Solid-State Electromechanical Smart Material Actuators for Pumps—A Review

Abstract

:1. Introduction

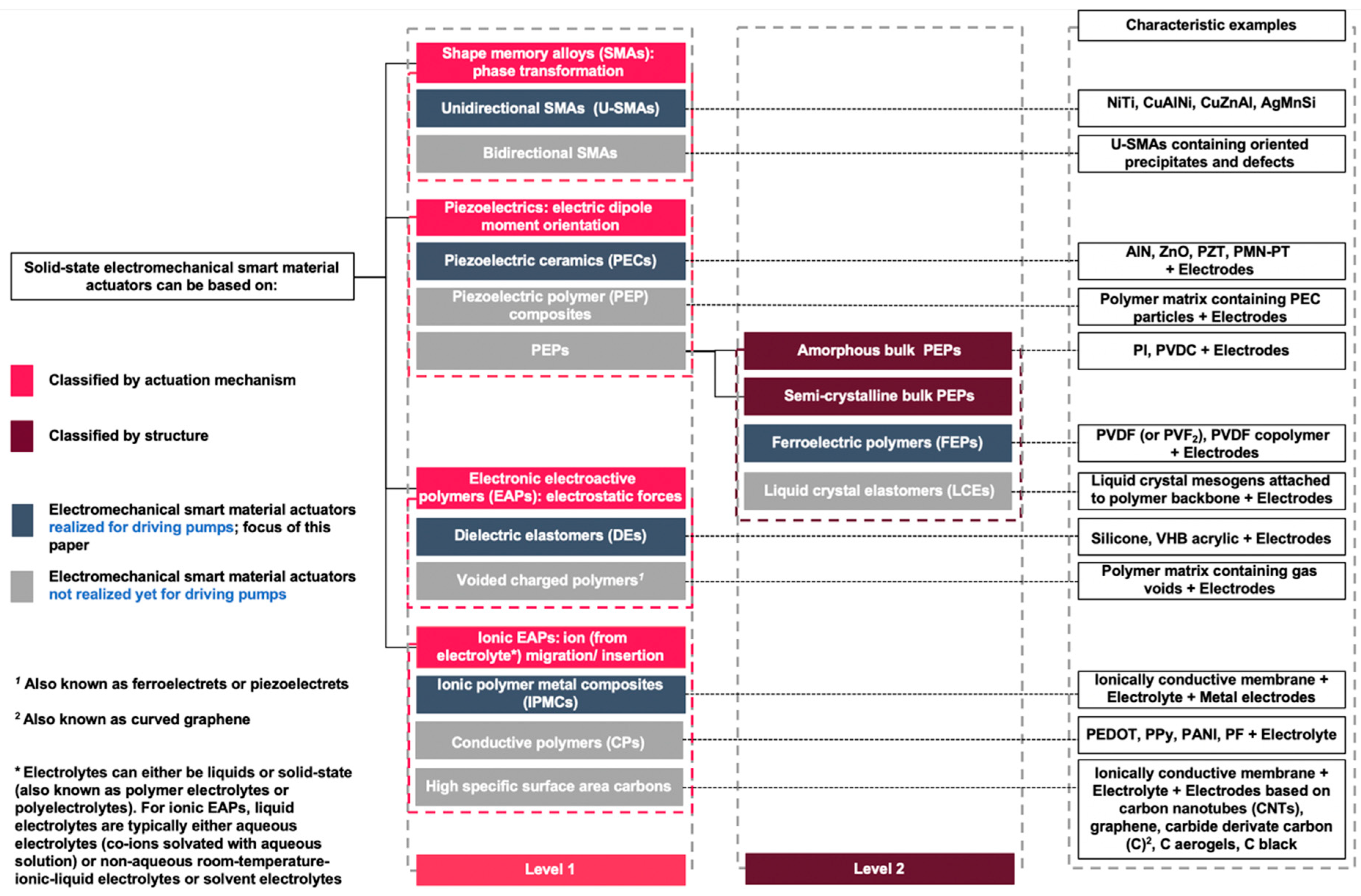

2. Taxonomy of Solid-State Electromechanical Smart Material Actuators

3. Electromechanical Smart Material Actuators

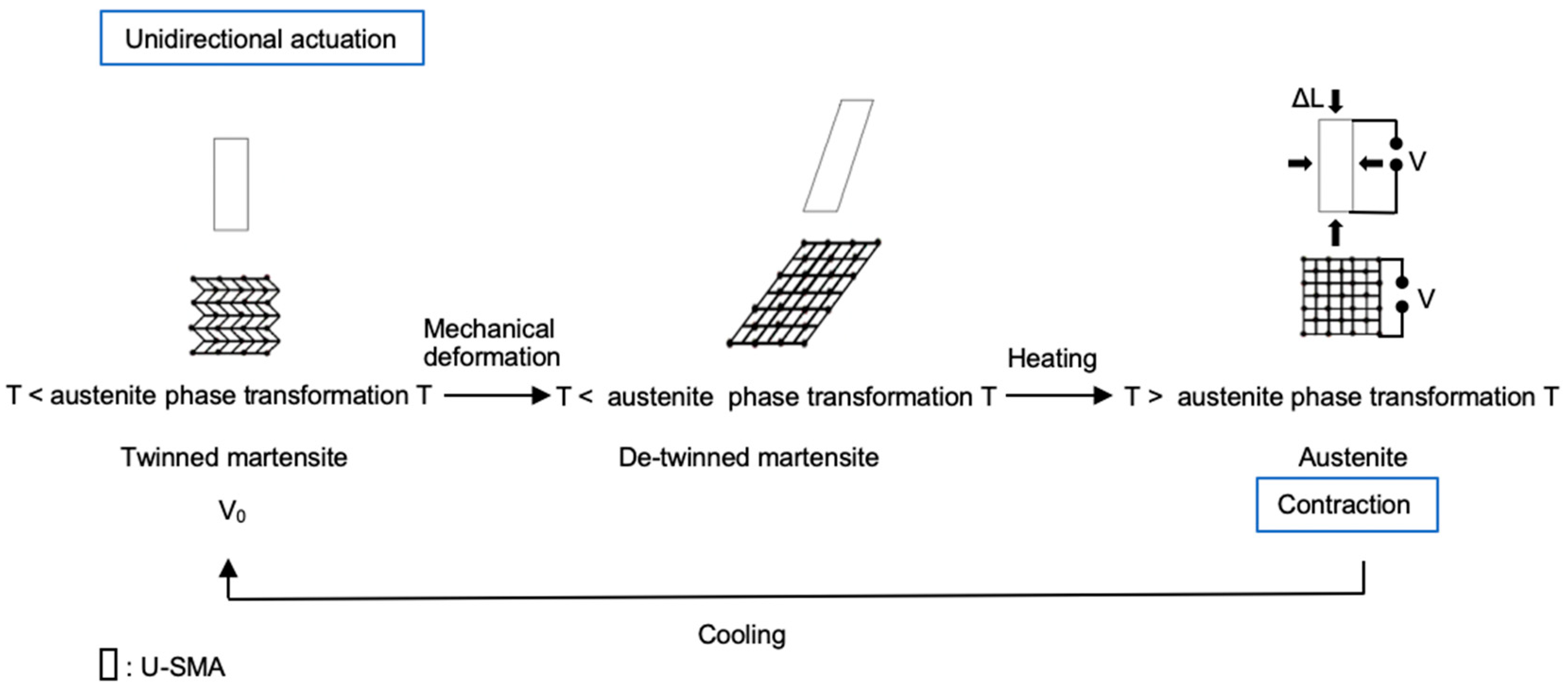

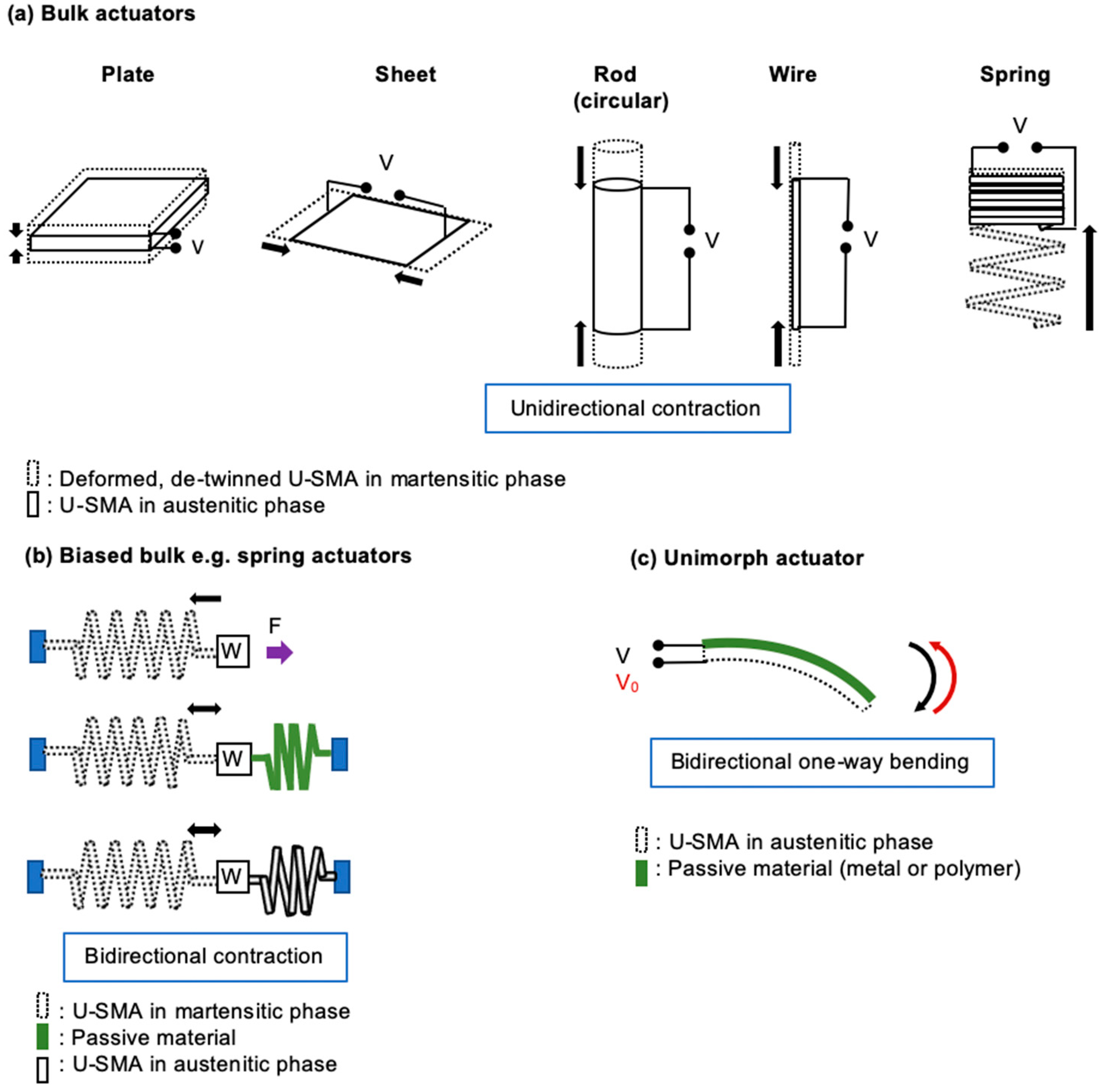

3.1. Actuators Based on Unidirectional Shape Memory Alloys

3.1.1. Materials, Actuators and Working Principles

3.1.2. Properties of Unidirectional Shape Memory Alloys

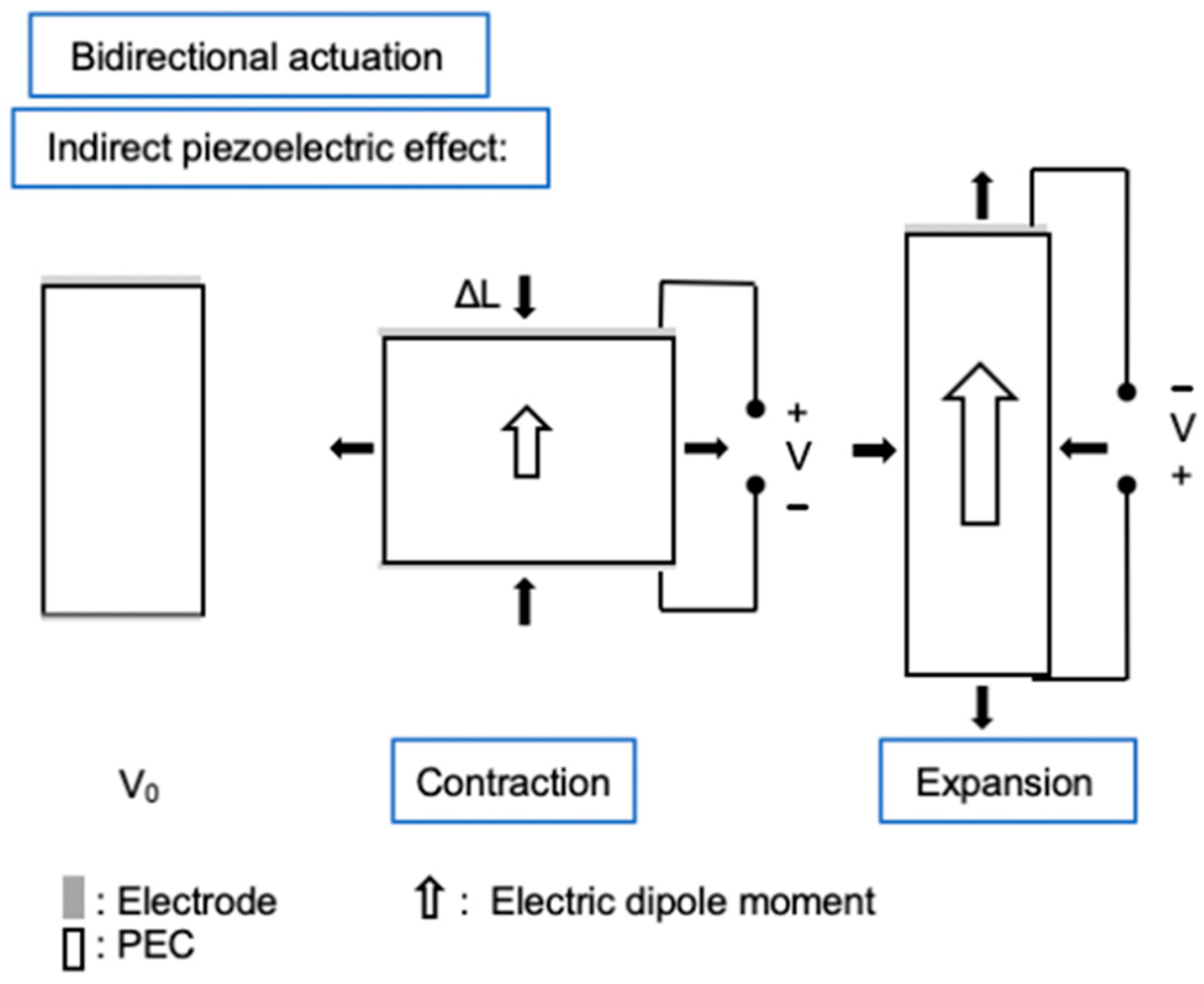

3.2. Actuators Based on Piezoelectric Ceramics

3.2.1. Materials, Actuators and Working Principles

3.2.2. Properties of Piezoelectric Ceramics

| Smart Material (Single Crystal) | PMN-PT | PZT-5H | |

|---|---|---|---|

| Properties | |||

| Young’s modulus, Y (GPa) | 27 [72] | 37 [72] | |

| Dielectric constant | 4700 [72] | 3300 [72] | |

| Normal longitudinal piezoelectric strain coefficient, d33 (pC/N) | 2000–3000 [61] | 593 [61] | |

| Typical actuation strain, ε (%) | 0.6 [12] | 0.2 [73] | |

| Typical actuation stress, σ (MPa) | 100 [12] | 108 [73] | |

| Driving electric field (MV/m) | 100 [12] | ||

| Bandwidth (Hz) | ≤10 MHz (resonance frequency) [13] | ||

| Cycle life | 106 [72] | ||

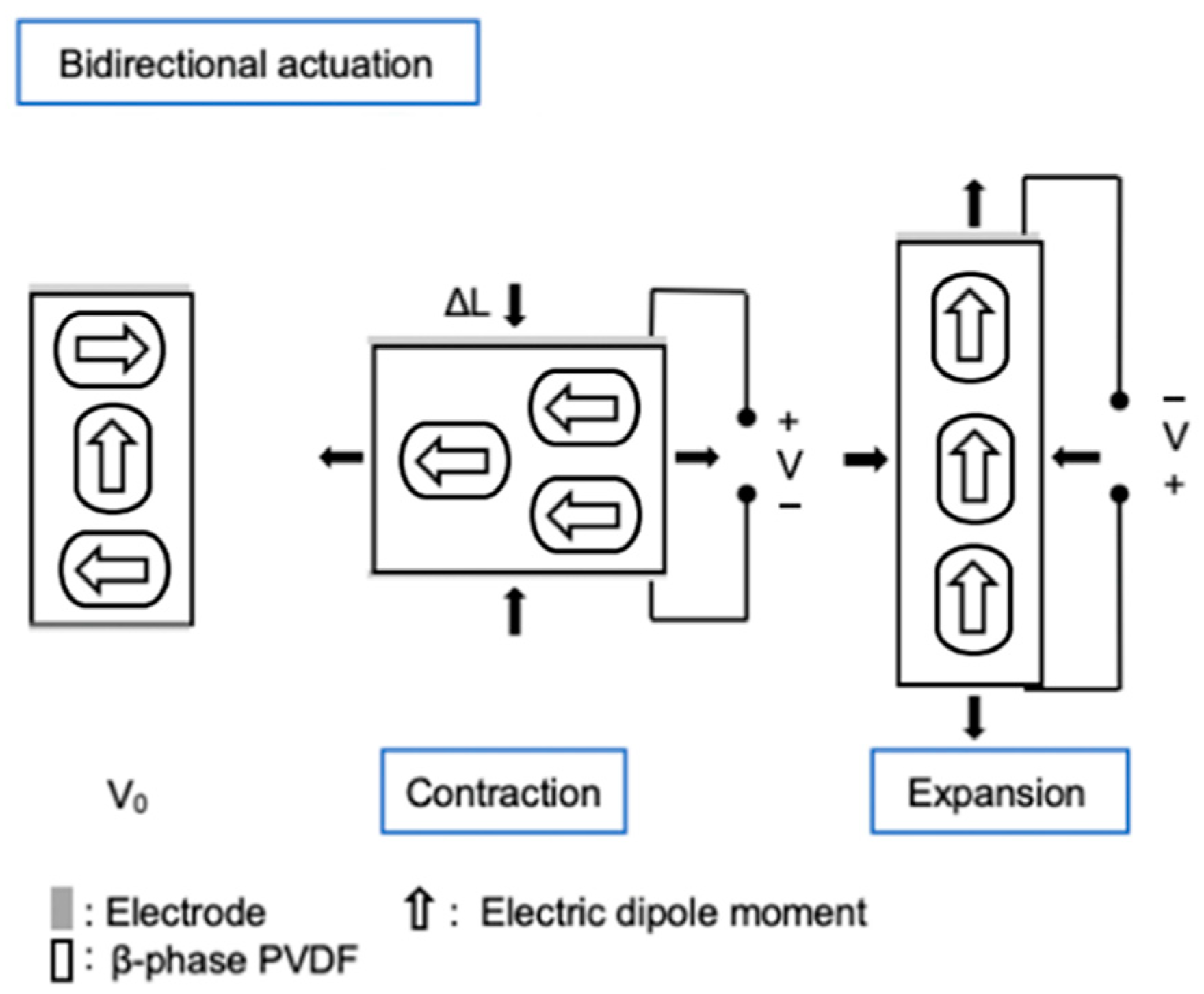

3.3. Actuators Based on Ferroelectric Polymers

3.3.1. Materials, Actuators and Working Principles

3.3.2. Properties of Ferroelectric Polymers

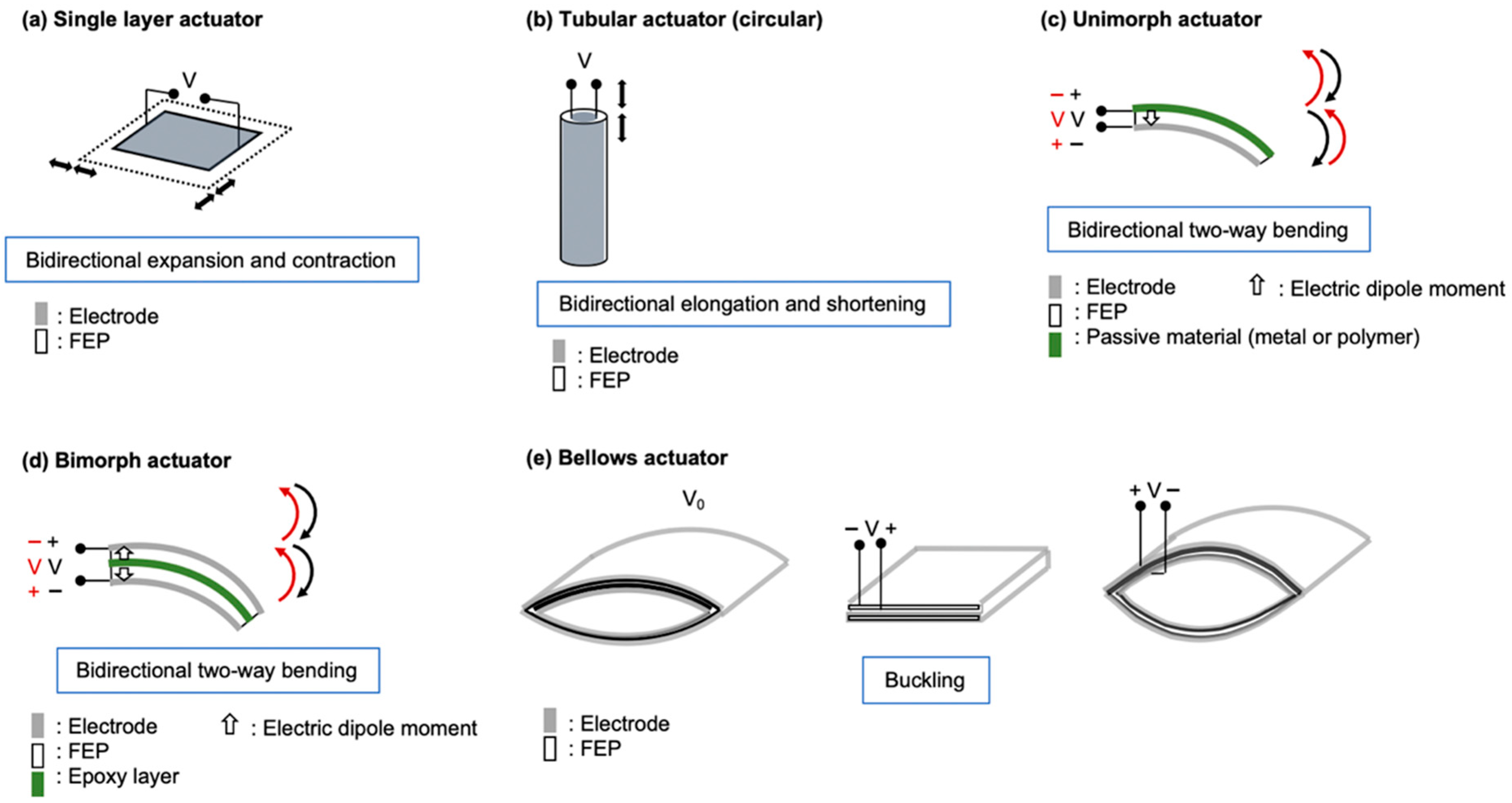

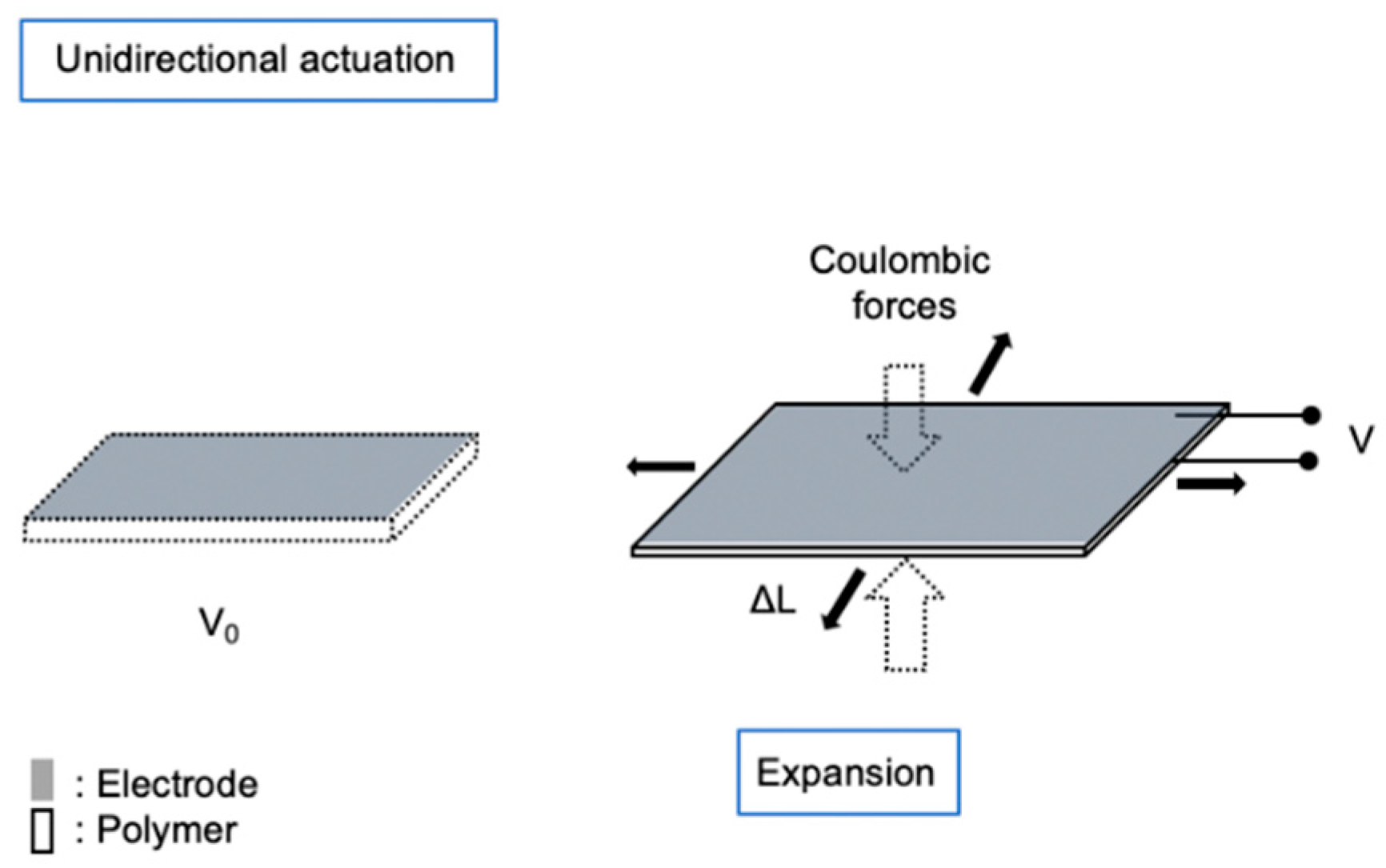

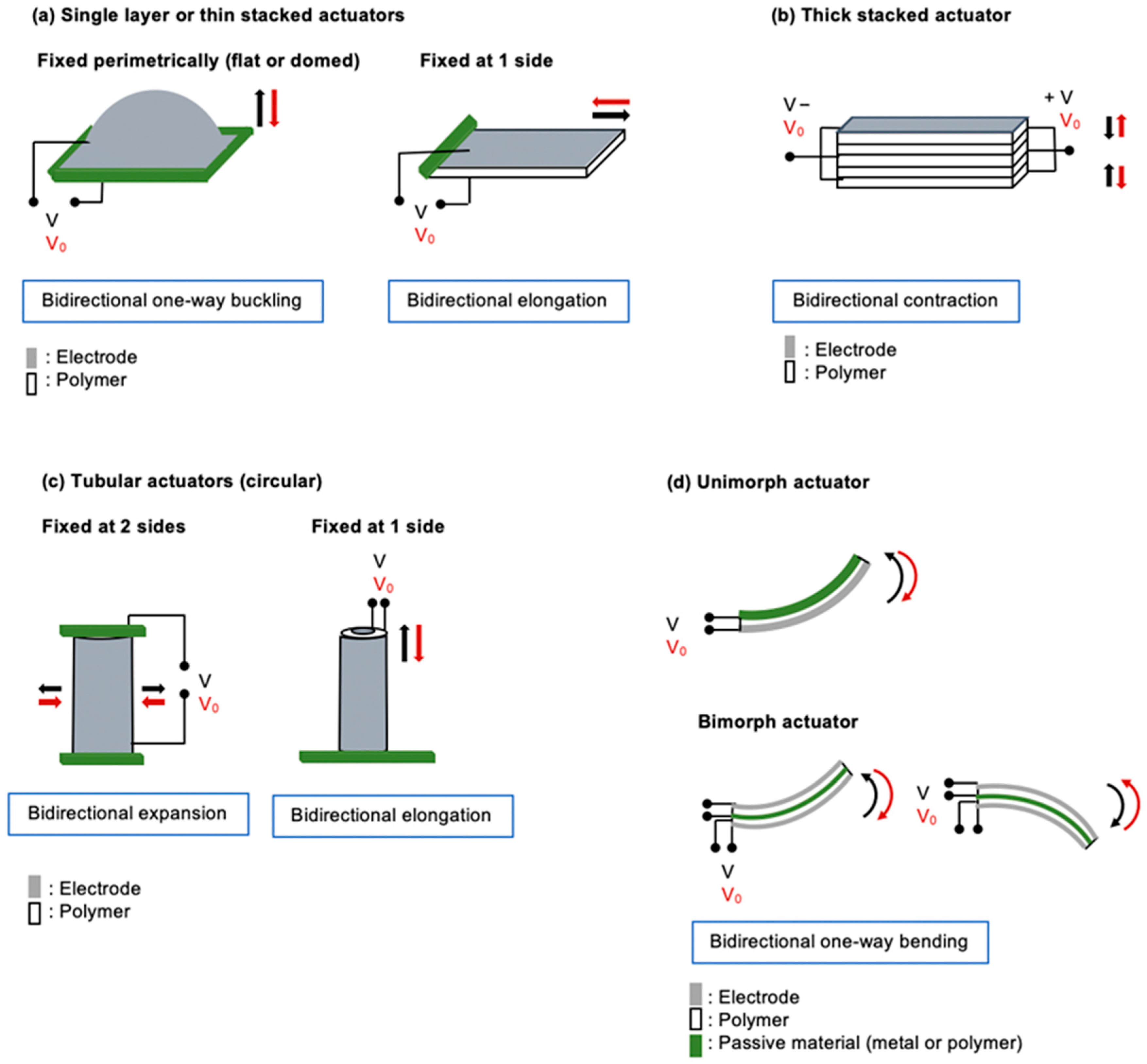

3.4. Actuators Based on Dielectric Elastomers

3.4.1. Materials, Actuators and Working Principles

3.4.2. Properties of Dielectric Elastomers

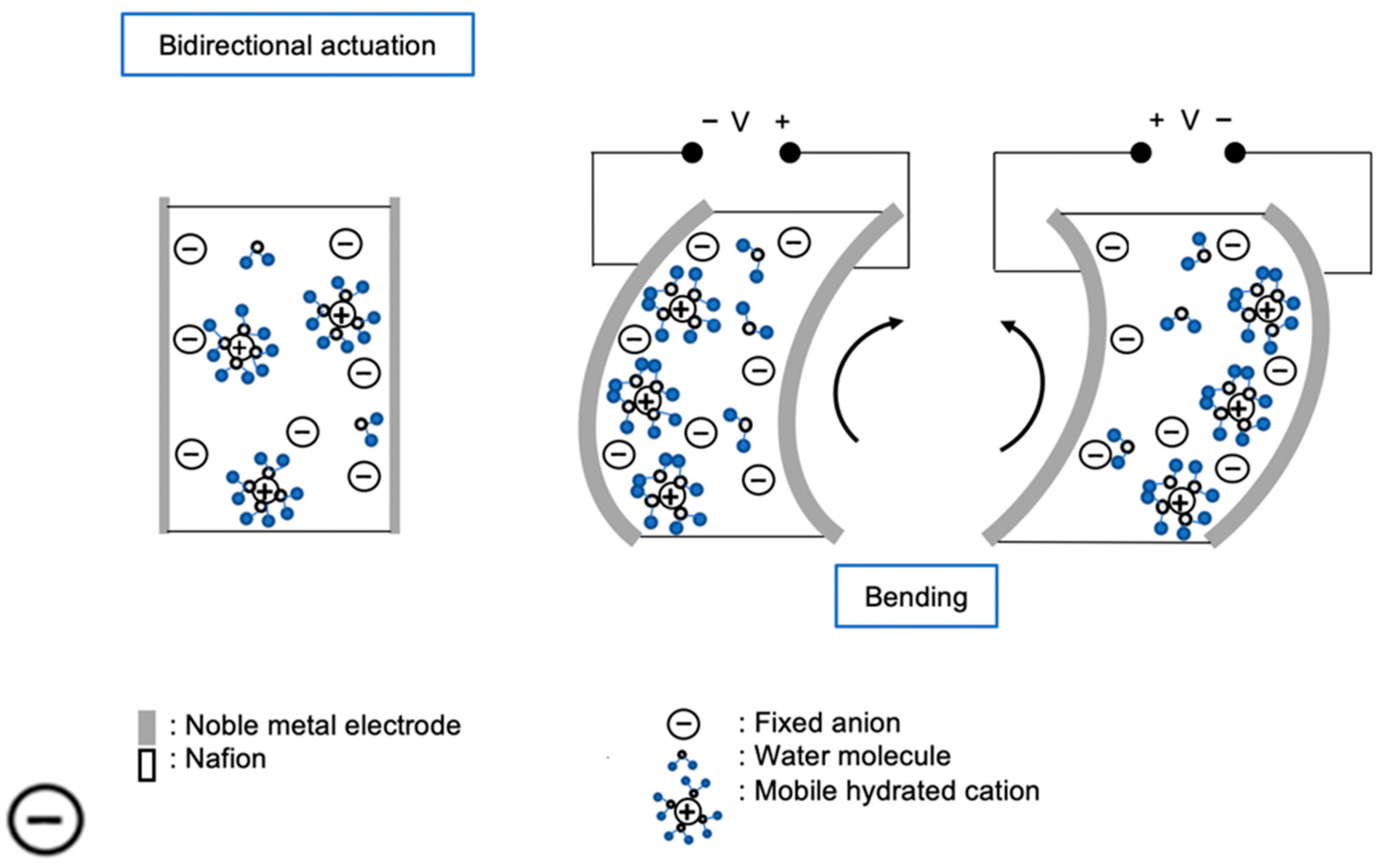

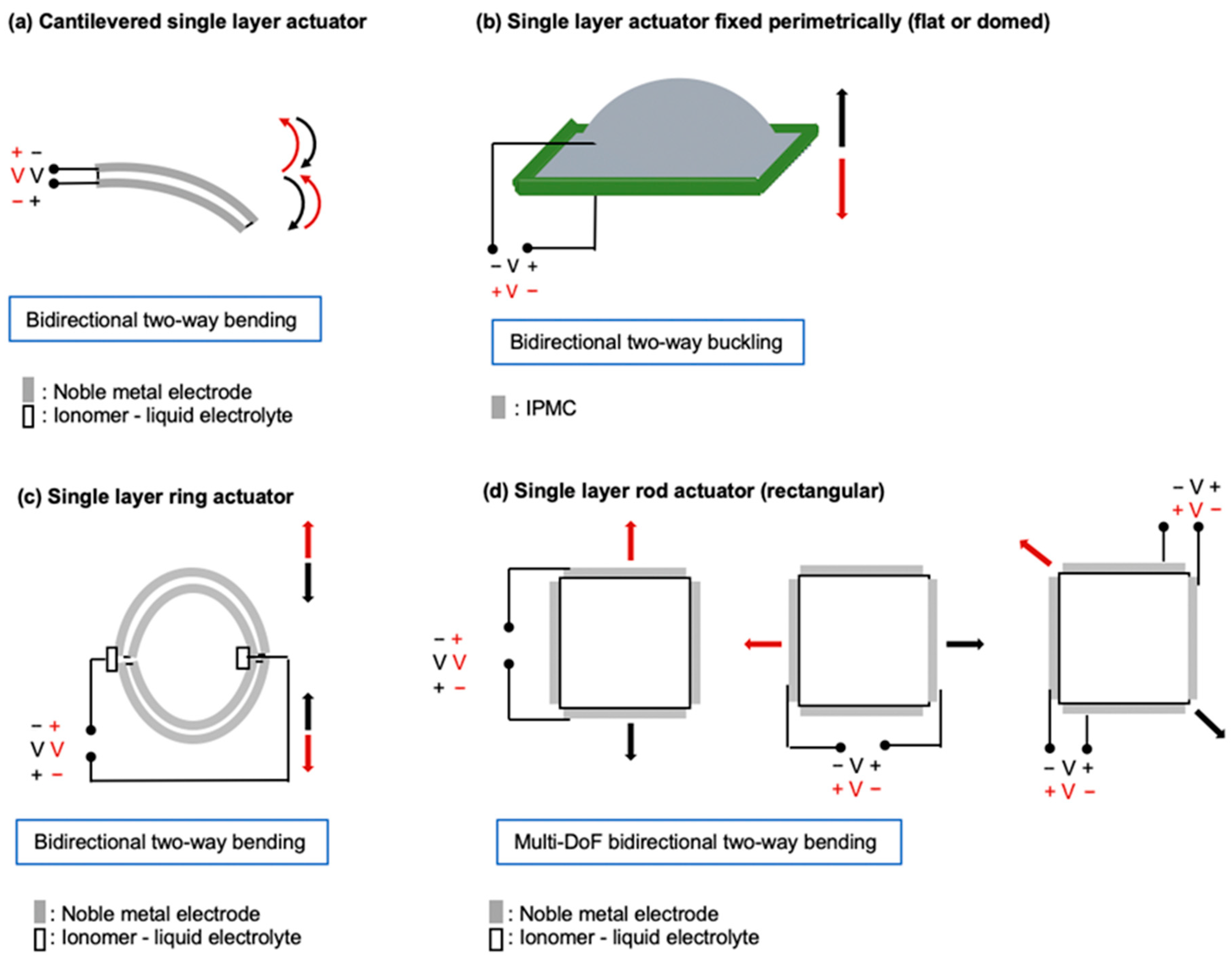

3.5. Actuators Based on Ionic Polymer Metal Composites

3.5.1. Materials, Actuators and Working Principles

3.5.2. Properties of Ionic Polymer Metal Composites

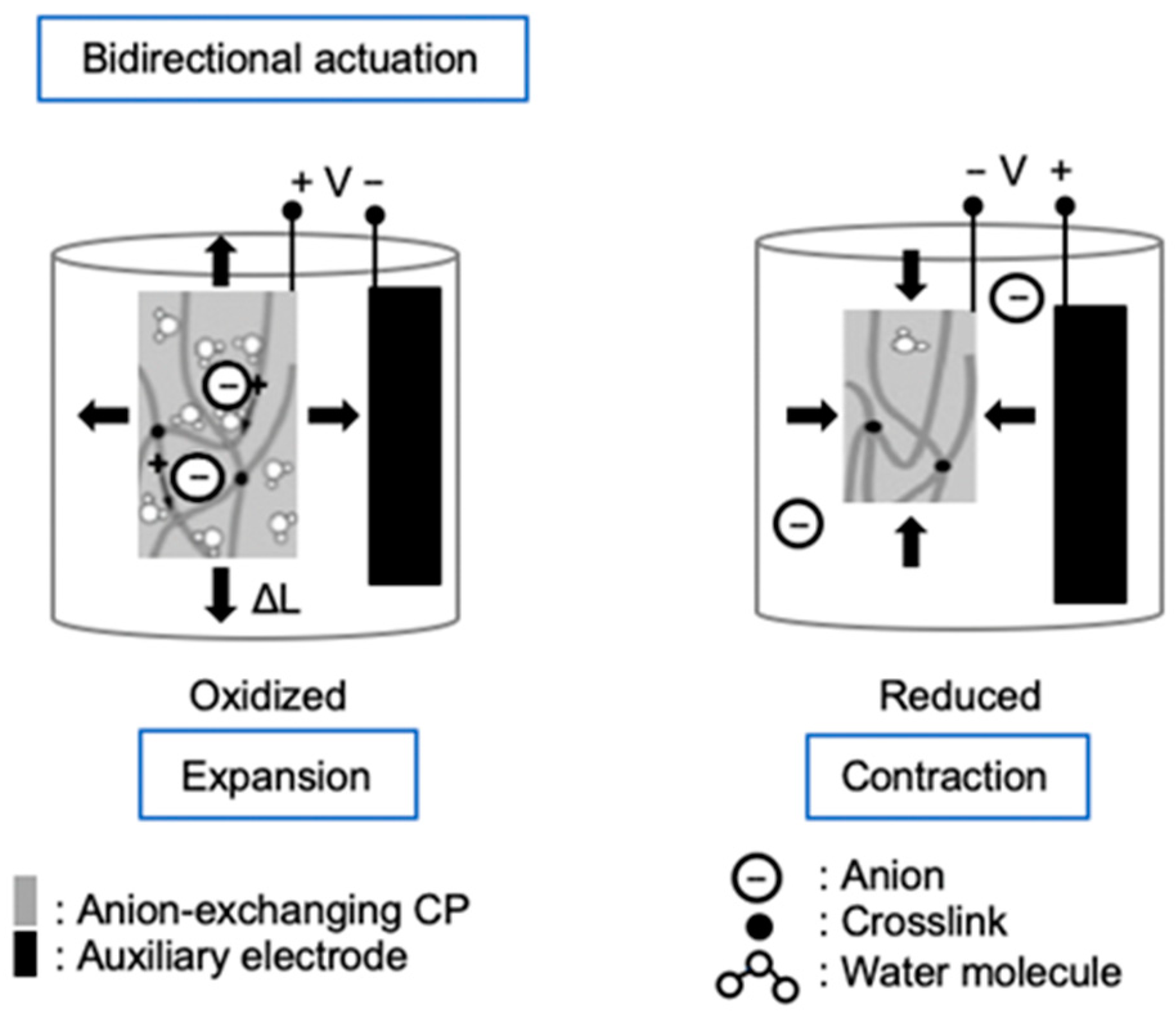

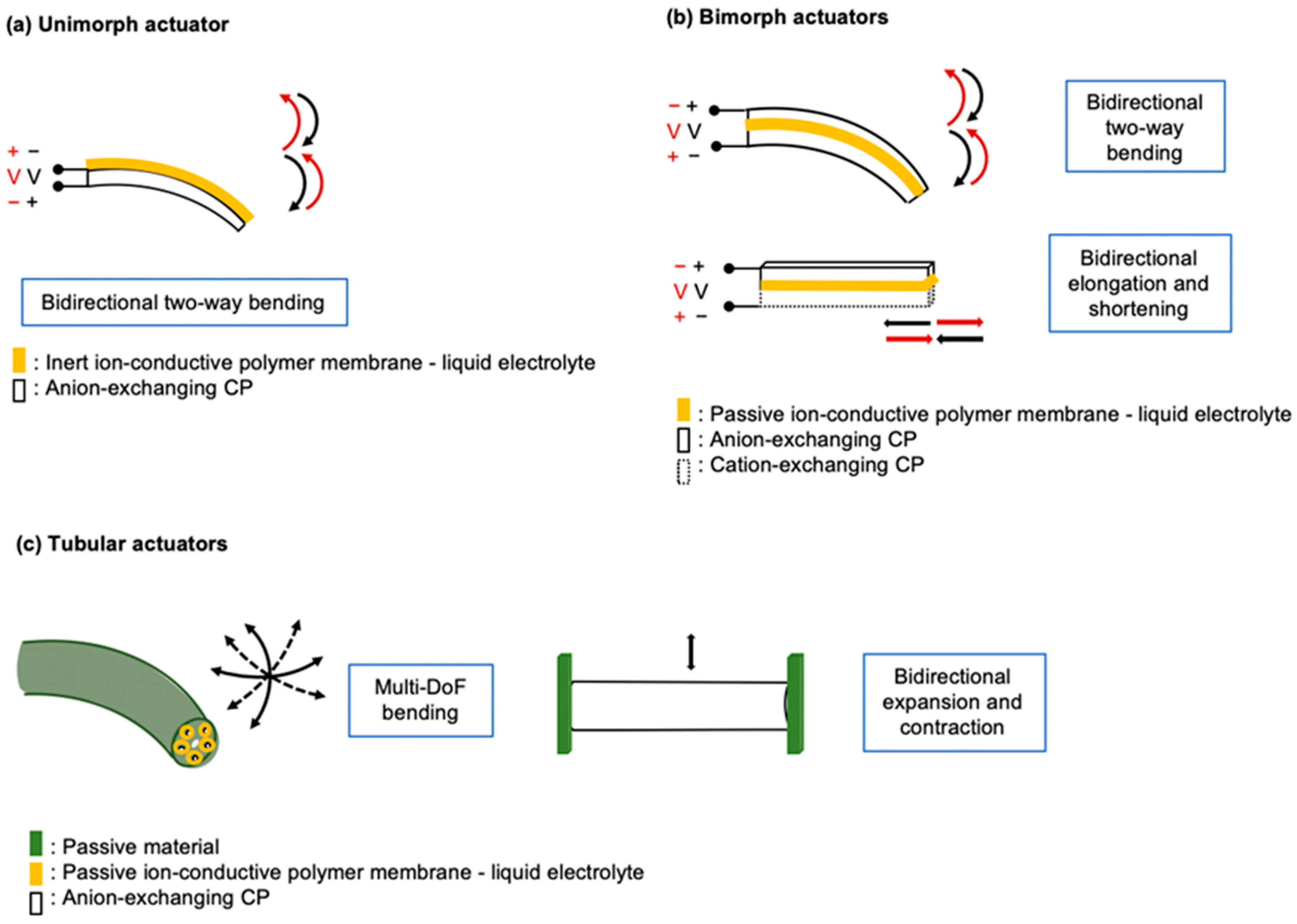

3.6. Actuators Based on Conducting Polymers

3.6.1. Materials, Actuators and Working Principles

3.6.2. Properties of Conducting Polymers

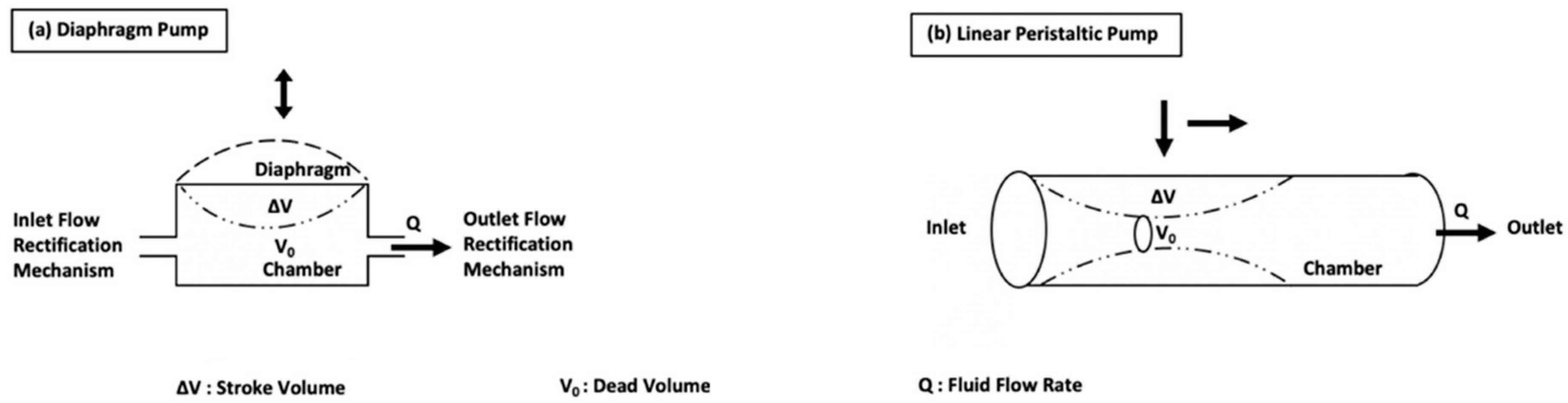

4. Actuator Considerations in Pumps

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Co-ions | Counter-ions |

| DoF | Degrees-of-freedom |

| ε | Strain |

| σ | Stress |

| CNT | Carbon nanotube |

| CP | Conducting polymer |

| DE | Dielectric elastomer |

| FEP | Ferroelectric polymer |

| IPMC | Ionic polymer metal composite |

| LIPCA | Lightweight piezo-composite actuator |

| PEC | Piezoelectric ceramic |

| SMA | Shape Memory Alloy |

| U-SMA | Unidirectional Shape Memory Alloy |

| AlN | Aluminum nitride |

| BaTiO3 | Barium titanate |

| CFE | Chlorofluoroethylene |

| PA | Polyacetylene |

| PANI | Polyaniline |

| PDMS | Polydimethylsiloxane |

| PEDOT | Poly(3,4-ethylenedioxythiophene) |

| PF | Polyfluorene |

| PMN-PT | Lead magnesium niobate-lead titanate |

| PPP | Poly(p-phenylene) |

| PPy | Polypyrrole |

| PTh | Polythiophene |

| PVDF or PVF2 | Polyvinylidene fluoride |

| PZT | Lead zirconate titanate |

| TrFE | Trifluoroethylene |

| ZnO | Zinc oxide |

| VHB | Very high bond |

References

- Drossel, W.G.; Kunze, H.; Bucht, A.; Weisheit, L.; Pagel, K. Smart—Smart Materials for Smart Applications. Procedia CIRP 2015, 36, 211–216. [Google Scholar] [CrossRef]

- Samatham, R.; Kim, K.J.; Dogruer, D.; Choi, H.R.; Konyo, M.; Madden, J.D. Active Polymers: An Overview; Springer: London, UK, 2007; pp. 1–36. [Google Scholar]

- Bar-Cohen, Y. Electroactive Polymers as Artificial Muscles—Reality and Challenges. In Proceedings of the 19th AIAA Applied Aerodynamics Conference, Anaheim, CA, USA, 11–14 June 2001; Paper #2021-1492. pp. 1–13. [Google Scholar] [CrossRef]

- Meng, H.; Hu, J. A Brief Review of Stimulus-Active Polymers Responsive to Thermal, Light, Magnetic, Electric, and Water/Solvent Stimuli. J. Intell. Mater. Syst. Struct. 2010, 21, 859–885. [Google Scholar] [CrossRef]

- Thomas, L.J., Jr.; Bessman, S.P. Prototype for an Implantable Micropump Powdered by Piezoelectric Disk Benders. Trans.-Am. Soc. Artif. Intern. Organs 1975, 21, 516–522. [Google Scholar] [PubMed]

- Yokota, S. A Review on Micropumps from the Viewpoint of Volumetric Power Density. Mech. Eng. Rev. 2014, 1, DSM0014. [Google Scholar] [CrossRef]

- Peng, Y.; Li, D.; Yang, X.; Ma, Z.; Mao, Z. A Review on Electrohydrodynamic (EHD) Pump. Micromachines 2023, 14, 321. [Google Scholar] [CrossRef] [PubMed]

- Sideris, E.A.; de Lange, H.C. Pumps Operated by Solid-State Electromechanical Smart Material Actuators—A Review. Sens. Actuators A Phys. 2020, 305, 111915. [Google Scholar] [CrossRef]

- Luo, X.; Yang, L.; Cui, Y. Micropumps: Mechanisms, Fabrication, and Biomedical Applications. Sens. Actuators A Phys. 2023, 363, 114732. [Google Scholar] [CrossRef]

- Smela, E. Conjugated Polymer Actuators for Biomedical Applications. Adv. Mater. 2003, 15, 481–494. [Google Scholar] [CrossRef]

- Punning, A.; Must, I.; Põldsalu, I.; Vunder, V.; Temmer, R.; Kruusamäe, K.; Kaasik, F.; Torop, J.; Rinne, P.; Lulla, T.; et al. Lifetime Measurements of Ionic Electroactive Polymer Actuators. J. Intell. Mater. Syst. Struct. 2014, 25, 2267–2275. [Google Scholar] [CrossRef]

- Mirvakili, S.M.; Hunter, I.W. Artificial Muscles: Mechanisms, Applications, and Challenges. Adv. Mater. 2018, 30, 1704407. [Google Scholar] [CrossRef]

- Mirfakhrai, T.; Madden, J.D.W.; Baughman, R.H. Polymer Artificial Muscles. Mater. Today 2007, 10, 30–38. [Google Scholar] [CrossRef]

- Pierce, M.D.; Mascaro, S.A. A Biologically Inspired Wet Shape Memory Alloy Actuated Robotic Pump. IEEE/ASME Trans. Mechatron. 2013, 18, 536–546. [Google Scholar] [CrossRef]

- He, S.; Chen, P.; Sun, X.; Peng, H. Stimuli-Responsive Materials from Carbon Nanotubes. In Industrial Applications of Carbon Nanotubes; Elsevier: Amsterdam, The Netherlands, 2017; pp. 151–178. [Google Scholar] [CrossRef]

- Bar-Cohen, Y.; Sherrit, S.; Lih, S. Characterization of the Electromechanical Properties of EAP Materials. Electroact. Polym. Actuators Devices (EAPAD) 2001, 4329, 5–8. [Google Scholar]

- Baughman, R.H.; Zakhidov, A.A.; De Heer, W.A. Carbon Nanotubes—The Route toward Applications. Science 2002, 297, 787–792. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Huang, W.M.; Ding, Z.; Zhao, Y.; Wang, C.C.; Purnawali, H.; Tang, C. Stimulus-Responsive Shape Memory Materials: A Review. Mater. Des. 2012, 33, 577–640. [Google Scholar] [CrossRef]

- Seok, S.; Onal, C.D.; Cho, K.; Wood, R.J.; Rus, D.; Kim, S. Meshworm: A Peristaltic Soft Robot with Antagonistic Nickel Titanium Coil Actuators. IEEE/ASME Trans. Mechatron. 2012, 18, 1485–1497. [Google Scholar] [CrossRef]

- Guo, S.; Sun, X. SMA Actuator-Based Novel Type of Peristaltic Micropump. In Proceedings of the 2008 IEEE International Conference on Information and Automation, Changsha, China, 20–23 June 2008; pp. 1620–1625. [Google Scholar]

- Otsuka, K.; Ren, X. Physical Metallurgy of Ti–Ni-Based Shape Memory Alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Nishida, M.; Honma, T. All-Round Shape Memory Effect in Ni-Rich TiNi Alloys Generated by Constrained Aging. Scripta Metallurgica 1984, 18, 1293–1298. [Google Scholar] [CrossRef]

- Bataillard, L.; Bidaux, J.E.; Gotthardt, R. Interaction between Microstructure and Multiple-Step Transformation in Binary NiTi Alloys Using in-Situ Transmission Electron Microscopy Observations. Philos. Mag. A 1998, 78, 327–344. [Google Scholar] [CrossRef]

- Khalil-Allafi, A.J.; Dlouhy, G.E. Ni4Ti3 Precipitation during Aging of NiTi Shape Memory Alloys and Its Influence on Martensite Phase Transformation. Acta Mater. 2002, 50, 4255–4274. [Google Scholar] [CrossRef]

- Tirry, W.; Schryvers, D. Quantitative Determination of Strain Fields around Ni4Ti3 Precipitates in NiTi. Acta Mater. 2005, 53, 1041–1049. [Google Scholar] [CrossRef]

- Lehnert, T.; Tixier, S.; Böni, P.; Gotthardt, R. A New Fabrication Process for Ni-Ti Shape Memory Thin Films. Mater. Sci. Eng. A 1999, 273–275, 713–716. [Google Scholar] [CrossRef]

- Bellouard, Y. Shape Memory Alloys for Microsystems: A Review from a Material Research Perspective. Mater. Sci. Eng. A 2008, 481–482, 582–589. [Google Scholar] [CrossRef]

- Kao, K.C. Ferroelectrics, Piezoelectrics, and Pyroelectrics. In Dielectric Phenomena in Solids with Emphasis on Physical Concepts of Electronic Processes; Academic Press: Cambridge, MA, USA, 2004; pp. 213–282. [Google Scholar] [CrossRef]

- Sabina, W.U.; Traugutt, N.A.; Volpe, R.H.; Patel, R.R.; Yu, K.; Yakacki, C.M. Liquid Crystal Elastomers: An Introduction and Review of Emerging Technologies. Liq. Cryst. Rev. 2018, 6, 78–107. [Google Scholar]

- Pelrine, R.; Kornbluh, R. Introduction: History of Dielectric Elastomer Actuators. In Dielectric Elastomers as Electromechanical Transducers; Elsevier: Amsterdam, The Netherlands, 2008; pp. 11–13. [Google Scholar] [CrossRef]

- Bar-Cohen, Y.; Xue, T.; Shahinpoor, M.; Harrison, J.S.; Smith, J.G. Low-Mass Muscle Actuators Using Electroactive Polymers (EAP). In Proceedings of the SPIE Smart Structures and Materials Symposium, EAPAD Conference, San Diego, CA, USA, 20 July 1998; Volume 3324, pp. 218–223. [Google Scholar] [CrossRef]

- Fukushima, T.; Asaka, K.; Kosaka, A.; Aida, T. Fully Plastic Actuator through Layer-by-Layer Casting with Ionic-Liquid-Based Bucky Gel. Angewendte Chem. 2005, 117, 2462–2465. [Google Scholar] [CrossRef]

- Lee, B.K.; Park, S.J.; Kim, D.S. Fabrication of Ionic Polymer Actuator with Graphene Nanocomposite Electrodes and Its Characterization. Curr. Appl. Phys. 2013, 13, 1520–1524. [Google Scholar] [CrossRef]

- Palmre, V.; Brandell, D.; Mäeorg, U.; Torop, J.; Volobujeva, O.; Punning, A.; Johanson, U.; Kruusmaa, M.; Aabloo, A. Nanoporous Carbon-Based Electrodes for High Strain Ionomeric Bending Actuators. Smart Mater. Struct. 2009, 18, 095028. [Google Scholar] [CrossRef]

- Palmre, V.; Lust, E.; Jänes, A.; Koel, M.; Peikolainen, A.L.; Torop, J.; Johanson, U.; Aabloo, A. Electroactive Polymer Actuators with Carbon Aerogel Electrodes. J. Mater. Chem. 2011, 21, 2577–2583. [Google Scholar] [CrossRef]

- Terasawa, N.; Takeuchi, I. Electrochemical and Electromechanical Properties of Carbon Black/Carbon Fiber Composite Polymer Actuator with Higher Performance than Single-Walled Carbon Nanotube Polymer Actuator. Electrochim. Acta 2014, 123, 340–345. [Google Scholar] [CrossRef]

- Lagoudas, D. Shape Memory Alloys: Modeling and Engineering Applications; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Kim, B.; Lee, M.; Lee, Y.; Kim, Y.; Lee, G. An Earthworm-like Micro Robot Using Shape Memory Alloy Actuator. Sens. Actuators A Phys. 2006, 125, 429–437. [Google Scholar] [CrossRef]

- Lee, J.J.; Lee, H.J. Evaluation of the Characteristics of a Shape Memory Alloy Spring Actuator. Smart Mater. Struct. 2000, 9, 817–823. [Google Scholar] [CrossRef]

- Dong, Y.; Boming, Z.; Jun, L. A Changeable Aerofoil Actuated by Shape Memory Alloy Springs. Mater. Sci. Eng. A 2008, 485, 243–250. [Google Scholar] [CrossRef]

- Cho, K.; Hawkes, E.; Quinn, C.; Wood, R.J. Design, Fabrication and Analysis of a Body-Caudal Fin Propulsion System for a Microrobotic Fish. In Proceedings of the IEEE International Conference on Robotics and Automation, Pasadena, CA, USA, 19–23 May 2008; pp. 706–711. [Google Scholar]

- Johnson, A.D.; Martynov, V.V. Applications of Shape Memory Alloy Thin Film. In Proceedings of the International Organization on Shape Memory and Superelastic Technologies, Pacific Grove, CA, USA, 2–6 March 1997; pp. 1–6. [Google Scholar]

- Shoji, S.; Esashi, M.; Matsuo, T. Prototype Miniature Blood Gas Analyser Fabricated on a Silicon Wafer. Sens. Actuators 1988, 14, 101–107. [Google Scholar] [CrossRef]

- Kostov, M.; Todorov, T.; Mitrev, R.; Kamberov, K.; Nikolov, R. A Study of a Bistable Reciprocating Piston Pump Driven by Shape Memory Alloys and Recuperative Springs. Actuators 2023, 12, 90. [Google Scholar] [CrossRef]

- Kostov, M.; Todorov, T.; Mitrev, R.; Todorov, G.; Kamberov, K. Synthesis of a Bistable Recuperative Pump Powered by Shape Memory Alloys and a Two-Section Involute Cam. Actuators 2023, 12, 381. [Google Scholar] [CrossRef]

- Krulevitch, P.; Lee, A.P.; Ramsey, P.B.; Trevino, J.C.; Hamilton, J.; Northrup, M.A. Thin Film Shape Memory Alloy Microactuators. J. Microelectromechanical Syst. 1996, 5, 270–282. [Google Scholar] [CrossRef]

- Winzek, B.; Schmitz, S.; Rumpf, H.; Serzl, T.; Hassdorf, R.; Tienhaus, S.; Feydt, J.; Moske, M.; Quandt, E. Recent Developments in Shape Memory Thin Film Technology. Mater. Sci. Eng. A 2004, 378, 40–46. [Google Scholar] [CrossRef]

- Madden, J.D.W.; Vandesteeg, N.A.; Anquetil, P.A.; Madden, P.G.A.; Takshi, A.; Pytel, R.Z.; Lafontaine, S.R.; Wieringa, P.A.; Hunter, I.W. Artificial Muscle Technology: Physical Principles and Naval Prospects. IEEE J. Ocean. Eng. 2004, 29, 706–728. [Google Scholar] [CrossRef]

- Shahinpoor, M.; Bar-Cohen, Y.; Simpson, J.O.; Smith, J. Ionic Polymer-Metal Composites (IPMCs) as Biomimetic Sensors, Actuators and Artificial Muscles-a Review. Smart Mater. Struct. 1998, 7, R15. [Google Scholar] [CrossRef]

- Hunter, I.W.; Lafontaine, S.; Hollerbach, J.M.; Hunter, P.J. Fast Reversible NiTi Fibers for Use in Microrobotics. In Proceedings of the IEEE Micro Electro Mechanical Systems, Montreal, QC, Canada, 30 January 1991; pp. 166–170. [Google Scholar]

- Benard, W.L.; Kahn, H.; Heuer, A.H.; Huff, M.A. Thin-Film Shape-Memory Alloy Actuated Micropumps. J. Microelectromechanical Syst. 1998, 7, 245–251. [Google Scholar] [CrossRef]

- Shin, D.D.; Mohanchandra, K.P.; Carman, G.P. Development of Hydraulic Linear Actuator Using Thin Film SMA. Sens. Actuators A Phys. 2005, 119, 151–156. [Google Scholar] [CrossRef]

- Iverson. Garimella Recent Advances in Microscale Pumping Technologies: A Review and Evaluation. Microfluid. Nanofluid 2008, 5, 145–174. [Google Scholar] [CrossRef]

- Tadesse, Y.; Hong, D.; Priya, S. Twelve Degree of Freedom Baby Humanoid Head Using Shape Memory Alloy Actuators. J. Mech. Robot. 2011, 3, 011008. [Google Scholar] [CrossRef]

- Kahn, H.; Huff, M.A.; Heuer, A.H. The TiNi Shape-Memory Alloy and Its Applications for MEMS. J. Micromech. Microeng. 1998, 8, 213–221. [Google Scholar] [CrossRef]

- Huang, W. On the Selection of Shape Memory Alloys for Actuators. Mater. Des. 2002, 23, 11–19. [Google Scholar] [CrossRef]

- Zanotti, C.; Giuliani, P.; Tuissi, A.; Arnaboldi, S.; Casati, R. Response of NiTi SMA Wire Electrically Heated. In Proceedings of the 8th International Symposium on Martensic Transformation, Milano, Italy, 1 September 2009. [Google Scholar]

- Curie, J.; Curie, P. Development by Pressure of Polar Electricity in Hemihedral Crystals with Inclined Faces. Bull. Société Des Sci. Minéralogie Fr. 1880, 3, 90–93. [Google Scholar]

- Jaffe, B.; Cook, W.; Jaffe, H. Piezoelectric Ceramics; Academic Press: Cambridge, MA, USA, 1971. [Google Scholar]

- TRS Technologies. Available online: http://www.trstechnologies.com/Materials/High-Performance-PMN-PT-Piezoelectric-Single-Crystal (accessed on 23 January 2024).

- Chorsi, M.T.; Curry, E.J.; Chorsi, H.T.; Das, R.; Baroody, J.; Purohit, P.K.; Ilies, H.; Nguyen, T.D. Piezoelectric Biomaterials for Sensors and Actuators. Adv. Mater. 2019, 31, e1802084. [Google Scholar] [CrossRef]

- Ramadan, K.S.; Sameoto, D.; Evoy, S. A Review of Piezoelectric Polymers as Functional Materials for Electromechanical Transducers. Smart Mater. Struct. 2014, 23, 033001. [Google Scholar] [CrossRef]

- Heywang, W.; Lubitz, K.; Wersing, W. Piezoelectricity Evolution and Future of a Technology; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- King, T.G.; Preston, M.E.; Murphy, B.J.M.; Cannell, D.S. Piezoelectric Ceramic Actuators: A Review of Machinery Applications. Precis. Eng. 1990, 12, 131–136. [Google Scholar] [CrossRef]

- Mauck, L.M.; Lynch, C.S. Piezoelectric Hydraulic Pump Development. J. Intell. Mater. Syst. Struct. 2000, 11, 758–764. [Google Scholar] [CrossRef]

- Sitti, M.; Campolo, D.; Yan, J.; Fearing, R.S. Development of PZT and PZN-PT Based Unimorph Actuators for Micromechanical Flapping Mechanisms. IEEE Int. Conf. Robot. Autom. 2001, 4, 3839–3846. [Google Scholar]

- Haertling, G.H. Rainbow Actuators and Sensors: A New Smart Technology. In Proceedings of the SPIE Smart Structures and Materials Symposium, EAPAD Conference, San Diego, CA, USA, 14 February 1997; Volume 3040, pp. 1–12. [Google Scholar]

- Lawver, K. Thunders: A New Frontier in Research Smart Materials. Smart Mater. Bull. 2001, 2001, 5–9. [Google Scholar] [CrossRef]

- Qing-Ming, W.; Cross, L.E. Determination of Young’s Modulus of the Reduced Layer of a Piezoelectric RAINBOW Actuator. J. Appl. Phys. 1998, 83, 5358–5363. [Google Scholar]

- Yoon, K.J.; Shin, S.; Park, H.C.; Goo, N.S. Design and Manufacture of a Lightweight Piezo-Composite Curved Actuator. Smart Mater. Struct. 2002, 11, 163–168. [Google Scholar] [CrossRef]

- Ramirez-Garcia, S.; Diamond, D. Biomimetic, Low Power Pumps Based on Soft Actuators. Sens. Actuators A Phys. 2007, 135, 229–235. [Google Scholar] [CrossRef]

- Bruno, B.P.; Fahmy, A.R.; Stürmer, M.; Wallrabe, U.; Wapler, M.C. Properties of Piezoceramic Materials in High Electric Field Actuator Applications. Smart Mater. Struct. 2018, 28, 015029. [Google Scholar] [CrossRef]

- Bauer, F. Review on the Properties of the Ferrorelaxor Polymers and Some New Recent Developments. Appl. Phys. A Mater. Sci. Process 2012, 107, 567–573. [Google Scholar] [CrossRef]

- Ku, C.C.; Liepins, R. Electrical Properties of Polymers. Chemical Principles; Hanser Publishers: Munich, Germany, 1987. [Google Scholar]

- Piézotech S.A.S. PIEZOTECH Films Properties; Piézotech S.A.S.: Hésingue, France, 2019; pp. 1–19. [Google Scholar]

- Precision Acoustics Guide to Using Poled PVDF—Properties and Uses. Available online: https://www.acoustics.co.uk/product/pvdf/ (accessed on 23 January 2024).

- Miriyev, A.; Stack, K.; Lipson, H. Soft Material for Soft Actuators. Nat. Commun. 2017, 8, 596. [Google Scholar] [CrossRef]

- Jurczuk, K.; Galeski, A.; Mackey, M.; Hiltner, A.; Baer, E. Orientation of PVDF α and γ Crystals in Nanolayered Films. Colloid. Polym. Sci. 2015, 293, 1289–1297. [Google Scholar] [CrossRef]

- Ruan, L.; Yao, X.; Chang, Y.; Zhou, L.; Qin, G.; Zhang, X. Properties and Applications of the β Phase Poly(Vinylidene Fluoride). Polymers 2018, 10, 228. [Google Scholar] [CrossRef]

- Sharma, T.; Je, S.; Gill, B.; Zhang, J.X.J. Patterning Piezoelectric Thin Film PVDF–TrFE Based Pressure Sensor for Catheter Application. Sens. Actuators A 2012, 177, 87–92. [Google Scholar] [CrossRef]

- Dargaville, T.R.; Celina, M.C.; Elliott, J.M.; Chaplya, P.M.; Jones, G.D.; Mowery, D.M.; Assink, R.A.; Clough, R.L.; Martin, J.W. Characterization, Performance and Optimization of PVDF as a Piezoelectric Film for Advanced Space Mirror Concepts; SAND2005-6846; Sandia National Laboratories: Albuquerque, NM, USA; Livermore, CA, USA, 2005; pp. 1–40. [Google Scholar]

- Zhang, Q.M.; Furukawa, T.; Bar-Cohen, Y.; Scheinbeim, J. Electroactive Polymers (EAP). Mater. Res. Soc. Symosium Proc. 1999, 600, 1–335. [Google Scholar]

- Zhang, Q.M.; Bharti, V.; Zhao, X. Giant Electrostriction and Relaxor Ferroelectric Behavior in Electron-Irradiated Poly-(Vinylidene Fluoride-Trifluoroethylene) Copolymer. Science 1998, 280, 2101–2104. [Google Scholar] [CrossRef] [PubMed]

- Lallart, M.; Cottinet, P.; Lebrun, L.; Guiffard, B.; Guyomar, D. Evaluation of Energy Harvesting Performance of Electrostrictive Polymer and Carbon-Filled Terpolymer Composites. J. Appl. Phys. 2010, 108, 34901–34907. [Google Scholar] [CrossRef]

- Ramaratnam, A.; Jalili, N. Reinforcement of Piezoelectric Polymers with Carbon Nanotubes: Pathway to next-Generation Sensors. J. Intell. Mater. Syst. Struct. 2006, 17, 199–208. [Google Scholar] [CrossRef]

- Ye, H.; Shao, W.; Zhen, L. Crystallization Kinetics and Phase Transformation of Poly(Vinylidene Fluoride) Films Incorporated with Functionalized BaTiO3 Nanoparticles. J. Appl. Polym. Sci. 2013, 129, 2940–2949. [Google Scholar] [CrossRef]

- Graz, I.; Krause, M.; Bauer-Gogonea, S.; Bauer, S.; Lacour, S.P.; Ploss, B.; Zirkl, M.; Stadlober, B.; Wagner, S. Flexible Active-Matrix Cells with Selectively Poled Bifunctional Polymer-Ceramic Nanocomposite for Pressure and Temperature Sensing Skin. J. Appl. Phys. 2009, 106, 34503–34505. [Google Scholar] [CrossRef]

- Dodds, J.S.; Meyers, F.N.; Loh, K.J. Piezoelectric Characterization of PVDF-TrFE Thin Films Enhanced with ZnO Nanoparticles. IEEE Sens. J. 2012, 12, 1889–1890. [Google Scholar] [CrossRef]

- Ueberschlag, P. PVDF Piezoelectric Polymer. Sens. Rev. 2001, 21, 118–126. [Google Scholar] [CrossRef]

- Schmidt Department of Physics/Electro-Active Materials Piezoelectric and Conductive Polymers. Available online: http://www.physics.montana.edu/eam/polymers/index.html (accessed on 23 January 2024).

- Pérez, R.; Král, M.; Bleuler, H. Study of Polyvinylidene Fluoride (PVDF) Based Bimorph Actuators for Laser Scanning Actuation at KHz Frequency Range. Sens. Actuators A Phys. 2012, 183, 84–94. [Google Scholar] [CrossRef]

- Levard, T.; Diglio, P.J.; Lu, S.G.; Rahn, C.D.; Zhang, Q.M. Core-Free Rolled Actuators for Braille Displays Using P(VDF–TrFE–CFE). Smart Mater. Struct. 2011, 21, 12001–12007. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.; Klein, R.; Li, H.; Zhang, Q.M.; Bauer, F.; Cheng, Z.Y. Poly(Vinylidene Floride-Trifluoroethylene) Based High Performance Electroactive Polymers. IEEE Trans. Dielectr. Electr. Insul. 2004, 20, 299–311. [Google Scholar] [CrossRef]

- Bauer, F.; Fousson, E.; Zhang, Q.M. Recent Advances in Highly Electrostrictive P(VDF-TrFE-CFE) Terpolymers. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 1149–1154. [Google Scholar] [CrossRef]

- Xia, F.; Tadigadapa, S.; Zhang, Q.M. Electroactive Polymer Based Microfluidic Pump. Sens. Actuators A Phys. 2006, 125, 346–352. [Google Scholar] [CrossRef]

- Polasik, J.; Schmidt, V.H. Conductive Polymer PEDOT/PSS Electrodes on the Piezoelectric Polymer PVDF. In Proceedings of the SPIE Smart Structures and Materials Symposium, EAPAD Conference, San Diego, CA, USA, 6 May 2005; Volume 5759, pp. 114–120. [Google Scholar]

- Xia, F.; Li, H.; Huang, C.; Huang, M.; Xu, H.; Bauer, F.; Cheng, Z.-Y.; Zhang, Q. Poly(Vinylidene Fluoride-Trifluoroethylene) Based High Performance Electroactive Polymers. In Proceedings of the SPIE Smart Structures and Materials Symposium, EAPAD Conference, San Diego, CA, USA, 28 July 2003; Volume 5051, pp. 133–142. [Google Scholar]

- Pelrine, R.; Kornbluh, R.; Joseph, J.; Heydt, R.; Pei, Q.; Chiba, S. High-Field Deformation of Elastomeric Dielectrics for Actuators. Mater. Sci. Eng. C 2000, 11, 89–100. [Google Scholar] [CrossRef]

- Fan, F.; Szpunar, J. Characterization of Viscoelasticity and Self-Healing Ability of VHB 4910. Macromol. Mater. Eng. 2015, 300, 99–106. [Google Scholar] [CrossRef]

- Ha, S.M.; Yuan, W.; Pei, Q. Interpenetrating Polymer Networks for High-Performance Electroelastomer Artificial Muscles. Adv. Mater. 2006, 18, 887–891. [Google Scholar] [CrossRef]

- Huang, J.; Lu, T.; Zhu, J. Large, Uni-Directional Actuation in Dielectric Elastomers Achieved by Fiber Stiffening. Appl. Phys. Lett. 2012, 100, 4068–4844. [Google Scholar] [CrossRef]

- Lu, T.; Huang, J.; Jordi, C. Dielectric Elastomer Actuators under Equal-Biaxial Forces, Uniaxial Forces and Uniaxial Constraint of Stiff Fibers. Soft Matter 2012, 8, 61–67. [Google Scholar] [CrossRef]

- Shian, S.; Huang, J.; Zhu, S. Optimizing the Electrical Energy Conversion Cycle of Dielectric Elastomer Generators. Adv. Mater. 2014, 26, 6617–6621. [Google Scholar] [CrossRef]

- Tavakol, B.; Bozlar, M.; Punckt, C.; Froehlicher, G.; Stone, H.A.; Aksay, I.A.; Holmes, D.P. Buckling of Dielectric Elastomeric Plates for Soft, Electrically Active Micro Fluidic Pumps. Soft Matter 2014, 10, 4789–4794. [Google Scholar] [CrossRef] [PubMed]

- Romasanta, L.J.; Lopez-Manchado, M.A.; Verdejo, R. Increasing the Performance of Dielectric Elastomer Actuators: A Review from the Materials Perspective. Prog. Polym. Sci. 2015, 51, 188–211. [Google Scholar] [CrossRef]

- Pei, Q.; Rosenthal, M.A.; Pelrine, R.; Stanford, S.; Kornbluh, R.D. Multifunctional Electroelastomer Roll Actuators and Their Application for Biomimetic Walking Robots. In Proceedings of the SPIE Smart Structures and Materials Symposium, EAPAD Conference, San Diego, CA, USA, 28 July 2003; pp. 281–290. [Google Scholar]

- Adkins, J.E.; Rivlin, R.S. Large Elastic Deformations of Isotropic Materials. IX. The Deformation of Thin Sshells. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 1952, 244, 505–531. [Google Scholar]

- Carpi, F.; Rossi, D.D. Improvement of Electromechanical Actuating Performances of a Silicone Dielectric Elastomer by Dispersion of Titanium Dioxide Powder. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 835–843. [Google Scholar] [CrossRef]

- Rosset, S.; Shea, H.R. Flexible and Stretchable Electrodes for Dielectric Elastomer Actuators. Appl. Phys. A Mater. Sci. Process 2012, 110, 281–307. [Google Scholar] [CrossRef]

- Goulbourne, N.; Frecker, M.I.; Snyder, A.J. Modeling of a Dielectric Elastomer Diaphragm for a Prosthetic Blood Pump. In Proceedings of the SPIE Smart Structures and Materials Symposium, EAPAD Conference, San Diego, CA, USA, 28 July 2003; Volume 5051, pp. 1–13. [Google Scholar]

- Shankar, R.; Ghosh, K.; Spontak, R.J.; Gilbert, S.R.D. Dielectric Elastomers as Next-Generation Polymeric Actuators. Soft. Matter. 2007, 3, 1116–1129. [Google Scholar] [CrossRef] [PubMed]

- Carpi, F.; Rossi, D.D.; Kornbluh, R.; Pelrine, R.; Sommer-Larsen, P. Dielectric Elastomers as Electromechanical Transducers. In Fundamental Configurations for Dielectric Eelastomer Actuators; Elsevier: Oxford, UK, 2008. [Google Scholar]

- Schlaak, H.F.; Jungmann, M.; Matysek, M.; Lotz, P. Novel Multilayer Electrostatic Solid State Actuators with Elastic Dielectric. In Proceedings of the SPIE Smart Structures and Materials Symposium, EAPAD Conference, San Diego, CA, USA, 6 May 2005; Volume 5759, pp. 1–13. [Google Scholar]

- Schlaak, H.F.; Lotz, P.; Matysek, M. Multilayer Stack Contractile Actuators. In Dielectric Elastomers as Electromechanical Transducers; Elsevier Ltd.: Berlin/Heidelberg, Germany, 2008; ISBN 9780080474885. [Google Scholar]

- Kovacs, G.; Lochmatter, P.; Wissler, M. An Arm Wrestling Robot Driven by Dielectric Elastomer Actuators. Smart Mater. Struct. 2007, 16, 260–265. [Google Scholar] [CrossRef]

- Sarban, R.; Jones, R.W.; Mac, E.B.R.; Rustighi, E. A Tubular Dielectric Elastomer Actuator: Fabrication, Characterization and Active Vibration Isolation. Mech. Syst. Signal Process 2011, 25, 2879–2891. [Google Scholar] [CrossRef]

- Arora, S.; Ghosh, T.; Muth, J. Dielectric Elastomer Based Prototype Fiber Actuators. Sens. Actuators A Phys. 2007, 136, 321–328. [Google Scholar] [CrossRef]

- Carpi, F.; De Rossi, D. Dielectric Elastomer Cylindrical Actuators: Electromechanical Modelling and Experimental Evaluation. Mater. Sci. Eng. C 2004, 24, 555–562. [Google Scholar] [CrossRef]

- Cameron, C.G.; Szabo, J.P.; Johnstone, S.; Massey, J.; Leidner, J. Linear Actuation in Coextruded Dielectric Elastomer Tubes. Sens. Actuators A Phys. 2008, 147, 286–291. [Google Scholar] [CrossRef]

- Kofod, G.; Stoyanov, H.; Gerhard, R. Multilayer Coaxial Fiber Dielectric Elastomers for Actuation and Sensing. Appl. Phys. A Mater. Sci. Process 2011, 102, 577–581. [Google Scholar] [CrossRef]

- Lau, G.K.; Goh, S.C.K.; Shiau, L.L. Dielectric Elastomer Unimorph Using Flexible Electrodes of Electrolessly Deposited (ELD) Silver. Sens. Actuators A Phys. 2011, 169, 234–241. [Google Scholar] [CrossRef]

- Araromi, O.A.; Conn, A.T.; Ling, C.S.; Rossiter; Vaidyanathan, J.M.R.; Burgess, S.C. Spray Deposited Multilayered Dielectric Elastomer Actuators. Sens. Actuators A Phys. 2011, 167, 459–467. [Google Scholar] [CrossRef]

- Chun-Kiat, S.G.; Lau, G.K. Dielectric Elastomeric Bimorphs Using Electrolessly Deposited Silver Electrodes. In Proceedings of the SPIE Smart Structures and Materials Symposium, EAPAD Conference, San Diego, CA, USA, 9 April 2010; Volume 7642, pp. 1–13. [Google Scholar]

- O’Halloran, A.; O’Malley, F.; McHugh, P. A Review on Dielectric Elastomer Actuators, Technology, Applications, and Challenges. J. Appl. Phys. 2008, 104, 71101–711010. [Google Scholar] [CrossRef]

- Pelrine, R.E.; Kornbluh, R.D.; Joseph, J.P. Electrostriction of Polymer Dielectrics with Compliant Electrodes as a Means of Actuation. Sens. Actuators A Phys. 1998, 64, 77–85. [Google Scholar] [CrossRef]

- Kornbluh, R.; Pelrine, Q.R.; Pei, S.; Oh, J.J. Ultrahigh Strain Response of Field-Actuated Elastomeric Polymers. In Proceedings of the SPIE Smart Structures and Materials Symposium, EAPAD Conference, Newport Beach, CA, USA, 7 June 2000; Volume 3987, pp. 51–64. [Google Scholar]

- Ho, S.; Banerjee, H.; Foo, Y.Y.; Godaba, H.; Aye, W.M.M.; Zhu, J.; Yap, C.H. Experimental Characterization of a Dielectric Elastomer Fluid Pump and Optimizing Performance via Composite Materials. J. Intell. Mater. Syst. Struct. 2017, 28, 3054–3065. [Google Scholar] [CrossRef]

- Suo, Z. Theory of Dielectric Elastomers. Acta Mech. Solida Sinica 2010, 23, 549–578. [Google Scholar] [CrossRef]

- Koh, S.J.A.; Li, T.; Zhou, J.; Zhao, X.; Hong, W.; Zhu, J.; Suo, Z. Mechanisms of Large Actuation Strain in Dielectric Elastomers. J. Polym. Sci. B Polym. Phys. 2011, 49, 504–515. [Google Scholar] [CrossRef]

- Zhu, J.; Stoyanov, H.; Kofod, G.; Suo, Z. Large Deformation and Electromechanical Instability of a Dielectric Elastomer Tube Actuator. J. Appl. Phys. 2010, 108, 074113. [Google Scholar] [CrossRef]

- Hines, L.; Petersen, K.; Sitti, M. Inflated Soft Actuators with Reversible Stable Deformations. Adv. Mater. 2016, 28, 3690–3696. [Google Scholar] [CrossRef] [PubMed]

- Keplinger, C.; Li, T.; Baumgartner, R.; Suo, Z.; Bauer, S. Harnessing Snap-through Instability in Soft Dielectrics to Achieve Giant Voltage-Triggered Deformation. Soft Matter 2012, 8, 285–288. [Google Scholar] [CrossRef]

- Godaba, H.; Foo, C.C.; Zhang, Z.Q.; Khoo, B.C.; Zhu, J. Giant Voltage-Induced Deformation of a Dielectric Elastomer under a Constant Pressure. Appl. Phys. Lett. 2014, 105, 112901–112904. [Google Scholar] [CrossRef]

- Li, B.; Liu, L.; Suo, Z. Extension Limit, Polarization Saturation, and Snap-through Instability of Dielectric Elastomers. Int. J. Smart Nano Mater. 2011, 2, 59–67. [Google Scholar] [CrossRef]

- Pelrine, R.; Kornbluh, R. Electromechanical Transduction Effects in Dielectric Elastomers: Actuation, Sensing, Stiffness Modulation and Electric Energy Generation; Elsevier Ltd.: Amsterdam, The Netherlands, 2008; Volume 1, ISBN 9780080474885. [Google Scholar]

- Pelrine, R.; Kornbluh, R.D.; Pei, Q. Dielectric Elastomers: Past, Present, and Potential Future. In Proceedings of the SPIE Smart Structures and Materials Symposium, EAPAD Conference, Denver, CO, USA, 27 March 2018; Volume 10594, pp. 1–9. [Google Scholar] [CrossRef]

- Kar, K.K. Composite Materials; Springer: Berlin/Heidelberg, Germany, 2017; ISBN 9783662495124. [Google Scholar]

- Adolf, D.; Shahinpoor, M.; Segalman, D.; Witkowski, W. Electrically Controlled Polymeric Gel Actuators. 1993. Available online: https://patents.google.com/patent/US5250167A/en (accessed on 23 January 2024).

- Oguro, K.; Takenaka, H.; Kawami, Y. Actuator Element 1993. Available online: https://patents.google.com/patent/US5268082A/en (accessed on 23 January 2024).

- Shahinpoor, M. Fundamentals of Ionic Polymer Metal Composites (IPMCs). In Ionic Polymer Metal Composites (IPMCs): Smart Multi-Functional Materials and Artificial Muscles; Royal Society of Chemistry: London, UK, 2016; Volume 1, ISBN 9781782622581. [Google Scholar]

- Bar-Cohen, Y.; Bao, X.; Sherrit, S.; Lih, S. Characterization of the Electromechanical Properties of Ionomeric Polymer-Metal Composite (IPMC). In Proceedings of the SPIE Smart Structures and Materials Symposium, EAPAD Conference, San Diego, CA, USA, 11 July 2002; pp. 1–8. [Google Scholar]

- Tiwari, R.; Kim, K.J. Disc-Shaped Ionic Polymer Metal Composites for Use in Mechano-Electrical Applications. Smart Mater. Struct. 2010, 19, 065016. [Google Scholar] [CrossRef]

- Shahinpoor, M. Ionic Polymer Metal Composites (IPMCs) Optimal Manufacturing. In Ionic Polymer Metal Composites (IPMCs): Smart Multi-Functional Materials and Artificial Muscles; Royal Society of Chemistry: London, UK, 2016; Volume 1. [Google Scholar]

- Bennett, M.D.; Leo, D.J. Ionic Liquids as Stable Solvents for Ionic Polymer Transducers. Sens. Actuators A Phys. 2004, 115, 79–90. [Google Scholar] [CrossRef]

- Johanson, U.; Punning, A.; Aabloo, A. Ionic Polymer Metal Composites with Electrochemically Active Electrodes. In RSC Smart Materials; Royal Society of Chemistry: London, UK, 2016; Volume 1, ISBN 9781782622581. [Google Scholar]

- Kruusamäe, K.; Punning, A.; Aabloo, A.; Asaka, K. Self-Sensing Ionic Polymer Actuators: A Review. Actuators 2015, 4, 17–38. [Google Scholar] [CrossRef]

- Carrico, J.; Fleming, M.; Tsugawa, M.A.; Leang, K.K. Precision Feedback and Feedforward Control of Ionic Polymer-Metal Composite Actuators. In Ionic Polymer Metal Composites (IPMCs): Smart Multi-Functional Materials and Artificial Muscles; Royal Society of Chemistry: London, UK, 2016; Volume 1, ISBN 9781782622581. [Google Scholar]

- Carrico, J.D.; Leang, K.K. Fused Filament 3D Printing of Ionic Polymer-Metal Composites for Soft Robotics. In Proceedings of the SPIE Smart Structures and Materials Symposium, EAPAD Conference, Portland, OR, USA, 17 April 2017; Volume 10163, pp. 1–13. [Google Scholar] [CrossRef]

- Lee, S.J.; Han, M.J.; Kim, S.J.; Jho, J.Y.; Lee, H.Y.; Kim, Y.H. A New Fabrication Method for IPMC Actuators and Application to Artificial Fingers. Smart Mater. Struct. 2006, 15, 1217–1224. [Google Scholar] [CrossRef]

- Riddle, R.O.; Jung, Y.; Kim, S.-M.; Song, S.; Stolpman, B.; Kim, K.J.; Leang, K.K. Sectored-Electrode IPMC Actuator for Bending and Twisting Motion. In Proceedings of the SPIE Smart Structures and Materials Symposium, EAPAD Conference, San Diego, CA, USA, 9 April 2010; pp. 1–9. [Google Scholar] [CrossRef]

- Nam, D.N.C.; Il, Y.J.; Kwan, A.K. A Novel Design Technique for IPMC Diaphragm in Micropump Application. In Proceedings of the 12th International Conference on Control, Automation and Systems, Jeju, Republic of Korea, 17–21 October 2012; pp. 360–365. [Google Scholar]

- Wang, Y.; Liu, J.; Zhu, D.; Chen, H. Active Tube-Shaped Actuator with Embedded Square Rod-Shaped Ionic Polymer-Metal Composites for Robotic-Assisted Manipulation. Appl. Bionics Biomech. 2018, 2018, 4031705. [Google Scholar] [CrossRef]

- Wang, J.; Mcdaid, A.; Sharma, R.; Aw, K.C. A Compact Ionic Polymer Metal Composite (IPMC) System with Inductive Sensor for Closed Loop Feedback. Actuators 2015, 4, 114–126. [Google Scholar] [CrossRef]

- Yang, W.; Choi, H.; Choi, S.; Jeon, M.; Lee, S.Y. Carbon Nanotube-Graphene Composite for Ionic Polymer Actuators. Smart Mater. Struct. 2012, 21, 055012. [Google Scholar] [CrossRef]

- Shahinpoor, M.; Kim, K.J. Ionic Polymer-Metal Composites—I.Fundamentals. Smart Mater. Struct. 2001, 10, 819–833. [Google Scholar] [CrossRef]

- Nemat-Nasser, S.; Wu, Y. Comparative Experimental Study of Ionic Polymer-Metal Composites with Different Backbone Ionomers and in Various Cation Forms. J. Appl. Phys. 2003, 93, 5255–5267. [Google Scholar] [CrossRef]

- Pak, J.J.; Kim, J.; Oh, S.W.; Son, J.H.; Cho, S.H.; Lee, S.; Park, J.; Kim, B. Fabrication of Ionic—Polymer—Metal—Composite (IPMC) Micropump Using a Commercial Nafion. In Proceedings of the SPIE Smart Structures and Materials Symposium, EAPAD Conference, San Diego, CA, USA, 27 July 2004; Volume 5385, pp. 272–280. [Google Scholar] [CrossRef]

- Punning, A.; Kruusmaa, M.; Aabloo, A. Surface Resistance Experiments with IPMC Sensors and Actuators. Sens. Actuators A Phys. 2007, 133, 200–209. [Google Scholar] [CrossRef]

- Rasmussen, S.C. Early History of Conjugated Polymers. In Handbook of Conducting Polymers; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Zhong, Y.; Filippini, D.; Jager, E.W.H. A Versatile Flexible Polymer Actuator System for Pumps, Valves, and Injectors Enabling Fully Disposable Active Microfluidics. Adv. Mater. Technol. 2021, 6, 2000769. [Google Scholar] [CrossRef]

- Li, Y. Organic Optoelectronic Materials; Springer: Berlin/Heidelberg, Germany, 2015; Volume 91, ISBN 978-3-319-16861-6. [Google Scholar]

- Harun, M.H.; Saion, E.; Kassim, A.; Yahya, N.; Mahmud, E. Conjugated Conducting Polymers: A Brief Overview. JASA 2 2007, 2, 63–68. [Google Scholar]

- Dai, L. Conducting Polymers. In Materials Synthesis to Device Applications; Springer: Berlin/Heidelberg, Germany, 2004; Volume 16, ISBN 978-1-85233-510-6. [Google Scholar]

- Wallace, G.G.; Teasdale, P.R.; Spinks, G.M.; Kane-Maguire, L.A.P. Conductive Electroactive Polymers: Intelligent Polymer Systems, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Kar, P. Doping in Conjugated Polymers; Scrivener Publishing: Beverly, Ma, USA, 2013. [Google Scholar]

- Punning, A.; Vunder, V.; Must, I.; Johanson, U.; Anbarjafari, G.; Aabloo, A. In Situ Scanning Electron Microscopy Study of Strains of Ionic Electroactive Polymer Actuators. J. Intell. Mater. Syst. Struct. 2015, 27, 1061–1074. [Google Scholar] [CrossRef]

- Otero, T.F.; Angulo, E.; Rodríguez, J.; Santamaría, C. Electrochemomechanical Properties from a Bilayer: Polypyrrole/Non-Conducting and Flexible Material—Artificial Muscle. J. Electroanal. Chem. 1992, 341, 369–375. [Google Scholar] [CrossRef]

- Pei, Q.; Inganaes, O. Electrochemical Applications of the Bending Beam Method. 1. Mass Transport and Volume Changes in Polypyrrole during Redox. J. Phys. Chem. 1992, 95, 10507–10514. [Google Scholar] [CrossRef]

- Kaneko, M.; Kaneto, K. Electrochemomechanical Deformation of Polyaniline Films Doped with Self-Existent and Giant Anions. React. Funct. Polym. 1998, 37, 155–161. [Google Scholar] [CrossRef]

- Baughman, R.H. Conducting Polymer Artificial Muscles. Synth. Met. 1996, 78, 339–353. [Google Scholar] [CrossRef]

- Shoa, T.; Munce, N.R.; Yang, V.; Madden, J.D. Conducting Polymer Actuator Driven Catheter: Overview and Applications. In Proceedings of the SPIE Smart Structures and Materials Symposium, EAPAD Conference, San Diego, CA, USA, 6 April 2009; Volume 7287, pp. 1–9. [Google Scholar] [CrossRef]

- Mazzoldi, A.; DeglInnocenti, C.; Michelucci, M.; Rossi, D. Actuative Properties of Polyaniline Fibers under Electrochemical Stimulation. Mater. Sci. Eng. C 1998, 6, 65–72. [Google Scholar] [CrossRef]

- Lee, A.S.; Peteu, S.F.; Ly, J.V.; Requicha, A.A.G.; Thompson, M.E.; Zhou, C. Actuation of Polypyrrole Nanowires. Nanotechnology 2008, 19, 165501. [Google Scholar] [CrossRef] [PubMed]

- Xi, B.; Truong, V.T.; Mottaghitalab, V.; Whitten, P.G.; Spinks, G.M.; Wallace, G.G. Actuation Behaviour of Polyaniline Films and Tubes Prepared by the Phase Inversion Technique. Smart Mater. Struct. 2007, 16, 1549–1554. [Google Scholar] [CrossRef]

- Zondaka, Z.; Kivilo, A.; Nakshatharan, S.; Küppar, K.-A.; Johanson, U.; Tamm, T.; Kiefer, R. Carbide-Derived Carbon and Poly-3,4-Ethylenedioxythiphene Composite Laminate: Linear and Bending Actuation. Synth. Met. 2018, 245, 67–73. [Google Scholar] [CrossRef]

- Torop, J.; Aabloo, A.; Jager, W.H.E. Novel Actuators Based on Polypyrrole/Carbide-Derived Carbon Hybrid Materials. Carbon. N. Y. 2014, 80, 387–395. [Google Scholar] [CrossRef]

- Zondaka, Z.; Valner, R.; Tamm, T.; Aabloo, A.; Kiefer, R. Carbide-Derived Carbon in Polypyrrole Changing the Elastic Modulus with a Huge Impact on Actuation. RSC Adv. 2016, 6, 26380–26385. [Google Scholar] [CrossRef]

- Madden, J.D.; Madden, P.G.; Anquetil, P.A.; Hunter, I.W. Load and Time Dependence of Displacement in a Conducting Polymer Actuator. Available online: https://www.researchgate.net/publication/281993878 (accessed on 23 January 2024).

- Rinne, P.; Põldsalu, I.; Johanson, U.; Tamm, T.; Põhako-Esko, K.; Punning, A.; van den Ende, D.; Aabloo, A. 1 Encapsulation of Ionic Electromechanically Active Polymer Actuators. Smart Mater. Struct. 2019, 28, 074002. [Google Scholar] [CrossRef]

- Gil, J.; Planell, J.A.; Libenson, C. Differences in the Pseudoelasticity Behaviour of Nickel-Titanium Orthodontic Wires. J. Mater. Sci. Mater. Med. 1993, 4, 281–284. [Google Scholar] [CrossRef]

- Song, C. History and Current Situation of Shape Memory Alloys Devices for Minimally Invasive Surgery. Open Med. Device J. 2010, 2, 24–31. [Google Scholar] [CrossRef]

- Filip, P. Titanium-Nickel Shape Memory Alloys in Medical Applications. In Titanium in Medicine. Engineering Materials; Springer: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Uchino, K. Advanced Piezoelectric Materials: Science and Technology; Elsevier Ltd.: Amsterdam, The Netherlands, 2017. [Google Scholar]

- McCoul, D.; Pei, Q. Dielectric Elastomers for Fluidic and Biomedical Applications, University of California, Los Angeles, CA, USA, 2015.

- Elhi, F.; Priks, H.; Rinne, P.; Niilo, K.; Žusinaite, E.; Johanson, U.; Aabloo, A.; Tamm, T.; Põhako-Esko, K. Electromechanically Active Polymer Actuators Based on Biofriendly Choline Ionic Liquids. Smart Mater. Struct. 2020, 29, 055021. [Google Scholar] [CrossRef]

| Smart | NiTi | CuZnAl | CuAlNi | |

|---|---|---|---|---|

|

Materials Properties | ||||

| Young’s modulus (GPa) | 28–83 [56] | 70–100 [56] | 80–100 [56] | |

| Resistivity (106 Ωm) | 0.5–1.1 [56] | 0.07–0.12 [56] | 0.1–0.14 [56] | |

| Phase transformation temperature (austenite finish temperature Af) (°C) | 200 [56] | 200 [56] | 200 [56] | |

| Typical actuation strain, ε (%) | 4% [31] | |||

| Maximum actuation strain, εmax (%) (1st actuation cycle) | 6–8 [56] | 4–6 [56] | 5–6 [56] | |

| Typical actuation stress, σ (MPa) | 100–130 [56] | 40 [56] | 70 [56] | |

| Maximum actuation stress, σmax (MPa) | 500–900 [56] | 400–700 [56] | 300–600 [56] | |

| Driving voltage (V) | 5 [31] | |||

| Bandwidth (Hz) | milliseconds (active cooling)–minutes (passive cooling) [51,52,53,57] | |||

| Cycle life | 300 @ ε = 5%–>105 @ ε = 0.5% [58] | >104 [56] | >5 × 103 [56] | |

| Smart Material | Irradiated P (VDF-TrFE) | |

|---|---|---|

| Properties | ||

| Young’s modulus, Y (GPa) (depending on composition and level of irradiation) | 0.3–1.2 [48] | |

| Dielectric constant | 55 [48] | |

| Dielectric breakdown (MV/m) | 200 [2,13] | |

| Normal longitudinal piezoelectric strain coefficient, d33 (pC/N) | −33 [73] | |

| Typical actuation strain, ε (%) | 2 [73] | |

| Maximum actuation strain, εmax (%) | 7 [73] | |

| Typical actuation stress, σ (MPa) | 20 [13] | |

| Maximum actuation stress, σmax (MPa) | 40 [83,93,97] | |

| Driving electric field (MV/m) | 100 [13] | |

| Bandwidth (Hz) | 100 [13] | |

| Cycle life | ≤5 × 107 [48] | |

| Smart Material | Silicone-Based | VHB Acrylic-Based | |

|---|---|---|---|

| Properties | |||

| Young’s modulus, Y (MPa) (depending on fabrication process and strain) | 0.1–1 [48] | 1–3 [48] | |

| Dielectric constant | ∼3 @ 1 kHz [48] | ∼4.8 @ 1 kHz [48] | |

| Dielectric breakdown (MV/m) | 200 [2,13] | ||

| Typical actuation strain, ε (%) | 10–30% [125] | ||

| Maximum actuation strain, εmax (%) | 120 [48] | 380 [48] | |

| Typical actuation stress, σ (MPa) | 0.3 [48] | 1.6 [48] | |

| Maximum actuation stress, σmax (MPa) | 3.2 [48] | 7.7 [48] | |

| Driving electric field (MV/m) | 110–350 [48] | 125–440 [48] | |

| Bandwidth (Hz) | 1400 [126] | 10 [126] | |

| Cycle life | 107 @ ε = 5% (no failures observed)–106 @ ε = 10% [48] | 107 @ ε = 5% (no failures observed)–106 @ ε = 50% [48] | |

| Smart Material | IPMC with Noble Metal Electrodes | |

|---|---|---|

| Electro-Mechanical Properties | ||

| Young’s modulus, Y (MPa) | 0.1 [48] | |

| Typical actuation strain, ε (%) | 0.5 [48] | |

| Maximum actuation strain, εmax (%) | >10 [153,154] | |

| Typical actuation stress, σ (MPa) | 3 [155] | |

| Maximum actuation stress, σmax (MPa) | 30 [82,156] | |

| Driving voltage (V) | 1–5 [153,157] | |

| Bandwidth (Hz) | 100 [153,157] | |

| Cycle life | 106 @ ε = extremely small [157] | |

| Smart Material | CP | |

|---|---|---|

| Electro-Mechanical Properties | ||

| Young’s modulus, Y (GPa) | 0.8–3 [48] | |

| Conductivity (S/m) | 10,000–45,000 [47] | |

| Typical actuation strain, ε (%) | 2–10 [77] | |

| Maximum actuation strain, εmax (%) | 40 [77] | |

| Typical actuation stress, σ (MPa) | 1 [77,178] | |

| Maximum actuation stress, σmax (MPa) | 35 [77,178] | |

| Driving voltage (V) | ≤1 [10] | |

| Bandwidth (Hz) | 1 Hz [10] | |

| Cycle life | 106 [48] | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sideris, E.A.; de Lange, H.C.; Johanson, U.; Tamm, T. Solid-State Electromechanical Smart Material Actuators for Pumps—A Review. Actuators 2024, 13, 232. https://doi.org/10.3390/act13070232

Sideris EA, de Lange HC, Johanson U, Tamm T. Solid-State Electromechanical Smart Material Actuators for Pumps—A Review. Actuators. 2024; 13(7):232. https://doi.org/10.3390/act13070232

Chicago/Turabian StyleSideris, Eva Ann, Hendrik Cornelis de Lange, Urmas Johanson, and Tarmo Tamm. 2024. "Solid-State Electromechanical Smart Material Actuators for Pumps—A Review" Actuators 13, no. 7: 232. https://doi.org/10.3390/act13070232

APA StyleSideris, E. A., de Lange, H. C., Johanson, U., & Tamm, T. (2024). Solid-State Electromechanical Smart Material Actuators for Pumps—A Review. Actuators, 13(7), 232. https://doi.org/10.3390/act13070232