A Tillage Depth Monitoring and Control System for the Independent Adjustment of Each Subsoiling Shovel

Abstract

:1. Introduction

2. Materials and Methods

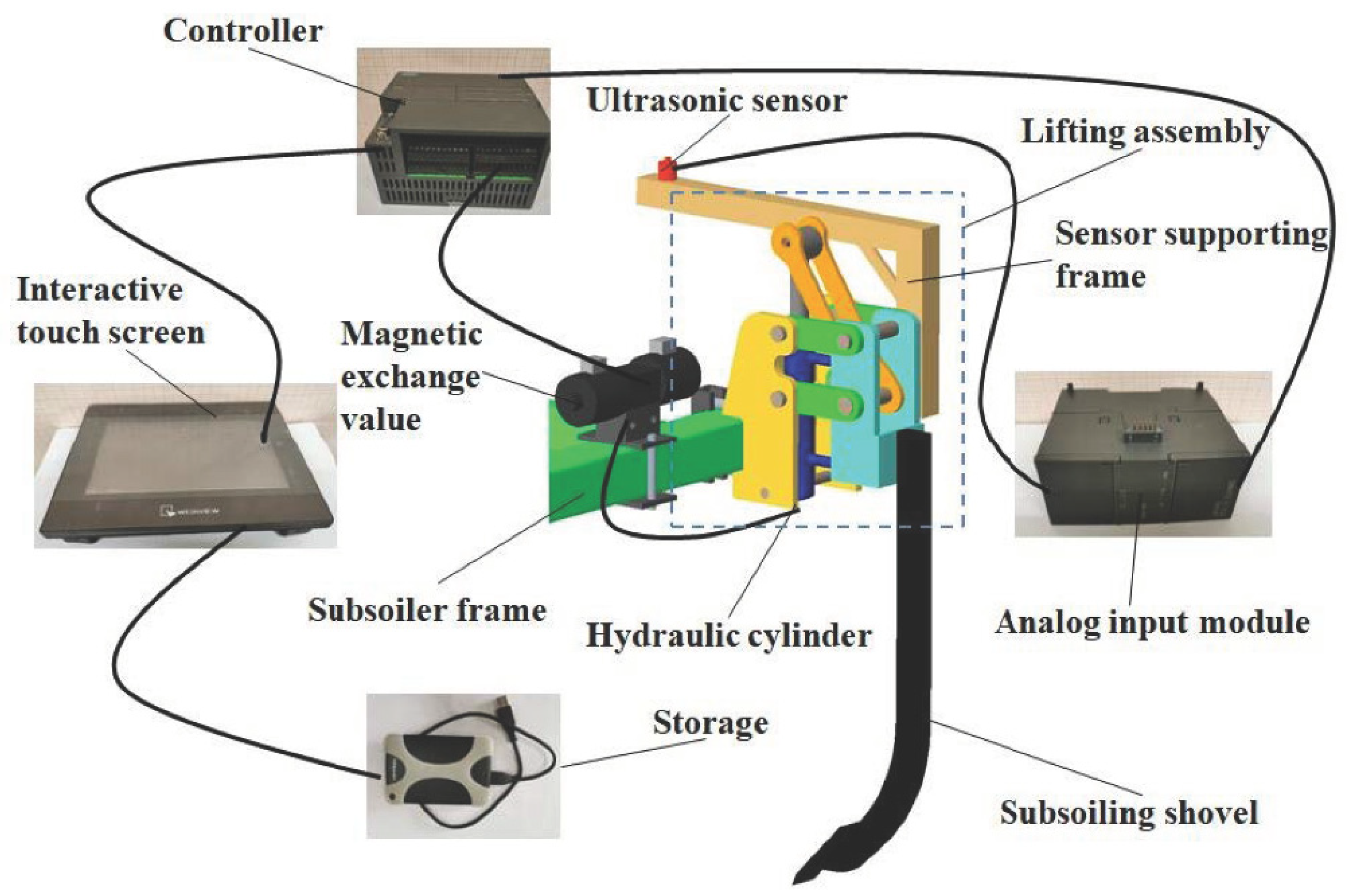

2.1. Description of the Single Subsoiling Assembly

2.2. Design of the Tillage Depth Monitoring and Control System

2.2.1. Tillage Depth MONITORING and Control System

2.2.2. Tillage Depth Detecting by Ultrasonic Sensor

2.2.3. Tillage Depth Displaying via Interactive Touch Screen

2.3. Evaluation Experiments

2.3.1. Test Arrangement

2.3.2. Test Conditions

3. Results and Discussion

3.1. Accuracy in Detecting Tillage Depth

3.2. Tillage Depth

3.3. Transient Response Time

3.4. Advantages of the Control System

4. Conclusions

- (1)

- Comparing the tillage depth obtained by ultrasonic sensors and measured manually in the field with straw mulching, the errors at the speeds of 3 km/h, 4 km/h, and 5 km/h, respectively, were 8.35%, 8.1%, and 8.38%, which demonstrated that the errors were acceptable and the method of applying ultrasonic sensors to detect the tillage depth was reliable and accurate.

- (2)

- The mean value of the coefficient of the tillage depth stability at the speeds of 3 km/h, 4 km/h, and 5 km/h, respectively, were 97.5%, 97.9%, and 94.9%, which were far better than the standard requirement of a subsoiling machine, and indicated that higher stability of tillage depth was obtained by equipping with the tillage depth monitoring and control system.

- (3)

- The tillage depth monitoring and control system had good output response characteristics. The response time of the control system was 0.46 s. No matter that the tillage depth was less than the minimum set value or greater than the maximum set value, the system was able to accurately detect the change of the tillage depth and timely adjust the tillage depth to the set range within 1 s.

- (4)

- Compared with the unified adjustment of each row via the three-point suspension, applying the system was more advantageous to obtain the desired tillage depth and improve the stability of the tillage depth of each subsoiling shovel. The standard deviations of tillage depth obtained by the independent adjustment of a single row and unified adjustment of each row, respectively, were 38.31 and 51.52.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Poehlitz, J.; Ruecknagel, J.; Schlueter, S.; Vogel, H.J.; Christen, O. Computed tomography as an extension of classical methods in the analysis of soil compaction, exemplified on samples from two tillage treatments and at two moisture tensions. Geoderma 2019, 346, 52–62. [Google Scholar] [CrossRef]

- Romaneckas, K.; Šarauskis, E.; Avižienytė, D.; Buragienė, S.; Arney, D. The main physical properties of planosol in maize (Zea mays L.) cultivation under different long-term reduced tillage practices in the Baltic region. J. Integr. Agric. 2015, 14, 1309–1320. [Google Scholar] [CrossRef]

- Meharban, S.K.; Rattan, L.; Merrie, A.V. Twenty two years of tillage and mulching impacts on soil physical characteristics and carbon sequestration in Central Ohio. Soil Tillage Res. 2013, 126, 151–158. [Google Scholar] [CrossRef]

- Haytham, M.; Salema, B.; Constantino, V.; Miguel, A.M.; María, G.R.; Silvac, L.L. Short-term effects of four tillage practices on soil physical properties, soil water potential, and maize yield. Geoderma 2015, 237, 60–70. [Google Scholar] [CrossRef] [Green Version]

- Zhang, R.F.; Yang, H.S.; Gao, J.L.; Zhang, Y.Q.; Wang, Z.G.; Fan, X.Y.; Bi, W.B. Effect of subsoiling on root morphological and physiological characteristics of spring maize. Trans. CSAE 2015, 31, 78–84. [Google Scholar] [CrossRef]

- Luo, Z.Z.; Huang, G.B.; Zhang, G.S. Effects of conservation tillage on soil bulk density and water infiltration in dry land of Loess Plateau. Agric. Res. Arid Areas 2005, 23, 7–11. [Google Scholar]

- Somerville, P.D.; May, P.B.; Livesley, S.J. Effects of deep tillage and municipal green waste compost amendments on soil properties and tree growth in compacted urban soils. J. Environ. Manag. 2018, 227, 365–374. [Google Scholar] [CrossRef] [PubMed]

- Hargreaves, P.R.; Baker, K.L.; Graceson, A.; Bonnett, S.; Ball, B.C.; Cloy, J.M. Soil compaction effects on grassland silage yields and soil structure under different levels of compaction over three years. Eur. J. Agron. 2019, 109, 1–9. [Google Scholar] [CrossRef]

- Kristoffersen, A.O.; Riley, H. Effects of soil compaction and moisture regime on the root and shoot growth and phosphorus uptake of barley plants growing on soils with varying phosphorus status. Nutr. Cycl. Agorecosyst. 2005, 72, 135–146. [Google Scholar] [CrossRef]

- Singh, K.; Choudhary, O.P.; Singh, H.P.; Singh, A.; Mishra, S.K. Sub-soiling improves productivity and economic returns of cotton-wheat cropping system. Soil Tillage Res. 2019, 189, 131–139. [Google Scholar] [CrossRef]

- Borek, L. Effect of double subsoiling on physical properties of soil lessives. Acta Sci. Pol. 2016, 15, 21–34. [Google Scholar] [CrossRef]

- Lzumi, Y.; Yoshida, T.; Lijima, M. Effects of subsoiling to the non-tilled field of wheat-soybean rotation on the root system development, water uptake, and yield. Plant Prod. Sci. 2009, 12, 327–335. [Google Scholar] [CrossRef] [Green Version]

- Guaman, V.; Bath, B.; Hagman, J.; Gunnarsson, A.; Persson, P. Short time effects of biological and inter-row subsoiling on yield of potatoes grown on a loamy sand, and on soil penetration resistance, root growth and nitrogen uptake. Eur. J. Agron. 2016, 80, 55–65. [Google Scholar] [CrossRef]

- He, J.; Li, H.W.; Chen, H.T.; Lu, C.Y.; Wang, Q.J. Research progress of conservation tillage technology and machine. Trans. Chin. Soc. Agric. Mach. 2018, 49, 1–18. [Google Scholar] [CrossRef]

- Wang, S.B.; Guo, L.L.; Zhou, P.C.; Wang, X.J.; Shen, Y.; Han, H.F.; Ning, T.Y.; Han, K. Effect of subsoiling depth on soil physical properties and summer maize (Zea mays L.) yield. Plant Soil Environ. 2019, 65, 131–137. [Google Scholar] [CrossRef] [Green Version]

- Schneider, F.; Don, A.; Hennings, I.; Schmittmann, O.; Seidel, S.J. The effect of deep tillage on crop yield-What do we really know? Soil Tillage Res. 2017, 174, 193–204. [Google Scholar] [CrossRef]

- Sun, M.; Gao, Z.Q.; Ren, A.X.; Deng, Y.; Zhao, W.F.; Zhao, H.M.; Yang, Z.P.; He, L.H.; Zong, Y.Z. Contribution of Subsoiling in Fallow Period and Nitrogen Fertilizer to the Soil-Water Balance and Grain Yield of Dry-Land Wheat. Int. J. Agric. Biol. 2015, 17, 175–180. [Google Scholar]

- Feng, X.M.; Hao, Y.B.; Latifmanesh, H.; Lal, R.; Cao, T.H.; Guo, J.R.; Deng, A.X.; Song, Z.W.; Zhang, W.J. Effects of subsoiling tillage on soil properties, maize root distribution, and grain yield on mollisols of northeastern China. Soil Tillage Conserv. Manag. 2018, 110, 1607–1615. [Google Scholar] [CrossRef]

- Pereira, D.P.; Fiedler, N.C.; Juliao, S.L. Efficiency of subsoiling depth according to the slope of the land. Cerene 2012, 18, 607–612. [Google Scholar] [CrossRef]

- Wang, Y.X. Research and Experiment on a Tillage Depth Control System for Hydraulically Self-Excited Subsoiler. Ph.D. Thesis, China Agriculture University, Beijing, China, 2019. [Google Scholar]

- Bernsten, R.; Berre, B.; Torp, T.; Aasen, H. Tine forces established by a two-level model and the draught requirement of rigid and flexible tines. Soil Tillage Res. 2006, 90, 230–241. [Google Scholar] [CrossRef]

- Karoonboonyanan, R.; Salokhe, V.M.; Niyamapa, T.; Nakashima, H. Vibration effects on the performance of a single-shank subsoiler. Agric. Eng. Int. CIGR Ejournal 2008, 6, 126–147. [Google Scholar]

- Radite, P.; Hermawan, W.; Rizkianda, A.B.; Crosby, H.B. Experimental investigation on the application of vibration to reduce draft requirement of subsoiler. Int. Agric. Eng. J. 2010, 19, 31–38. [Google Scholar]

- Wang, Y.X.; Osman, A.N.; Zhang, D.X.; Yang, L.; Cui, T.; Zhong, X.J. Optimized design and field experiment of a staggered vibrating subsoiler for conservation tillage. Int. J. Agric. Biol. Eng. 2019, 12, 59–65. [Google Scholar] [CrossRef]

- Eshagh, B.A.; Tabatabaeifar, A.; Keyhain, A.R.; Raoufat, M.H. Development and field evaluation of an oblique blade subsoiler and comparison of performance with a conventional L-shape subsoiler. J. Agric. Sci. 2002, 12, 67–81. [Google Scholar]

- Jafari, R.; Raoufat, M.H.; TavakoliHashjin, T. Soil bin performance of a modified bentleg plow. Trans. ASABE. 2008, 24, 301–307. [Google Scholar]

- Raper, R.L. Force requirements and soil disruption of straight ang bentleg subsoilers for convention tillage system. Appl. Eng. In Agric. 2005, 21, 787–794. [Google Scholar] [CrossRef] [Green Version]

- Raper, R.L. Subsoiler shapes for site-specific tillage. Appl. Eng. Agric. 2005, 21, 25–30. [Google Scholar] [CrossRef]

- Zhao, J.; He, P.X.; Li, Q.D.; Jiang, M.; Kang, J.; Liu, H.B.; Zhu, K.X. Design of depth display system for micro-tiller. J. Agric. Mech. Res. 2016, 10, 83–86. [Google Scholar] [CrossRef]

- Li, Q.L.; Sun, Y.J.; Sun, Y.T.; Shen, J.X.; Chen, G.; Dou, Q.Q. Development of DSP-based joint operations subsoiling machine monitoring system. J. Agric. Mech. Res. 2016, 11, 118–122. [Google Scholar] [CrossRef]

- Xie, B.; Li, H.; Zhu, Z.X.; Mao, E.R. Measuring tillage depth for tractor implement automatic using inclinometer. Trans. CSAE 2013, 39, 15–21. [Google Scholar] [CrossRef]

- Ayiding, K.; Wu, M.T.; He, P.X.; Liu, X.R.; Sun, B. The control system of automatic adjust for plowing depth. J. Agric. Mech. Res. 2013, 3, 160–163. [Google Scholar] [CrossRef]

- Wang, Y.X.; Jing, H.R.; Zhang, D.X.; Cui, T.; Zhong, X.J.; Yang, L. Development and performance evaluation of an electric-hydraulic control system for subsoiler with flexible tines. Comput. Electron. Agric. 2018, 151, 249–257. [Google Scholar] [CrossRef]

- Jia, H.L.; Guo, M.Z.; Yu, H.B.; Li, Y.; Feng, X.Z.; Zhao, J.L.; Qi, J.T. An adaptable tillage depth monitoring system for tillage machine. Biosyst. Eng. 2016, 151, 187–199. [Google Scholar] [CrossRef]

- Mouazen, A.M.; Anthonis, J.; Saeys, W.; Ramon, H. An automatic depth control system for online measurement of spatial variation in soil compaction.1.Sensor design for measurement of frame height variation from soil surface. Biosyst. Eng. 2004, 89, 139–150. [Google Scholar] [CrossRef]

- Adamchuk, V.I.; Hummel, J.W.; Morgan, M.T.; Upadhyaya, S.K. On-the-go soil sensors for precision agriculture. Comput. Electron. Agric. 2004, 44, 71–91. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Y.W.; Fang, X.F.; Yang, B.N.; Liang, X.X.; Dong, X.; Zhou, L.M.; Zhang, J.N. A Suspended Subsoiler and Its Online Detection Device and Method, CHN, CN104977586-A, 14 October 2015. Available online: http://pss-system.cnipa.gov.cn/sipopublicsearch/portal/uiIndex.shtml?params=991CFE73D4DF553253D44E119219BF31366856FF4B15222634FE161157CF765B (accessed on 18 September 2021).

- Li, Z.X. Research and design of operating depth measurement apparatus for farm implement. Trans. Chin. Soc. Agric. Mach. 2000, 31, 8–91. [Google Scholar] [CrossRef]

- Nie, Y.H.; Kang, J.; He, J.H.; He, P.X.; Li, Q.R. Deep tillage automatically adjust the design and test of control system. J. Agric. Mech. Res. 2015, 2, 143–145. [Google Scholar] [CrossRef]

- Suomi, P.; Oksanen, T. Automatic working depth control for seed drill using ISO 11783 remote control messages. Comput. Electron. Agric. 2015, 116, 30–35. [Google Scholar] [CrossRef]

- Topcon Agriculture Releases Tillage Depth Control Powered by Norac. Available online: https://www.topconpositioning.com/insights/topcon-agriculture-releases-tillage-depth-control-powered-norac (accessed on 16 June 2021).

- John Deere 2633VT with TruSet™ Tillage Technology. Available online: https://www.deere.com/en/tillage/truset/ (accessed on 16 June 2021).

- CASE IH Tillage Tools Equipped with Advanced Farming System. Available online: https://www.caseih.com/northamerica/en-us/products/advanced-farming-systems/field-solutions/afs-soil-command (accessed on 18 June 2021).

- Chen, L.Q.; Li, Z.Q.; Yang, J.J.; Song, Y. Lateral Stability Control of Four-Wheel-Drive Electric Vehicle Based on Coordinated Control of Torque Distribution and ESP Differential Braking. Actuators 2021, 10, 135. [Google Scholar] [CrossRef]

- Zhang, Z.; Jia, X.H.; Yang, T.; Gu, Y.L.; Wang, W.W.; Chen, L.Q. Multi-objective optimization of lubricant volume in an ELSD considering thermal effects. Int. J. Thermal Sci. 2021, 164. [Google Scholar] [CrossRef]

- Nielsen, S.K.; Norremark, M.; Green, O. Sensor and control for consistent seed drill coulter depth. Comput. Electron. Agric. 2016, 127, 690–698. [Google Scholar] [CrossRef]

- Nielsen, S.K.; Munkholm, L.J.; Lamande, M.; Norremark, M.; Skou-Nielsen, N.; Edwards, G.T.C.; Green, O. Seed drill instrumentation for spatial coulter depth measurements. Comput. Electron. Agric. 2017, 141, 207–214. [Google Scholar] [CrossRef]

- China Machinery Industry Standards, 2015. Ministry of Industry and Information Technology of PR China. Specifications for Subsoiling Tillage. NT/T 2845–2015. Available online: https://www.docin.com/p-1652675474.html. (accessed on 10 June 2016).

- Yang, S.M.; Yang, Q.; Yang, Y.H.; Yang, S.C. An ultrasonic-based header height control system of the combine harvester. J. Agric. Mech. Res. 2008, 10, 134–137. [Google Scholar] [CrossRef]

- Mu, X.Y.; Zhao, Y.L.; Liu, K.; Ji, B.Y.; Guo, H.B.; Xue, Z.W.; Li, C.H. Responses of soil properties, root growth and crop yield to tillage and crop residue management in a wheat–maize cropping system on the North China Plain. Eur. J. Agron. 2016, 78, 32–43. [Google Scholar] [CrossRef]

- Celik, A.; Raper, R.L. Design and evaluation of ground-driven rotary subsoilers. Soil Tillage Res. 2012, 124, 203–210. [Google Scholar] [CrossRef]

| Type of Tillage Machine | Sensor Type for Tillage Depth Detection | With or without the Function of Automatically Adjusting Tillage Depth | Mechanism for Adjusting Tillage Depth | Adjustment Type |

|---|---|---|---|---|

| Single tillage machine [41] | Ultrasonic sensor | Without | / | / |

| Combined tillage machine [42] | Multi-sensor fusion | With | Hydraulic cylinder | Adjusting the tillage depth of a group of tillage components of the combined machine |

| Combined tillage machine [43] | Prescription map combined with stroke detection sensor | With | Hydraulic cylinder | Adjusting the tillage depth of a group of tillage components of the combined machine |

| H.Wark@cern.ch | H.Wark@cern.ch | |||

| Single tillage machine [34] | Rotary encoder | Without | / | / |

| Single tillage machine [39] | Potentiometer | Without | / | / |

| Single tillage machine [32] | Potentiometer | With | Stepping motor | Adjusting the tillage depth of the whole machine |

| Single tillage machine [35] | Ultrasonic sensor combined with displacement sensor | Without | / | / |

| Single tillage machine (this study) | Ultrasonic sensor | With | Hydraulic cylinder | Adjusting the tillage depth of each subsoiling shovel independently |

| At Forward Speed of 3 km/h | Errors (%) | At Forward Speed of 4 km/h | Errors (%) | At Forward Speed of 5 km/h | Errors (%) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Mean Tillage Depth Obtained by Sensor (mm) | Mean Tillage Depth Measured Manually (mm) | Mean Tillage Depth Obtained by Sensor (mm) | Mean Tillage Depth Measured Manually (mm) | Mean Tillage Depth Obtained by Sensor (mm) | Mean Tillage Depth Measured Manually (mm) | ||||

| First row | 417.09 | 387.04 | 7.8 | 385.65 | 354.98 | 8.6 | 381.70 | 352.23 | 8.4 |

| Second row | 402.48 | 372.05 | 8.2 | 400.92 | 371.55 | 7.9 | 402.48 | 370.39 | 8.7 |

| Third row | 396.40 | 365.62 | 8.4 | 421.37 | 389.22 | 8.3 | 427.61 | 397.79 | 7.5 |

| Fourth row | 379.31 | 348.13 | 9.0 | 429.10 | 398.81 | 7.6 | 370.06 | 339.78 | 8.9 |

| Mean | 8.35 | 8.1 | 8.38 | ||||||

| Coefficient of Tillage Depth Stability (%) | 5.0 km/h | ||

|---|---|---|---|

| 3.0 km/h | 4.0 km/h | ||

| First row | 97.1 | 97.6 | 91.0 |

| Second row | 97.9 | 97.6 | 96.2 |

| Third row | 97.4 | 98.4 | 97.4 |

| Mean | 97.5 | 97.9 | 94. 9 |

| Fourth row | 97.7 | 91.5 | 97.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lou, S.; He, J.; Lu, C.; Liu, P.; Li, H.; Zhang, Z. A Tillage Depth Monitoring and Control System for the Independent Adjustment of Each Subsoiling Shovel. Actuators 2021, 10, 250. https://doi.org/10.3390/act10100250

Lou S, He J, Lu C, Liu P, Li H, Zhang Z. A Tillage Depth Monitoring and Control System for the Independent Adjustment of Each Subsoiling Shovel. Actuators. 2021; 10(10):250. https://doi.org/10.3390/act10100250

Chicago/Turabian StyleLou, Shangyi, Jin He, Caiyun Lu, Peng Liu, Hui Li, and Zhenguo Zhang. 2021. "A Tillage Depth Monitoring and Control System for the Independent Adjustment of Each Subsoiling Shovel" Actuators 10, no. 10: 250. https://doi.org/10.3390/act10100250

APA StyleLou, S., He, J., Lu, C., Liu, P., Li, H., & Zhang, Z. (2021). A Tillage Depth Monitoring and Control System for the Independent Adjustment of Each Subsoiling Shovel. Actuators, 10(10), 250. https://doi.org/10.3390/act10100250