1. Introduction

In many parts of the world, the numerous constructions of municipal tunnels are creating unforeseen problems, such as blocking of roads, existing pipelines failure, and buildings subsidence. This has motivated attempts at the development of trenchless construction technology, such as pipe jacking, especially in metropolitan cities [

1,

2]. Pipe jacking is defined as a trenchless excavation technique, which employs hydraulic jacks to thrust specially made pipes through the ground behind a jacking machine, from a drive shaft to a reception shaft, as illustrated in

Figure 1. It has many technical merits, such as a short time limit, high security, low environmental effect, and little traffic disturbance [

3,

4,

5,

6]. Because of that, pipe jacking has been widely used in the construction of infrastructure for traffic and transportation systems in cities [

7,

8].

In pipe jacking, the jacking force is a critical factor that determines the thickness of pipe and reaction wall, selection or design of jacking machine and lubricant requirements [

9]. The accuracy of prediction of jacking force is directly related to the structural safety and construction cost.

The main component of the jacking force is due to frictional resistance. Application of a lubricant such as bentonite slurry in pipe jacking (so-called ‘slurry pipe jacking’) is essential to reduce the friction resistance and, therefore, the jacking force [

3,

10,

11,

12,

13]. However, the use of slurry makes it more complex to calculate or predict the friction resistance because of the change in contact conditions between the pipe and soil and lubricant slurry. The new contact state, which is due to the pipe-soil-slurry interaction, is affected by factors such as pipe diameter, soil properties, overcut [

3,

9], lubrication efficiency [

9], pipeline misalignments [

10,

14,

15,

16], and stoppages [

9,

14,

17,

18,

19]. The existing prediction models have not fully taken these factors into consideration, leading to an overestimation or underestimation of the friction resistance [

9,

20,

21,

22,

23]. It is therefore obvious that a new prediction approach or model is imperatively needed to be established to solve the problem in slurry pipe jacking [

24].

2. Overview of the Existing Prediction Models of Friction Resistance

Numerous models that calculate the friction resistance of pipe jacking have been proposed by authors from all over the world. The superposition principle is usually used, which holds that the comprehensive outcome of two or more linear factors of a system is equal to the accumulation of the effect of each factor. In pipe jacking, the linear factors to generate friction resistance are due to the weight of pipe (

fW), soil pressure (

fs), slurry pressure (

fm), pipe-soil cohesion (

fsc), and pipe-slurry cohesion (

fmc). Their equations can be expressed as [

5,

6,

9,

10,

14,

19,

21,

22,

25,

26].

where

μs and

μm are the kinematic friction coefficient of pipe-soil and pipe-slurry, respectively;

W is the weight of pipe per unit length, kN/m;

N is the total normal force acting on the pipe, kN/m;

cs and

cm are the pipe-soil cohesion resistance and pipe-slurry cohesion resistance, respectively, kPa;

Bs and

Bm are the pipe-soil contact width and pipe-slurry contact width, respectively, m.

Some hypotheses have been made to establish the prediction models, by which one or some of the items listed above should be considered. Typical hypotheses are:

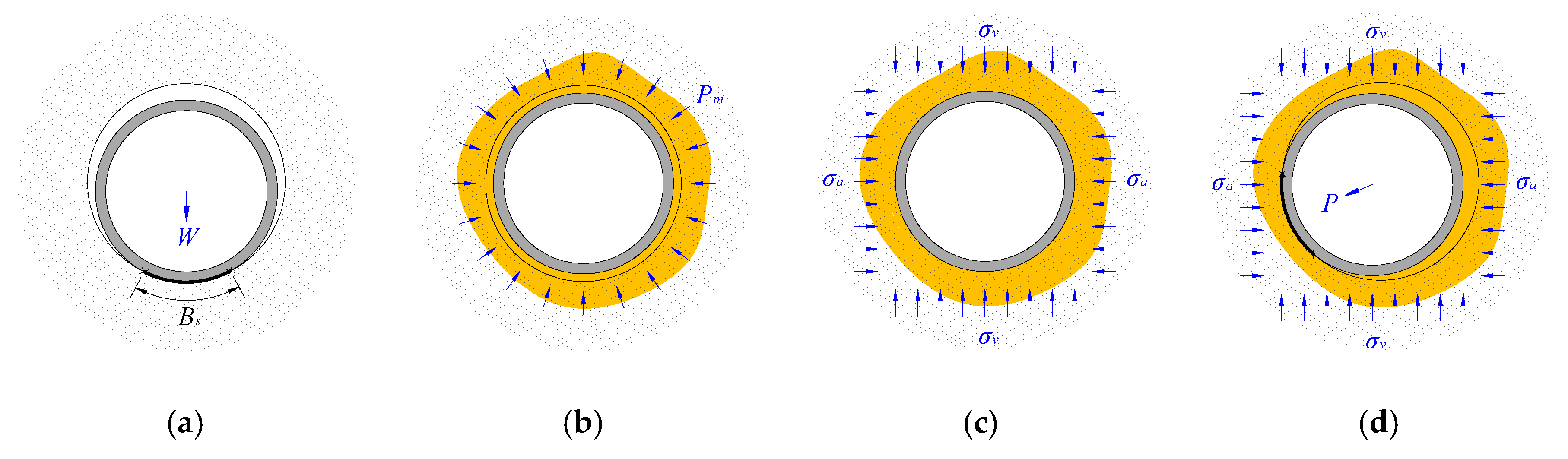

Hypothesis 1. The excavated tunnel is self-stable, the pipeline simply slides along the bottom of the tunnel due to its own weight (see Figure 2a) [9,10,14]. Hypothesis 2. The angular space due to overcut is completely filled with lubricant slurry, and the excavated tunnel is stable under the slurry pressure (see Figure 2b) [22,25]. Hypothesis 3. The excavated tunnel is unstable, the surrounding soil collapses and is in full contact with the whole area of the jacking pipes (see Figure 2c) [5,6,9,21,26]. Hypothesis 4. The excavated tunnel is stable under the pressure of slurry, and part of the pipe comes in contact with the surrounding soil (see in Figure 2d) [3]. According to Hypothesis 1, there are two kinds of prediction models, in which the item of

fw has to be taken into consideration. The first one assumes that the friction resistance is only due to the weight of pipe [

9,

21]. It is given as

The second one also takes the pipe-soil cohesion resistance (item of

fsc) into account [

10,

14,

21], which is given by

where the pipe-soil contact width

Bs is calculated by Hertzian contact model, as [

10,

14,

21]

where

Dc and

Dp are the internal diameter of cavity and external diameter of pipe, respectively, m;

νp and

νs are the Poisson’s ratio for pipe and soil material, respectively;

Ep and

Es are the elasticity modulus of the pipe and soil, respectively, kPa; and

P is the effective external force acting on the center of the pipe, kN/m, usually it is considered as equal to the weight of pipe per unit length

W.

According to Hypothesis 2, the friction resistance is related only to the properties of lubricant slurry, and the only model found was one that takes both the items of

fm and

fmc into account [

22,

25].

where

Pm is the mud slurry pressure.

It is noted that most of the studies completed to date have focused exclusively on the prediction models established by Hypothesis 3. This may be attributed to the assumption of full contact of the pipe and soil that leads to a large prediction value of friction resistance, or in other words, Hypothesis 3 is conservative. Because of that, this kind of model is widely accepted by authorities and standards from all over the world, such as Japan Sewage Association (JSA) [

22], UK Pipe Jacking Association (PJA) [

27], Chinese Trenchless Technology Association (CTTA) [

28], and Germany Standard (AVT A-161) [

29]. This kind of model can be summarized and divided into the following four categories.

The fourth kind of model (Equation (17)) introduces an empirical constant β (smaller than 1) on the basis of the third model (Equation (16)) to reflect the effect of lubrication.

For the models summarized above, the item of

fs (=

μsN) has to be taken into consideration. Thus, the key problem for this kind of model is exactly focused on the calculation of soil pressure

N. CTTA suggests

N to be calculated by Rankine’s formula, which gives that [

28]

where

σv is the vertical soil stress;

K is the coefficient of soil pressure above the pipe;

γ is the unit weight of soil;

h is the overburden depth of the pipeline; and

φ is the internal friction angle of soil.

However, JSA suggests using Terzaghi’s silo model, the expression of

N is then expressed as [

22]

where

cs is the cohesion of soil;

δ is the friction angle between the pipe and soil;

b is the influencing silo width of soil above the pipe, and the other symbols have the same meanings as before.

Although a lot of prediction equations of friction resistance have been proposed and even some of them have been applied to engineering practice, it is obvious that their hypotheses are quite different, and even for the same hypothesis, models and parameters can be different too. Thus, it is bound to make the prediction friction resistances vary greatly. Furthermore, apart from Equations (11) and (17), the other models completely ignore the effect of lubrication, which is very important to slurry pipe jacking.

In the design philosophy of slurry pipe jacking, the angular space due to overcut is expected to be completely filled with lubricant slurry, to reduce the friction resistance with maximum efficiency, creating a ‘filter cake’ layer around the cavity and is then pressurized to the support pressure required for the soil (see

Figure 2b) [

3,

10]. In this case, the friction resistance should be only related to the slurry pressure and the friction coefficient between slurry and the pipe. From this point of view, the expression Equation (11) seems a convincing explanation here.

However, the more general case is that the excavated tunnel is stable under pressure of slurry and part of the pipe inevitably comes in contact with the soil (see

Figure 2d) [

3]. The reasons for the occurrence of pipe-soil contact can be complex, such as insufficient design and control of grouting amount of slurry, the pipeline deviates from the intended line and level, irregular deformation of the surrounding soil, and interpenetration between the soil and slurry. Thereby, the state of contact can change from ‘pipe-slurry’ into ‘pipe-soil-slurry’ (

Figure 2b,d). In such a case, a simple form of Equation (17) seems more suitable to reflect the effect of lubricant slurry. However, it is logical that the greater the contact width between the pipe and the soil, the smaller the effect of lubrication will be, and, therefore, the greater the friction resistance will be. Thus, the value of

β should be highly affected by the pipe-soil contact width. For different soils, grouting amount of slurry and design parameters (such as buried depth and overcut) is bound to lead to completely different contact widths of pipe-soil. Thus,

β should be in a large range, and it would be rather difficult to pick out a value to use in application.

In fact, a successful prediction model of friction resistance should not only consider the effect of lubrication but also needs to be able to reflect the effect of pipe-soil-slurry interaction. It is based on this understanding that the following model comes into being.

3. Calculation of Friction Resistance for Slurry Pipe Jacking

The general contact state of pipe-soil-slurry due to the interaction of the pipe, surrounding soil, and lubricant slurry is shown in

Figure 3. In the picture, the position of pipe-soil contact is arbitrary, with a contact width of

Bs and the corresponding contact angle of 2

ε.

From

Figure 3, it is obvious that to calculate friction resistance

f, both of the items of

fs and

fm have to be taken into account, which can be expressed as

where

μ is an effective friction coefficient introduced to reflect the effect of lubrication and the influence of pipe-soil contact width. It is generally accepted that

μs = tan(

φ/2) for the coefficient of kinematic friction between soil and the pipe [

21,

22];

μm for the coefficient of kinematic friction between mud slurry and the pipe can be taken as 0.01, according to the test result reported by Guo [

30].

Ns and

Nm are the total normal force of pipe-soil and pipe-slurry in contact, respectively.

To calculate

Ns and

Nm precisely, the location of pipe-soil contact and the magnitude of contact angle (or contact width) and the contact force have to be determined. For various reasons leading to the occurrence of pipe-soil contact, it seems impossible to calculate these quantities in a target section of the pipeline. However, if taking the whole pipeline into consideration, and assuming that the pipe-soil contact can occur at any position of a section of the pipeline with a same probability and the contact force is approximately equal to the soil pressure in the contact area, this problem can be greatly simplified. In this case, we have the following equations:

where

C (=

πDp) is the external circumference of pipe and

ε is the semi-angle of contact (

Figure 3).

By substituting Equations (24) and (25) in Equation (23), after some algebra, giving that

where

e is the void ratio of soil.

By substituting Equation (27) in Equation (26), the expression of

μ can be further rewritten as

According to Equation (28), the calculation of

ε is essential to calculate

μ. Hertzian model provides a simple way for the calculation of the width of contact (or contact angle) as we have mentioned before (see Equations (8) and (10)); however, the Hertzian contact problem is approached only when the applied force is small, or the large radial clearance is large, and the limited angle of contact is smaller than about 30° [

31]. Due to the technical limitations, most of the pipe jacking projects encounter clay or sandy soils and with a small overcut, it is therefore important that the applicability of the Hertzian contact model should be extremely limited here. Actually, the Hertzian contact model is just a special case of the Persson’s contact model with a small contact width (or angle) [

31]. If a large contact angle (larger than 30°) occurs, the more general contact model proposed by Persson should be taken as the first choice. The following singular integro-differential governing equation of contact angle is derived by Persson, as [

31,

32]

or

The involved auxiliary variables are defined as [

31]

After some approximate treatments, the key terms of Equation (30) have been solved by Michele [

32], as follows:

By substituting these equations into Equation (29), Michele obtained an approximate form of general contact angle relation.

As compared with Equation (9), Equation (35) is a far more complex nonlinear equation. It can be further simplified with respect to that the elastic modulus of soil

Es is generally much smaller than that of pipe

Ep (the difference between the two can be three orders of magnitude). Thus, from Equation (30), the magnitude of auxiliary variable

η should be very large, and, therefore, the following approximate relations can be obtained:

Using Equation (36), Equation (35) can be then simplified as

From Equation (37), it is essential to calculate

P, which requires one to calculate the total normal force

N. It can be gained by integrating the normal stress

σn on an element of the pipe surface and is determined on the basis of vertical and horizontal soil stresses.

where

θ is defined as the angle between the corresponding radius line and the horizontal line at each point of the pipe (

Figure 4).

By substituting Equation (38) in Equation (39), it is easy to obtain the equation of N, which has the same form as Equation (18).

To calculate Equation (18), the vertical soil stress

σv has to be first determined. It is noted that at the present time, by far the most commonly used model for soil pressure calculation is Terzaghi’s silo model (Equation (22)) [

5,

6,

9,

19,

21,

26]. According to Equation (22), the calculation of the vertical soil stress requires some physical parameters that may be determined with some accuracy, such as the height of cover

h, the cohesion

cs, and the unit weight of soil

γ, but also some empirical parameters, such as

b,

δ, and

K. The definition of these empirical parameters varies from one author to another. Here, typical approaches of Terzaghi, Germany Standard ATV-A 161 E-90 [

29], Chinese Standard GB 50332-2002 [

33], UK Standard BS EN 1594-09 [

34], US Standard ASTM F 1962-11 [

35], UK PJA [

27], Japan JMTA [

36], and Japan JSA [

22] would be discussed and compared.

For the calculation of silo width

b, three kinds of boundary planes of wedge failure assumed by different authors and the corresponding equations are clearly illustrated in

Figure 5. The width of the boundary plane is related to the ‘vault’ effect of soil. Generally, a smaller

b means a lower ‘vault’ effect of soil, leading to a larger vertical soil stress.

For the determination of δ, most of the guidelines, such as PJA, JSA, JMTA, BS EN 1594-90, and GB 50332-2002 assume shear planes as perfectly rough and take an angle of friction in the shear planes δ equal to the soil internal friction angle φ. However, ATV-A 161 E-90 and ASTM F 1962-11 make a more cautious assumption and only takes into account half the internal friction angle φ/2.

For the lateral pressure coefficient K above the tunnel, Terzaghi assumes K coefficient is equal to 1, which corresponds to the range of values encountered in clayey soils. PJA, ASTM F 1962-11, and GB 50332-2002 suggest K = Ka (calculated by Rankine’s formula of active soil pressure coefficient), while BS EN 1594 and ATV-A 161 assume K = K0 (calculated by Rankine’s formula of soil pressure coefficient at rest). Moreover, according to ATV-A 161, this K coefficient is equal to 0.5, which corresponds to an internal soil friction angle of 30°, a typical value for sandy soils.

Parameters of

b,

δ, and

K chosen by the different authors have been summarized in

Table 1.

It is noted that none of the approaches use the same parameters. Consequently, the vertical soil stress calculated by these approaches would be quite different. Thus, it is not convincing to pick out an approach to use without checking the field data. This work will be carried out in the next section.

Thus far, all the equations needed to calculate friction resistance have been determined. If the parameters needed for the prediction equations are quantified, by using Equations (18) and (22) the total normal force

N can be determined, then together with Equations (23), (24), (27), (31), and (37), the contact angle 2

ε, the effective friction coefficient

μ, and the friction force

f now can be uniquely identified. The flow chart is shown in

Figure 6.

Apparently, the effective friction coefficient here is not just related to the interfriction angle of soil φ but also the state of pipe-soil contact and the effect of lubrication.

6. Conclusions

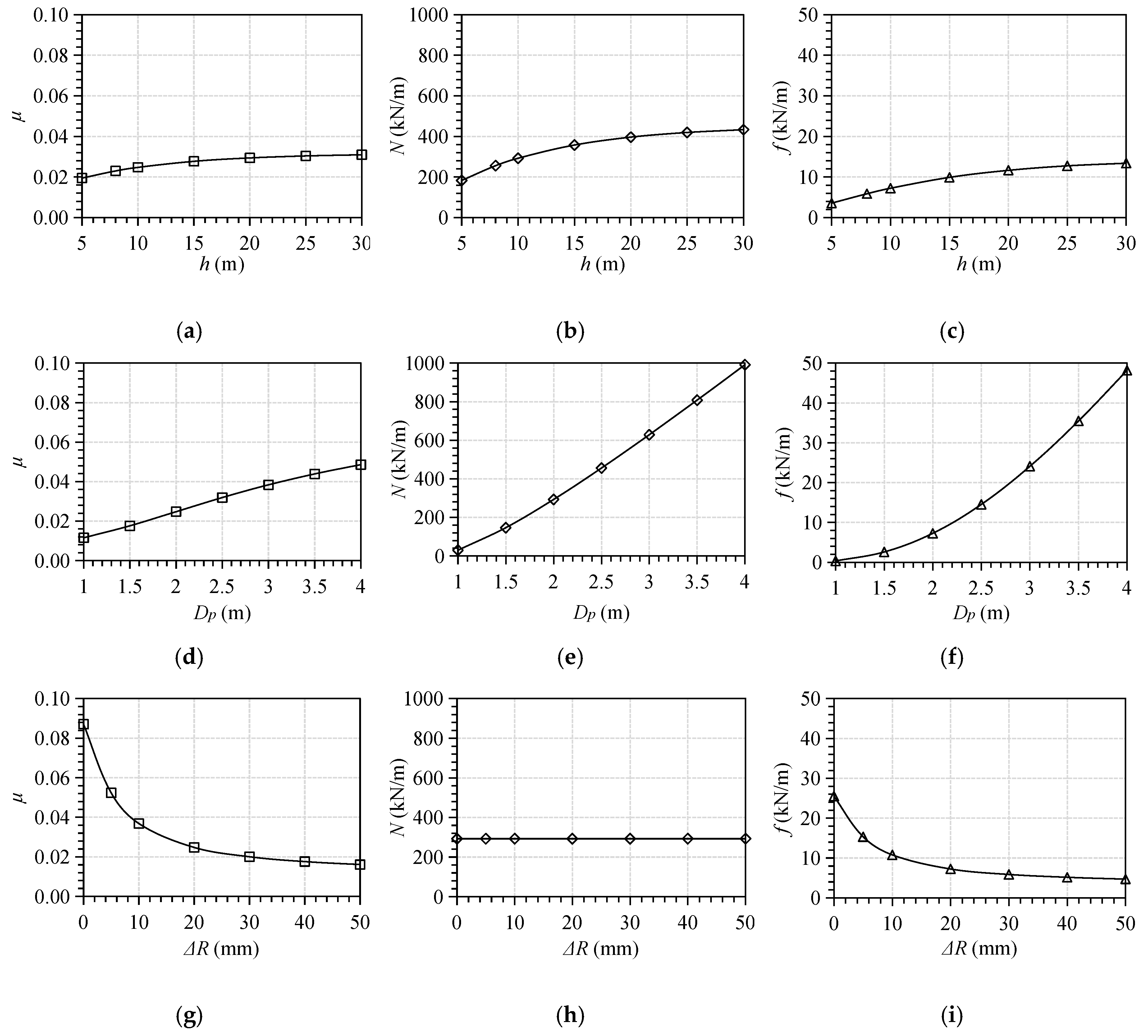

Some typical prediction models of friction resistance have been presented and detailed comparisons and analyses have also been made. Then, a new approach considering both the effect of lubrication and the interaction of pipe-soil-slurry, by introducing an effective friction coefficient, has been established. Values of friction resistance calculated using them have been compared with values measured in four field cases and a numerical simulation case with various soils and design parameters. Better agreements are obtained, which indicate a more flexible and wider applicability of the approach in this paper as compared to the existing prediction models and numerical simulation approach. Explanations have also been sought for limited use of the existing models that may be attributed to their hypotheses not that suitable for slurry pipe jacking. The numerical simulation approach can accurately predict the friction resistance, but it is hard to determine the contact angle of pipe-soil reasonably with respect to various soils, overcut, and other conditions to obtain good prediction results.

Using the approach of this paper, for higher prediction accuracy, the cohesion of soil has to be taken into account in the calculation for drives in clayey soils. The Terzaghi’s silo model together with parameters determined by the approach of UK PJA is verified as the most well-considered to calculate earth pressure.

For better design in the future, the influences of design factors (buried depth, pipe diameter, and overcut) on friction resistance and lubrication efficiency have been analyzed too. The increase of pipe diameter has a strong influence on the increase of friction resistance; however, the friction amplitude appears not to be greatly affected by the buried depth. As the selection of pipe diameter and buried depth are limited by various objective conditions, special attention should be paid on the design of overcut. The overcut has to be sufficiently wide. When the overcut is small (for example smaller than 15 mm), the decrease of overcut strongly affects the decrease of lubrication efficiency, and, therefore, leads to a notable increase in friction resistance. Moreover, pipe diameter has an obvious influence on the effect of overcut on lubrication efficiency, the larger the pipe diameter the larger the overcut needed.