Abstract

The hazardous and unpredictable nature of construction work poses substantial safety challenges. Despite the long-standing reliance on traditional safety practices, accident rates in the construction industry remain unacceptably high, highlighting the urgent need for innovative solutions. Integrating digital technologies into construction offers a promising approach to safety enhancement with diverse applications. However, successful technology implementation requires user acceptance and strategic guidance. Consequently, this study develops a conceptual framework to guide digital technology implementation efforts to improve construction safety in Sri Lanka. The framework incorporates essential aspects of technology implementation, including safety application areas, benefits, barriers, and facilitators. The research methodology combines an industry-based cross-sectional survey of 101 construction industry professionals followed by a relative importance index analysis to evaluate the perceived significance of these factors. The findings indicate that the primary barriers to technology implementation are the skills and training gap, as well as the cost and investment constraints. The optimal facilitators to overcome barriers include research and development, education and training, and the establishment of industry-wide standards and guidelines. The framework is validated through an expert survey, ensuring its reliability and applicability. Ultimately, the findings present a structured approach to enhancing construction safety standards in Sri Lanka through digital transformation.

1. Introduction

1.1. Overview

Despite significant advancements in the construction industry, safety remains a persistent challenge [1,2]. Globally, the construction sector employs about 7% of the workforce [3]. However, it is responsible for 30–40% of workplace fatalities [3]. Although government organizations, industry, and academia continue to implement various safety measures, accident rates in the construction sector remain unacceptably high [4].

For instance, in China, the construction industry accounts for over one-third of annual industrial accidents [5]. In the United Kingdom, about one-third of occupational fatalities are from the construction industry [6]. In Norway, the construction industry reports a substantially higher number of incidents than other industries [4]. In Australia, fatality rates among construction workers are significantly higher than in other sectors [7]. These statistics underscore the alarming prevalence of workplace accidents in the construction industry.

The primary reasons behind this frequent occurrence of workplace accidents are the hazardous nature of construction work and the unpredictable environments in which they take place [8,9,10]. Furthermore, each construction workplace has unique characteristics, such as its organizational culture, available resources, processes, and workforce behavior, which contribute to high variability and additional risks [11].

The consequences of workplace accidents are substantial, not only in terms of human lives, but also through time and financial losses [12]. Therefore, prioritizing safety not only protects workers, but also enhances the efficiency, recognition, and overall performance of the industry [13]. This emphasizes the urgent need for novel and proactive strategies to improve construction safety.

1.2. Limitations of Traditional Practices and the Role of Digital Technologies in Enhancing Safety

Although continuous research and practical interventions have reduced accident rates [3], the construction industry is significantly behind the goal of “zero accidents/injuries” promoted by many organizations [14]. This is primarily because of the industry’s heavy reliance on traditional safety practices, which are based on parametric models and manual methods [15]. While these practices such as toolbox talks, hazard reporting, and adherence to safety regulations help maintain baseline safety [16], they are insufficient for addressing the complex and evolving risks of modern construction projects [9,10].

This highlights the need for innovative safety solutions that perform beyond traditional methods [14,15]. The integration of advanced digital technologies into construction presents a promising approach, offering enhanced capabilities in hazard recognition, safety planning, and safety management [1,2]. Consequently, integrating these technologies into the construction industry can foster safer and more sustainable working environments [10,17].

Over the years, numerous digital technologies have emerged, offering a wide array of safety applications [13]. These include, but are not limited to, Building Information Modeling (BIM), Virtual Reality (VR), Augmented Reality (AR), Geographic Information Systems (GIS), the Internet of Things (IoT), Serious Games, drones, and mobile and wearable devices [1,18]. Additionally, Natural Language Processing (NLP) and machine learning techniques, such as Stochastic Gradient Descent, have demonstrated effective applications in occupational health and safety by automating risk assessment processes [19]. By enabling advanced visualization, simulation, and analysis of construction processes, these technologies empower stakeholders to identify and mitigate safety risks and hazards more effectively.

1.3. Current Status of Digital Transformation of the Construction Industry in Sri Lanka

While many developed countries have successfully implemented digital technologies to enhance construction safety, developing countries remain in the early stages of digital transformation [1,20]. Thus, this transition remains particularly challenging for countries like Sri Lanka [21], where conventional safety practices have long been the norm [14,22].

Despite these challenges, the Sri Lankan construction industry is making significant progress in its digital transformation. For instance, Chamikara et al. [23] explored the use of BIM to manage cost overruns in design and building projects, concluding that it is a promising solution. Amirthavarshan et al. [24] examined the potential of digital twin technology for construction progress monitoring, highlighting its benefits, applications, and challenges.

Epasinghe and Jayasena [25] identified the low potential for adopting open BIM in Sri Lanka, citing key technical and industrial challenges. Abeywickrama et al. [26] discussed the integration of digital technologies for alternative dispute resolution, while Senanayake et al. [27] explored the use of AR in construction cost management. Perera et al. [28] analyzed the challenges of fire hazard management in high-rise buildings, advocating for the extension of BIM to improve collaboration and automate fire safety processes.

In addition, Rathnayake [29] examined the barriers and drivers of BIM adoption in Sri Lankan quantity surveying organizations and proposed a framework to foster its adoption. Gunasekara and Jayasena [30] developed a framework aimed at overcoming the technological and financial challenges associated with BIM adoption in Sri Lanka. Gamage et al. [31] investigated the barriers to adopting blockchain and smart contracts in the industry and proposed a framework for their successful integration. Moreover, Chathuranga et al. [12,32] developed an organizational readiness model to assess the Sri Lankan construction industry’s preparedness for adopting digital technologies to enhance productivity.

Consequently, these studies underscore the growing interest in integrating digital technologies into the Sri Lankan construction industry. However, most of this research has concentrated on other aspects of construction, with a relatively limited focus on enhancing construction safety.

1.4. Knowledge Gaps, Research Aims, and Significance

Many previous studies have focused on the implementation of individual technologies to enhance construction safety. Consequently, comprehensive frameworks that facilitate multiple digital technology implementations are still lacking [33]. In Sri Lanka, there have been efforts to adopt digital technologies to improve aspects like construction productivity, cost management, and progress monitoring. However, there is no structured framework specifically designed to provide strategic guidance for the implementation of digital technologies to improve construction safety.

This research aims to fill these gaps by developing a conceptual framework that can provide strategic guidance for digital technology implementation to enhance construction safety in Sri Lanka. The framework is based on a thorough evaluation of key safety application areas, safety benefits, barriers, and facilitators of technology implementation. It also assesses the preparedness of employees for digital transformation, providing valuable insights to guide the transition.

Although the primary focus is on the Sri Lankan construction industry, the framework’s principles and methods can be adapted and applied to other developing countries facing similar challenges. The findings offer critical insights that can inform policies and industry practices, supporting a broader move towards a safer and more sustainable construction industry.

2. Literature Review

2.1. Digital Technologies and Construction Safety

To ensure the feasible implementation of digital technologies, this study prioritizes the most impactful and widely researched technologies [34]. A systematic review by Afzal et al. [1] identifies BIM, AR, VR, GIS, and Serious Games as the most frequently explored technologies for construction safety enhancement. Given that Sri Lanka is still in the early stages of digital transformation, focusing on these already-established technologies offers a practical and effective approach. Accordingly, these five technologies were selected to develop the technology implementation framework. The following sections present a detailed overview of their specific safety applications in the construction industry.

2.1.1. Building Information Modeling (BIM)

BIM encompasses a precise 3D digital model enriched with information used for planning, designing, building, and facility operations [1,35]. BIM plays a crucial role in enhancing construction safety through visualization, training, rule-based checking, automatic rule checking, and design for safety suggestions [36,37]. Additionally, BIM can be applied to tasks such as planning temporary facilities, modeling crane operations, conducting fire safety analysis, providing simulation-based training, performing automated safety checks, and enhancing overall safety measures and coordination [28,35,38,39]. Consequently, safety planning and management, safety compliance and enforcement, and safety training and education were identified as the primary safety application areas facilitated by BIM implementation.

2.1.2. Virtual Reality (VR)

VR is a technology that creates simulated environments where users can interact with a 3D space as if it were real [40]. VR provides immersive simulations for safety training and education [40,41,42]. VR-based training can simulate risky situations and practice construction activities without actual hazards, enhancing safety awareness and preparedness [43]. VR also has significant potential in hazard identification and safety inspections by immersing stakeholders in a virtual environment to visualize, analyze, and address safety risks [44]. Consequently, VR implementation prominently focuses on safety training and education, safety inspection and instructions, and hazard identification as core safety application areas.

2.1.3. Augmented Reality (AR)

AR technology overlays digital information in the real world, enhancing users’ perception and interaction with their surrounding environment [45]. It improves the effectiveness of safety inspections and instructions by superimposing real-time information, such as safety guidelines, equipment details, and hazard warnings, directly on-site [46]. AR-based simulations enable employees to train for hazardous situations and emergency responses in realistic yet controlled environments [42,47]. This is highly effective in reducing on-the-job risks by enhancing workers’ preparedness, knowledge, competency, and confidence while reinforcing safety awareness and practical skills [33]. Consequently, safety training and education, as well as safety inspection and instructions, were identified as the primary safety application areas facilitated by AR implementation.

2.1.4. Geographic Information Systems (GIS)

GIS is an advanced technology for acquiring, storing, analyzing, and displaying geographic data [48]. Its potential in safety planning and management is evident through the integration of spatial and temporal data for site safety analysis [49]. GIS is also vital in simulating potential hazards at a construction site, enabling stakeholders to assess risks and make adjustments to the site layout, workflows, or safety protocols before construction works begin [50]. Additionally, it has significant potential for site selection by evaluating the safety, cost, and environmental impacts [50,51]. It further facilitates the proactive handling of health and safety risks through spatial analysis [49]. Consequently, GIS implementation prominently focuses on safety planning and management, as well as safe site selection as core safety application areas.

2.1.5. Serious Games

Serious games combine gaming elements with real-world challenges to enhance safety training and education [52]. Serious games in immersive virtual reality provide an interactive and engaging platform for safety education, enabling individuals to develop hazard identification skills in risk-free environments [53]. These gamified systems not only enhance user engagement but also provide effective training in recognizing potential hazards on a construction site before actual work begins [54,55]. Consequently, the primary safety area of serious games was identified as safety training and education.

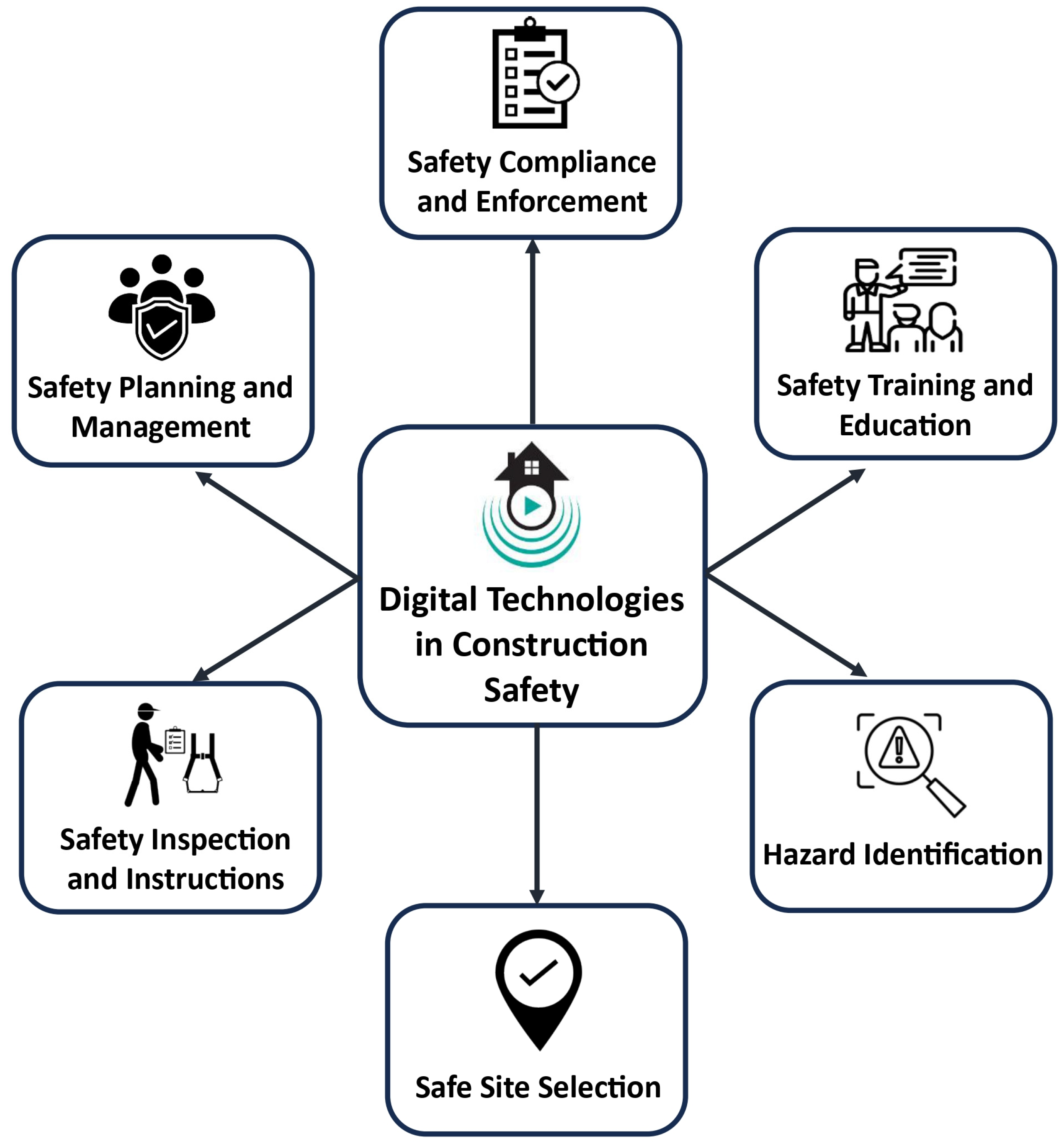

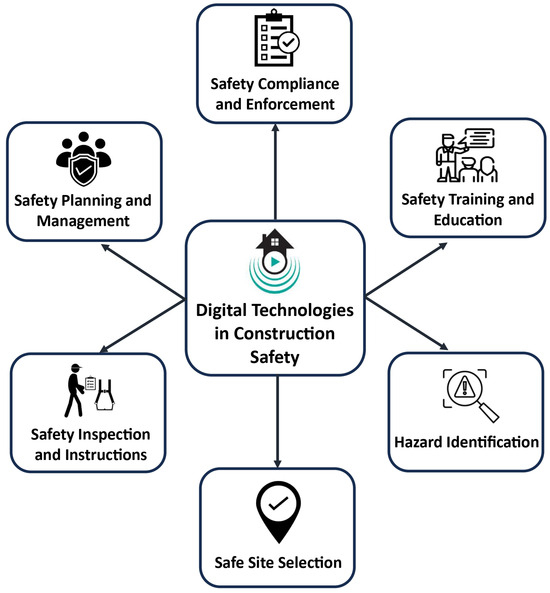

2.2. Key Safety Application Areas

Based on the diverse safety applications for the selected five technologies, six key safety application areas were identified (Figure 1). These areas are safety planning and management, safety compliance and enforcement, safety training and education, safety inspection and instructions, hazard identification, and safe site selection.

Figure 1.

Key safety application areas of selected digital technologies.

2.3. Main Aspects of Digital Technology Implementation

Based on the literature review, this study identifies key safety application areas, safety benefits, barriers, and facilitators related to digital technology implementation. These aspects act as the foundational pillars of the developed technology implementation framework.

The six key safety application areas identified in the previous section are summarized in Table 1 for clarity and ease of reference.

Table 1.

Key safety application areas of digital technology implementation.

The digital transformation of the construction industry provides numerous safety benefits. An awareness of these benefits is crucial in enhancing the acceptance of digital technology integration in the construction industry. Consequently, Table 2 presents the potential safety benefits identified through the literature review.

Table 2.

Potential safety benefits of digital technology implementation.

The digital transformation of the Sri Lankan construction industry is still in its early stages. Thus, critical aspects such as technologies, policies, regulations, and infrastructure are still evolving [18]. Consequently, this transformation is hindered by several significant barriers. Based on the literature review, the authors have identified eight technology implementation barriers that are particularly relevant to the context of developing countries, as summarized in Table 3.

Table 3.

Barriers to digital technology implementation.

The success of technology implementation hinges on how effectively the industry addresses the identified barriers. Facilitators of technology implementation have to play a crucial role in this process. Table 4 summarizes six key facilitators with the potential to overcome these barriers. These facilitators are instrumental in creating an environment that supports and promotes the effective integration of digital technologies in the construction industry.

Table 4.

Facilitators of digital technology implementation.

All factors identified across the four categories of safety application areas, potential safety benefits, barriers, and facilitators were surveyed among construction industry professionals in Sri Lanka to integrate industry perspectives. These factors, along with their relative importance in the local context, served as the foundation for the development of the proposed digital technology implementation framework.

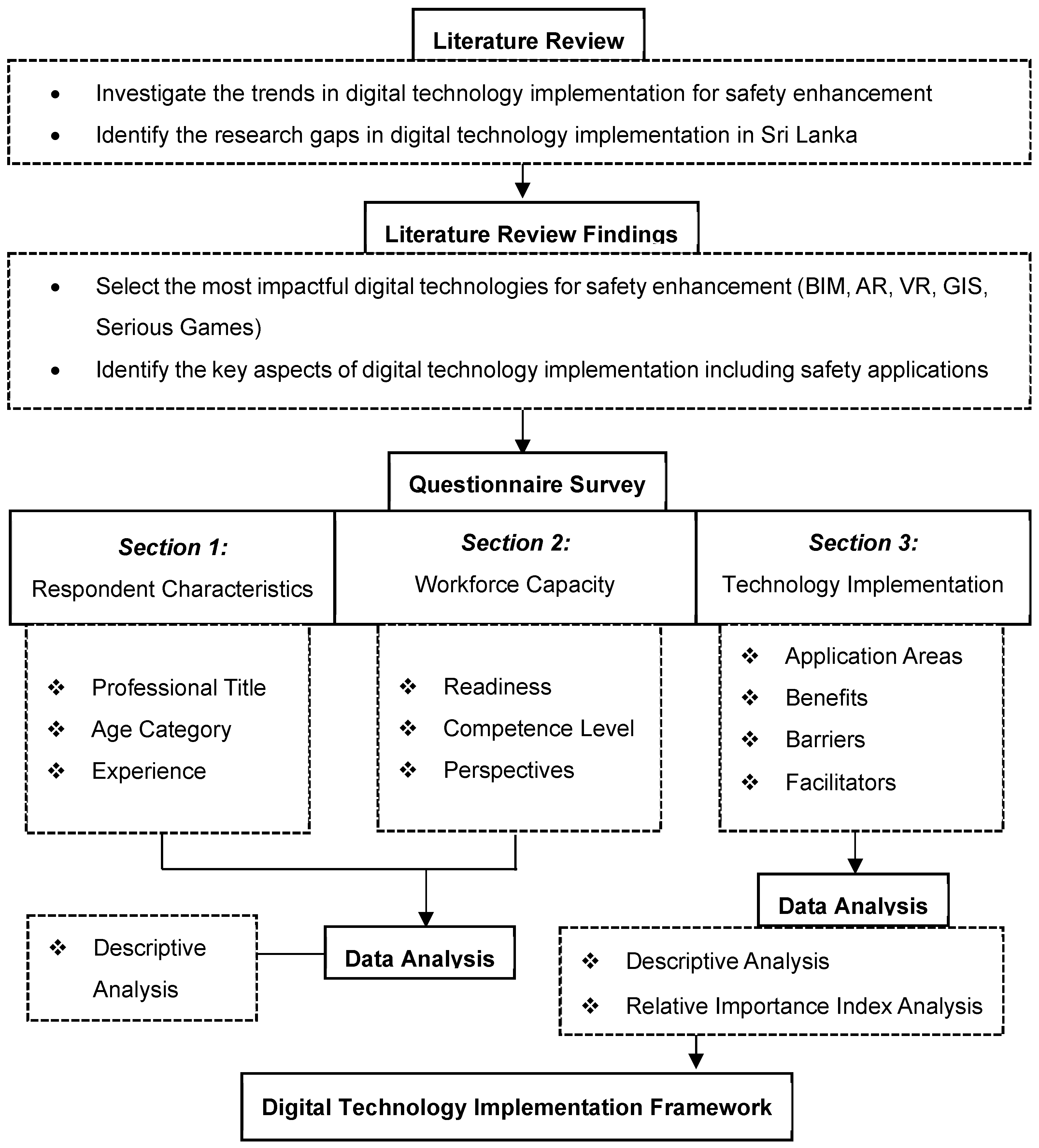

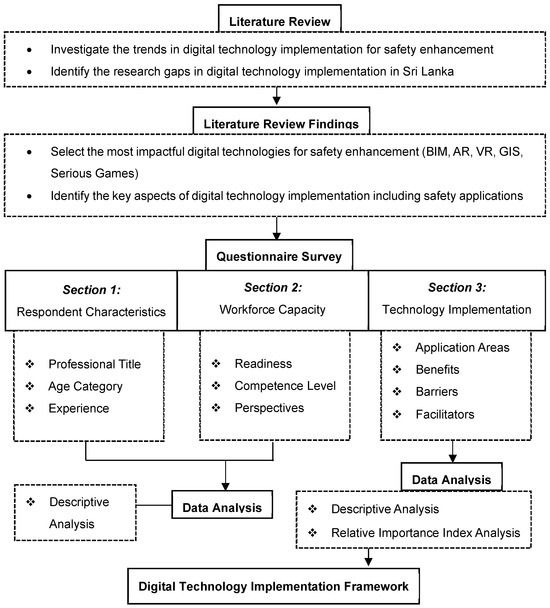

3. Methodology

The research adopted the mixed-methods approach, integrating a literature review and a comprehensive questionnaire survey among construction industry professionals in Sri Lanka [67]. This section provides a detailed overview of the research methodology. Figure 2 illustrates the overall research process.

Figure 2.

Overall research process.

3.1. Survey Design

The cross-sectional survey conducted among construction industry professionals is comprised of three main sections. The first section collected respondents’ characteristics to contextualize the study sample, including their professional title, experience in construction, and the age category. The second section focused on collecting data to evaluate the respondents’ perspectives, readiness, and competence in utilizing selected digital technologies.

The third section gathered data to assess the perceived importance of factors within the categories of safety application areas, safety benefits, barriers, and facilitators. In the third section, data were collected using a 5-point Likert scale, ranging from 1 (Not Significant) to 5 (Highly Significant) unless otherwise specified. Some questions use alternative terminology for the 5-point scale, which is clearly indicated within the respective sections.

This study collected only technical information, with no personal data of the respondents included. As a result, ethical approval was waived. Respondents were informed of the survey’s objectives in advance, and only those who voluntarily consented to participate were included.

3.2. Sampling Methods and Respondent Characteristics

The research utilized both convenience sampling and snowball sampling methods. The first layer of respondents was selected using convenience sampling [2,76,77], targeting construction professionals known to the authors, with sufficient representation across various regions of Sri Lanka. These respondents were then asked to refer other professionals within their network who were suitable to participate in the survey, following the snowball sampling [67]. Consequently, a total of 101 questionnaires were completed and received.

Accordingly, the respondent sample includes 101 construction industry professionals from various roles, age groups, and experience levels. Table 5 summarizes the characteristics of the respondents.

Table 5.

Respondent characteristics.

The sample reflects a balanced representation of both emerging and experienced construction professionals. The inclusion of younger professionals is particularly valuable, as they are more likely to be familiar with digital technologies and are the future leaders of the industry.

3.3. Data Analysis Methods

Descriptive statistics were utilized to present a comprehensive summary of the respondents’ demographic characteristics and the overall dataset. To assess the perceived importance of various factors, the Relative Importance Index (RII) method was employed. This approach facilitated a structured evaluation of factors across four key categories: safety application areas, perceived benefits, barriers, and facilitators related to the implementation of safety technologies, based on the respondents’ insights [31,36,62]. A widely accepted RII threshold value of 0.6 was adopted to identify factors considered significant [31]. The RII for each factor was calculated using Equation (1).

- W = Weighting (1 to 5) given to each factor by the respondents.

- A = Highest weight (i.e., a score of 5 on the scale).

- N = Total number of responses.

4. Results and Discussion

4.1. Workforce Capacity Assessment in Utilizing Digital Technologies

Proficiency and prior training in using digital technologies are essential prerequisites for successful technology integration. Without these skills, post-implementation processes may be hindered, with fewer individuals capable of managing the new technologies. Therefore, this study conducted a workforce capacity assessment.

The analysis revealed that 70.6% of respondents had not received any prior training in using digital technologies. The self-assessment of expertise in using digital technologies informs that 52.9% have ‘moderate’ expertise, 27.9% rated their expertise as ‘high’ or ‘very high’, while 19.2% reported ‘low’ or ‘very low’.

Despite these skill gaps, 86.8% of respondents believe digital technology integration will significantly enhance construction safety within the next 5–10 years. Furthermore, 42.6% consider the technology implementation ‘very important’, while 51.5% consider it ‘important’ for safety enhancement, reflecting a positive industry outlook on implementing digital technologies.

4.2. Contextual Significance of Key Aspects of Technology Implementation

This section presents the relative importance of factors under the categories of safety application areas, safety benefits, barriers, and facilitators according to the RII analysis. This analysis is valuable as it incorporates context-specific industry perspectives, enhancing the relevance and applicability of this study’s findings.

4.2.1. Familiarity with Digital Technologies

Based on the RII analysis with the 5-point Likert scale (1—Not familiar at all to 5—Highly familiar), GIS was identified as the most familiar digital technology among respondents, while AR was the least familiar. Following GIS technology, BIM, Serious Games, and VR were ranked in the sequence of familiarity, positioned as 2nd, 3rd, and 4th (Table 6). The relatively low RII values (below 0.6) indicate a moderate familiarity with these digital technologies among industry professionals in Sri Lanka.

Table 6.

Digital technology familiarity.

4.2.2. Relative Importance of Safety Application Areas

Table 7 presents the relative importance of safety application areas of digital technologies according to the industry perspectives.

Table 7.

Relative importance of safety application areas.

According to the RII analysis, BIM (RII = 0.80) and GIS (RII = 0.77) perform well in safety planning and management. However, the respondents perceived BIM as slightly more effective in this area, as reflected by its marginally higher RII. Additionally, BIM is pivotal in safety training and education [39], with an RII of 0.78. GIS also plays a significant role in safe site selection, with an RII of 0.74, highlighting its importance in informed site selection and risk mitigation strategies [51].

AR and Serious Games are significantly effective in safety training and education, both with an RII of 0.73. Their ability to offer interactive, engaging training solutions improves learning retention and skill development among employees [54,61]. VR is highly effective in safety inspection and instruction, as well as hazard identification, with a high RII of 0.76, emphasizing its value in immersive and interactive safety solutions [40].

Overall, these digital technologies show great potential across various safety areas. BIM and GIS are most effective for safety planning and management, AR and Serious Games lead in safety training and education, while VR excels in safety inspection and instructions.

4.2.3. Relative Importance of Safety Benefits

Table 8 outlines the relative importance of the potential safety benefits of each technology based on industry perspectives.

Table 8.

Relative importance of safety benefits.

The primary benefit of BIM is the early detection of safety issues, with the highest RII of 0.74. The enhanced risk assessment (RII = 0.73) and improved hazard identification (RII = 0.72) were also instrumental. Moreover, the findings highlight BIM’s strengths in proactive safety management through interactive simulations and visualizations [13].

Enhanced learning retention and decision-making skills (RII = 0.73) can be identified as the key benefit of VR, according to industry perspectives. This underscores its effectiveness in immersive training environments that improve the understanding and competency of employees [41]. VR also serves as an immersive platform for realistic safety training (RII = 0.71), emphasizing its role in interactive and engaging training sessions [43]. Moreover, VR is instrumental in enhancing worker competency in safety protocols.

AR is highly effective in risk-reduced learning (RII = 0.72), demonstrating its capability to provide safe training environments before actual construction begins. Furthermore, the on-site guidance of AR is instrumental (RII = 0.71), which potentially reduces the risk of workplace accidents. AR also enhances the learning retention and decision-making skills of employees, while offering interactive platforms for realistic safety training, similar to VR [47].

GIS facilitates a comprehensive site evaluation (RII = 0.73) and enhanced risk assessment (RII = 0.68), demonstrating its ability to integrate safety, cost, and environmental considerations into the analysis [51]. However, its role in hazard identification is comparatively lower according to industry perspectives (RII = 0.65).

Serious Games provide valuable real-time feedback and performance tracking, achieving a significant RII of 0.70. It also offers engaging and interactive safety training with an RII of 0.68. This indicates its utility in providing dynamic training experiences that facilitate effective learning and performance monitoring [54,55].

4.2.4. Relative Importance of Technology Implementation Barriers

The RII analysis highlights the relative importance of barriers to digital technology implementation, as summarized in Table 9. The table prioritizes these barriers based on their criticality and assigns unique codes to each barrier.

Table 9.

Relative importance of technology implementation barriers.

The skills and training gap (RII = 0.71) is the most critical barrier to technology implementation, aligning with previous findings that highlight this as a common challenge in developing countries [2]. Digital literacy in developing countries is comparatively lower than in developed countries, which hinders the efficiency of digital transformation [2]. This highlights the urgent need for tailored incentives to improve related skills and training in utilizing digital technologies [31].

The second most critical barrier is cost and investment constraints (RII = 0.69). Several researchers have also highlighted that the high upfront costs associated with advanced infrastructure, hardware, and software present a significant challenge to technology adoption in the construction sector [13,78]. Also, the limited demand from clients for technology integration to construction activities reduces investment incentives [10,67,79], particularly in developing countries like Sri Lanka.

Most Sri Lankan construction organizations operate on small- to medium-scale projects, where cost reduction and being within the allowable budget is vital for profitability. Consequently, organizations tend to rely on well-established construction practices that are familiar and perceived as cost-effective. Therefore, striking a balance between technology implementation and return on investment is a key strategy for advancing construction safety while driving digital transformation.

A lack of standardization (RII = 0.67) also emerged as a significant barrier from the perspective of industry professionals. Previous studies have shown that the absence of industry-wide standards often results in the fragmented implementation of digital tools, weakening the overall effectiveness of safety and efficiency efforts in construction projects [65]. Such inconsistencies can hinder digital transformation by causing compatibility, security, and functionality challenges across platforms [78]. As a result, the limited interoperability between software and hardware systems restricts the full potential of these technologies within the industry.

The complexity, technological challenges, and time constraints (RII = 0.67) of modern construction projects complicate efforts to implement digital technologies [66]. The unique characteristics of different construction projects often require tailored technological approaches. Concurrently, organizations face intense pressure to complete projects on time [67]. These conditions lead organizations to prioritize conventional methods over digital technological advancements.

The organizational culture and resistance to change (RII = 0.66), as well as a lack of awareness and understanding of digital technologies (RII = 0.65), are also significant technology implementation barriers. Employees tend to adhere to established organizational practices due to familiarity and a preference for conventional workflows [67], which hinders the integration of new technologies. Moreover, implementing digital technologies demands specific knowledge and skills, which may not receive early acceptance from employees [78]. Accordingly, overcoming this resistance requires substantial organizational changes and strong leadership [36]. Furthermore, the lack of awareness and understanding about technologies can create uncertainty and fear, discouraging employees from embracing these innovative solutions [63]. This lack of awareness can also reinforce resistance to change, making digital transformation even more challenging. Therefore, strategic interventions are needed to highlight the benefits of digital technology implementation and cultivate a positive attitude in construction organizations toward digital transformation [72].

Significant yet less critical barriers include data management and privacy concerns (RII = 0.60) and regulatory and legal issues (RII = 0.62) within the Sri Lankan context from an industry perspective. While these issues are still crucial in construction digitalization, they may be of lower concern due to respondents’ limited experience with these technologies. As construction operations become increasingly digitalized, data management, data security, and data privacy will become more critical, driven by industry competitiveness [62]. However, the prevailing data management approaches in Sri Lanka are still in their early stages, which highlights the lack of readiness to achieve effective digitalization.

Also, the regulatory and legal issues need to be streamlined to facilitate smoother technology implementation. Given that the country is still in the early stages of digital transformation, essential policy incentives must be introduced, and existing regulations should be updated to support successful and feasible integration. The Sri Lankan government has a key role to play in this process. Addressing these challenges will enhance digital technology implementation, ensuring better data management and legal compliance [68].

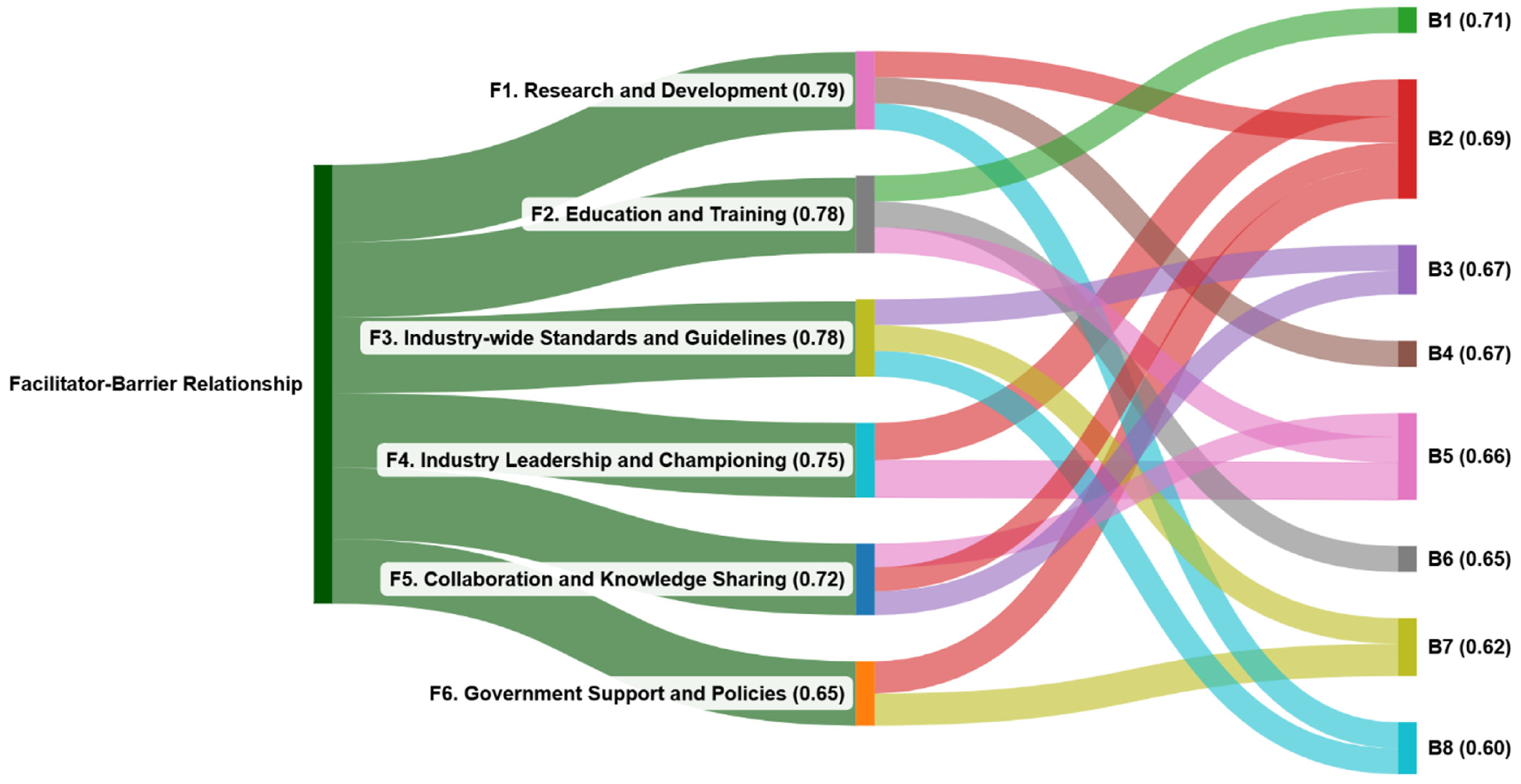

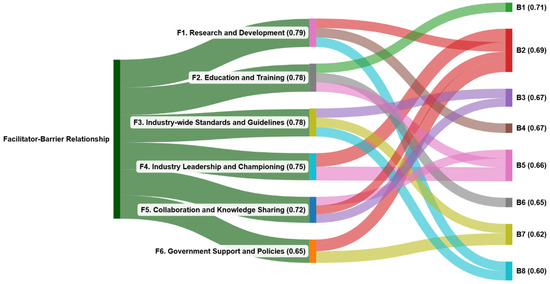

4.2.5. Relative Importance of Technology Implementation Facilitators

The optimal facilitators to overcome potential implementation barriers were ranked using RII analysis, incorporating industry perspectives (Table 10). Research and development (RII = 0.79), education and training (RII = 0.78), and industry-wide standards and guidelines (RII = 0.78) emerged as the top facilitators for digital technology implementation in Sri Lanka. Other facilitators were also considered significant, with RII values exceeding 0.6 [31].

Table 10.

Strategic guidance to overcome barriers using facilitators.

Table 10 further provides a detailed discussion of how facilitators can be utilized to address specific implementation barriers. Concurrently, Figure 3 visually illustrates the facilitator–barrier relationship, with corresponding RII values presented in the parentheses. By examining these findings together, readers can gain a comprehensive understanding of how facilitators can be strategically leveraged to overcome barriers. These insights enable stakeholders to develop targeted strategies that foster a more resilient, efficient, and technologically advanced construction sector, ultimately ensuring long-term safety.

Figure 3.

Relationship between facilitators and barriers.

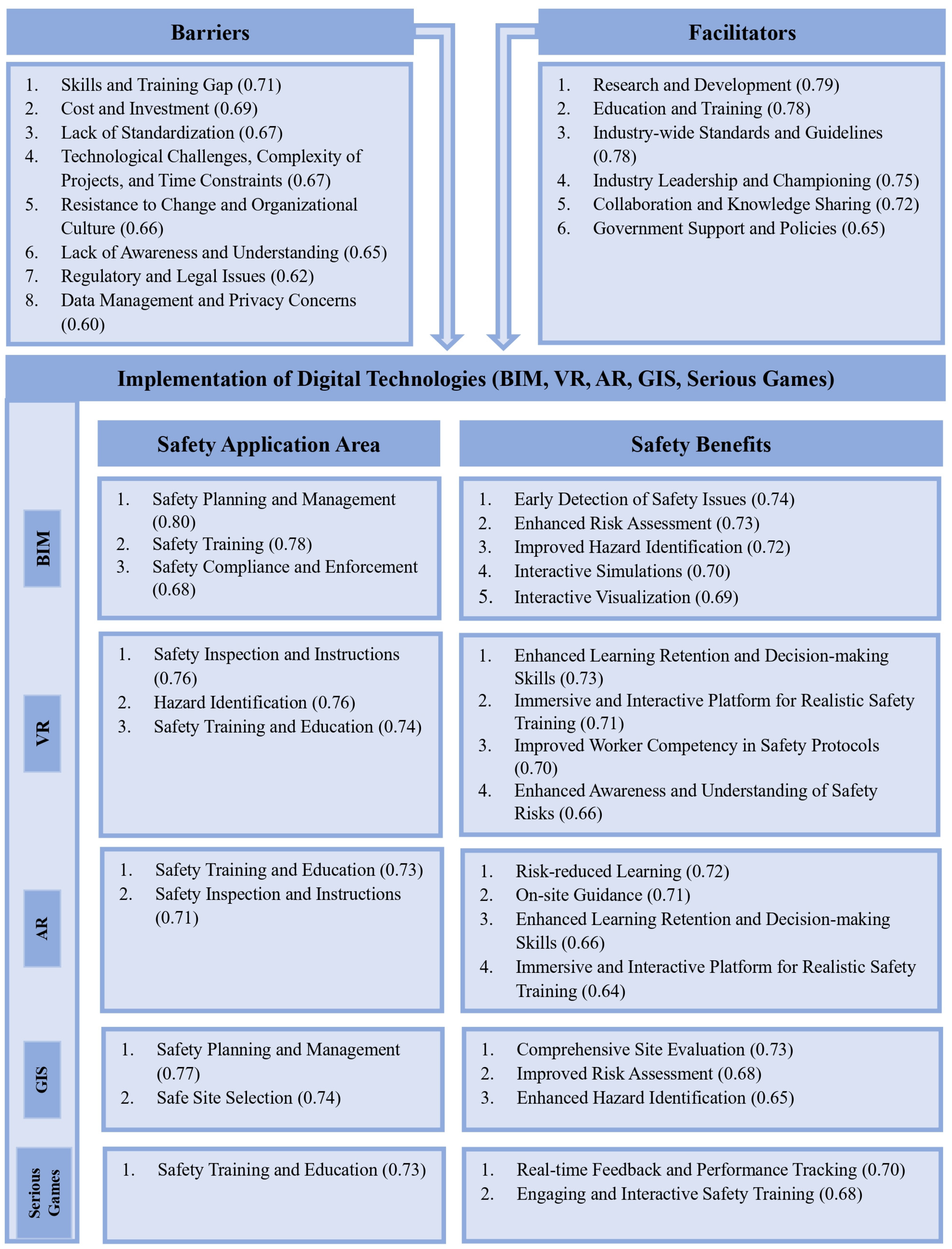

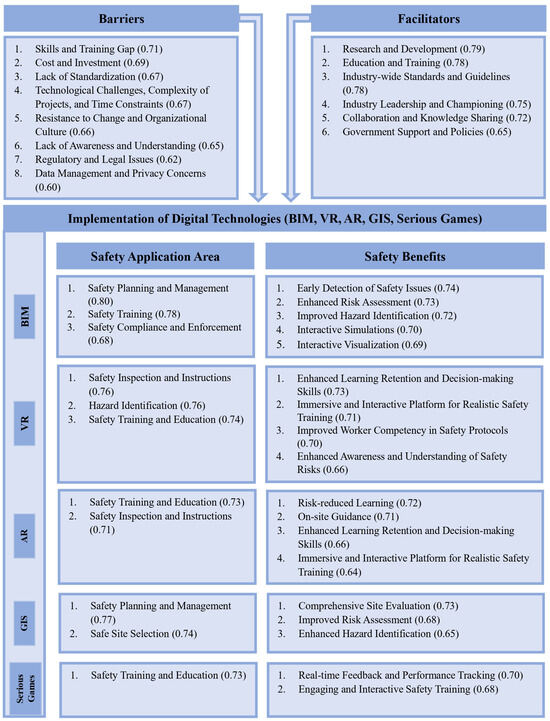

4.3. Digital Technology Implementation Framework

Based on the comprehensive evaluation of safety application areas, safety benefits, barriers, and facilitators using RII analysis, the digital technology implementation framework has been developed (Figure 4). The rankings in Figure 4 are derived from the RII analysis, with corresponding RII values presented in the parentheses.

Figure 4.

Digital technology implementation framework.

The developed framework is further strengthened by the detailed discussion provided in Table 10 and the illustrated relationship between facilitators and barriers in Figure 3, demonstrating how facilitators can be utilized to overcome technology implementation barriers. This integrated approach provides critical insights for policymakers, industry practitioners, and academics to accelerate digital transformation to enhance construction safety in Sri Lanka.

4.4. Validation of the Developed Technology Implementation Framework

The developed technology implementation framework was validated using the expert survey approach. Eight professionals from the construction industry, including five from the private sector and three from the public sector, each with a minimum of five years of experience in digital technology utilization and construction safety management, participated in the survey. The group included one project manager, two construction engineers, one planning engineer, two safety officers, one quantity surveyor, and one technical officer.

The survey questionnaire assessed the developed framework based on seven validation statements, rated on a 5-point Likert scale (1 = Strongly Disagree to 5 = Strongly Agree) [15]. The mean Likert scale rating for the validation statements is presented in Table 11. Additionally, a one-sample t-test was conducted to justify that there is a significant difference between the theoretical mean of 3.0 and the respondents’ mean ratings.

Table 11.

Results of the validation survey (n = 8).

The S2, S6, and S7 statements received a significant mean rating of 4.6. Accordingly, experts strongly believe that the framework comprehensively incorporates all necessary aspects of technology implementation. Additionally, they affirm that the methodology employed is logical and replicable while holding high scholarly value by providing future scalability of technology implementation to enhance construction safety in Sri Lanka.

Furthermore, the significant mean rating of 4.4 for the S3 and S5 statements suggests that the developed framework is both objective and reliable, offering a comprehensive and detailed overview of technology implementation. In contrast, the S1 statement received a comparatively lower mean rating of 4.0. This implies that experts were slightly less confident in the suitability of the selected technologies to enhance construction safety, potentially due to the industry’s early stage of digital transformation.

While the practical guidance (S4) provided by the framework is somewhat less emphasized compared to other aspects, experts still acknowledge that it offers a clear roadmap for digital technology implementation. Consequently, industry experts validated the framework for the Sri Lankan context, confirming its applicability and finalizing its development.

4.5. Research Implications

4.5.1. Theoretical Implications

This study introduces a novel, comprehensive framework that guides multiple digital technology implementations to enhance construction safety. The rigorous literature review incorporates all essential aspects of technology implementation, including safety application areas, safety benefits, barriers, and facilitators. The factors under each of these four categories were assessed for relative importance using an industry-based RII analysis, which shows the context-specific and replicable methodical approach taken. The validation of the framework by industry experts further enhances its theoretical significance. While the framework is grounded in the Sri Lankan context, its adaptability across similar contexts offers opportunities for future theoretical exploration.

4.5.2. Practical Implications

The framework provides a comprehensive perspective on key aspects of digital technology implementation and their relative importance, which is crucial for context-specific interventions for effective digital transformation. The detailed discussion on how to overcome implementation barriers using facilitators (Table 9 and Figure 3), along with the developed conceptual framework (Figure 4), provides strategic guidance for the digital technology implementation efforts to enhance construction safety. These findings are particularly valuable for policymakers, industry practitioners, and academics, enabling collaborative efforts to leverage facilitators in overcoming critical implementation barriers. This well-informed approach helps organizations align their digitalization objectives with the developed framework, ensuring a more structured and efficient digital transformation of the Sri Lankan construction industry.

4.6. Strengths and Limitations

This study is the first to propose a tailored framework for integrating digital technologies into Sri Lanka’s construction industry to enhance safety. It encompasses all key aspects of technology implementation while also incorporating their relative importance from an industry perspective. This approach is both comprehensive and detailed yet remains replicable for broader applications. Furthermore, it provides strategic guidance to achieve an efficient digital transformation of the construction industry. The framework’s credibility is further reinforced through expert validation.

Although there are many strengths, some limitations are also present. This study’s comparatively low sample size may limit the representation of the broader Sri Lankan context. Additionally, the research does not deeply explore the unique requirements and challenges of individual technology implementation. These limitations have to be considered when interpreting the findings.

4.7. Recommendations and Future Studies

To enhance the robustness and applicability of the framework, future research should focus on expanding the sample size and including professionals from various levels and roles within the construction industry. Additionally, testing the framework in regions with similar socio-economic contexts will further strengthen its applicability.

The periodic refinement of the framework is essential to capture emerging trends and ensure its continued relevance. Future studies should also investigate the specific challenges associated with the implementation of individual technologies, thereby expanding the framework’s scope. Furthermore, sensitivity analyses are recommended to systematically evaluate the framework’s reliability and adaptability across different contexts.

5. Conclusions

This study offers a novel contribution to the field by developing the first context-specific conceptual framework for implementing digital technologies to enhance construction safety in Sri Lanka. The framework focuses on key technologies, including building information modeling, virtual reality, augmented reality, geographic information systems, and serious games, which offer a wide array of construction safety applications.

A comprehensive literature review guided the identification of essential components for effective technology implementation, including safety application areas, associated benefits, barriers, and facilitators. To evaluate the practical relevance of these elements, this study employed a Relative Importance Index (RII) analysis based on responses from a cross-sectional survey of 101 construction professionals across Sri Lanka. This analysis provided valuable insights into the relative significance of these factors within the local industry context.

This study further prioritizes the most critical barriers to technology implementation and identifies the most effective facilitators to overcome them. These findings form the foundation of the proposed implementation framework (Figure 4). Furthermore, the strategic guidance provided in Table 10 along with the relationships illustrated in Figure 3 demonstrates how these facilitators can be effectively leveraged to overcome key implementation challenges. To ensure the framework’s reliability and practical relevance, it was validated through an expert survey involving eight experienced professionals from both the public and private sectors in Sri Lanka. The results confirmed the framework’s applicability and credibility within the local construction context.

In summary, this research offers a structured and actionable roadmap for integrating digital technologies to improve construction safety. It provides valuable insights for policymakers, industry professionals, and academics, supporting collaborative efforts to drive sustainable digital transformation in Sri Lanka’s construction sector.

Author Contributions

Conceptualization: F.T. and C.S.; methodology: F.T., C.S. and N.C.; investigation: F.T.; data curation: N.C. and F.T.; formal analysis: N.C. and F.T.; writing—original draft: N.C.; writing—review and editing: N.C. and C.S.; visualization: N.C.; supervision: C.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Ethical review and approval were waived for this study because the data collected was purely technical and did not include any personal information.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors express their sincere gratitude to the construction industry professionals who contributed to the development and validation of the framework.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Afzal, M.; Shafiq, M.T.; Jassmi, H.A. Improving construction safety with virtual-design construction technologies—A review. J. Inf. Technol. Constr. 2021, 26, 319–340. [Google Scholar] [CrossRef]

- Malomane, R.; Musonda, I.; Okoro, C.S. The opportunities and challenges associated with the implementation of Fourth Industrial Revolution technologies to manage health and safety. Int. J. Environ. Res. Public Health 2022, 19, 846. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Goh, Y.M.; Li, Q. Overview and analysis of safety management studies in the construction industry. Saf. Sci. 2015, 72, 337–350. [Google Scholar] [CrossRef]

- Sandberg, E.; Albrechtsen, E. A study of experience feedback from reported unwanted occurrences in a construction company. Saf. Sci. 2018, 107, 46–54. [Google Scholar] [CrossRef]

- Choi, S.D.; Guo, L.; Kim, J.; Xiong, S. Comparison of fatal occupational injuries in the construction industry in the United States, South Korea, and China. Int. J. Ind. Ergon. 2019, 71, 64–74. [Google Scholar] [CrossRef]

- Health and Safety Executive, U.K. Fatal Injuries Arising from Accidents at Work in Great Britain: Headline Results. HSE. 2021. Available online: http://www.hse.gov.uk/statistics/fatals.htm (accessed on 25 January 2024).

- Dodshon, P.; Hassall, M.E. Practitioners’ perspectives on incident investigations. Saf. Sci. 2017, 93, 187–198. [Google Scholar] [CrossRef]

- Deng, H.; Ou, Z.; Deng, Y. Multi-angle fusion-based safety status analysis of construction workers. Int. J. Environ. Res. Public Health 2021, 18, 11815. [Google Scholar] [CrossRef]

- Singh, A.; Misra, S.C. Safety performance and evaluation framework in the Indian construction industry. Saf. Sci. 2021, 134, 105023. [Google Scholar] [CrossRef]

- Daniel, E.I.; Oshodi, O.S.; Nwankwo, N.; Emuze, F.A.; Chinyio, E. Barriers to the application of digital technologies in construction health and safety: A systematic review. Buildings 2024, 14, 2386. [Google Scholar] [CrossRef]

- Bagir, M. Adoption of Digital Occupational Safety and Health Technologies in the Construction Sector. Available online: https://urn.kb.se/resolve?urn=urn:nbn:se:kth:diva-307375 (accessed on 5 February 2025).

- Chathuranga, I.H.N.; Siriwardana, C.S.A.; Ariyaratne, I.E. Assessing the Readiness for Digital Technologies Adoption for Enhancing Productivity in the Sri Lankan Construction Industry. Available online: https://www.researchgate.net/publication/380857195 (accessed on 25 December 2024).

- Bandara, D.M.U.S.; Jayasinghe, J.A.S.K.; Coomasaru, P. Advancing digital technology adaptation in Sri Lankan construction firms. In Proceedings of the 12th World Construction Symposium, Moratuwa, Sri Lanka, 9–10 August 2024; pp. 120–131. [Google Scholar] [CrossRef]

- Chansik, P.; Doyeop, L.; Numan, K. An analysis on safety risk judgment patterns towards computer vision-based construction safety management. In Proceedings of the Creative Construction E-Conference 2020, Budapest University of Technology and Economics, Online, 28 June–1 July 2020; pp. 31–38. [Google Scholar] [CrossRef]

- Chen, X.; Chang-Richards, A.; Ling, F.Y.Y.; Yiu, T.W.; Pelosi, A.; Yang, N. Developing a readiness model and a self-assessment tool for adopting digital technologies in construction organizations. Build. Res. Inf. 2022, 51, 241–256. [Google Scholar] [CrossRef]

- Pereira, R.E.; Gheisari, M.; Esmaeili, B. Using panoramic augmented reality to develop a virtual safety training environment. In Proceedings of the Construction Research Congress 2018, New Orleans, LA, USA, 2–4 April 2018. [Google Scholar] [CrossRef]

- Lop, N.S.; Kamar, I.F.M.; Yusoff, A.S. Building tomorrow: Shaping the future of construction through the adoption of digital technologies. Malays. J. Sustain. Environ. 2024, 11, 165–182. [Google Scholar] [CrossRef]

- Naji, K.K.; Gunduz, M.; Alhenzab, F.H.; Al-Hababi, H.; Al-Qahtani, A.H. A systematic review of the digital transformation of the building construction industry. IEEE Access 2024, 12, 31461–31487. [Google Scholar] [CrossRef]

- Eker, H. Natural Language Processing Risk Assessment Application Developed for Marble Quarries. Appl. Sci. 2024, 14, 9045. [Google Scholar] [CrossRef]

- Mésároš, P.; Mandičák, T.; Spišáková, M.; Behúnová, A.; Behún, M. The implementation factors of information and communication technology in the life cycle costs of buildings. Appl. Sci. 2021, 11, 2934. [Google Scholar] [CrossRef]

- Karunasena, G.; Jayasuriya, S. Construction safety assessment framework for developing countries: A case study of Sri Lanka. J. Constr. Dev. Ctries. 2013, 18, 33–51. [Google Scholar]

- Weerakoon, H.D.; Chandanie, H. Analysis of feasibility of blockchain technology for international trade related to Sri Lankan construction industry. In Proceedings of the 9th World Construction Symposium, Moratuwa, Sri Lanka, 9–10 July 2021; Sandanayake, Y.G., Gunatilake, S., Waidyasekara, K.G.A.S., Eds.; pp. 75–85. [Google Scholar]

- Chamikara, K.L.; Perera, B.A.K.S.; Kurukulasooriya, I.N. Use of building information modeling to mitigate cost overruns in design and build projects. In Proceedings of the 11th World Construction Symposium—2023, Ceylon Institute of Builders—Sri Lanka, Colombo, Sri Lanka, 21–22 July 2023; pp. 1104–1115. [Google Scholar] [CrossRef]

- Amirthavarshan, K.; Gallage, S.D.; Costa, M.D.D.; Eranga, B.A.I.E. Potential use of digital twin for construction progress monitoring. In Proceedings of the 11th World Construction Symposium—2023, Ceylon Institute of Builders—Sri Lanka, Colombo, Sri Lanka, 21–22 July 2023; pp. 873–884. [Google Scholar] [CrossRef]

- Epasinghe, E.A.K.; Jayasena, H.S. Open BIM Adoption in Sri Lankan Construction Industry; University of Moratuwa: Moratuwa, Sri Lanka, 2018. [Google Scholar]

- Abeywickrama, A.P.T.M.; Abeynayake, M.D.T.E.; Eranga, B.A.I.; Illeperuma, I.E. Incorporating digital technologies for alternative dispute resolution in the Sri Lankan construction industry. In Proceedings of the 12th World Construction Symposium—2024, Department of Building Economics, Colombo, Sri Lanka, 9–10 August 2024; pp. 568–580. [Google Scholar] [CrossRef]

- Senanayake, S.M.A.H.; Gunawardana, P.A.M.; Perera, B.A.K.S.; Rajaratnam, D. Examining the potential use of augmented reality in construction cost management tools and techniques. J. Eng. Des. Technol. 2024, 22, 1847–1869. [Google Scholar] [CrossRef]

- Perera, U.D.S.; Kulatunga, U.; Abdeen, F.N.; Sepasgozar, S.M.E.; Tennakoon, M. Application of building information modeling for fire hazard management in high-rise buildings: An investigation in Sri Lanka. Intell. Build. Int. 2022, 14, 207–221. [Google Scholar] [CrossRef]

- Rathnayake, A.P. A Framework to Enhance the Adoption of Building Information Modelling Amongst Sri Lankan Quantity Surveying Organizations to Increase the Accuracy of Pre-Tender Cost Estimates; University of Salford: Salford, UK, 2021. [Google Scholar]

- Gunasekara, H.; Jayasena, H. Identification of a Technological Framework for Implementing Building Information Modelling in Sri Lanka. Available online: https://www.researchgate.net/publication/334162685 (accessed on 12 November 2024).

- Gamage, N.; Ambagala, A.P.K.K.; Nanayakkara, S.; Perera, S. Towards a framework for implementing blockchain technology in the construction industry of Sri Lanka. Built Environ. Proj. Asset Manag. 2024. ahead of print. [Google Scholar] [CrossRef]

- Chathuranga, I.H.N.; Siriwardana, C.S.A. Assessing the Readiness for Digital Technologies Adoption for Enhancing Productivity in the Sri Lankan Construction Industry. Available online: https://www.researchgate.net/publication/374922393 (accessed on 4 January 2025).

- Naji, K.K.; Gunduz, M.; Al-Hababi, H. Mapping the digital transformation maturity of the building construction industry using structural equation modeling. Buildings 2024, 14, 2786. [Google Scholar] [CrossRef]

- Musarat, M.A.; Sadiq, A.; Alaloul, W.S.; Abdul Wahab, M.M. A systematic review on enhancement in quality of life through digitalization in the construction industry. Sustainability 2022, 15, 202. [Google Scholar] [CrossRef]

- Azhar, S. Role of visualization technologies in safety planning and management at construction jobsites. Procedia Eng. 2017, 171, 215–226. [Google Scholar] [CrossRef]

- Marefat, A.; Toosi, H.; Mahmoudi Hasankhanlo, R. A BIM approach for construction safety: Applications, barriers and solutions. Eng. Constr. Archit. Manag. 2019, 26, 1855–1877. [Google Scholar] [CrossRef]

- Mihić, M.; Vukomanović, M.; Završki, I. Review of previous applications of innovative information technologies in construction health and safety. Organ. Technol. Manag. Constr. Int. J. 2019, 11, 1952–1967. [Google Scholar] [CrossRef]

- Takim, R.; Zulkifli, M.H.; Nawawi, A.H. Integration of automated safety rule checking (ASRC) system for safety planning BIM-based projects in Malaysia. Procedia Soc. Behav. Sci. 2016, 222, 103–110. [Google Scholar] [CrossRef][Green Version]

- Ahn, S.; Kim, T.; Park, Y.-J.; Kim, J.-M. Improving effectiveness of safety training at construction worksites using 3D BIM simulation. Adv. Civ. Eng. 2020, 2020, 2473138. [Google Scholar] [CrossRef]

- Jeelani, I.; Han, K.; Albert, A. Development of immersive personalized training environment for construction workers. In Proceedings of the Computing in Civil Engineering 2017, Seattle, WA, USA, 25–27 June 2017. [Google Scholar] [CrossRef]

- Ku, K.; Mahabaleshwarkar, P.S. Building interactive modeling for construction education in virtual worlds. J. Inf. Technol. Constr. 2011, 16, 189–208. [Google Scholar]

- Li, X.; Yi, W.; Chi, H.-L.; Wang, X.; Chan, A.P.C. A critical review of virtual and augmented reality (VR/AR) applications in construction safety. Autom. Constr. 2018, 86, 150–162. [Google Scholar] [CrossRef]

- Lucas, J.; Thabet, W.; Worlikar, P. A VR-based training program for conveyor belt safety. J. Inf. Technol. Constr. 2008, 13, 381–407. [Google Scholar]

- Md, N.; Faizah, S.; Majid, A. Effectiveness of construction safety hazards identification in virtual reality learning environment. Environ. Behav. Proc. J. 2019, 4, 375–381. [Google Scholar] [CrossRef]

- Dong, S.; Feng, C.; Kamat, V.R. Sensitivity analysis of augmented reality-assisted building damage reconnaissance using virtual prototyping. Autom. Constr. 2013, 33, 24–36. [Google Scholar] [CrossRef]

- Yeh, K.-C.; Tsai, M.-H.; Kang, S.-C. On-site building information retrieval by using projection-based augmented reality. J. Comput. Civ. Eng. 2012, 26, 342–355. [Google Scholar] [CrossRef]

- Wang, X.; Dunston, P.S. Design, strategies, and issues towards an augmented reality-based construction training platform. J. Inf. Technol. Constr. 2007, 12, 363–380. [Google Scholar]

- Yu, Q.; Jiang, J.; Yu, H. Research on the emergency response system of major dangerous chemical accidents on highway based on the GIS. Procedia Eng. 2012, 45, 716–721. [Google Scholar] [CrossRef]

- Akindele, O.; Ajayi, S.; Oyegoke, A.S.; Alaka, H.A.; Omotayo, T. Application of Geographic Information System (GIS) in construction: A systematic review. Smart Sustain. Built Environ. 2025, 14, 210–236. [Google Scholar] [CrossRef]

- Bansal, V.K. Application of geographic information systems in construction safety planning. Int. J. Proj. Manag. 2011, 29, 66–77. [Google Scholar] [CrossRef]

- Kumar, S.; Bansal, V.K. A GIS-based methodology for safe site selection of a building in a hilly region. Front. Archit. Res. 2016, 5, 39–51. [Google Scholar] [CrossRef]

- Pietrafesa, E.; Bentivenga, R.; Lalli, P.; Capelli, C.; Farina, G.; Stabile, S. Becoming safe: A serious game for occupational safety and health training in a WBL Italian experience. In Methodologies and Intelligent Systems for Technology Enhanced Learning, 10th International Conference, MIS4TEL 2020; Kubincová, Z., Lancia, L., Popescu, E., Nakayama, M., Scarano, V., Gil, A., Eds.; Springer: Cham, Switzerland, 2021; Volume 1236, pp. 303–312. [Google Scholar] [CrossRef]

- Boel, C.; Rotsaert, T.; Valcke, M.; Vanhulsel, A.; Schellens, T. Applying educational design research to develop a low-cost, mobile immersive virtual reality serious game teaching safety in secondary vocational education. Educ. Inf. Technol. 2024, 29, 8609–8646. [Google Scholar] [CrossRef]

- Dzeng, R.-J.; Hsueh, H.-H.; Chang, R.-N. 3D game-based training system for hazard identification on construction site. In Proceedings of the 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015. [Google Scholar] [CrossRef]

- Lin, K.-Y.; Son, J.W.; Rojas, E.M. A pilot study of a 3D game environment for construction safety education. J. Inf. Technol. Constr. 2011, 16, 69–84. Available online: https://www.itcon.org/2011/5 (accessed on 3 January 2025).

- Li, M.; Yu, H.; Liu, P. An automated safety risk recognition mechanism for underground construction at the pre-construction stage based on BIM. Autom. Constr. 2018, 91, 284–292. [Google Scholar] [CrossRef]

- Zhao, D.; McCoy, A.; Kleiner, B.; Feng, Y. Integrating safety culture into OSH risk mitigation: A pilot study on electrical safety. J. Civ. Eng. Manag. 2016, 22, 800–807. [Google Scholar] [CrossRef]

- Eiris Pereira, R.; Moore, H.F.; Gheisari, M.; Esmaeili, B. Development and usability testing of a panoramic augmented reality environment for fall hazard safety training. In Advances in Informatics and Computing in Civil and Construction Engineering. Proceedings of the 35th CIB W78 2018 Conference: IT in Design, Construction, and Management; Springer: Cham, Switzerland, 2018; pp. 271–279. [Google Scholar]

- Zhou, Y.; Luo, H.; Yang, Y. Implementation of augmented reality for segment displacement inspection during tunneling construction. Autom. Constr. 2017, 82, 112–121. [Google Scholar] [CrossRef]

- Golovina, O.; Teizer, J.; Pradhananga, N. Heat map generation for predictive safety planning: Preventing struck-by and near miss interactions between workers-on-foot and construction equipment. Autom. Constr. 2016, 71, 99–115. [Google Scholar] [CrossRef]

- Shin, D.H.; Dunston, P.S. Identification of application areas for augmented reality in industrial construction based on technology suitability. Autom. Constr. 2008, 17, 882–894. [Google Scholar] [CrossRef]

- Olanrewaju, O.I.; Chileshe, N.; Babarinde, S.A.; Sandanayake, M. Investigating the barriers to building information modeling (BIM) implementation within the Nigerian construction industry. Eng. Constr. Archit. Manag. 2020, 27, 2931–2958. [Google Scholar] [CrossRef]

- Won, D.; Hwang, B.G.; Binte Mohd Samion, N.K. Cloud computing adoption in the construction industry of Singapore: Drivers, challenges, and strategies. J. Manag. Eng. 2022, 38, 05021017. [Google Scholar] [CrossRef]

- Gerges, M.; Austin, S.; Mayouf, M.; Ahiakwo, O.; Jaeger, M.; Saad, A.; El Gohary, T. An investigation into the implementation of building information modeling in the Middle East. J. Inform. Technol. Constr. 2017, 22, 1–15. Available online: https://www.itcon.org/2017/1 (accessed on 12 October 2024).

- Eadie, R.; Odeyinka, H.; Browne, M.; McKeown, C.; Yohanis, M. Building Information Modelling Adoption: An Analysis of the Barriers to Implementation. J. Eng. Archit. 2014, 2, 77–101. [Google Scholar]

- Hoang, T.; Greater, S.; Taylor, S.; Aranda, G.; Mulvany, G.T. An evaluation of virtual reality for fear arousal safety training in the construction industry. In Proceedings of the 2021 IEEE International Symposium on Mixed and Augmented Reality Adjunct (ISMAR-Adjunct), Bari, Italy, 4–8 October 2021; pp. 177–182. [Google Scholar] [CrossRef]

- Chen, X.; Chang-Richards, A.Y.; Yiu, T.W.; Ling, F.Y.Y.; Pelosi, A.; Yang, N. A multivariate regression analysis of barriers to digital technologies adoption in the construction industry. Eng. Constr. Archit. Manag. 2024, 31, 4281–4307. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, Y.; Yang, J.-B. Barriers to BIM implementation strategies in China. Eng. Constr. Archit. Manag. 2019, 26, 554–574. [Google Scholar] [CrossRef]

- Hwang, B.G.; Ngo, J.; Teo, J.Z.K. Challenges and strategies for the adoption of smart technologies in the construction industry: The case of Singapore. J. Manag. Eng. 2022, 38, 05021014. [Google Scholar] [CrossRef]

- Häikiö, J.; Kallio, J.; Mäkelä, S.M.; Karänen, J. IoT-based safety monitoring from the perspective of construction site workers. Int. J. Occup. Environ. Saf. 2020, 4, 1–14. [Google Scholar] [CrossRef]

- Gamil, Y.; Rahman, I.A.R. Awareness and challenges of building information modeling (BIM) implementation in the Yemen construction industry. J. Eng. Des. Technol. 2019, 17, 1077–1084. [Google Scholar] [CrossRef]

- Zulu, S.L.; Khosrowshahi, F. A taxonomy of digital leadership in the construction industry. Constr. Manag. Econ. 2021, 39, 565–578. [Google Scholar] [CrossRef]

- Fayad, T.; Siriwardana, C.S.A. Testing the Applicability of Innovative Technologies in Improving Construction Safety in Sri Lanka; University of Moratuwa: Moratuwa, Sri Lanka, 2023. [Google Scholar]

- Oke, A.; Fernandes, F.A.P. Innovations in teaching and learning: Exploring the perceptions of the education sector on the 4th Industrial Revolution (4IR). J. Open Innov. Technol. Mark. Complex. 2020, 6, 31. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, M.; Ballesteros-Pérez, P.; Ke, Y.; Gong, Z.; Ni, Q. A new framework to evaluate and optimize digital transformation policies in the construction industry: A China case study. J. Build. Eng. 2023, 70, 106388. [Google Scholar] [CrossRef]

- Etikan, I.; Musa, S.A.; Alkassim, R.S. Comparison of convenience sampling and purposive sampling. Am. J. Theor. Appl. Stat. 2016, 5, 1–4. [Google Scholar] [CrossRef]

- Tissaveerasinghe, S.P.; Chathuranga, N.; Siriwardana, C. Compressed stabilised earth blocks as a sustainable building material: Investigation of customer purchase intentions. Built Environ. Proj. Asset Manag. 2025. ahead of print. [Google Scholar] [CrossRef]

- Thirumal, S.; Udawatta, N.; Karunasena, G.; Al-Ameri, R. Barriers to adopting digital technologies to implement circular economy practices in the construction industry: A systematic literature review. Sustainability 2024, 16, 3185. [Google Scholar] [CrossRef]

- Nyqvist, R.; Peltokorpi, A.; Lavikka, R.; Ainamo, A. Building the digital age: Management of digital transformation in the construction industry. Constr. Manag. Econ. 2024, 43, 262–283. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).