A Reliable and Efficient I-f Startup Method of Sensorless Ultra-High-Speed SPMSM for Fuel Cell Air Compressors

Abstract

:1. Introduction

- (1)

- The speed convergence performance can be effectively improved by correcting the frequency of reference current vector adaptively based on not only the instantaneous active power but also the real-time motor torque, which reduces speed fluctuations distinctly.

- (2)

- The amplitude of reference current vector is compensated dynamically during speedup stage instead of during a constant speed stage, which is the basic requirement and distinctiveness for the UHS-SPMSM. Therefore, the reference startup torque can be reduced with improved efficiency under the premise of guaranteeing the startup rapidity.

- (3)

- The transition process to EMF-based sensorless FOC can be enhanced by designing a bandwidth-variable regulating scheme of speed loop PI controller, which achieves low transitional speed fluctuation. Moreover, the designed scheme can ensure high control stability over rated motor speed, compared with fixed-gain speed loop PI controller.

- (4)

- To the best of our knowledge, this is the first time that an innovative closed-loop I-f startup strategy is used for UHS-SPMSM startup, especially for driving fuel cell air compressors.

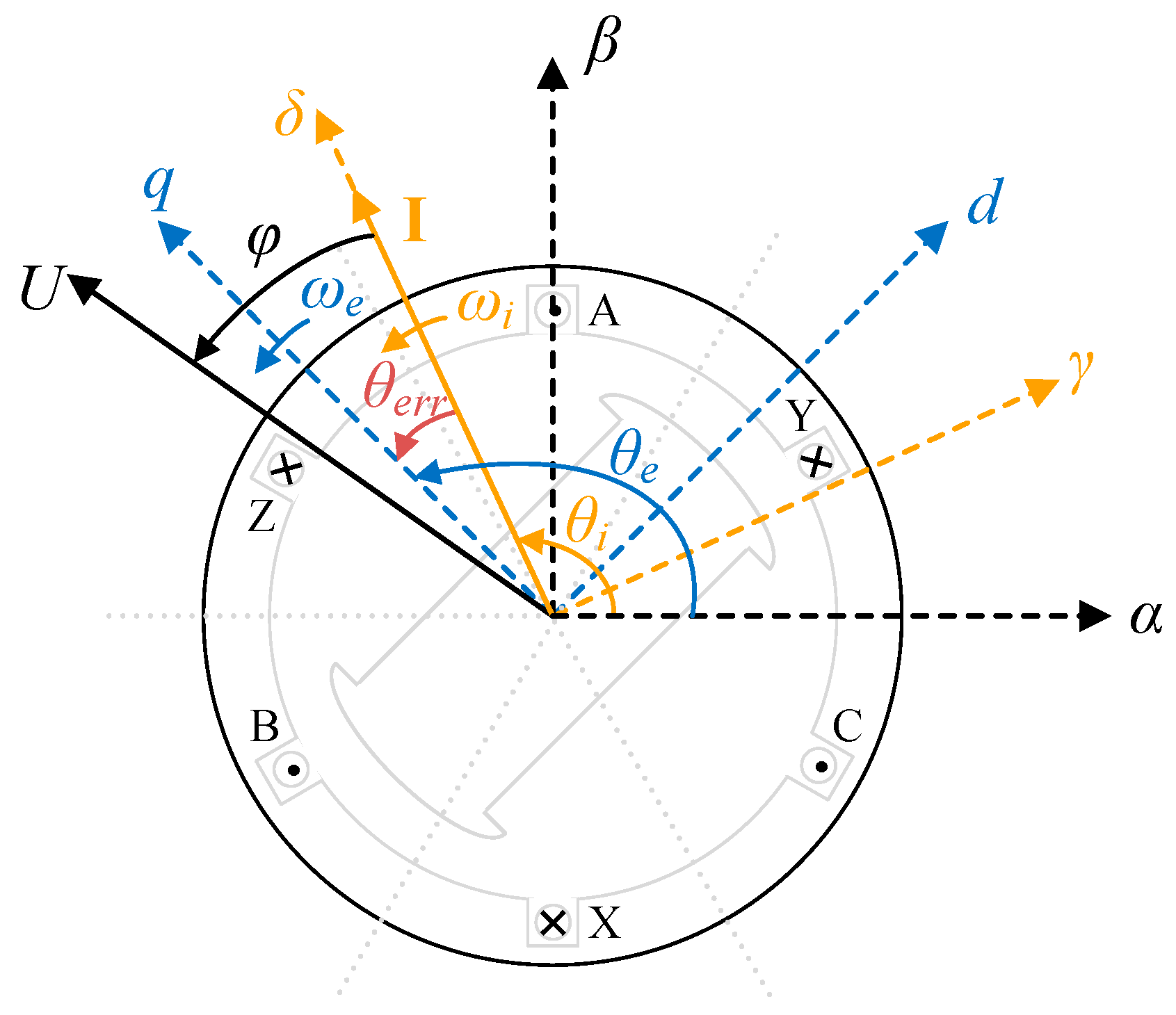

2. Mathematical UHS-SPMSM Model with I-f Control

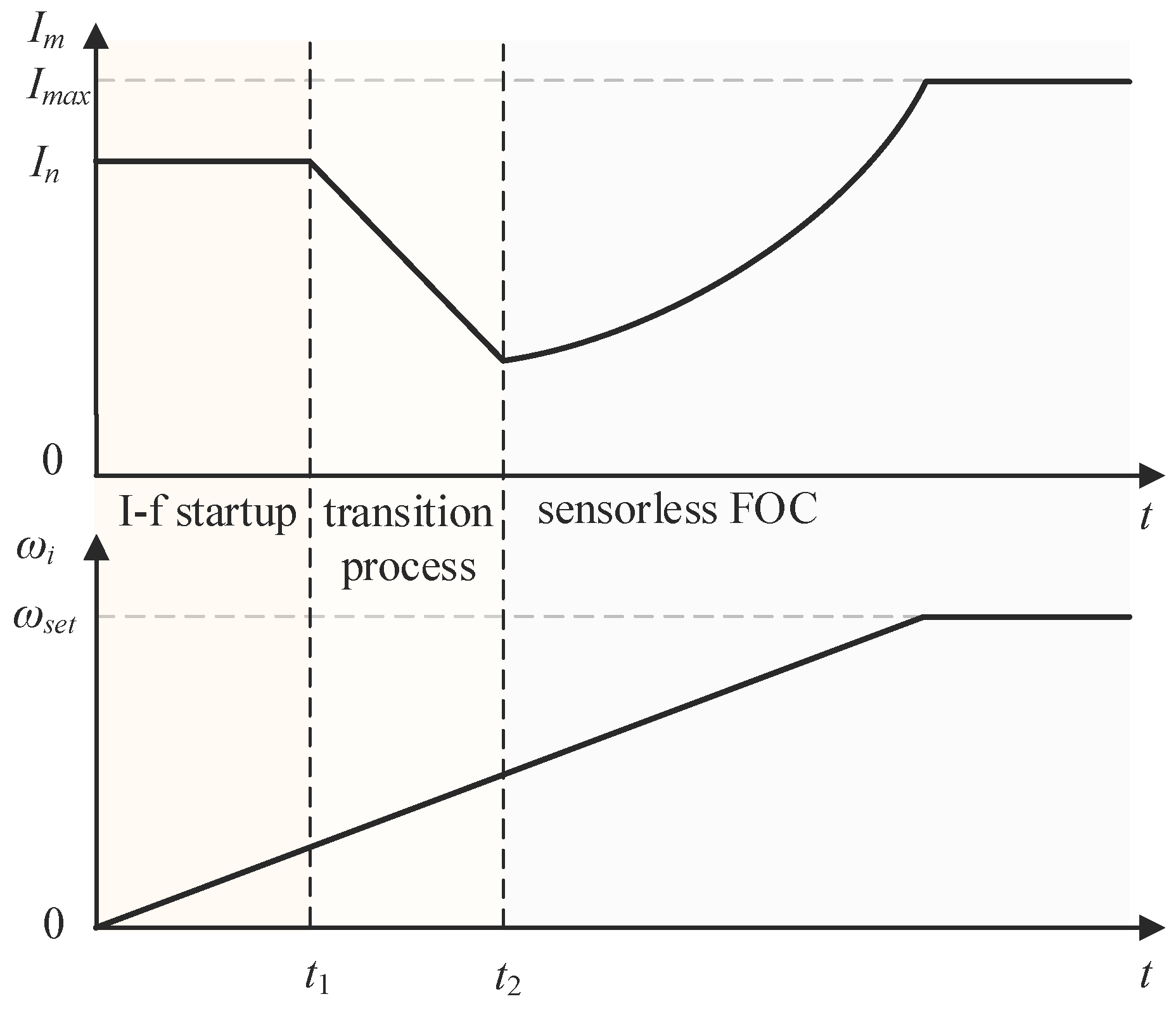

3. Conventional I-f Startup Method

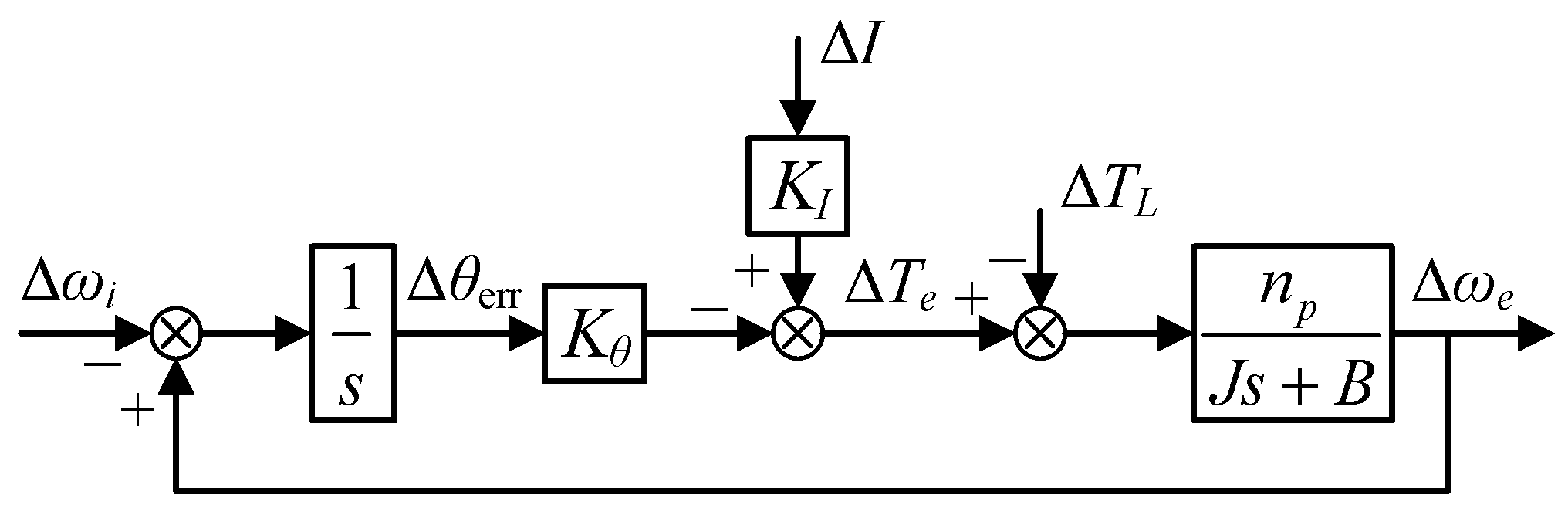

3.1. Inherent Speed Oscillation

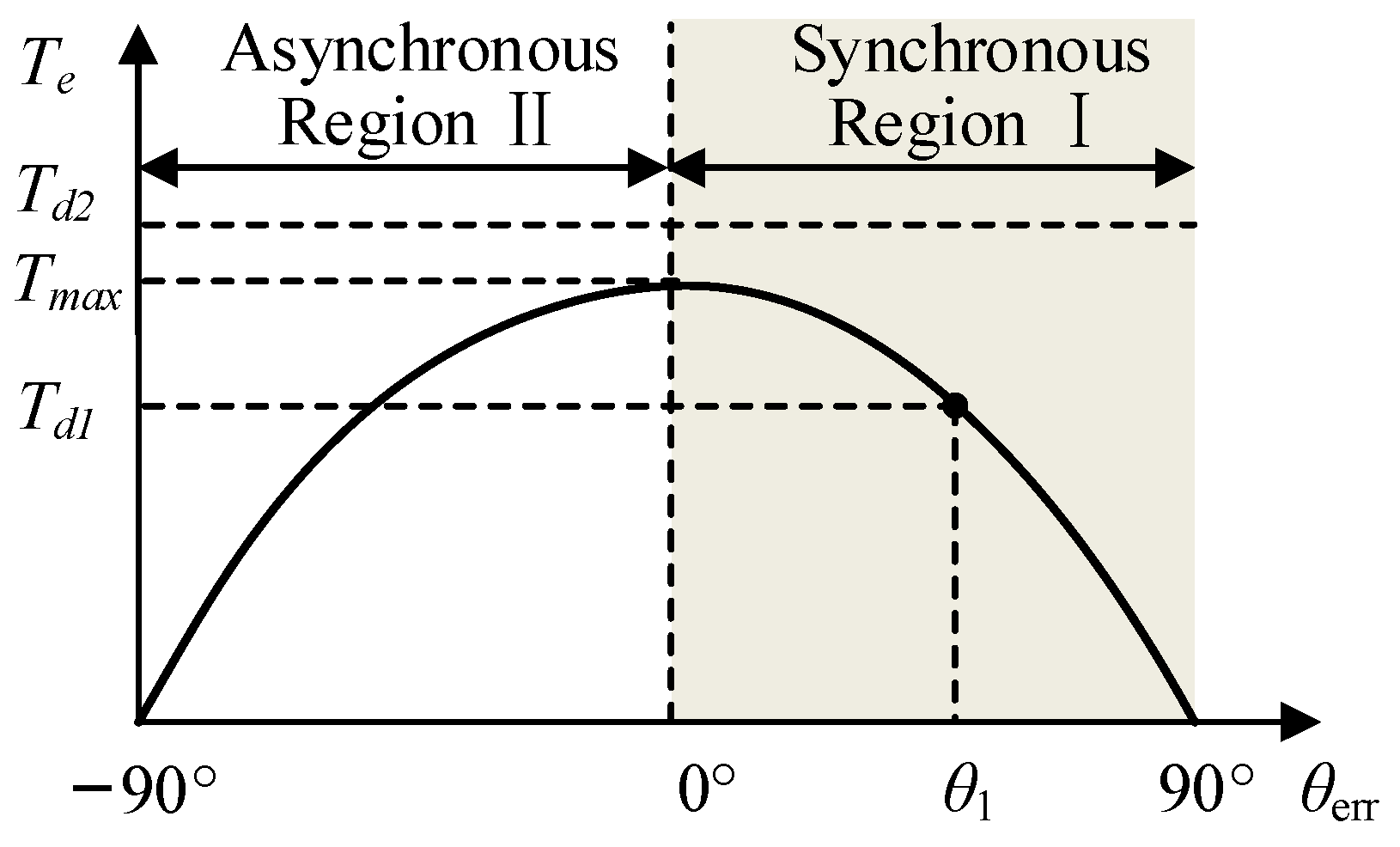

3.2. Prone Asynchronous Operation

4. Proposed Closed-Loop I–f Startup Method with Transition Enhancement

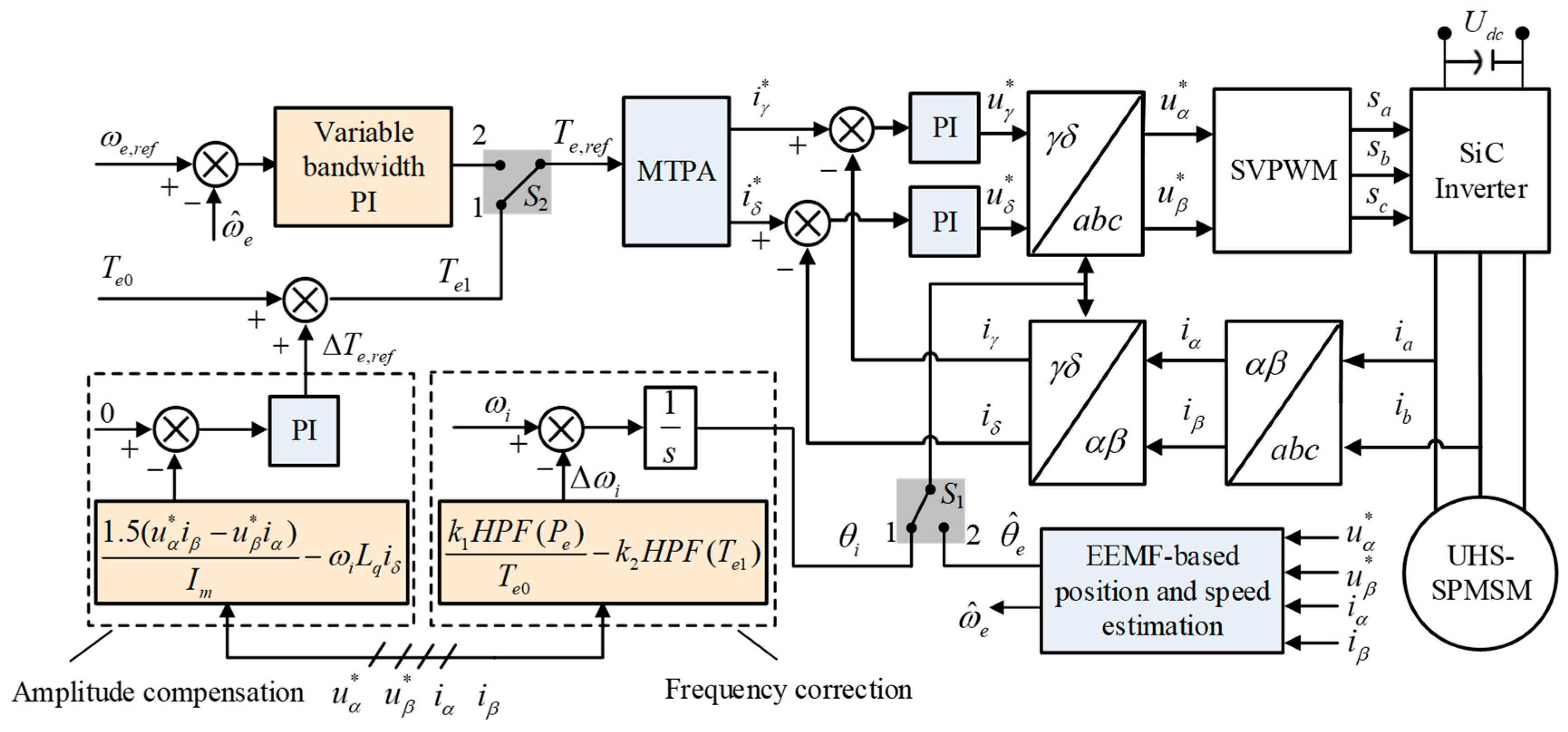

4.1. Frequency Correction Design

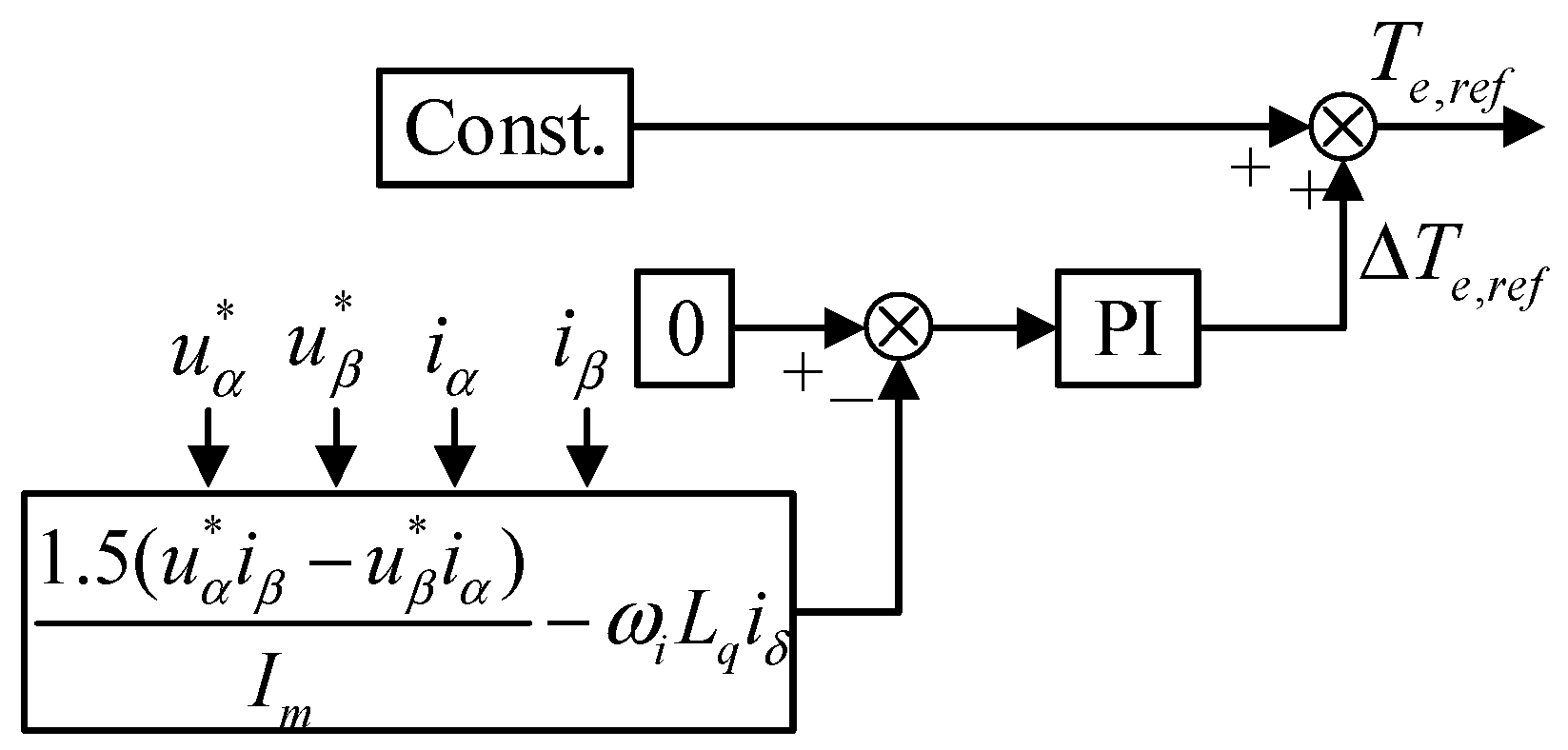

4.2. Amplitude Compensation Design

4.3. Sensorless Transition Enhancement

5. Experimental Results

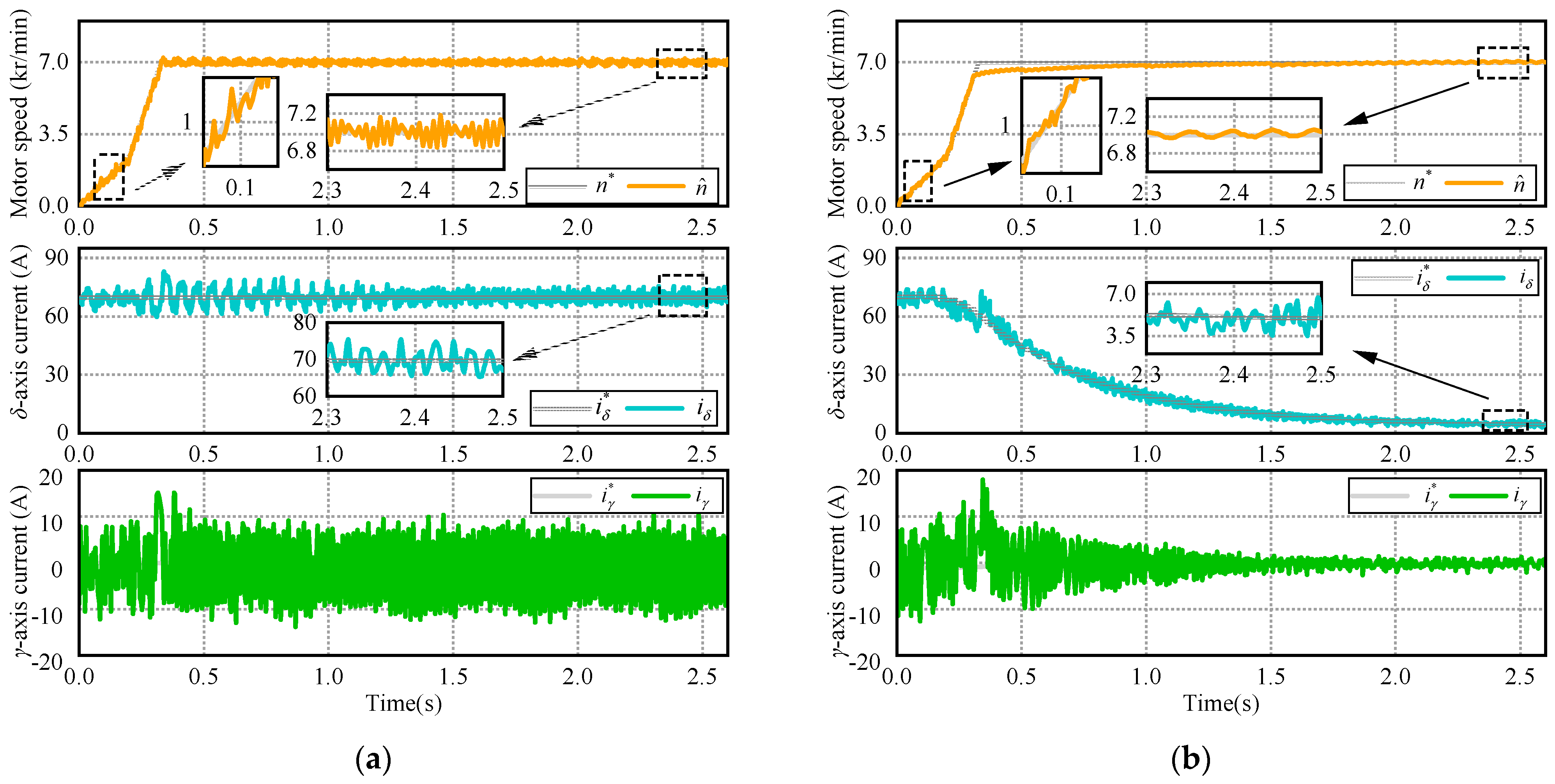

5.1. Startup Performance Comparison with Conventional I–f Startup Strategy

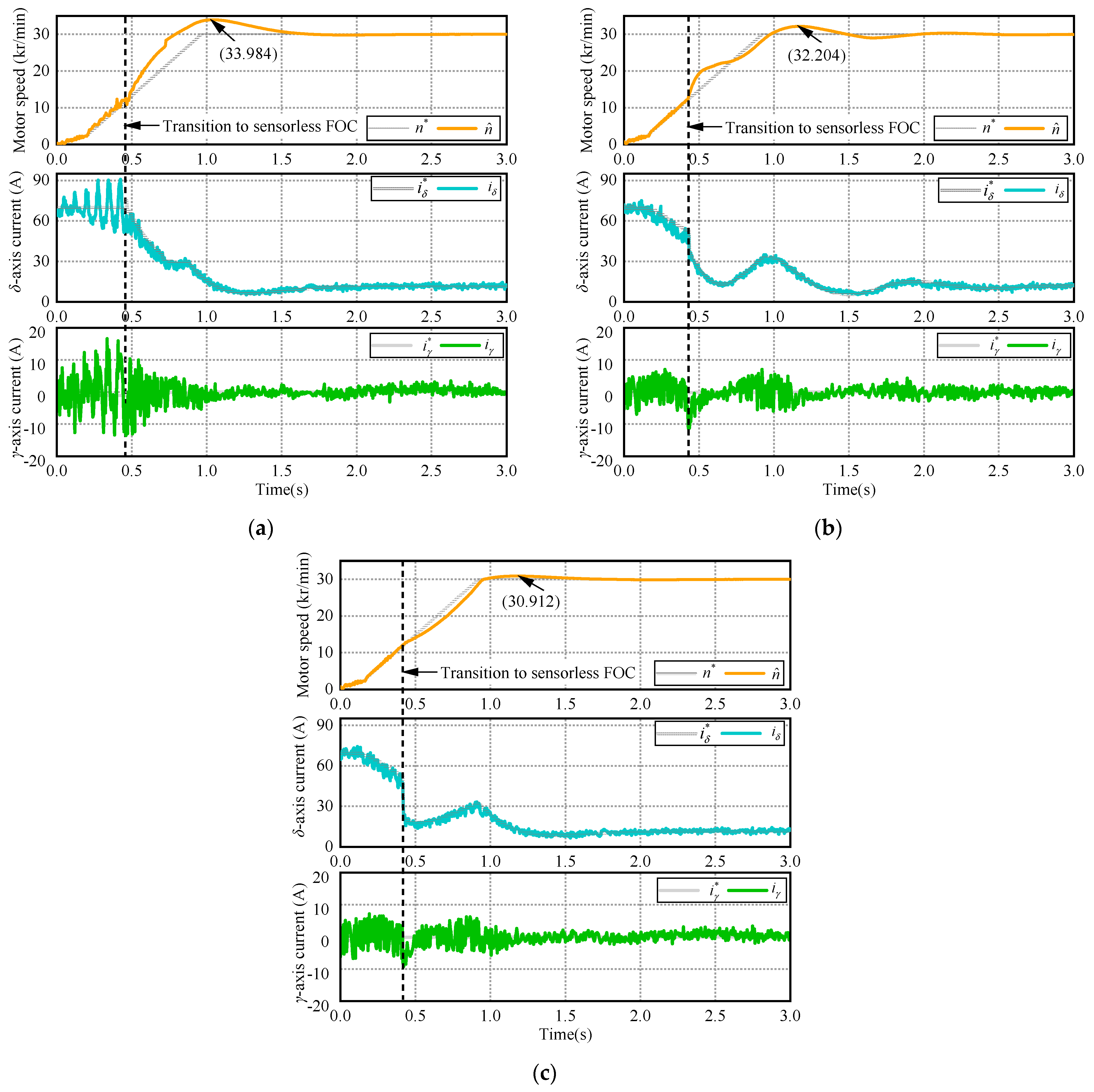

5.2. Transition Performance Comparison from I–f Startup to Sensorless FOC

6. Conclusions

- (1)

- During the speed up stage, the proposed frequency correction of reference current vector considering the active power and motor torque simultaneously, which reduces the speed oscillation significantly, while decreasing the possibility of startup failure.

- (2)

- The proposed amplitude compensator of reference current vector obviously reduces the current amplitude under the same startup condition, which ensures MTPA operation. This characteristic improves the motor efficiency significantly and prerequisites smoother transition from I-f startup to sensorless FOC due to minimizing the current vector angle.

- (3)

- After the transition to sensorless FOC with an enabling speed PI controller, the proposed variable bandwidth scheme ensures reduction of current amplitude and speed fluctuation, avoiding transition failure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.; Peng, F.; Huang, Y.; Yao, Y.; Zhu, Z. Online Inductance Identification Using PWM Current Ripple for Position Sensorless Drive of High-Speed Surface-Mounted Permanent Magnet Synchronous Machines. IEEE Trans. Ind. Electron. 2022, 69, 12426–12436. [Google Scholar] [CrossRef]

- Zhang, Q.; Yu, R.; Li, C.; Chen, Y.-H.; Gu, J. Servo Robust Control of Uncertain Mechanical Systems: Application in a Compressor/PMSM System. Actuators 2022, 11, 42. [Google Scholar] [CrossRef]

- Looser, A.; Kolar, J.W. An Active Magnetic Damper Concept for Stabilization of Gas Bearings in High-Speed Permanent-Magnet Machines. IEEE Trans. Ind. Electron. 2014, 61, 3089–3098. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, D.M.; Jung, Y.H.; Lim, M.S. Design of Ultra-High-Speed Motor for FCEV Air Compressor Considering Mechanical Properties of Rotor Materials. IEEE Trans. Energy Convers. 2021, 36, 2850–2860. [Google Scholar] [CrossRef]

- Xu, Y.; Lin, C.; Xing, J.; Li, X. Extended State Observer-Based Position Sensorless Control for Automotive Ultra-high-Speed PMSM. In Proceedings of the China SAE Congress 2022: Selected Papers; Springer: Singapore, 2023; pp. 787–799. [Google Scholar]

- Chi, W.-C.; Cheng, M.-Y. Implementation of a sliding-mode-based position sensorless drive for high-speed micro permanent-magnet synchronous motors. ISA Trans. 2014, 53, 444–453. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, D.; Kong, Q.; Sun, X.; Hu, Z. A super-high-speed PM motor drive for centrifugal air compressor used in fuel cell unmanned aerial vehicle. IET Electr. Power Appl. 2023, 17, 1459–1468. [Google Scholar] [CrossRef]

- Niedermayr, P.; Alberti, L.; Bolognani, S.; Abl, R. Implementation and Experimental Validation of Ultrahigh-Speed PMSM Sensorless Control by Means of Extended Kalman Filter. IEEE J. Emerging Sel. Top. Power Electron. 2022, 10, 3337–3344. [Google Scholar] [CrossRef]

- Hu, M.; Yu, W.; Lei, J.; Wu, Z.; Hua, W.; Hu, Y. Sensorless Control of a High-Speed PMSM with Rapid Acceleration for Air Compressors using a High-order Extended State Observer. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Virtual Conference, 10–14 October 2021; pp. 4781–4787. [Google Scholar]

- Du, B.; Wu, S.; Han, S.; Cui, S. Application of Linear Active Disturbance Rejection Controller for Sensorless Control of Internal Permanent-Magnet Synchronous Motor. IEEE Trans. Ind. Electron. 2016, 63, 3019–3027. [Google Scholar] [CrossRef]

- Griffo, A.; Drury, D.; Sawata, T.; Mellor, P.H. Sensorless starting of a wound-field synchronous starter/generator for aerospace applications. IEEE Trans. Ind. Electron. 2012, 59, 3579–3587. [Google Scholar] [CrossRef]

- Looser, A.; Tüysüz, A.; Zwyssig, C.; Kolar, J.W. Active Magnetic Damper for Ultrahigh-Speed Permanent-Magnet Machines with Gas Bearings. IEEE Trans. Ind. Electron. 2017, 64, 2982–2991. [Google Scholar] [CrossRef]

- Zhao, L.; Ham, C.H.; Han, Q.; Wu, T.X.; Zheng, L.; Sundaram, K.B.; Kapat, J.; Chow, L. Design of optimal digital controller for stable super-high-speed permanent-magnet synchronous motor. IEE Proc. Electr. Power Appl. 2006, 153, 213–218. [Google Scholar] [CrossRef]

- Ancuti, R.; Boldea, I.; Andreescu, G.-D. Sensorless V/f control of high-speed surface permanent magnet synchronous motor drives with two novel stabilising loops for fast dynamics and robustness. IET Electr. Power Appl. 2010, 4, 149–157. [Google Scholar] [CrossRef]

- Tang, Z.; Li, X.; Dusmez, S.; Akin, B. A New V/f-Based Sensorless MTPA Control for IPMSM Drives. IEEE Trans. Power Electron. 2016, 31, 4400–4415. [Google Scholar] [CrossRef]

- Datta, S.; Chandra, A.; Chowdhuri, S. High performance sensor-less V/f control of surface PMSM in voltage vector plane with ZVV injection and SMO-based position estimation method. Electr. Eng. 2022, 104, 657–666. [Google Scholar] [CrossRef]

- Xu, Y.; Lin, C.; Xing, J.; Zeng, Q.; Sun, J. I-f Starting Rapid and Smooth Transition Method of Full-Speed Sensorless Control for Low Current Harmonic Ultra-high-speed PMSM. In Proceedings of the 2022 IEEE Applied Power Electronics Conference and Exposition (APEC), Houston, TX, USA, 20–24 March 2022; pp. 1820–1826. [Google Scholar]

- Xing, J.; Qin, Z.; Lin, C.; Jiang, X. Research on Startup Process for Sensorless Control of PMSMs Based on I-F Method Combined with an Adaptive Compensator. IEEE Access 2020, 8, 70812–70821. [Google Scholar] [CrossRef]

- Haichao, F.; Boyang, S.; Lizhen, G. A closed-loop I/f vector control for permanent magnet synchronous motor. In Proceedings of the 2017 9th International Conference on Modelling, Identification and Control (ICMIC), Kunming, China, 10–12 July 2017; pp. 965–969. [Google Scholar]

- Xu, G.; Zhao, F.; Liu, T. I–f closed-loop starting strategy of high-speed PMSM based on current vector adaptive regulation. IET Power Electron. 2023, 16, 2724–2738. [Google Scholar] [CrossRef]

- Liu, J.; Nondahl, T.A.; Schmidt, P.B.; Royak, S.; Rowan, T.M. Generalized Stability Control for Open-Loop Operation of Motor Drives. IEEE Trans. Ind. Appl. 2017, 53, 2517–2525. [Google Scholar] [CrossRef]

- Liu, J.; Nondahl, T.A.; Dai, J.; Royak, S.; Schmidt, P.B. A Seamless Transition Scheme of Position Sensorless Control in Industrial Permanent Magnet Motor Drives with Output Filter and Transformer for Oil Pump Applications. IEEE Trans. Ind. Appl. 2020, 56, 2180–2189. [Google Scholar] [CrossRef]

- Yu, Y.; Chang, D.; Zheng, X.; Mi, Z.; Li, X.; Sun, C. A Stator Current Oriented Closed-Loop I--f Control of Sensorless SPMSM with Fully Unknown Parameters for Reverse Rotation Prevention. IEEE Trans. Power Electron. 2018, 33, 8607–8622. [Google Scholar] [CrossRef]

- Song, Z.; Yao, W.; Lee, K.; Li, W. An Efficient and Robust I-f Control of Sensorless IPMSM with Large Startup Torque Based on Current Vector Angle Controller. IEEE Trans. Power Electron. 2022, 37, 15308–15321. [Google Scholar] [CrossRef]

- Chen, D.; Lu, K.; Wang, D. An I-f Startup Method for Back-EMF based Sensorless FOC of PMSMs with Improved Stability During the Transition. In Proceedings of the 2020 International Symposium on Industrial Electronics and Applications (INDEL), Banja Luka, Bosnia and Herzegovina, 4–6 November 2020; pp. 1–6. [Google Scholar]

- Consoli, A.; Scelba, G.; Scarcella, G.; Cacciato, M. An Effective Energy-Saving Scalar Control for Industrial IPMSM Drives. IEEE Trans. Ind. Electron. 2013, 60, 3658–3669. [Google Scholar] [CrossRef]

- Chen, D.; Lu, K.; Wang, D.; Hinkkanen, M. I-F Control with Zero D-Axis Current Operation for Surface-Mounted Permanent Magnet Synchronous Machine Drives. IEEE Trans. Power Electron. 2023, 38, 7504–7513. [Google Scholar] [CrossRef]

- Nair, S.V.; Hatua, K.; Prasad, N.V.P.R.D.; Reddy, D.K. A Quick I-f Starting of PMSM Drive with Pole Slipping Prevention and Reduced Speed Oscillations. IEEE Trans. Ind. Electron. 2021, 68, 6650–6661. [Google Scholar] [CrossRef]

- Na, H.; Cho, K.-Y.; Kim, H.-W.; Kim, S.-H. Stable sensorless transition algorithm for PM synchronous motors under load. J. Power Electron. 2024, 24, 608–617. [Google Scholar] [CrossRef]

- Ning, B.; Zhao, Y.; Cheng, S. An Improved Sensorless Hybrid Control Method of Permanent Magnet Synchronous Motor Based on I/F Startup. Sensors 2023, 23, 635. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Lu, K.; Blaabjerg, F. A Simple Startup Strategy Based on Current Regulation for Back-EMF-Based Sensorless Control of PMSM. IEEE Trans. Power Electron. 2012, 27, 3817–3825. [Google Scholar] [CrossRef]

- Tang, Q.; Chen, D.; He, X. Integration of Improved Flux Linkage Observer and I–f Starting Method for Wide-Speed-Range Sensorless SPMSM Drives. IEEE Trans. Power Electron. 2020, 35, 8374–8383. [Google Scholar] [CrossRef]

- Liu, L.; Jin, D.; Si, J.; Liang, D. A novel nonsingular fast terminal sliding mode observer combining I-F method for wide-speed sensorless control of PMSM drives. IET Power Electron. 2023, 16, 843–855. [Google Scholar] [CrossRef]

- Fatu, M.; Teodorescu, R.; Boldea, I.; Andreescu, G.D.; Blaabjerg, F. I-F starting method with smooth transition to EMF based motion-sensorless vector control of PM synchronous motor/generator. In Proceedings of the 2008 IEEE Power Electronics Specialists Conference, Rhodes, Greece, 15–19 June 2008; pp. 1481–1487. [Google Scholar]

- Xu, Y.; Lin, C.; Xing, J. Transient Response Characteristics Improvement of Permanent Magnet Synchronous Motor Based on Enhanced Linear Active Disturbance Rejection Sensorless Control. IEEE Trans. Power Electron. 2023, 38, 4378–4390. [Google Scholar] [CrossRef]

- Chen, D.; Lu, K.; Wang, D. An I-f Startup Method with Compensation Loops for PMSM with Smooth Transition. IEEJ J. Ind. Appl. 2020, 9, 263–270. [Google Scholar] [CrossRef]

- Du, C.Y.; Yu, G.R. Optimal PI Control of a Permanent Magnet Synchronous Motor Using Particle Swarm Optimization. In Proceedings of the Second International Conference on Innovative Computing, Informatio and Control (ICICIC 2007), Kumamoto, Japan, 5–7 September 2007; p. 255. [Google Scholar]

- Choi, J.W.; Lee, S.C. Antiwindup Strategy for PI-Type Speed Controller. IEEE Trans. Ind. Electron. 2009, 56, 2039–2046. [Google Scholar] [CrossRef]

| Symbol | Parameter | Value |

|---|---|---|

| PN | Rated power | 35 kW |

| ωe,rated | Rated speed | 9245 rad/s (90 kr/min) |

| ωe,max | Maximum speed | 9948 rad/s (95 kr/min) |

| ωe,min | Minimum speed | 3142 rad/s (30 kr/min) |

| ωN | Fundamental frequency | 1.583 kHz |

| np | Pole pairs | 1 |

| Rs | Stator resistance | 0.0085 Ω |

| Ld | d-axis inductance | 66.46 μH |

| Lq | q-axis inductance | 66.46 μH |

| φf | Flux linkage | 0.02387 Wb |

| J | Motor inertia | 0.0005672 kg·m2 |

| UDC | DC bus voltage | 550 V |

| fsw | Switching frequency | 40 kHz |

| fc | Control frequency | 20 kHz |

| Ts | Sampling period | 0.00005 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, J.; Xu, Y.; Zhang, J.; Li, Y.; Jiang, X. A Reliable and Efficient I-f Startup Method of Sensorless Ultra-High-Speed SPMSM for Fuel Cell Air Compressors. Actuators 2024, 13, 203. https://doi.org/10.3390/act13060203

Xing J, Xu Y, Zhang J, Li Y, Jiang X. A Reliable and Efficient I-f Startup Method of Sensorless Ultra-High-Speed SPMSM for Fuel Cell Air Compressors. Actuators. 2024; 13(6):203. https://doi.org/10.3390/act13060203

Chicago/Turabian StyleXing, Jilei, Yao Xu, Junzhi Zhang, Yongshen Li, and Xiongwei Jiang. 2024. "A Reliable and Efficient I-f Startup Method of Sensorless Ultra-High-Speed SPMSM for Fuel Cell Air Compressors" Actuators 13, no. 6: 203. https://doi.org/10.3390/act13060203

APA StyleXing, J., Xu, Y., Zhang, J., Li, Y., & Jiang, X. (2024). A Reliable and Efficient I-f Startup Method of Sensorless Ultra-High-Speed SPMSM for Fuel Cell Air Compressors. Actuators, 13(6), 203. https://doi.org/10.3390/act13060203