Advanced Automatic Welding System for Offshore Pipeline System with Seam Tracking Function

Abstract

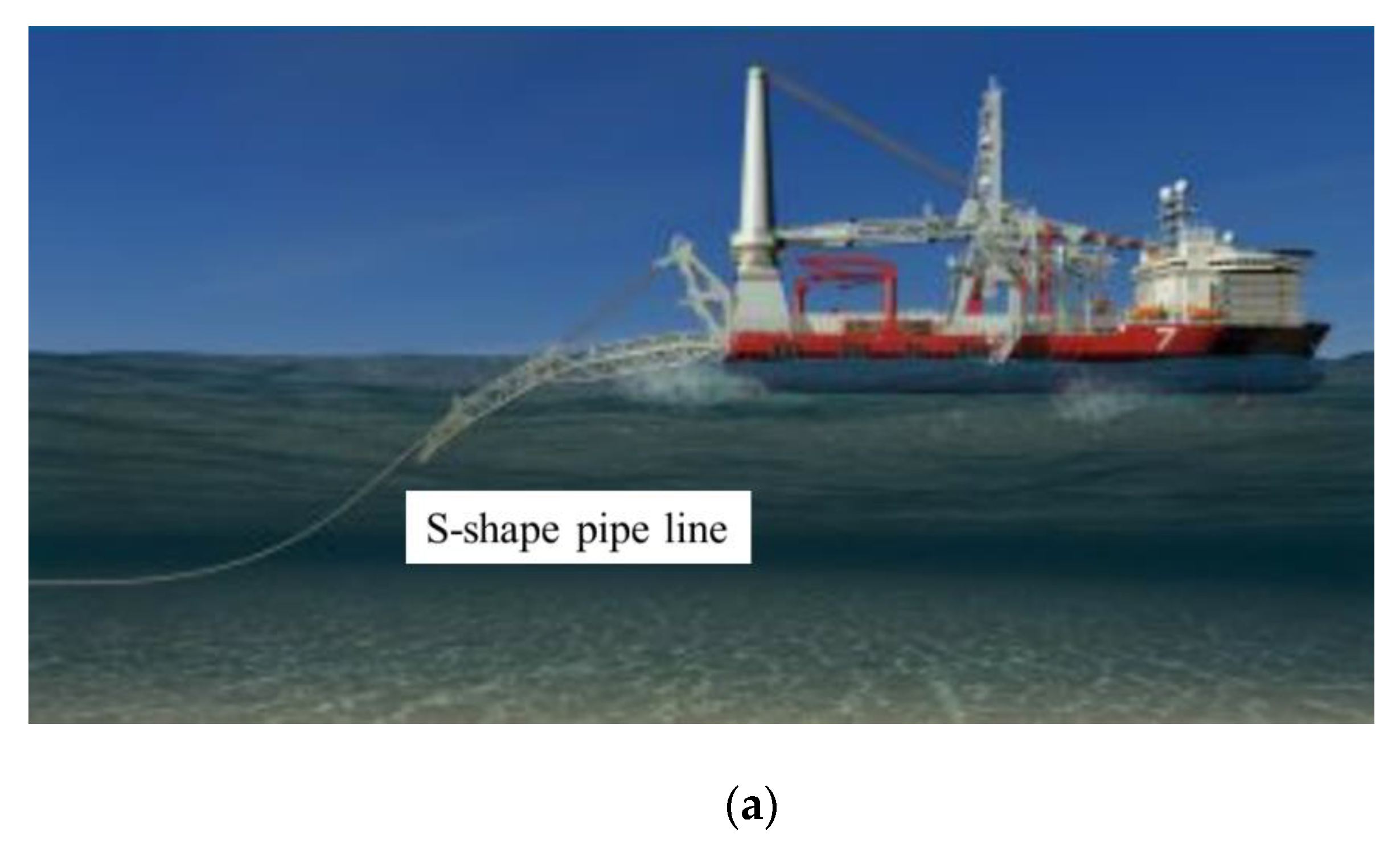

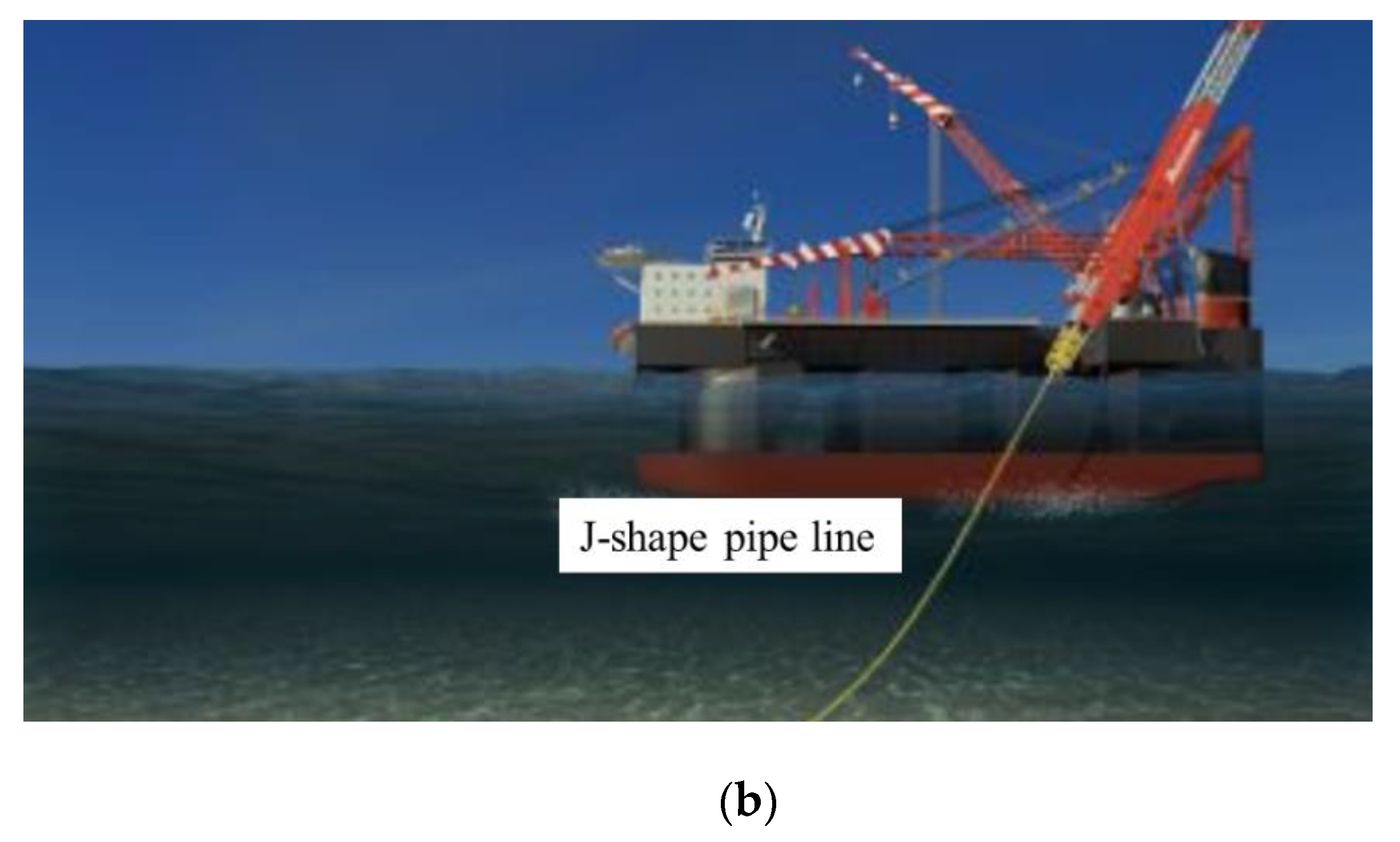

:1. Introduction

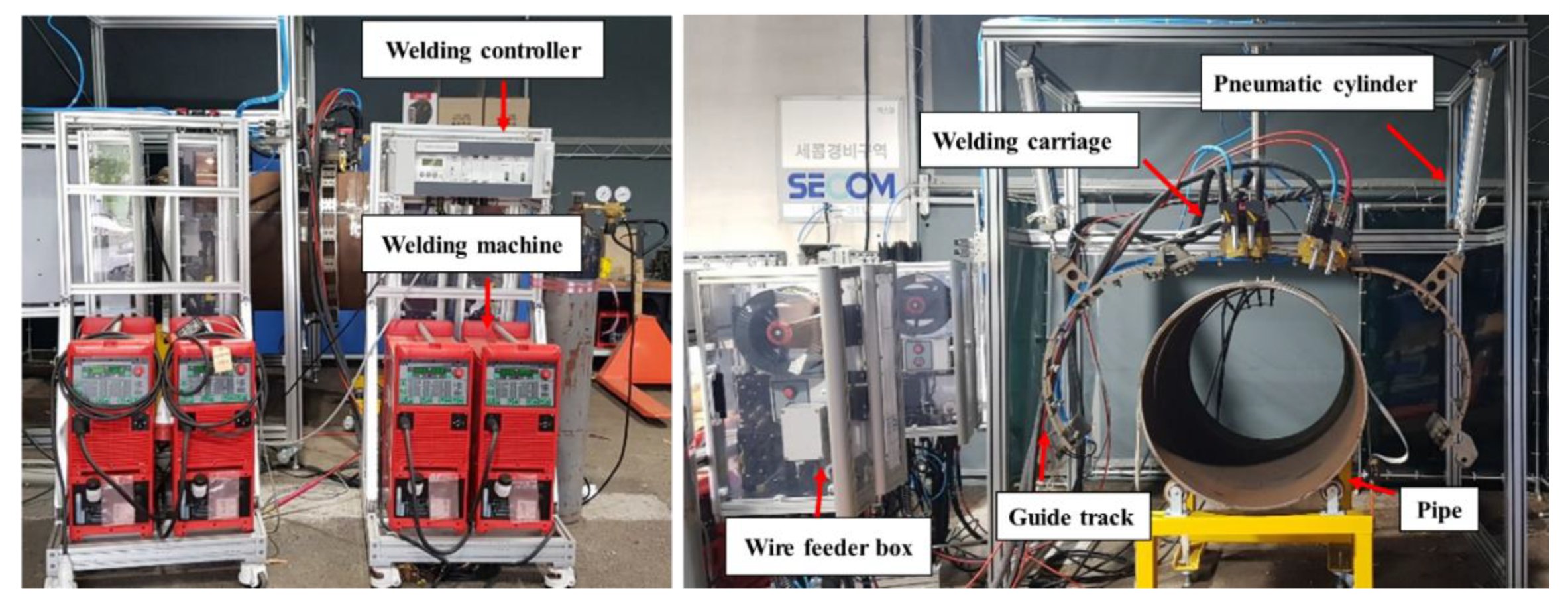

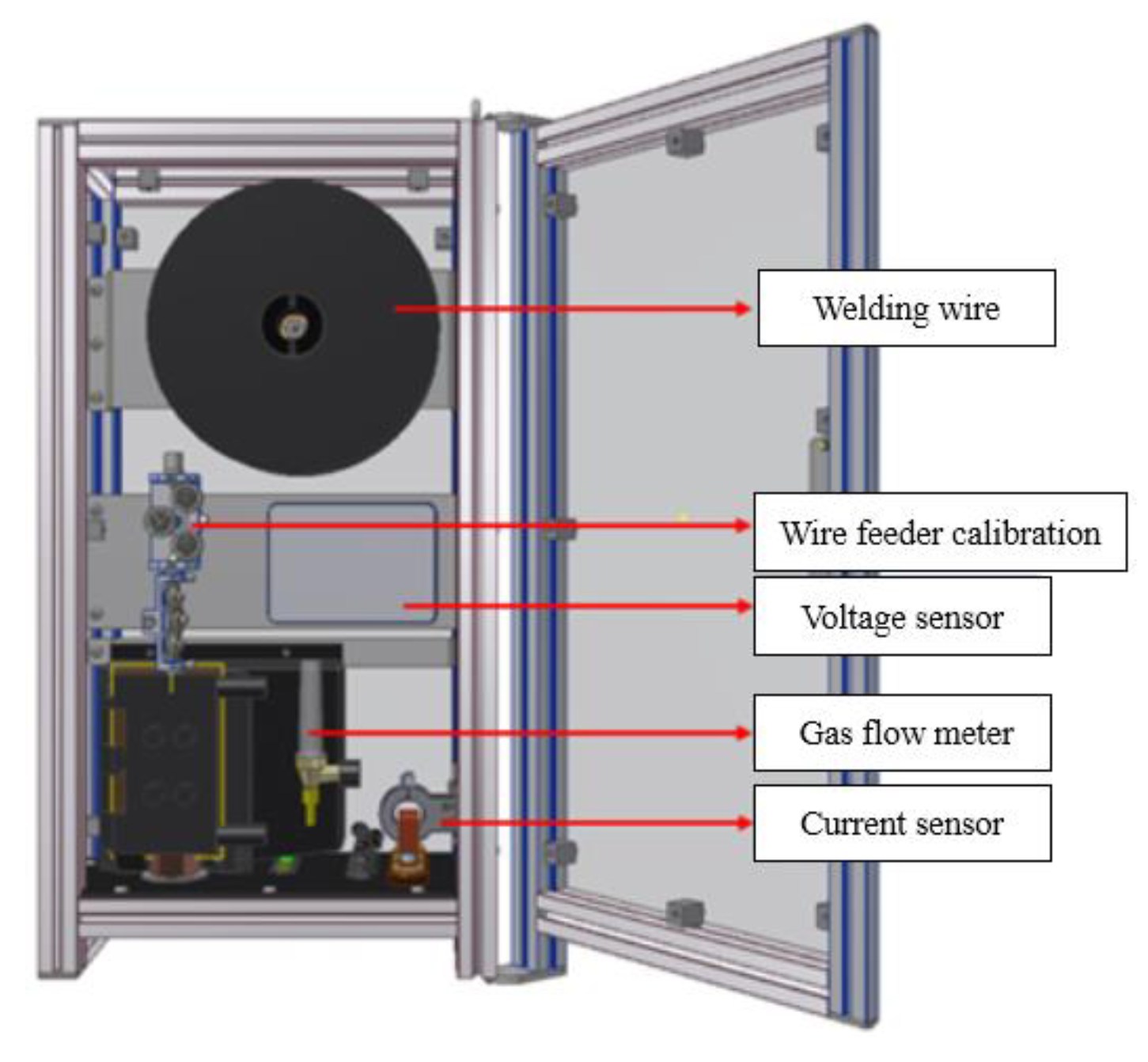

2. The Automatic Welding System

3. Characteristics of the Automatic Welding System

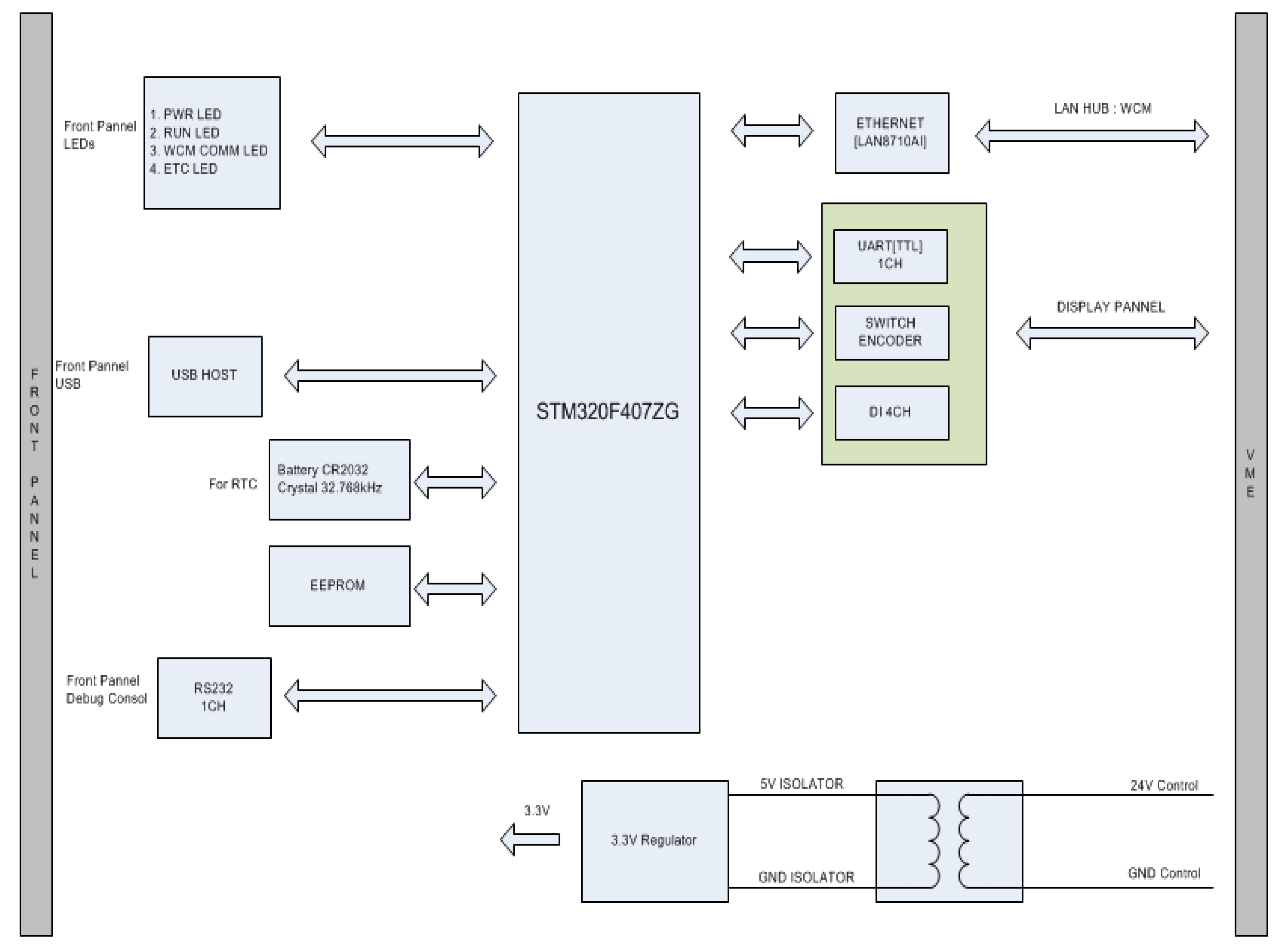

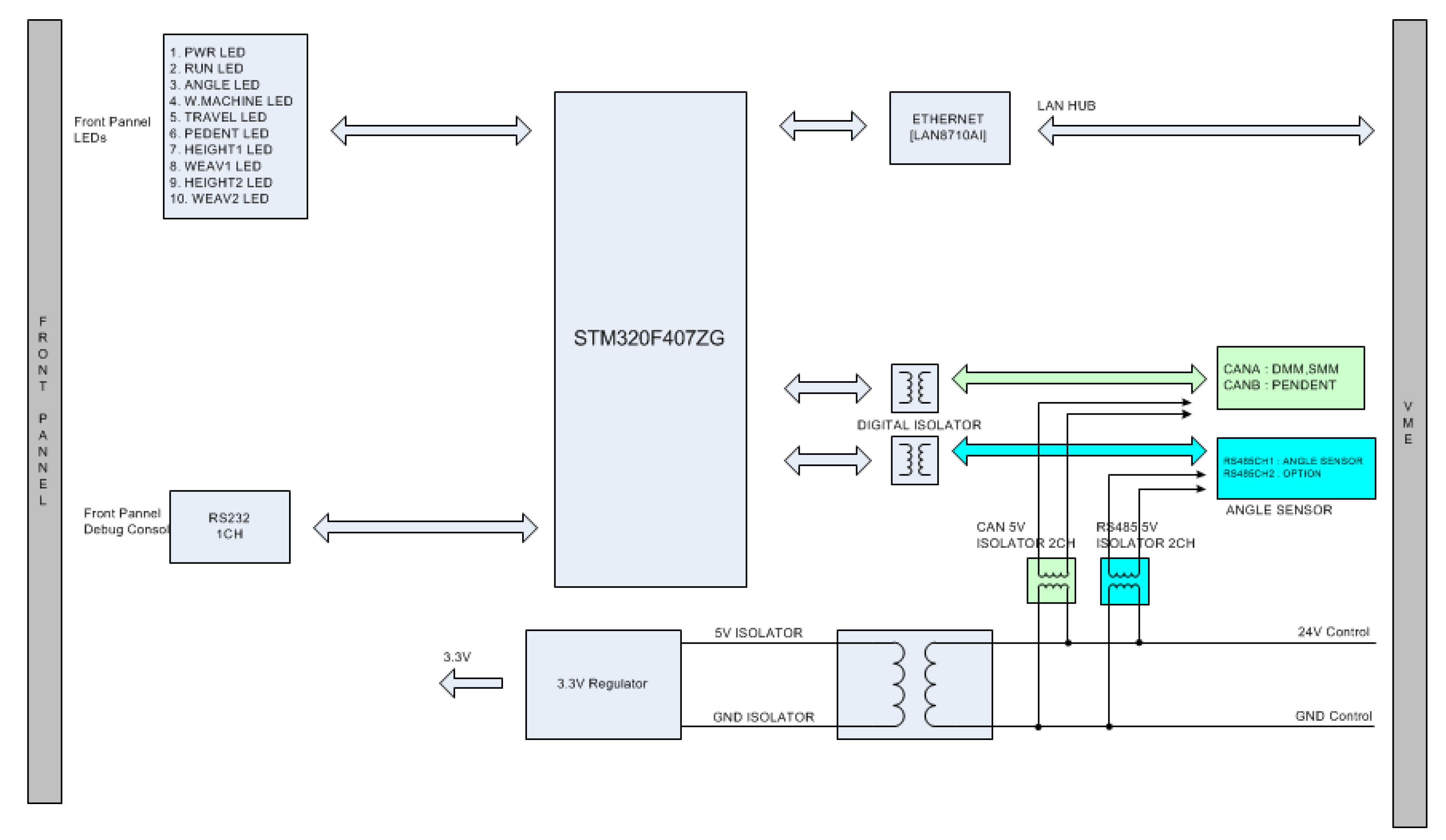

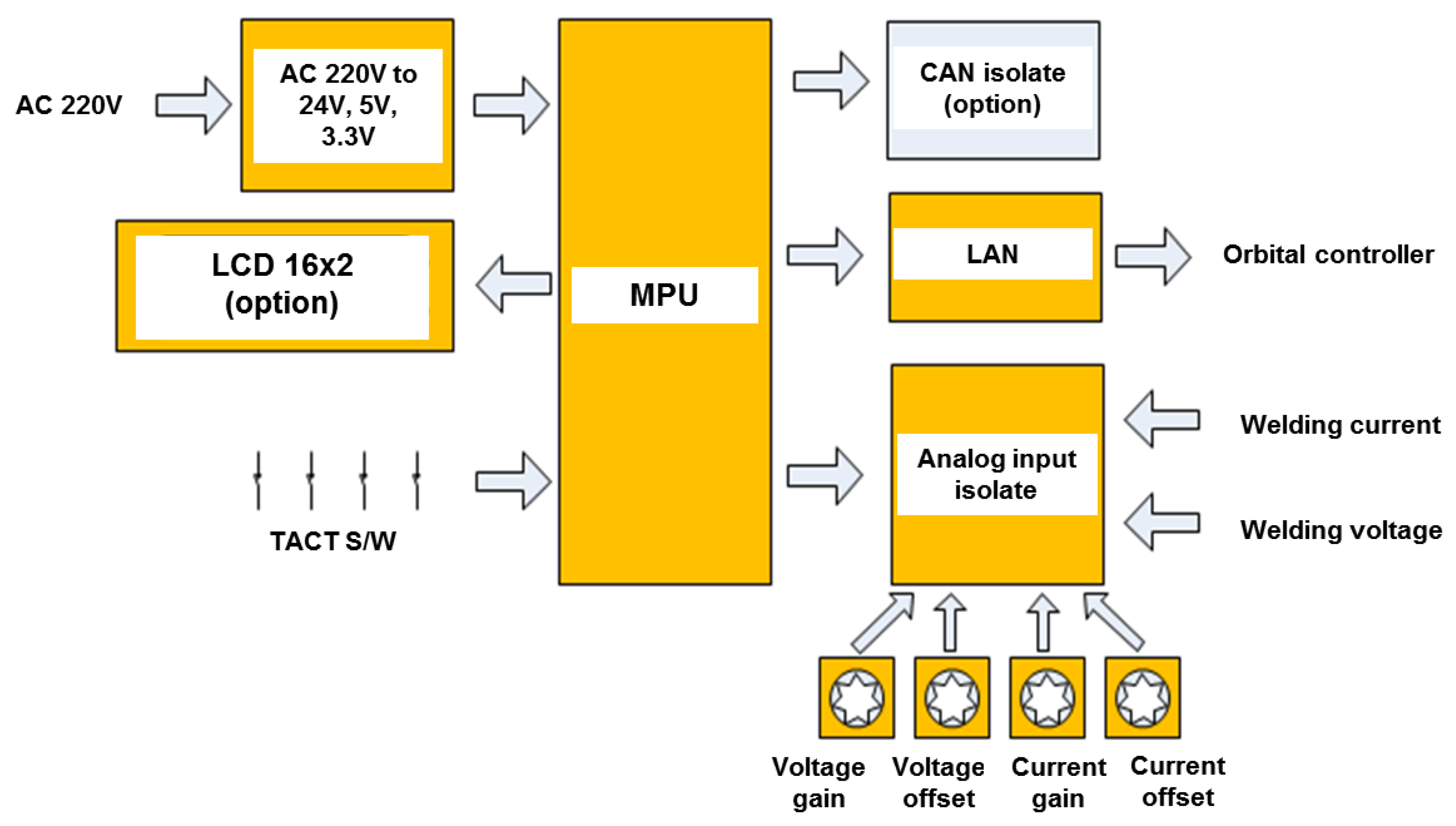

3.1. Control System

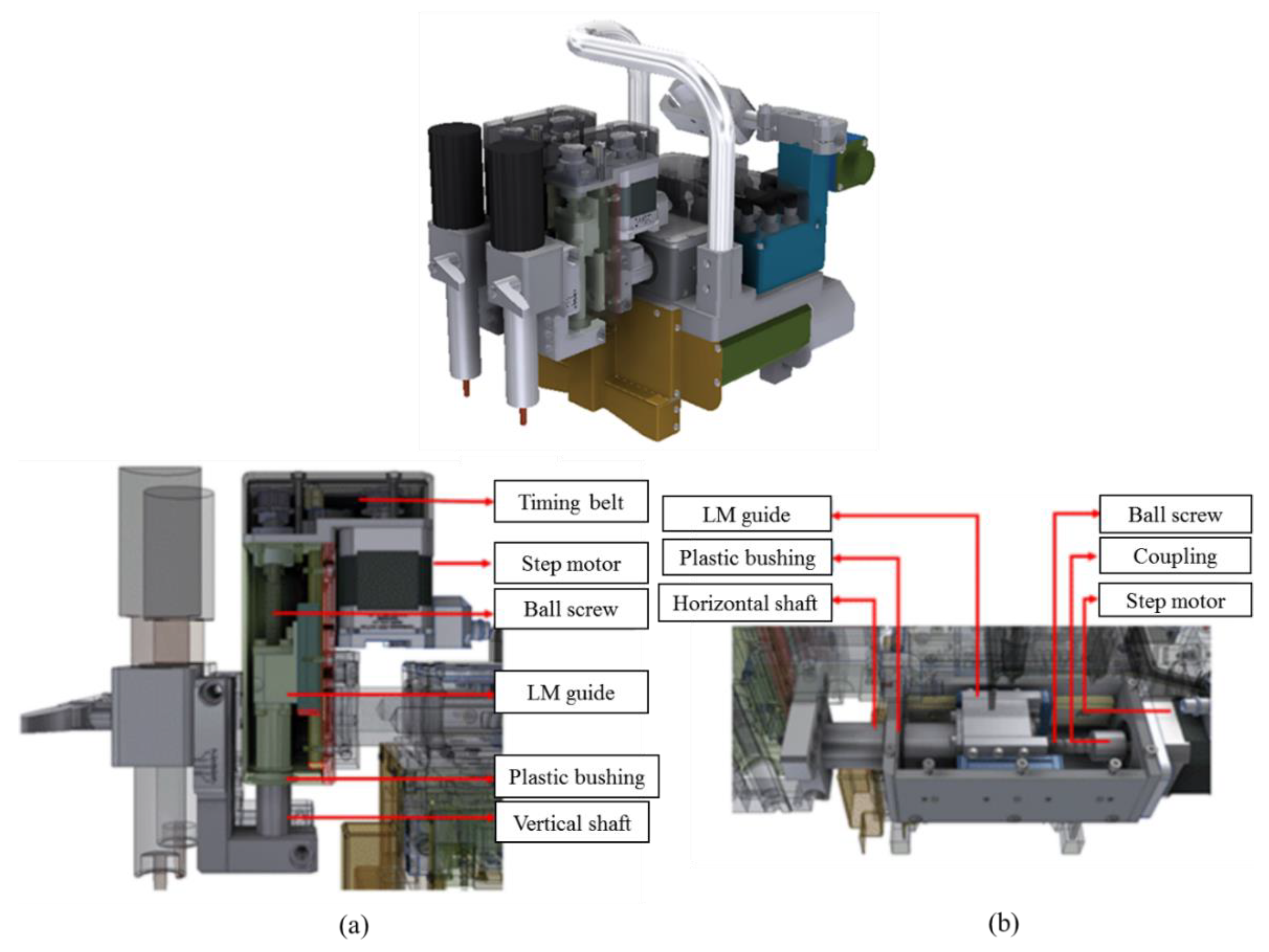

3.2. Welding Carriage

3.3. Control of the SMM

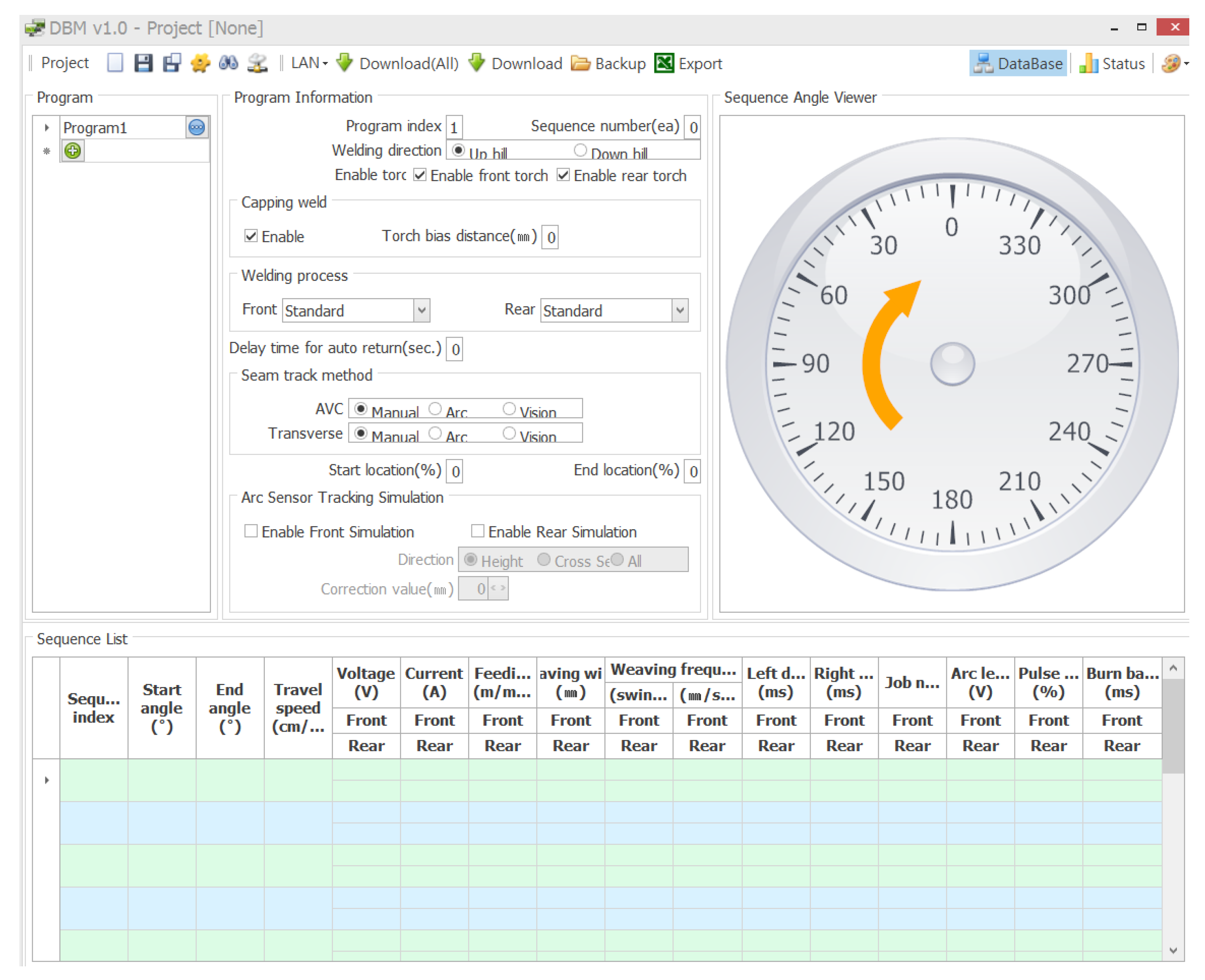

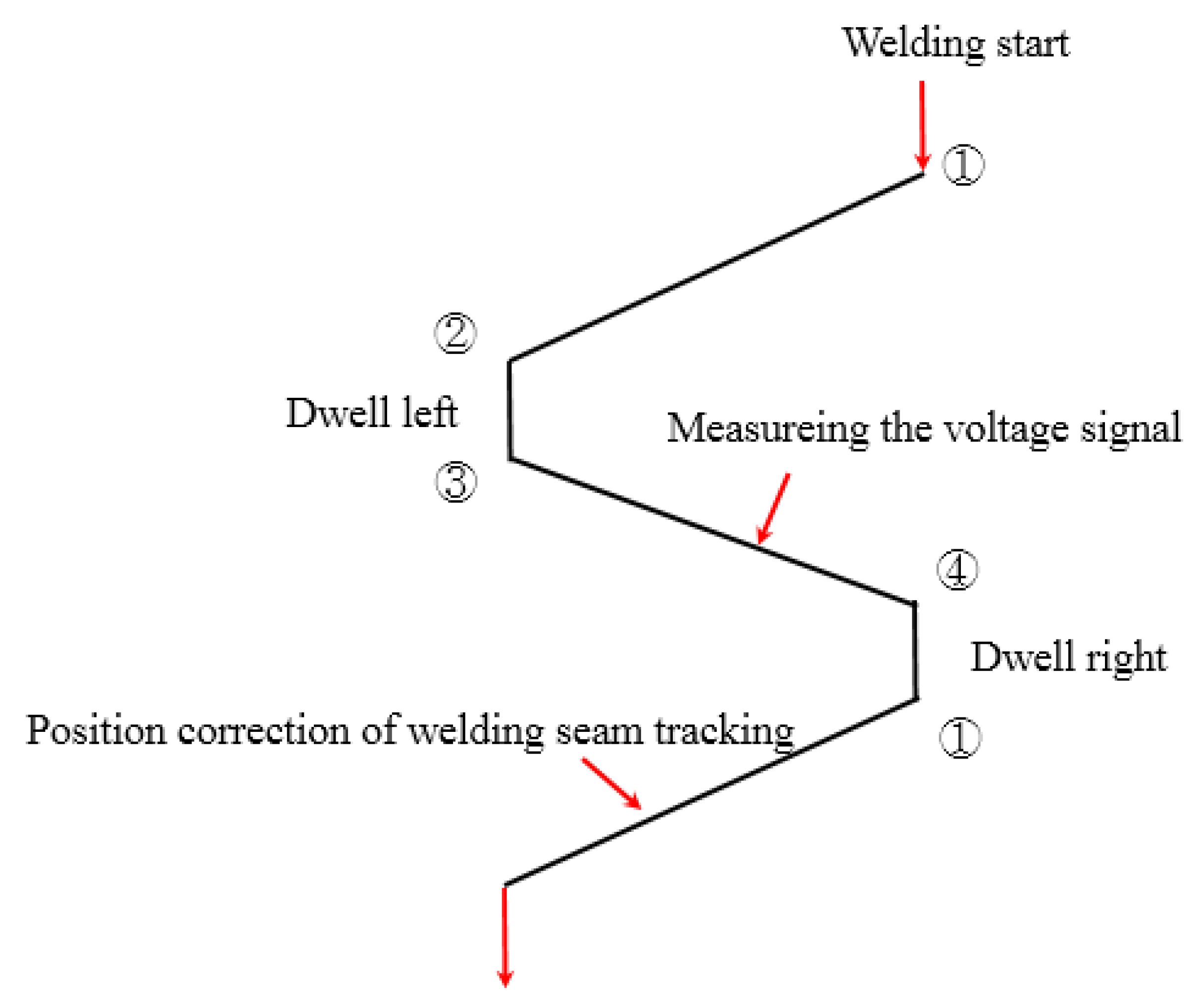

3.4. Control of the CCM

3.5. Control of the WCM

3.6. Control of WMM

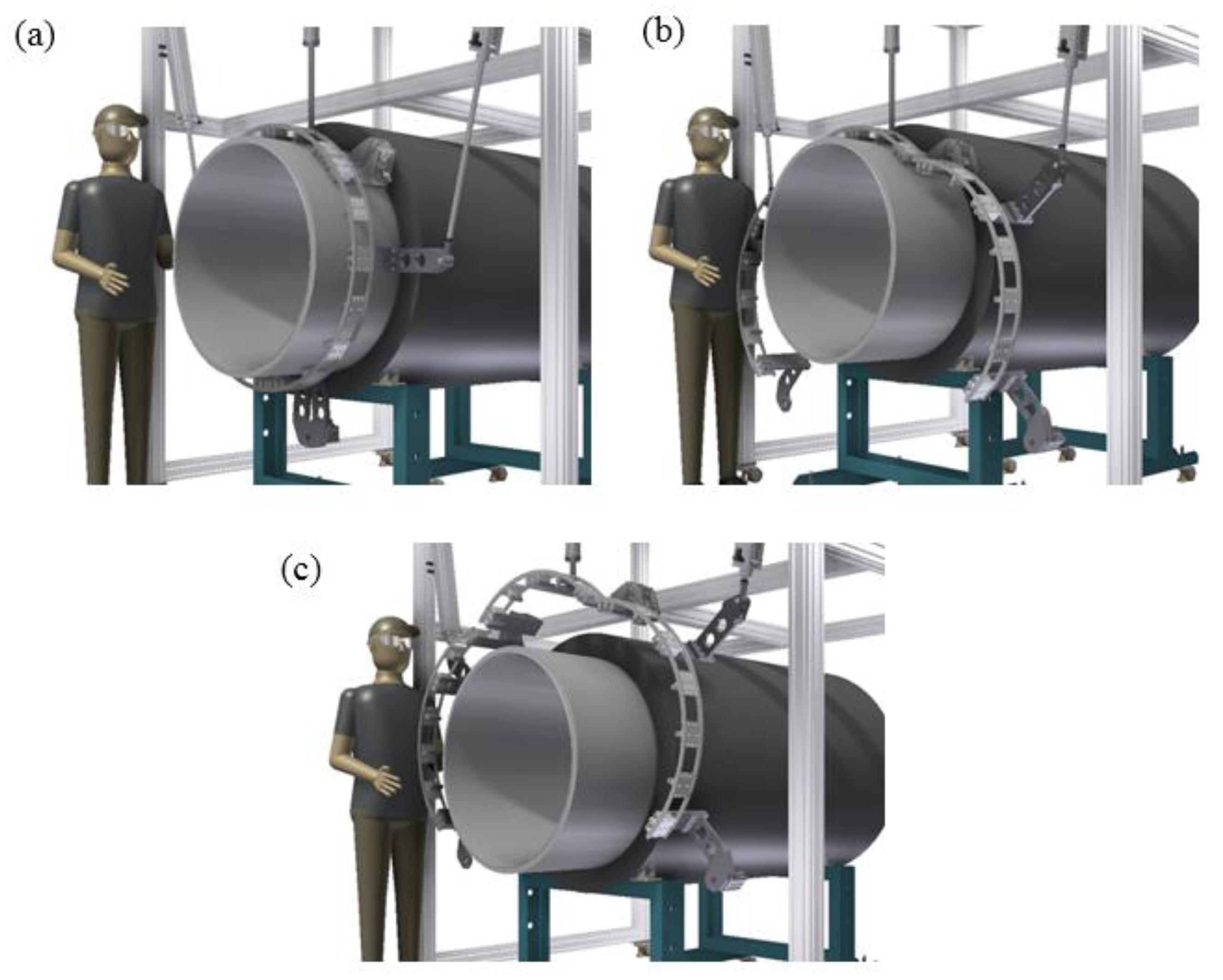

4. Integrated Welding Carriage with a Guide Track

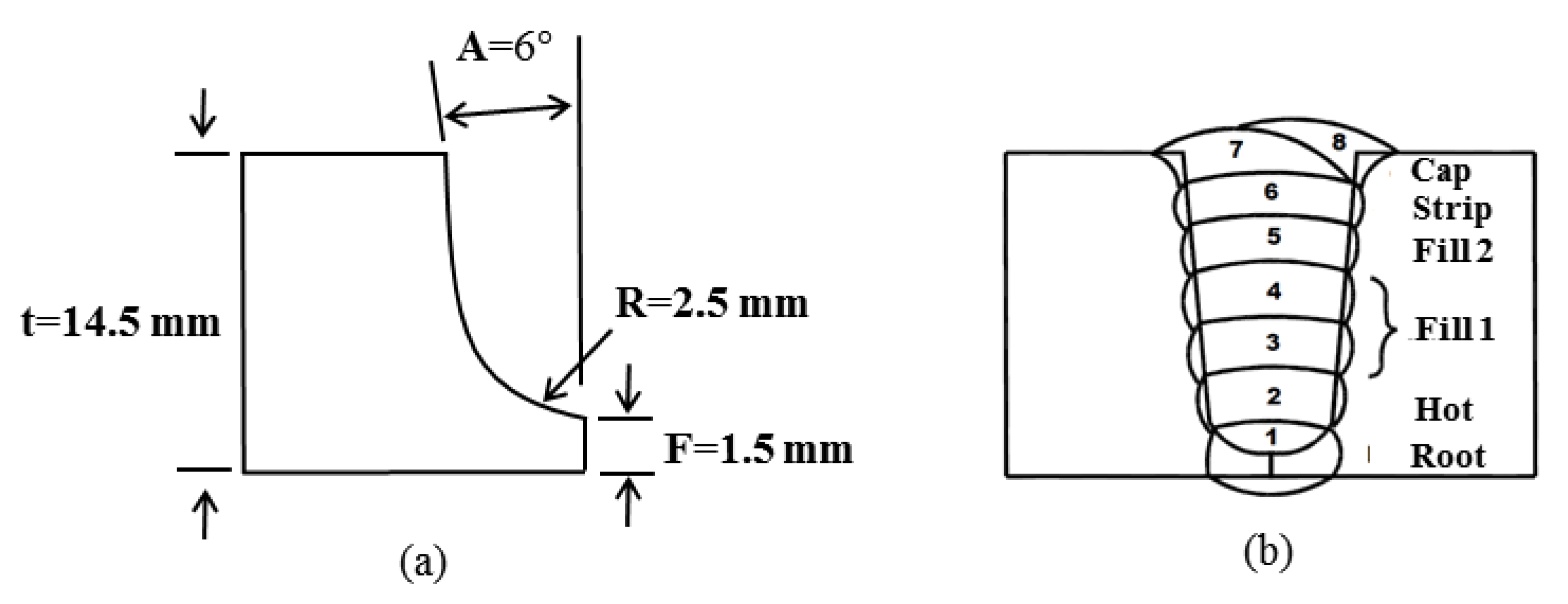

5. Application of the Automatic Welding System

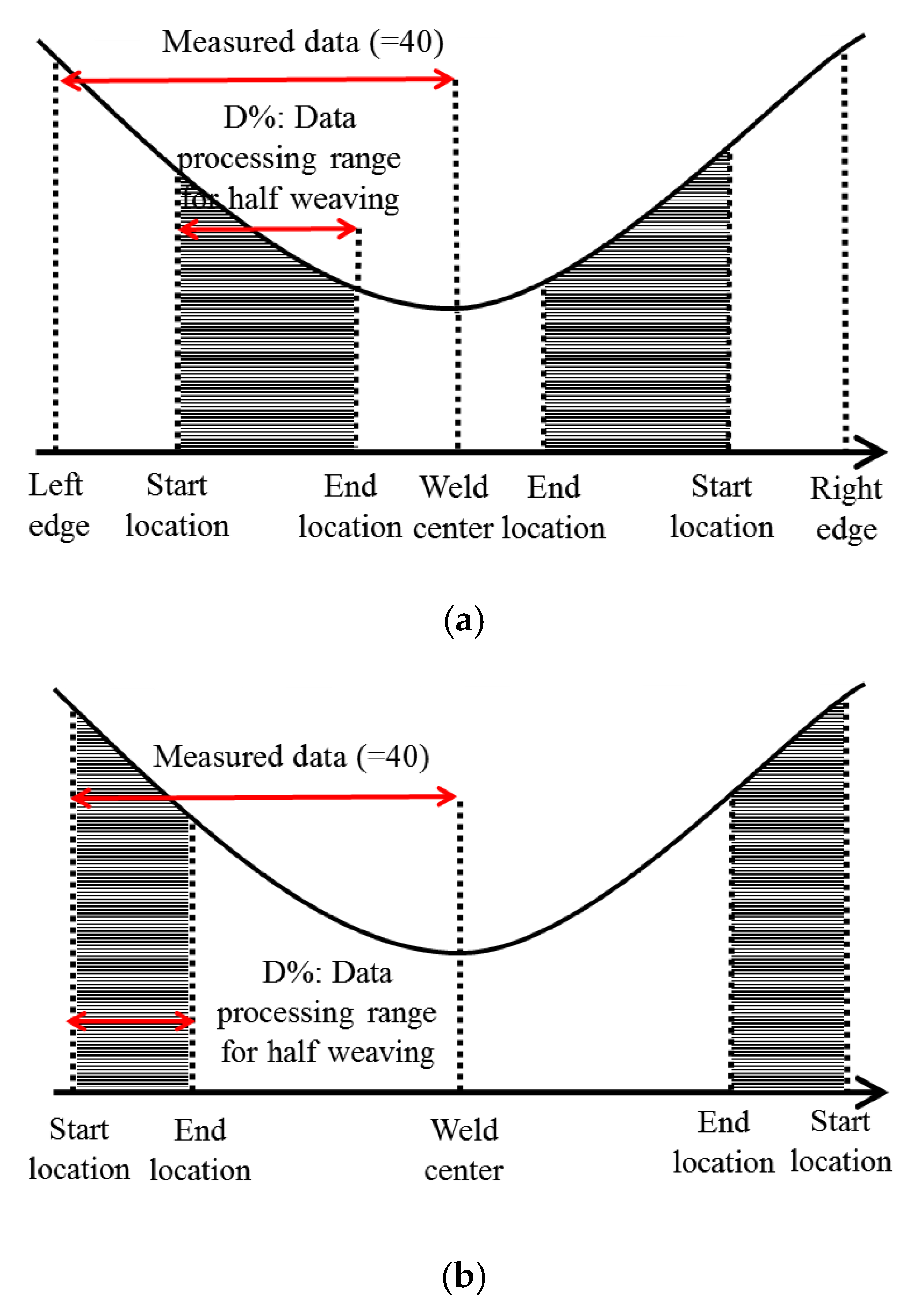

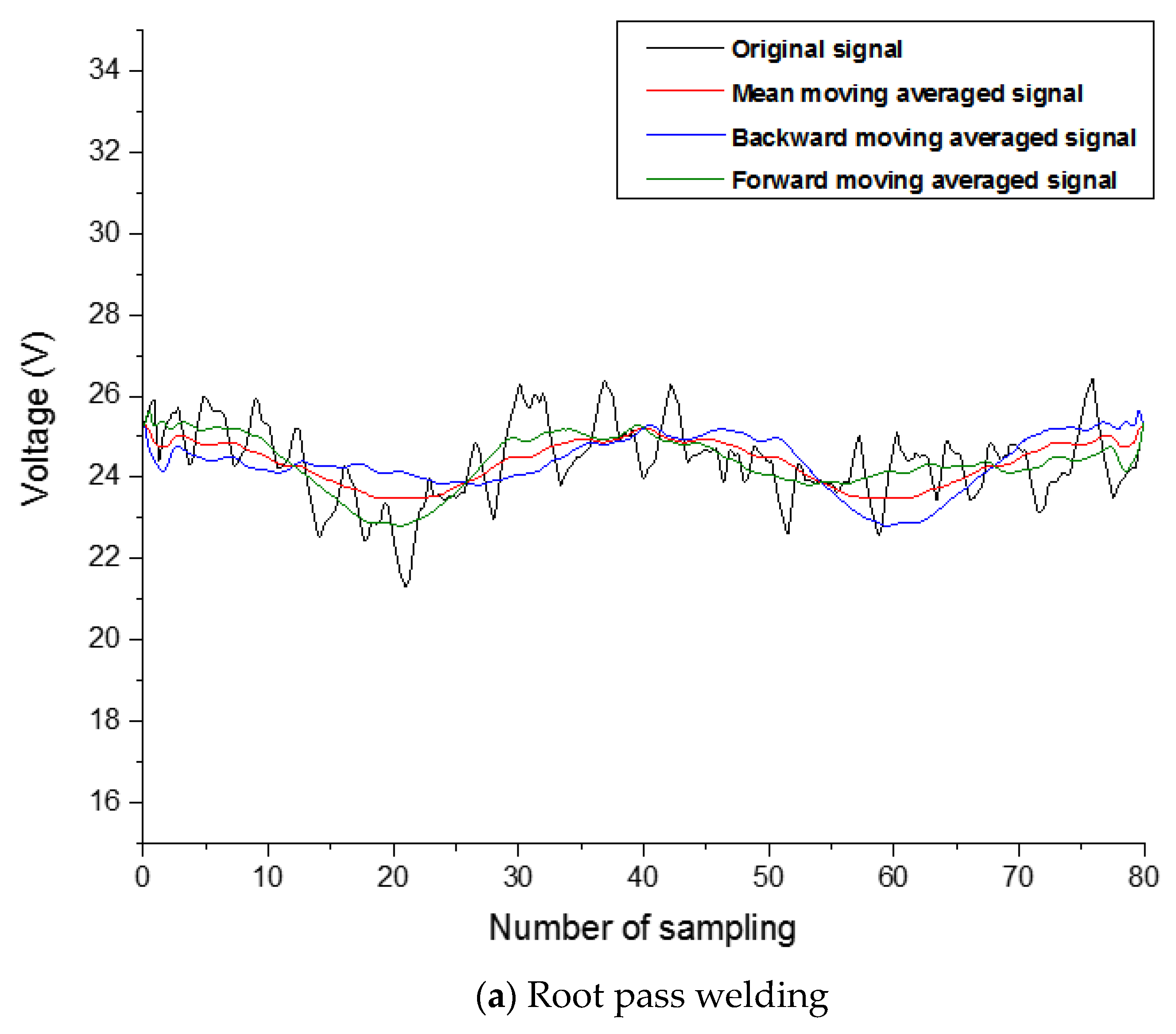

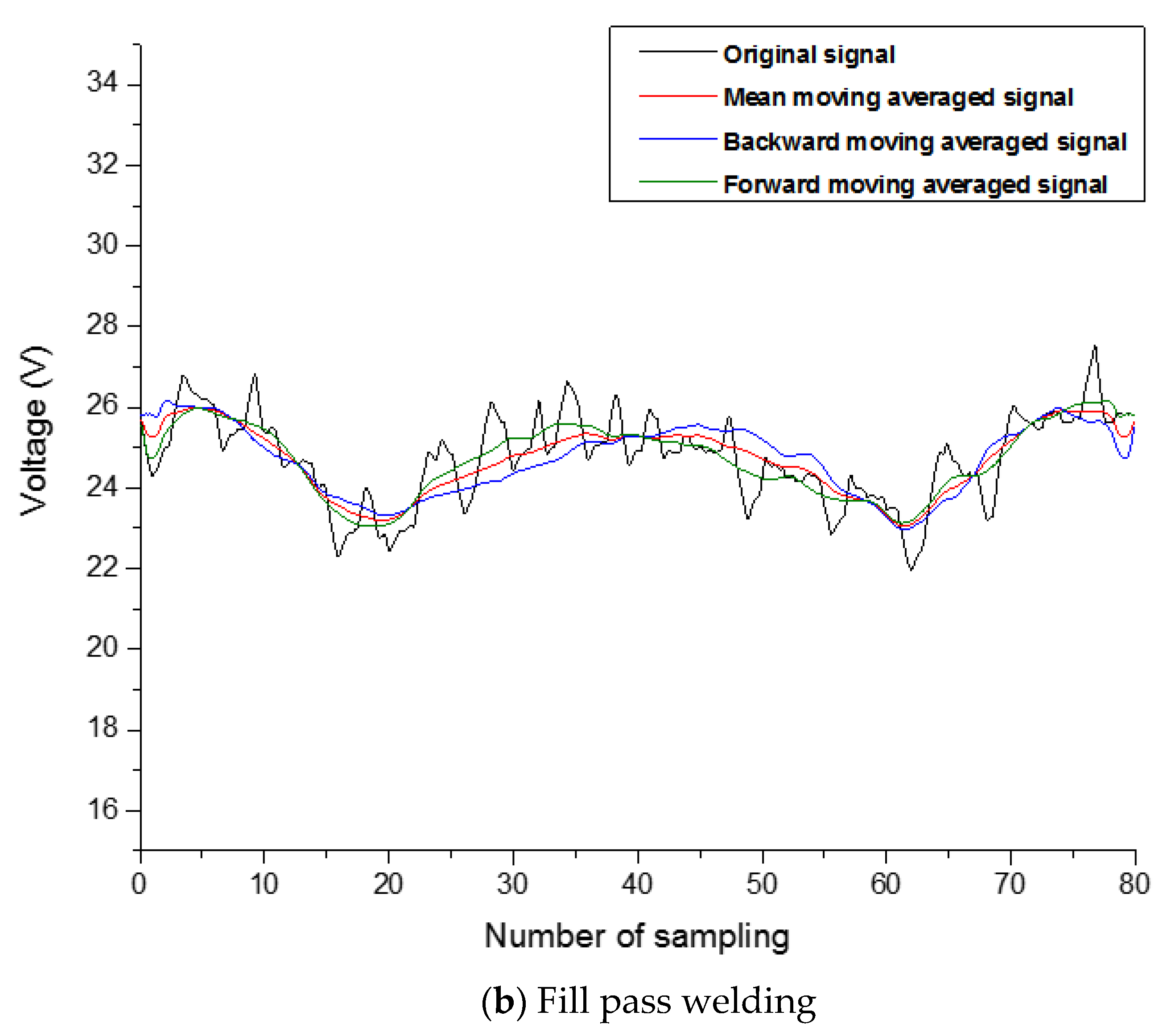

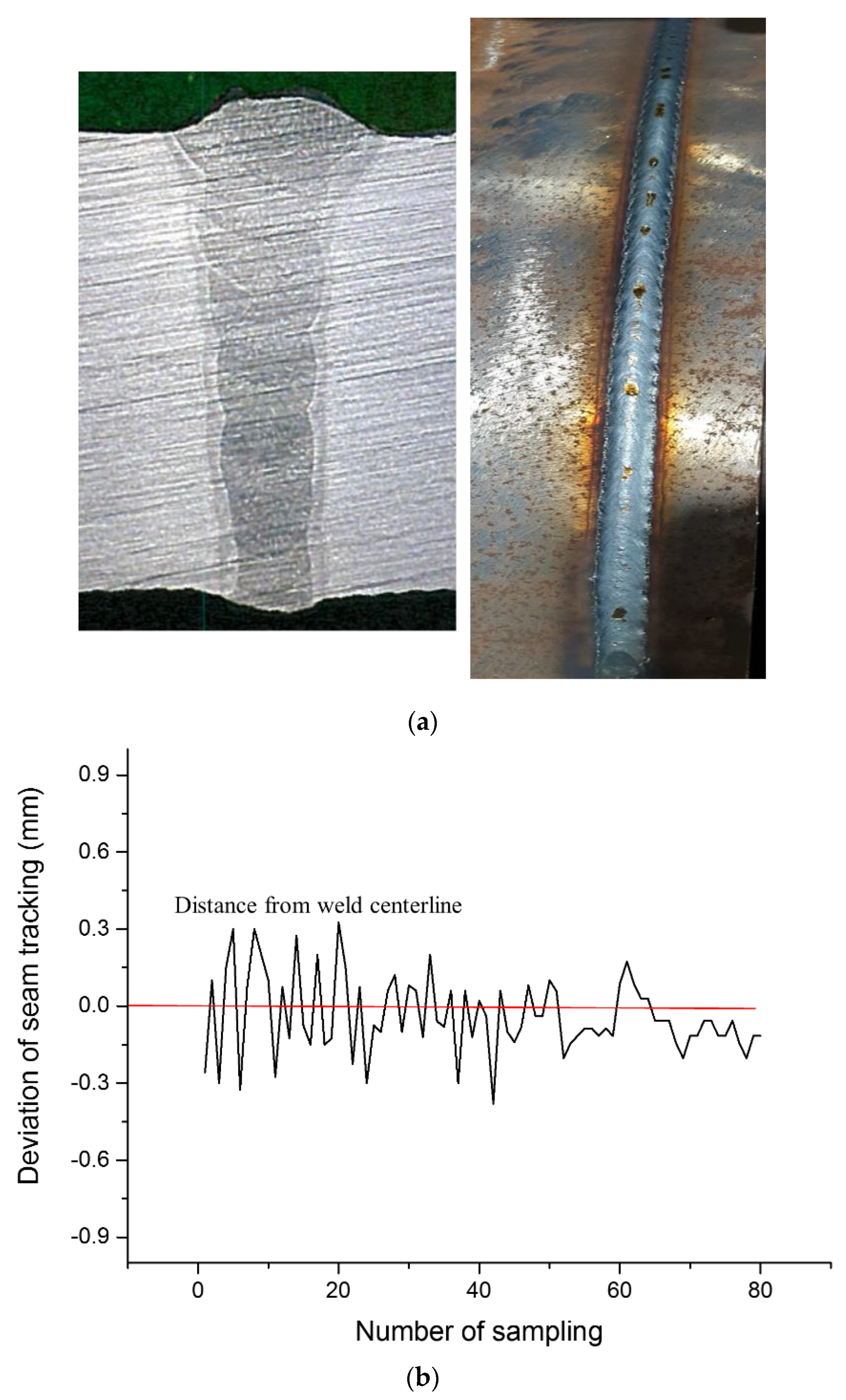

Welding Seam Tracking

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gao, Y.; Zhao, H.; Zhang, H. The application of automatic welding technology in West-to-East gas pipeline project. Oil Gas Storage Transp. 2003, 22, 53–55. [Google Scholar]

- Wang, R.; Guo, R.J. Developments of automatic girth welding technology in pipelines. Electr. Weld. Mach. 2011, 41, 53–55. [Google Scholar]

- Anxin, H.; Su, X.; Huafeng, S. Current situation of automatic welding of domestic long distance pipelines. Nat. Gas Oil 2006, 24, 12–14. [Google Scholar]

- Li Helin, J.L.; Wei, T. High grade line pipe and high pressure transportation: Significant progress of oil & gas transportation pipeline technology in China. China Eng. Sci. 2010, 12, 84–90. [Google Scholar]

- Yapp, D.; Blackman, S.A. Recent developments in high productivity pipeline welding. Braz. Manuf. Congr. 2004, 26, 89–97. [Google Scholar] [CrossRef] [Green Version]

- Yu, Z.; Zhang, W.; Zhang, Z. Development trend of China’s gas pipeline and relevant technical problems. Oil Gas Storage Transp. 2012, 31, 321–325. [Google Scholar]

- Kim, R.-H.; Choi, G.-D.; Kim, C.-H.; Cho, D.-W.; Na, S.-J. Arc characteristics in pulse-GMA welding with acute groove angles. Weld. J. 2012, 91, 101–105. [Google Scholar]

- Kim, J.W. A Study on the Analysis of Weld Pool Convection and Seam Tracking by Considering the Arc Length Characteristics in GMA Welding. Ph.D. Thesis, KAIST, Daejeon, Korea, 1991. [Google Scholar]

- Moon, H.-S.; Ko, S.-H. Automatic pipeline welding system equipped with six welding carriages, laser vision sensor and arc sensor for offshore pipeline laying. In Proceedings of the ISOPE Conference, Vancouver, BC, Canada, 6–11 July 2008. [Google Scholar]

- Moon, H.-S.; Na, S. A study on algorithm for seam tracking by considering weld defects in horizontal fillet welding. Korean Weld. Soc. 1996, 2, 139–141. [Google Scholar]

- Khosla, P.K.; Neuman, C.P.; Prinz, F.B. An algorithm for seam tracking applications. Int. J. Robot. Res. 1985, 4, 27–41. [Google Scholar] [CrossRef]

- Kim, J.W.; Na, S.J. A study on arc sensor algorithm for weld seam tracking in gas metal arc welding of butt joints. Proc. Inst. Mech. Eng. 1991, 205, 247–255. [Google Scholar] [CrossRef]

| Index | Weaving | WCM | WMM | SMM |

|---|---|---|---|---|

| 1 | ① → ② | Calculation of weaving time | − | Correction value for left and right |

| 2 | ② → ③ | Transmit the measurement of the voltage value | Receive the measurement of voltage | − |

| 3 | ③ → ④ | − | Receive the voltage value and number of samples | − |

| 4 | ④ → ① | Receive the voltage value Calculate the correction value Transmit the correction value | Calculate the mean moving average Transmit the voltage value | Receive the correction value |

| Pass No. | Current & Polarity | Current (A) & Lead/Trail | Voltage (V) & Lead/Trail | Travel Speed (cm/min) | Ocill. Width (mm) | Ocill. Frequency [spm] |

|---|---|---|---|---|---|---|

| Root | DC (+) | Lead: 252 | Lead: 25.5 | 63 | 0.6 | 220 |

| Trail: 246 | Trail: 24.5 | |||||

| Hot | DC (+) | Lead: 252 | Lead: 25.5 | 63 | 0.6 | 220 |

| Trail: 246 | Trail: 24.5 | |||||

| Fill 1 | DC (+) | Lead: 247 | Lead: 25 | 62 | 1.8 | 200 |

| Trail: 233 | Trail: 24.5 | |||||

| Fill 2 | DC (+) | Lead: 243 | Lead: 25 | 63 | 2.7 | 200 |

| Strip | DC (+) | Trail: 237 | Trail: 25.5 | 62 | 2.7 | 200 |

| Cap | DC (+) | Lead: 247 | Lead: 24.5 | 66 | 2.7 | 200 |

| Trail: 233 | Trail: 24 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.-H.; Moon, H.-S. Advanced Automatic Welding System for Offshore Pipeline System with Seam Tracking Function. Appl. Sci. 2020, 10, 324. https://doi.org/10.3390/app10010324

Park J-H, Moon H-S. Advanced Automatic Welding System for Offshore Pipeline System with Seam Tracking Function. Applied Sciences. 2020; 10(1):324. https://doi.org/10.3390/app10010324

Chicago/Turabian StylePark, Jin-Hyeong, and Hyeong-Soon Moon. 2020. "Advanced Automatic Welding System for Offshore Pipeline System with Seam Tracking Function" Applied Sciences 10, no. 1: 324. https://doi.org/10.3390/app10010324

APA StylePark, J.-H., & Moon, H.-S. (2020). Advanced Automatic Welding System for Offshore Pipeline System with Seam Tracking Function. Applied Sciences, 10(1), 324. https://doi.org/10.3390/app10010324