A Review of Cooperative Actuator and Sensor Systems Based on Dielectric Elastomer Transducers

Abstract

:1. Introduction

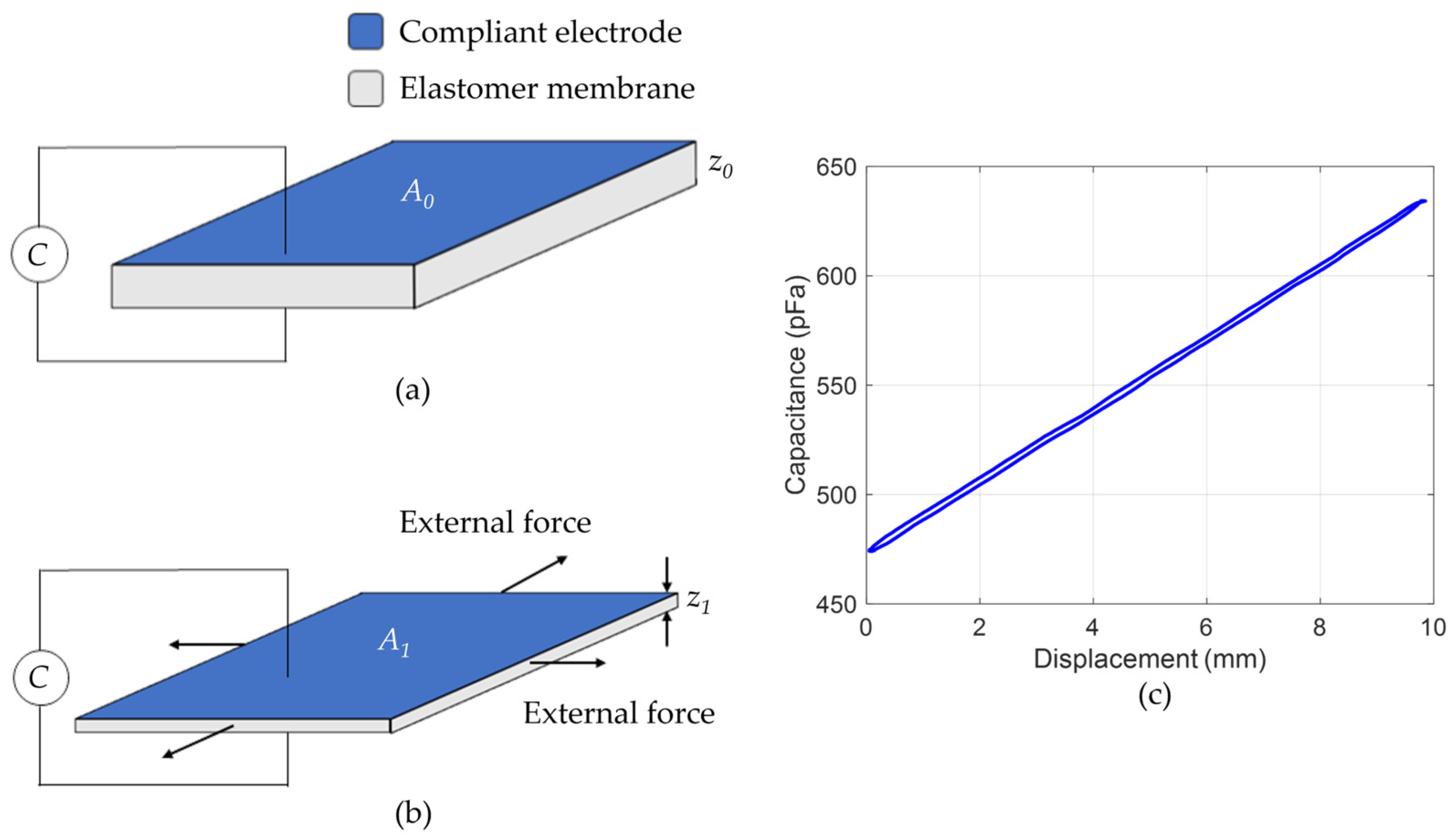

2. Dielectric Elastomer Transducers

2.1. Dielectric Elastomer Material and Operating Principle

2.2. Dielectric Elastomer Actuators Configurations

3. Dielectric Elastomer Applications in Cooperative Actuator and Sensor Systems

3.1. Towards Meso- and Micro-Scale Dielectric Elastomer Actuators

3.2. Cooperative Dielectric Elastomer Actuators

3.2.1. One-Dimensional Arrays

3.2.2. Cooperative Bio-Inspired Robots

3.2.3. Two-Dimensional Arrays for Out-of-Plane Actuation

3.2.4. Two-Dimensional Arrays for in-Plane Actuation

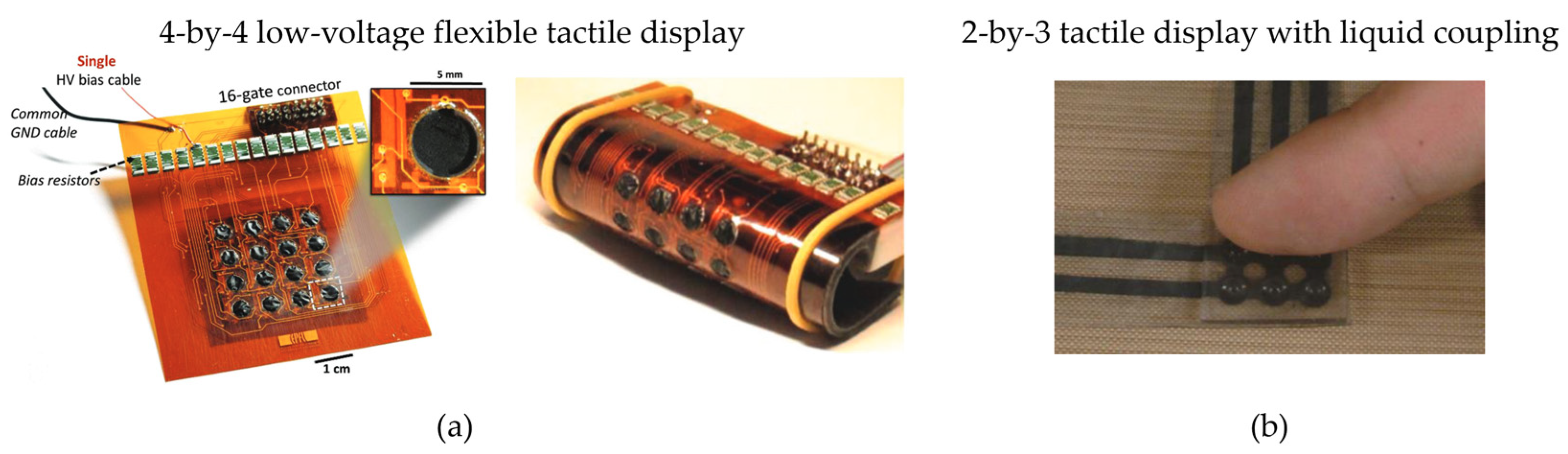

3.2.5. Two-Dimensional Arrays for Haptics and Wearables

3.2.6. Two-Dimensional Arrays for Refreshable Braille Displays

3.2.7. Three-Dimensional Reconfigurable Structures

3.3. Cooperative Dielectric Elastomer Sensors

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Butenko, S.; Murphey, R.; Pardalos, P.M. Cooperative Control: Models, Applications and Algorithms; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- Wilson, S.A.; Jourdain, R.P.J.; Zhang, Q.; Dorey, R.A.; Bowen, C.R.; Willander, M.; Wahab, Q.U.; Willander, M.; Al-hilli, S.M.; Nur, O.; et al. New materials for micro-scale sensors and actuators: An engineering review. Mater. Sci. Eng. R Rep. 2007, 56, 1–129. [Google Scholar] [CrossRef] [Green Version]

- Gao, J.; Xiao, Y.; Liu, J.; Liang, W.; Chen, C.L.P. A survey of communication/networking in Smart Grids. Futur. Gener. Comput. Syst. 2012, 28, 391–404. [Google Scholar] [CrossRef]

- Chen, F.; Ren, W. On the Control of Multi-Agent Systems: A Survey. Found. Trends® Syst. Control 2019, 6, 339–499. [Google Scholar] [CrossRef]

- Vaccaro, A.; Velotto, G.; Zobaa, A.F. A Decentralized and Cooperative Architecture for Optimal Voltage Regulation in Smart Grids. IEEE Trans. Ind. Electron. 2011, 58, 4593–4602. [Google Scholar] [CrossRef]

- Patwari, N.; Ash, J.N.; Kyperountas, S.; Hero, A.O.; Moses, R.L.; Correal, N.S. Locating the nodes: Cooperative localization in wireless sensor networks. IEEE Signal Process. Mag. 2005, 22, 54–69. [Google Scholar] [CrossRef]

- Lee, J.; Park, B. Development and Evaluation of a Cooperative Vehicle Intersection Control Algorithm Under the Connected Vehicles Environment. IEEE Trans. Intell. Transp. Syst. 2012, 13, 81–90. [Google Scholar] [CrossRef]

- Khamis, A.; Hussein, A.; Elmogy, A. Multi-Robot Task Allocation: A Review of the State-of-the-Art; Springer: Cham, Switzerland, 2015; pp. 31–51. [Google Scholar]

- Chandler, P.R.; Swaroop, D.; Howlett, J.K.; Pachter, M.; Fowler, J.M. Complexity in UAV Cooperative Control. In Proceedings of the 2002 American Control Conference, Anchorage, AK, USA, 8–10 May 2002; pp. 1831–1836. [Google Scholar]

- Laurent, G.J.; Delettre, A.; Zeggari, R.; Yahiaoui, R.; Manceau, J.-F.; Le Fort-Piat, N. Micropositioning and Fast Transport Using a Contactless Micro-Conveyor. Micromachines 2014, 5, 66–80. [Google Scholar] [CrossRef] [Green Version]

- Petit, L.; Hassine, A.; Terrien, J.; Lamarque, F.; Prelle, C. Development of a Control Module for a Digital Electromagnetic Actuators Array. IEEE Trans. Ind. Electron. 2014, 61, 4788–4796. [Google Scholar] [CrossRef]

- Ataka, M.; Legrand, B.; Buchaillot, L.; Collard, D.; Fujita, H. Design, Fabrication, and Operation of Two-Dimensional Conveyance System with Ciliary Actuator Arrays. IEEE/ASME Trans. Mechatron. 2009, 14, 119–125. [Google Scholar] [CrossRef]

- Konishi, S.; Fujita, H. A conveyance system using air flow based on the concept of distributed micro motion systems. J. Microelectromech. Syst. 1994, 3, 54–58. [Google Scholar] [CrossRef]

- Luntz, J.E.; Messner, W.; Choset, H. Distributed Manipulation Using Discrete Actuator Arrays. Int. J. Robot. Res. 2001, 20, 553–583. [Google Scholar] [CrossRef]

- Yahiaoui, R.; Zeggari, R.; Malapert, J.; Manceau, J.-F. A MEMS-based pneumatic micro-conveyor for planar micromanipulation. Mechatronics 2012, 22, 515–521. [Google Scholar] [CrossRef]

- Berlin, A.; Biegelsen, D.; Cheung, P.; Fromherz, M.; Goldberg, D.; Jackson, W.; Preas, B.; Reich, J.; Swartz, L.-E. Motion Control of Planar Objects Using Large-Area Arrays of Mems-Like Distributed Manipulators. Micromechatronics 2000, 1–5. [Google Scholar]

- Vandelli, N.; Wroblewski, D.; Velonis, M.; Bifano, T. Development of a MEMS Microvalve Array for Fluid Flow Control. J. Microelectromech. Syst. 1998, 7, 395–403. [Google Scholar] [CrossRef]

- Tellers, M.C.; Pulskamp, J.S.; Bedair, S.S.; Rudy, R.Q.; Kierzewski, I.M.; Polcawich, R.G.; Bergbreiter, S.E. Piezoelectric actuator array for motion-enabled reconfigurable RF circuits. In Proceedings of the 2015 Transducers-2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (Transducers), Anchorage, AK, USA, 21–25 June 2015; pp. 819–822. [Google Scholar] [CrossRef]

- El-Baz, D.; Piranda, B.; Bourgeois, J. A Distributed Algorithm for a Reconfigurable Modular Surface. In Proceedings of the 2014 IEEE International Parallel & Distributed Processing Symposium Workshops, Phoenix, AZ, USA, 19–23 May 2014; pp. 1591–1598. [Google Scholar] [CrossRef] [Green Version]

- Bourgeois, J.; Goldstein, S.C. Distributed Intelligent MEMS: Progresses and Perspectives. IEEE Syst. J. 2015, 9, 1057–1068. [Google Scholar] [CrossRef] [Green Version]

- Boutoustous, K.; Laurent, G.J.; Dedu, E.; Matignon, L.; Bourgeois, J.; Le Fort-Piat, N. Distributed Control Architecture for Smart Surfaces. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010; pp. 2018–2024. [Google Scholar]

- Konishi, S.; Fujita, H. System design for cooperative control of a microactuator array. IEEE Trans. Ind. Electron. 1995, 42, 449–454. [Google Scholar] [CrossRef]

- Matignon, L.; Laurent, G.J.; Le Fort-Piat, N.; Chapuis, Y.-A. Designing Decentralized Controllers for Distributed-Air-Jet MEMS-Based Micromanipulators by Reinforcement Learning. J. Intell. Robot. Syst. 2010, 59, 145–166. [Google Scholar] [CrossRef] [Green Version]

- Fukuta, Y.; Chapuis, Y.-A.; Mita, Y.; Fujita, H. Design, Fabrication, and Control of MEMS-Based Actuator Arrays for Air-Flow Distributed Micromanipulation. J. Microelectromech. Syst. 2006, 15, 912–926. [Google Scholar] [CrossRef]

- Amato, M.; De Vittorio, M.; Petroni, S. Advanced MEMS Technologies for Tactile Sensing and Actuation. MEMS Fundam. Technol. Appl. 2013, 351–380. [Google Scholar]

- Chouvardas, V.G.; Miliou, A.N.; Hatalis, M.K. Tactile Display Applications: A State of the Art Survey. In Proceedings of the 2nd Balkan Conference in Informatics, Ohrid, Macedon, 26–28 September 2005; pp. 290–303. [Google Scholar]

- Velázquez, R. Wearable Assistive Devices for the Blind. In Wearable and Autonomous Biomedical Devices and Systems for Smart Environment; Springer: Berlin/Heidelberg, Germany, 2010; pp. 331–349. [Google Scholar]

- Wilhelm, E.; Schwarz, T.; Jaworek, G.; Voigt, A.; Rapp, B.E. Towards Displaying Graphics on a Cheap, Large-Scale Braille Display; Springer: Cham, Switzerland, 2014; pp. 662–669. [Google Scholar]

- Munasinghe, K.C.; Bowatta, B.G.C.T.; Abayarathne, H.Y.R.; Kumararathna, N.; Maduwantha, L.K.A.H.; Arachchige, N.M.P.; Amarasinghe, Y.W.R. New MEMS based micro gripper using SMA for micro level object manipulation and assembling. In Proceedings of the 2016 Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, 5–6 April 2016; pp. 36–41. [Google Scholar]

- Kornbluh, R.D.; Pelrine, R.; Prahlad, H.; Heydt, R. Electroactive Polymers: An Emerging Technology for MEMS; Janson, S.W., Henning, A.K., Eds.; International Society for Optics and Photonics: Bellingham, WA, USA, 2004; Volume 5344, pp. 13–27. [Google Scholar]

- Liu, H.; Jui Tay, C.; Quan, C.; Kobayashi, T.; Lee, C. Piezoelectric MEMS Energy Harvester for Low-Frequency Vibrations With Wideband Operation Range and Steadily Increased Output Power. Artic. J. Microelectromech. Syst. 2011, 20, 1131–1142. [Google Scholar] [CrossRef]

- Dhanalakshmi, K. Demonstration of self-sensing in Shape Memory Alloy actuated gripper. In Proceedings of the IEEE International Symposium on Intelligent Control (ISIC), Hyderabad, India, 28–30 August 2013; pp. 218–222. [Google Scholar]

- Islam, M.N.; Seethaler, R.J. Sensorless Position Control for Piezoelectric Actuators Using A Hybrid Position Observer. IEEE/ASME Trans. Mechatron. 2014, 19, 667–675. [Google Scholar] [CrossRef]

- Rizzello, G.; Naso, D.; York, A.; Seelecke, S. A Self-Sensing Approach for Dielectric Elastomer Actuators Based on Online Estimation Algorithms. IEEE/ASME Trans. Mechatron. 2017, 22, 728–738. [Google Scholar] [CrossRef]

- Mineta, T.; Yanatori, H.; Hiyoshi, K.; Tsuji, K.; Ono, Y.; Abe, K. Tactile display MEMS device with SU8 micro-pin and spring on SMA film actuator array. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; pp. 2031–2034. [Google Scholar]

- Hishinuma, Y.; Yang, E.-H. Piezoelectric Unimorph Microactuator Arrays for Single-Crystal Silicon Continuous-Membrane Deformable Mirror. J. Microelectromech. Syst. 2006, 15, 370–379. [Google Scholar] [CrossRef]

- Besse, N.; Zarate, J.J.; Rosset, S.; Shea, H.R. Flexible haptic display with 768 independently controllable shape memory polymers taxels. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; pp. 323–326. [Google Scholar]

- Richter, A.; Paschew, G. Optoelectrothermic Control of Highly Integrated Polymer-Based MEMS Applied in an Artificial Skin. Adv. Mater. 2009, 21, 979–983. [Google Scholar] [CrossRef]

- Carpi, F.; De Rossi, D.; Kornbluh, R.; Pelrine, R.E.; Sommer-Larsen, P. Dielectric Elastomers as Electromechanical Transducers: Fundamentals, Materials, Devices, Models and Applications of an Emerging Electroactive Polymer Technology; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Hill, M.; Rizzello, G.; Seelecke, S. Development and Experimental Characterization of a Pneumatic Valve Actuated by a Dielectric Elastomer Membrane. Smart Mater. Struct. 2017, 26, 085023. [Google Scholar] [CrossRef]

- Loverich, J.J.; Kanno, I.; Kotera, H. Concepts for a new class of all-polymer micropumps. Lab Chip 2006, 6, 1147–1154. [Google Scholar] [CrossRef]

- Gu, G.-Y.; Zhu, J.; Zhu, L.-M.; Zhu, X. A survey on dielectric elastomer actuators for soft robots. Bioinspir. Biomim. 2017, 12, 011003. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Liu, L.; Liu, Y.; Leng, J. Review of Dielectric Elastomer Actuators and their Applications in Soft Robots. Adv. Intell. Syst. 2021, 3, 2000282. [Google Scholar] [CrossRef]

- Huang, B.; Li, M.; Mei, T.; McCoul, D.; Qin, S.; Zhao, Z.; Zhao, J. Wearable stretch sensors for motion measurement of the wrist joint based on dielectric elastomers. Sensors 2017, 17, 2708. [Google Scholar] [CrossRef] [Green Version]

- Kelley, C.R.; Kauffman, J.L. Towards wearable tremor suppression using dielectric elastomer stack actuators. Smart Mater. Struct. 2020, 30, 025006. [Google Scholar] [CrossRef]

- Kovacs, G.; Lochmatter, P.; Wissler, M. An arm wrestling robot driven by dielectric elastomer actuators. Smart Mater. Struct. 2007, 16, S306–S317. [Google Scholar] [CrossRef]

- Pelrine, R.; Kornbluh, R.D.; Pei, Q.; Stanford, S.; Oh, S.; Eckerle, J.; Full, R.J.; Rosenthal, M.A.; Meijer, K. Smart Structures and Materials. In Proceedings of the SPIE’S 9th Annual International Symposium on Smart Structures and Materials, San Diego, CA, USA, 17–21 March 2002; Volume 4695, pp. 126–137. [Google Scholar]

- Wang, N.F.; Cui, C.Y.; Guo, H.; Chen, B.C.; Zhang, X.M. Advances in dielectric elastomer actuation technology. Sci. China Technol. Sci. 2018, 61, 1512–1527. [Google Scholar] [CrossRef]

- Balakrisnan, B.; Smela, E. Challenges in the Microfabrication of Dielectric Elastomer Actuators; Bar-Cohen, Y., Ed.; International Society for Optics and Photonics: Bellingham, WA, USA, 2010; Volume 7642, pp. 141–150. [Google Scholar]

- Patrick, L.; Gabor, K.; Silvain, M. Characterization of dielectric elastomer actuators based on a hyperelastic film model. Sens. Actuators A Phys. 2007, 135, 748–757. [Google Scholar] [CrossRef]

- York, A.; Dunn, J.; Seelecke, S. Experimental characterization of the hysteretic and rate-dependent electromechanical behavior of dielectric electro-active polymer actuators. Smart Mater. Struct. 2010, 19, 094014. [Google Scholar] [CrossRef]

- Kaltseis, R.; Keplinger, C.; Koh, S.J.A.; Baumgartner, R.; Goh, Y.F.; Ng, W.H.; Kogler, A.; Tröls, A.; Foo, C.C.; Suo, Z.; et al. Natural rubber for sustainable high-power electrical energy generation. RSC Adv. 2014, 4, 27905–27913. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Agostini, L.; Moretti, G.; Fontana, M.; Vertechy, R. Dielectric elastomer materials for large-strain actuation and energy harvesting: A comparison between styrenic rubber, natural rubber and acrylic elastomer. Smart Mater. Struct. 2019, 28, 114001. [Google Scholar] [CrossRef]

- Chen, T.; Qiu, J.; Zhu, K.; Li, J. Electro-mechanical performance of polyurethane dielectric elastomer flexible micro-actuator composite modified with titanium dioxide-graphene hybrid fillers. Mater. Des. 2016, 90, 1069–1076. [Google Scholar] [CrossRef]

- Fasolt, B.; Hodgins, M.; Rizzello, G.; Seelecke, S. Effect of screen printing parameters on sensor and actuator performance of dielectric elastomer (DE) membranes. Sens. Actuators A Phys. 2017, 265, 10–19. [Google Scholar] [CrossRef]

- Rosset, S.; Shea, H.R. Flexible and stretchable electrodes for dielectric elastomer actuators. Appl. Phys. A 2012, 110, 281–307. [Google Scholar] [CrossRef] [Green Version]

- Röntgen, W.C. Ueber die durch Electricität bewirkten Form- und Volumenänderungen von dielectrischen Körpern. Ann. Der Phys. Und Chem. 1880, 247, 771–786. [Google Scholar] [CrossRef]

- Pelrine, R.; Kornbluh, R.; Joseph, J. Electrostriction of polymer dielectrics with compliant electrodes as a means of actuation. Sens. Actuators A Phys. 1998, 64, 77–85. [Google Scholar] [CrossRef]

- Carpi, F.; Anderson, I.; Bauer, S.; Frediani, G.; Gallone, G.; Gei, M.; Graaf, C.; Jean-Mistral, C.; Kaal, W.; Kofod, G.; et al. Standards for dielectric elastomer transducers. Smart Mater. Struct. 2015, 24, 105025. [Google Scholar] [CrossRef] [Green Version]

- Rizzello, G.; Loew, P.; Agostini, L.; Fontana, M.; Seelecke, S. A lumped parameter model for strip-shaped dielectric elastomer membrane transducers with arbitrary aspect ratio. Smart Mater. Struct. 2020, 29, 115030. [Google Scholar] [CrossRef]

- Shian, S.; Huang, J.; Zhu, S.; Clarke, D.R. Optimizing the Electrical Energy Conversion Cycle of Dielectric Elastomer Generators. Adv. Mater. 2014, 26, 6617–6621. [Google Scholar] [CrossRef]

- Michel, S.; Zhang, X.Q.; Wissler, M.; Löwe, C.; Kovacs, G. A comparison between silicone and acrylic elastomers as dielectric materials in electroactive polymer actuators. Polym. Int. 2009, 59, 391–399. [Google Scholar] [CrossRef]

- Chen, Y.; Agostini, L.; Moretti, G.; Berselli, G.; Fontana, M.; Vertechy, R. Fatigue life performances of silicone elastomer membranes for dielectric elastomer transducers: Preliminary results. In Proceedings of the SPIE-The International Society for Optical Engineering, Denver, CO, USA, 3–7 March 2019; Volume 10966, pp. 158–167. [Google Scholar]

- Youn, J.-H.; Jeong, S.M.; Hwang, G.; Kim, H.; Hyeon, K.; Park, J.; Kyung, K.-U. Dielectric Elastomer Actuator for Soft Robotics Applications and Challenges. Appl. Sci. 2020, 10, 640. [Google Scholar] [CrossRef] [Green Version]

- Pelrine, R.; Kornbluh, R.; Joseph, J.; Heydt, R.; Pei, Q.; Chiba, S. High-field deformation of elastomeric dielectrics for actuators. Mater. Sci. Eng. C 2000, 11, 89–100. [Google Scholar] [CrossRef]

- Romasanta, L.J.; Lopez-Manchado, M.A.; Verdejo, R. Increasing the performance of dielectric elastomer actuators: A review from the materials perspective. Prog. Polym. Sci. 2015, 51, 188–211. [Google Scholar] [CrossRef] [Green Version]

- Hodgins, M.; Seelecke, S. Systematic experimental study of pure shear type dielectric elastomer membranes with different electrode and film thicknesses. Smart Mater. Struct. 2016, 25, 095001. [Google Scholar] [CrossRef]

- Schlatter, S.; Rosset, S.; Shea, H. Inkjet Printing of Carbon Black Electrodes for Dielectric Elastomer Actuators. In SPIE Electroactive Polymer Actuators and Devices; SPIE: Bellingham, WA, USA, 2017; Volume 10163, pp. 177–185. [Google Scholar]

- Klug, F.; Solano-Arana, S.; Hoffmann, N.J.; Schlaak, H.F. Multilayer dielectric elastomer tubular transducers for soft robotic applications. Smart Mater. Struct. 2019, 28, 104004. [Google Scholar] [CrossRef]

- Hubertus, J.; Neu, J.; Croce, S.; Rizzello, G.; Seelecke, S.; Schultes, G. Nanoscale Nickel-Based Thin Films as Highly Conductive Electrodes for Dielectric Elastomer Applications with Extremely High Stretchability up to 200%. ACS Appl. Mater. Interfaces 2021, 13, 39894–39904. [Google Scholar] [CrossRef] [PubMed]

- Hubertus, J.; Croce, S.; Neu, J.; Rizzello, G.; Seelecke, S.; Schultes, G. Electromechanical characterization and laser structuring of Ni-based sputtered metallic compliant electrodes for DE applications. In Proceedings of the International Conference and Exhibition on New Actuator Systems and Applications, online, 17–19 February 2021; pp. 321–324. [Google Scholar]

- Jung, K.; Kim, K.J.; Choi, H.R. A self-sensing dielectric elastomer actuator. Sens. Actuators A Phys. 2008, 143, 343–351. [Google Scholar] [CrossRef]

- Gisby, T.A.; O’Brien, B.M.; Anderson, I.A. Self sensing feedback for dielectric elastomer actuators. Appl. Phys. Lett. 2013, 102, 193703. [Google Scholar] [CrossRef]

- Hoffstadt, T.; Griese, M.; Maas, J. Online identification algorithms for integrated dielectric electroactive polymer sensors and self-sensing concepts. Smart Mater. Struct. 2014, 23, 104007. [Google Scholar] [CrossRef]

- Rizzello, G.; Fugaro, F.; Naso, D.; Seelecke, S. Simultaneous Self-Sensing of Displacement and Force for Soft Dielectric Elastomer Actuators. IEEE Robot. Autom. Lett. 2018, 3, 1230–1236. [Google Scholar] [CrossRef]

- Rizzello, G.; Naso, D.; York, A.; Seelecke, S. Closed loop control of dielectric elastomer actuators based on self-sensing displacement feedback. Smart Mater. Struct. 2016, 25, 035034. [Google Scholar] [CrossRef]

- Hoffstadt, T.; Maas, J. Sensorless force control for dielectric elastomer transducers. J. Intell. Mater. Syst. Struct. 2018, 30, 1419–1434. [Google Scholar] [CrossRef]

- Rizzello, G.; Serafino, P.; Naso, D.; Seelecke, S. Towards Sensorless Soft Robotics: Self-Sensing Stiffness Control of Dielectric Elastomer Actuators. IEEE Trans. Robot. 2020, 36, 174–188. [Google Scholar] [CrossRef]

- Gatti, D.; Haus, H.; Matysek, M.; Frohnapfel, B.; Tropea, C.; Schlaak, H.F. The dielectric breakdown limit of silicone dielectric elastomer actuators. Appl. Phys. Lett. 2014, 104, 052905. [Google Scholar] [CrossRef] [Green Version]

- Fasolt, B.; Welsch, F.; Jank, M.; Seelecke, S. Effect of actuation parameters and environment on the breakdown voltage of silicone dielectric elastomer films. Smart Mater. Struct. 2019, 28, 094002. [Google Scholar] [CrossRef]

- Suo, Z. Theory of dielectric elastomers. Acta Mech. Solida Sin. 2010, 23, 549–578. [Google Scholar] [CrossRef]

- Croce, S.; Neu, J.; Moretti, G.; Hubertus, J.; Schultes, G.; Rizzello, G. Finite element modeling and validation of a soft array of spatially coupled dielectric elastomer transducers. Smart Mater. Struct. 2022, 31, 084001. [Google Scholar] [CrossRef]

- Hajiesmaili, E.; Clarke, D.R. Dielectric elastomer actuators. J. Appl. Phys. 2021, 129, 151102. [Google Scholar] [CrossRef]

- Kovacs, G.; Düring, L.; Michel, S.; Terrasi, G. Stacked dielectric elastomer actuator for tensile force transmission. Sens. Actuators A Phys. 2009, 155, 299–307. [Google Scholar] [CrossRef]

- Maas, J.; Tepel, D.; Hoffstadt, T. Actuator design and automated manufacturing process for DEAP-based multilayer stack-actuators. Meccanica 2015, 50, 2839–2854. [Google Scholar] [CrossRef]

- Hau, S.; Bruch, D.; Rizzello, G.; Motzki, P.; Seelecke, S. Silicone based dielectric elastomer strip actuators coupled with nonlinear biasing elements for large actuation strains. Smart Mater. Struct. 2018, 27, 074003. [Google Scholar] [CrossRef]

- Kwak, J.W.; Chi, H.J.:; Jung, K.M.; Koo, J.C.; Jeon, J.W.; Lee, Y.; Nam, J.-D.; Ryew, Y.; Choi, H.-R. A Face Robot Actuated With Artificial Muscle Based on Dielectric Elastomer. J. Mech. Sci. Technol. 2005, 19, 578–588. [Google Scholar] [CrossRef]

- Kunze, J.; Prechtl, J.; Bruch, D.; Fasolt, B.; Nalbach, S.; Motzki, P.; Seelecke, S.; Rizzello, G. Design, Manufacturing, and Characterization of Thin, Core-Free, Rolled Dielectric Elastomer Actuators. Actuators 2021, 10, 69. [Google Scholar] [CrossRef]

- Rajamani, A.; Grissom, M.; Rahn, C.; Ma, Y.; Zhang, Q. Wound roll dielectric elastomer actuators: Fabrication, analysis and experiments. In Proceedings of the 2005 IEEE/RSJ International Conference on Intelligent Robots and Systems, IROS, Edmonton, AB, Canada, 2–6 August 2005; Volume 13, pp. 2587–2592. [Google Scholar]

- Moretti, G.; Sarina, L.; Agostini, L.; Vertechy, R.; Berselli, G.; Fontana, M. Styrenic-rubber dielectric elastomer actuator with inherent stiffness compensation. Actuators 2020, 9, 44. [Google Scholar] [CrossRef]

- Follador, M.; Cianchetti, M.; Mazzolai, B. Design of a compact bistable mechanism based on dielectric elastomer actuators. Meccanica 2015, 50, 2741–2749. [Google Scholar] [CrossRef]

- Berselli, G.; Vertechy, R.; Vassura, G.; Parenti-Castelli, V. Optimal Synthesis of Conically Shaped Dielectric Elastomer Linear Actuators: Design Methodology and Experimental Validation. IEEE/ASME Trans. Mechatron. 2011, 16, 67–79. [Google Scholar] [CrossRef]

- Rizzello, G.; Hodgins, M.; Naso, D.; York, A.; Seelecke, S. Modeling of the effects of the electrical dynamics on the electromechanical response of a DEAP circular actuator with a mass-spring load. Smart Mater. Struct. 2015, 24, 094003. [Google Scholar] [CrossRef]

- Nalbach, S.; Banda, R.M.; Croce, S.; Rizzello, G.; Naso, D.; Seelecke, S. Modeling and Design Optimization of a Rotational Soft Robotic System Driven by Double Cone Dielectric Elastomer Actuators. Front. Robot. AI 2020, 6, 150. [Google Scholar] [CrossRef] [PubMed]

- Cao, C.; Chen, L.; Li, B.; Chen, G.; Nie, Z.; Wang, L.; Gao, X. Toward broad optimal output bandwidth dielectric elastomer actuators. Sci. China Technol. Sci. 2022, 65, 1137–1148. [Google Scholar] [CrossRef]

- Kofod, G.; Wirges, W.; Paajanen, M.; Bauer, S. Energy minimization for self-organized structure formation and actuation. Appl. Phys. Lett. 2007, 90, 081916. [Google Scholar] [CrossRef]

- McGough, K.; Ahmed, S.; Frecker, M.; Ounaies, Z. Finite element analysis and validation of dielectric elastomer actuators used for active origami. Smart Mater. Struct. 2014, 23, 094002. [Google Scholar] [CrossRef]

- Hau, S.; Rizzello, G.; Seelecke, S. A novel dielectric elastomer membrane actuator concept for high-force applications. Extrem. Mech. Lett. 2018, 23, 24–28. [Google Scholar] [CrossRef]

- Hodgins, M.; York, A.; Seelecke, S. Experimental comparison of bias elements for out-of-plane DEAP actuator system. Smart Mater. Struct. 2013, 22, 094016. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, J. Artificial muscles for jaw movements. Extrem. Mech. Lett. 2016, 6, 88–95. [Google Scholar] [CrossRef]

- Zhang, R.; Lochmatter, P.; Kunz, A.; Kovacs, G. Spring roll dielectric elastomer actuators for a portable force feedback glove. In Proceedings of the Smart Structures and Materials 2006: Electroactive Polymer Actuators and Devices (EAPAD), San Diego, CA, USA, 26 February–2 March 2006; Volume 6168, pp. 505–516. [Google Scholar]

- He, T.; Cui, L.; Chen, C.; Suo, Z. Nonlinear deformation analysis of a dielectric elastomer membrane–spring system. Smart Mater. Struct. 2010, 19, 085017. [Google Scholar] [CrossRef]

- Keplinger, C.; Li, T.; Baumgartner, R.; Suo, Z.; Bauer, S. Harnessing snap-through instability in soft dielectrics to achieve giant voltage-triggered deformation. Soft Matter 2012, 8, 285. [Google Scholar] [CrossRef]

- Li, T.; Keplinger, C.; Baumgartner, R.; Bauer, S.; Yang, W.; Suo, Z. Giant voltage-induced deformation in dielectric elastomers near the verge of snap-through instability. J. Mech. Phys. Solids 2013, 61, 611–628. [Google Scholar] [CrossRef]

- Jordi, C.; Michel, S.; Kovacs, G.; Ermanni, P. Scaling of planar dielectric elastomer actuators in an agonist-antagonist configuration. Sens. Actuators A Phys. 2010, 161, 182–190. [Google Scholar] [CrossRef]

- Carpi, F.; Frediani, G.; De Rossi, D. Hydrostatically Coupled Dielectric Elastomer Actuators. IEEE/ASME Trans. Mechatron. 2010, 15, 308–315. [Google Scholar] [CrossRef]

- Loew, P.; Rizzello, G.; Seelecke, S. A novel biasing mechanism for circular out-of-plane dielectric actuators based on permanent magnets. Mechatronics 2018, 56, 48–57. [Google Scholar] [CrossRef]

- Cao, C.; Chen, L.; Hill, T.L.; Wang, L.; Gao, X. Exploiting Bistability for High-Performance Dielectric Elastomer Resonators. IEEE/ASME Trans. Mechatron. 2022, 27, 5994–6005. [Google Scholar] [CrossRef]

- Neu, J.; Hubertus, J.; Croce, S.; Schultes, G.; Seelecke, S.; Rizzello, G. Fully Polymeric Domes as High-Stroke Biasing System for Soft Dielectric Elastomer Actuators. Front. Robot. AI 2021, 8, 695918. [Google Scholar] [CrossRef]

- Dubois, P.; Rosset, S.; Koster, S.; Stauffer, J.; Mikhaïlovc, S.; Dadras, M.; de Rooij, N.-F.; Shea, H. Microactuators based on ion implanted dielectric electroactive polymer (EAP) membranes. Sens. Actuators A Phys. 2006, 131, 147–154. [Google Scholar] [CrossRef] [Green Version]

- Marette, A.; Poulin, A.; Besse, N.; Rosset, S.; Briand, D.; Shea, H. Thin Film Transistors: Flexible Zinc-Tin Oxide Thin Film Transistors Operating at 1 kV for Integrated Switching of Dielectric Elastomer Actuators Arrays. Adv. Mater. 2017, 29, 1700880. [Google Scholar] [CrossRef]

- Poulin, A.; Rosset, S.; Shea, H. Fully printed 3 microns thick dielectric elastomer actuator. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, Las Vegas, NV, USA, 20–24 March 2016; Volume 9798, pp. 36–46. [Google Scholar]

- Lotz, P.; Matysek, M.; Schlaak, H.F. Fabrication and Application of Miniaturized Dielectric Elastomer Stack Actuators. IEEE/ASME Trans. Mechatron. 2011, 16, 58–66. [Google Scholar] [CrossRef]

- Wang, K.; Ouyang, G.; Chen, X.; Jakobsen, H. Engineering Electroactive Dielectric Elastomers for Miniature Electromechanical Transducers. Polym. Rev. 2017, 57, 369–396. [Google Scholar] [CrossRef]

- Carpi, F.; Frediani, G.; Turco, S.; De Rossi, D. Bioinspired Tunable Lens with Muscle-Like Electroactive Elastomers. Adv. Funct. Mater. 2011, 21, 4152–4158. [Google Scholar] [CrossRef]

- Carpi, F.; Frediani, G.; Tarantino, S.; De Rossi, D. Millimetre-scale bubble-like dielectric elastomer actuators. Polym. Int. 2009, 59, 407–414. [Google Scholar] [CrossRef]

- Kim, U.; Kang, J.; Lee, C.; Kwon, H.Y.; Hwang, S.; Moon, H.; Koo, J.C.; Nam, J.-D.; Hong, B.H.; Choi, J.-B.; et al. A transparent and stretchable graphene-based actuator for tactile display. Nanotechnology 2013, 24, 145501. [Google Scholar] [CrossRef]

- Hau, S.; Rizzello, G.; Hodgins, M.; York, A.; Seelecke, S. Design and control of a high-speed positioning system based on dielectric elastomer membrane actuators. IEEE/ASME Trans. Mechatron. 2017, 22, 1259–1267. [Google Scholar] [CrossRef]

- Soulimane, S.; Pinon, S.; Shih, W.P.; Camon, H. Dielectric Elastomer Micro Actuator Made In Micromachining Technology: Finite Element Modelling and Deformation Measurement. Procedia Eng. 2011, 25, 479–482. [Google Scholar] [CrossRef] [Green Version]

- Pimpin, A.; Suzuki, Y.; Kasagi, N. Microelectrostrictive actuator with large out-of-plane deformation for flow-control application. J. Microelectromech. Syst. 2007, 16, 753–764. [Google Scholar] [CrossRef]

- Murray, C.; McCoul, D.; Sollier, E.; Ruggiero, T.; Niu, X.; Pei, Q.; Di Carlo, D. Electro-adaptive microfluidics for active tuning of channel geometry using polymer actuators. Microfluid. Nanofluidics 2013, 14, 345–358. [Google Scholar] [CrossRef]

- Tanaka, Y.; Fujikawa, T.; Kazoe, Y.; Kitamori, T. An active valve incorporated into a microchip using a high strain electroactive polymer. Sens. Actuators B Chem. 2013, 184, 163–169. [Google Scholar] [CrossRef]

- Mohd Ghazali, F.A.; Mah, C.K.; AbuZaiter, A.; Chee, P.S.; Mohamed Ali, M.S. Soft dielectric elastomer actuator micropump. Sens. Actuators A Phys. 2017, 263, 276–284. [Google Scholar] [CrossRef]

- Ren, Z.; Kim, S.; Ji, X.; Zhu, W.; Niroui, F.; Kong, J.; Chen, Y. A High-Lift Micro-Aerial-Robot Powered by Low-Voltage and Long-Endurance Dielectric Elastomer Actuators. Adv. Mater. 2022, 34, 2106757. [Google Scholar] [CrossRef]

- Rosset, S.; Niklaus, M.; Dubois, P.; Shea, H.R. Mechanical characterization of a dielectric elastomer microactuator with ion-implanted electrodes. Sens. Actuators A Phys. 2008, 144, 185–193. [Google Scholar] [CrossRef] [Green Version]

- Poulin, A.; Rosset, S.; Shea, H.R. Printing low-voltage dielectric elastomer actuators. Appl. Phys. Lett. 2015, 107, 244104. [Google Scholar] [CrossRef]

- Neu, J.; Croce, S.; Willian, T.; Hubertus, J.; Schultes, G.; Seelecke, S.; Rizzello, G. Distributed Electro-Mechanical Coupling Effects in a Dielectric Elastomer Membrane Array. Exp. Mech. 2022, 63, 79–95. [Google Scholar] [CrossRef]

- Yu, X.; Lu, Z.; Cui, F.; Cheng, L.; Cui, Y. Tunable acoustic metamaterial with an array of resonators actuated by dielectric elastomer. Extrem. Mech. Lett. 2017, 12, 37–40. [Google Scholar] [CrossRef] [Green Version]

- Ji, X.; Liu, X.; Cacucciolo, V.; Civet, Y.; El Haitami, A.; Cantin, S.; Perriard, Y.; Shea, H. Untethered Feel-Through Haptics Using 18-µm Thick Dielectric Elastomer Actuators. Adv. Funct. Mater. 2021, 31, 2006639. [Google Scholar] [CrossRef]

- Solano-Arana, S.; Klug, F.; Mößinger, H.; Förster-Zügel, F.; Schlaak, H.F. A novel application of dielectric stack actuators: A pumping micromixer. Smart Mater. Struct. 2018, 27, 074008. [Google Scholar] [CrossRef]

- Schlatter, S.; Grasso, G.; Rosset, S.; Shea, H. Inkjet Printing of Complex Soft Machines with Densely Integrated Electrostatic Actuators. Adv. Intell. Syst. 2020, 2, 2000136. [Google Scholar] [CrossRef]

- O’Brien, B.; Gisby, T.; Calius, E.; Xie, S.; Anderson, I. FEA of Dielectric Elastomer Minimum Energy Structures as a Tool for Biomimetic Design. In SPIE Electroactive Polymer Actuators and Devices; SPIE: Bellingham, WA, USA, 2009; Volume 7287, pp. 61–71. [Google Scholar]

- Dai, B.; Li, S.; Xu, T.; Wang, Y.; Zhang, F.; Gu, Z.; Wang, S. Artificial Asymmetric Cilia Array of Dielectric Elastomer for Cargo Transportation. ACS Appl. Mater. Interfaces 2018, 10, 42979–42984. [Google Scholar] [CrossRef]

- Zhao, J.; Niu, J.; Liu, L.; Yu, J. A Soft Creeping Robot Actuated by Dielectric Elastomer. In SPIE Electroactive Polymer Actuators and Devices; SPIE: Bellingham, WA, USA, 2014; Volume 9056, pp. 40–45. [Google Scholar]

- Lu, X.J.; Wang, K.; Hu, T.T. Development of an annelid-like peristaltic crawling soft robot using dielectric elastomer actuators. Bioinspir. Biomim. 2020, 15, 046012. [Google Scholar] [CrossRef] [PubMed]

- Li, W.B.; Zhang, W.M.; Zou, H.X.; Peng, Z.K.; Meng, G. Multisegment annular dielectric elastomer actuators for soft robots. Smart Mater. Struct. 2018, 27, 115024. [Google Scholar] [CrossRef]

- Pfeil, S.; Henke, M.; Katzer, K.; Zimmermann, M.; Gerlach, G. A Worm-Like Biomimetic Crawling Robot Based on Cylindrical Dielectric Elastomer Actuators. Front. Robot. AI 2020, 7, 9. [Google Scholar] [CrossRef]

- Henke, E.-F.M.; Schlatter, S.; Anderson, I.A. Soft Dielectric Elastomer Oscillators Driving Bioinspired Robots. Soft Robot. 2017, 4, 353–366. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nguyen, C.T.; Phung, H.; Nguyen, T.D.; Jung, H.; Choi, H.R. Multiple-degrees-of-freedom dielectric elastomer actuators for soft printable hexapod robot. Sens. Actuators A Phys. 2017, 267, 505–516. [Google Scholar] [CrossRef]

- Chen, F.; Cao, J.; Zhang, H.; Wang, M.Y.; Zhu, J.; Zhang, Y.F. Programmable Deformations of Networked Inflated Dielectric Elastomer Actuators. IEEE/ASME Trans. Mechatron. 2019, 24, 45–55. [Google Scholar] [CrossRef]

- Hajiesmaili, E.; Clarke, D.R. Optically addressable dielectric elastomer actuator arrays using embedded percolative networks of zinc oxide nanowires. Mater. Horiz. 2022, 9, 3110–3117. [Google Scholar] [CrossRef]

- Wang, L.; Hayakawa, T.; Ishikawa, M. Dielectric-elastomer-based fabrication method for varifocal microlens array. Opt. Express 2017, 25, 31708. [Google Scholar] [CrossRef]

- Burugupally, S.P.; Koppolu, B.; Danesh, N.; Lee, Y.; Indeewari, V.; Li, B. Enhancing the performance of dielectric elastomer actuators through the approach of distributed electrode array with fractal interconnects architecture. J. Micromech. Microeng. 2021, 31, 064002. [Google Scholar] [CrossRef]

- Yang, W.-P.; Chen, L.-W.; McGough, K.; Ahmed, S. The tunable acoustic band gaps of two-dimensional phononic crystals with a dielectricelastomer cylindrical actuator. Smart Mater. Struct. 2007, 17, 015011. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, J.; Hong, J.; Wang, M.Y. Dielectric Elastomer Actuators for Soft Wave-Handling Systems. Soft Robot. 2017, 4, 61–69. [Google Scholar] [CrossRef]

- Akbari, S.; Shea, H.R. Microfabrication and characterization of an array of dielectric elastomer actuators generating uniaxial strain to stretch individual cells. J. Micromech. Microeng. 2012, 22, 045020. [Google Scholar] [CrossRef]

- Akbari, S.; Shea, H.R. An array of 100 m × 100 m dielectric elastomer actuators with 80% strain for tissue engineering applications. Sens. Actuators A 2012, 186, 236–241. [Google Scholar] [CrossRef] [Green Version]

- Matysek, M.; Lotz, P.; Winterstein, T.; Schlaak, H.F. Dielectric elastomer actuators for tactile displays. In Proceedings of the World Haptics 2009-Third Joint EuroHaptics conference and Symposium on Haptic Interfaces for Virtual Environment and Teleoperator Systems, Online, 18–20 March 2009; pp. 290–295. [Google Scholar]

- Phung, H.; Hoang, P.T.; Jung, H.; Nguyen, T.D.; Nguyen, C.T.; Choi, H.R. Haptic Display Responsive to Touch Driven by Soft Actuator and Soft Sensor. IEEE/ASME Trans. Mechatron. 2021, 26, 2495–2505. [Google Scholar] [CrossRef]

- Lee, H.S.; Phung, H.; Lee, D.-H.; Kim, U.K.; Nguyen, C.T.; Moon, H.; Koo, J.C.; Choi, H.R. Design analysis and fabrication of arrayed tactile display based on dielectric elastomer actuator. Sens. Actuators A Phys. 2014, 205, 191–198. [Google Scholar] [CrossRef]

- Lee, D.-Y.; Jeong, S.H.; Cohen, A.J.; Vogt, D.M.; Kollosche, M.; Lansberry, G.; Mengüç, Y.; Israr, A.; Clarke, D.R.; Wood, R.J. A Wearable Textile-Embedded Dielectric Elastomer Actuator Haptic Display. Soft Robot. 2022, 9, 1186–1197. [Google Scholar] [CrossRef]

- Zhao, H.; Hussain, A.M.; Israr, A.; Vogt, D.M.; Duduta, M.; Clarke, D.R.; Wood, R.J. A Wearable Soft Haptic Communicator Based on Dielectric Elastomer Actuators. Soft Robot. 2020, 7, 451–461. [Google Scholar] [CrossRef]

- Chakraborti, P.; Toprakci, H.A.K.; Yang, P.; Di Spigna, N.; Franzon, P.; Ghosh, T. A compact dielectric elastomer tubular actuator for refreshable Braille displays. Sens. Actuators A Phys. 2012, 179, 151–157. [Google Scholar] [CrossRef]

- Qu, X.; Ma, X.; Shi, B.; Li, H.; Zheng, L.; Wang, C.; Liu, Z.; Fan, Y.; Chen, X.; Li, Z.; et al. Refreshable Braille Display System Based on Triboelectric Nanogenerator and Dielectric Elastomer. Adv. Funct. Mater. 2020, 31, 2006612. [Google Scholar] [CrossRef]

- Frediani, G.; Busfield, J.; Carpi, F. Enabling portable multiple-line refreshable Braille displays with electroactive elastomers. Med. Eng. Phys. 2018, 60, 86–93. [Google Scholar] [CrossRef]

- Pang, W.; Cheng, X.; Zhao, H.; Guo, X.; Ji, Z.; Li, G.; Liang, Y.; Xue, Z.; Song, H.; Zhang, F.; et al. Electro-mechanically controlled assembly of reconfigurable 3D mesostructures and electronic devices based on dielectric elastomer platforms. Natl. Sci. Rev. 2020, 7, 342–354. [Google Scholar] [CrossRef]

- Sun, Y.; Li, D.; Wu, M.; Yang, Y.; Su, J.; Wong, T.; Xu, K.; Li, Y.; Li, L.; Yu, X.; et al. Origami-inspired folding assembly of dielectric elastomers for programmable soft robots. Microsyst. Nanoeng. 2022, 8, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Aksoy, B.; Shea, H. Reconfigurable and Latchable Shape-Morphing Dielectric Elastomers Based on Local Stiffness Modulation. Adv. Funct. Mater. 2020, 30, 2001597. [Google Scholar] [CrossRef]

- Meng, J.; Qiu, Y.; Hou, C.; Zhang, Q.; Li, Y.; Wang, H. Bistable dielectric elastomer actuator with directional motion. Sens. Actuators A Phys. 2021, 330, 112889. [Google Scholar] [CrossRef]

- Xu, D.; Tairych, A.; Anderson, I.A. Where the rubber meets the hand: Unlocking the sensing potential of dielectric elastomers. J. Polym. Sci. Part B Polym. Phys. 2016, 54, 465–472. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, M.Y.; Li, J.; Zhu, J. A soft compressive sensor using dielectric elastomers. Smart Mater. Struct. 2016, 25, 035045. [Google Scholar] [CrossRef]

- Ham, J.; Huh, T.M.; Kim, J.; Kim, J.-O.; Park, S.; Cutkosky, M.R.; Bao, Z. Porous Dielectric Elastomer Based Flexible Multiaxial Tactile Sensor for Dexterous Robotic or Prosthetic Hands. Adv. Mater. Technol. 2022, in press. [CrossRef]

- Kadooka, K.; Imamura, H.; Taya, M. Tactile Sensor Integrated Dielectric Elastomer Actuator for Simultaneous Actuation and Sensing. In Electroactive Polymer Actuators and Devices; SPIE: Bellingham, WA, USA, 2016; Volume 9798, pp. 489–498. [Google Scholar]

- Zhu, Y.; Giffney, T.; Aw, K. A Dielectric Elastomer-Based Multimodal Capacitive Sensor. Sensors 2022, 22, 622. [Google Scholar] [CrossRef] [PubMed]

- Meyer, A.; Lenz, S.; Gratz-Kelly, S.; Motzki, P.; Nalbach, S.; Seelecke, S.; Rizzello, G. Experimental Characterization of a Smart Dielectric Elastomer Multi-Sensor Grid. In SPIE Electroactive Polymer Actuators and Devices (EAPAD) XXII; SPIE: Bellingham, WA, USA, 2020; Volume 11375, pp. 262–268. [Google Scholar]

- Lee, B.Y.; Kim, J.; Kim, H.; Kim, C.; Lee, S.D. Low-cost flexible pressure sensor based on dielectric elastomer film with micro-pores. Sens. Actuators A Phys. 2016, 240, 103–109. [Google Scholar] [CrossRef]

- Kwon, D.; Lee, T.-I.; Shim, J.; Ryu, S.; Kim, M.S.; Kim, S.; Kim, T.-S.; Park, I. Highly Sensitive, Flexible, and Wearable Pressure Sensor Based on a Giant Piezocapacitive Effect of Three-Dimensional Microporous Elastomeric Dielectric Layer. ACS Appl. Mater. Interfaces 2016, 8, 16922–16931. [Google Scholar] [CrossRef]

- Kyaw, A.K.K.; Loh, H.H.C.; Yan, F.; Xu, J. A polymer transistor array with a pressure-sensitive elastomer for electronic skin. J. Mater. Chem. C 2017, 5, 12039–12043. [Google Scholar] [CrossRef]

- Larson, C.; Spjut, J.; Knepper, R.; Shepherd, R. A Deformable Interface for Human Touch Recognition Using Stretchable Carbon Nanotube Dielectric Elastomer Sensors and Deep Neural Networks. Soft Robot. 2019, 6, 611–620. [Google Scholar] [CrossRef] [PubMed]

- Vishniakou, S.; Lewis, B.W.; Niu, X.; Kargar, A.; Sun, K.; Kalajian, M.; Park, N.; Yang, M.; Jing, Y.; Brochu, P.; et al. Tactile Feedback Display with Spatial and Temporal Resolutions. Sci. Rep. 2013, 3, 2521. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rizzello, G. A Review of Cooperative Actuator and Sensor Systems Based on Dielectric Elastomer Transducers. Actuators 2023, 12, 46. https://doi.org/10.3390/act12020046

Rizzello G. A Review of Cooperative Actuator and Sensor Systems Based on Dielectric Elastomer Transducers. Actuators. 2023; 12(2):46. https://doi.org/10.3390/act12020046

Chicago/Turabian StyleRizzello, Gianluca. 2023. "A Review of Cooperative Actuator and Sensor Systems Based on Dielectric Elastomer Transducers" Actuators 12, no. 2: 46. https://doi.org/10.3390/act12020046