Abstract

Given the importance of light construction in terms of better performance of structure, in case of earthquake, reduction of life and financial casualties, as well as shortage of studies in this field, the present research studied building non-structural lightweight blocks using lightweight aggregates of Scoria, Pumice and Leca. On the other hand, density, compressive strength, and water absorption volume of these blocks have been investigated in this research in order to replace traditional materials with them. The experiments’ results show that, due to hardness and strong texture, high mechanical resistance of their lightweight aggregate Scoria blocks have higher compressive strength and density but lower water absorption volume compared to Pumice and Leca lightweight aggregate blocks. Despite desirable compressive strength and lower density compared to the other two blocks, pumice blocks have higher water absorption volume, and they do not meet standards. This makes them less interesting. Among these Leca blocks with density of 1151.94 (kg/m3) below 2000 kg/m3 of Iran density standard of 7782 (28-day compressive strength of 2.57 MPa), higher than 2.5 MPa of Iran compressive strength standard of 7782 (and water absorption volume of 282.92 kg/m3) and below 288 kg/m3 of Iran water absorption volume standard of 7782 (as a non-load-bearing lightweight block), has been recognized desirable.

1. Introduction

With the occurrence of numerous deadly earthquakes around the world these days, engineers have found that light construction structures against seismic force is one of the most scientific, practical and economic strategies for risk mitigation and damage caused by earthquakes [1]. One such method is to use new materials along with modern techniques in construction industry [2]. Fortunately, in Iran, large bulks of lightweight aggregates have been identified. It is expected that more reserves can be exploited by further exploration and development of the use of these materials [3]. Lightweight aggregates are grains with low spatial weight due to their porosity. They are used for the production of lightweight concrete, lightweight concrete blocks, and other lightweight building products [4]. Some lightweight aggregates are naturally available; others are artificially produced [5]. Lightweight aggregates that are naturally formed often have volcanic origin like Pumice (Pumice stone), Scoria (Pumice), volcanic ash, and tuffs. They have been created as the result of lava entrance into the water reservoirs such as seas and lakes and its rapid cooling, which forms gas bubbles in minerals. Others, however, such as Diatomite, are sedimentary, and some others have metamorphic origins such as Vermiculite.

With increasing demand for lightweight concrete and a lack of accessibility to natural aggregate, the technology of artificial lightweight aggregates has emerged [6]. Artificial lightweight aggregates produced in the old methods, but, today, advancement of technology has caused the ways and materials to alter, such as:

- -

- cold bonding palletization [7];

- -

- reuse of waste materials—for instance, coal combustion waste [8];

- -

- use alkali activator in granulation of peat wood fly ash [9].

Unfortunately the only old methods used in Iran such as thermal expansion [10].

Various types of lightweight concrete can be classified into three forms according to their production method. The first and the most widely used way is to use porous aggregates with low bulk mass. The resulting concrete is called lightweight aggregate concrete. The second way is to create large holes in concrete ingredients or cement mortar. These holes should be clearly distinguished from super-fine bubbles caused by bubble forming. Concretes called spongy concrete, porous concrete, foam concrete, and gas concrete are included in this category. The third way is based on the removal of fine aggregates of firm concrete mixture called fine aggregate concrete [11]. Considering the results of existing initial investigations performed on natural lightweight aggregates of Scoria and Pumice, it seems that their application had useful results. Besides examining the effect of Pumice lightweight aggregates on resistance behaviors of lightweight aggregates concrete, Binici [12] investigated the effect of these materials on the resistance of concrete mortar made of it. Altun and colleagues [13] in a new piece of research have investigated the resistance of lightweight aggregate concrete reinforced by steel fibers using the theory of neural networks. Gunduz [14] has investigated the resistance of lightweight aggregate concretes made of Scoria, Pumice and Perlite and examined the results on non-load-bearing lightweight blocks. Scoria and Pumice produced the best results in this research. While selecting Scoria as a resistant lightweight aggregate, Moufti and Sabatan [15] carried out research on compressive strength of concrete and mortar made of this lightweight aggregate molded in the laboratory. Their obtained results met the requirements of ASTM standards. Some studies in Iran have also investigated the lightweight aggregates in Structural Lightweight Concrete. Zekavati and colleagues [16] have investigated the properties of lightweight aggregates of Pumice and Scoria in Structural Lightweight Concrete. They observed that the mechanical strength of lightweight aggregates clearly influences concrete compressive strength. Baghini and Karamuzian [17] concluded that since Leca lightweight aggregate in Iran is often non-structural, it is better to use natural lightweight aggregate of volcanic origin in order to form high strength lightweight aggregate concrete. Unfortunately, no research has been conducted on the physical properties of concrete and non-structural lightweight blocks (non-load-bearing) based on Iranian standard.

It should be noted that the present study has been conducted in the laboratory level but by considering workshop conditions and industrial consumptions. Thus, perhaps more favorable results can be achieved without workshop conditions.

2. Materials and Methods

2.1. Materials Used

Cement: the use of different types of cements is allowed in the market. The type and amount of cement are determined based on the required properties, usage, and durability. Tehran Portland cement type II (in accordance with ASTM C595) with density of 3150 kg/m3 and chemical characteristics of Table 1, according to data quality control of this factory, has been used in this research.

Table 1.

Chemical characteristics of Tehran Portland cement type II.

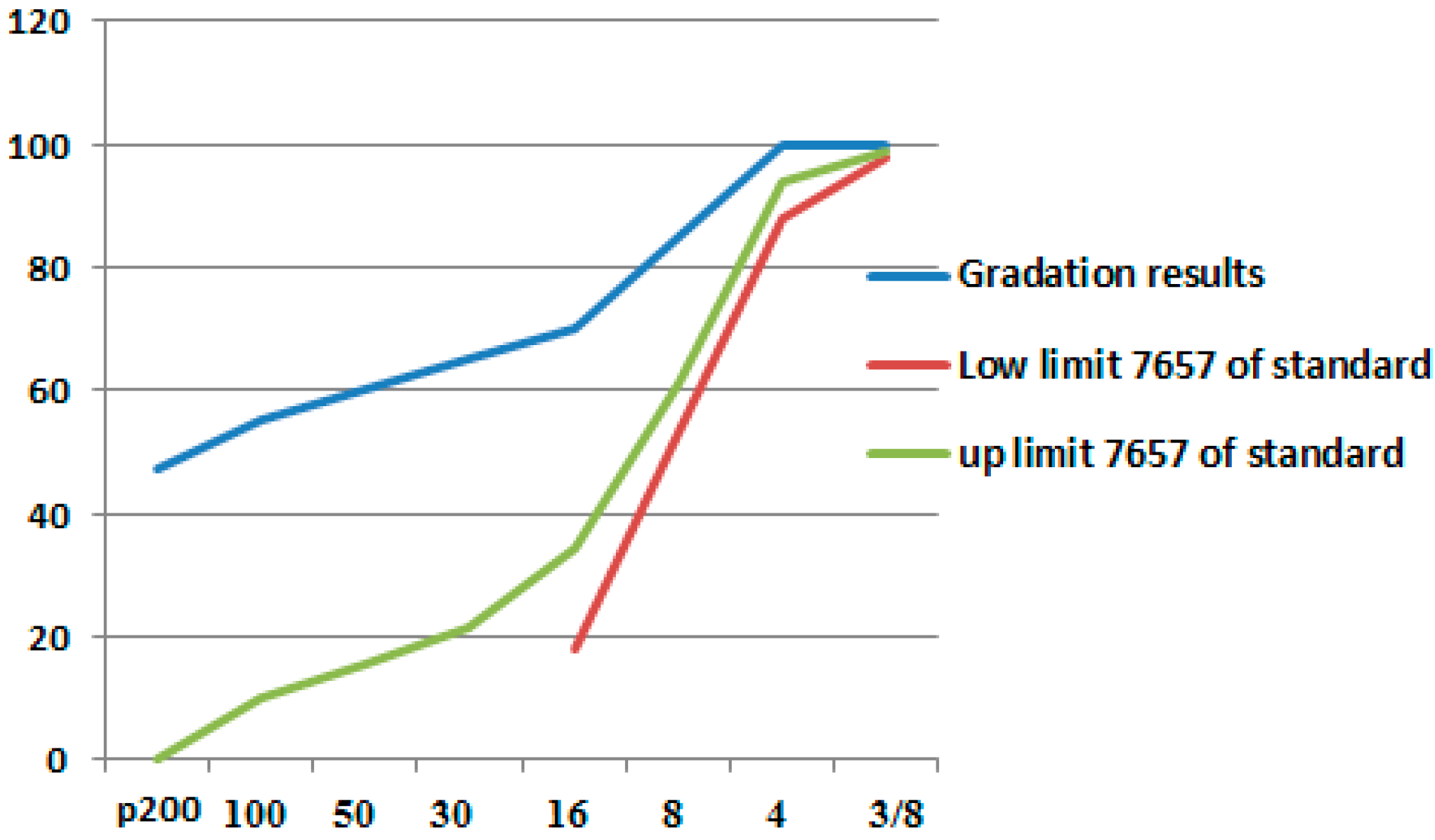

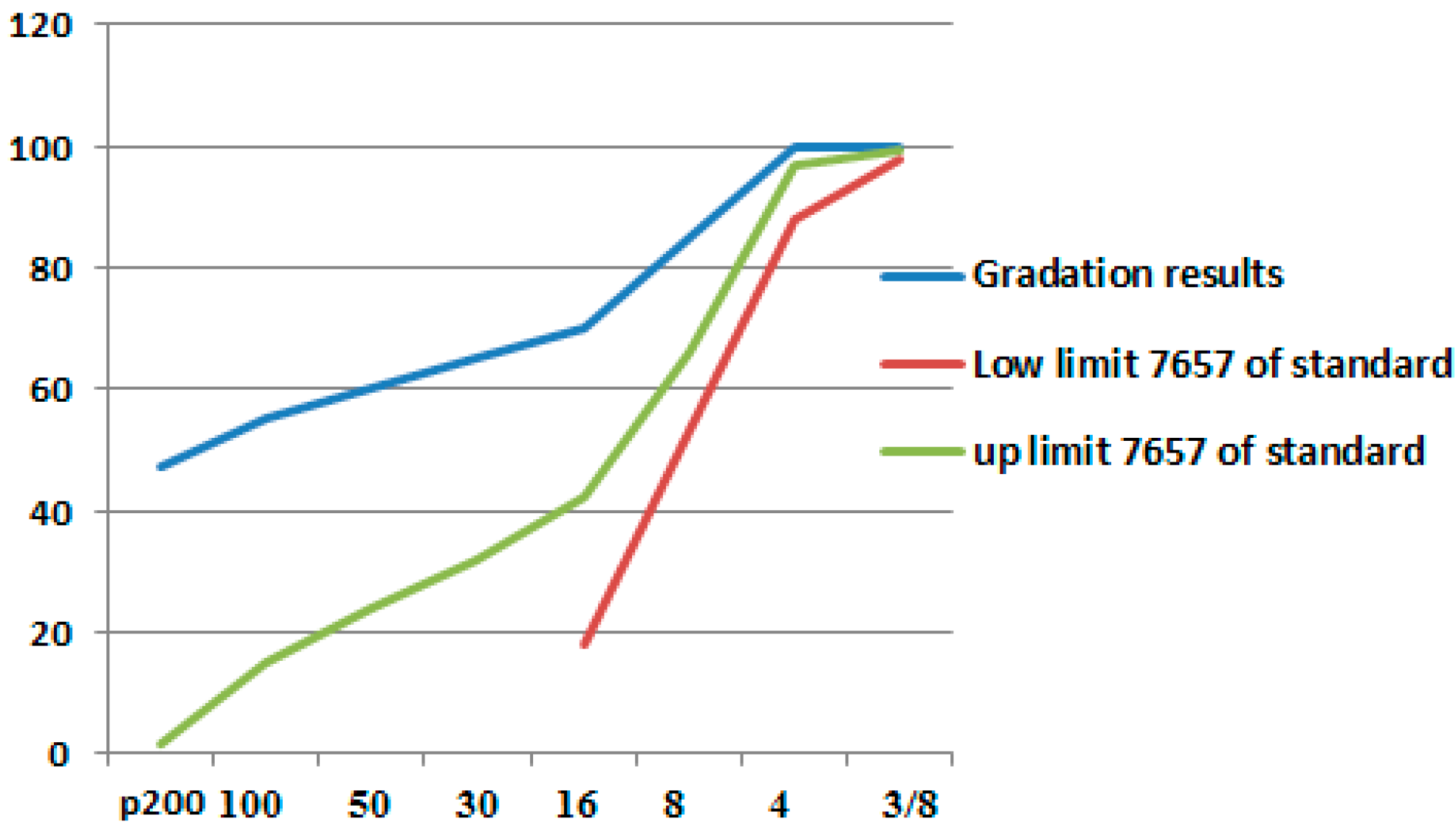

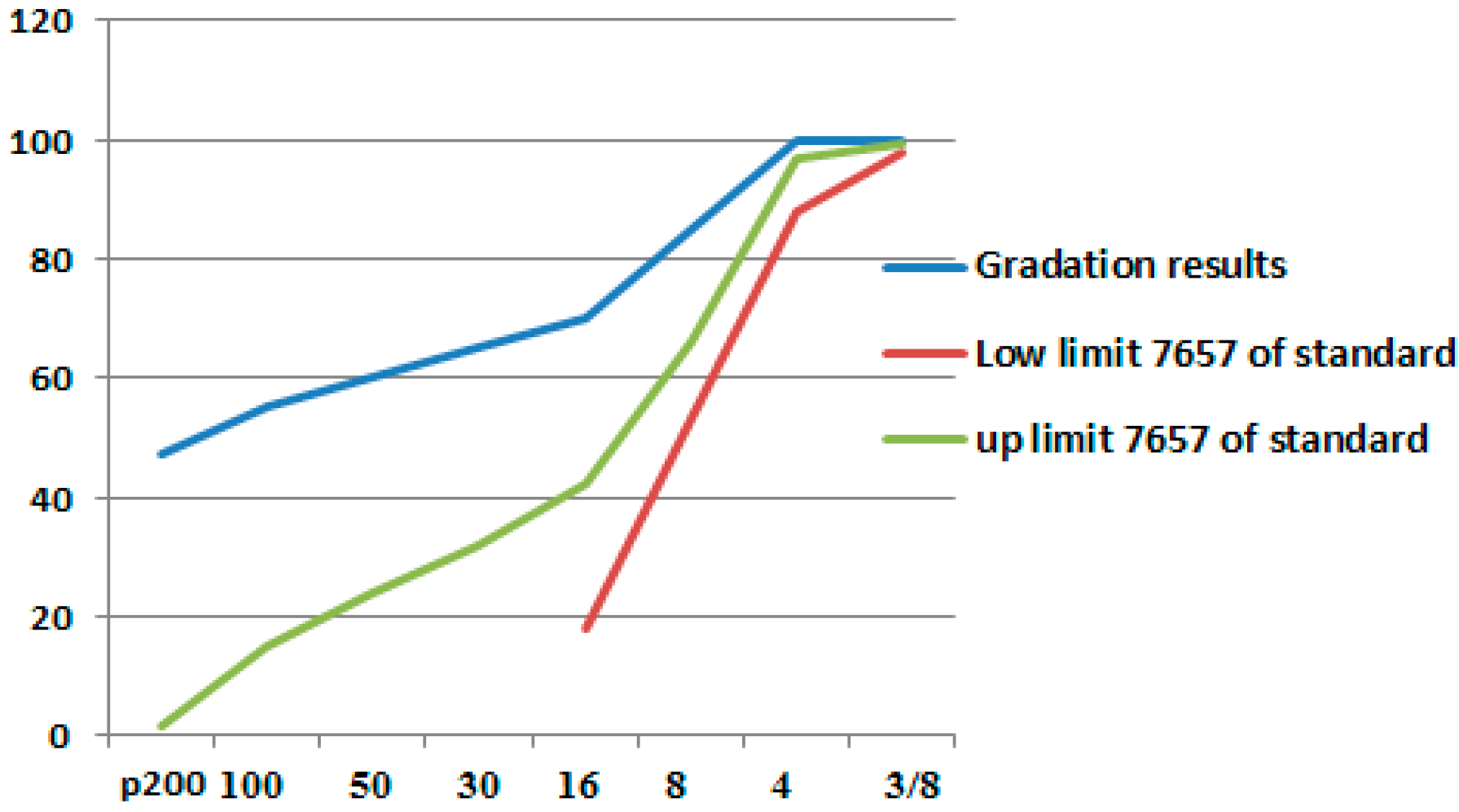

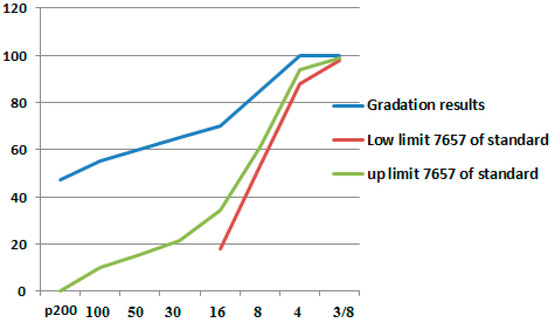

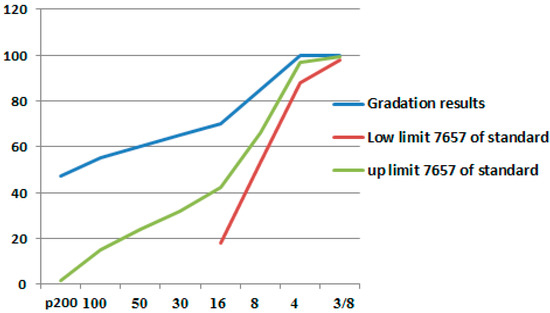

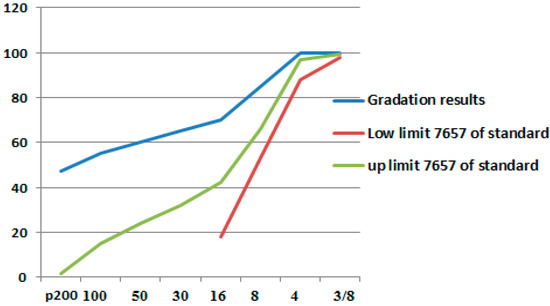

Coarse-grained materials: natural and artificial lightweight aggregates in lightweight aggregate concrete are used instead of coarse grains. Scoria of the Sanandaj, Ghorveh mine with a specific weight of 910 kg/m3 and grading curve of Figure 1 (in accordance with Table 2), as well as Pumice of Tabriz, Bostanabad mine with a specific weight of 685 kg/m3 and a grading curve of Figure 2 (in accordance with Table 3), and light expanded clay aggregate (Leca) of the Tehran Leca company of Iran with a specific weight of 475 kg/m3 and a grading curve of Figure 3 (in accordance with Table 4) have been used to make samples of natural lightweight aggregates.

Figure 1.

The diagram of grading Scoria of the Sanandaj, Ghorveh mine.

Table 2.

Grading test specifications of Scoria of the Sanandaj, Ghorveh mine.

Figure 2.

Diagram of the grading of Pumice of the Tabriz, Bostanabad mine.

Table 3.

Grading test specifications of Pumice of the Tabriz, Bostanabad mine.

Figure 3.

Diagram of the grading of Leca from the Leca company.

Table 4.

Grading test specifications of Leca from the Leca company.

As it is clear, all grading curves are consistent with the standard of 7657 [18]. In addition, the chemical properties of consuming lightweight aggregates used have also been presented in Table 5.

Table 5.

Chemical properties of lightweight aggregates used.

It is worth noting that lightweight aggregates can absorb higher amounts of water compared to aggregates with normal weight, due to their cellular structure. According to ASTM C127 standard (water absorption test defined in 24 h) [19], lightweight aggregates usually absorb water between 5 to 25 mass percent of dry aggregate depending on their pores’ system. In contrast, most aggregates with normal weight absorb less than 2% of moisture. However, the amount of moisture in a normal weight aggregate depot may increase up to 5 to 10 percent or more. The important difference is that the amount of moisture in lightweight aggregates is absorbed into the grains, as well as on the surface, while the moisture in the normal weight aggregates is mostly surface moisture. This difference is important in the proportion of mixture of batching. Water absorption rate in lightweight aggregates is also impressive in the contribution of concrete mixture, and it depends on the characteristics of the pores of the aggregates. Water absorbed internally in lightweight aggregates is not immediately available for cement and should not be considered as mixing water. On the other hand, almost all of the moisture in natural sand may be surface moisture; thus, it is part of the mixing water.

This shows the necessity of determining the average amount of water absorbed by lightweight aggregates in according to Table 6.

Table 6.

The water absorption of natural and synthetic lightweight aggregates in accordance with ISO 7782 style.

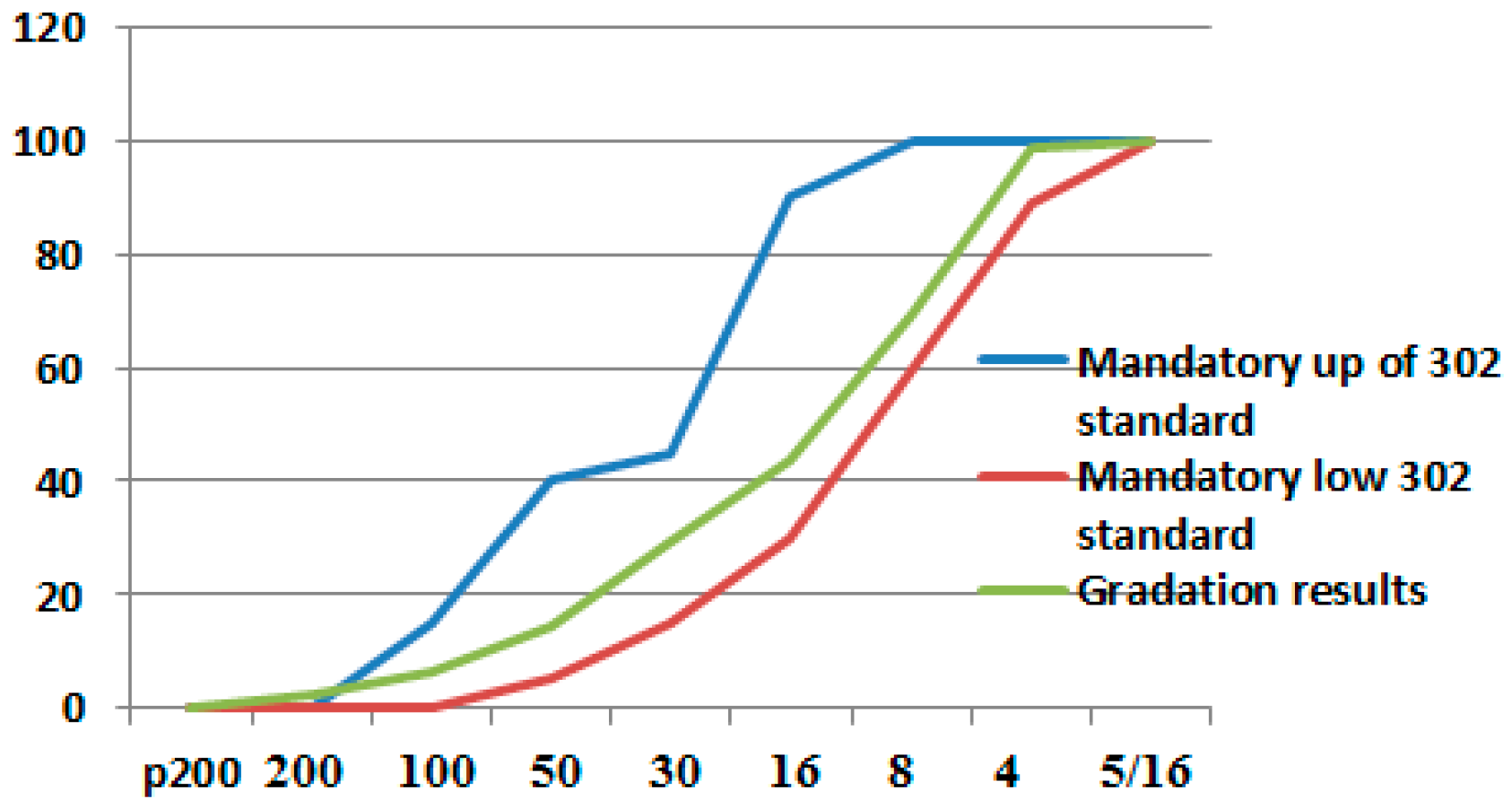

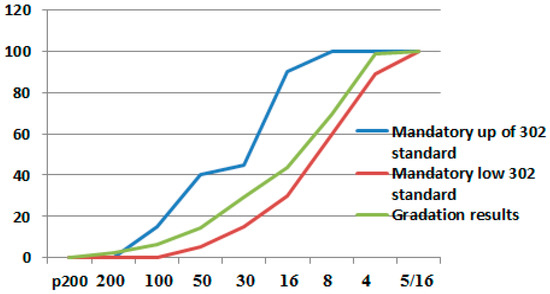

Fine materials: natural sand used to make samples is sand with a broken format with a density of 2320 kg/m3 and fineness modulus of 3.39, 24 h water absorption of 3% and chemical characteristics of Table 7. Grading curve of this sand from Figure 4 is presented in Table 8. On the other hand, because of higher fineness modulus and higher resistance that silica sand has in comparison to natural sand, it has also been used to make samples. The silica sand is Qazvin silica sand with a density of 2150 kg/m3 in according Table 9, and fineness modulus of 1.50, 24-h water absorption of 23%, and chemical characteristics of Table 7.

Table 7.

Chemical characteristics of natural sand roving round of Ferbet and Qazvin silica sand.

Figure 4.

Sand diagram under mandatory standards.

Table 8.

Grading test specifications sand under mandatory standards.

Table 9.

Grading test specifications of silica sand.

The grading curve of sand becomes out of the optional range defined in the standard of 302 (characteristics of concrete aggregates) [20], so a broader, mandatory range has been considered.

Water: Drinking water can generally be used in making concrete because of low impurities. Excessive impurity of mixing water not only affects the consumption time and ultimate strength, but it may also cause efflorescence, soiling, the corrosion of bars, volume instability, and reduction of concrete durability. Drinking water has been used in this study.

Superplasticizer: Consumption of these additives increases the fluency of concrete and can reduce the amount of water consumed in concrete, so that concrete fluency remains constant and its compressive strength increases. Superplasticizer from the Fiton company of Tehran of Iran with a density of 1.13 gr/cm3 has been used to make samples according to the catalog.

2.2. Mix Design

The volume method has been used to determine the mix design [21]. The same mixing method is intended to unify the conditions for making samples and to increase the accuracy of the results of experiments. Using this mixing method, the lightweight aggregates of Scoria, Pumice, and Leca are first poured into a mixer-type blender with two-thirds water for 30 min to reach saturation mode. After this, sand is added to the mixture and mixing operation begins. One-and-a-half minutes after mixing starts, cementitious materials are gradually added to the mixture. After two more minutes, soluble super lubricants are added to the remaining water and the mixing operation continues for two more minutes. Then, samples are produced using a block device.

In addition, in order to treat samples after they are produced, they are preserved for 72 h at 22 °C and humidity of 55%, and, in the end, they are placed in an in vitro environment for 24 h.

Briefly, for every type of lightweight aggregate, five series of projects have been presented with different ratios as the basic projects to reduce density and water volume absorption, and to increase compressive strength as in Table 10. Other projects have not been mentioned due to similarity in the mixing ratios to each of these projects.

Table 10.

Mix of natural and artificial lightweight aggregate blocks.

2.3. Experiments

Lightweight aggregate blocks are classified based on density. Thus, three samples of each mix design for the three types of lightweight aggregates of Scoria, Pumice and Leca are soaked in the water for 24 h with temperatures of 16 °C to 27 °C, which are dimensions of 49 cm × 15 cm × 20 cm to become fully saturated. The weight of the immersion mode of samples saturated in water is measured (Wi). Then, they are removed from water and are put on a metal grid with springs of at least 9.5 mm for 1 min until surface water is removed from the samples. After this, visible water is collected with a damp cloth, and the sample is weighted in this state (Ws). Then, the samples are incubated for 24 h at 100 °C to 150 °C and are dried to stabilize weight. Their weights are measured after cooling them down in the air (Wd).

Density is calculated using Equation (1), and its water absorption is obtained using Equation (2) (Standard 70-2) [22]:

where D is density in kilograms per cubic meter; Wd is sample weight after drying in kilograms; Ws is saturation sample weight in kilograms; and Wi is saturated sample weight in the case of immersion in water in kilograms.

To conduct a compressive strength experiment, lightweight aggregate block samples must be treated in a greenhouse for 48 h with a maximum relative humidity of 80% at 16 °C to 32 °C, standard (70-2).

To determine the compressive strength of samples, a testing machine must be used. It must be thoroughly cleaned with a speed of 0.5 N/cm2/s. The maximum force on the sample must be noted and divided by the sample surface to obtain compressive strength according to Newton per square millimeter (MPa).

3. Investigation of Results

Standard 7782 for non-load-bearing lightweight aggregate concrete blocks [23] follows in Table 11, Table 12 and Table 13. The measurement results of the blocks’ dimensions are ignored. However, it is noteworthy that all of these sizes are compatible with standard conditions.

Table 11.

Density classification of cement blocks in accordance with ISO 7782 style.

Table 12.

Water absorption of concrete blocks in accordance with ISO 7782 style.

Table 13.

Compressive strength of non-bearing concrete in accordance with ISO 7782 style.

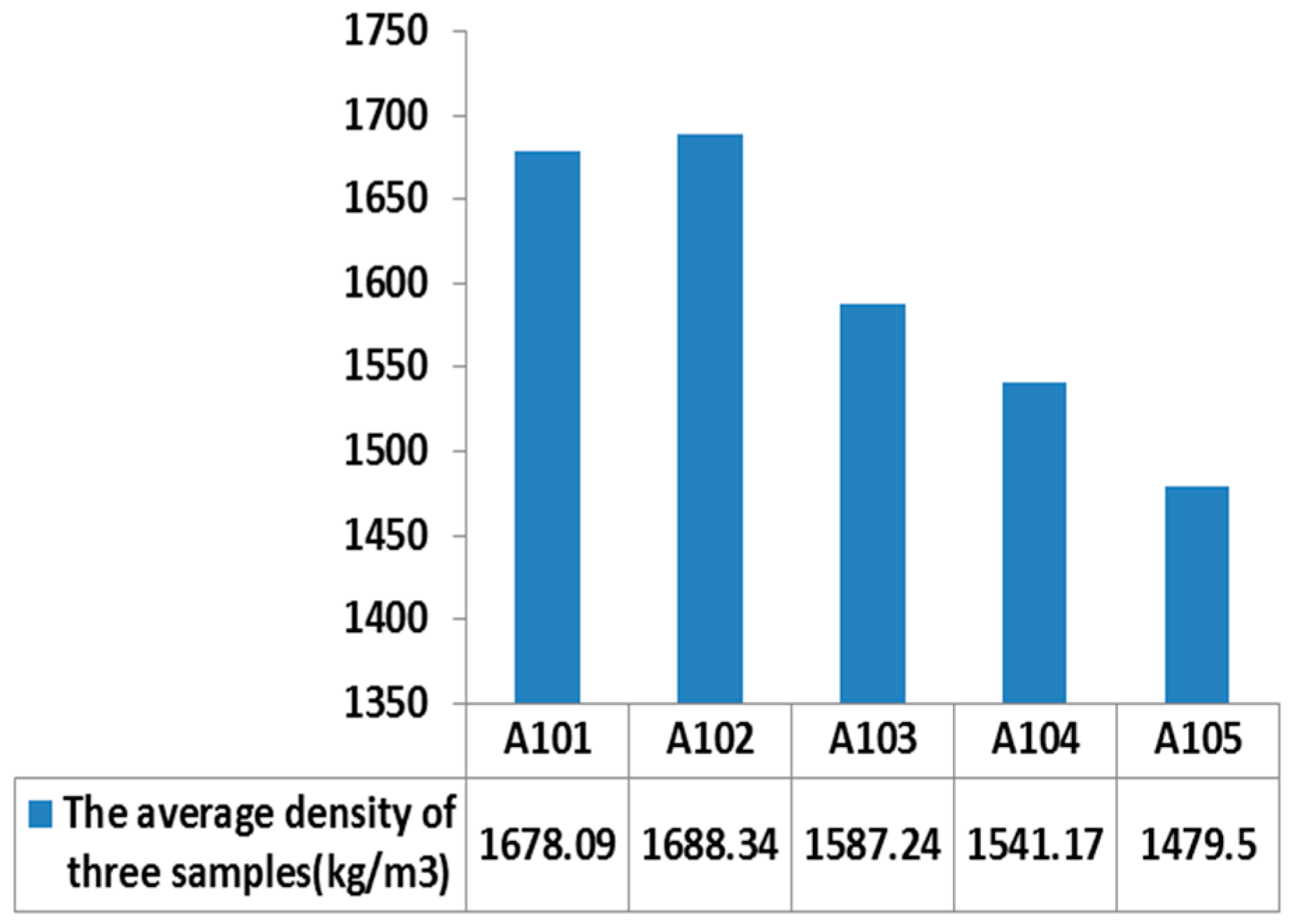

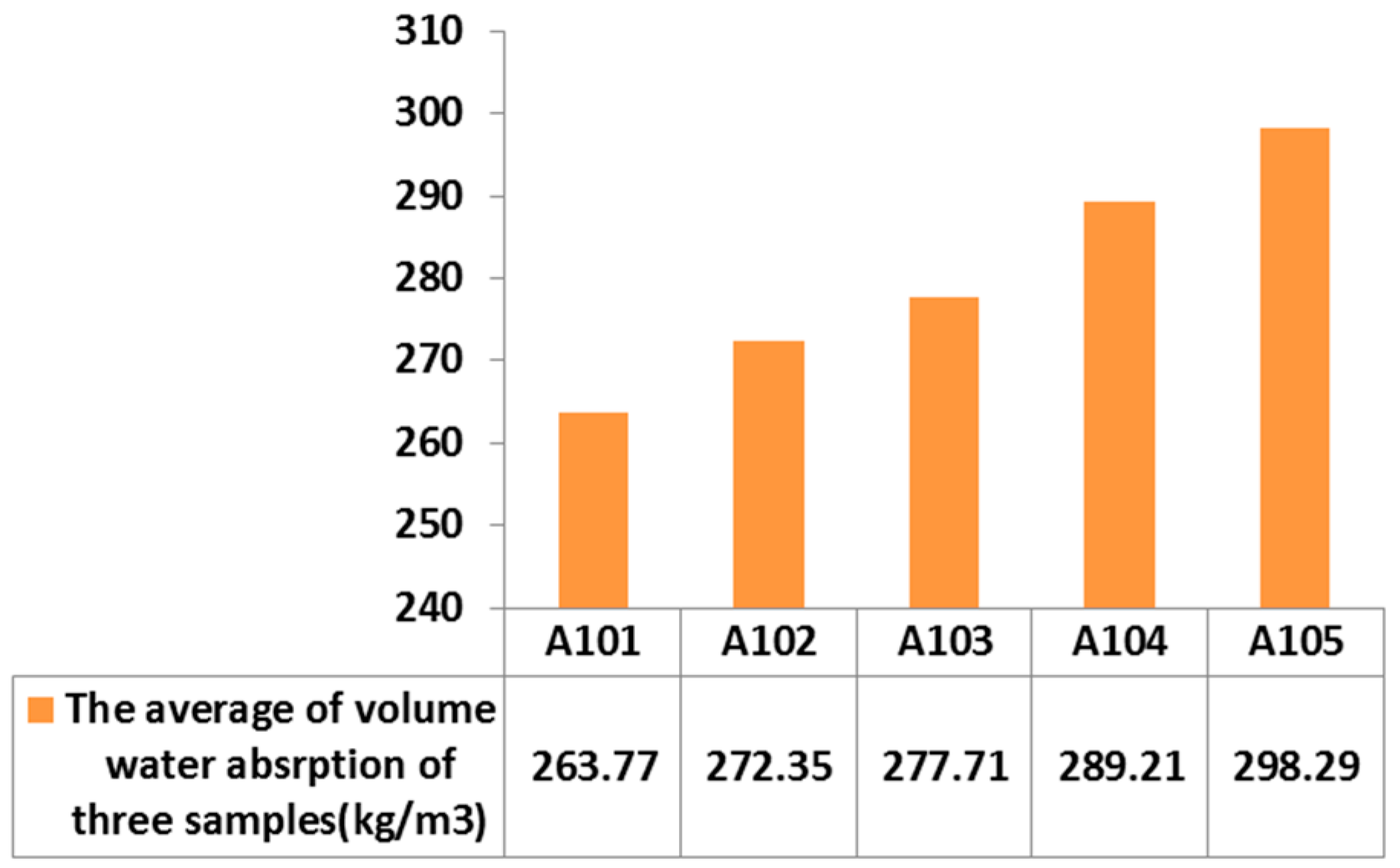

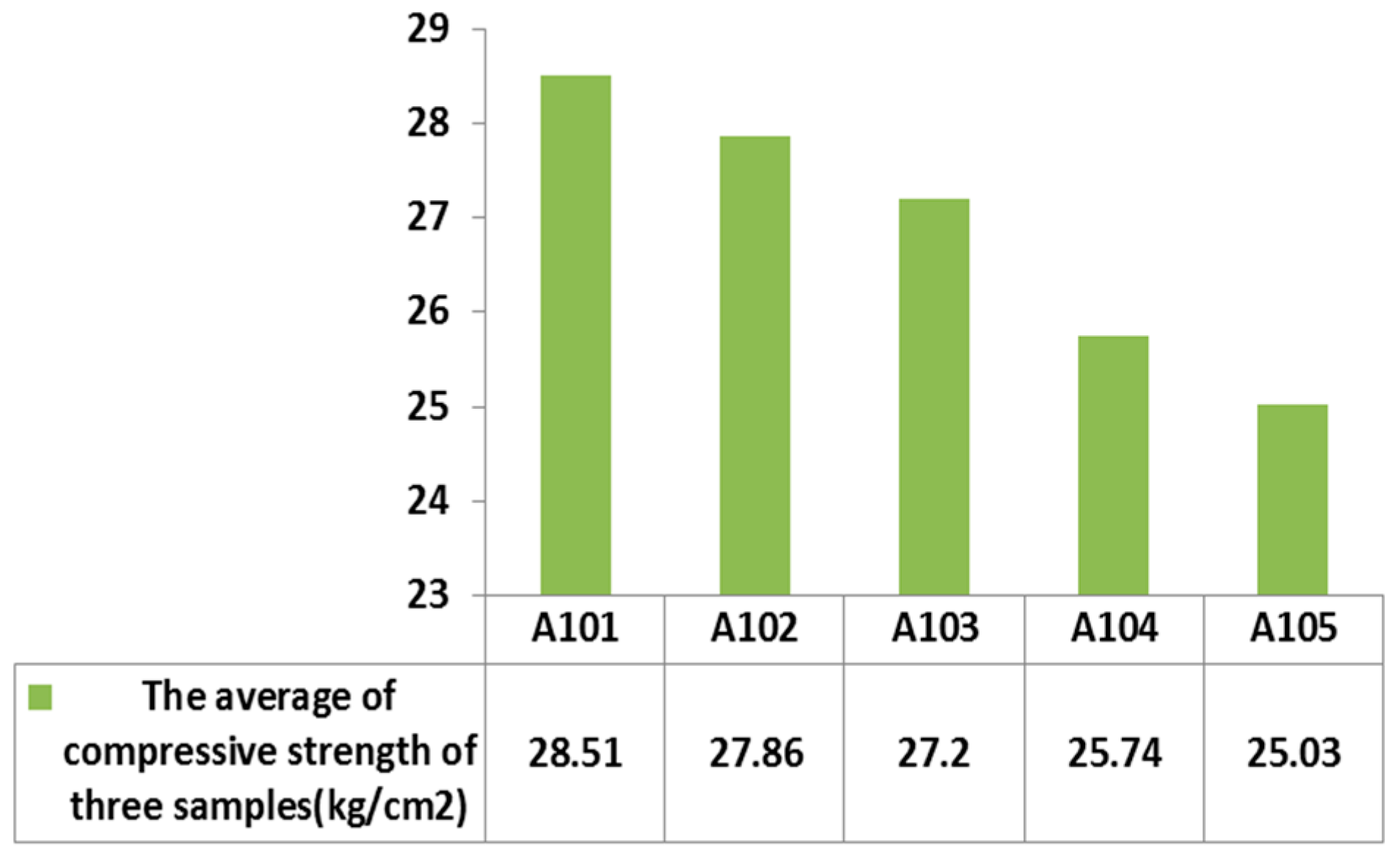

3.1. The Results of the Experiments on Lightweight Blocks of Scoria are Visinle in Figure 5, Figure 6 and Figure 7 (in Accordance with ISO 7782 Style)

Figure 5.

The test results of density (kg/m3).

Figure 6.

The test results of volume water absorption (kg/m3).

Figure 7.

The test results of the compressive strength (kg/cm2).

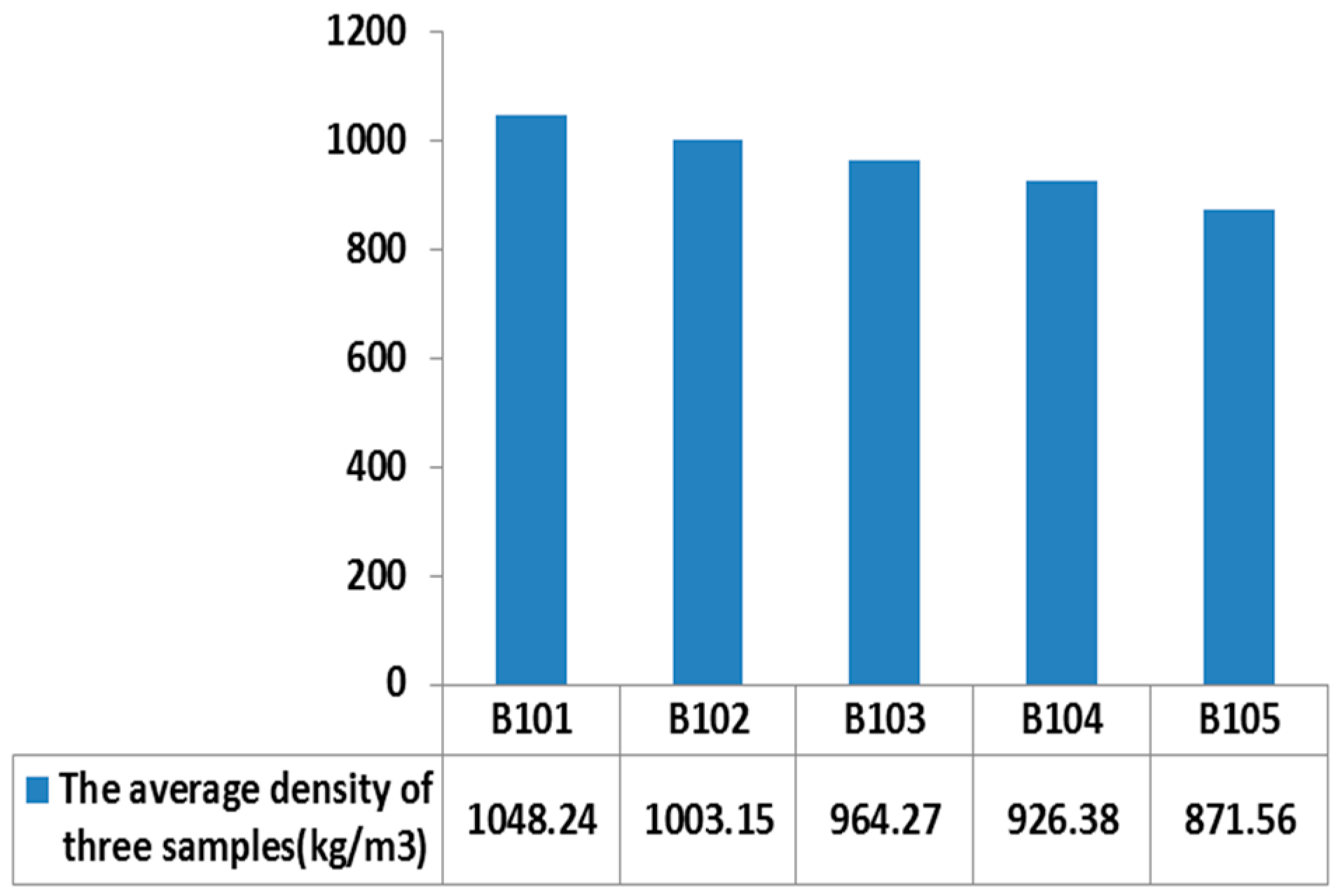

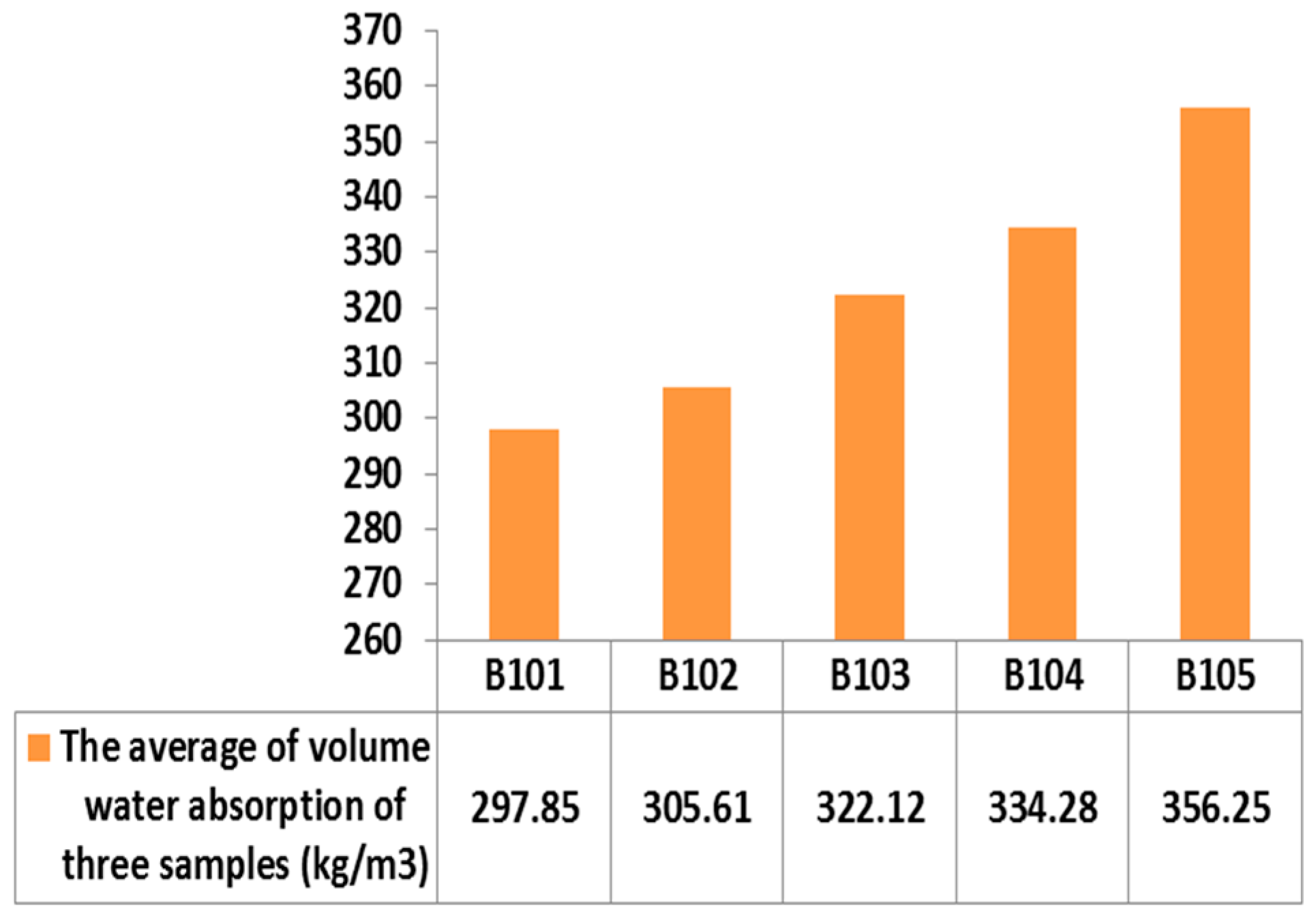

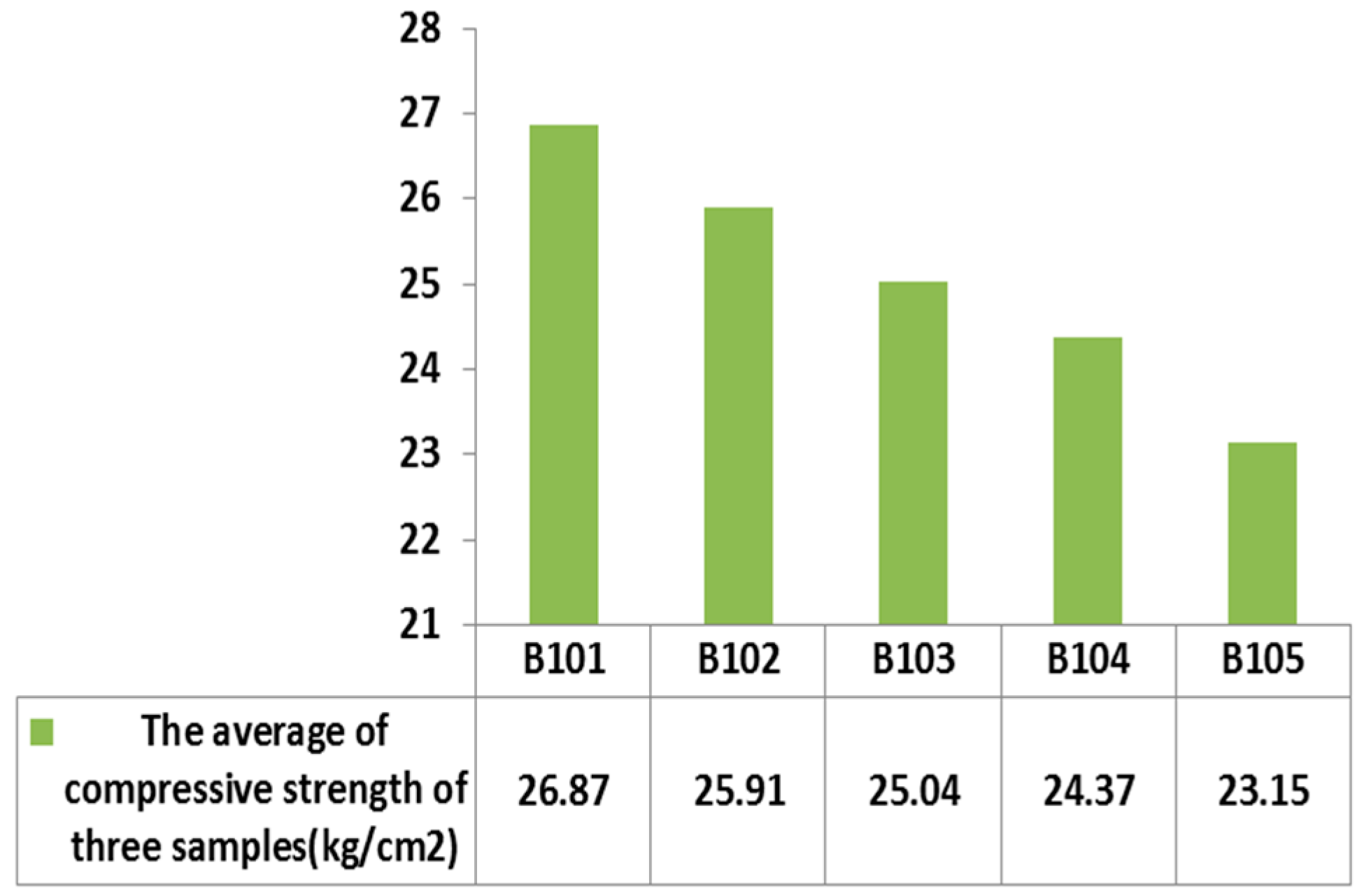

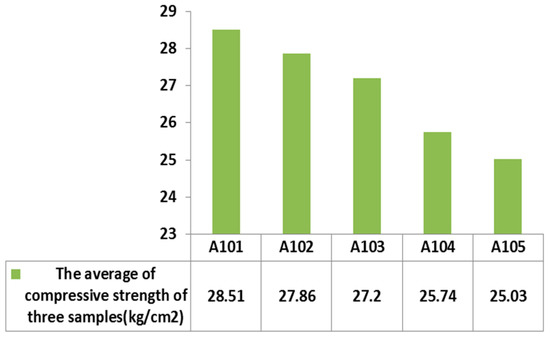

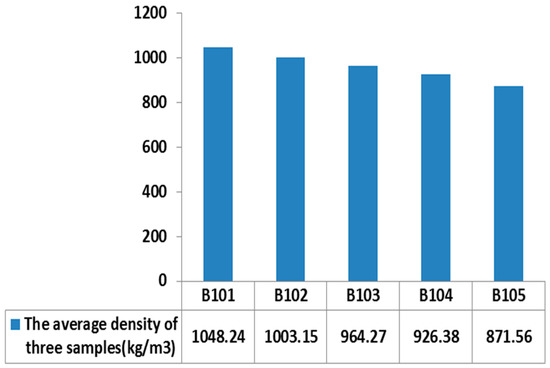

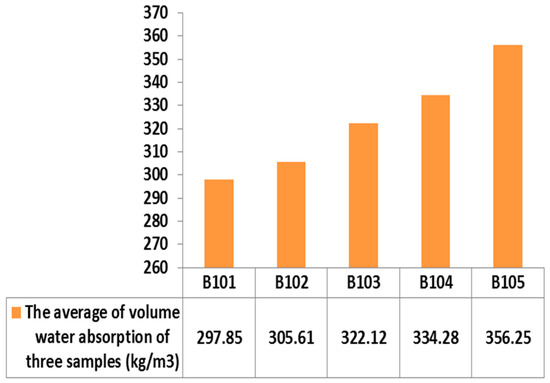

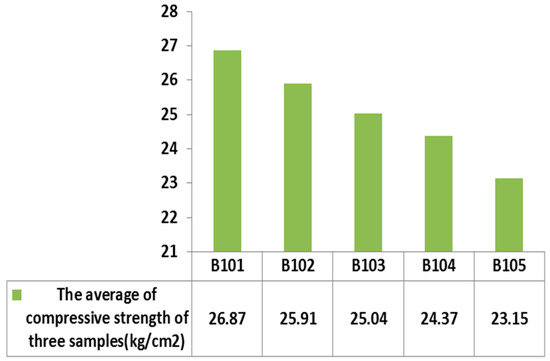

3.2. The Results of the Experiments on Lightweight Blocks of Pumice are Visible in Figure 8, Figure 9 and Figure 10 (in Accordance with ISO 7782 Style)

Figure 8.

The test results of density (kg/m3).

Figure 9.

The test results of volume water absorption (kg/m3).

Figure 10.

The test results of the compressive strength (kg/cm2).

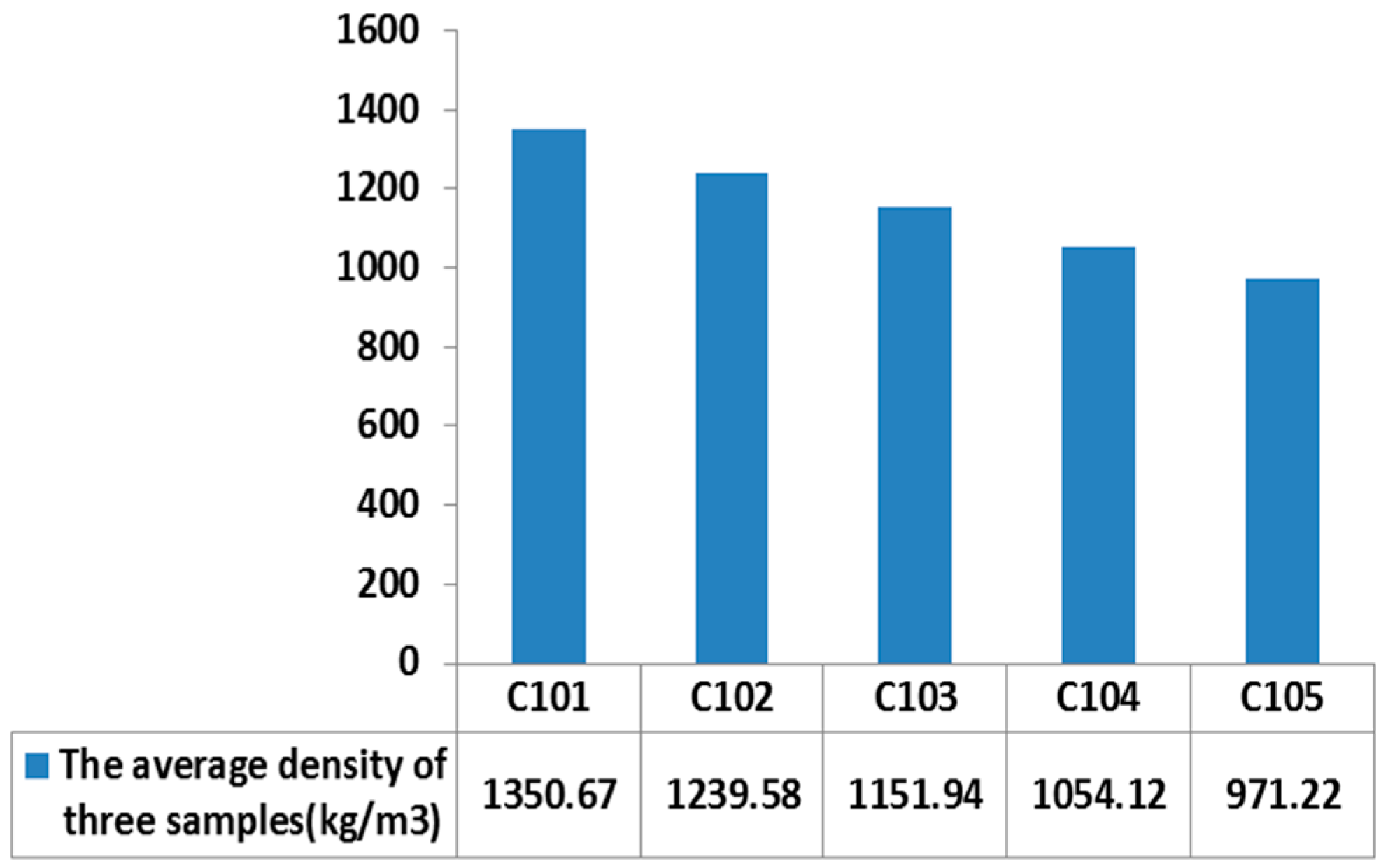

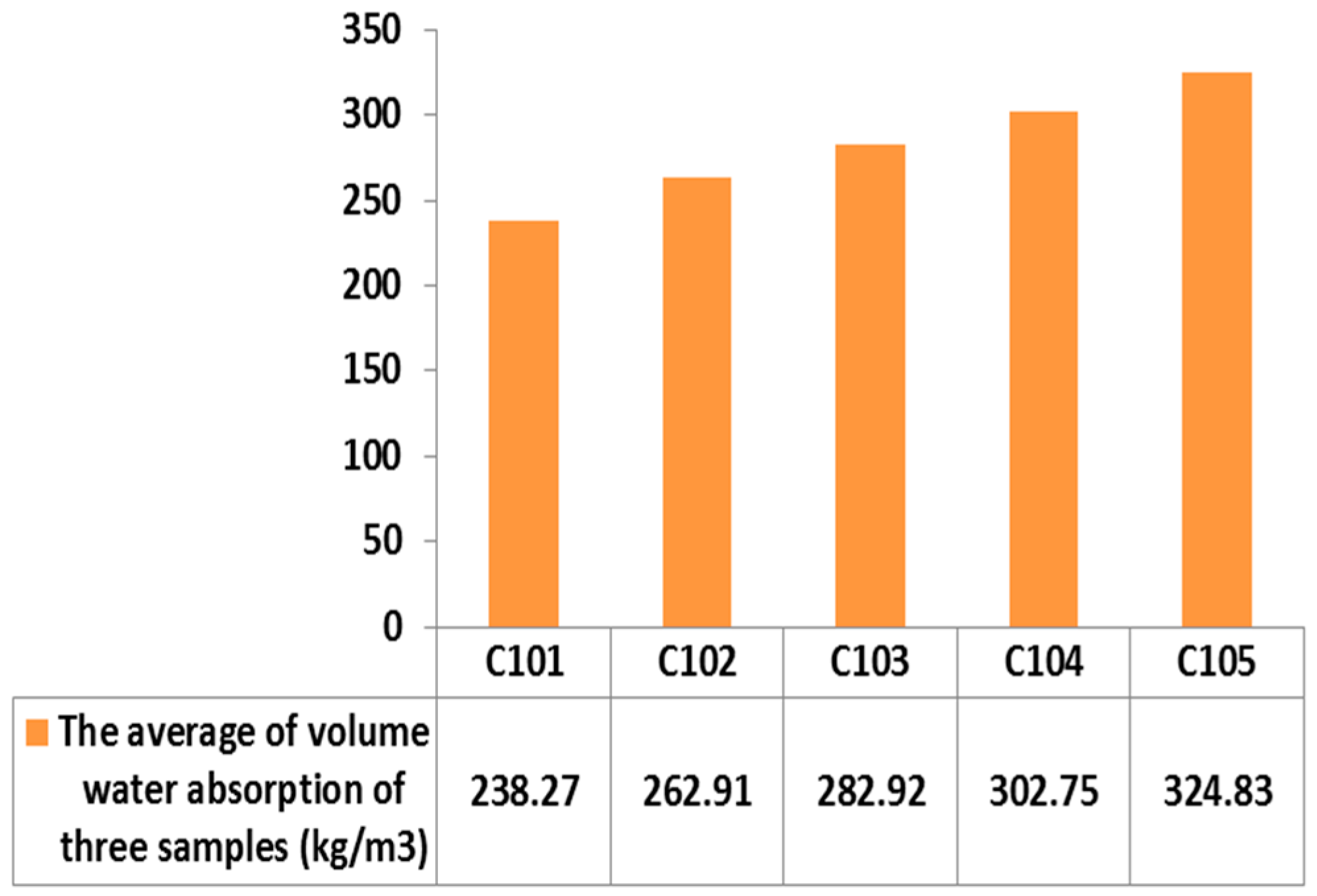

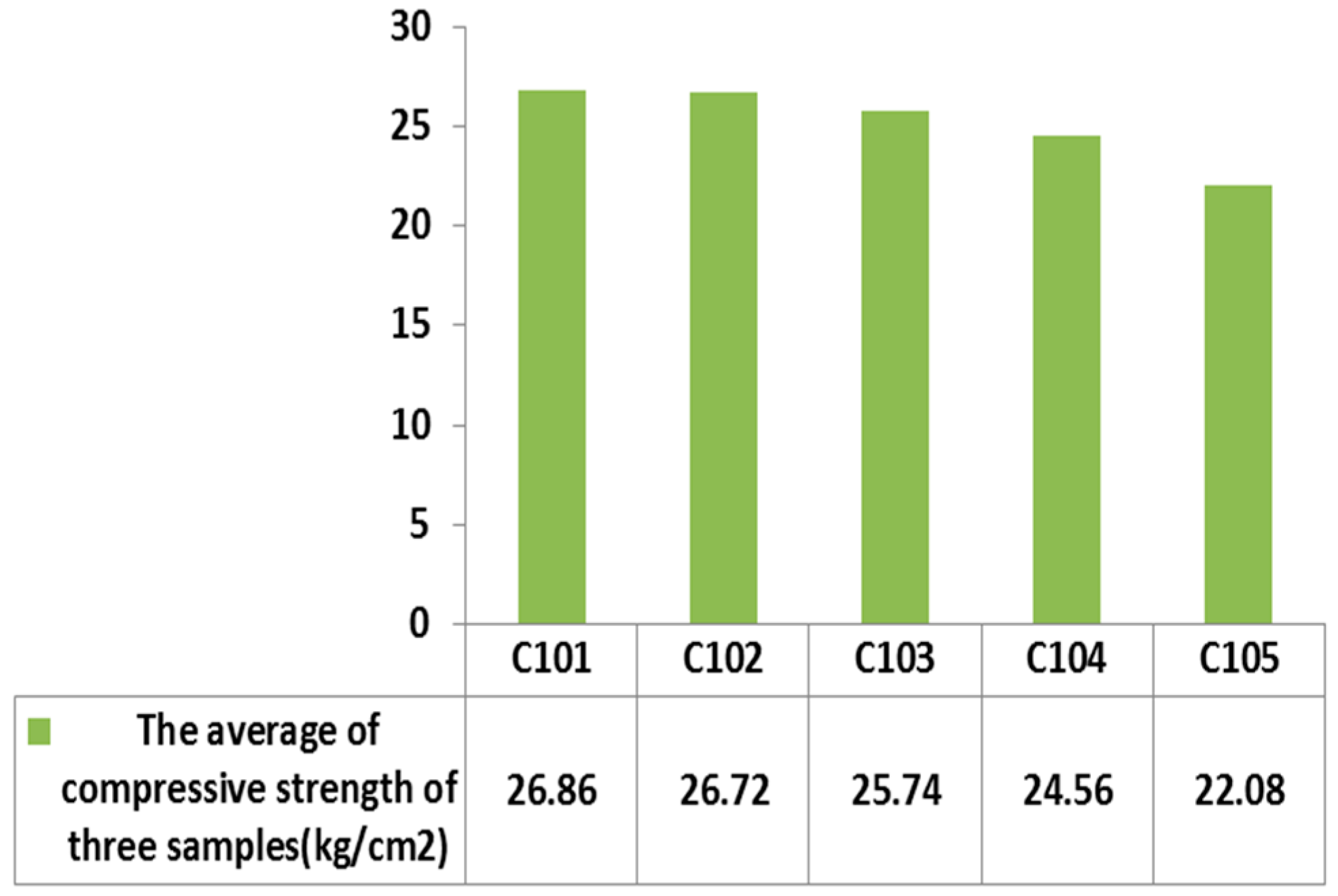

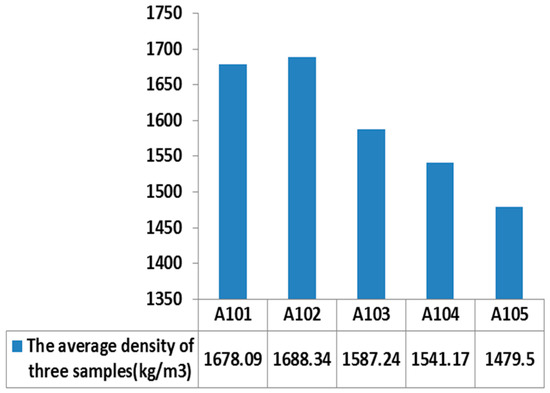

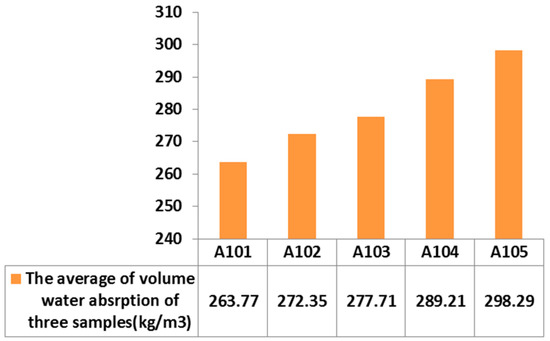

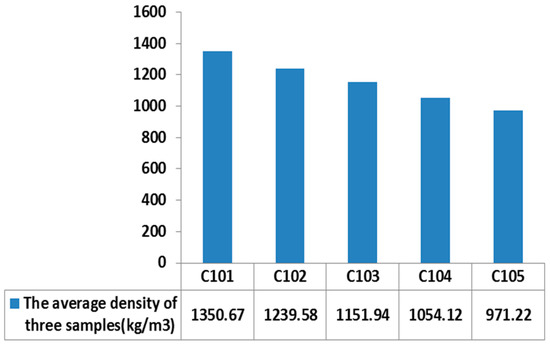

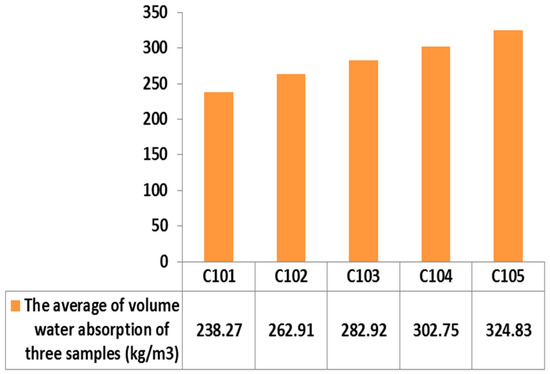

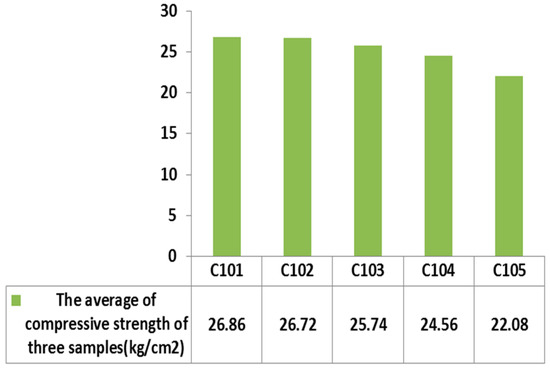

3.3. The Results of the Experiments on Leca Lightweight Aggregate Blocks are Visible in Figure 11, Figure 12 and Figure 13 (in Accordance with ISO 7782 Style)

Figure 11.

The test results of density (kg/m3).

Figure 12.

The test results of volume water absorption (kg/m3).

Figure 13.

The test results of the compressive strength (kg/cm2).

3.4. Discussion of Results

Compressive strength of lightweight aggregate concrete is a function of both used and mortar lightweight aggregates. Thus, low mechanical strength of aggregates can help reduce problems such as high water absorption and gradual erosion of these mixing by reducing the ratio of coarse aggregate to total aggregates, saturating lightweight aggregate before pouring them in the project, using appropriate blenders, and using silica sand instead of natural sand as filler.

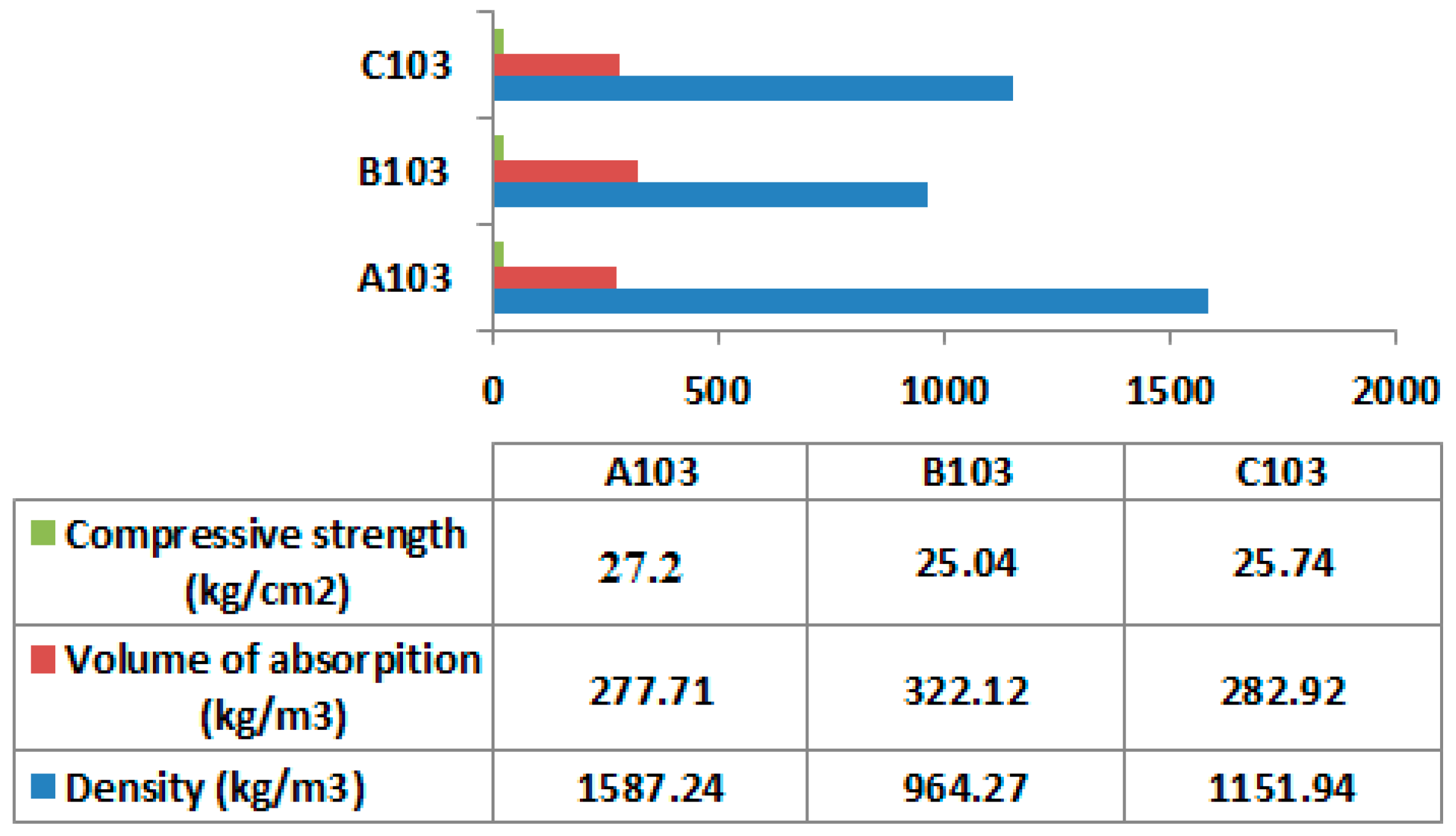

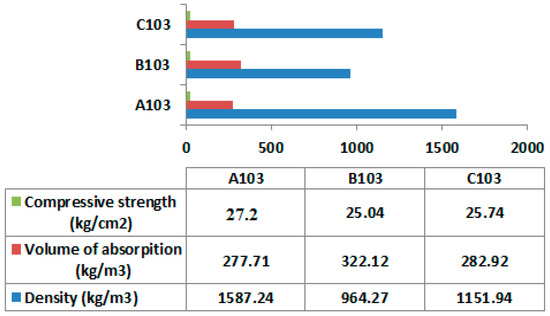

According to the results of experiments, the most desirable state of mix design for lightweight aggregate block of Scoria is the design code of A103, for Pumice, the design code of B103, and, for Leca, the design code of C103 that are visible in Figure 14 and Table 14.

Figure 14.

Comparison chart of compressive strength, density, and water absorption volume of lightweight aggregate blocks with optimal mix.

Table 14.

Ranking density, compressive strength, and water absorption volume of lightweight aggregate block in accordance with ISO 7782.

Regarding the comparison, Scoria lightweight aggregate blocks had higher compressive strength and lower water absorption volume compared to lightweight aggregates of Pumice and Leca due to hard texture and high mechanical strength of its lightweight aggregates. Despite having desirable compressive strength and low density compared to other lightweight aggregates, Tabriz Pumice blocks had higher water absorption volume. Thus, they cannot meet standard conditions and this makes them less welcomed.

Among them, it can be said that Leca blocks are placed between these two blocks in terms of strength, density and water absorption volume, and they have normal conditions.

In addition, although these lightweight aggregates have different mechanical and physical structures and create blocks with different physical characteristics, it can be implied from the obtained results that, regardless of the behavior of lightweight aggregates, block density plays an important role in compressive strength and water absorption volume.

4. Conclusions

Within the scope of the conducted studies, it can be concluded that:

- The best cement content in the mix design of lightweight aggregate blocks is 250 and the water–cement ratios are 0.33 for Scoria, 0.36 for Pumice, and 0.32 for Leca, respectively.

- Density has an inverse relationship with water absorption volume in lightweight aggregate blocks.

- Scoria blocks have the highest density of 1587.24 kg/m3 and the lowest water absorption volume (277.71 kg/m3).

- Pumice blocks with the lowest density (964.27 kg/m3) have the highest water absorption volume (322.20 kg/m3). This is not in accordance with the national standard of 7782, so it is not acceptable.

- Density has a direct relationship with compressive strength.

- Scoria blocks have the highest compressive strength (2.72 MPa) and Leca blocks follow Scoria with 2.57 MPa. Finally, there are Pumice blocks with the compressive strength of 2.50 MPa.

- Accordingly, one of the objectives of using lightweight aggregate blocks is reducing a building’s dead load. Consequently, Leca blocks should be preferred because they have a density of 1151.94 kg/m3 and water absorption volume of 282.92 kg/m3, and have normal compressive strength.

Author Contributions

All the authors have quota to the article according to what they did (first person: M.S.M after that H.R.A. then P.B.). M.S.M., H.R.A. and P.B. designed the study of patterns at restaurants; H.R.A. suggested using lightweight concrete; M.S.M. conceived and designed the experiments; also she performed the experiments and analyzed date P.B. did measures to complete this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ramezanianpour, A.; Nilforoshan, A.; Peidayesh, M. Earthquake risk reduction with using lightweight aggregate concrete of structures in building. In Proceedings of the First Conference of Seismic Retrofit, Tehran, Iran, 25–27 April 2006.

- Kayali, O. Flashag—New Lightweight Aggregate for High Strength and Durable Concrete. In Proceedings of the 2005 World of Coal Ash (WOCA), Lexington, KY, USA, 11–15 April 2005.

- Esmaeili, K.; Rashidisabet, P. Compound of special lightweight concrete proportional mixed with other material for achieving the new structural system in building industry. In Proceedings of the Seventh Conference of Housing Development Policy in Iran, Tehran, Iran, 11–12 October 2001.

- Majdi, A.; Shekarchizade, M.; Jafari, A.; Aliliber, N.; Naseri, A. Check the capacity to resist lightweight Scoria for using in lightweight aggregate concrete of structures. In Proceedings of the First National Conference Lightweight Concrete, Tehran, Iran, 15–16 February 2012.

- Neville, A.; Brooks, J.J. Concrete Technology; Trans-Atlantic Publications: Philadelphia, PA, USA, 2008; p. 465. [Google Scholar]

- Clarke, J.L. Structural Lightweight Aggregate Concrete; CRC Press: London, UK, 1993. [Google Scholar]

- Colangelo, F.; Messina, F.; Cioffi, R. Recycling of MSWI fly ash by means of cementitious double step cold bonding pelletization: Technological assessment for the production of lightweight artificial aggregates. J. Hazard. Mater. 2015, 299, 181–191. [Google Scholar] [CrossRef] [PubMed]

- Ferone, C.; Colangelo, F.; Messina, F.; Iucolano, F.; Liguori, B.; Cioffi, R. Coal combustion wastes reuse in low energy artificial aggregates manufacturing. Materials 2013, 6, 5000–5015. [Google Scholar] [CrossRef]

- Yliniemi, J.; Nugteren, H.; Illikainen, M.; Tiainen, M.; Weststrate, R.; Niinimäki, J. Lightweight aggregates produced by granulation of peat-wood fly ash with alkali activator. Int. J. Miner. Process. 2016, 149, 42–49. [Google Scholar] [CrossRef]

- Vise, S.; Mirmohamadi, S. Lightweight natural source and lightweight artificial source in Iran. In Proceedings of the First National Conference Lightweight Concrete, Tehran, Iran, 15–16 February 2012.

- Shekarchizade, M.; Aliliber, N.; Ashori, A. Expanded Clay Lightweight Aggregate (LECA) Concrete of Structure; Scientific Report, No. 860-6234; Building Material Institution of Technical College of Tehran University: Tehran, Iran, 2007. [Google Scholar]

- Binici, H. Effect of crushed ceramic and basaltic Pumice as fine aggregate on concrete mortars properties. Constr. Build. Mater. 2007, 21, 1191–1197. [Google Scholar] [CrossRef]

- Altun, F.; Zgurkisi, O.; Aydin, K. Predicting the compressive strength of steel fiber added lightweight concrete using neural network. Comput. Mater. Sci. 2008, 42, 259–262. [Google Scholar] [CrossRef]

- Gunduz, L. Use of quartet blends containing fly ash, Scoria, Perlite, Pumice and cement for produce cellular hollow lightweight masonry blocks for non-loud bearing walls. Constr. Build. Mater. Mag. 2007, 22, 747–754. [Google Scholar] [CrossRef]

- Moufi, M.R.; Sabtan, A.A.; El-Mahdy, O.R.; Shehata, W.M. Assessment of the industrial utilization of Scoria materials in central Harrat Rahat, Saudi Arabia. Eng. Geol. 2000, 57, 155–162. [Google Scholar] [CrossRef]

- Zekavati, A.; Abdizade, N.; Afshin, H. Check and compare some mechanical properties of variety natural and artificial lightweight. In Proceedings of the First National Conference Lightweight Concrete, Tehran, Iran, 15–16 February 2012.

- Ghazaviyebaghini, A.; Karamozan, A. The usage mineral shells in lightweight structures concrete. In Proceedings of the First National Conference of Industry, Tehran, Iran, 24–25 May 2012.

- Standard Institute and Industrial Research of Iran 7657 Aggregate—Lightweight Aggregate of Consumable in Concrete Blocks—Features; National Standard of Iran: Tehran, Iran, 2006.

- ASTM C127 Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate; American Society for Testing and Materials: West Conshohocken, PA, USA, 2001.

- Standard Institute And industrial Research of Iran 302 Aggregate of Concrete—Features; National Standard of Iran: Tehran, Iran, 2002.

- American Concrete Institute. ACI Committee 213, Guide for Structural of Lightweight Aggregate Concrete, ACI Manual of Concrete Practice; ACI: Farmington Hills, MI, USA, 2011. [Google Scholar]

- Standard Institute and Industrial Research of Iran (70-2) Hollow Concrete Block; Second Part: Test Methods; National Standard of Iran: Tehran, Iran, 2008.

- Standard Institute and Industrial Research of Iran 7782 Building Materials—Nonloadbearing Lightweight Concrete Blocks—Specifications; National Standard of Iran: Tehran, Iran, 2013.

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).