New Technique for Enhancing Residual Oil Recovery from Low-Permeability Reservoirs: The Cooperation of Petroleum Hydrocarbon-Degrading Bacteria and SiO2 Nanoparticles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Displacement Fluids

2.3. Preparation of Glass Micromodels

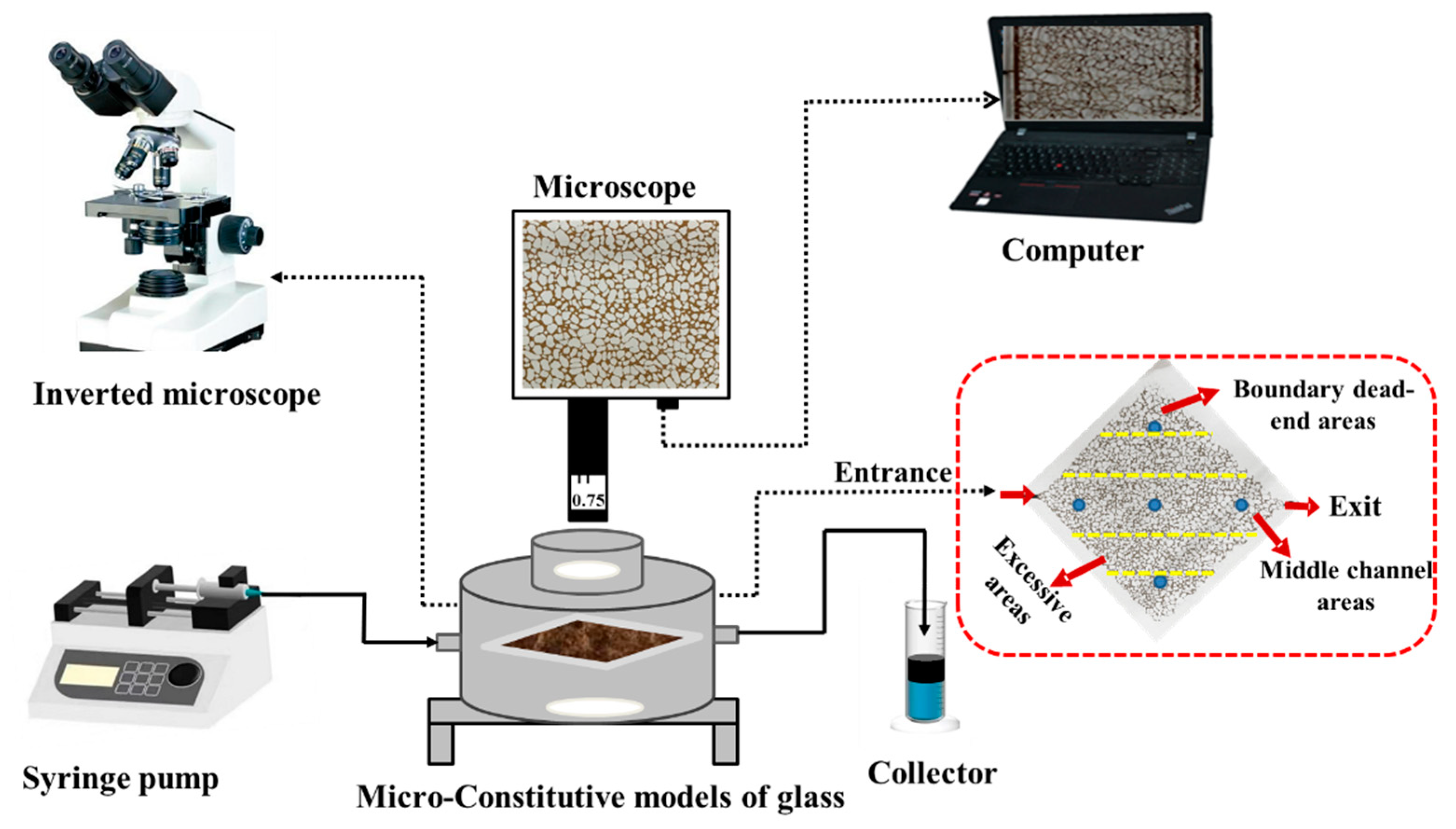

2.4. Micromodel Displacement Experiments

2.5. Analysis of Residual Oil

3. Results and Discussion

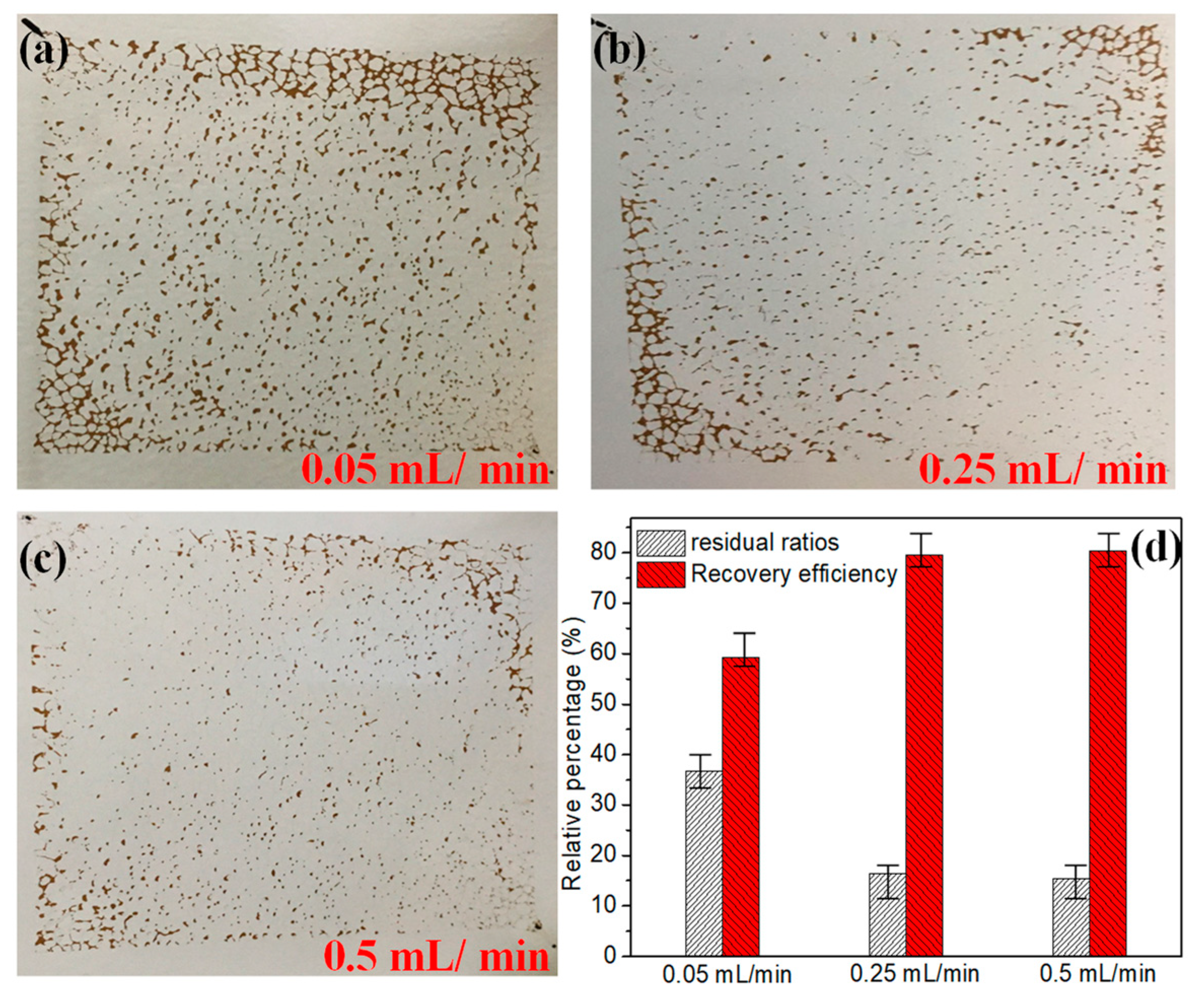

3.1. Migration Characteristics of Crude Oil under Primary Water Flooding

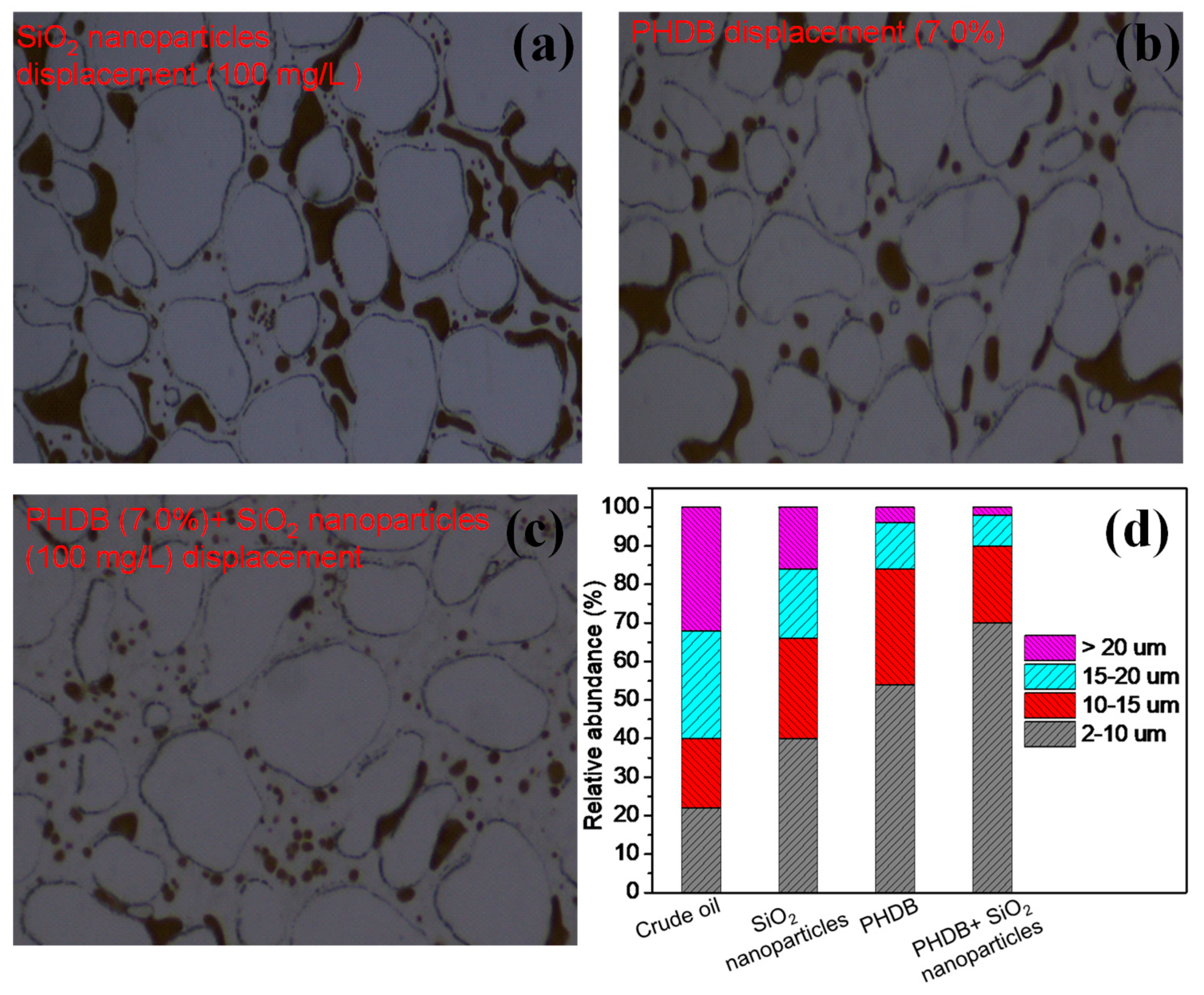

3.2. Effects of Displacement Fluids on Residual Oil Recovery

3.3. Mobilization Characteristics of Residual Oil in Different Displacement Areas

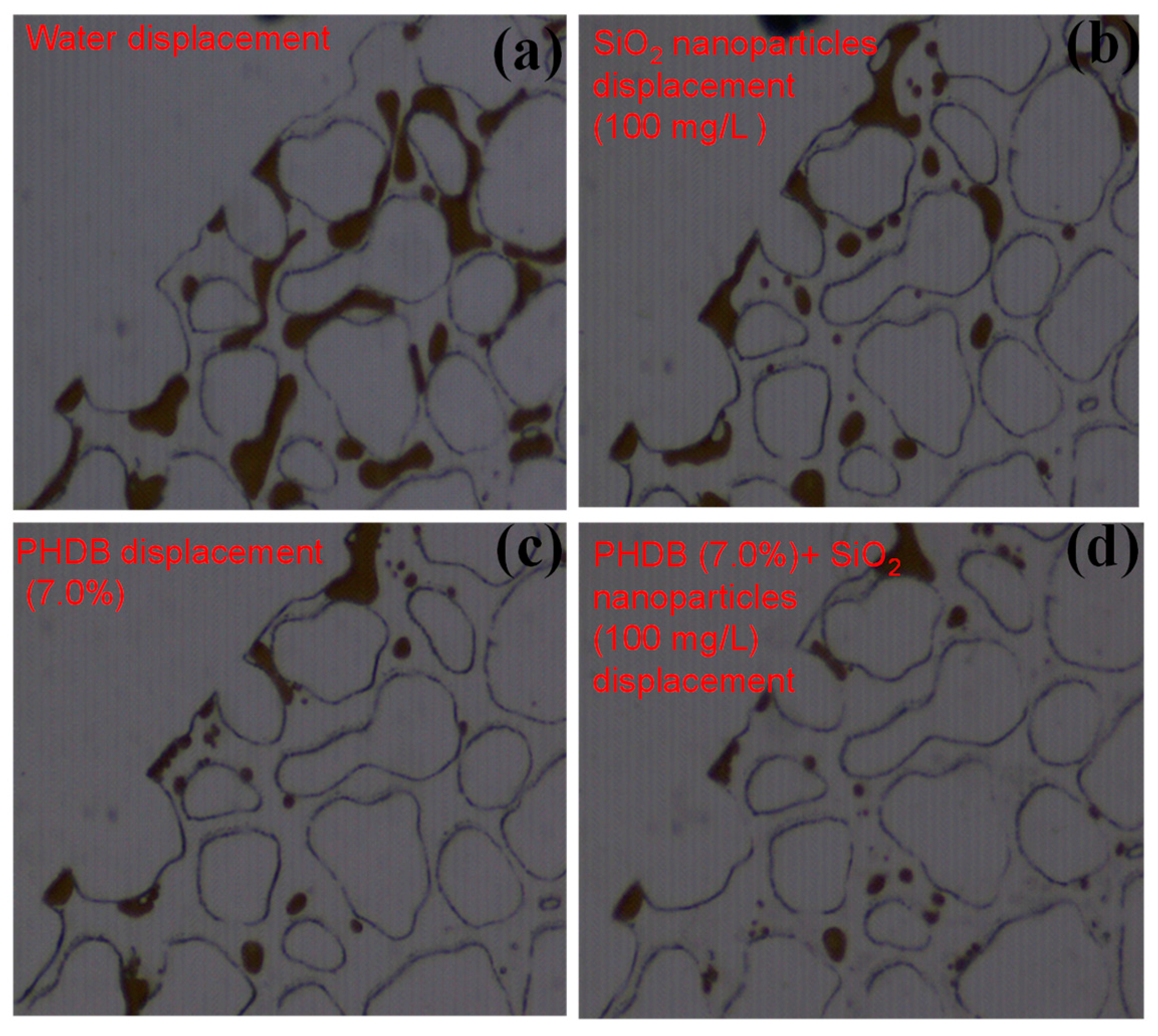

3.3.1. Middle Channel Areas

3.3.2. Excessive Areas

3.3.3. Boundary Dead-End Areas

3.4. Theoretical Mechanism Analysis of Microbial-Nanofluids for EOR

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, H.X.; Liu, Q.W.; Wen, C.Y.; Chen, P.; Wang, C.J. Review of residual oil distribution and potential tapping. Spec. Oil Gas Reserv. 2006, 13, 8–11. [Google Scholar]

- Cui, K.; Zhang, Z.Y.; Zhang, Z.Z.; Sun, S.S.; Li, H.L.; Fu, P. Stimulation of indigenous microbes by optimizing the water cut in low permeability reservoirs for green and enhanced oil recovery. Sci. Rep. 2019, 9, 15772–15783. [Google Scholar] [CrossRef] [PubMed]

- Saravanan, A.; Kumar, P.S.; Vardhan, K.H.; Jeevanantham, S.; Karishma, S.B.; Yaashikaa, P.R.; Vellaichamy, P. A review on a systematic approach for microbial enhanced oil recovery technologies: Opportunities and challenges. J. Clean. Prod. 2020, 258, 120777. [Google Scholar] [CrossRef]

- Chen, H.; Li, H.; Li, Z.; Li, S.; Wang, Y.; Wang, J.; Li, B. Effects of matrix permeability and fracture on production characteristics and residual oil distribution during flue gas flooding in low permeability/tight reservoirs. J. Pet. Sci. Eng. 2020, 195, 107813–107822. [Google Scholar] [CrossRef]

- Wang, D.; Sun, S.; Sha, T.; Liu, T.; Dong, H.; Cui, K.; Li, H.; Gong, Y.; Hou, J.; Zhang, Z.; et al. Synergistic effect of silica nanoparticles and rhamnolipid on wettability alteration of low permeability sandstone rocks. Energy Fuels 2018, 32, 8098–8107. [Google Scholar] [CrossRef]

- Xu, H.Y.; Jia, W.H.; Ren, S.L.; Wang, J.Q. Novel and recyclable demulsifier of expanded perlite grafted by magnetic nanoparticles for oil separation from emulsified oil wastewaters. Chem. Eng. J. 2018, 337, 10–18. [Google Scholar] [CrossRef]

- Wang, D.; Luo, Y.; Lai, R.; Cui, K.; Li, H.; Zhang, Z.; Zhang, Y.; Shi, R. New technique for enhancing oil recovery from low-permeability reservoirs: The synergy of silica nanoparticles and biosurfactant. Energy Fuels 2021, 35, 318–328. [Google Scholar] [CrossRef]

- Sofia, S.J.D.; James, L.A.; Zhang, Y. Insight into the stability of hydrophilic silica nanoparticles in seawater for Enhanced oil recovery implications. Fuel 2018, 216, 559–571. [Google Scholar]

- Hendraningrat, L.; Li, S.D.; Torsæter, O. Enhancing oil recovery of low-Permeability berea sandstone through optimized nanofluids concentration. J. Pet. Sci. Eng. 2013, 23, 949–950. [Google Scholar]

- Munawar, K.; Badrul, M.J.; Chong, W.T.; Mohammed, A.B. Advanced nanomaterials in oil and gas industry: Design, application, and challenges. Appl. Energy 2017, 191, 287–310. [Google Scholar]

- Kakati, A.; Bera, A.; Al-Yaseri, A. A review on advanced nanoparticle-induced polymer flooding for enhanced oil recovery. Chem. Eng. Sci. 2022, 262, 117994. [Google Scholar] [CrossRef]

- Nwidee, L.; Lebedev, M.; Barifcani, A.; Sarmadivaleh, M.; Iglauer, S. Wettability alteration of oil-wet limestone using surfactant-nanoparticle formulation. J. Colloid Interface Sci. 2017, 504, 334–345. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Huang, J.J.; Babadagli, T. Dynamics of emulsion generation and stability during heavy oil displacement with chemicals and nanoparticles: Qualitative analysis using visual 2D data. Fuel 2020, 270, 117502. [Google Scholar] [CrossRef]

- Ke, C.; Sun, W.; Li, Y.; Lu, G.; Zhang, Q.; Zhang, X. Microbial enhanced oil recovery in Baolige Oilfield using an indigenous facultative anaerobic strain Luteimonas Huabeiensis Sp. Nov. J. Pet. Sci. Eng. 2018, 167, 160–167. [Google Scholar] [CrossRef]

- Patel, J.; Borgohain, S.; Kumar, M.; Rangarajan, V.; Somasundaran, P.; Sen, R. Recent developments in microbial enhanced oil recovery. Renew. Sustain. Energy Rev. 2015, 52, 1539–1558. [Google Scholar] [CrossRef]

- Kostka, J.E.; Om, P.; Overholt, W.A.; Green, S.J.; Freyer, G.; Canion, A.; Delgardio, J.; Norton, N.; Hazen, T.C.; Huettel, M. Hydrocarbon-degrading bacteria and the bacterial community response in the gulf of Mexico beach sands impacted by the deepwater horizon oil spill. Appl. Environ. Microbiol. 2011, 77, 7962–7974. [Google Scholar] [CrossRef]

- Wang, B.; Peng, Y.; Guo, Y.; Zhao, M.; Wang, S. Illumina MiSeq sequencing reveals the key microorganisms involved in partial nitritation followed by simultaneous sludge fermentation, denitrification, and anammox process. Bioresour. Technol. 2016, 207, 118–125. [Google Scholar] [CrossRef]

- Song, W.-F.; Wang, J.-W.; Yan, Y.-C.; An, L.-Y.; Zhang, F.; Wang, L.; Xu, Y.; Tian, M.-Z.; Nie, Y.; Wu, X.-L. Shifts of the indigenous microbial communities from reservoir production water in crude oil and asphaltene-degrading microcosms. Int. Biodeterior. Biodegrad. 2018, 132, 18–29. [Google Scholar] [CrossRef]

- Li, H.; Lai, R.; Jin, Y.; Fang, X.; Cui, K.; Sun, S.; Gong, Y.; Li, H.; Zhang, Z.; Zhang, G.; et al. Directional culture of petroleum hydrocarbon degrading bacteria for enhancing crude oil recovery. J. Hazard. Mater. 2020, 390, 122160–122171. [Google Scholar] [CrossRef]

- Zhao, M.; Lv, W.; Li, Y.; Dai, C.; Wang, X.; Zhou, H.; Zou, C.; Gao, M.; Zhang, Y.; Wu, Y. Study on the synergy between silica nanoparticles and surfactants for enhanced oil recovery during spontaneous imbibition. J. Mol. Liq. 2018, 261, 373–378. [Google Scholar] [CrossRef]

- Richard, A.D.; Carlos, A.G. Fluid flow behavior of gas-condensate and near-miscible fluids at the pore scale. J. Pet. Sci. Eng. 2007, 55, 228–236. [Google Scholar]

- Zeinijahromi, A.; Al-Jassasi, H.; Begg, S.; Bedrikovetski, P. Improving sweep efficiency of edge-water drive reservoirs using induced formation damage. J. Pet. Sci. Eng. 2015, 130, 123–129. [Google Scholar] [CrossRef]

- Wang, D.; Sun, S.S.; Cui, K.; Li, H.; Gong, Y.; Hou, J.; Zhang, Z. Wettability alteration in low permeability sandstone reservoirs by “SiO2-rhamnolipid” nanofluid. Energy Fuels 2019, 33, 12170–12181. [Google Scholar] [CrossRef]

- Gao, H.; Zhang, J.; Lai, H.; Xue, Q. Degradation of asphaltenes by two Pseudomonas aeruginosa strains and their effects on physicochemical properties of crude oil. Int. Biodeterior. Biodegrad. 2017, 122, 12–22. [Google Scholar] [CrossRef]

- Ke, C.-Y.; Lu, G.-M.; Wei, Y.-L.; Sun, W.-J.; Hui, J.-F.; Zheng, X.-Y.; Zhang, Q.-Z.; Zhang, X.-L. Biodegradation of crude oil by Chelatococcus daeguensis HB-4 and its potential for microbial enhanced oil recovery (MEOR) in heavy oil reservoirs. Bioresour. Technol. 2019, 287, 121442–121450. [Google Scholar] [CrossRef] [PubMed]

- Pang, S.; Pu, W.; Jiang, F.; Gao, H.; Wang, Y.; Chen, Y.; Wei, P. Effect of water content on features of W/O emulsion during water flooding in heavy oil reservoir: Bulk properties and mobility control characteristics. J. Pet. Sci. Eng. 2021, 207, 109075–109080. [Google Scholar] [CrossRef]

- Zhu, Y.W.; Tian, Y.A.; Wang, W.D.; Song, Z.Y. Mechanisms of oil displacement by indigenous microorganism producing bio-emulsifier using microscopic modeling. J. Cent. South Univ. 2016, 9, 3280–3289. (In Chinese) [Google Scholar]

- Zhou, J.F.; Gao, P.K.; Dai, X.H.; Cui, X.Y.; Tian, H.M.; Xie, J.-J.; Li, G.-Q.; Ma, T. Heavy hydrocarbon degradation of crude oil by a novel thermophilic Geobacillus stearothermophilus strain A-2. Int. Biodeterior. Biodegrad. 2018, 126, 224–230. [Google Scholar] [CrossRef]

- Yuan, X.; Zhang, X.; Chen, X.; Kong, D.; Liu, X.; Shen, S. Synergistic degradation of crude oil by an indigenous bacterial consortium and exogenous fungus Scedosporium Boydii. Bioresour. Technol. 2018, 264, 190–197. [Google Scholar] [CrossRef]

- Briceño-Ahumada, Z.; Soltero-Martínez, J.; Castillo, R. Aqueous foams and emulsions stabilized by mixtures of silica nanoparticles and surfactants: A state-of-the-art review. Chem. Eng. J. Adv. 2021, 7, 100116–100150. [Google Scholar] [CrossRef]

- Wei, B.; Li, Q.; Jin, F.; Li, H.; Wang, C. The potential of a novel nanofluid in enhancing oil recovery. Energy Fuels 2016, 30, 2882–2891. [Google Scholar] [CrossRef]

- Li, Y.F.; Block, E.; Squier, J.; Oakey, J. Investigating low salinity waterflooding via glass micromodels with triangular pore-throat architectures. Fuel 2021, 283, 119264–119272. [Google Scholar] [CrossRef] [PubMed]

- Das, K.; Mukherjee, A.K. Crude petroleum-oil biodegradation efficiency of Bacillus subtilis and Pseudomonas aeruginosa strains isolated from a petroleum-oil contaminated soil from North-East India. Bioresour. Technol. 2007, 98, 1339–1345. [Google Scholar] [CrossRef] [PubMed]

- Gong, Y.; Li, L.; Huang, W.; Zou, J.; Zhong, X.; Wang, L.; Kang, D.; Zhang, Z.; Zhang, Z. A study of alkali-silica nanoparticle-polymer (ANP) flooding for enhancing heavy oil recovery. J. Pet. Sci. Eng. 2022, 213, 110465. [Google Scholar] [CrossRef]

- Wasan, D.T.; Nikolov, A.D. Spreading of nanofluids on solids. Nature 2003, 423, 156–159. [Google Scholar] [CrossRef]

- Zhang, H.; Ramakrishnan, T.S.; Nikolov, A.; Wasan, D. Enhanced oil displacement by nanofluid’s structural disjoining pressure in model fractured porous media. J. Colloid Interface Sci. 2018, 511, 48–56. [Google Scholar] [CrossRef]

- Chang, Y.H.; Xiao, S.B.; Ma, R.; Zhang, G.L.; He, J.Y. Atomistic insight into oil displacement on the rough surface by Janus nanoparticles. Appl. Energy 2022, 245, 123264. [Google Scholar] [CrossRef]

- Cui, K.; Wang, C.J.; Li, L.; Zou, J.; Huang, W.; Zhang, Z.; Wang, H.; Guo, K. Controlling the hydro-swelling of smectite clay minerals by Fe(III) reducing bacteria for enhanced oil recovery from low-permeability reservoirs. Energies 2022, 15, 4393. [Google Scholar] [CrossRef]

| Experimental Number | Primary Flooding (0.05 mL/min) | Slug Displacement Fluids (3.0 PV) | Objectives |

|---|---|---|---|

| 1 | Water flooding | Produced water (sterilization) | Experimental control |

| 2 | Water flooding | PHDB fluids (3%, 5%, and 7%) | To screen the optimal PHDB concentration |

| 3 | Water flooding | SiO2 nanoparticles fluids (50, 100, and 200 mg/L) | To screen the optimal nanoparticles concentration |

| 4 | Water flooding | PHDB (7%) + SiO2 nanoparticles (100 mg/L) fluids | To investigate the EOR effects of composite displacement |

| Displacement Fluids | Injection Concentration | Initial Residual Oil Ratio, % | Final Residual Oil Ratio, % | Average Recovery Efficiency, % |

|---|---|---|---|---|

| Water | — | 70 ± 3 | 36.8 ± 2.5 | 68.8 |

| SiO2 nanoparticles | 50 mg/L | 70 ± 3 | 7.3 ± 1.5 | 82.6 |

| SiO2 nanoparticles | 100 mg/L | 70 ± 3 | 4.8 ± 0.5 | 86.5 |

| SiO2 nanoparticles | 200 mg/L | 70 ± 3 | 6.1 ± 0.4 | 84.4 |

| PHDB | 3.0% v/v | 70 ± 3 | 4.2 ± 0.3 | 87.8 |

| PHDB | 5.0% v/v | 70 ± 3 | 3.8 ± 0.2 | 89.3 |

| PHDB | 7.0% v/v | 70 ± 3 | 2.1 ± 0.3 | 90.5 |

| PHDB + SiO2 nanoparticles | 7.0% v/v + 100 mg/L | 70 ± 3 | 1.0 ± 0.2 | 98.9 |

| Displacement Agent | Injection Concentration | Primary Flooding Method | Injection Method | Final OR, % | Relative Water Flooding EOR, % | Ref. |

|---|---|---|---|---|---|---|

| Water | — | Waterflooding | Normal waterflooding | 40–50% | — | [2] |

| Chemical agents | 100 mg/L | Waterflooding | Slug displacement | 60–70% | 20–30% | [10] |

| SiO2 nanoparticles | 100 mg/L | Waterflooding | Slug displacement | >80% | >20% | [5] |

| Biosurfactants | 100 mg/L | Waterflooding | Slug displacement | 70–80% | 20–30% | [7] |

| SiO2 nanoparticles +Biosurfactants | 50 mg/L +50 mg/L | Waterflooding | Slug displacement | >80% | >25% | [23] |

| Other microbial fluids | 7.0% v/v | Waterflooding | Slug displacement | 50–60% | 10–20% | [38] |

| PHDB fluids | 7.0% v/v | Waterflooding | Slug displacement | >70% | >20% | [19] |

| PHDB+SiO2 nanoparticles | 7.0% v/v +100 mg/L | Waterflooding | Slug displacement | >90% | >30% | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, K.; Li, H.; Chen, P.; Li, Y.; Jiang, W.; Guo, K. New Technique for Enhancing Residual Oil Recovery from Low-Permeability Reservoirs: The Cooperation of Petroleum Hydrocarbon-Degrading Bacteria and SiO2 Nanoparticles. Microorganisms 2022, 10, 2104. https://doi.org/10.3390/microorganisms10112104

Cui K, Li H, Chen P, Li Y, Jiang W, Guo K. New Technique for Enhancing Residual Oil Recovery from Low-Permeability Reservoirs: The Cooperation of Petroleum Hydrocarbon-Degrading Bacteria and SiO2 Nanoparticles. Microorganisms. 2022; 10(11):2104. https://doi.org/10.3390/microorganisms10112104

Chicago/Turabian StyleCui, Kai, Hailan Li, Ping Chen, Yong Li, Wenxue Jiang, and Kun Guo. 2022. "New Technique for Enhancing Residual Oil Recovery from Low-Permeability Reservoirs: The Cooperation of Petroleum Hydrocarbon-Degrading Bacteria and SiO2 Nanoparticles" Microorganisms 10, no. 11: 2104. https://doi.org/10.3390/microorganisms10112104

APA StyleCui, K., Li, H., Chen, P., Li, Y., Jiang, W., & Guo, K. (2022). New Technique for Enhancing Residual Oil Recovery from Low-Permeability Reservoirs: The Cooperation of Petroleum Hydrocarbon-Degrading Bacteria and SiO2 Nanoparticles. Microorganisms, 10(11), 2104. https://doi.org/10.3390/microorganisms10112104