Effect of Lactiplantibacillus plantarum on the Conversion of Linoleic Acid of Vegetable Oil to Conjugated Linoleic Acid, Lipolysis, and Sensory Properties of Cheddar Cheese

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Cheddar Cheese Production and Experimental Plan

2.3. Analysis of Safflower Oil

2.4. Milk and Cheese Composition

2.4.1. CLA Isomers and Other Fatty Acids

2.4.2. Population of Lactiplantibacillus plantarum (Lp. plantarum)

2.4.3. Organic Acids

2.4.4. Lipolysis

2.5. Sensory Evaluation

2.6. Statistical Analysis

3. Results and Discussion

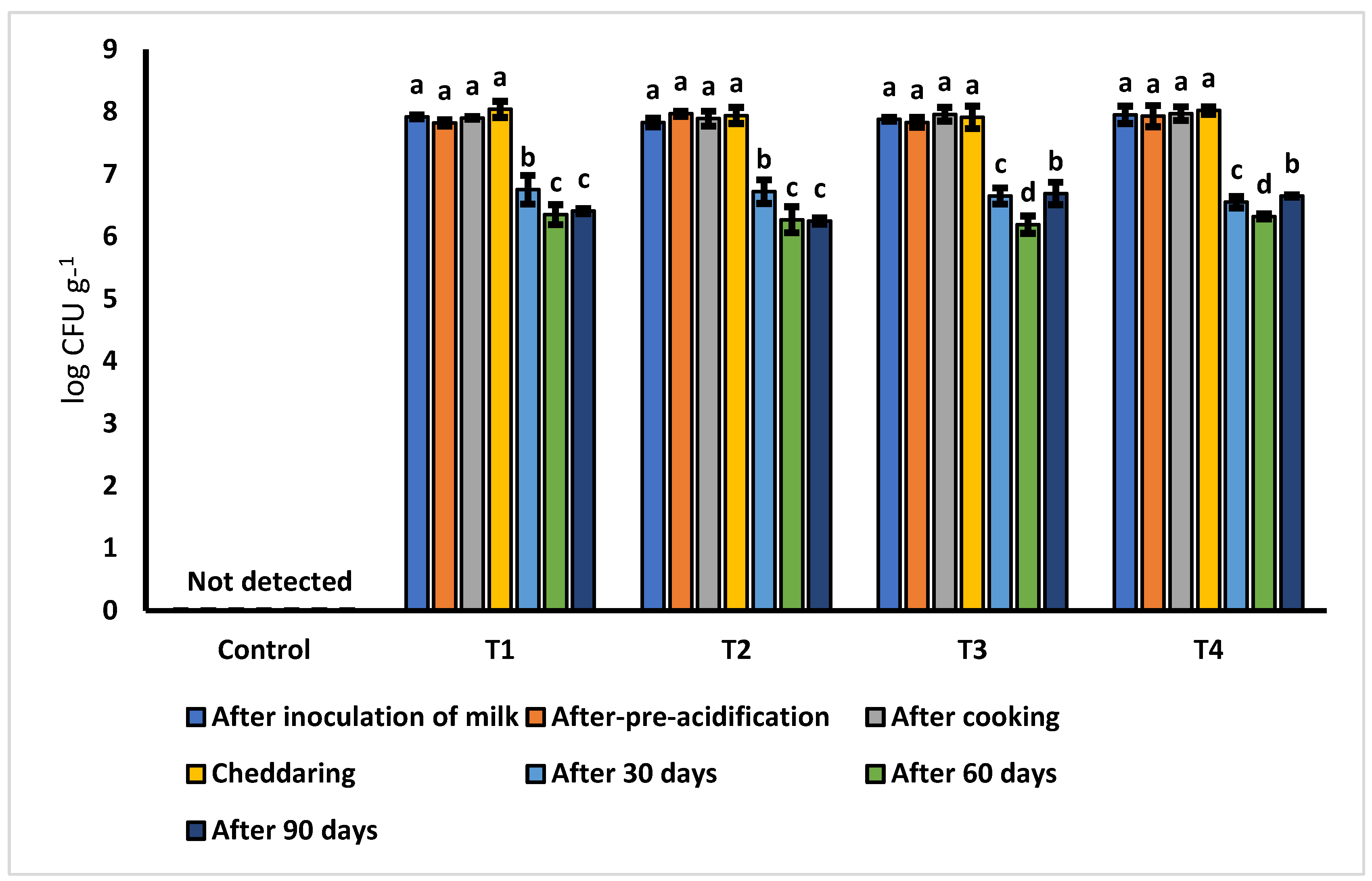

3.1. Population of Lactiplantibacillus plantarum (Lp. plantarum)

3.2. Fatty Acid Composition

3.3. Organic Acids

3.4. Lipolysis

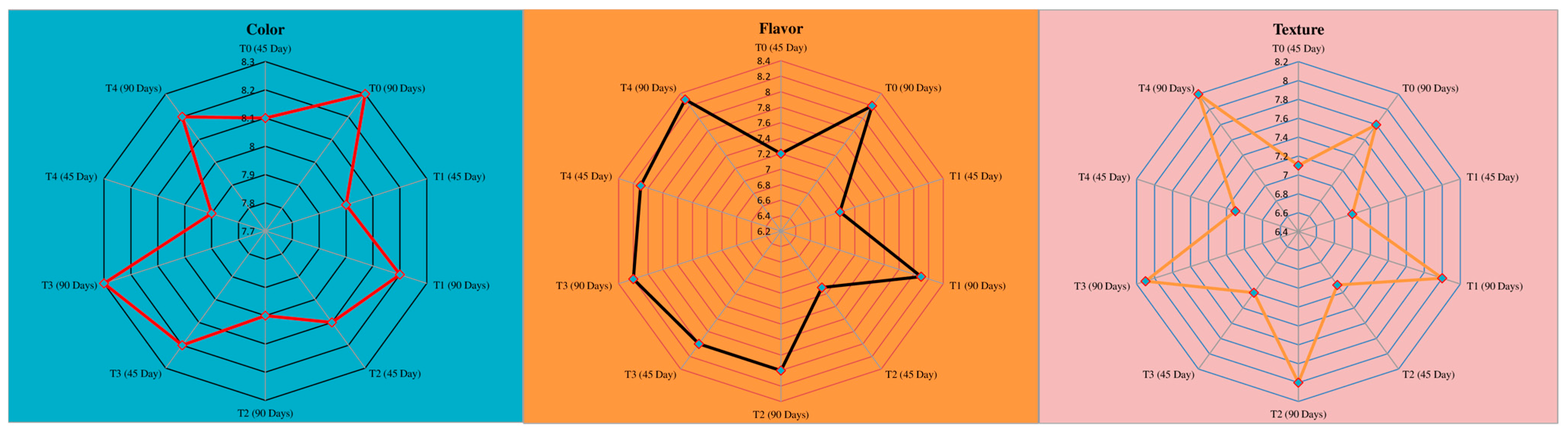

3.5. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Smith, J.; Charter, E. Functional Food Product Development; John Wiley & Sons: Hoboken, NJ, USA, 2011; p. 673. [Google Scholar]

- Rungapamestry, V.; McMonagle, J.; Reynolds, C.; Rucklidge, G.; Reid, M.; Duncan, G.; Ross, K.; Horgan, G.; Toomey, S.; Moloney, A. Inter-organ proteomic analysis reveals insights into the molecular mechanisms underlying the anti-diabetic effects of cis-9, trans-11-conjugated linoleic acid in ob/ob mice. Proteomics 2012, 12, 461–476. [Google Scholar] [CrossRef]

- Griinari, J.; Bauman, D. Biosynthesis of conjugated linoleic acid and its incorporation into meat and milk in ruminants. Adv. Conjug. Linoleic Acid Res. 1999, 1, 180–200. [Google Scholar]

- Yurawecz, M.P. Advances in Conjugated Linoleic Acid Research; The American Oil Chemists Society: Urbana, IL, USA, 2003; Volume 2. [Google Scholar]

- Khan, I.T.; Nadeem, M.; Imran, M.; Ayaz, M.; Ajmal, M.; Ellahi, M.Y.; Khalique, A. Antioxidant capacity and fatty acids characterization of heat treated cow and buffalo milk. Lipids Health Dis. 2017, 16, 1–10. [Google Scholar] [CrossRef]

- Khan, A.; Nadeem, M.; Imran, M.; Khalique, A. Preservation. Impact of winterization on fatty acids’ composition, isomers, and oxidative stability of conjugated linoleic acids produced from selected vegetable oils. J. Food Process. Preserv. 2021, 45, e15254. [Google Scholar] [CrossRef]

- Gorissen, L.; Raes, K.; Weckx, S.; Dannenberger, D.; Leroy, F.; De Vuyst, L.; De Smet, S. Production of conjugated linoleic acid and conjugated linolenic acid isomers by Bifidobacterium species. Appl. Microbial. Biotechnol. 2010, 87, 2257–2266. [Google Scholar] [CrossRef]

- Alonso, L.; Cuesta, E.; Gilliland, S. Production of free conjugated linoleic acid by Lactobacillus acidophilus and Lactobacillus casei of human intestinal origin. J. Dairy Sci. 2003, 86, 1941–1946. [Google Scholar] [CrossRef] [PubMed]

- Kishino, S.; Ogawa, J.; Omura, Y.; Matsumura, K.; Shimizu, S. Conjugated linoleic acid production from linoleic acid by lactic acid bacteria. J. Am. Chem. Soc. 2002, 79, 159–163. [Google Scholar] [CrossRef]

- Ogawa, J.; Matsumura, K.; Kishino, S.; Omura, Y.; Shimizu, S. Conjugated Linoleic Acid Accumulation via 10-Hydroxy-12-octadecaenoic Acid During Microaerobic Transformation of Linoleic Acid by Lactobacillus acidophilus. Appl. Environ. Microbiol. 2001, 67, 1246–1252. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Björck, B.; Fondén, F. Production of conjugated linoleic acid by dairy starter cultures. J. Appl. Microbiol. 1998, 85, 95–102. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Yang, M.; Qi, B.; Chen, X.; Su, Z.; Wan, Y. Optimizing l-(+)-lactic acid production by thermophile Lactobacillus plantarum As. 1.3 using alternative nitrogen sources with response surface method. Biochem. Eng. J. 2010, 52, 212–219. [Google Scholar] [CrossRef]

- Guidone, A.; Zotta, T.; Ross, R.P.; Stanton, C.; Rea, M.C.; Parente, E.; Ricciardi, A. Functional properties of Lactobacillus plantarum strains: A multivariate screening study. LWT-Food Sci. Technol. 2014, 56, 69–76. [Google Scholar] [CrossRef]

- Rahim, M.A.; Ayub, H.; Sehrish, A.; Ambreen, S.; Khan, F.A.; Itrat, N.; Nazir, A.; Shoukat, A.; Shoukat, A.; Ejaz, A.; et al. Essential Components from Plant Source Oils: A Review on Extraction, Detection, Identification, and Quantification. Molecules 2023, 28, 6881. [Google Scholar] [CrossRef]

- PMcSweeney, L.H.; Sousa, M.J. Biochemical pathways for the production of flavour compounds in cheeses during ripening: A review. Le Lait 2000, 80, 293–324. [Google Scholar] [CrossRef]

- Asif, M.; Nadeem, M.; Imran, M.; Ullah, R.; Tayyab, M.; Khan, F.A.; Al-Asmari, F.; Rahim, M.A.; Rocha, J.M.; Korma, S.A.; et al. Effect of fat contents of buttermilk on fatty acid composition, lipolysis, vitamins and sensory properties of cheddar-type cheese. Front. Microbiol. 2023, 14. [Google Scholar] [CrossRef] [PubMed]

- AOAC. Official Methods of Analysis of AOAC International, 18th ed.; AOAC International: Gaitherburg, MD, USA, 2011; p. 2590. [Google Scholar]

- AOAC. Official Method 965.33 Peroxide Value in Oils and Fats/Pearson’s Composition and Analysis of Foods, 9th ed.; Association of Analytical Chemists: Rockville, MD, USA, 2000; p. 64. [Google Scholar]

- Qian, G.; Li, L. Profitability of Small and Medium-Sized Enterprises in High-Tech Industries: The Case for Biotechnology Industry. Strateg. Manag. J. 2003, 24, 881–887. [Google Scholar] [CrossRef]

- Qian, M. Gas Chromatography, Food Analysis Laboratory Manual; Kluwer Academic Publishers: New York, NY, USA, 2003. [Google Scholar] [CrossRef]

- Veselá, K.; Kumherová, M.; Klojdová, I.; Solichová, K.; Horáčková, Š.; Plocková, M. Selective culture medium for the enumeration of Lactobacillus plantarum in the presence of Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus thermophilus. LWT Food Sci. Technol. 2019, 114, 108365. [Google Scholar] [CrossRef]

- Adnan, A.; Nadeem, M.; Ahmad, M.H.; Tayyab, M.; Khan, M.K.; Imran, M.; Iqbal, A.; Rahim, M.A.; Awuchi, C.G. Effect of lactoferrin supplementation on composition, fatty acids composition, lipolysis and sensory characteristics of cheddar cheese. Int. J. Food Prop. 2023, 26, 437–452. [Google Scholar] [CrossRef]

- American Oil Chemists’ Society. Official Methods and Recommended Practices of the American Oil Chemists’ Society; AOCS Press: Champaign, IL, USA, 2011. [Google Scholar]

- Larmond, E. Laboratory Methods for Sensory Evaluation of Food; University of Illinois at Urbana-Champaign, Ottawa Publications, Canadian Department of Agriculture: Ottawa, ON, Canada, 1977; pp. 1637–1674. [Google Scholar]

- Milesi, M.M.; McSweeney, P.; Hynes, E.R. Viability and contribution to proteolysis of an adjunct culture of Lactobacillus plantarum in two model cheese systems: Cheddar cheese-type and soft-cheese type. J. Appl. Microbiol. 2008, 105, 884–892. [Google Scholar] [CrossRef]

- Das, S.; Holland, R.; Crow, V.L.; Bennett, R.J.; Manderson, G.J. Effect of yeast and bacterial adjuncts on the CLA content and flavour of a washed-curd, dry-salted cheese. Int. Dairy J. 2005, 15, 807–815. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, X.; Liu, C.; Li, C.; Li, S.; Li, T.; Li, D.; Zhao, Y.; Yang, Z. Manufacture of Cheddar cheese using probiotic Lactobacillus plantarum K25 and its cholesterol-lowering effects in a mice model. World J. Microbiol. Biotechnol. 2013, 29, 127–135. [Google Scholar] [CrossRef]

- Murtaza, M.A.; Anees-Ur-Rehman, M.; Hafiz, I.; Ameer, K.; Celik, O.F. Preservation. Effects of probiotic adjuncts on physicochemical properties, organic acids content, and proteolysis in cheese prepared from buffalo milk. J. Food Process. Preserv. 2022, 46, e16385. [Google Scholar] [CrossRef]

- Ullah, R.; Nadeem, M.; Imran, M.; Taj Khan, I.; Shahbaz, M.; Mahmud, A.; Tayyab, M. Omega fatty acids, phenolic compounds, and lipolysis of cheddar cheese supplemented with chia (Salvia hispanica L.) oil. J. Food Process. Preserv. 2018, 42, e13566. [Google Scholar] [CrossRef]

- Ahmed, S.; Ahmad, M.S.; Yousaf, M.; Mothana, R.A.; Al-Rehaily, A. Evaluation of acute toxicity and anti-inflammatory effects of Baccharoides schimperi (DC.) in experimental animals. Afr. J. Tradit. Complement. Altern. Med. 2015, 12, 99–103. [Google Scholar] [CrossRef]

- Ahmad, S.; Nadeem, M.; Ayaz, M.; Jaspal, M.H. Effect of low-melting fractions of milk fat on lipolysis of cheddar cheese. J. Food Process Preserv. 2015, 39, 2516–2522. [Google Scholar] [CrossRef]

- Abd El-Salam, M.; Hippen, A.; Assem, F.M.; El-Shafei, K.; Tawfik, N.; El-Aassar, M.J. Preparation and properties of probiotic cheese high in conjugated linoleic acid content. Int. J. Dairy Technol. 2011, 64, 64–74. [Google Scholar] [CrossRef]

- Gómez-Torres, N.; Ávila, M.; Gaya, P.; Garde, S. Prevention of late blowing defect by reuterin produced in cheese by a Lactobacillus reuteri adjunct. Food Microbiol. 2014, 42, 82–88. [Google Scholar] [CrossRef]

- Marchiani, R.; Bertolino, M.; Ghirardello, D.; Mcsweeney, P.L.; Zeppa, G. Physicochemical and nutritional qualities of grape pomace powder-fortified semi-hard cheeses. J. Food Sci. Technol. 2016, 53, 1585–1596. [Google Scholar] [CrossRef]

- Trigueros, L.; Sendra, E. Fatty acid and conjugated linoleic acid (CLA) content in fermented milks as assessed by direct methylation. LWT-Food Sci. Technol. 2015, 60, 315–319. [Google Scholar] [CrossRef]

- Rodrigues, D.; Rocha-Santos, T.A.; Gomes, A.M.; Goodfellow, B.J.; Freitas, A.C. Lipolysis in probiotic and synbiotic cheese: The influence of probiotic bacteria, prebiotic compounds and ripening time on free fatty acid profiles. Food Chem. 2012, 131, 1414–1421. [Google Scholar] [CrossRef]

- Chung, S.H.; Kim, I.H.; Park, H.G.; Kang, H.S.; Yoon, C.S.; Jeong, H.Y.; Choi, N.J.; Kwon, E.G.; Kim, Y.J. Synthesis of conjugated linoleic acid by human-derived Bifidobacterium breve LMC 017: Utilization as a functional starter culture for milk fermentation. J. Agric. Food Chem. 2008, 56, 3311–3316. [Google Scholar] [CrossRef]

- Ardö, Y.; McSweeney, P.L.; Magboul, A.A.; Upadhyay, V.K.; Fox, P.F. Biochemistry of cheese ripening: Proteolysis. In Cheese; Elsevier: Amsterdam, The Netherlands, 2017; pp. 445–482. [Google Scholar]

- Khan, A.; Nadeem, M.; Imran, M.; Gulzar, N.; Ahmad, M.H.; Tayyab, M.; Rahim, M.A.; Awuchi, C.G. Impact of safflower oil derived conjugated linoleic acid supplementation on fatty acids profile, lipolysis and sensory properties of cheddar cheese. Int. J. Food Prop. 2022, 25, 2223–2236. [Google Scholar] [CrossRef]

- McSweeney, P.L.; Fox, P.F. Advanced Dairy Chemistry; Springer: Berlin/Heidelberg, Germany, 2003; Volume 1. [Google Scholar]

- Kilcawley, K.; Wilkinson, M.; Fox, P. A survey of lipolytic and glycolytic end-products in commercial Cheddar enzyme-modified cheese. J. Dairy Sci. 2001, 84, 66–73. [Google Scholar] [CrossRef] [PubMed]

| Attribute | Control | T1 | T2 | T3 | T4 |

|---|---|---|---|---|---|

| Moisture% | 40.52 ± 1.03 a | 41.22 ± 1.05 a | 40.16 ± 1.02 a | 41.11 ± 1.06 a | 40.85 ± 1.02 a |

| Fat% | 30.47 ± 0.9 a | 29.91 ± 0.9 a | 30.17 ± 0.9 a | 30.37 ± 0.9 a | 29.78 ± 0.9 a |

| Protein% | 26.19 ± 0.7 a | 26.37 ± 0.7 a | 26.14 ± 0.7 a | 26.65 ± 0.7 a | 26.88 ± 0.7 a |

| pH | 5.24 ± 0.2 a | 5.22 ± 0.2 a | 5.21 ± 0.2 a | 5.23 ± 0.2 a | 5.22 ± 0.2 a |

| Fatty Acid | Safflower Oil | Control | T1 | T2 | T3 | T4 | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0-Day | 90-Days | 0-Day | 90-Days | 0-Day | 90-Days | 0-Day | 90-Days | 0-Day | 90-Days | ||

| C4:0 | Not Found | 1.89 ± 0.01 a | 1.90 ± 0.01 a | 1.85 ± 0.02 a | 1.80 ± 0.01 a | 1.79 ± 0.03 a | 1.75 ± 0.02 a | 1.77 ± 0.01 a | 1.70 ± 0.02 b | 1.78 ± 0.02 a | 1.72 ± 0.01 b |

| C6:0 | Not Found | 2.36 ± 0.03 a | 2.32 ± 0.06 a | 2.34 ± 0.04 a | 2.28 ± 0.05 a | 2.26 ± 0.01 a | 2.23 ± 0.01 a | 2.25 ± 0.04 a | 2.13 ± 0.01 a | 2.21 ± 0.01 a | 2.10 ± 0.01 b |

| C8:0 | Not Found | 2.51 ± 0.06 a | 2.49 ± 0.05 a | 2.48 ± 0.03 a | 2.42 ± 0.07 a | 2.40 ± 0.04 a | 2.25 ± 0.03 b | 2.37 ± 0.02 a | 2.23 ± 0.02 b | 2.31 ± 0.03 a | 2.18 ± 0.06 b |

| C10:0 | Not Found | 2.77 ± 0.10 a | 2.74 ± 0.10 a | 2.75 ± 0.07 a | 2.70 ± 0.09 a | 2.67 ± 0.02 a | 2.62 ± 0.02 b | 2.75 ± 0.04 a | 2.61 ± 0.07 b | 2.70 ± 0.04 a | 2.57 ± 0.02 c |

| C12:0 | Not Found | 2.94 ± 0.12 a | 2.93 ± 0.13 a | 2.93 ± 0.11 a | 2.87 ± 0.02 a | 2.86 ± 0.22 a | 2.74 ± 0.06 b | 2.83 ± 0.06 a | 2.70 ± 0.08 b | 2.77 ± 0.03 a | 2.53 ± 0.07 c |

| C14:0 | 0.11 ± 0.01 f | 11.25 ± 0.23 a | 11.13 ± 0.02 a | 10.65 ± 0.16 b | 10.49 ± 0.24 b | 10.33 ± 0.17 b | 9.98 ± 0.42 b | 9.14 ± 0.16 c | 8.55 ± 0.02 d | 8.51 ± 0.20 d | 7.66 ± 0.11 e |

| C16:0 | 1.22 ± 0.02 h | 26.74 ± 0.29 a | 26.25 ± 0.74 a | 25.16 ± 0.33 b | 24.75 ± 0.45 c | 24.37 ± 0.31 c | 23.38 ± 0.51 d | 22.74 ± 0.31 e | 21.27 ± 0.52 f | 21.20 ± 0.08 f | 18.41 ± 0.28 g |

| C18:0 | 4.74 ± 0.15 f | 8.19 ± 0.15 a | 8.13 ± 0.20 a | 7.81 ± 0.17 b | 7.44 ± 0.35 b | 7.16 ± 0.10 c | 6.62 ± 0.09 d | 6.11 ± 0.09 d | 5.43 ± 0.19 e | 5.35 ± 0.13 e | 4.11 ± 0.16 g |

| C18:1 | 6.89 ± 0.13 h | 23.94 ± 0.34 a | 21.17 ± 0.16 c | 23.51 ± 0.54 a | 22.98 ± 0.77 b | 22.36 ± 0.29 b | 21.87 ± 0.39 c | 20.19 ± 0.37 d | 19.13 ± 0.22 e | 18.98 ± 0.09 f | 16.14 ± 0.18 g |

| C18:2 | 85.19 ± 0.22 a | 2.56 ± 0.21 e | 1.87 ± 0.16 g | 2.52 ± 0.09 e | 2.18 ± 0.04 f | 5.98 ± 0.05 d | 1.34 ± 0.42 h | 8.25 ± 0.24 c | 0.98 ± 0.17 j | 11.49 ± 0.12 b | 1.11 ± 0.02 i |

| ∆9c,11t-18:2 | Not Found | 0.23 ± 0.09 f | 0.37 ± 0.02 e | 0.22 ± 0.03 f | 0.58 ± 0.10 d | 0.22 ± 0.02 f | 1.12 ± 0.03 c | 0.21 ± 0.01 f | 1.34 ± 0.04 b | 0.26 ± 0.04 f | 1.91 ± 0.03 a |

| ∆10t,12c-18:2 | Not Found | 0.10 ± 0.06 f | 0.16 ± 0.01 e | 0.11 ± 0.01 f | 0.42 ± 0.02 d | 0.08 ± 0.01 f | 0.79 ± 0.15 c | 0.07 ± 0.01 f | 1.12 ± 0.02 b | 0.12 ± 0.02 f | 1.54 ± 0.06 a |

| ∆9c,11c-18:2 | Not Found | 0.09 ± 0.02 f | 0.14 ± 0.03 e | 0.08 ± 0.01 f | 0.47 ± 0.05 d | 0.07 ± 0.01 f | 0.91 ± 0.01 c | 0.09 ± 0.02 f | 1.05 ± 0.01 b | 0.10 ± 0.03 f | 1.48 ± 0.02 a |

| ∆9t, 11c-18:2 | Not Found | 0.05 ± 0.01 f | 0.09 ± 0.01 e | 0.06 ± 0.01 f | 0.29 ± 0.06 d | 0.06 ± 0.01 f | 0.48 ± 0.05 c | 0.11 ± 0.01 e | 0.92 ± 0.02 b | 0.15 ± 0.01 e | 1.39 ± 0.1 a |

| ∆10c,12t-18:2 | Not Found | 0.08 ± 0.02 f | 0.17 ± 0.01 e | 0.19 ± 0.02 e | 0.31 ± 0.02 d | 0.05 ± 0.01 g | 0.35 ± 0.03 c | 0.09 ± 0.01 f | 0.68 ± 0.03 b | 0.10 ± 0.05 f | 1.18 ± 0.01 a |

| ∆8,9,11,10,12c-c18:2 | Not Found | 0.03 ± 0.01 f | 0.05 ± 0.02 f | 0.06 ± 0.02 f | 0.15 ± 0.01 d | 0.04 ± 0.01 f | 0.27 ± 0.02 c | 0.05 ± 0.01 | 0.51 ± 0.01 b | 0.09 ± 0.06 e | 1.10 ± 0.02 a |

| ∆8,9,11,10,12t-t18:2 | Not Found | 0.04 ± 0.01 f | 0.07 ± 0.01 e | 0.08 ± 0.01 e | 0.12 ± 0.01 d | 0.05 ± 0.01 f | 0.21 ± 0.01 c | 0.07 ± 0.02 e | 0.38 ± 0.01 b | 0.13 ± 0.02 d | 0.82 ± 0.04 a |

| C18:3 | 0.25 ± 0.02 | 0.58 ± 0.02 a | 0.41 ± 0.01 c | 0.56 ± 0.1 a | 0.39 ± 0.03 c | 0.53 ± 0.03 a | 0.31 ± 0.02 d | 0.49 ± 0.04 b | 0.24 ± 0.02 e | 0.25 ± 0.01 e | 0.15 ± 0.01 f |

| ∑ CLA | - | 1.18 ± 0.02 f | 1.46 ± 0.04 e | 1.36 ± 0.09 e | 2.73 ± 0.03 d | 1.10 ± 0.01 f | 4.44 ± 0.11 c | 1.18 ± 0.06 f | 6.24 ± 0.15 b | 1.20 ± 0.03 f | 9.57 ± 0.19 a |

| Treatments | Ripening Days | FFA% | Cholesterol (mg/100 g) | POV (MeqO2/kg) |

|---|---|---|---|---|

| Control | 0 | 0.08 ± 0.01 h | 165 ± 1.27 a | 0.24 ± 0.02 e |

| 45 | 0.13 ± 0.02 g | 155 ± 1.14 b | 0.25 ± 0.01 e | |

| 90 | 0.17 ± 0.01 f | 121 ± 0.87 c | 0.45 ± 0.05 d | |

| T1 | 0 | 0.08 ± 0.02 h | 161 ± 1.26 a | 0.25 ± 0.03 e |

| 45 | 0.14 ± 0.03 f | 144 ± 1.49 b | 0.28 ± 0.02 e | |

| 90 | 0.21 ± 0.01 d | 119 ± 0.45 c | 0.47 ± 0.06 d | |

| T2 | 0 | 0.09 ± 0.01 h | 158 ± 0.88 b | 0.22 ± 0.02 e |

| 45 | 0.19 ± 0.04 e | 139 ± 0.78 d | 0.30 ± 0.05 e | |

| 90 | 0.25 ± 0.02 c | 122 ± 0.26 e | 0.64 ± 0.07 c | |

| T3 | 0 | 0.08 ± 0.01 h | 155 ± 0.96 b | 0.26 ± 0.04 e |

| 45 | 0.22 ± 0.01 d | 125 ± 1.32 e | 0.29 ± 0.02 e | |

| 90 | 0.29 ± 0.02 b | 114 ± 0.66 f | 0.72 ± 0.01 b | |

| T4 | 0 | 0.08 ± 0.01 h | 152 ± 1.19 b | 0.23 ± 0.01 e |

| 45 | 0.26 ± 0.02 c | 121 ± 1.55 e | 0.31 ± 0.02 e | |

| 90 | 0.37 ± 0.01 a | 78 ± 1.31 g | 0.85 ± 0.03 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, A.; Nadeem, M.; Al-Asmari, F.; Imran, M.; Ambreen, S.; Rahim, M.A.; Oranab, S.; Esatbeyoglu, T.; Bartkiene, E.; Rocha, J.M. Effect of Lactiplantibacillus plantarum on the Conversion of Linoleic Acid of Vegetable Oil to Conjugated Linoleic Acid, Lipolysis, and Sensory Properties of Cheddar Cheese. Microorganisms 2023, 11, 2613. https://doi.org/10.3390/microorganisms11102613

Khan A, Nadeem M, Al-Asmari F, Imran M, Ambreen S, Rahim MA, Oranab S, Esatbeyoglu T, Bartkiene E, Rocha JM. Effect of Lactiplantibacillus plantarum on the Conversion of Linoleic Acid of Vegetable Oil to Conjugated Linoleic Acid, Lipolysis, and Sensory Properties of Cheddar Cheese. Microorganisms. 2023; 11(10):2613. https://doi.org/10.3390/microorganisms11102613

Chicago/Turabian StyleKhan, Awais, Muhammad Nadeem, Fahad Al-Asmari, Muhammad Imran, Saadia Ambreen, Muhammad Abdul Rahim, Sadaf Oranab, Tuba Esatbeyoglu, Elena Bartkiene, and João Miguel Rocha. 2023. "Effect of Lactiplantibacillus plantarum on the Conversion of Linoleic Acid of Vegetable Oil to Conjugated Linoleic Acid, Lipolysis, and Sensory Properties of Cheddar Cheese" Microorganisms 11, no. 10: 2613. https://doi.org/10.3390/microorganisms11102613

APA StyleKhan, A., Nadeem, M., Al-Asmari, F., Imran, M., Ambreen, S., Rahim, M. A., Oranab, S., Esatbeyoglu, T., Bartkiene, E., & Rocha, J. M. (2023). Effect of Lactiplantibacillus plantarum on the Conversion of Linoleic Acid of Vegetable Oil to Conjugated Linoleic Acid, Lipolysis, and Sensory Properties of Cheddar Cheese. Microorganisms, 11(10), 2613. https://doi.org/10.3390/microorganisms11102613