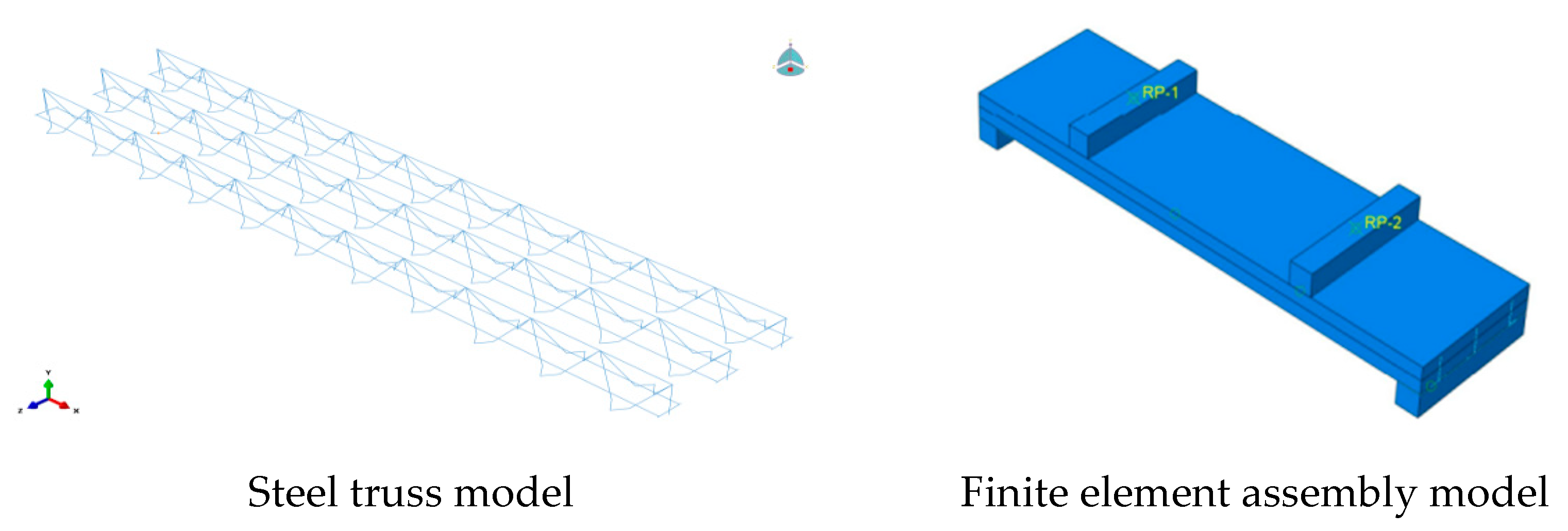

5. Finite Element Simulation of Phosphogypsum Concrete Composite Slabs

5.1. Establishment of the Finite Element Model

- (1)

- To complement the experimental study, the finite element model can systematically explore more critical parameters (e.g., forces under static loading, tensile damage cloud, bending moment–deflection relationship, and bearing strength of concrete laminated slabs embedded with different admixtures of phosphogypsum) due to material limitations and possible errors in the test;

- (2)

- For different working conditions in the actual project, the results obtained in the process of modeling and simulation and the results from the experiment can be compared and referenced to complement each other, which can more accurately provide theoretical references for the actual construction. The finite element analysis results and experimental data show good consistency, which confirms the reliability of the model.

- —Parameters for the descending branch of the uniaxial tensile stress–strain curve of concrete;

- —Uniaxial tensile strength of concrete;

- —Corresponding peak tensile strain of fc,r concrete;

- —Damage evolution parameter for the uniaxial tensile behavior of concrete.

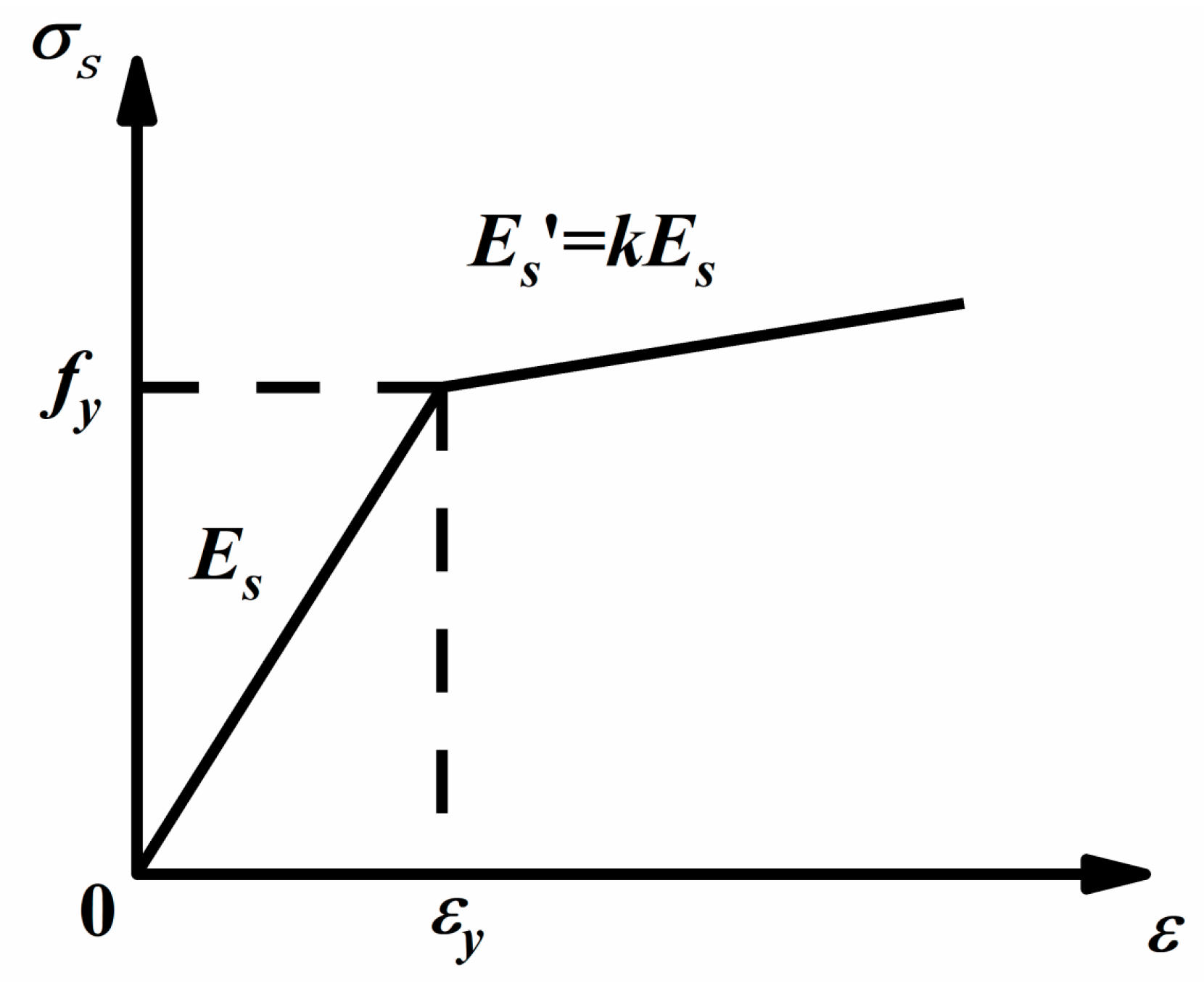

- —Elastic modulus of steel reinforcement;

- —Stress of steel reinforcement;

- —Strain of steel reinforcement;

- —Yield strength of steel reinforcement;

- —Yield strain of steel reinforcement corresponding to the yield strength;

- —Slope of the hardening stage of steel reinforcement.

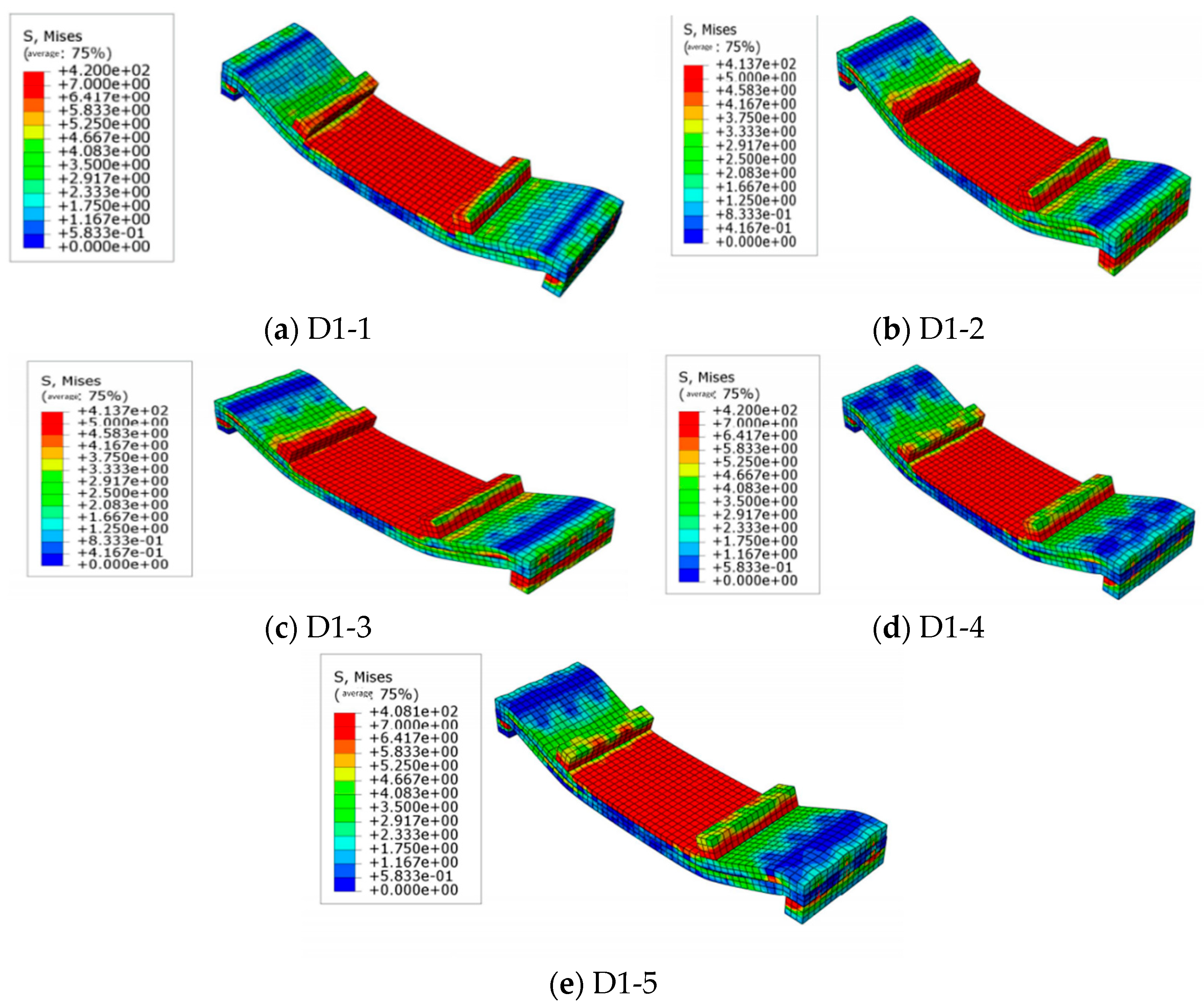

5.2. Analysis of Simulation Results

- (1)

- Stress Concentration and Failure Initiation:

- (2)

- Crack Propagation and Failure Progression:

- (3)

- Material Yielding and Ductile Failure:

- (4)

- Implications for Design:

6. Conclusions

- 1.

- Effect of PG Content on Mechanical Properties:

- 2.

- Optimal PG Content:

- 3.

- Finite Element Simulation:

- 4.

- Practical Applications and Environmental Benefits:

Future Research Directions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jalali, J.; Gaudin, P.; Capiaux, H.; Ammar, E.; Lebeau, T. Fate and transport of metal trace elements from phosphogypsum piles in Tunisia and their impact on soil bacteria and wild plants. Ecotoxicol. Environ. Saf. 2019, 174, 12–25. [Google Scholar] [CrossRef]

- Lin, Z.S.; Shi, H.D.; Beguedou, E. Effect of polycarboxylate superplasticizer on properties of phosphogypsum-based cement. Key Eng. Mater. 2012, 509, 13–19. [Google Scholar]

- Yang, J.K.; Liu, W.C.; Zhang, L.L.; Xiao, B. Preparation of load-bearing building materials from autoclaved phosphogypsum. Constr. Build. Mater. 2009, 23, 687–693. [Google Scholar] [CrossRef]

- Lütke, S.F.; Oliveira, M.L.S.; Silva, L.F.O.; Cadaval, T.R.S.; Dotto, G.L. Nanominerals assemblages and hazardous elements assessment in phosphogypsum from an abandoned phosphate fertilizer industry. Chemosphere 2020, 256, 127138. [Google Scholar] [PubMed]

- Meskini, S.; Mechnou, I.; Benmansour, M.; Remmal, T.; Samdi, A. Environmental investigation on the use of a phosphogypsum-based road material: Radiological and leaching assessment. J. Environ. Manag. 2023, 345, 118597. [Google Scholar]

- Baolin, K.; Qin, Z.; Xianhai, L.; Zhihui, S. Adsorption and solidification of cadmium by calcium sulfate dihydrate (gypsum) in an aqueous environment: A dispersion-corrected DFT and ab initio molecular dynamics study. Phys. Chem. Chem. Phys. 2022, 24, 9521–9533. [Google Scholar] [CrossRef]

- Wu, F.; Ren, Y.; Qu, G.; Liu, S.; Chen, B.; Liu, X.; Zhao, C.; Li, J. Utilization path of bulk industrial solid waste: A review on the multi-directional resource utilization path of phosphogypsum. J. Environ. Manag. 2022, 313, 114957. [Google Scholar] [CrossRef]

- Bilal, E.; Bellefqih, H.; Bourgier, V.; Mazouz, H.; Dumitraş, D.-G.; Bard, F.; Laborde, M.; Caspar, J.P.; Guilhot, B.; Iatan, E.-L.; et al. Phosphogypsum circular economy considerations: A critical review from more than 65 storage sites worldwide. J. Clean. Prod. 2023, 414, 137561. [Google Scholar]

- Garbaya, H.; Jraba, A.; Khadimallah, M.A.; Elaloui, E. The Development of a New Phosphogypsum-Based Construction Material: A Study of the Physicochemical, Mechanical and Thermal Characteristics. Materials 2021, 14, 7369. [Google Scholar] [CrossRef]

- Meng, W.; Dong, Y. Mechanical properties and chemical microscopic characteristics of all-solid-waste composite cementitious materials prepared from phosphogypsum and granulated blast furnace slag. Mater. Today Commun. 2024, 41, 110809. [Google Scholar] [CrossRef]

- Rashad, M. Phosphogypsum as a construction material. J. Clean. Prod. 2017, 166, 732–743. [Google Scholar] [CrossRef]

- Calderon-Morales, B.R.S.; García-Martínez, A.; Pineda, P.; García-Tenorio, R. Valorization of phosphogypsum in cement-based materials: Limits and potential in eco-efficient construction. J. Build. Eng. 2021, 44, 32. [Google Scholar] [CrossRef]

- Akfas, F.; Elghali, A.; Aboulaich, A.; Munoz, M.; Benzaazoua, M.; Bodinier, J.L. Exploring the potential reuse of phosphogypsum: A waste or a resource. Sci. Total Environ. 2024, 908, 168196. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.Y.; Luo, H.M.; Zheng, L.W.; Wang, K.J.; Li, H.X.; Wang, Y.; Feng, H.X. Utilization of waste phosphogypsum to prepare hydroxyapatite nanoparticles and its application towards removal of fluoride from aqueous solution. J. Hazard Mater. 2012, 241, 418–426. [Google Scholar] [CrossRef]

- Wang, Z.; Shui, Z.; Sun, T.; Li, X.; Zhang, M. Recycling utilization of phosphogypsum in eco excess-sulphate cement: Synergistic effects of metakaolin and slag additives on hydration, strength and microstructure. J. Clean. Prod. 2022, 358, 131901. [Google Scholar] [CrossRef]

- Reijnders, L. Cleaner phosphogypsum, coal combustion ashes and waste incineration ashes for application in building materials: A review. Build. Environ. 2007, 42, 1036–1042. [Google Scholar] [CrossRef]

- Chernysh, Y.; Yakhnenko, O.; Chubur, V.; Roubik, H. Phosphogypsum recycling: A review of environmental issues, current trends, and prospects. Appl. Sci. 2021, 11, 1575. [Google Scholar] [CrossRef]

- Romero-Hermida, M.I.; Borrero-López, A.M.; Alejandre, F.J.; Flores-Alés, V.; Santos, A.; Franco, J.M.; Esquivias, L. Phosphogypsum waste lime as a promising substitute of commercial limes: A rheological approach. Cem. Concr. Compos. 2019, 95, 205–216. [Google Scholar] [CrossRef]

- Kutymbek, N.; Musabekov, K.; Yestayev, K.; Yessengeldiyeva, P.; Omarova, G. Evaluating the efficacy of phosphogypsum as a soil amendment for enhancing fertility in compacted gray-earth soils of Kazakhstan during comprehensive land reclamation. Int. J. Des. Nat. Ecodynamics 2023, 18, 529–536. [Google Scholar] [CrossRef]

- Ennaciri, Y.; Bettach, M.; El Alaoui-Belghiti, H. Phosphogypsum conversion into calcium fluoride and sodium sulfate. Ann. Chim.-Sci. Matériaux 2020, 44, 407–412. [Google Scholar] [CrossRef]

- Gawatre, D.W. Advantages of Waste—Phosphogypsum in Concrete. IJSR-Int. J. Sci. Res. 2012, 2. [Google Scholar]

- Al Qadi AN, S.; Khedaywi, T.S.; Haddad, M.A.; AlRababa’ah, O.A. Investigating the effect of olive husk ash on the properties of asphalt concrete mixture. Ann. Chim.-Sci. Matériaux 2021, 45, 11–15. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, X.; Pan, H.; Yang, X.; Zhang, X.; Lyu, Y.; Liao, W.; Shui, W.; Wu, J.; Xu, M.; et al. Investigating effects of phosphogypsum disposal practices on the environmental performance of phosphate fertilizer production using emergy analysis and carbon emission amounting: A case study from China. J. Clean. Prod. 2023, 409, 137248. [Google Scholar] [CrossRef]

- Chen, G.; Yao, N.; Ye, Y.C.; Fu, F.H.; Hu, N.Y.; Zhang, Z. Influence of partial cement substitution by ground blast furnace slag on the mechanical properties of phosphogypsum cemented backfill. Environ. Sci. Pollut. Res. 2023, 30, 102972–102985. [Google Scholar]

- Chen, Q.S.; Sun, S.Y.; Wang, Y.M.; Zhang, Q.L.; Zhu, L.M.; Liu, Y.K. In-situ remediation of phosphogypsum in a cement-free pathway: Utilization of ground granulated blast furnace slag and NaOH pretreatment. Chemosphere 2023, 313, 11. [Google Scholar] [CrossRef]

- Pu, S.Y.; Zhu, Z.D.; Huo, W.W. Evaluation of engineering properties and environmental effect of recycled gypsum stabilized soil in geotechnical engineering: A comprehensive review. Resour. Conserv. Recycl. 2021, 174, 105780. [Google Scholar] [CrossRef]

- Silva, L.F.O.; Oliveira, M.L.S.; Crissien, T.J.; Santosh, M.; Bolivar, J.; Shao, L.; Dotto, G.L.; Gasparotto, J.; Schindler, M. A review on the environmental impact of phosphogypsum and potential health impacts through the release of nanoparticles. Chemosphere 2022, 286, 131513. [Google Scholar] [PubMed]

- Qin, X.; Cao, Y.; Guan, H.; Hu, Q.; Liu, Z.; Xu, J.; Hu, B.; Zhang, Z.; Luo, R. Resource utilization and development of phosphogypsum-based materials in civil engineering. J. Clean. Prod. 2023, 387, 135858. [Google Scholar] [CrossRef]

- Yang, Q.; Xiang, Z.; Liu, T.; Deng, C.; Zhang, H. Study on the Mechanical Properties of Cast-In-Situ Phosphogypsum as Building Material for Structural Walls. Materials 2023, 16, 1481. [Google Scholar] [CrossRef]

- Diwa, R.R.; Tabora, E.U.; Palattao, B.L.; Haneklaus, N.H.; Vargas, E.P.; Reyes, R.Y.; Ramirez, J.D. Evaluating radiation risks and resource opportunities associated with phosphogypsum in the Philippines. J. Radioanal. Nucl. Chem. 2021, 331, 967–974. [Google Scholar]

- Ma, L.; Zhang, H.; Wang, X.; Chen, L. Application and Development Prospects of Phosphogypsum in Different Phases: A Review. Preprints 2023, 2023091677. [Google Scholar] [CrossRef]

- Sun, Q.Q.; Xu, W.; Huang, Q.L.; Ma, R.; Zhang, J.H.; Ji, H.X.; Yao, S.; Hui, Y.; Lin, J.C.; Ren, Q.F.; et al. Recovery and reuse of phosphogypsum: Effect of ternary cementitious materials on the performance of phosphogypsum pavement base layers. Constr. Build. Mater. 2024, 433, 13. [Google Scholar] [CrossRef]

- Sun, C.Y.; Zhang, J.; Yan, C.W.; Yin, L.Q.; Wang, X.X.; Liu, S.G. Hydration characteristics of low carbon cementitious materials with multiple solid wastes. Constr. Build. Mater. 2022, 322, 13. [Google Scholar] [CrossRef]

- Xiao, Y.; Tan, Y.Z.; Zhou, C.L.; Sun, W.J.; Sun, D.; Yuan, H.; Xing, D.L. Utilisation of silica-rich waste in eco phosphogypsum-based cementitious materials: Strength, microstructure, thermodynamics and CO2 sequestration. Constr. Build. Mater. 2024, 411, 11. [Google Scholar] [CrossRef]

- Qi, W.Y.; Duan, G.; Han, Y.J.; Zhao, Q.X.; Huang, Y.L.; Zhu, W.H.; Pang, H.T.; Zhang, J.H. Comparison of mechanical properties and microstructure of GGBS-based cementitious materials activated by different combined alkaline wastes. Constr. Build. Mater. 2024, 422, 134469. [Google Scholar] [CrossRef]

- Dhalape, P.; Sathe, S.; Dekhane, C. An experimental study on cement concrete with industrial fly ash and phosphogypsum. Mater. Today Proc. 2023, 77, 717–723. [Google Scholar] [CrossRef]

- Bandopadhyay, A. Improvement of expansive soils mixed with red mud and phosphogypsum. Arab. J. Geosci. 2023, 16, 322. [Google Scholar] [CrossRef]

- GB50010-2010; Code for Design of Architecture & Concrete Structures. China Architecture & Building Press: Beijing, China, 2010.

- Niu, Y.; Wang, W.; Su, Y.; Jia, F.; Long, X. Plastic damage prediction of concrete under compression based on deep learning. Acta Mech. 2024, 235, 255–266. [Google Scholar] [CrossRef]

| Parameter | 0% Phosphogypsum Dosage | 2% Phosphogypsum Dosage |

|---|---|---|

| Compressive strength fc | 42.19 | 40.38 |

| Split compressive strength fts | 4.17 | 4.04 |

| Axial compressive strength fcp | 33.060 | 31.470 |

| Modulus of elasticity Ec | 33,086 | 32,687 |

| Poisson’s ratio μ | 0.190 | 0.190 |

| Performance Parameters | CPB550 Steel | HRB400 Steel |

|---|---|---|

| Yield stress/MPa | - | 400 |

| Strength design value/MPa | 360 | 360 |

| Ultimate stress/MPa | 550 | 540 |

| Modulus of elasticity/MPa | 2.00 × 105 | 2.00 × 105 |

| Flexural strength/MPa | 550 | 400 |

| Modulus of rupture/MPa | 200 | 200 |

| Serial Number | ||||

|---|---|---|---|---|

| D1-1 | 5.62 | 4.79 | 4.75 | 0.85 |

| D1-2 | 5.13 | 4.84 | 4.75 | 0.94 |

| D1-3 | 5.79 | 6.11 | 4.75 | 1.06 |

| D1-4 | 5.40 | 5.29 | 4.75 | 0.98 |

| D1-5 | 5.64 | 5.75 | 4.75 | 1.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sha, L.; Zhang, A. Static Load Test and Finite Element Analysis of Phosphogypsum Concrete Composite Slabs. Buildings 2025, 15, 1122. https://doi.org/10.3390/buildings15071122

Sha L, Zhang A. Static Load Test and Finite Element Analysis of Phosphogypsum Concrete Composite Slabs. Buildings. 2025; 15(7):1122. https://doi.org/10.3390/buildings15071122

Chicago/Turabian StyleSha, Lirong, and Ao Zhang. 2025. "Static Load Test and Finite Element Analysis of Phosphogypsum Concrete Composite Slabs" Buildings 15, no. 7: 1122. https://doi.org/10.3390/buildings15071122

APA StyleSha, L., & Zhang, A. (2025). Static Load Test and Finite Element Analysis of Phosphogypsum Concrete Composite Slabs. Buildings, 15(7), 1122. https://doi.org/10.3390/buildings15071122