Methodology for Quantification and Identification of Environmental Aspect in Urban Infrastructure Projects in the Planning Phase

Abstract

1. Introduction

2. Literature Review

2.1. Sustainability

2.2. Environmental Management Standards

2.3. Environmental Certification Systems

2.4. Environmental Assessment Methodologies

3. Materials and Methods

3.1. Quantification

3.1.1. Total Suspended Particles

- TSP Emission Rate during Fuel Consumption

- TSP Emission Rate Traveling on Unpaved Roads

- TSP Emission Rate for Loading and Unloading Soil

3.1.2. Greenhouse Gas Emissions

3.1.3. Noise Pollution

3.1.4. Soil Alteration

3.1.5. Soil Pollution

3.1.6. Water Pollution

3.1.7. Use of Resources and Raw Materials

3.1.8. Construction and Demolition Waste

3.1.9. Water Use

3.1.10. Energy Use

3.2. Inventory

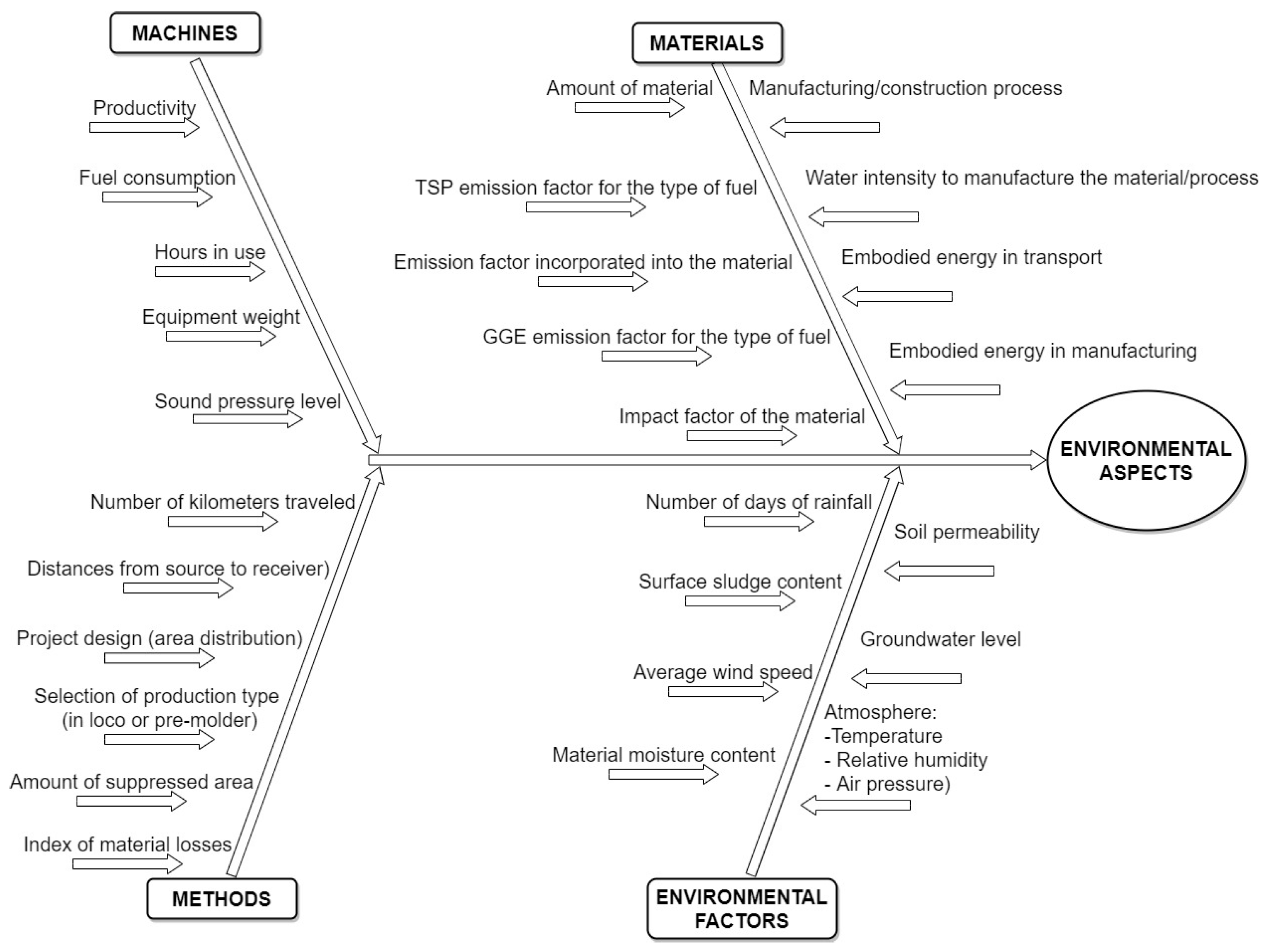

3.3. Identification of Causes

4. Real Cases

5. Results

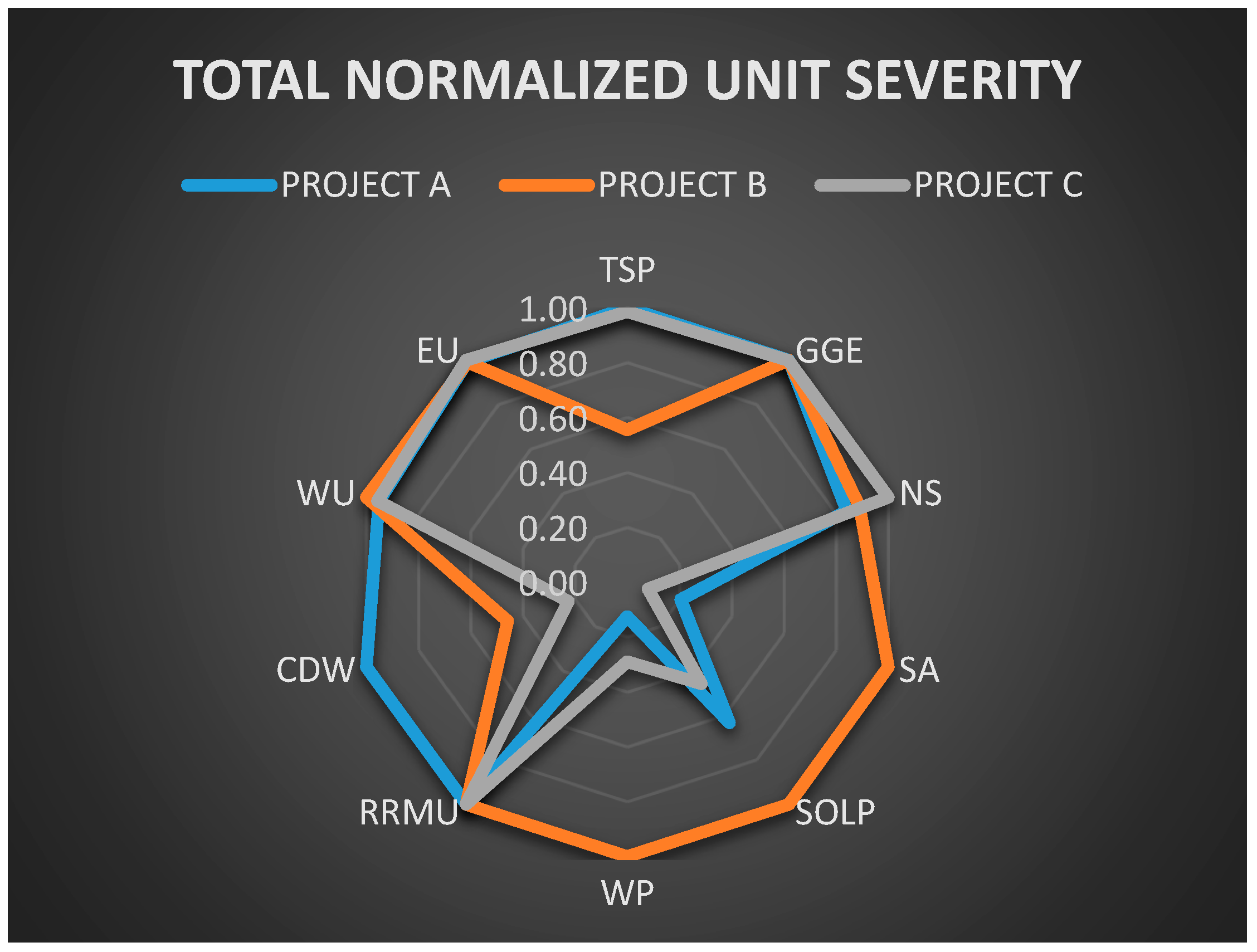

5.1. Quantification

5.2. Inventory Result

5.3. Identifying the Causes of the Environmental Aspects

6. Discussion

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alhumaid, A.M.; Bin Mahmoud, A.A.; Almohsen, A.S. Value Engineering Adoption’s Barriers and Solutions: The Case of Saudi Arabia’s Construction Industry. Buildings 2024, 14, 1017. [Google Scholar] [CrossRef]

- Fredriksson, A.; Nolz, P.C.; Seragiotto, C. A Mixed Method Evaluation of Economic and Environmental Considerations in Construction Transport Planning: The Case of Ostlänken. Sustain. Cities Soc. 2021, 69, 102840. [Google Scholar] [CrossRef]

- Hopfe, C.J.; McLeod, R.S. Enhancing Resilient Community Decision-Making Using Building Performance Simulation. Build. Environ. 2021, 188, 107398. [Google Scholar] [CrossRef]

- Det Udomsap, A.; Hallinger, P. A Bibliometric Review of Research on Sustainable Construction, 1994–2018. J. Clean Prod. 2020, 254, 120073. [Google Scholar] [CrossRef]

- Thomé, A.M.T.; Ceryno, P.S.; Scavarda, A.; Remmen, A. Sustainable Infrastructure: A Review and a Research Agenda. J. Environ. Manag. 2016, 184, 143–156. [Google Scholar] [CrossRef]

- Hatefi, S.M.; Tamošaitiene, J. Construction Projects Assessment Based on the Sustainable Development Criteria by an Integrated Fuzzy AHP and Improved GRA Model. Sustainability 2018, 10, 991. [Google Scholar] [CrossRef]

- Kabir, Z.; Morgan, R.K. Strategic Environmental Assessment of Urban Plans in New Zealand: Current Practice and Future Directions. J. Environ. Plan. Manag. 2020, 64, 954–977. [Google Scholar] [CrossRef]

- Arogundade, S.; Dulaimi, M.; Ajayi, S. Holistic Review of Construction Process Carbon-Reduction Measures: A Systematic Literature Review Approach. Buildings 2023, 13, 1980. [Google Scholar] [CrossRef]

- Kennedy, C.; Zhong, M.; Corfee-Morlot, J. Infrastructure for China’s Ecologically Balanced Civilization. Engineering 2016, 2, 414–425. [Google Scholar] [CrossRef]

- Poderytė, I.; Banaitienė, N.; Banaitis, A. Life Cycle Sustainability Assessment of Buildings: A Scientometric Analysis. Buildings 2025, 15, 381. [Google Scholar] [CrossRef]

- Chen, Z.; Li, H.; Wong, C.T.C. Environmental Management of Urban Construction Projects in China. J. Constr. Eng. Manag. 2000, 126, 320–324. [Google Scholar] [CrossRef]

- Fernández-Sánchez, G.; Rodríguez-López, F. A Methodology to Identify Sustainability Indicators in Construction Project Management—Application to Infrastructure Projects in Spain. Ecol. Indic. 2010, 10, 1193–1201. [Google Scholar] [CrossRef]

- Firmawan, F.; Othman, F.; Yahya, K.; Haron, Z. The Green Construction Site Index (GCSI): A Quantitative Tool Used to Assess an Ongoing Project to Meet the Green Construction Concept. Int. J. Technol. 2016, 7, 530–543. [Google Scholar] [CrossRef]

- Cao, G.; Yang, L.; Liu, L.; Ma, Z.; Wang, J.; Bi, J. Environmental Incidents in China: Lessons from 2006 to 2015. Sci. Total Environ. 2018, 633, 1165–1172. [Google Scholar] [CrossRef]

- Lonsdorf, E.V.; Nootenboom, C.; Janke, B.; Horgan, B.P. Assessing Urban Ecosystem Services Provided by Green Infrastructure: Golf Courses in the Minneapolis-St. Paul Metro Area. Landsc. Urban Plan 2021, 208, 104022. [Google Scholar] [CrossRef]

- Guerin, T. Understanding Causes of Leaking Plant and Equipment on Construction Sites That Can Lead to Soil and Groundwater Contamination. Remediation 2014, 25, 115–131. [Google Scholar] [CrossRef]

- Guerin, T.F. Understanding the Causes of Spills from the Supply and Handling of Chemicals at Resource Construction Sites: A Case Study. Remediation 2015, 25, 115–145. [Google Scholar] [CrossRef]

- Kolaventi, S.S.; Momand, H.; Tadepalli, T.; Siva Kumar, M.V.N. Construction Waste in India: A Structural Equation Model for Identification of Causes. Proc. Inst. Civ. Eng. Eng. Sustain. 2020, 173, 303–314. [Google Scholar] [CrossRef]

- Formoso, C.T.; Soibelman, L.; De Cesare, C.; Isatto, E.L. Material Waste in Building Industry: Main Causes and Prevention. J. Constr. Eng. Manag. 2002, 128, 316–325. [Google Scholar] [CrossRef]

- Lehmann, S. Research Methods in Urban Design: A Framework for Researching the Performance and Resilience of Places. Buildings 2023, 13, 1548. [Google Scholar] [CrossRef]

- Guerin, T.F. Heavy Equipment Maintenance Wastes and Environmental Management in the Mining Industry. J. Environ. Manag. 2002, 66, 185–199. [Google Scholar] [CrossRef] [PubMed]

- Newman, P. The Environmental Impact of Cities. Environ. Urban 2006, 18, 275–295. [Google Scholar] [CrossRef]

- Pauleit, S.; Ennos, R.; Golding, Y. Modeling the Environmental Impacts of Urban Land Use and Land Cover Change—A Study in Merseyside, UK. Landsc. Urban Plan 2005, 71, 295–310. [Google Scholar] [CrossRef]

- Beckford, J. Quality, 2nd, ed.; Tayllor & Francis Group: London, UK, 2002; ISBN 0203361563. [Google Scholar]

- Perdicoúlis, A.; Piper, J. Network and System Diagrams Revisited: Satisfying CEA Requirements for Causality Analysis. Environ. Impact. Assess Rev. 2008, 28, 455–468. [Google Scholar] [CrossRef]

- Ding, G.K.C. Sustainable Construction—The Role of Environmental Assessment Tools. J. Environ. Manag. 2008, 86, 451–464. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Ding, G.; Feng, Z. Developing a Quantitative Construction Waste Estimation Model for Building Construction Projects. Res. Conserv. Recycl. 2016, 106, 9–20. [Google Scholar] [CrossRef]

- Khan, A.N.; Kwan, H.K. AI, Agility, and Environmental Performance: A New Framework for Construction Project Managers. J. Constr. Eng. Manag. 2025, 151, 04025003. [Google Scholar] [CrossRef]

- Casanelles-Abella, J.; Chauvier, Y.; Zellweger, F.; Villiger, P.; Frey, D.; Ginzler, C.; Moretti, M.; Pellissier, L. Applying Predictive Models to Study the Ecological Properties of Urban Ecosystems: A Case Study in Zürich, Switzerland. Landsc. Urban Plan 2021, 214, 104137. [Google Scholar] [CrossRef]

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the Construction Industry: A Review of Recent Developments Based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A Framework of Sustainable Supply Chain Management: Moving toward New Theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Bocchini, P.; Frangopol, D.M.; Ummenhofer, T.; Zinke, T. Resilience and Sustainability of Civil Infrastructure: Toward a Unified Approach. J. Infrastruct. Syst. 2014, 20, 04014004. [Google Scholar] [CrossRef]

- Neppach, S.; Nunes, K.R.A.; Schebek, L. Organizational Environmental Footprint in German Construction Companies. J. Clean Prod. 2017, 142, 78–86. [Google Scholar] [CrossRef]

- Brundtland, G.H. Our Common Future (‘The Brundtland Report’): World Commission on Environment and Development. 1987. Available online: https://www.are.admin.ch/are/en/home/media/publications/sustainable-development/brundtland-report.html (accessed on 1 March 2025).

- Ball, J. Can ISO 14000 and Eco-Labelling Turn the Construction Industry Green? Build. Environ. 2002, 37, 421–428. [Google Scholar] [CrossRef]

- Christini, G.; Fetsko, M.; Hendrickson, C. Environmental Management Systems and ISO 14001 Certification for Construction Firms. J. Constr. Eng. Manag. 2004, 130, 330–336. [Google Scholar] [CrossRef]

- Jang, W.; Lee, S.K.; Han, S.H. Sustainable Performance Index for Assessing the Green Technologies in Urban Infrastructure Projects. J. Manag. Eng. 2018, 34, 04017056. [Google Scholar] [CrossRef]

- Akbari, S.; Khanzadi, M.; Gholamian, M.R. Building a Rough Sets-Based Prediction Model for Classifying Large-Scale Construction Projects Based on Sustainable Success Index. Eng. Constr. Archit. Manag. 2018, 25, 534–558. [Google Scholar] [CrossRef]

- Oliver-Solà, J.; Gabarrell, X.; Rieradevall, J. Environmental Impacts of the Infrastructure for District Heating in Urban Neighbourhoods. Energy Policy 2009, 37, 4711–4719. [Google Scholar] [CrossRef]

- Kaminski, I. Road from Rio the Past, the Present and the Future of ISO 14001; International Organization for Standardization: London, UK, 2013. [Google Scholar]

- EMAS. EMAS—Sistema Comunitário de Ecogestão e Auditoria; European Union: Brussels, Belgium, 2001; pp. 1–16. [Google Scholar]

- EMAS. EMAS—Eco-Management and Audit Scheme; European Union: Brussels, Belgium, 2009; pp. 1–45. [Google Scholar]

- ISO 14001; Environmental Management Systems—Requirements with Guidance for Use. ISO: Geneva, Switzerland, 2004; p. 34.

- Wells, C. BS7750 Environmental Systems Management. Proc. Inst. Civ. Eng.-Munic. Eng. 1993, 98, 119–123. [Google Scholar]

- Johnston, A.; Hutchison, J.; Smith, A. Significant Environmental Impact Evaluation: A Proposed Methodology. Eco-Manag. Audit. 2000, 7, 186–195. [Google Scholar] [CrossRef]

- Zobel, T.; Burman, J.O. Factors of Importance in Identification and Assessment of Environmental Aspects in an EMS Context: Experiences in Swedish Organizations. J. Clean Prod. 2004, 12, 13–27. [Google Scholar] [CrossRef]

- Szymańska-Brałkowska, M. Environmental Management in Germany. Equilibrium 2010, 5, 153–164. [Google Scholar] [CrossRef][Green Version]

- ISO 14004; Environmental Management Systems—General Guidelines on Principles, Systems and Support Techniques. ISO: Geneva, Switzerland, 2007; p. 53.

- ISO 14010; Diretrizes Para Auditoria Ambiental—Principios Gerais. ISO: Geneva, Switzerland, 2004; Volume 6, pp. 1–46.

- ISO 14015; Environmental Management—Environmental Assessment of Sites and Organizations (EASO). ISO: Geneva, Switzerland, 2003; p. 18.

- ISO 14021; Environmental Labels and Declarations—Self-Declared Environmental Claims (Type II Environmental Labelling). ISO: Geneva, Switzerland, 2016; Volume 2, p. 13.

- ISO/TR 14032; Environmental Management—Examples of Environmental Performance Evaluation (EPE). ISO: Geneva, Switzerland, 1999; p. 11.

- ISO 14031; Environmental Management—Envirionmental Performance Evaluation—Guidelines. ISO: Geneva, Switzerland, 2004; p. 38.

- ISO 14040; Gestão Ambiental—Avaliação do Ciclo de Vida—Principios e Estrutura. ISO: Geneva, Switzerland, 2001; pp. 1–10.

- ISO 14041; Environmental Management—Life Cycle Assessment—Goal and Scope Definition and Inventory Analysis. ISO: Geneva, Switzerland, 1998; Volume 1998.

- ISO 14042; Environmental Management—Life Cycle Assessment—Life Cycle Impact Assessment. ISO: Geneva, Switzerland, 2000; pp. 2–7.

- ISO 14043; Environmental Management—Life Cycle Assessment—Life Cycle Interpretation. ISO: Geneva, Switzerland, 2000; pp. 2–7.

- Chang, Y.T.; Hsieh, S.H. A Review of Building Information Modeling Research for Green Building Design through Building Performance Analysis. J. Inf. Technol. Constr. 2020, 25, 1–40. [Google Scholar] [CrossRef]

- Hong, S.H.; Lee, S.K.; Yu, J.H. Automated Management of Green Building Material Information Using Web Crawling and Ontology. Autom. Constr. 2019, 102, 230–244. [Google Scholar] [CrossRef]

- Zhong, Y.; Wu, P. Economic Sustainability, Environmental Sustainability and Constructability Indicators Related to Concrete- and Steel-Projects. J. Clean Prod. 2015, 108, 748–756. [Google Scholar] [CrossRef]

- De Mattos Bezerra, M.R.D.V.; Oliveira, A.J. De Qualificação Qualiverde. In Proceedings of the 5th Simpósio de Design Sustentável, Rio de Janeiro, Brazil, 11–13 November 2015; pp. 42–51. [Google Scholar]

- Shen, L.Y.; Lu, W.S.; Yao, H.; Wu, D.H. A Computer-Based Scoring Method for Measuring the Environmental Performance of Construction Activities. Autom. Constr. 2005, 14, 297–309. [Google Scholar] [CrossRef]

- Borja, L.C.A.; César, S.F.; Cunha, R.D.A.; Kiperstok, A. A Quantitative Method for Prediction of Environmental Aspects in Construction Sites of Residential Buildings. Sustainability 2018, 10, 1870. [Google Scholar] [CrossRef]

- Piccoli, R.; Kern, A.P.; González, M.A.; Hirota, E.H. A Certificação de Desempenho Ambiental de Prédios: Exigências Usuais e Novas Atividades Na Gestão Da Construção. Ambiente Construído 2010, 10, 69–79. [Google Scholar] [CrossRef]

- Côrtes, R.; França, S.; Quelhas, O.; Moreira, M.; Meirino, M. Contribuições Para a Sustentabilidade Na Construção Civil. Sist. Gestão 2011, 6, 384–397. [Google Scholar] [CrossRef]

- Chen, Z.; Li, H.; Wong, C.T.C. EnvironalPlanning: Analytic Network Process Model for Environmentally Conscious Construction Planning. J. Constr. Eng. Manag. 2005, 131, 92–101. [Google Scholar] [CrossRef]

- Bell, S.; Morse, S. Sustainability Indicators: Measuring the Immeasurable? 2nd ed.; Earthscan, International Institute for Environment and Development, Eds.; Earthscan: London, UK, 2008; ISBN 978-1-84407-299-6. [Google Scholar]

- De Araújo, A.G.; Carneiro, A.M.P.; Palha, R.P. Sustainable Construction Management: A Systematic Review of the Literature with Meta-Analysis. J. Clean Prod. 2020, 256, 120350. [Google Scholar] [CrossRef]

- Chen, Z.; Li, H.; Hong, J. An Integrative Methodology for Environmental Management in Construction. Autom. Constr. 2004, 13, 621–628. [Google Scholar] [CrossRef]

- Bentivegna, V.; Curwell, S.; Deakin, M.; Lombardi, P.; Mitchell, G.; Nijkamp, P. A Vision and Methodology for Integrated Sustainable Urban Development: BEQUEST. Build. Res. Inf. 2002, 30, 83–94. [Google Scholar] [CrossRef]

- Li, F.; Liu, X.; Hu, D.; Wang, R.; Yang, W.; Li, D.; Zhao, D. Measurement Indicators and an Evaluation Approach for Assessing Urban Sustainable Development: A Case Study for China’s Jining City. Landsc. Urban Plan 2009, 90, 134–142. [Google Scholar] [CrossRef]

- Gangolells, M.; Casals, M.; Gassó, S.; Forcada, N.; Roca, X.; Fuertes, A. A Methodology for Predicting the Severity of Environmental Impacts Related to the Construction Process of Residential Buildings. Build. Environ. 2009, 44, 558–571. [Google Scholar] [CrossRef]

- Cheung, S.O.; Tam, C.M.; Tam, V.; Cheung, K.; Suen, H. A Web-Based Performance Assessment System for Environmental Protection: WePass. Constr. Manag. Econ. 2004, 22, 927–935. [Google Scholar] [CrossRef]

- Eom, C.S.; Paek, J.H. Risk Index Model for Minimizing Environmental Disputes in Construction. J. Constr. Eng. Manag. 2009, 135, 34–41. [Google Scholar] [CrossRef]

- Ruiz, M.C.; Fernández, I. Environmental Assessment in Construction Using a Spatial Decision Support System. Autom. Constr. 2009, 18, 1135–1143. [Google Scholar] [CrossRef]

- Tam, C.M.; Tam, V.W.Y.; Tsui, W.S. Green Construction Assessment for Environmental Management in the Construction Industry of Hong Kong. Int. J. Proj. Manag. 2004, 22, 563–571. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M.; Zeng, S.X.; Chan, K.K. Environmental Performance Measurement Indicators in Construction. Build. Environ. 2006, 41, 164–173. [Google Scholar] [CrossRef]

- Lützkendorf, T.; Lorenz, D. Sustainable Property Investment: Valuing Sustainable Buildings through Property Performance Assessment. Build. Res. Inf. 2005, 33, 212–234. [Google Scholar] [CrossRef]

- Wallbaum, H.; Krank, S.; Teloh, R. Prioritizing Sustainability Criteria in Urban Planning Processes: Methodology Application. J. Urban Plan Dev. 2011, 137, 20–28. [Google Scholar] [CrossRef]

- Ozcan-Deniz, G.; Zhu, Y. A System Dynamics Model for Construction Method Selection with Sustainability Considerations. J. Clean Prod. 2016, 121, 33–44. [Google Scholar] [CrossRef]

- Lin, T.; Ge, R.; Huang, J.; Zhao, Q.; Lin, J.; Huang, N.; Zhang, G.; Li, X.; Ye, H.; Yin, K. A Quantitative Method to Assess the Ecological Indicator System’s Effectiveness: A Case Study of the Ecological Province Construction Indicators of China. Ecol. Indic. 2016, 62, 95–100. [Google Scholar] [CrossRef]

- Lin, H.; Zeng, S.; Ma, H.; Zeng, R.; Tam, V.W.Y. An Indicator System for Evaluating Megaproject Social Responsibility. Int. J. Proj. Manag. 2017, 35, 1415–1426. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Banihashemi, S.; Rameezdeen, R.; Golizadeh, H.; Arashpour, M.; Ma, L. Sustainability by Information and Communication Technology: A Paradigm Shift for Construction Projects in Iran. J. Clean Prod. 2017, 168, 1–13. [Google Scholar] [CrossRef]

- Krajangsri, T.; Pongpeng, J. Effect of Sustainable Infrastructure Assessments on Construction Project Success Using Structural Equation Modeling. J. Manag. Eng. 2017, 33, 04016056. [Google Scholar] [CrossRef]

- Andrić, J.M.; Wang, J.; Mahamadu, A.M.; Zhong, R. Understanding Environmental Incidents on Construction Sites in Australia: The Causal Factors, Environmental Impact and Their Relations. J. Civ. Eng. Manag. 2019, 25, 617–630. [Google Scholar] [CrossRef]

- Jung, S.; Kang, H.; Sung, S.; Hong, T. Health Risk Assessment for Occupants as a Decision-Making Tool to Quantify the Environmental Effects of Particulate Matter in Construction Projects. Build. Environ. 2019, 161, 106267. [Google Scholar] [CrossRef]

- De Araújo, A.G.; Carneiro, A.M.P.; Palha, R.P. Predictive Methodology for the Quantification of Environmental Aspects in Urban Infrastructures. Sustainability 2020, 12, 7636. [Google Scholar] [CrossRef]

- Li, X.; Zhu, Y.; Zhang, Z. An LCA-Based Environmental Impact Assessment Model for Construction Processes. Build. Environ. 2010, 45, 766–775. [Google Scholar] [CrossRef]

- Medineckienė, M.; Turskis, Z.; Zavadskas, E.K. Sustainable Construction Taking Into Account the Building Impact on the Environment. J. Environ. Eng. Landsc. Manag. 2010, 18, 118–127. [Google Scholar] [CrossRef]

- Gangolells, M.; Casals, M.; Forcada, N.; Fuertes, A.; Roca, X. Model for Enhancing Integrated Identification, Assessment, and Operational Control of On-Site Environmental Impacts and Health and Safety Risks in Construction Firms. J. Constr. Eng. Manag. 2013, 139, 138–147. [Google Scholar] [CrossRef]

- Gangolells, M.; Casals, M.; Gassó, S.; Forcada, N.; Roca, X.; Fuertes, A. Assessing Concerns of Interested Parties When Predicting the Significance of Environmental Impacts Related to the Construction Process of Residential Buildings. Build. Environ. 2011, 46, 1023–1037. [Google Scholar] [CrossRef]

- Fuertes, A.; Casals, M.; Gangolells, M.; Forcada, N.; Macarulla, M.; Roca, X. An Environmental Impact Causal Model for Improving the Environmental Performance of Construction Processes. J. Clean Prod. 2013, 52, 425–437. [Google Scholar] [CrossRef]

- Namini, S.B.; Shakouri, M.; Tahmasebi, M.M.; Preece, C. Managerial Sustainability Assessment Tool for Iran’s Buildings. Proc. Inst. Civ. Eng. Eng. Sustain. 2014, 167, 12–23. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, Y.; Shen, L.; Skitmore, M. A Prototype System Dynamic Model for Assessing the Sustainability of Construction Projects. Int. J. Proj. Manag. 2014, 32, 66–76. [Google Scholar] [CrossRef]

- Salzer, C.; Wallbaum, H.; Lopez, L.F.; Kouyoumji, J.L. Sustainability of Social Housing in Asia: A Holistic Multi-Perspective Development Process for Bamboo-Based Construction in the Philippines. Sustainability 2016, 8, 151. [Google Scholar] [CrossRef]

- Apanavičiene, R.; Daugeliene, A.; Baltramonaitis, T.; Maliene, V. Sustainability Aspects of Real Estate Development: Lithuanian Case Study of Sports and Entertainment Arenas. Sustainability 2015, 7, 6497–6522. [Google Scholar] [CrossRef]

- Dobrovolskienė, N.; Tamošiūnienė, R. An Index to Measure Sustainability of a Business Project in the Construction Industry: Lithuanian Case. Sustainability 2016, 8, 14. [Google Scholar] [CrossRef]

- Hassan, O.A.B. An Integrated Approach to Assessing the Sustainability of Buildings. J. Eng. Des. Technol. 2016, 14, 832–850. [Google Scholar] [CrossRef]

- Sandanayake, M.; Zhang, G.; Setunge, S. Estimation of Environmental Emissions and Impacts of Building Construction—A Decision Making Tool for Contractors. J. Build. Eng. 2019, 21, 173–185. [Google Scholar] [CrossRef]

- Hong, J.; Kang, H.; Jung, S.; Sung, S.; Hong, T.; Park, H.S.; Lee, D.E. An Empirical Analysis of Environmental Pollutants on Building Construction Sites for Determining the Real-Time Monitoring Indices. Build. Environ. 2020, 170, 106636. [Google Scholar] [CrossRef]

- Attal, E.; Dubus, B.; Leblois, T.; Cretin, B. An Optimal Dimensioning Method of a Green Wall Structure for Noise Pollution Reduction. Build. Environ. 2021, 187, 107362. [Google Scholar] [CrossRef]

- Chan, M.; Masrom, M.A.N.; Yasin, S.S. Selection of Low-Carbon Building Materials in Construction Projects: Construction Professionals’ Perspectives. Buildings 2022, 12, 486. [Google Scholar] [CrossRef]

- Gupta, P.; Elhag, T. Applicability of Lean Techniques and Processes on Improving Sustainability in Construction Projects. Built Environ. Proj. Asset Manag. 2025, 15, 24. [Google Scholar] [CrossRef]

- USEPA. USEPA Emission Factor Documentation for AP-42, Unpaved Roads; USEPA: Durham, NC, USA, 1998. [Google Scholar]

- Akan, A.M.Ö.; Dhavale, D.G.; Sarkis, J. Greenhouse Gas Emissions in the Construction Industry: An Analysis and Evaluation of a Concrete Supply Chain. J. Clean Prod. 2017, 167, 1195–1207. [Google Scholar] [CrossRef]

- Yim, S.Y.C.; Ng, S.T.; Hossain, M.U.; Wong, J.M.W. Comprehensive Evaluation of Carbon Emissions for the Development of High-Rise Residential Building. Buildings 2018, 8, 147. [Google Scholar] [CrossRef]

- EPA Documentation. Greenhouse Gas Emission and Energy Factors Used in the Waste Reduction Model (WARM)—Containers, Packaging, and Non-Durable Good Materials Chapters; EPA: Durham, CN, USA, 2016. [Google Scholar]

- Haron, Z.; Yahya, K.; Jahya, Z. Prediction of Noise Pollution from Construction Sites at the Planning Stage Using Simple Prediction Charts. Energy Educ. Sci. Technol. Part A Energy Sci. Res. 2012, 29, 989–1002. [Google Scholar]

- Lee, H.P.; Wang, Z.; Lim, K.M. Assessment of Noise from Equipment and Processes at Construction Sites. Build. Acoust. 2017, 24, 21–34. [Google Scholar] [CrossRef]

- Li, W.; Zhou, W.; Bai, Y.; Pickett, S.T.A.; Han, L. The Smart Growth of Chinese Cities: Opportunities Offered by Vacant Land. Land. Degrad. Dev. 2018, 29, 3512–3520. [Google Scholar] [CrossRef]

- Qu, Y.; Long, H. The Economic and Environmental Effects of Land Use Transitions under Rapid Urbanization and the Implications for Land Use Management. Habitat. Int. 2018, 82, 113–121. [Google Scholar] [CrossRef]

- Wu, Q.; Hao, J.; Yu, Y.; Liu, J.; Li, P.; Shi, Z.; Zheng, T. The Way Forward Confronting Eco-Environmental Challenges during Land-Use Practices: A Bibliometric Analysis. Environ. Sci. Pollut. Res. 2018, 25, 28296–28311. [Google Scholar] [CrossRef] [PubMed]

- Eikelboom, R.T.; Ruwiel, E.; Goumans, J.J.J.M. The Building Materials Decree: An Example of a Dutch Regulation Based on the Potential Impact of Materials on the Environment. Waste Manag. Ser. 2001, 1, 963–974. [Google Scholar] [CrossRef]

- Belayutham, S.; González, V.A.; Yiu, T.W. A Cleaner Production-Pollution Prevention Based Framework for Construction Site Induced Water Pollution. J. Clean Prod. 2016, 135, 1363–1378. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2001; pp. 1–22l.

- Ng, T.S.T.; Chan, J.H.L.; Chan, G.K.C.; Zou, J.W.W. Environmental Impacts of Construction Material Production. Proc. Inst. Civ. Eng. Eng. Sustain. 2017, 170, 169–184. [Google Scholar] [CrossRef]

- Mersiowsky, I. Mersiowsky 2002-Long-Term Fate PVC in Landfills.Pdf. Prog. Polym. Sci. 2002, 27, 2227–2277. [Google Scholar] [CrossRef]

- McCormack, M.; Treloar, G.J.; Palmowski, L.; Crawford, R. Modelling Direct and Indirect Water Requirements of Construction. Build. Res. Inf. 2007, 35, 156–162. [Google Scholar] [CrossRef]

- Souza, J.L.; Filho, F.d.A.d.S.; Neto, J.d.P.B. Pegada Hídrica Azul Dos Insumos Utilizados Na Blue Water Footprint of Supplies Used in Building. In Proceedings of the XXI Simpósio Brasileiro de Recursos Hídricos: XXI SBRH, Brasília, Brazil, 22–27 November 2015; pp. 1–7. [Google Scholar]

- Waidyasekara, K.G.A.S.; De Silva, L.; Rameezdeen, R. Water Use Efficiency and Conservation during Construction: Drivers, Barriers and Practices. Built Environ. Proj. Asset Manag. 2016, 6, 553–566. [Google Scholar] [CrossRef]

- Waylen, C. WATER: A Progress Report on Reducing Water Use on Construction Wrap; WRAP: London, UK, 2011. [Google Scholar]

- Chanda, M.; Roy, S.K. Plastics Technology Handbook. Mater. Des. 2006, 8, 361. [Google Scholar] [CrossRef]

- Paulsen, J.S.; Sposto, R.M. A Life Cycle Energy Analysis of Social Housing in Brazil: Case Study for the Program “MY HOUSE MY LIFE”. Energy Build. 2013, 57, 95–102. [Google Scholar] [CrossRef]

- Teodoro, M.I.T.d.M. Energia Embutida na Construção de Edificações no Brasil: Contribuições Para o Desenvolvimento de Políticas Públicas a Partir de um Estudo de Caso em Mato Grosso do Sul; Tese, Universidade de São Paulo: São Paulo, Brazil, 2017. [Google Scholar]

- Treloar, G.J. Extracting Embodied Energy Paths from Input-Output Tables: Towards an Input-Output-Based Hybrid Energy Analysis Method. Econ. Syst. Res. 1997, 9, 375–391. [Google Scholar] [CrossRef]

- Treloar, G.J.; Love, P.E.D.; Holt, G.D. Using National Input/Output Data for Embodied Energy Analysis of Individual Residential Buildings. Constr. Manag. Econ. 2001, 19, 49–61. [Google Scholar] [CrossRef]

- Doane, D.P.; Seward, L.E. Applied Statistics in Business & Economics, 3rd ed.; Mcgraw-Hill: New York, NY, USA, 2011; Volume 66, ISBN 9780073373690. [Google Scholar]

- Min, J.H.; Jang, W.; Han, S.H.; Kim, D.; Kwak, Y.H. How Conflict Occurs and What Causes Conflict: Conflict Analysis Framework for Public Infrastructure Projects. J. Manag. Eng. 2018, 34, 04018019. [Google Scholar] [CrossRef]

- ISO 15392; Sustainability in Building Construction—General Principles. ISO: Geneva, Switzerland, 2008; Volume 2008, p. 20.

- Homaei, S.; Hamdy, M. Thermal Resilient Buildings: How to Be Quantified? A Novel Benchmarking Framework and Labelling Metric. Build. Environ. 2021, 201, 108022. [Google Scholar] [CrossRef]

- Kim, Y.A.; Ryoo, B.Y.; Kim, Y.-S.; Huh, W.C. Major Accident Factors for Effective Safety Management of Highway Construction Projects. J. Constr. Eng. Manag. 2013, 139, 628–640. [Google Scholar] [CrossRef]

- dos Santos, F.C.; Carvalho, M.T.M.; de Oliveira Brandstetter, M.C.G. Tool for the Integration of Building Performance Information within the BIM Process. Rev. Constr. 2022, 21, 645–657. [Google Scholar] [CrossRef]

- Fedorova, A.; Jelle, B.P.; Hrynyszyn, B.D.; Geving, S. A Testing Methodology for Quantification of Wind-Driven Rain Intrusion for Building-Integrated Photovoltaic Systems. Build. Environ. 2021, 199, 107917. [Google Scholar] [CrossRef]

- Voordeckers, D.; Lauriks, T.; Denys, S.; Billen, P.; Tytgat, T.; Van Acker, M. Guidelines for Passive Control of Traffic-Related Air Pollution in Street Canyons: An Overview for Urban Planning. Landsc. Urban Plan 2021, 207, 103980. [Google Scholar] [CrossRef]

- Zhang, J.; Ouyang, Y.; Ballesteros-Pérez, P.; Li, H.; Philbin, S.P.; Li, Z.; Skitmore, M. Understanding the Impact of Environmental Regulations on Green Technology Innovation Efficiency in the Construction Industry. Sustain. Cities Soc. 2021, 65, 102647. [Google Scholar] [CrossRef]

- Saif, W.; Rogage, K.; Martinez, P.; Kassem, M. Decarbonising Construction Equipment: Management Practices and Strategies for Net Zero in UK Infrastructure Projects. Build. Environ. 2025, 270, 112503. [Google Scholar] [CrossRef]

- Lim, H.; Tae, S.; Roh, S. Major Building Materials in Terms of Environmental Impact Evaluation of School Buildings in South Korea. Buildings 2022, 12, 498. [Google Scholar] [CrossRef]

- Shan, S.; Genç, S.Y.; Kamran, H.W.; Dinca, G. Role of Green Technology Innovation and Renewable Energy in Carbon Neutrality: A Sustainable Investigation from Turkey. J. Environ. Manag. 2021, 294, 113004. [Google Scholar] [CrossRef] [PubMed]

- Associação Brasileira de Normas Técnicas. NBR 10151 Acústica—Avaliação Do Ruído Em Áreas Habitadas, Visando o Conforto Da Comunifade—Procedimentos; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2000; p. 4. [Google Scholar]

- Honeck, E.; Sanguet, A.; Schlaepfer, M.A.; Wyler, N.; Lehmann, A. Methods for Identifying Green Infrastructure. SN Appl. Sci. 2020, 2, 1–25. [Google Scholar] [CrossRef]

- Pereira, P.; Barceló, D.; Panagos, P. Soil and Water Threats in a Changing Environment. Environ. Res. 2020, 186, 109501. [Google Scholar] [CrossRef] [PubMed]

- Jost, E.; Schönhart, M.; Skalský, R.; Balkovič, J.; Schmid, E.; Mitter, H. Dynamic Soil Functions Assessment Employing Land Use and Climate Scenarios at Regional Scale. J. Environ. Manag. 2021, 287, 112318. [Google Scholar] [CrossRef]

- Domingo, D.; Palka, G.; Hersperger, A.M. Effect of Zoning Plans on Urban Land-Use Change: A Multi-Scenario Simulation for Supporting Sustainable Urban Growth. Sustain. Cities Soc. 2021, 69, 102833. [Google Scholar] [CrossRef]

- Halonen, J.I.; Erhola, M.; Furman, E.; Haahtela, T.; Jousilahti, P.; Barouki, R.; Bergman, Å.; Billo, N.E.; Fuller, R.; Haines, A.; et al. A Call for Urgent Action to Safeguard Our Planet and Our Health in Line with the Helsinki Declaration. Environ. Res. 2021, 193, 110600. [Google Scholar] [CrossRef]

- Olazabal, M.; Ruiz De Gopegui, M. Adaptation Planning in Large Cities Is Unlikely to Be Effective. Landsc. Urban Plan 2021, 206, 103974. [Google Scholar] [CrossRef]

- Muthukannan, M.; Sankar, A.; Ganesh, C. The Environmental Impact Caused by the Ceramic Industries and Assessment Methodologies. Int. J. Qual. Res. 2018, 13, 315–334. [Google Scholar] [CrossRef]

- Feese, C.; Li, Y.; Bulleit, W.M. Assessment of Seismic Damage of Buildings and Related Environmental Impacts. J. Perform. Constr. Facil. 2015, 29, 04014106. [Google Scholar] [CrossRef]

- Fulton, L.; Beauvais, B.; Brooks, M.; Kruse, S.; Lee, K. Sustainable Residential Building Considerations for Rural Areas: A Case Study. Land 2020, 9, 152. [Google Scholar] [CrossRef]

- van Capelleveen, G.; Amrit, C.; Zijm, H.; Yazan, D.M.; Abdi, A. Toward Building Recommender Systems for the Circular Economy: Exploring the Perils of the European Waste Catalogue. J. Environ. Manag. 2021, 277, 111430. [Google Scholar] [CrossRef]

- Bossink, B.A.G.; Brouwers, H.J.H. Construction Waste: Quantification and Source Evaluation. J. Constr. Eng. Manag. 1996, 55, 55–60. [Google Scholar] [CrossRef]

- Gangolells, M.; Casals, M.; Forcada, N.; Macarulla, M. Analysis of the Implementation of Effective Waste Management Practices in Construction Projects and Sites. Res. Conserv. Recycl. 2014, 93, 99–111. [Google Scholar] [CrossRef]

- Llatas, C. A Model for Quantifying Construction Waste in Projects According to the European Waste List. Waste Manag. 2011, 31, 1261–1276. [Google Scholar] [CrossRef] [PubMed]

- Marrero, M. Demolition Waste Management in Spanish Legislation. Open Constr. Build. Technol. J. 2011, 5, 162–173. [Google Scholar] [CrossRef]

- Osmani, M.; Glass, J.; Price, A.D.F. Architects’ Perspectives on Construction Waste Reduction by Design. Waste Manag. 2008, 28, 1147–1158. [Google Scholar] [CrossRef]

- Solís-Guzmán, J.; Marrero, M.; Montes-Delgado, M.V.; Ramírez-de-Arellano, A. A Spanish Model for Quantification and Management of Construction Waste. Waste Manag. 2009, 29, 2542–2548. [Google Scholar] [CrossRef]

- Villoria Sáez, P.; Del Río Merino, M.; Porras-Amores, C. Estimation of Construction and Demolition Waste Volume Generation in New Residential Buildings in Spain. Waste Manag. Res. 2012, 30, 137–146. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, J.M.; Cha, H.S.; Shin, D.W. Development of the Construction Waste Management Performance Evaluation Tool (WMPET). In Proceedings of the 2006 23rd International Symposium on Robotics and Automation in Construction (ISARC 2006), Tokyo, Japan, 3–5 October 2006; pp. 263–268. [Google Scholar]

- Bardhan, S. Assessment of Water Resource Consumption in Building Construction in India. WIT Trans. Ecol. Environ. 2011, 144, 93–101. [Google Scholar] [CrossRef]

- Roșca, O.M.; Dippong, T.; Marian, M.; Mihali, C.; Mihalescu, L.; Hoaghia, M.A.; Jelea, M. Impact of Anthropogenic Activities on Water Quality Parameters of Glacial Lakes from Rodnei Mountains, Romania. Environ. Res. 2020, 182, 109136. [Google Scholar] [CrossRef] [PubMed]

- Vanek, F.M. The Sector-Stream Matrix: Introducing a New Framework for the Analysis of Environmental Performance. Sustain. Dev. 2002, 10, 12–24. [Google Scholar] [CrossRef]

- Galadanci, A.S.; Ianakiev, A.; Kromanis, R.; Robinson, J. Energy Investigation Framework: Understanding Buildings from an Energy Perspective View. J. Build. Eng. 2020, 28, 101046. [Google Scholar] [CrossRef]

- Nahuelhual, L.; Carmona, A.; Lara, A.; Echeverría, C.; González, M.E. Land-Cover Change to Forest Plantations: Proximate Causes and Implications for the Landscape in South-Central Chile. Landsc. Urban Plan 2012, 107, 12–20. [Google Scholar] [CrossRef]

- Ke, Y.; Zhang, J.; Philbin, S.P. Tradition and Innovation in Construction Project Management. Buildings 2023, 13, 1537. [Google Scholar] [CrossRef]

- Rumane, A.R. Quality Management in Construction Projects, 2nd ed.; Taylor & Francis: New York, NY, USA; CRC Press: Boca Raton, FL, USA, 2017; ISBN 9781498781671. [Google Scholar]

- Woodward, J. Civil Engineering Management. Int. J. Proj. Manag. 1985, 3, 105–108. [Google Scholar] [CrossRef]

- Huang, B.; Lei, J.; Ren, F.; Chen, Y.; Zhao, Q.; Li, S.; Lin, Y. Contribution and Obstacle Analysis of Applying BIM in Promoting Green Buildings. J. Clean Prod. 2021, 278, 123946. [Google Scholar] [CrossRef]

- Yahya, K.; Halim Boussabaine, A. Eco-Costing of Construction Waste. Manag. Environ. Qual. Int. J. 2006, 17, 6–19. [Google Scholar] [CrossRef]

- Markou, I.; Sinnott, D.; Thomas, K. Current Methodologies of Creating Material Passports: A Systematic Literature Review. Case Stud. Constr. Mater. 2025, 22, e04267. [Google Scholar] [CrossRef]

| Project Description | Project A | Project B | Project C | |

|---|---|---|---|---|

| City/State | Santana do | Ipanema/AL | Arapiraca/AL | Estância/SE |

| Number of lots | 847 units | 614 units | 771 units. | |

| Total area | 300,000.00 m2 | 190,000.00 m2 | 415,732.00 m2 | |

| Area of the lots | 174,236.64 m2 | 119,512.93 m2 | 163,733.15 m2 | |

| Green area | 71,945.34 m2 | 24,794.46 m2 | 198,797.58 m2 | |

| Area of the highway system | 53,818.02 m2 | 45,692.61 m2 | 53,201.27 m2 | |

| Earthmoving (E) | 191,461.24 m3 | 20,340.32 m3 | 104,399.08 m3 | |

| Rainfall drainage systems (RDS) | 6698.00 m | 967.61 m | 1575.53 m | |

| Water supply system (WSS) | 6698.00 m | 5378.00 m | 4976.00 m | |

| Electric energy system (EES) | 222 units | 155 units | 130 units | |

| Paving (P) | 53,243.18 m2 | 31,878.00 m2 | 39,138.85 m2 | |

| Curbing (C). | 13,590.00 m | 9278.00 m | 11,393.96 m | |

| Description of Activities | Total Suspended Particles (TSPs)—Dust | Greenhouse Gas Emissions (GGE) | Noise Pollution (NP) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| (g) | (KgCO2e) | (dB) | |||||||

| Project A | Project B | Project C | Project A | Project B | Project C | Project A | Project B | Project C | |

| A-E | 3092,263.15 | 161,764.65 | 1,458,627.49 | 279,157.83 | 26,346.32 | 129,269.90 | 70.86 | 67.74 | 76.76 |

| A-RDS | 53,846.90 | 5612.17 | 14,697.19 | 384,395.35 | 55,742.66 | 90,294.97 | 61.46 | 58.40 | 67.51 |

| A-WSS | 5083.54 | 4041.33 | 3816.60 | 17,477.43 | 14,033.09 | 12,984.13 | 61.46 | 58.40 | 67.51 |

| A-EES | 1587.34 | 955.46 | 1009.94 | 59,801.02 | 41,740.63 | 35,005.80 | 61.83 | 58.79 | 67.55 |

| A-P | 262,144.07 | 19,846.06 | 184,115.51 | 143,261.11 | 83,192.48 | 101,176.61 | 54.06 | 51.06 | 60.11 |

| A-C | 23,640.40 | 1913.93 | 19,123.43 | 372,501.98 | 254,042.21 | 311,879.34 | 51.05 | 48.05 | 57.10 |

| Description of Activities | Soil Alteration (SA) | Soil Pollution (SOILP) | Water Pollution (WP) | ||||||

| (%) | (mg/m2) | (%) | |||||||

| Project A | Project B | Project C | Project A | Project B | Project C | Project A | Project B | Project C | |

| A-E | 74.80 | 213.45 | 26.76 | 0.00 | 0.00 | 0.00 | 3.59 | 16.71 | 7.68 |

| A-RDS | 8.94 | 3.75 | 0.76 | 718.03 | 163.78 | 121.88 | 0.625 | 0.428 | 0.318 |

| A-WSS | 3.72 | 8.68 | 1.00 | 0.00 | 0.00 | 0.00 | 0.179 | 0.679 | 0.287 |

| A-EES | 0.13 | 0.27 | 0.03 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| A-P | 74.00 | 128.57 | 19.69 | 0.00 | 0.00 | 0.00 | 3.55 | 10.07 | 5.65 |

| A-C | 5.67 | 11.22 | 1.72 | 695.81 | 750.05 | 420.97 | 0.272 | 0.879 | 0.493 |

| Description of Activities | Resource—Raw Material Use (RRMU) | Waste (CDW) | |||||||

| (total impact) | (t) | ||||||||

| Project A | Project B | Project C | Project A | Project B | Project C | ||||

| A-E | 0.00 | 0.00 | 0.00 | 69,677.15 | 3145.89 | 6831.65 | |||

| A-RDS | 7.147 × 10−9 | 1.03248 × 10−9 | 1.6811 × 10−9 | 30.96 | 4.47 | 7.28 | |||

| A-WSS | 5.345 × 10−10 | 4.27926 × 10−10 | 3.9594 × 10−10 | 0.18 | 0.15 | 0.14 | |||

| A-EES | 4.759 × 10−10 | 3.32309 × 10−10 | 2.7871 × 10−10 | 0.00 | 0.00 | 0.00 | |||

| A-P | 5.491 × 10−7 | 3.28726 × 10−7 | 4.036 × 10−7 | 816.28 | 488.72 | 600.05 | |||

| A-C | 6.926 × 10−9 | 4.72834 × 10−9 | 5.8067 × 10−9 | 30.01 | 20.49 | 25.16 | |||

| Description of Activities | Water Use (WU) | Energy Use (EU) | |||||||

| (L) | (Mj) | ||||||||

| Project A | Project B | Project C | Project A | Project B | Project C | ||||

| A-E | 161,454.06 | 137,077.92 | 159,603.81 | 3241,499.60 | 326,737.67 | 1607,567.88 | |||

| A-RDS | 112,191.25 | 16,207.50 | 26,390.00 | 3327,247.19 | 479,974.74 | 815,138.25 | |||

| A-WSS | 0.00 | 0.00 | 0.00 | 661,203.93 | 530,671.75 | 491,192.65 | |||

| A-EES | 17,575.00 | 12,270.83 | 10,291.67 | 543,881.90 | 379,190.02 | 317,890.53 | |||

| A-P | 632,684.42 | 374,757.77 | 460,116.31 | 687,586.83 | 484,889.38 | 456,888.81 | |||

| A-C | 108,720.00 | 74,223.75 | 91,151.25 | 3224,118.26 | 2198,078.92 | 2815,493.39 | |||

| Description of Activities | Total Suspended Particles (TSPs) | Greenhouse Gas Emissions (GGE) | Noise Pollution (NP) | Soil Alteration (SA) | Soil Pollution (SOILP) | |||||||||||

| Unit | (g) | (KgCO2e) | (dB) | (%) | (mg/m²) | |||||||||||

| MEAN | SD | C. V. | MEAN | SD | C. V. | MEAN | SD | C. V. | MEAN | SD | C. V. | MEAN | SD | C. V. | ||

| A-E | m³ | 1.27 × 101 | 4.25 | 33.46 | 1.33 × 100 | 0.11 | 8.57 | 1.48 × 101 | 1.23 | 8.29 | 3.71 × 10−3 | 0.01 | 158.13 | 0.00 | 0.00 | * |

| A-RDS | m | 7.72 × 100 | 1.79 | 23.12 | 5.74 × 101 | 0.15 | 0.27 | 1.89 × 101 | 2.59 | 13.68 | 1.90 × 10−3 | 0.00 | 93.03 | 1.18 × 10−1 | 0.05 | 39.75 |

| A-WSS | m | 7.59 × 10−1 | 0.01 | 1.02 | 2.61 × 100 | 0.00 | 0.00 | 1.67 × 101 | 1.40 | 8.42 | 7.90 × 10−4 | 0.00 | 93.01 | 0.00 | 0.00 | * |

| A-EES | unit | 7.03 × 100 | 0.81 | 11.51 | 2.69 × 102 | 0.05 | 0.02 | 2.84 × 101 | 3.10 | 10.93 | 8.57 × 10−4 | 0.00 | 91.92 | 0.00 | 0.00 | * |

| A-P | m² | 3.42 × 100 | 2.42 | 70.90 | 2.63 × 100 | 0.06 | 2.10 | 1.20 × 101 | 0.98 | 8.22 | 1.98 × 10−3 | 0.00 | 92.97 | 0.00 | 0.00 | * |

| A-C | m | 1.21× 100 | 0.87 | 71.86 | 2.74 × 101 | 0.02 | 0.07 | 1.28 × 101 | 1.07 | 8.34 | 5.92 × 10−4 | 0.00 | 92.92 | 5.63 × 10−2 | 0.02 | 39.75 |

| Description of Activities | Water Pollution (WP) | Resource—Raw Material Use (RRMU) | Waste (CDW) | Water Use (WU) | Energy Use (EU) | |||||||||||

| Unit | (%) | (total impact) | (t) | (L) | (Mj) | |||||||||||

| MEAN | SD | C. V. | MEAN | SD | C. V. | MEAN | SD | C. V. | MEAN | SD | C. V. | MEAN | SD | C. V. | ||

| A-E | m³ | 3.05 × 10−4 | 0.00 | 147.23 | 0.00 | 0.00 | * | 1.95 × 10−1 | 0.15 | 78.70 | 3.04 × 100 | 3.22 | 106.17 | 1.61 × 101 | 0.77 | 4.76 |

| A-RDS | m | 2.46 × 10−4 | 0.00 | 72.66 | 1.07 × 10−12 | 0.00 | 0.00 | 4.62 × 10−3 | 0.00 | 0.03 | 1.67 × 101 | 0.00 | 0.00 | 5.03 × 102 | 12.12 | 2.41 |

| A-WSS | m | 7.02 × 10−5 | 0.00 | 72.54 | 7.96 × 10−14 | 0.00 | 0.00 | 2.76 × 10−5 | 0.00 | 2.42 | 0.00 | 0.00 | * | 9.87 × 101 | 0.02 | 0.02 |

| A-EES | unit | 0.00 | 0.00 | * | 2.14 × 10−12 | 0.00 | 0.00 | 0.00 | 0.00 | * | 7.92 × 101 | 0.00 | 0.00 | 2.45 × 103 | 2.41 | 0.10 |

| A-P | m² | 1.76 × 10−4 | 0.00 | 72.60 | 1.03 × 10−11 | 0.00 | 0.00 | 1.53 × 10−2 | 0.00 | 0.00 | 1.18 × 101 | 0.07 | 0.62 | 1.33 × 101 | 1.79 | 13.53 |

| A-C | m | 5.27 × 10−5 | 0.00 | 72.60 | 5.10 × 10−13 | 0.00 | 0.00 | 2.21 × 10−3 | 0.00 | 0.01 | 8.00 × 100 | 0.00 | 0.00 | 2.40 × 102 | 5.79 | 2.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Araújo, A.G.d.; Gusmão, A.D.; Carneiro, A.M.P.; Palha, R.P. Methodology for Quantification and Identification of Environmental Aspect in Urban Infrastructure Projects in the Planning Phase. Buildings 2025, 15, 1328. https://doi.org/10.3390/buildings15081328

Araújo AGd, Gusmão AD, Carneiro AMP, Palha RP. Methodology for Quantification and Identification of Environmental Aspect in Urban Infrastructure Projects in the Planning Phase. Buildings. 2025; 15(8):1328. https://doi.org/10.3390/buildings15081328

Chicago/Turabian StyleAraújo, Adolpho Guido de, Alexandre Duarte Gusmão, Arnaldo Manoel Pereira Carneiro, and Rachel Perez Palha. 2025. "Methodology for Quantification and Identification of Environmental Aspect in Urban Infrastructure Projects in the Planning Phase" Buildings 15, no. 8: 1328. https://doi.org/10.3390/buildings15081328

APA StyleAraújo, A. G. d., Gusmão, A. D., Carneiro, A. M. P., & Palha, R. P. (2025). Methodology for Quantification and Identification of Environmental Aspect in Urban Infrastructure Projects in the Planning Phase. Buildings, 15(8), 1328. https://doi.org/10.3390/buildings15081328