Integrated Assessment of Productive, Environmental, and Social Performances of Adopting Low-Protein Diets Technology for Laying Hens

Simple Summary

Abstract

1. Introduction

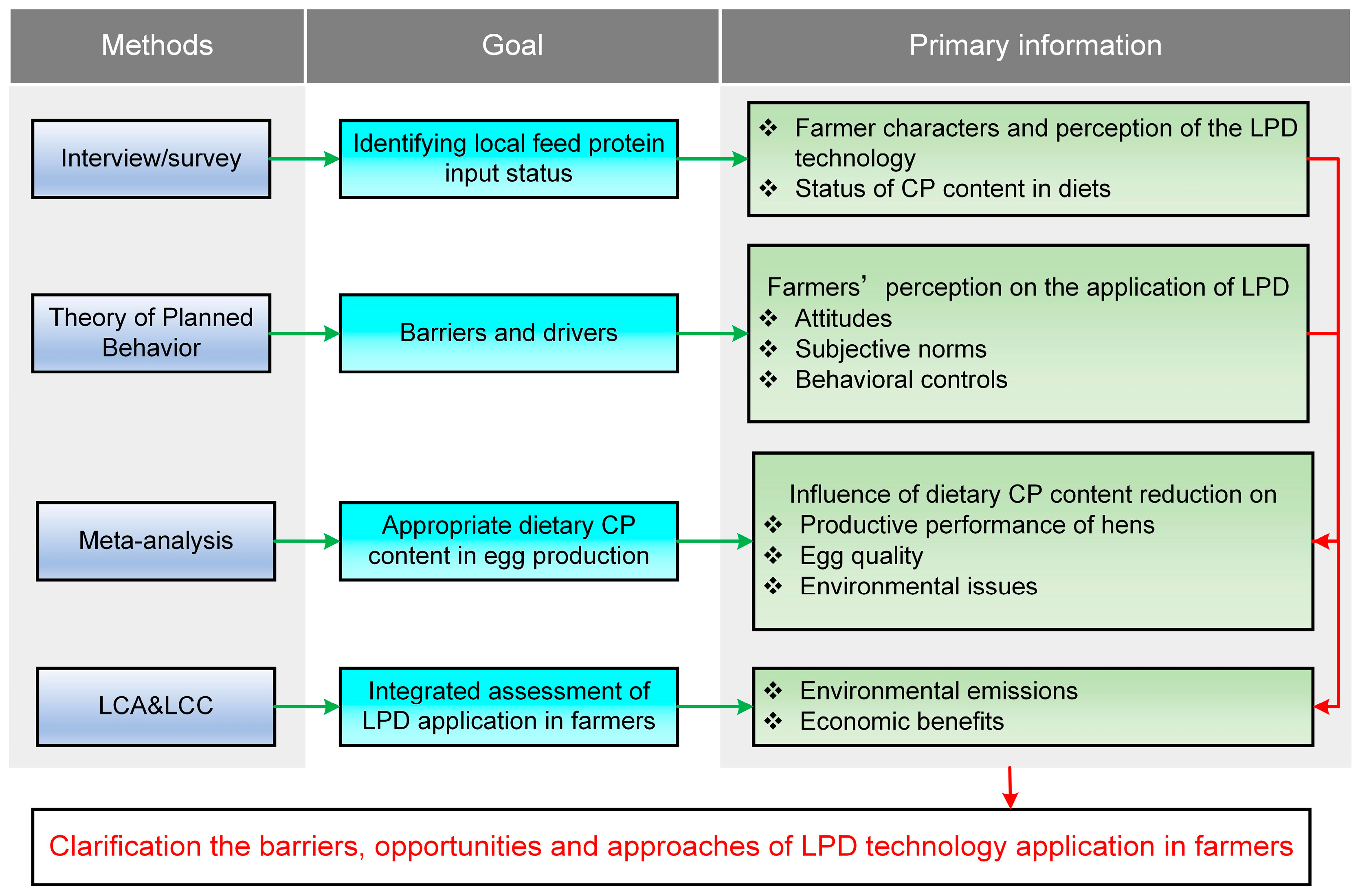

2. Materials and Methods

2.1. Theory of Planned Behavior (TPB) Methodology

2.1.1. Questionnaire Design and Statistical Analysis

2.1.2. Farm Survey and Feed Sampling

2.2. Meta-Analysis Methodology

2.3. Calculations of Nr Losses

2.4. Life-Cycle Costing and Profitability

3. Results

3.1. Drivers and Barriers to the Application of LPD Technology

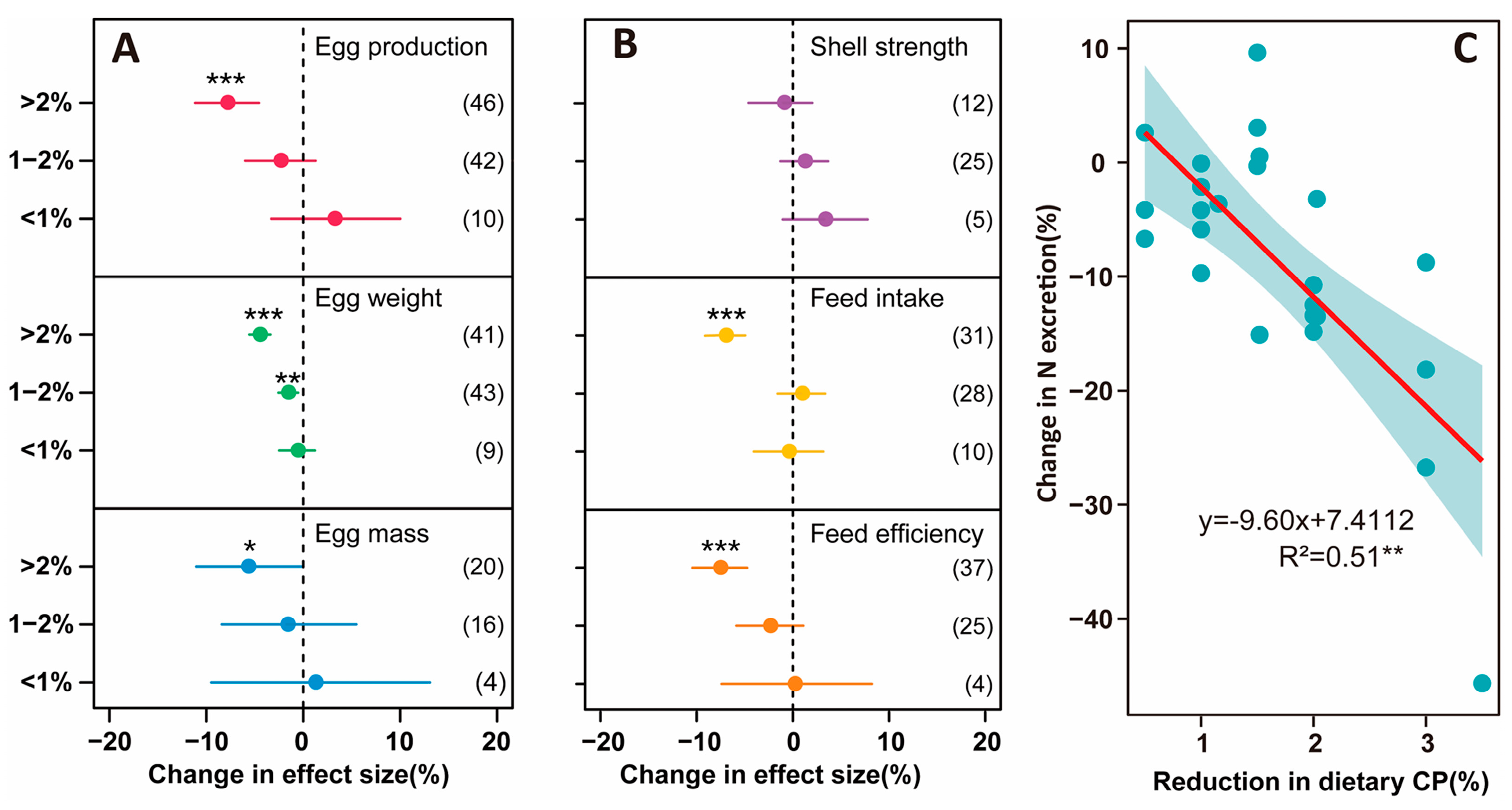

3.2. Meta-Analysis of LPD Technology on Egg Productivity, Quality, and Feed Efficiency

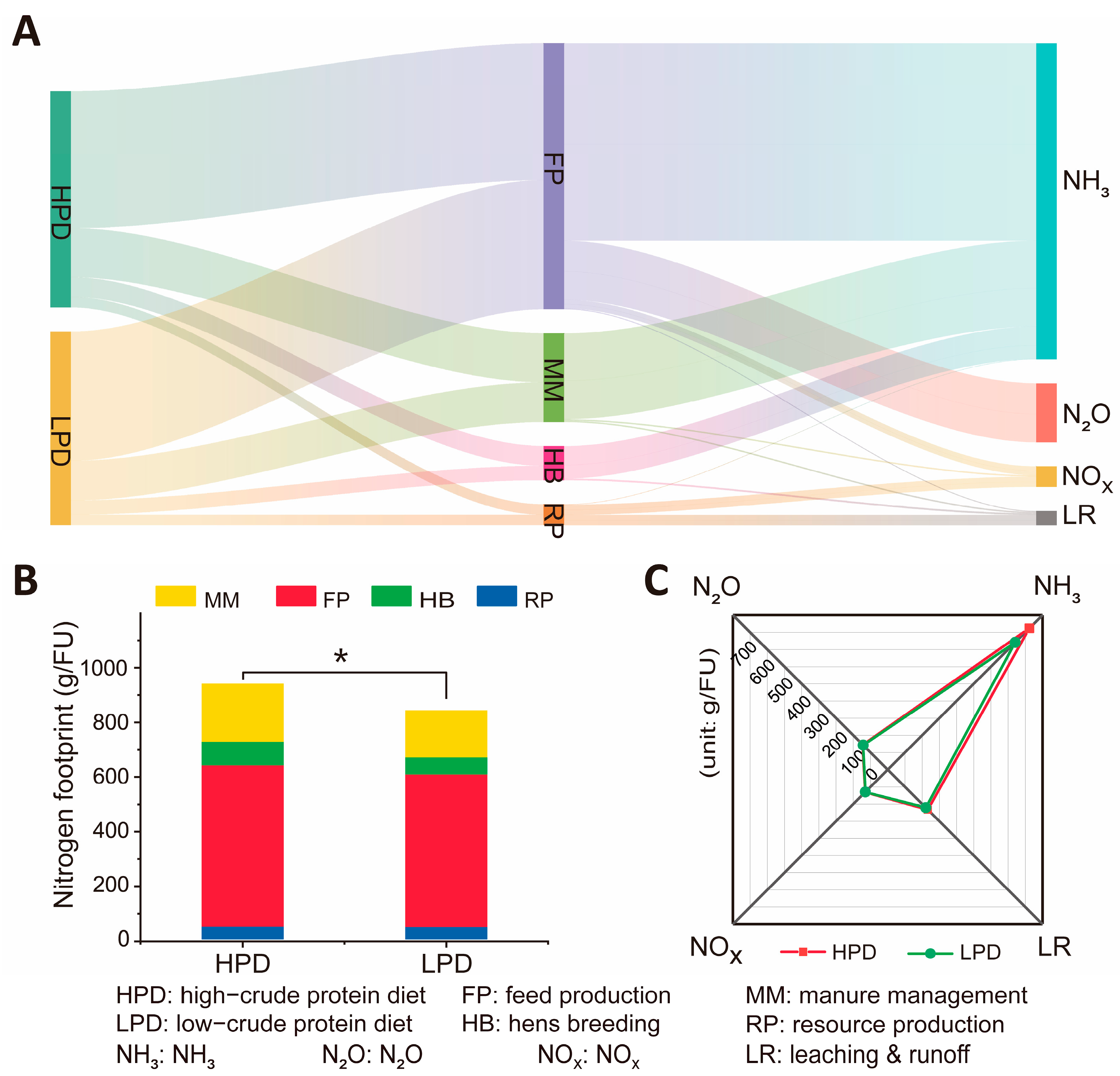

3.3. N Footprint and Life-Cycle Costs of the Laying Hen Supply Chain with LPD Technology

4. Discussion

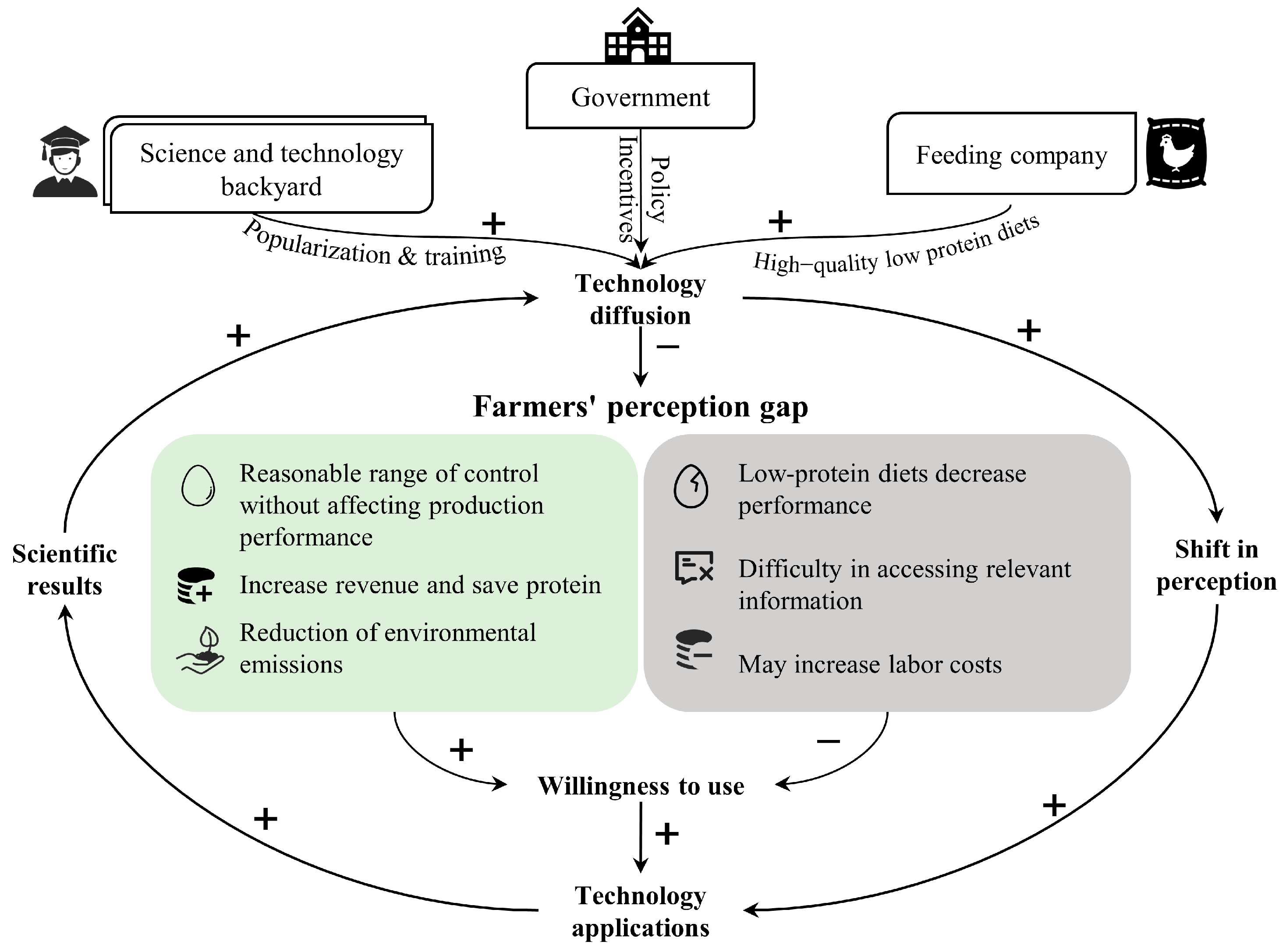

4.1. Why Farmers Do Not Use LPDs and How to Motivate Them to Use LPDs

4.2. Opportunities and Trade-Offs Among Environmental and Economic Performances in Applying LPDs

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bai, Z.; Ma, W.; Ma, L.; Velthof, G.L.; Wei, Z.; Havlík, P.; Oenema, O.; Lee, M.R.F.; Zhang, F. China’s Livestock Transition: Driving Forces, Impacts, and Consequences. Sci. Adv. 2018, 4, eaar8534. [Google Scholar] [CrossRef]

- Zhang, Q.; Reed, M. Examining the Impact of the World Crude Oil Price on China’s Agricultural Commodity Prices: The Case of Corn, Soybean, and Pork. In Proceedings of the Southern Agricultural Economics Association Annual Meetings, Dallas, TX, USA, 2–5 February 2008; Volume 7. [Google Scholar] [CrossRef]

- Wang, Y.; Ling, X.; Ma, C.; Liu, C.; Zhang, W.; Huang, J.; Peng, S.; Deng, N. Can China Get out of Soy Dilemma? A Yield Gap Analysis of Soybean in China. Agron. Sustain. Dev. 2023, 43, 47. [Google Scholar] [CrossRef]

- Yan, Y.; Wang, X.; Wang, J.; Mei, X.; Tang, H.; Wu, K. National Food Security Strategy Against the Backdrop of Domestic and International Dual Circulation. Chin. J. Eng. Sci. 2023, 25, 14. [Google Scholar] [CrossRef]

- Bougouin, A.; Hristov, A.; Dijkstra, J.; Aguerre, M.J.; Ahvenjärvi, S.; Arndt, C.; Bannink, A.; Bayat, A.R.; Benchaar, C.; Boland, T.; et al. Prediction of Nitrogen Excretion from Data on Dairy Cows Fed a Wide Range of Diets Compiled in an Intercontinental Database: A Meta-Analysis. J. Dairy Sci. 2022, 105, 7462–7481. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Sharma, P.; Shu, S.; Lin, T.-S.; Ciais, P.; Tubiello, F.N.; Smith, P.; Campbell, N.; Jain, A.K. Global Greenhouse Gas Emissions from Animal-Based Foods Are Twice Those of Plant-Based Foods. Nat. Food 2021, 2, 724–732. [Google Scholar] [CrossRef]

- Cao, Y.; Bai, Z.; Misselbrook, T.; Wang, X.; Ma, L. Ammonia Emissions from Different Pig Production Scales and Their Temporal Variations in the North China Plain. J. Air Waste Manag. Assoc. 2021, 71, 23–33. [Google Scholar] [CrossRef] [PubMed]

- Philippe, F.; Cabaraux, J.-F.; Nicks, B. Ammonia Emissions from Pig Houses: Influencing Factors and Mitigation Techniques. Agric. Ecosyst. Environ. 2011, 141, 245–260. [Google Scholar] [CrossRef]

- Jin, X.; Zhang, N.; Zhao, Z.; Bai, Z.; Ma, L. Nitrogen Budgets of Contrasting Crop-Livestock Systems in China. Environ. Pollut. 2021, 288, 117633. [Google Scholar] [CrossRef] [PubMed]

- Latshaw, J.D.; Zhao, L. Dietary Protein Effects on Hen Performance and Nitrogen Excretion. Poult. Sci. 2011, 90, 99–106. [Google Scholar] [CrossRef] [PubMed]

- Sajeev, E.P.M.; Amon, B.; Ammon, C.; Zollitsch, W.; Winiwarter, W. Evaluating the Potential of Dietary Crude Protein Manipulation in Reducing Ammonia Emissions from Cattle and Pig Manure: A Meta-Analysis. Nutr. Cycl. Agroecosyst. 2018, 110, 161–175. [Google Scholar] [CrossRef]

- Wang, H.; Wang, X.; Zhao, J.; Jiao, H.; Lin, H. Low Protein Diet Supplemented with Crystalline Amino Acids Suppressing Appetite and Apo-Lipoprotein Synthesis in Laying Hens. Anim. Feed Sci. Technol. 2020, 266, 114533. [Google Scholar] [CrossRef]

- Galassi, G.; Colombini, S.; Malagutti, L.; Crovetto, G.M.; Rapetti, L. Effects of High Fibre and Low Protein Diets on Performance, Digestibility, Nitrogen Excretion and Ammonia Emission in the Heavy Pig. Anim. Feed Sci. Technol. 2010, 161, 140–148. [Google Scholar] [CrossRef]

- Yang, N. Egg Production in China: Current Status and Outlook. Front. Agric. Sci. Eng. 2021, 8, 25–34. [Google Scholar] [CrossRef]

- Bryden, W.L.; Li, X.; Ruhnke, I.; Zhang, D.; Shini, S. Nutrition, Feeding and Laying Hen Welfare. Anim. Prod. Sci. 2021, 61, 893–914. [Google Scholar] [CrossRef]

- Tan, M.; Hou, Y.; Zhang, L.; Shi, S.; Long, W.; Ma, Y.; Zhang, T.; Oenema, O. Decision-Making Environment of Low-Protein Animal Feeding in Dairy and Poultry Farms in China. Nutr. Cycl. Agroecosyst. 2023, 127, 85–96. [Google Scholar] [CrossRef]

- Reijneveld, A.G.T.; Bohemen, F.J.V.; Termorshuizen, A.A.J.; Oenema, O. Farmer’s Perceptions of Soil Tests: A Case Study in the Netherlands. Acta Sci. Agric. 2019, 3, 96–103. [Google Scholar] [CrossRef]

- Truelove, H.B.; Carrico, A.R.; Thabrew, L. A Socio-Psychological Model for Analyzing Climate Change Adaptation: A Case Study of Sri Lankan Paddy Farmers. Glob. Environ. Change 2015, 31, 85–97. [Google Scholar] [CrossRef]

- Geng, S.; Huang, S.; Ma, Q.; Li, F.; Gao, Y.; Zhao, L.; Zhang, J. Alterations and Correlations of the Gut Microbiome, Performance, Egg Quality, and Serum Biochemical Indexes in Laying Hens with Low-Protein Amino Acid-Deficient Diets. ACS Omega 2021, 6, 13094–13104. [Google Scholar] [CrossRef]

- Zhou, J.-M.; Qiu, K.; Wang, J.; Zhang, H.-J.; Qi, G.-H.; Wu, S.-G. Effect of Dietary Serine Supplementation on Performance, Egg Quality, Serum Indices, and Ileal Mucosal Immunity in Laying Hens Fed a Low Crude Protein Diet. Poult. Sci. 2021, 100, 101465. [Google Scholar] [CrossRef] [PubMed]

- Iio, W.; Shimada, R.; Nonaka, I.; Ogino, A. Effects of a Low-Protein Diet Supplemented with Essential Amino Acids on Egg Production Performance and Environmental Gas Emissions from Layer-Manure Composting in Laying Hens in the Later Laying Period. Anim. Sci. J. 2023, 94, e13853. [Google Scholar] [CrossRef]

- Amirdahri, S.; Janmohammadi, H.; Taghizadeh, A.; Lambert, W.; Soumeh, E.A.; Oliayi, M. Valine Requirement of Female Cobb Broilers from 8 to 21 Days of Ag. J. Appl. Poult. Res. 2021, 29, 775–785. [Google Scholar] [CrossRef]

- Dao, T.H.; Sharma, N.K.; Bradbury, E.; Swick, R. Response of Laying Hens to L-Arginine, L-Citrulline and Guanidinoacetic Acid Supplementation in Reduced Protein Diet. Anim. Nutr. 2021, 7, 460–471. [Google Scholar] [CrossRef]

- Kim, W.K.; Singh, A.K.; Wang, J.; Applegate, T. Functional Role of Branched Chain Amino Acids in Poultry: A Review. Poult. Sci. 2022, 101, 101715. [Google Scholar] [CrossRef] [PubMed]

- Roffeis, M.; Wakefield, M.E.; Almeida, J.; Alves Valada, T.R.; Devic, E.; Koné, N.; Kenis, M.; Nacambo, S.; Fitches, E.C.; Koko, G.K.D.; et al. Life Cycle Cost Assessment of Insect Based Feed Production in West Africa. J. Clean. Prod. 2018, 199, 792–806. [Google Scholar] [CrossRef]

- Degieter, M.; Gellynck, X.; Goyal, S.; Ott, D.; De Steur, H. Life Cycle Cost Analysis of Agri-Food Products: A Systematic Review. Sci. Total Environ. 2022, 850, 158012. [Google Scholar] [CrossRef] [PubMed]

- Vlad, I.M.; Butcaru, A.C.; Fîntîneru, G.; Bădulescu, L.A.; Stănică, F.; Mihai, C.A. A Life Cycle Cost Analysis—Relevant Method Supporting the Decision to Establish an Apple Orchard in an Organic System. Horticulturae 2023, 9, 1263. [Google Scholar] [CrossRef]

- Ajzen, I. The Theory of Planned Behaviour: Reactions and Reflections. Psychol. Health 2011, 26, 1113–1127. [Google Scholar] [CrossRef] [PubMed]

- Hijbeek, R.; Pronk, A.A.; van Ittersum, M.K.; ten Berge, H.f.m.; Bijttebier, J.; Verhagen, A. What Drives Farmers to Increase Soil Organic Matter? Insights from the Netherlands. Soil Use Manag. 2018, 34, 85–100. [Google Scholar] [CrossRef]

- Caffaro, F.; Micheletti Cremasco, M.; Roccato, M.; Cavallo, E. Drivers of Farmers’ Intention to Adopt Technological Innovations in Italy: The Role of Information Sources, Perceived Usefulness, and Perceived Ease of Use. J. Rural Stud. 2020, 76, 264–271. [Google Scholar] [CrossRef]

- Tan, M.; Hou, Y.; Zhang, L.; Shi, S.; Long, W.; Ma, Y.; Zhang, T.; Li, F.; Oenema, O. Operational Costs and Neglect of End-Users Are the Main Barriers to Improving Manure Treatment in Intensive Livestock Farms. J. Clean. Prod. 2021, 289, 125149. [Google Scholar] [CrossRef]

- Zhang, T.; Hou, Y.; Meng, T.; Ma, Y.; Tan, M.; Zhang, F.; Oenema, O. Replacing Synthetic Fertilizer by Manure Requires Adjusted Technology and Incentives: A Farm Survey across China. Resour. Conserv. Recycl. 2021, 168, 105301. [Google Scholar] [CrossRef]

- Wang, H.; Long, W.; Chadwick, D.; Velthof, G.L.; Oenema, O.; Ma, W.; Wang, J.; Qin, W.; Hou, Y.; Zhang, F. Can Dietary Manipulations Improve the Productivity of Pigs with Lower Environmental and Economic Cost? A Global Meta-Analysis. Agric. Ecosyst. Environ. 2020, 289, 106748. [Google Scholar] [CrossRef]

- Hedges, L.V.; Gurevitch, J.; Curtis, P.S. The Meta-Analysis of Response Ratios in Experimental Ecology. Ecology 1999, 80, 1150–1156. [Google Scholar] [CrossRef]

- Hunkeler, D.; Lichtenvort, K.; Rebitzer, G. Environmental Life Cycle Costing; CRC Press: Boca Raton, FL, USA, 2008; ISBN 978-0-429-14044-0. [Google Scholar]

- Heo, Y.-J.; Park, J.; Kim, Y.-B.; Kwon, B.-Y.; Kim, D.-H.; Song, J.-Y.; Lee, K.-W. Effects of Dietary Protein Levels on Performance, Nitrogen Excretion, and Odor Emission of Growing Pullets and Laying Hens. Poult. Sci. 2023, 102, 102798. [Google Scholar] [CrossRef]

- Wang, Y.; Xue, W.; Zhu, Z.; Yang, J.; Li, X.; Tian, Z.; Dong, H.; Zou, G. Mitigating Ammonia Emissions from Typical Broiler and Layer Manure Management—A System Analysis. Waste Manag. 2019, 93, 23–33. [Google Scholar] [CrossRef]

- Sun, M.; Ma, N.; Liu, H.; Liu, Y.; Zhou, Y.; Zhao, J.; Wang, X.; Li, H.; Ma, B.; Jiao, H.; et al. The Optimal Dietary Arginine Level of Laying Hens Fed with Low-Protein Diets. J. Anim. Sci. Biotechnol. 2022, 13, 63. [Google Scholar] [CrossRef] [PubMed]

- Trujillo-Barrera, A.; Pennings, J.M.E.; Hofenk, D. Understanding Producers’ Motives for Adopting Sustainable Practices: The Role of Expected Rewards, Risk Perception and Risk Tolerance. Eur. Rev. Agric. Econ. 2016, 43, 359–382. [Google Scholar] [CrossRef]

- Bocquého, G.; Jacquet, F.; Reynaud, A. Expected Utility or Prospect Theory Maximisers? Assessing Farmers’ Risk Behaviour from Field-Experiment Data. Eur. Rev. Agric. Econ. 2014, 41, 135–172. [Google Scholar] [CrossRef]

- Faridi, A.A.; Kavoosi-Kalashami, M.; Bilali, H.E. Attitude Components Affecting Adoption of Soil and Water Conservation Measures by Paddy Farmers in Rasht County, Northern Iran. Land Use Policy 2020, 99, 104885. [Google Scholar] [CrossRef]

- Ji, C.; Jin, S.; Wang, H.; Ye, C. Estimating Effects of Cooperative Membership on Farmers’ Safe Production Behaviors: Evidence from Pig Sector in China. Food Policy 2019, 83, 231–245. [Google Scholar] [CrossRef]

- Zou, Q.; Zhang, Z.; Yi, X.; Yin, C. The Direction of Promoting Smallholders’ Adoption of Agricultural Green Production Technologies in China. J. Clean. Prod. 2023, 415, 137734. [Google Scholar] [CrossRef]

- Ren, C.; Zhou, X.; Wang, C.; Guo, Y.; Diao, Y.; Shen, S.; Reis, S.; Li, W.; Xu, J.; Gu, B. Ageing Threatens Sustainability of Smallholder Farming in China. Nature 2023, 616, 96–103. [Google Scholar] [CrossRef] [PubMed]

- Zhao, P.; Cao, G.; Zhao, Y.; Zhang, H.; Chen, X.; Li, X.; Cui, Z. Training and Organization Programs Increases Maize Yield and Nitrogen-Use Efficiency in Smallholder Agriculture in China. Agron. J. 2016, 108, 1944–1950. [Google Scholar] [CrossRef]

- Cranfield, J.; Henson, S.; Holliday, J. The Motives, Benefits, and Problems of Conversion to Organic Production. Agric. Hum. Values 2010, 27, 291–306. [Google Scholar] [CrossRef]

- Cai, T.; Steinfield, C.; Chiwasa, H.; Ganunga, T. Understanding Malawian Farmers’ Slow Adoption of Composting: Stories about Composting Using a Participatory Video Approach. Land Degrad. Dev. 2019, 30, 1336–1344. [Google Scholar] [CrossRef]

- Yang, J. Science and Technology Backyard Improves Farmers’ Productivity. Sci. China Life Sci. 2016, 59, 1348–1349. [Google Scholar] [CrossRef][Green Version]

- Liu, Z.; Sun, J.; Zhu, W.; Qu, Y. Exploring Impacts of Perceived Value and Government Regulation on Farmers’ Willingness to Adopt Wheat Straw Incorporation in China. Land 2021, 10, 1051. [Google Scholar] [CrossRef]

- Kim, S.W.; Less, J.F.; Wang, L.; Yan, T.; Kiron, V.; Kaushik, S.J.; Lei, X.G. Meeting Global Feed Protein Demand: Challenge, Opportunity, and Strategy. Annu. Rev. Anim. Biosci. 2019, 7, 221–243. [Google Scholar] [CrossRef]

- Law, F.L.; Zulkifli, I.; Soleimani, A.F.; Liang, J.B.; Awad, E.A. The Effects of Low-Protein Diets and Protease Supplementation on Broiler Chickens in a Hot and Humid Tropical Environment. Asian-Australas. J. Anim. Sci. 2017, 31, 1291–1300. [Google Scholar] [CrossRef] [PubMed]

- Oluwabiyi, C.T.; Zhao, J.; Jiao, H.; Wang, X.; Lin, H. Dietary Protein Levels during the Pullet Phase (8–18 Week) Influence the Mortality during Laying Stage. J. Appl. Poult. Res. 2022, 31, 100223. [Google Scholar] [CrossRef]

- Ma, M.; Geng, S.; Liu, M.; Zhao, L.; Zhang, J.; Huang, S.; Ma, Q. Effects of Different Methionine Levels in Low Protein Diets on Production Performance, Reproductive System, Metabolism, and Gut Microbiota in Laying Hens. Front. Nutr. 2021, 8, 739676. [Google Scholar] [CrossRef]

- Greenhalgh, S.; Chrystal, P.V.; Selle, P.H.; Liu, S.Y. Reduced-Crude Protein Diets in Chicken-Meat Production: Justification for an Imperative. World’s Poult. Sci. J. 2020, 76, 537–548. [Google Scholar] [CrossRef]

- Cui, S.; Li, Y.; Jiao, X.; Zhang, D. Hierarchical Linkage between the Basic Characteristics of Smallholders and Technology Awareness Determines Small-Holders’ Willingness to Adopt Green Production Technology. Agriculture 2022, 12, 1275. [Google Scholar] [CrossRef]

- Biggs, J.B. From Theory to Practice: A Cognitive Systems Approach. High. Educ. Res. Dev. 1993, 12, 73–85. [Google Scholar] [CrossRef]

- Gunjević, V.; Grbeša, D.; Zurak, D.; Kiš, G.; Janječić, Z.; Svečnjak, Z.; Bedeković, D.; Duvnjak, M.; Pirgozliev, V.; Kljak, K. Effect of Maize Hybrid in Complete Feed on the Production Performance and Economic Considerations in Laying Hens. Sustainability 2023, 15, 15748. [Google Scholar] [CrossRef]

- An, Z.; Yang, Y.; Yang, X.; Ma, W.; Jiang, W.; Li, Y.; Chen, G.; Zhang, W.; Zhuang, M.; Wang, C.; et al. Promoting Sustainable Smallholder Farming via Multistakeholder Collaboration. Proc. Natl. Acad. Sci. USA 2024, 121, e2319519121. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Cao, G.; Li, X.; Zhang, H.; Wang, C.; Liu, Q.; Chen, X.; Cui, Z.; Shen, J.; Jiang, R.; et al. Closing Yield Gaps in China by Empowering Smallholder Farmers. Nature 2016, 537, 671–674. [Google Scholar] [CrossRef] [PubMed]

| Items | Farmers Using HPD (n = 91) | Farmers Using LPD (n = 5) | |||

|---|---|---|---|---|---|

| Total Price | Percentage | Total Price | Percentage | ||

| Life- Cycle Cost | 60-day-old chicken cost | 15.00 | 8.51 | 15.00 | 8.53 |

| Water and electricity cost | 2.25 | 1.28 | 2.25 | 1.28 | |

| Disease prevention cost | 3.00 | 1.70 | 3.00 | 1.71 | |

| Construction cost | 6.00 | 3.40 | 6.00 | 3.41 | |

| Feed cost | 150.10 | 85.11 | 149.66 | 85.08 | |

| Total cost | 176.35 | 100 | 175.91 | 100 | |

| Revenue | Eggs | 160.34 | 169.12 | ||

| Spent hens | 24.00 | 24.00 | |||

| Profitability | Profit | 8.00 | 17.21 | ||

| Cost–benefit ratio | 4.53 | 9.79 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Zhang, X.; Zhao, Z.; Wang, S.; Wang, J.; Wang, H. Integrated Assessment of Productive, Environmental, and Social Performances of Adopting Low-Protein Diets Technology for Laying Hens. Animals 2025, 15, 146. https://doi.org/10.3390/ani15020146

Li D, Zhang X, Zhao Z, Wang S, Wang J, Wang H. Integrated Assessment of Productive, Environmental, and Social Performances of Adopting Low-Protein Diets Technology for Laying Hens. Animals. 2025; 15(2):146. https://doi.org/10.3390/ani15020146

Chicago/Turabian StyleLi, Dongsheng, Xiaoying Zhang, Zhiyang Zhao, Siqi Wang, Jing Wang, and Hongliang Wang. 2025. "Integrated Assessment of Productive, Environmental, and Social Performances of Adopting Low-Protein Diets Technology for Laying Hens" Animals 15, no. 2: 146. https://doi.org/10.3390/ani15020146

APA StyleLi, D., Zhang, X., Zhao, Z., Wang, S., Wang, J., & Wang, H. (2025). Integrated Assessment of Productive, Environmental, and Social Performances of Adopting Low-Protein Diets Technology for Laying Hens. Animals, 15(2), 146. https://doi.org/10.3390/ani15020146