Microbial Surfactants: The Next Generation Multifunctional Biomolecules for Applications in the Petroleum Industry and Its Associated Environmental Remediation

Abstract

:1. Introduction

2. Application of Biosurfactants in the Petroleum Industry

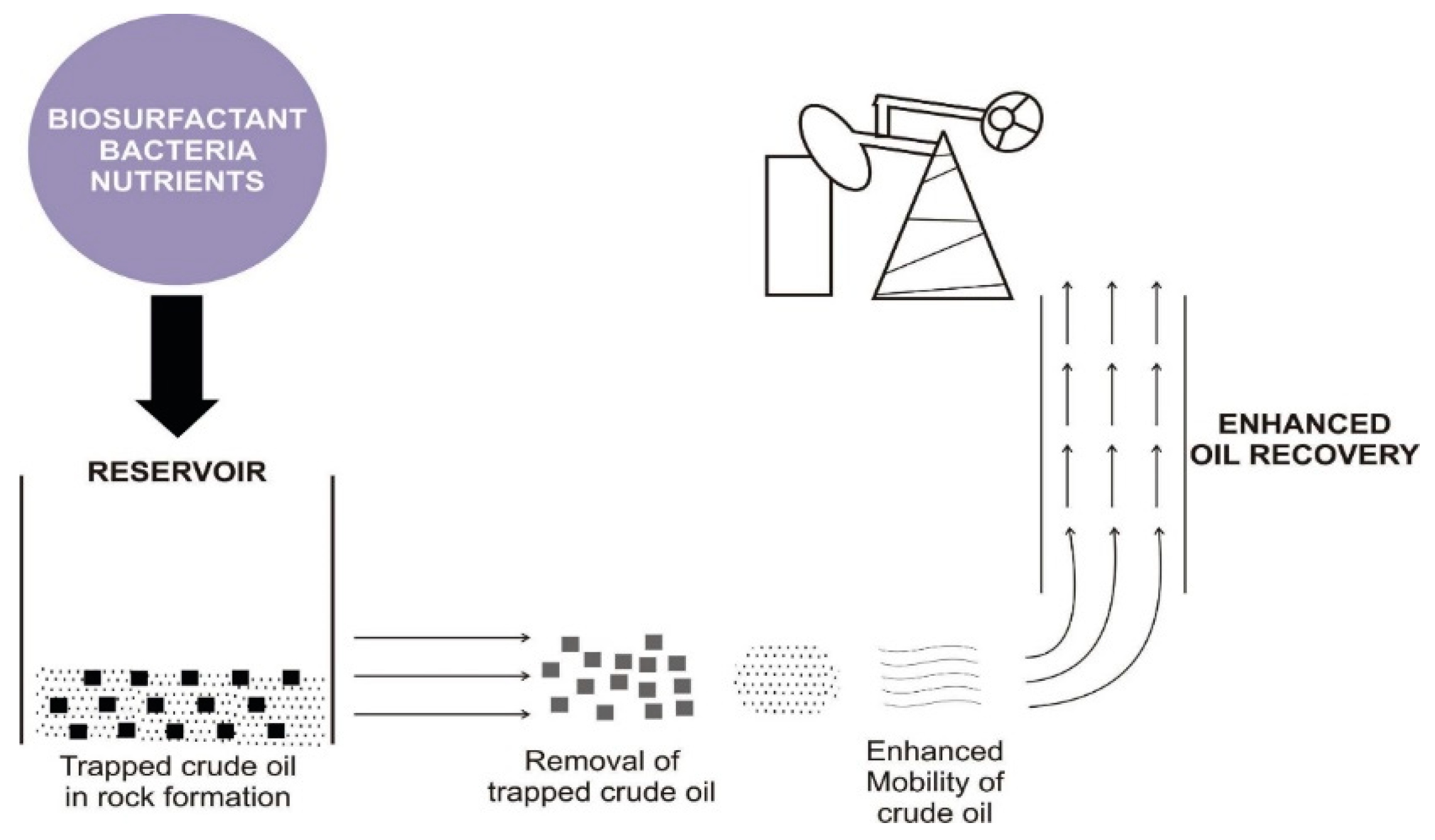

2.1. Extraction of Crude Oil from Reservoirs

2.2. Biosurfactants for the Formulation of Fuels

2.3. Biosurfactants in Biodesulphurization

2.4. Transport of Crude Oil by Pipelines

2.5. Oil Storage Tank Cleaning

3. Biosurfactants for Environmental Remediation

3.1. Bioremediation of Hydrocarbon-Contaminated Marine Environments

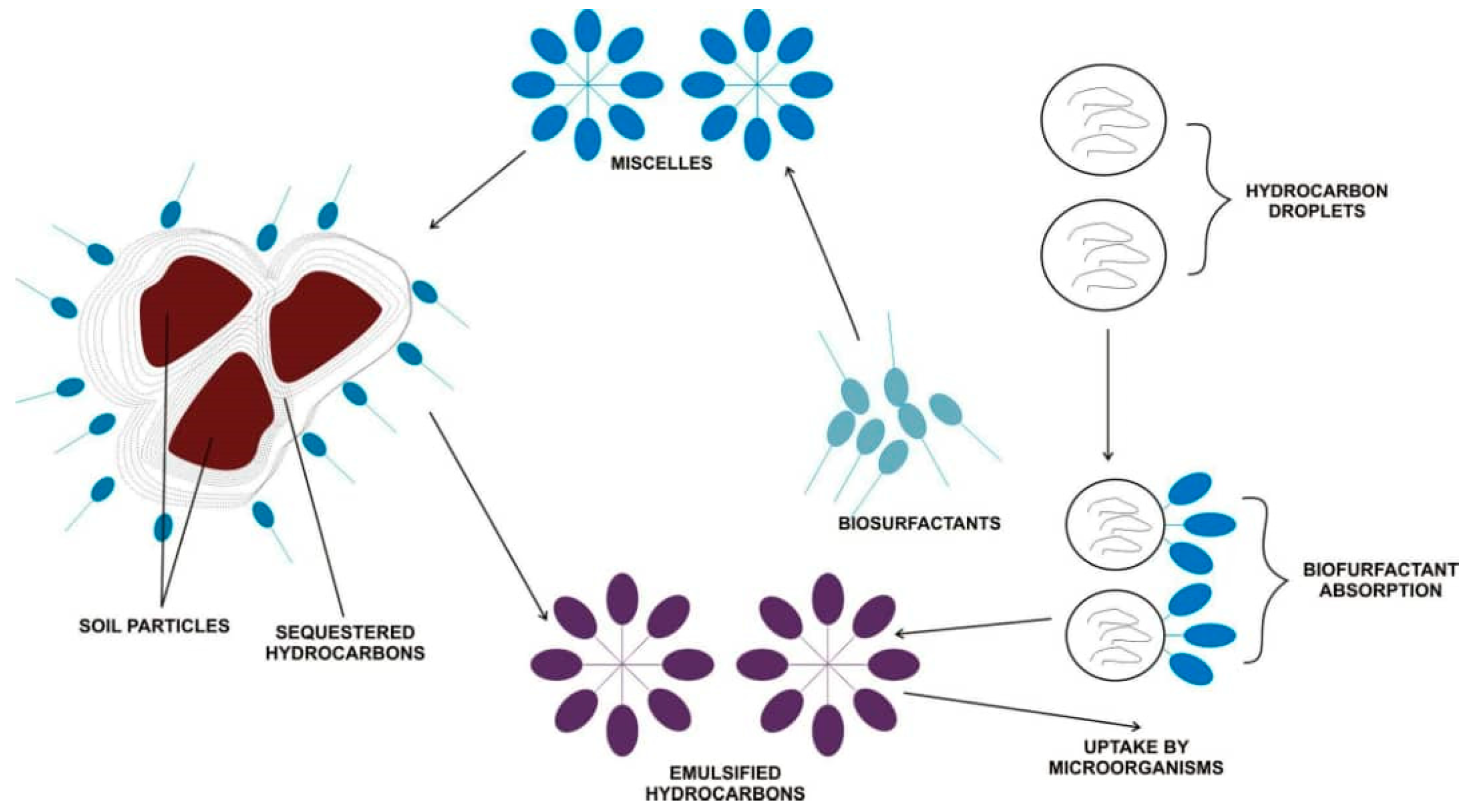

3.2. Bioremediation of Hydrocarbon-Contaminated Soil

3.3. Soil Washing

3.4. Metal Bioremediation

4. Application of Biosurfactants in Agriculture

5. Biosurfactants in Other Industries

6. Conclusion

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Liu, J.F.; Mbadinga, S.M.; Yang, S.Z.; Gu, J.D.; Mu, B.Z. Chemical structure, property and potential applications of biosurfactants produced by Bacillus subtilis in petroleum recovery and spill mitigation. Int. J. Mol. Sci. 2015, 16, 4814–4837. [Google Scholar] [CrossRef] [PubMed]

- Sobrinho, H.B.; Luna, J.M.; Rufino, R.D.; Porto, A.L.F.; Sarubbo, L.A. Biosurfactants: Classification, properties and environmental applications. Recent Dev. Biotechnol. 2013, 11, 1–29. [Google Scholar]

- Deleu, M.; Paquot, M. From renewable vegetables resources to microorganisms: New trends in surfactants. Comptes. Rendus. Chimie. 2004, 7, 641–646. [Google Scholar] [CrossRef]

- Abbasi, H.; Sharafi, H.; Alidost, L.; Bodagh, A.; Zahiri, H.S.; Noghabi, K.A. Response surface optimization of biosurfactant produced by Pseudomonas aeruginosa MA01 isolated from spoiled apples. Prep. Biochem. Biotech. 2013, 43, 398–414. [Google Scholar] [CrossRef] [PubMed]

- Jagtap, S.; Yavankar, S.; Pardesi, K.; Chopade, B. Production of bioemulsifier by Acinetobacter species isolated from healthy human skin. Indian J. Exp. Biol. 2010, 48, 70–76. [Google Scholar]

- Bhardwaj, G.; Cameotra, S.S.; Chopra, H.K. Biosurfactants from fungi: A review. J. Pet. Environ. Biotechnol. 2013, 4, 1–6. [Google Scholar] [CrossRef]

- Morita, T.; Konishi, M.; Fukuoka, T.; Imura, T.; Kitamoto, D. Physiological differences in the formation of the glycolipid biosurfactants, mannosylerythritol lipids, between Pseudozyma antarctica and Pseudozyma aphidis. Appl. Microbiol. Biotechnol. 2007, 74, 307–315. [Google Scholar] [CrossRef]

- Stancu, M.M. Response of Rhodococcus erythropolis strain IBBPo1 to toxic organic solvents. Braz. J. Microbiol. 2015, 46, 1009–1018. [Google Scholar] [CrossRef]

- Pacwa-Płociniczak, M.; Płaza, G.A.; Piotrowska-Seget, Z.; Cameotra, S.S. Environmental applications of biosurfactants: Recent advances. Int. J. Mol. Sci. 2011, 12, 633–654. [Google Scholar] [CrossRef]

- Muthusamy, K.; Gopalakrishnan, S.; Ravi, T.K.; Sivachidambaram, P. Biosurfactants: Properties, commercial production and application. Curr. Sci. 2008, 94, 736–747. [Google Scholar]

- Shekhar, S.; Sundaramanickam, A.; Balasubramanian, T. Biosurfactant producing microbes and their potential applications: A review. Crit. Rev. Environ. Sci. Technol. 2015, 45, 1522–1554. [Google Scholar] [CrossRef]

- Marques, E.F.; Silva, B.F.B. Surfactants, Phase Behavior. In Encyclopedia of Colloid and Interface Science; Springer: Berlin, Germany, 2013; pp. 1290–1333. [Google Scholar]

- Dave, N.; Joshi, T.A. Concise review on surfactants and its significance. Int. J. Appl. Chem. 2017, 13, 663–672. [Google Scholar]

- Bratovcic, A.; Nazdrajic, S.; Odobasic, A.; Sestan, I. The influence of type of surfactant on physicochemical properties of liquid soap. Int. J. Mat. Chem. 2018, 8, 31–37. [Google Scholar]

- Sil, J.; Dandapat, P.; Das, S. Health care applications of different biosurfactants: Review. Int. J. Sci. Res. 2017, 6, 41–50. [Google Scholar]

- Akbari, S.; Abdurahman, N.H.; Yunus, R.M.; Fayaz, F.; Alara, O.R. Biosurfactants—a new frontier for social and environmental safety: A mini review. Biotechnol. Res. Innov. 2018, 2, 81–90. [Google Scholar] [CrossRef]

- Rhein, L. Surfactant action on skin and hair: Cleansing and skin reactivity mechanisms. In Handbook for Cleaning/Decontamination of Surfaces, 1st ed.; Johansson, I., Somasundaran, P., Eds.; Elsevier: Amsterdam, The Netherlands; Boston, MA, USA, 2002; pp. 305–369. [Google Scholar]

- Alwadani, N.; Fatehi, P. Synthetic and lignin based surfactants: Challenges and opportunities. Carbon Resour. Convers. 2018, 1, 126–138. [Google Scholar] [CrossRef]

- Lukic, M.; Pantelic, I.; Savic, S. An overview of novel surfactants for formulation of cosmetics with certain emphasis on acidic active substances. Tenside Surfact Det. 2016, 53, 7–19. [Google Scholar] [CrossRef]

- Bucci, A.R.; Marcelino, L.; Mendes, R.K.; Etchegaray, A. The antimicrobial and antiadhesion activities of micellar solutions of surfactin, CTAB and CPCl with terpinen-4-ol: Applications to control oral pathogens. World J. Microbiol. Biotechnol. 2018, 34, 86. [Google Scholar] [CrossRef]

- Yuewen, L.; Ran, L.; Zhifei, L.; Jing, C.; Xinli, L. Comparison of the pharmaceutical activities of sophorolipids and nano-hydroxyapatite sophorolipids on cervical cancer cells. Chin. J. Appl. Environ. Biol. 2017, 3, 386–490. [Google Scholar]

- Al-wazni, W.S. Immunomodulator activity of biosurfactant extract from Serratia marcescens. Int. J. Microbiol. Res. 2016, 7, 36–42. [Google Scholar]

- Pasiar, M.; Rouhi, L.; Bamzadeh, Z.; Hejazi, S.H. In vitro selective growth inhibition of breast adenocarcinoma cell lines by Pseudomonas sp. UW4 metabolites. Tehran. Niv. Med. J. 2016, 74, 614–620. [Google Scholar]

- Rodrigues, L.; Banat, I.M.; Teixeira, J.; Oliveira, R. Biosurfactants: Potential applications in medicine. J. Antimicrob. Chemother. 2006, 57, 609–618. [Google Scholar] [CrossRef] [PubMed]

- Gharaei-Fathabad, E. Biosurfactants in pharmaceutical industry: A mini-review. Am. J. Drug Discov. Devel. 2011, 1, 58–69. [Google Scholar]

- Kitamoto, D.; Isoda, H.; Nakahara, T. Functions and potential applications of glycolipid biosurfactants—from energy-saving materials to gene delivery carriers. J. Biosci. Bioeng. 2002, 94, 187–201. [Google Scholar] [CrossRef]

- Sekhon-Randhawa, K.K.; Rahman, P.K. Rhamnolipid biosurfactants—past, present, and future scenario of global market. Front. Microbiol. 2014, 5, 1–8. [Google Scholar] [CrossRef]

- Invally, K.; Sancheti, A.; Ju, L.K. A new approach for downstream purification of rhamnolipid biosurfactants. Food Bioprod. Process 2019, 114, 122–131. [Google Scholar] [CrossRef]

- Araujo, H.W.; Andrade, R.F.; Montero-Rodríguez, D.; Rubio-Ribeaux, D.; da Silva, C.A.; Campos-Takaki, G.M. Sustainable biosurfactant produced by Serratia marcescens UCP 1549 and its suitability for agricultural and marine bioremediation applications. Microb. Cell Fact. 2019, 18, 2. [Google Scholar] [CrossRef]

- Liu, G.; Zhong, H.; Yang, X.; Liu, Y.; Shao, B.; Liu, Z. Advances in applications of rhamnolipids biosurfactant in environmental remediation: A review. Biotechnol. Bioeng. 2018, 115, 796–814. [Google Scholar] [CrossRef]

- Singh, R.; Glick, B.R.; Rathore, D. Biosurfactants as a biological tool to increase micronutrient availability in soil: A review. Pedosph 2018, 28, 170–189. [Google Scholar] [CrossRef]

- Biniarz, P.; Łukaszewicz, M.; Janek, T. Screening concepts, characterization and structural analysis of microbial-derived bioactive lipopeptides: A review. Crit. Rev. Biotechnol. 2017, 37, 393–410. [Google Scholar] [CrossRef] [PubMed]

- Yazid, N.A.; Barrna, R.; Kolimis, D.; Shanchez, A. Solid –state fermentation as a novel paradigm for organic waste valorization:a review. Sustainability 2017, 9, 224. [Google Scholar] [CrossRef]

- Shah, M.U.; Sivapragasam, M.; Moniruzzaman, M.; Yusup, S.B. A comparison of recovery methods of rhamnolipids produced by Pseudomonas aeruginosa. Proc. Eng. 2016, 148, 494–500. [Google Scholar] [CrossRef]

- Khan, M.Y.; Karim, Z.A.; Hagos, F.Y.; Aziz, A.R.; Tan, I.M. Current trends in water-in-diesel emulsion as a fuel. Sci. World J. 2014, 527472, 1–14. [Google Scholar]

- Global Oil Demand Picks up but Still Lags Rising Supply. Available online: https://www.rigzone.com/news/wire/iea_global_oil_demand_picks_up_but_still_lags_rising_supply-15-mar-2018–153886-article/ (accessed on 19 May 2019).

- Luna, J.; Rufino, R.; Campos, G.; Sarubbo, L. Properties of the biosurfactant produced by Candida sphaerica cultivated in low-cost substrates. Chem. Eng. 2012, 27, 67–72. [Google Scholar]

- de Almeida, D.G.; Soares da Silva, R.D.; Luna, J.M.; Rufino, R.D.; Santos, V.A.; Banat, I.M.; Sarubbo, L.A. Biosurfactants: Promising molecules for petroleum biotechnology advances. Front. Microbiol. 2016, 7, 1718. [Google Scholar] [CrossRef]

- Mazaheri-Assadi, M.; Tabatabaee, M.S. Biosurfactants and their use in upgrading petroleum vacuum distillation residue: A review. Inter. J. Environ. Res. 2010, 4, 549–572. [Google Scholar]

- Satpute, S.K.; Kulkarni, G.R.; Banpurkar, A.G.; Banat, I.M.; Mone, N.S.; Patil, R.H.; Cameotra, S.S. Biosurfactants from Lactobacilli species: Properties, challenges and potential biomedical applications. J. Basic. Microbiol. 2016, 56, 1140–1158. [Google Scholar] [CrossRef]

- Alagorni, A.H.; Yaacob, Z.B.; Nour, A.H. An overview of oil production stages: Enhanced oil recovery techniques and nitrogen injection. Int. J. Environ. Sci. Dev. 2015, 6, 693–701. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, Y.; Chen, G.; Gai, Z. Application of nanoparticles in enhanced oil recovery: A critical review of recent progress. Energies 2017, 10, 345. [Google Scholar] [CrossRef]

- Crecente, C.; Rasmussen, K.; Torsaeter, O.; Storm, A.; Kowalewski, E. A experimental study of microbial improved oil recovery by using Rhodococcus sp.094. In Proceedings of the International Symposium of the Society of Core Analysts, Toronto, ON, Canada, 21–25 August 2005. [Google Scholar]

- Camara, J.M.; Sousa, M.A.; Neto, E.B.; Oliveira, M.C. Application of rhamnolipid biosurfactant produced by Pseudomonas aeruginosa in microbial-enhanced oil recovery (MEOR). J. Petrol. Explor. Prod. Technol. 2019, 1, 1–9. [Google Scholar]

- Negin, C.; Ali, S.; Xie, Q. Most common surfactants employed in chemical enhanced oil recovery. Petroleum 2017, 3, 197–211. [Google Scholar] [CrossRef]

- Yu, H.; Huang, G.H. Isolation and characterization of biosurfactant-and bioemulsifier-producing bacteria from petroleum contaminated sites in Western Canada. Soil Sediment Contam. 2011, 20, 274–288. [Google Scholar] [CrossRef]

- Geetha, S.J.; Banat, I.M.; Joshi, S.J. Biosurfactants: Production and potential applications in microbial enhanced oil recovery (MEOR). Biocatal Agric Biotechnol 2018, 14, 23–32. [Google Scholar]

- Al-Bahry, S.N.; Al-Wahaibi, Y.M.; Elshafie, A.E.; Al-Bemani, A.S.; Joshi, S.J.; Al-Makhmari, H.S.; Al-Sulaimani, H.S. Biosurfactant production by Bacillus subtilis B20 using date molasses and its possible application in enhanced oil recovery. Int. Biodeterior. Biodegrad. 2013, 81, 141–146. [Google Scholar] [CrossRef]

- Park, T.; Joo, H.W.; Kim, G.Y.; Kim, S.; Yoon, S.; Kwon, T.H. Biosurfactant as an enhancer of geologic carbon storage: Microbial modification of interfacial tension and contact angle in carbon dioxide/water/quartz systems. Front. Microbiol. 2017, 8, 1285. [Google Scholar] [CrossRef]

- Sarafzadeh, P.; Niazi, A.; Oboodi, V.; Ravanbakhsh, M.; Hezave, A.Z.; Ayatollahi, S.S.; Raeissi, S. Investigating the efficiency of MEOR processes using Enterobacter cloacae and Bacillus stearothermophilus SUCPM# 14 (biosurfactant-producing strains) in carbonated reservoirs. J. Petrol. Sci. Eng. 2014, 113, 46–53. [Google Scholar]

- She, H.; Kong, D.; Li, Y.; Hu, Z.; Guo, H. Recent Advance of Microbial Enhanced Oil Recovery (MEOR) in China. Geofluids 2019, 1871392, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Maudgalya, S.; Knapp, R.; McInerney, M. Microbial Enhanced Oil-Recovery Technologies: A Review of the Past, Present, and Future; Society of Petroleum Engineers: Oklahoma, OK, USA, 2007. [Google Scholar]

- Khire, J.M. Bacterial Biosurfactants, and Their Role in Microbial Enhanced Oil Recovery (MEOR); Springer: New York, NY, USA, 2010; pp. 146–157. [Google Scholar]

- Golabi, E.; Sogh, S.R.; Hosseini, S.N.; Gholamzadeh, M.A. Biosurfactant production by microorganism for enhanced oil recovery. Int. J. Sci. Eng. Res. 2012, 3, 1–6. [Google Scholar]

- Weidong, W.; Junzhang, L.; Xueli, G.; Jing, W.; Ximing, L.; Yan, J.; Fengmin, Z. MEOR field test at block Luo 801 of Shengli oil field in China. Petrol. Sci. Technol. 2014, 32, 673–679. [Google Scholar] [CrossRef]

- Basafa, M.; Hawboldt, K. Reservoir souring: Sulfur chemistry in offshore oil and gas reservoir fluids. J. Petrol. Explor. Prod. Technol. 2019, 9, 1105–1118. [Google Scholar] [CrossRef] [Green Version]

- Astuti, D.I.; Purwasena, I.A.; Putri, F.Z. Potential of biosurfactant as an alternative biocide to control biofilm associated biocorrosion. J. Environ. Sci. Technol. 2018, 11, 104–111. [Google Scholar]

- El-Sheshtawy, H.S.; Aiad, I.; Osman, M.E.; Abo-ELnasr, A.A.; Kobisy, A.S. Production of biosurfactant from Bacillus licheniformis for microbial enhanced oil recovery and inhibition the growth of sulfate reducing bacteria. Egyptian J. Petrol. 2015, 24, 155–162. [Google Scholar] [CrossRef] [Green Version]

- Hong, E.; Jeong, M.S.; Kim, T.H.; Lee, J.H.; Cho, J.H.; Lee, K.S. Development of Coupled Biokinetic and Thermal Model to Optimize Cold-Water Microbial Enhanced Oil Recovery (MEOR) in Homogenous Reservoir. Sustainability 2019, 11, 1652. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Xue, Q.; Gao, H.; Lai, H.; Wang, P. Production of lipopeptide biosurfactants by Bacillus atrophaeus 5–2a and their potential use in microbial enhanced oil recovery. Microb. Cell Fact. 2016, 15, 168. [Google Scholar] [CrossRef] [Green Version]

- Youssef, N.; Simpson, D.R.; Duncan, K.E.; McInerney, M.J.; Folmsbee, M.; Fincher, T.; Knapp, R.M. In situ biosurfactant production by Bacillus strains injected into a limestone petroleum reservoir. Appl. Environ. Microbiol. 2007, 73, 1239–1247. [Google Scholar] [CrossRef] [Green Version]

- Udoh, T.; Vinogradov, J. Experimental investigations of behaviour of biosurfactants in brine solutions relevant to hydrocarbon reservoirs. Colloids Interfaces 2019, 3, 24. [Google Scholar] [CrossRef] [Green Version]

- Mukherjee, A.K. Potential application of cyclic lipopeptide biosurfactants produced by Bacillus subtilis strains in laundry detergent formulations. Lett. Appl. Microbiol. 2007, 45, 330–335. [Google Scholar] [CrossRef]

- Bezza, F.; Chirwa, E.M. Possible use of biosurfactant produced by microbial consortium from contaminated soil for microbially enhanced oil recovery. Chem. Eng. Transact. 2017, 57, 1411–1416. [Google Scholar]

- Abass, K.I. The Impact of Various Surfactants on the Water-in-Diesel Fuel Emulsions. J. Mech. Civil. Eng. 2017, 14, 41–47. [Google Scholar] [CrossRef]

- Sai-Chaitanya, P.; Rambabu, V.; Simhadri, K. Investigation on effect of water emulsified with diesel by surfactant addition on performance and emission characteristics of diesel engine. Int. J. Chem. Sci. 2016, 14, 2835–2844. [Google Scholar]

- Syafiq, Z.; Fahmi, O.; Awad, O.I.; Adam, A. The study of stability, combustion characteristics and performance of water in diesel emulsion fuel. MATEC Web Conf. 2017, 90, 1–8. [Google Scholar] [CrossRef] [Green Version]

- El-Din, M.N.; El-Hamouly, S.H.; Mohamed, H.M.; Mishrif, M.R.; Ragab, A.M. Water-in-diesel fuel nanoemulsions: Preparation, stability and physical properties. Egyptian J. Petrol. 2013, 22, 517–530. [Google Scholar] [CrossRef] [Green Version]

- Hegde, R.R.; Sharma, P.; Raj, P.; Keny, R.V.; Bhide, P.J.; Kumar, S.; Bhattacharya, S.S.; Lohani, A.; Kumar, A.; Verma, A.; et al. Factors affecting emissions from diesel fuel and water-in-diesel emulsion. Energy Sources Part A Recovery Util. Environ. Eff. 2016, 38, 1771–1778. [Google Scholar] [CrossRef]

- Leng, L.; Yuan, X.; Zeng, G.; Chen, X.; Wang, H.; Li, H.; Fu, L.; Xiao, Z.; Jiang, L.; Lai, C. Rhamnolipid based glycerol-in-diesel microemulsion fuel: Formation and characterization. Fuel 2015, 147, 76–81. [Google Scholar] [CrossRef]

- Pekdemir, T.; Copur, M.; Urum, K. Emulsification of crude oil–water systems using biosurfactants. Process. Saf. Environ. 2005, 83, 38–46. [Google Scholar] [CrossRef]

- Perfumo, A.; Rancich, I.; Banat, I.M. Possibilities and challenges for biosurfactants use in petroleum industry. Adv. Exp. Med. Biol. 2010, 672, 135–145. [Google Scholar] [CrossRef]

- Dantas-Neto, A.A.; Fernandes, M.R.; Barros-Neto, E.L.; Castro-Dantas, T.N.; Moura, M.C. Alternative fuels composed by blends of nonionic surfactant with diesel and water: Engine performance and emissions. Braz. J. Chem. Eng. 2011, 28, 521–531. [Google Scholar] [CrossRef]

- Okoliegbe, I.N.; Agarry, O.O. Application of microbial surfactant (a review). Sch. J. Biotechnol. 2012, 1, 15–23. [Google Scholar]

- Rahema, H.; Kumari, S. Performance and emissions of emulsified biodiesel operated diesel engine. In Proceedings of the International Conference on Biological, Civil and Environmental Enginering, Dubai, UAE, 17–18 March 2014; 2014. [Google Scholar]

- Sharma, R.; Singh, J.; Verma, N. Biosurfactant production and biodesulphurization: Integrated approach for fuel processing. Adv. Biotech. Micrbiol. 2017, 4, 1–5. [Google Scholar]

- Raheb, J. The Role of Microorganisms and Productions in Biodesulfurization of Fossiel Fuels. J. Microb. Biochem. Technol. 2016, 8, 498–502. [Google Scholar] [CrossRef]

- Nazari, F.; Kefayati, M.E.; Raheb, J. The study of biological technologies for the removal of sulfur compounds. J. Sci. Islamic. Repub. Iran 2017, 28, 205–219. [Google Scholar]

- Bhanjadeo, M.M.; Rath, K.; Gupta, D.; Pradhan, N.; Biswal, S.K.; Mishra, B.K.; Subudhi, U. Differential desulfurization of dibenzothiophene by newly identified MTCC strains: Influence of operon array. PLoS ONE 2018, 13, e0192536. [Google Scholar] [CrossRef] [PubMed]

- Shahaby, A.F.; Essam-El-din, K.M. Desulfurization of crude oil and oil products by local isolated bacterial strains. Int. J. Curr. Microbiol. Appl. Sci. 2017, 6, 2695–2711. [Google Scholar]

- Bahuguna, A.; Lily, M.K.; Munjal, A.; Singh, R.N.; Dangwal, K. Desulfurization of dibenzothiophene (DBT) by a novel strain Lysinibacillus sphaericus DMT-7 isolated from diesel contaminated soil. J. Environ. Sci. 2011, 23, 975–982. [Google Scholar] [CrossRef]

- Derikvand, P.; Etemadifar, Z.; Saber, H. Sulfur removal from dibenzothiophene by newly isolated Paenibacillus validus strain PD2 and process optimization in aqueous and biphasic (model oil) systems. Polish. J. Microbiol. 2015, 64, 47–54. [Google Scholar]

- Boniek, D.; Figueiredo, D.; dos Santos, A.F.; de Resende-Stoianoff, M.A. Biodesulfurization: A mini review about the immediate search for the future technology. Clean Technol. Envir. 2015, 17, 29–37. [Google Scholar] [CrossRef]

- Kilbane, J.J. Microbial biocatalyst development to upgrade fossil fuels. Cuur. Opin. Biotechol. 2006, 17, 305–314. [Google Scholar] [CrossRef]

- Khosravinia, S.; Mahdavi, M.A.; Gheshlaghi, R.; Dehghani, H.; Rasekh, B. Construction and characterization of a new recombinant vector to remove sulfate repression of dsz promoter transcription in biodesulfurization of dibenzothiophene. Front. Microbiol. 2018, 9, 1578. [Google Scholar] [CrossRef]

- Raheb, J.; Hajipour, M.J. The stable rhamnolipid biosurfactant production in genetically engineered pseudomonas strain reduced energy consumption in biodesulfurization. Energ. Sources Part A 2011, 33, 2113–2121. [Google Scholar] [CrossRef]

- Amin, G.A.; Bazaid, S.A.; Abd El-Halim, M. A Two-stage immobilized cell bioreactor with Bacillus subtilis and Rhodococcus erythropolis for the simultaneous production of biosurfactant and biodesulfurization of model oil. Pet. Sci. Technol. 2013, 31, 2250–2257. [Google Scholar] [CrossRef]

- Lyu, Y.; Zhang, T.; Dou, B.; Li, G.; Ma, C.; Li, Y. A lipopeptide biosurfactant from Bacillus sp. Lv13 and their combined effects on biodesulfurization of dibenzothiophene. RSC Adv. 2018, 8, 38787–38791. [Google Scholar] [CrossRef] [Green Version]

- Morales, M.; le Borgne, S. Protocols for the isolation and preliminary characterization of bacteria for biodesulfurization and biodenitrogenation of petroleum-derived fuels. In Hydrocarbon and Lipid Microbiology Protocols; McGenity, T.J., Timmis, K.N., Fernandez, B.N., Eds.; Springer: Heidelberg, Berlin, 2014; pp. 201–218. [Google Scholar]

- Li, G.Q.; Li, S.S.; Zhang, M.L.; Wang, J.; Zhu, L.; Liang, F.L.; Liu, R.L.; Ma, T. Genetic rearrangement strategy for optimizing the dibenzothiophene biodesulfurization pathway in Rhodococcus erythropolis. Appl. Environ. Microbiol. 2008, 74, 971–976. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ceron-Camacho, R.; Martínez-Palou, R.; Chavez-Gomez, B.; Cuéllar, F.; Bernal-Huicochea, C.; Aburto, J. Synergistic effect of alkyl-O-glucoside and-cellobioside biosurfactants as effective emulsifiers of crude oil in water: A proposal for the transport of heavy crude oil by pipeline. Fuel 2013, 110, 310–317. [Google Scholar] [CrossRef]

- Kurup, A.S.; Vargas, F.M.; Wang, J.; Buckley, J.; Creek, J.L.; Subramani, H.J.; Chapman, W.G. Development and application of an asphaltene deposition tool (ADEPT) for well bores. Ener. Fuels 2011, 25, 4506–4516. [Google Scholar] [CrossRef]

- Chala, G.T.; Sulaiman, S.A.; Japper-Jaafar, A. Flow start-up and transportation of waxy crude oil in pipelines-A review. J. Non-Newtonian Fluid Mech. 2018, 251, 69–87. [Google Scholar] [CrossRef]

- Amani, H.; Kariminezhad, H. Study on emulsification of crude oil in water using emulsan biosurfactant for pipeline transportation. Pet. Sci. Technol. 2016, 34, 216–222. [Google Scholar] [CrossRef]

- Silva, R.; Almeida, D.; Rufino, R.; Luna, J.; Santos, V.; Sarubbo, L. Applications of biosurfactants in the petroleum industry and the remediation of oil spills. Int. J. Mol. Sci. 2014, 15, 12523–12542. [Google Scholar] [CrossRef]

- Matsui, T.; Namihira, T.; Mitsuta, T.; Saeki, H. Removal of oil tank bottom sludge by novel biosurfactant, JE 1058 BS. J. Jpn. Pet. Inst. 2012, 55, 138–141. [Google Scholar] [CrossRef]

- Islam, B. Petroleum sludge, its treatment and disposal: A review. Int. J. Chem. Sci. 2015, 13, 1584–1602. [Google Scholar]

- Saeki, H.; Sasaki, M.; Komatsu, K.; Miura, A.; Matsuda, H. Oil spill remediation by using the remediation agent JE1058BS that contains a biosurfactant produced by Gordonia sp. strain JE-1058. Biores. Technol. 2009, 100, 572–577. [Google Scholar] [CrossRef]

- Diab, A.; Din, G.E. Application of the biosurfactants produced by Bacillus sp. (SH 20 and SH 26) and P. aeruginosa SH 29 isolated from the rhizosphere soil of an Egyptian salt marsh plant for the cleaning of oil-contaminated vessels and enhancing the biodegradation. Afr. J. Environ. Sci. Technol. 2013, 7, 671–679. [Google Scholar]

- Silva, E.J.; Rocha, S.N.M.; Rufino, R.D.; Luna, J.M.; Silva, R.O.; Sarubbo, L.A. Characterization of a biosurfactant produced by Pseudomonas cepacia CCT6659 in the presence of industrial wastes and its application in the biodegradation of hydrophobic compounds in soil. Coll. Surf. B Biointer. 2014, 117, 36–41. [Google Scholar] [CrossRef]

- Chikere, C.B.; Fenibo, E.O. Distribution of PAH-ring hydroxylating dioxygenase genes in bacteria isolated from two illegal oil refining sites in the Niger Delta, Nigeria. Sci. Afr. 2018, 1, e00003. [Google Scholar]

- Patel, S.; Homaei, A.; Patil, S.; Daverey, A. Microbial biosurfactants for oil spill remediation: Pitfalls and potentials. Appl. Microbiol. Biotechnol. 2019, 103, 27–37. [Google Scholar] [CrossRef] [PubMed]

- Toledo, A.V.; Simurro, M.E.; Balatti, P.A. Morphological and molecular characterization of a fungus, Hirsutella spp., isolated from planthoppers and psocids in Argentina. J. Insect Sci. 2013, 13, 18. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Feng, J.Q.; Gang, H.Z.; Li, D.S.; Liu, J.F.; Yang, S.Z.; Mu, B.Z. Characterization of biosurfactant lipopeptide and its performance evaluation for oil-spill remediation. RSC Adv. 2019, 9, 9629–9632. [Google Scholar] [CrossRef] [Green Version]

- Dang, H.; Klotz, M.G.; Lovell, C.; Sievert, S.M. The responses of marine microorganisms, communities and ecofunctions to environmental gradients. Front. Microbiol. 2019, 10, 115. [Google Scholar] [CrossRef]

- Ron, E.Z.; Rosenberg, E. Biosurfactants and oil bioremediation. Curr. Opin. Biotechnol. 2002, 13, 249–252. [Google Scholar] [CrossRef]

- Chen, W.; Wilkes, G.; Khan, I.U.; Pintar, K.D.; Thomas, J.L.; Lévesque, C.A.; Chapados, J.T.; Topp, E.; Lapen, D.R. Aquatic bacterial communities associated with land use and environmental factors in agricultural landscapes using a metabarcoding approach. Front. Microbiol. 2018, 9, 2301. [Google Scholar] [CrossRef]

- Karlapudi, A.P.; Venkateswarulu, T.C.; Tammineedi, J.; Kanumuri, L.; Ravuru, B.K.; ramu Dirisala, V.; Kodali, V.P. Role of biosurfactants in bioremediation of oil pollution-a review. Petroleum 2018, 4, 241–249. [Google Scholar] [CrossRef]

- Whang, L.M.; Liu, P.W.G.; Ma, C.C.; Cheng, S.S. Application of biosurfactants, rhamnolipid, and surfactin, for enhanced biodegradation of diesel-contaminated water and soil. J. Hazard. Mater. 2008, 151, 155–163. [Google Scholar] [CrossRef] [PubMed]

- Płaza, G.A.; Łukasik, K.; Wypych, J.; Nałęcz-Jawecki, G.; Berry, C.; Brigmon, R.L. Biodegradation of crude oil and distillation products by biosurfactant-producing bacteria. Pol. J. Environ. Stud. 2008, 17, 87–94. [Google Scholar]

- Shah, M.U.; Moniruzzaman, M.; Sivapragasam, M.; Talukder, M.M.; Yusup, S.B.; Goto, M. A binary mixture of a biosurfactant and an ionic liquid surfactant as a green dispersant for oil spill remediation. J. Mol. Liquids 2019, 280, 111–119. [Google Scholar] [CrossRef]

- Neethu, C.S.; Saravanakumar, C.; Purvaja, R.; Robin, R.S.; Ramesh, R. Oil-spill triggered shift in indigenous microbial structure and functional dynamics in different marine environmental matrices. Sci. Rep. 2019, 9, 1354. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Zeng, G.; Zhong, H.; Wang, Z.; Liu, Z.; Cheng, M.; Liu, G.; Liu, S. Effect of rhamnolipid solubilization on hexadecane bioavailability: Enhancement or reduction? J. Hazard. Mater. 2017, 322, 394–401. [Google Scholar] [CrossRef]

- Cui, C.Z.; Zeng, C.; Wan, X.; Chen, D.; Zhang, J.Y.; Shen, P. Effect of rhamnolipids on degradation of anthracene by two newly isolated strains, Sphingomonas sp. 12A and Pseudomonas sp. 12B. J. Microbiol. Biotechnol. 2008, 18, 63–66. [Google Scholar]

- Olasanmi, I.O.; Thring, R.W. The role of biosurfactants in the continued drive forenvironmental sustainability. Sustainability 2018, 10, 4817. [Google Scholar] [CrossRef] [Green Version]

- Johnson, O.A.; Affam, A.C. Petroleum sludge treatment and disposal: A review. Environ. Eng. Res. 2018, 24, 191–201. [Google Scholar] [CrossRef]

- Kaczorek, E.; Pachholak, A.; Zdarta, A.; Smulek, W. The impact of biosurfactant on microbial properties leading to hydrocarbon bioavailability. Colloids Interfaces 2018, 2, 35. [Google Scholar] [CrossRef] [Green Version]

- Shin, K.H.; Kim, K.W.; Ahn, Y. Use of biosurfactant to remediate phenanthrene-contaminated soil by the combined solubilization–biodegradation process. J. Hazard. Mater. 2006, 137, 1831–1837. [Google Scholar] [CrossRef]

- Bustamante, M.; Duran, N.; Diez, M.C. Biosurfactants are useful tools for the bioremediation of contaminated soil: A review. J. Soil. Sci. Plant Nutr. 2012, 12, 667–687. [Google Scholar] [CrossRef] [Green Version]

- Jorfi, S.; Rezaee, A.; Jaafarzadeh, N.A.; Esrafili, A.; Akbari, H.; Ali, G.A. Bioremediation of pyrene-contaminated soils using biosurfactant. Jentashapir J. Health Res. 2014, 5, e23228. [Google Scholar] [CrossRef]

- Itrich, N.R.; McDonough, K.M.; van Ginkel, C.G.; Bisinger, E.C.; LePage, J.N.; Schaefer, E.C.; Menzies., J.Z.; Casteel, K.D.; Federle, T.W. Widespread microbial adaptation to L-glutamate-N, N-diacetate (L-GLDA) following its market introduction in a consumer cleaning product. Environ. Sci. Technol. 2015, 49, 13314–13321. [Google Scholar] [CrossRef] [PubMed]

- Usman, M.M.; Dadrasnia, A.; Lim, K.T.; Mahmud, A.F.; Ismail, S. Application of biosurfactants in environmental biotechnology; remediation of oil and heavy metal. AIMS Bioeng. 2016, 3, 289–304. [Google Scholar] [CrossRef]

- Matvyeyeva, O.L.; Vasylchenko, O.A.; Aliievan, O.R. Microbial biosurfactants role in oil products biodegradation. Int. J. Environ. Biorem. Biodegrad. 2014, 2, 69–74. [Google Scholar]

- Abdel-Moghny, T.; Mohamed, R.S.; El-Sayed, E.; Mohammed-Aly, S.; Snousy, M.G. Effect of soil texture on remediation of hydrocarbons-contaminated soil at El-Minia district, Upper Egypt. ISRN Chem. Eng. 2012, 406598, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Hazrina, H.Z.; Noorashikin, M.S.; Beh, S.Y.; Loh, S.H.; Zain, N.N. Formulation of chelating agent with surfactant in cloud point extraction of methylphenol in water. Royal Society Open Sci. 2018, 5, 180070. [Google Scholar] [CrossRef] [Green Version]

- Chu, W.; Choy, W.K.; Hunt, J.R. Effects of nonaqueous phase liquids on the washing of soil in the presence of nonionic surfactants. Water Res. 2005, 39, 340–348. [Google Scholar] [CrossRef]

- Christofi, N.; Ivshina, I.B. Microbial surfactants and their use in field studies of soil remediation. J. Appl. Microbiol. 2002, 93, 915–929. [Google Scholar] [CrossRef]

- Mao, X.; Jiang, R.; Xiao, W.; Yu, J. Use of surfactants for the remediation of contaminated soils: A review. J. Hazard. Mater. 2015, 285, 419–435. [Google Scholar] [CrossRef]

- Zhong, H.; Yang, X.; Tan, F.; Brusseau, M.L.; Yang, L.; Liu, Z.; Zeng, G.; Yuan, X. Aggregate-based sub-CMC solubilization of n-alkanes by monorhamnolipid biosurfactant. New J. Chem. 2016, 40, 2028–2035. [Google Scholar] [CrossRef] [PubMed]

- Ochoa-Loza, F.J.; Noordman, W.H.; Jannsen, D.B.; Brusseau, M.L.; Maier, R.M. Effect of clays, metal oxides, and organic matter on rhamnolipid biosurfactant sorption by soil. Chemotherapy 2007, 66, 1634–1642. [Google Scholar] [CrossRef] [PubMed]

- Lai, C.C.; Huang, Y.C.; Wei, Y.H.; Chang, J.S. Biosurfactant-enhanced removal of total petroleum hydrocarbons from contaminated soil. J. Hazard. Mater. 2009, 167, 609–614. [Google Scholar] [CrossRef] [PubMed]

- Conte, P.; Agretto, A.; Spaccini, R.; Piccolo, A. Soil remediation: Humic acids as natural surfactants in the washings of highly contaminated soils. Environ. Pollut. 2005, 135, 515–522. [Google Scholar] [CrossRef]

- Yu, H.; Xiao, H.; Wang, D. Effects of soil properties and biosurfactant on the behavior of PAHs in soil-water systems. Environ. Sys. Res. 2014, 3, 6. [Google Scholar] [CrossRef] [Green Version]

- Urum, K.; Pekdemir, T. Evaluation of biosurfactants for crude oil contaminated soil washing. Chemotherapy 2004, 57, 1139–1150. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, B.; Li, G.; Wu, T.; Sun, D. Efficient remediation of crude oil-contaminated soil using a solvent/surfactant system. RSC Adv. 2019, 9, 2402–2411. [Google Scholar] [CrossRef] [Green Version]

- Khodadadi, A.; Ganjidoust, H.; Razavi, S.S. Treatment of crude-oil contaminated soil using biosurfactants. J. Pet. Gas. Eng. 2012, 3, 92–98. [Google Scholar]

- Bandala, E.R.; Aguilar, F.; Torres, L.G. Surfactant-enhanced soil washing for the remediation of sites contaminated with pesticides. Land Contam. Reclamat. 2010, 18, 2. [Google Scholar] [CrossRef]

- Lopez-Vizcaino, R.; Saez, C.; Canizares, P.; Rodrigo, M.A. The use of a combined process of surfactant-aided soil washing and coagulation for PAH-contaminated soils treatment. Sep. Purif. Technol. 2012, 88, 46–51. [Google Scholar]

- Torres, L.G.; González, R.; Gracida, J. Production and Application of No-purified Rhamnolipids in the Soil-washing of TPHs Contaminated Soils. Asian Soil Res. J. 2013, 19, 1–2. [Google Scholar]

- Bezza, F.A.; Chirwa, E.M. Biosurfactant-assisted bioremediation of polycyclic aromatic hydrocarbons (PAHs) in liquid culture system and substrate interactions. Polycycl. Aromaat. Comp. 2017, 37, 375–394. [Google Scholar] [CrossRef]

- Ariffin, N.; Abdullah, M.M.; Zainol, M.R.; Murshed, M.F.; Faris, M.A.; Bayuaji, R. Review on adsorption of heavy metal in wastewater by using geopolymer. MATEC Web Conf. 2017, 97, 01023. [Google Scholar] [CrossRef]

- Wuana, R.A.; Okieimen, F.E. Heavy metals in contaminated soils: A review of sources, chemistry, risks and best available strategies for remediation. ISRN Ecol. 2011, 2011, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Santos, D.K.F.; Rufino, R.D.; Luna, J.M.; Santos, V.A.; Sarubbo, L. A Biosurfactants: Multifunctional biomolecules of the 21st century. Int. J. Mol. Sci. 2016, 17, 401. [Google Scholar] [CrossRef]

- Egorova, K.S.; Ananikov, V.P. Toxicity of metal compounds: Knowledge and myths. Organometallics 2017, 36, 4071–4090. [Google Scholar] [CrossRef] [Green Version]

- Zaghloul, A.; Saber, M. Modern Technologies in Remediation of Heavy Metals in Soils. Int. J. Environ. Poll. Environ. Model. 2019, 2, 10–19. [Google Scholar]

- Mulligan, C.N.; Yong, R.N.; Gibbs, B.F.; James, S.; Bennett, H.P. Metal removal from contaminated soil and sediments by the biosurfactant surfactin. Environ. Sci. Technol. 1999, 33, 3812–3820. [Google Scholar] [CrossRef]

- Ochoa-Loza, F.J.; Artiola, J.F.; Maier, R.M. Stability constants for the complexation of various metals with a rhamnolipid biosurfactant. J. Environ. Qual. 2001, 30, 479–485. [Google Scholar] [CrossRef]

- Franzetti, A.; Gandolfi, I.; Fracchia, L.; van Hamme, J.; Gkorezis, P.; Marchant, R.; Banat, I.M. Biosurfactant Use in Heavy Metal Removal from Industrial Effluents and Contaminated Sites. In Biosurfactants: Production and utilization—Processes, Technologies, and Economics; Kosaric, N., Sukan, F.V., Eds.; CRC Press: Florida, FL, USA, 2014; Volume 3, pp. 361–370. [Google Scholar]

- Rufino, R.D.; Luna, J.M.; Campos-Takaki, G.M.; Ferreira, S.R.; Sarubbo, L.A. Application of the biosurfactant produced by Candida lipolytica in the remediation of heavy metals. Chem. Eng. 2012, 27, 61–66. [Google Scholar]

- Delil, A.D.; Koleli, N. The removal of Pb and Cd from heavily contaminated soil in Kayseri, Turkey by a combined process of soil washing and electrodeposition. Soil Sediment Contam. Int. J. 2018, 27, 469–484. [Google Scholar] [CrossRef]

- Kim, S.I.; Song, J.S. A study on the evaluation of cesium removal performance in soil washing process using flocculating agent. J. Radioanal Nucl. Chem. 2018, 316, 1227–1232. [Google Scholar] [CrossRef]

- Nielsen, T.H.; Sorensen, J. Production of cyclic lipopeptides by Pseudomonas fluorescens strains in bulk soil and in the sugar beet rhizosphere. Appl. Environ. Microbial. 2003, 69, 861–868. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Qi, X.; Xu, X.; Zhong, C.; Jiang, T.; Wei, W.; Song, X. Removal of cadmium and lead from contaminated soils using sophorolipids from fermentation culture of Starmerella bombicola CGMCC 1576 fermentation. Int. J. Environ. Res. Public Health 2018, 15, 2334. [Google Scholar] [CrossRef] [Green Version]

- Liduino, V.S.; Servulo, E.F.; Oliveira, F.J. Biosurfactant-assisted phytoremediation of multi-contaminated industrial soil using sunflower (Helianthus annuus L.). J. Environ. Sci. Health Part A 2018, 53, 609–616. [Google Scholar] [CrossRef]

- Sarubbo, L.; Brasileiro, P.; Silveira, G.; Luna, J.; Rufino, R. Application of a low cost biosurfactant in the removal of heavy metals in soil. Chem. Eng. Trans. 2018, 64, 433–438. [Google Scholar]

- Bhaskar, P.V.; Bhosle, N.B. Bacterial extracellular polymeric substance (EPS): A carrier of heavy metals in the marine food-chain. Environ. Int. 2006, 32, 191–198. [Google Scholar] [CrossRef]

- Sandrin, T.R.; Maier, R.M. Effect of pH on cadmium toxicity, speciation, and accumulation during naphthalene biodegradation. Environ. Toxicol. Chem. 2002, 21, 2075–2079. [Google Scholar] [CrossRef]

- Sachdev, D.P.; Cameotra, S.S. Biosurfactants in agriculture. Appl Microbiol Biotechnol 2013, 97, 1005–1016. [Google Scholar] [CrossRef] [Green Version]

- Lucas, J.A.; García-Cristobal, J.; Bonilla, A.; Ramos, B.; Gutierrez-Manero, J. Beneficial rhizobacteria from rice rhizosphere confers high protection against biotic and abiotic stress inducing systemic resistance in rice seedlings. Plant Physiol. Biochem. 2014, 82, 44–53. [Google Scholar] [CrossRef]

- Choudhary, D.K.; Varma, A.; Tuteja, N. Plant-Microbe Interaction: An Approach to Sustainable Agriculture, 3rd ed.; Springer: Armstadarn, The Netherland, 2017; pp. 155–327. [Google Scholar]

- Ma, Y.; Oliveira, R.S.; Freitas, H.; Zhang, C. Biochemical and molecular mechanisms of plant-microbe-metal interactions: Relevance for phytoremediation. Front. Plant Sci. 2016, 7, 918. [Google Scholar] [CrossRef] [PubMed]

- Kruijt, M.; Tran, H.; Raaijmakers, J.M. Functional, genetic and chemical characterization of biosurfactants produced by plant growth-promoting Pseudomonas putida 267. J. Appl. Microbiol. 2009, 107, 546–556. [Google Scholar] [CrossRef]

- Hultberg, M.; Bergstrand, K.J.; Khalil, S.; Alsanius, B. Production of biosurfactants and antibiotics by fluorescent pseudomonads isolated from a closed hydroponic system equipped with a slow filter. Antonie van Leeuwenhoek 2008, 93, 373–380. [Google Scholar] [CrossRef]

- Mulligan, C.N. Environmental applications for biosurfactants. Environ. Poll. 2005, 133, 183–198. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.K.; Kim, Y.C.; Lee, S.; Kim, J.C.; Yun, M.Y.; Kim, I.S. Insecticidal activity of rhamnolipid isolated from Pseudomonas sp. EP-3 against green peach aphid (Myzus persicae). J. Agric. Food Chem. 2010, 59, 934–938. [Google Scholar] [CrossRef] [PubMed]

- Parthipan, P.; Sarankumar, R.K.; Jaganathan, A.; Amuthavalli, P.; Babujanarthanam, R.; Rahman, P.K.S.M.; Murugan, K.; Higuchi, A.; Benelli, G.; Rajasekar, A. Biosurfactants produced by Bacillus subtilis A1 and Pseudomonas stutzeri NA3 reduce longevity and fecundity of Anopheles stephensi and show high toxicity against young instars. Environ. Sci. Poll. Res. 2018, 25, 10471–10481. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Newton, J.A.; Fray, R.G. Integration of environmental and host-derived signals with quorum sensing during plant–microbe interactions. Cell Microbiol. 2004, 6, 213–224. [Google Scholar] [CrossRef]

- Dusane, D.H.; Zinjarde, S.S.; Venugopalan, V.P.; Mclean, R.J.; Weber, M.M.; Rahman, P.K. Quorum sensing: Implications on rhamnolipid biosurfactant production. Biotechnol. Genet. Eng. Rev. 2010, 27, 159–184. [Google Scholar] [CrossRef] [Green Version]

- Vatsa, P.; Sanchez, L.; Clement, C.; Baillieul, F.; Dorey, S. Rhamnolipid biosurfactants as new players in animal and plant defense against microbes. Int. J. Mol. Sci. 2010, 11, 5095–5108. [Google Scholar] [CrossRef] [Green Version]

- Chuo, S.C.; Abd-Talib, N.; Mohd-Setapar, S.H.; Hassan, H.; Nasir, H.M.; Ahmad, A.; Lokhat, D.; Ashraf, G.M. Reverse micelle extraction of antibiotics using an eco-friendly sophorolipids biosurfactant. Sci. Rep. 2018, 8, 477. [Google Scholar] [CrossRef] [Green Version]

- Maeng, Y.; Kim, K.T.; Zhou, X.; Jin, L.; Kim, K.S.; Kim, Y.H.; Lee, S.; Park, J.H.; Chen, X.; Kong, M.; et al. A novel microbial technique for producing high-quality sophorolipids from horse oil suitable for cosmetic applications. Microb. Biotechnol. 2018, 11, 917–929. [Google Scholar] [CrossRef] [PubMed]

- Vecino, X.; Cruz, J.M.; Moldes, A.B.; Rodrigues, L.R. Biosurfactants in cosmetic formulations: Trends and challenges. Crit. Rev. Biotechnol. 2017, 37, 911–923. [Google Scholar] [CrossRef] [PubMed]

- De Oliveira, M.R.; Magri, A.; Baldo, C.; Camilios-Neto, D.; Minucelli, T.; Celligoi, M.A. Sophorolipids A promising biosurfactant and its applications. Int. J. Adv. Biotechnol. Res. 2015, 6, 161–174. [Google Scholar]

- Rauwel, P.; Küünal, S.; Ferdov, S.; Rauwel, E. A review on the green synthesis of silver nanoparticles and their morphologies studied via TEM. Adv. Mat. Sci. Eng. 2015, 682749. [Google Scholar] [CrossRef] [Green Version]

- Fracchia, L.; Ceresa, C.; Franzetti, A.; Cavallo, M.; Gandolfi, I.; van Hamme, J.; Gkorezis, P.; Marchant, R.; Banat, I.M. Industrial applications of biosurfactants. In Biosurfact: Production and Utilization—Processes, Technologies, and Economics; Kosaric, N., Sukan, F.V., Eds.; CRC Press: Florida, FL, USA, 2014; Volume 3, pp. 245–360. [Google Scholar]

- Plaza, G.A.; Chojniak, J.; Banat, I.M. Biosurfactant mediated biosynthesis of selected metallic nanoparticles. Int. J. Mol. Sci. 2014, 15, 13720–13737. [Google Scholar] [CrossRef] [Green Version]

- Gudina, E.J.; Rangarajan, V.; Sen, R.; Rodrigues, L.R. Potential therapeutic applications of biosurfactants. Trends Phaarma. Sci. 2013, 34, 667–675. [Google Scholar] [CrossRef] [Green Version]

- Kilic, E. Evaluation of degreasing process with plant derived biosurfactant for leather making: An ecological approach. J. Text. Appar. 2013, 23, 181–187. [Google Scholar]

- Shoeb, E.; Akhlaq, F.; Badar, U.; Akhter, J.; Imtiaz, S. Classification and industrial applications of biosurfactants. AR Int. 2013, 4, 243. [Google Scholar]

- Mohd-Setapar, S.H.; Mahamad-Aziz, S.N.; Harun, N.H.; Mohd-Azizi, C.Y. Review on the extraction of biomolecules by biosurfactant reverse micelles. APCBEE Procedia 2012, 3, 78–83. [Google Scholar] [CrossRef] [Green Version]

- Pervaiz, M.; Sain, M. Extraction and Characterization of Extracellular Polymeric Substances (EPS) from Waste Sludge of Pulp and Paper Mill. Int. Rev. Chem. Eng. 2010, 2, 550–554. [Google Scholar]

- Das, K.; Mukherjee, A.K. Crude petroleum-oil biodegradation efficiency of Bacillus subtilis and Pseudomonas aeruginosa strains isolated from a petroleum-oil contaminated soil from North-East India. Biores. Technol. 2007, 98, 1339–1345. [Google Scholar] [CrossRef] [PubMed]

- Mukherjee, S.; Das, P.; Sen, R. Towards commercial production of microbial surfactants. Trends Biotechnol. 2006, 24, 509–515. [Google Scholar] [CrossRef] [PubMed]

- Kosaric, N. Biosurfactants and their application for soil bioremediation. Food Technol. Biotechnol. 2001, 39, 295–304. [Google Scholar]

- Banat, I.M.; Makkar, R.S.; Cameotra, S.S. Potential commercial applications of microbial surfactants. Appl. Microbiol. Biotechnol. 2000, 53, 495–508. [Google Scholar] [CrossRef]

- Biosurfactants Market- Segmented by Product Typr, Application, and Geography, Growth, Trend and Forcast (2019–2024). Available online: https://www.mordorintelligence.com/industry-reports/biosurfactants-market (accessed on 12 February 2019).

- Anic, I.; Apolonia, I.; Franco, P.; Wichmann, R. Production of rhamnolipids by integrated foam adsorption in a bioreactor system. AMB Express 2018, 8, 122. [Google Scholar] [CrossRef]

- Zeng, Z.; Liub, Y.; Zhong, H.; Xiao, H.; Zeng, G.; Liu, Z.; Cheng, M.; Lai, C.; Zhang, C.; Liu, G.; et al. Mechanisms for rhamnolipids-mediated biodegradation of hydrophobic organic compounds. Sc. Total. Environ. 2018, 634, 1–11. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, Q.; Wang, K.; Brian, K.; Liu, C.; Gu, Y. Study of the antifungal activity of Bacillus vallismortis ZZ185 in vitro and identification of its antifungal components. Biores. Technol. 2010, 101, 292. [Google Scholar] [CrossRef]

- Singh, P.; Cameotra, S.S. Potential applications of microbial surfactants in biomedical sciences. Trends Biotechnol. 2004, 22, 142–146. [Google Scholar] [CrossRef]

- Maitani, Y.; Yano, S.; Hattori, Y.; Furuhata, M.; Hayashi, K. Liposome vector containing biosurfactant-complexed DNA as herpes simplex virus thymidine kinase gene delivery system. J. Liposome. Res. 2006, 16, 359–372. [Google Scholar] [CrossRef]

- Alizadeh-Sani, M.; Hamishehkar, H.; Khezerlou, A.; Azizi-Lalabadi, M.; Azadi, Y.; Nattagh-Eshtivani, E.; Fasihi, M.; Ghavami, A.; Aynehchi, A.; Ehsani, A. Bioemulsifiers derived from microorganisms: Applications in the drug and food industry. Adv. Pharm. Bull. 2018, 8, 191. [Google Scholar] [CrossRef] [Green Version]

- Eswari, J.S.; Dhagat, S.; Mishra, P. Biosurfactant assisted silver nanoparticle synthesis: A critical analysis of its drug design aspects. Adv. Nat. Sci. Nanosci. Nanotechnol. 2018, 9, 045007. [Google Scholar] [CrossRef] [Green Version]

- Temiouwa, O.; Oluwaanmi, O.; Ifeanyi, S.; Tomiwa, O. Nano Augmented Biosurfactant Formulation for Recovery in Medium Oil Reservoirs. Society of Petroleum Engineers: Richardson, TX, USA, 2018. [Google Scholar] [CrossRef]

- Balakrishnan, G.; Déniel, M.; Nicolai, T.; Chassenieux, C.; Lagarde, F. Towards more realistic reference microplastics and nanoplastics: Preparation of polyethylene micro/nanoparticles with a biosurfactant. Environ. Sci. Nano. 2019, 6, 315–324. [Google Scholar] [CrossRef]

- Kitamoto, D.; Yanagishita, H.; Endo, A.; Nakaiwa, M.; Nakane, T.; Akiya, T. Remarkable antiagglomeration effect of a yeast biosurfactant, diacylmannosylerythritol, on ice-water slurry for cold thermal storage. Biotechnol. Prog. 2001, 17, 362–365. [Google Scholar] [CrossRef] [PubMed]

- Global Market Insight. Available online: https://www.gminsights.com/industry-analysis/biosurfactants-market-report. (accessed on 19 July 2019).

- Soonglerdsongpha, S.; Rongsyamanont, W.; Khondee, N.; Pinyakong, O.; Luepromchai, E. Production and application of lipopeptide biosurfactant for dispersing oil spill in seawater. In Proceedings of the 5th World Congress on Biotechnology, Valencia, Spain, 25–27 June 2014. [Google Scholar]

- Mulligan, C.N.; Sharma, S.K.; Mudhoo, A.; Makhijan, K. Green chemistry and biosurfactants. In Biosurfactants: Research Trends and Applications, 1st ed.; Mulligan, C.N., Sharma, S.K., Mudhoo, A., Eds.; CRC Press: Boca Raton, Fl, USA, 2014; pp. 1–30. [Google Scholar]

- Souza, E.C.; Vessoni-Penna, T.C.; de Souza-Oliveira, R.P. Biosurfactant-enhanced hydrocarbon bioremediation: An overview. Int. Biodeterior. Biodegrad. 2014, 89, 88–94. [Google Scholar] [CrossRef]

- Ahmad, Z.; Imran, M.; Qadee, S.; Hussain, S.; Kausar, R.; Dawson, L.; Khalid, A. Biosurfactants for sustainable soil management. In Advances in Agronomy, Sparks, D. Ed.; Academic Press: Massachusetts, MA, USA, 2018; Volume 150, pp. 81–130. [Google Scholar]

- Aulwar, U.; Awasthi, R. Production of Biosurfactant and their Role in Bioremediation. J. Ecosys. Ecogr. 2016, 6, 202. [Google Scholar] [CrossRef] [Green Version]

- Asci, Y.; Nurbaş, M.; Açıkel, Y.S. Investigation of sorption/desorption equilibria of heavy metal ions on/from quartz using rhamnolipid biosurfactant. J. Environ. Manag. 2010, 91, 724–731. [Google Scholar] [CrossRef]

- Marchut-Mikolajczyk, O.; Drożdżyński, P.; Pietrzyk, D.; Antczak, T. Biosurfactant production and hydrocarbon degradation activity of endophytic bacteria isolated from Chelidonium majus L. Microb. Cell Fact. 2018, 17, 171. [Google Scholar] [CrossRef] [Green Version]

- Oluwaseun, A.C.; Phazang, P.; Sarin, N.B. Significance of rhamnolipids as a biological control agent in the management of crops/plant pathogens. Curr. Trends Biomed. Eng. Biosci. 2017, 10, 1–2. [Google Scholar]

- Sitaraman, R. Pseudomonas spp. as models for plant-microbe interactions. Front. Plant Sci. 2015, 6, 787. [Google Scholar] [CrossRef] [Green Version]

- Lee, D.S.; Song, H.G. Antibacterial activity of isolated bacteria against Propionibacterium acnes causing acne vulgaris. Korean J. Microbiol. 2018, 54, 272–279. [Google Scholar]

- Kalyani, R.; Bishwambhar, M.; Suneetha, V. Recent potential usage of surfactant from microbial origin in pharmaceutical and biomedical arena: A perspective. J. Res. Pharm. 2011, 2, 11–15. [Google Scholar]

- Chai, T.; Yan, H.; Zhang, Z.; Xu, M.; Wu, Y.; Jin, L.; Huang, G.; Fu, H. Optimization of enhanced ultrafiltration conditions for cd with mixed biosurfactants using thebox-behnken response surface methodology. Water 2019, 11, 442. [Google Scholar] [CrossRef] [Green Version]

- Campos, J.M.; Stamford, T.L.; Sarubbo, L.A.; de Luna, J.M.; Rufino, R.D.; Banat, I.M. Microbial biosurfactants as additives for food industries. Biotechnol. Prog. 2013, 29, 1097–10108. [Google Scholar] [CrossRef] [PubMed]

- Roy, A. A review on the biosurfactants: Properties, types and its application. J. Fundam. Renew. Energy Appl. 2017, 8, 1–14. [Google Scholar] [CrossRef]

| Industry | Field | Biosurfactant | Mechanism/Functioning as/Property Used | Reference |

|---|---|---|---|---|

| Petroleum biotechnology | Extraction of crude oil from reservoirs | Glycolipids and Lipopeptide | Biosurfactants enhance the formation of stable water-oil emulsion, break down oil film in the rock and reduces tension/interfacial tensions thereby reducing the capillary forces that impede oil movement through the rock pores | [38,43] |

| Transport of crude by pipelines | Emulsan, alasan, biodispersan | High molecular weight biosurfactants form a stable water-in-oil emulsion which aids oil mobility, viscosity reduction and prevents drop coalescence | [72,199] | |

| Oil storage tank cleaning | Rhamnolipids | A well-circulated biosurfactant will form an oil-in-water and lift/mobilize oil sludge from the bottom of the tank and solubilize in the already formed emulsion | ||

| Bioremediation | Spill remediation (aquatic) | Glycolipid and Trehalose Lipids | Solubilization, oil bioavailable to hydrocarbon-degraders and longer shelf life, biodegradability | [200] |

| Soil washing Wastewater treatment | Rhamnolipids Lipopeptides | Reduction of surface and interfacial tensions lead to mobilization and consequent removal of oil from the soil Physically separate, concentrate and remove chemicals of concern for modification, recycling or disposal. Rely on detergency, act as emulsifiers/de-emulsifiers and as a bioavailability enhancer | [134,201] | |

| Hydrocarbon remediation (soil) | Rhamnolipids, sophorolipids, surfactins | The solubilization property enhances the distribution of contaminants into the aqueous phase, thereby increasing the contaminant bioavailability for biodegradation | [202] | |

| Heavy metal remediation | Rhamnolipids | Metal-removal mechanisms by biosurfactants from soils are complexation, ion exchange, electrostatic interactions and counterion binding resulting in metal desorption, metal mobilization and metal entrapment by micelles. | [30,203] | |

| Mining Nanotechnology | Precious metal recovery Silver and gold nanoparticles | Biodispersan EPS from algae | Lowers the energy required for cleaving the microstructure of ground limestone. Utilize solubilization property and act as a sequestering agent Biosurfactant producing organisms converts (Ag-Au) NO3 to silver/gold particle using enzyme such as nitrate reductase. | [176,185,193] |

| Agriculture | Improvement of soil quality | Glycolipid | Consideration of all the soil-related bioremediation | [204] |

| Plant pathogen elimination | Rhamnolipids, cyclic lipopeptides | The biosurfactants act on the target cell by disrupting cell surface structures, thereby liberating the intracellular contents of the plant pathogen | [205] | |

| Plant-microbe interaction | Rhamnolipids | The establishment of the plant-microbe interaction is dependent on the exchange and sensing of a variety of signals (biosurfactants inclusive) by both types of partners. | [158,206] | |

| Pest control | Lipopeptides by Bacillus subtilis | Detergency property of biosurfactants exhibit toxicity against nematodes and insects | [189] | |

| Medicine/Pharmaceuticals | Gene delivery Antimicrobial activity | MEL Anionic surfactin isoform, rhamnolipids | Cationic liposome bearing MEL-A effectively increased the transfection of genes into mammalian cells The antimicrobial effect of biosurfactants is manifested through detergent-like activities | [15,26,189,207] |

| Anticancer activity | Sophorolipids | Biosurfactants as an antiviral agent, halt cell replication in favour of cell differentiation | [10,21] | |

| Immunological adjuvants | Surfactin, | Immunomodulating biosurfactants stimulate the immune system by increasing the ratio of lymphocyte transformation and migration of polymorph nuclear cells | [22,208] | |

| Antiviral activity | Sophorolipid diacetate ethyl ester, surfactin | Inactivation of viral lipid envelopes and capsid | [10] | |

| Anti-adhesive agents | Sophorolipids | Biosurfactants adsorption to a substratum modifies the surface hydrophobicity thereby interfering with microbial adhesion and desorption process | [149] | |

| Bioprocessing | Product recovery | Sophorolipids Rhamnolipids | Biosurfactants form part of the reverse micelle extraction of antibiotics and proteins using their surfactant properties | [17,179,209] |

| Leather | Biodispersan | Degreasing: used as skin detergent, emulsifier; tanning and dyeing: wetting and penetration, and promoter | [175] | |

| Textile | Trehaosetetraester Unspecified cHAL2 | Removal of lipophilic components from fibre surface as a pre-treatment, removal of oil from fibres and enhanced dispersion of dyes for uniform and better penetration into fibre | [175] | |

| Paper | Pulp processing | Biodispersan | Used for washing and deresinification of pulp by defoaming, dispersion and colour levelling | [175] |

| Papermaking | Biodispersan | Limestone was effectively grounded using biodispersan and used as a filter in papermaking. Biosurfactant also used in calendaring through wetting, levelling, coating and colouring | [175] | |

| Paint/coating protection | Biodispersan | Employed as a dispersant and as a wetting agent during grinding and stabilization for improved mixing property | [184] | |

| Food industry | Food emulsifier | Polymeric biosurfactants | Modification of the rheological characteristics of the food to a desired consistency and texture using emulsification properties | [210] |

| Food stabilizer | Rhamnolipids | Modification of the rheological characteristics of the food to a desired consistency and texture | [210] | |

| Cosmetic industry | Sophorolipids Rhamnolipids MELs | Application of biosurfactants in cosmetics is due to their low irritancy, cytoprotective effect, anti-ageing, acts like an antioxidant, wettability, moisturizing properties, healing and skin toning features | [7,171,211] | |

| Laundry detergents | Sophorolipids MEL | Properties such as foaming, surface tension reduction, solubilization make it suitable for detergent making | [172] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fenibo, E.O.; Ijoma, G.N.; Selvarajan, R.; Chikere, C.B. Microbial Surfactants: The Next Generation Multifunctional Biomolecules for Applications in the Petroleum Industry and Its Associated Environmental Remediation. Microorganisms 2019, 7, 581. https://doi.org/10.3390/microorganisms7110581

Fenibo EO, Ijoma GN, Selvarajan R, Chikere CB. Microbial Surfactants: The Next Generation Multifunctional Biomolecules for Applications in the Petroleum Industry and Its Associated Environmental Remediation. Microorganisms. 2019; 7(11):581. https://doi.org/10.3390/microorganisms7110581

Chicago/Turabian StyleFenibo, Emmanuel O., Grace N. Ijoma, Ramganesh Selvarajan, and Chioma B. Chikere. 2019. "Microbial Surfactants: The Next Generation Multifunctional Biomolecules for Applications in the Petroleum Industry and Its Associated Environmental Remediation" Microorganisms 7, no. 11: 581. https://doi.org/10.3390/microorganisms7110581

APA StyleFenibo, E. O., Ijoma, G. N., Selvarajan, R., & Chikere, C. B. (2019). Microbial Surfactants: The Next Generation Multifunctional Biomolecules for Applications in the Petroleum Industry and Its Associated Environmental Remediation. Microorganisms, 7(11), 581. https://doi.org/10.3390/microorganisms7110581