Mechanical Characteristics and Failure Mode of Asphalt Concrete for Ballastless Track Substructure Based on In Situ Tests

Abstract

:1. Introduction

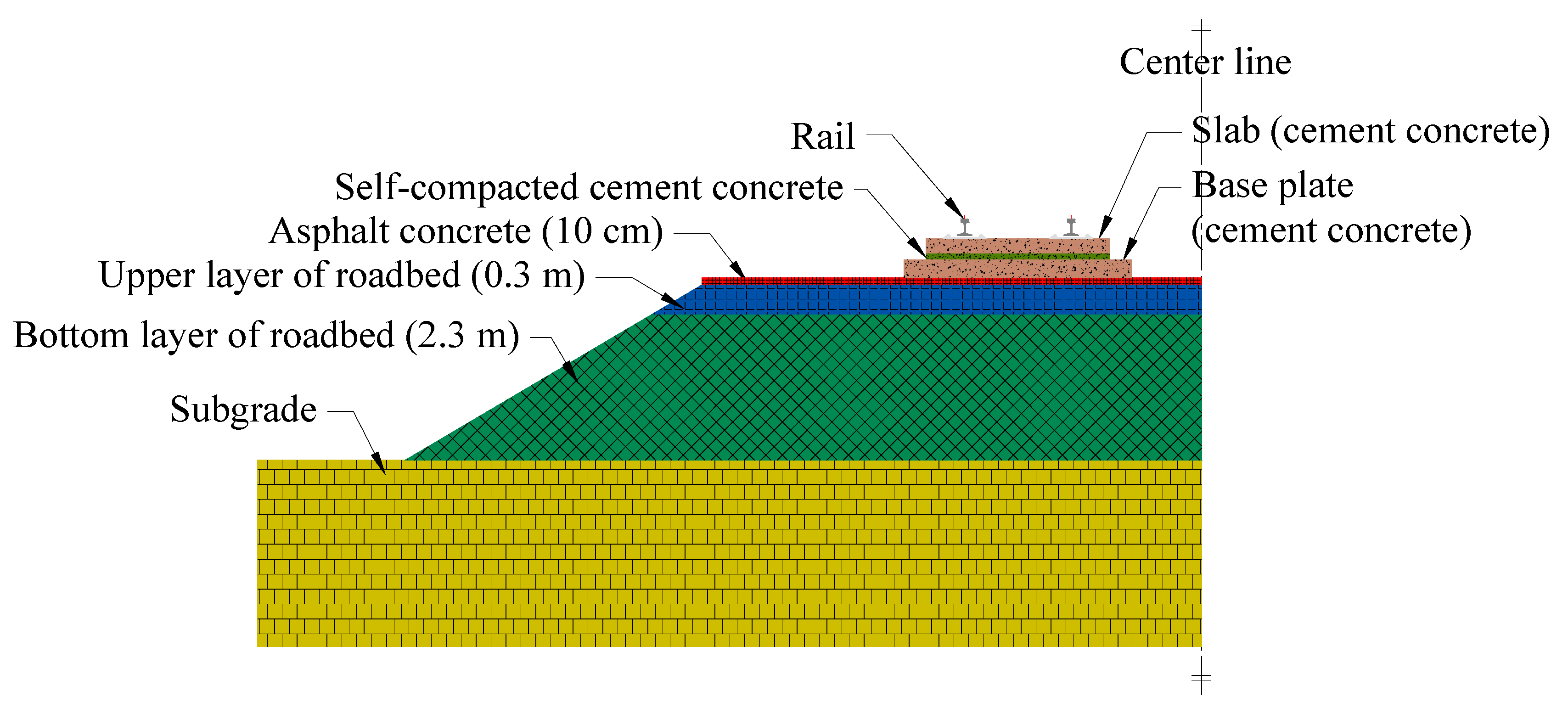

2. Working Conditions of Asphalt Concrete for Ballastless Track Substructure

2.1. Effect of the Cyclic Train Load

2.2. Effect of the Temperature

3. Test Section of Asphalt Concrete for Ballastless Track Substructure

3.1. Overview of the Test Section

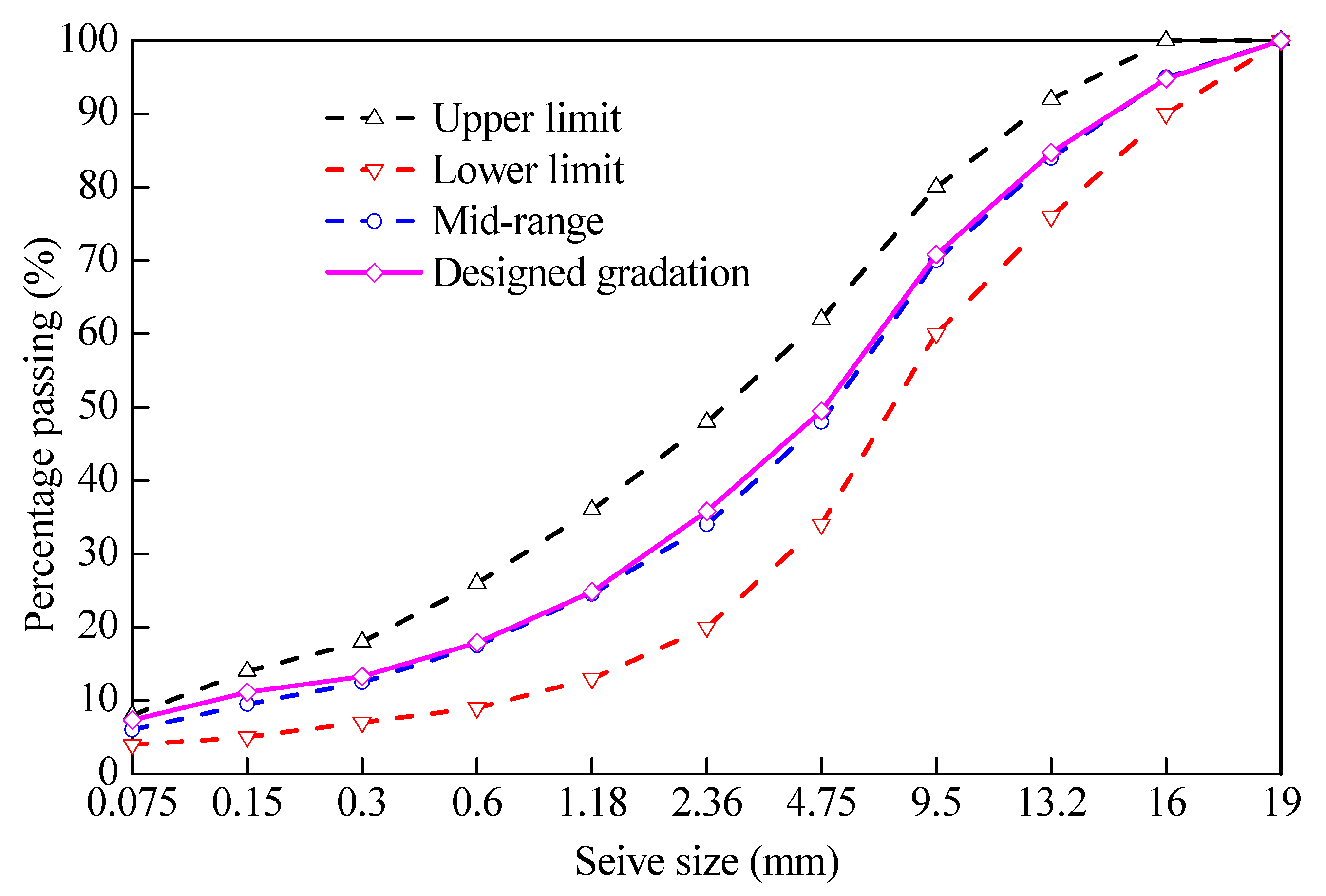

3.2. Design of the Asphalt Concrete

3.3. Performance Evaluation of the Asphalt Concrete

3.4. Construction Process of the Asphalt Concrete

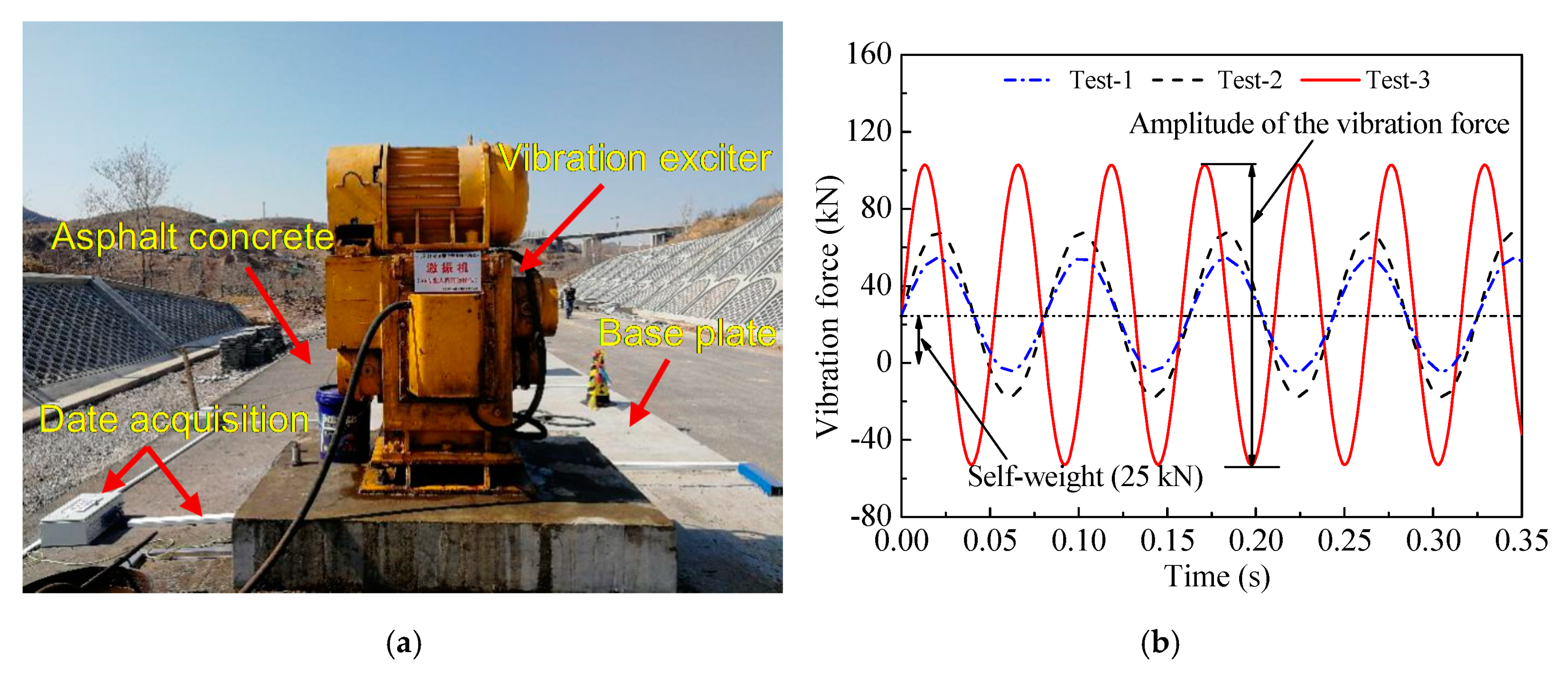

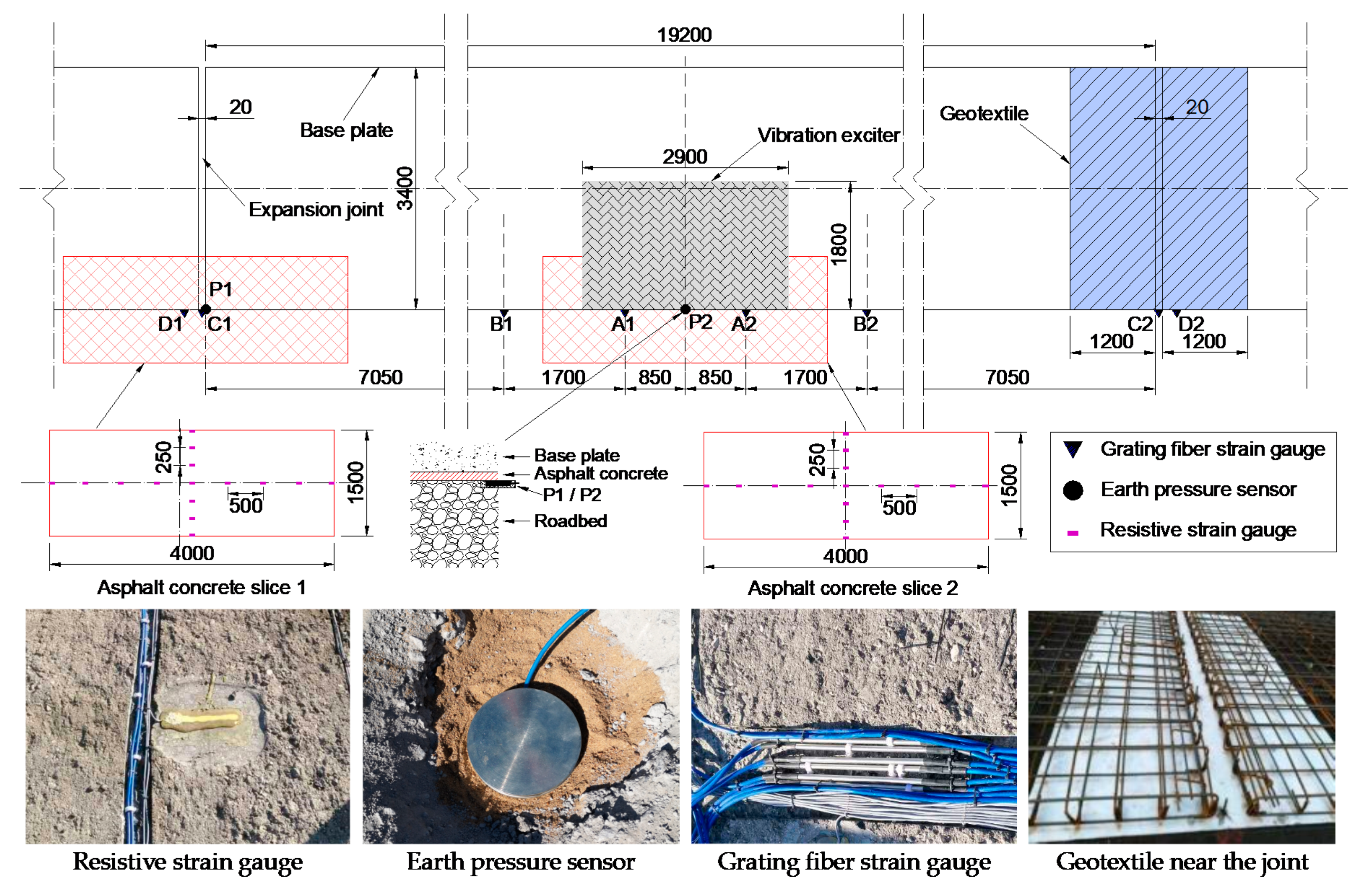

3.5. Test Program and Arrangement of Sensors

- (1)

- Cut and lift the asphalt concrete slice 1 and slice 2;

- (2)

- Locate the adhesive position of the strain gauges and polish the surface;

- (3)

- Stick the strain gauges;

- (4)

- Connect the wires and construct the bridge;

- (5)

- Coat the strain gauges with the epoxy for protection;

- (6)

- Put the asphalt concrete slices back to the original position;

- (7)

- Use rivets to connect the slices with the surrounding asphalt concrete into an integral structure.

4. Monitoring Result of Asphalt Concrete in the Test

4.1. Responses Induced by the Train Load

4.2. Responses Induced by the Temperature

5. Investigation and Failure Mode Analysis of Asphalt Concrete

- (1)

- In general, the asphalt concrete layer in the test section is in good service condition. There are only a few inconspicuous cracks in some locations, which may be caused by the removal of the base plate. Further, these cracks basically have no impact on the later service of the asphalt concrete;

- (2)

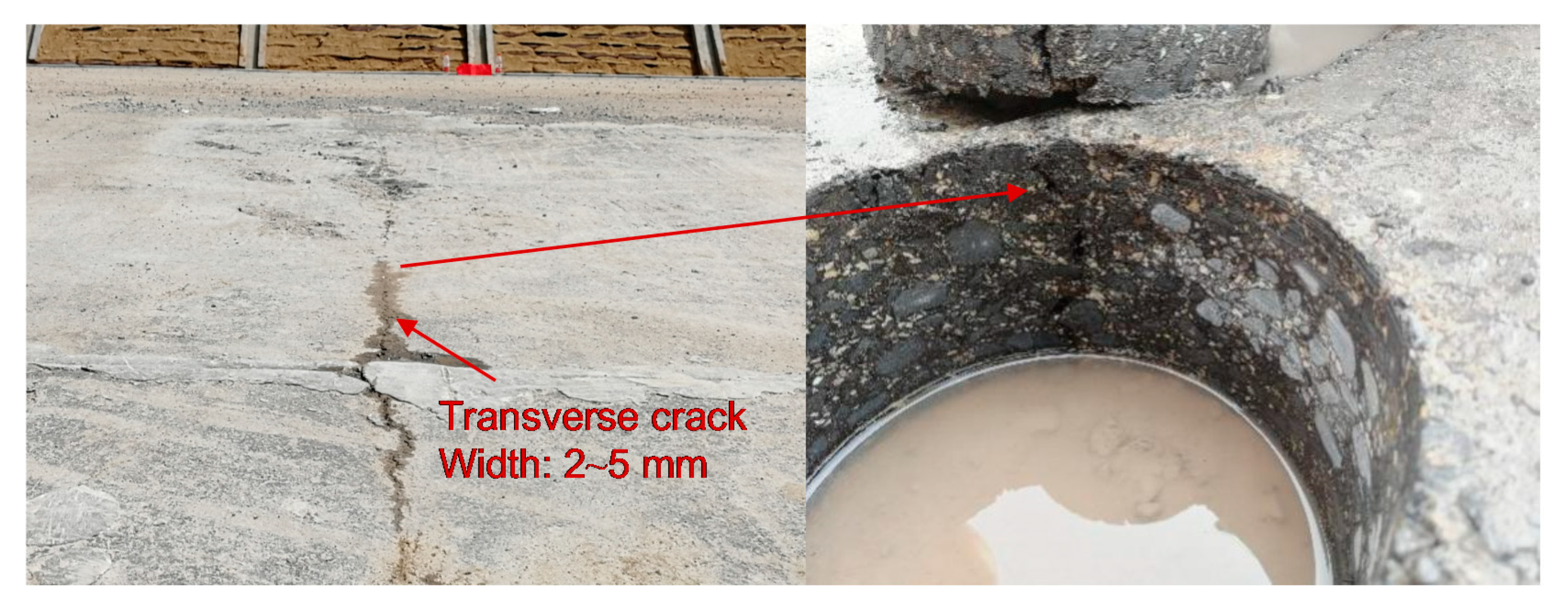

- There is a transverse crack with the width of 2~4 mm in the expansion joint of the base plate without the geotextile, as shown in Figure 9. Through the core sample at the crack location, it is found that the crack runs through the entire asphalt concrete layer, which will seriously affect the service performance, while no such cracks have been found in the expansion joint of the base plate with the geotextile;

- (3)

- It can be concluded that the cracks in the asphalt concrete in the expansion joints caused by the temperature-induced deformation of the base plate are the main failure mode of the asphalt concrete for the ballastless track substructure. By setting the isolation layer, mechanical responses near expansion joints can be effectively reduced, which is useful for resisting the potential passive tensile cracks of the asphalt concrete.

6. Conclusions and Discussion

- The bottom of the asphalt concrete layer is in the tensile state and the surface of the roadbed is in the compressive state under the action of cyclic train load. The surface of the asphalt concrete near the expansion joint is subjected to tensile stress under the action of the negative temperature gradient, which may cause potential cracks;

- The influence of environmental temperature changes on the mechanical characteristics of the asphalt concrete is greater than that of the cyclic train load. The tensile strain level, the earth pressure, and the diurnal variation range of the asphalt concrete near the expansion joint are also much larger than those near the middle position of the base plate. Therefore, more attention should be paid to the influence of temperature changes in future studies;

- Isolation layers, set under the base plate near the expansion joint, can significantly reduce the mechanical responses near the joint, which has a positive effect on resisting the passive tensile failure induced by the base plate. The geotextile is an effective material for the isolation layer and can be applied to similar railway projects in the future. However, the setting range of this isolation layer needs further studies;

- Besides, in the design and application of the asphalt concrete for the ballastless track substructure, the low-temperature cracking resistance and fatigue resistance should be paid more attention to, and asphalt materials with a good low-temperature and fatigue performance are more suitable, such as crumb rubber-modified asphalt binders.

Author Contributions

Funding

Conflicts of Interest

Data Availability

References

- D’Angelo, G.; Sol-Sánchez, M.; Navarro, F.M.M.; Presti, D.L.; Thom, N. Use of bitumen-stabilised ballast for improving railway trackbed conventional maintenance. Geotechnique 2018, 68, 518–527. [Google Scholar] [CrossRef]

- Fang, M. Structural behavior and mix design for asphalt concrete substructures in high-speed rail. Ph.D Thesis, Southwest Jiaotong University, Chengdu, China, 2017. [Google Scholar]

- Rose, J.G.; Souleyrette, R.R. Hot-Mix Asphalt (Bituminous) Railway Trackbeds: In-Track Tests, Evaluations, and Performances-a Global Perspective: Part I-Introduction to Asphalt Trackbeds and International Applications and Practices. In Proceedings of the 3rd International Conference on Transportation Infrastructure, Pisa, Italy, 22–25 April 2014; CRC Press: Pisa, Italy, 2014. [Google Scholar]

- Rose, J.G.; Teixeira, P.F.; Veit, P. International Design Practices, Applications, and Performance of Asphalt/Bituminous Railway Trackbeds. In Proceedings of the GEORAIL 2011-International Symposium, Paris, France, 19–20 May 2011. [Google Scholar]

- Chupin, O.; Martin, A.; Piau, J.-M.; Hicher, P.-Y. Calculation of the dynamic response of a viscoelastic railway structure based on a quasi-stationary approach. Int. J. Solids Struct. 2014, 51, 2297–2307. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, T.M.; Teixeira, P.; Cardoso, R. Impact of Bituminous Subballast on Railroad Track Deformation Considering Atmospheric Actions. J. Geotech. Geoenvironmental Eng. 2011, 137, 288–292. [Google Scholar] [CrossRef]

- Sol-Sánchez, M.; Pirozzolo, L.; Navarro, F.M.M.; Rubio-Gamez, M.C. Advanced characterisation of bituminous sub-ballast for its application in railway tracks: The influence of temperature. Constr. Build. Mater. 2015, 101, 338–346. [Google Scholar] [CrossRef]

- Sol-Sánchez, M.; Pirozzolo, L.; Navarro, F.M.M.; Rubio-Gamez, M.C. A study into the mechanical performance of different configurations for the railway track section: A laboratory approach. Eng. Struct. 2016, 119, 13–23. [Google Scholar] [CrossRef]

- Teixeira, P.; Pita, A.L.; Ferreira, P.A. New possibilities to reduce track costs on high-speed lines using a bituminous sub-ballast layer. Int. J. Pavement Eng. 2010, 11, 301–307. [Google Scholar] [CrossRef]

- Lee, S.-H.; Choi, Y.-T.; Lee, H.-M.; Park, D.-W. Performance evaluation of directly fastened asphalt track using a full-scale test. Constr. Build. Mater. 2016, 113, 404–414. [Google Scholar] [CrossRef]

- Momoya, Y.; Sekine, E. Performance-Based Design Method for Raailway Asphalt Roadbed. Doboku Gakkai Ronbunshuu E 2007, 63, 608–619. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.-H.; Tao, T.-Q.; Yang, G.-T.; Yan, H.-Y.; Yang, J. Long-Lasting Waterproofing Solution for the Subgrade of High-Speed Railway in Cold Region. J. Test. Evaluation 2018, 47, 20180046. [Google Scholar] [CrossRef]

- Liu, S.; Yang, J.; Chen, X.; Yang, G.; Cai, D. Application of Mastic Asphalt Waterproofing Layer in High-Speed Railway Track in Cold Regions. Appl. Sci. 2018, 8, 667. [Google Scholar] [CrossRef] [Green Version]

- Fu, Q.; Chen, X.; Cai, D.; Yang, J.; Yang, G. Full-section asphalt concrete waterproof sealing structure for high speed railway subgrade. China Railw. Sci. 2020, 41, 24–33. [Google Scholar] [CrossRef]

- Cardona, D.R.; Di Benedetto, H.; Sauzeat, C.; Calon, N.; Saussine, G. Use of a bituminous mixture layer in high-speed line trackbeds. Constr. Build. Mater. 2016, 125, 398–407. [Google Scholar] [CrossRef]

- Esmaeili, M.; Amiri, S.; Jadidi, K. An investigation into the use of asphalt layers to control stress and strain levels in railway track foundations. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2012, 228, 182–193. [Google Scholar] [CrossRef]

- Fang, M.; Qiu, Y.; Rose, J.G.; West, R.C.; Ai, C. Comparative analysis on dynamic behavior of two HMA railway substructures. J. Mod. Transp. 2011, 19, 26–34. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.; Chen, X.; Fu, Q.; Xu, G.; Cai, D. Dynamic Responses of Asphalt Concrete Waterproofing Layer in Ballastless Track. Appl. Sci. 2019, 9, 375. [Google Scholar] [CrossRef] [Green Version]

- Yu, Z.; Connolly, D.; Woodward, P.; Laghrouche, O. Settlement behaviour of hybrid asphalt-ballast railway tracks. Constr. Build. Mater. 2019, 208, 808–817. [Google Scholar] [CrossRef]

- Yang, E.; Wang, K.C.; Qiu, Y.; Luo, Q. Asphalt Concrete for High-Speed Railway Infrastructure and Performance Comparisons. J. Mater. Civ. Eng. 2016, 28, 04015202. [Google Scholar] [CrossRef]

- Yang, E.; Wang, K.C.P.; Luo, Q.; Qiu, Y. Asphalt Concrete Layer to Support Track Slab of High-Speed Railway. Transp. Res. Rec. J. Transp. Res. Board 2015, 2505, 6–14. [Google Scholar] [CrossRef]

- Liang, Y. Study on Low Temperature Response of Asphalt Concrete Structure under CRTS III Type Ballastless; Southeast Univeristy: Nanjing, China, 2019. [Google Scholar]

- Research Institute of Highway Ministry of Transport. Technical Specifications for Construction of Highway Asphalt Pavements; JTG F40-2004; China Communications Press: Beijing, China, 2004. [Google Scholar]

- Research Institute of Highway Ministry of Transport. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; JTG E20-2011; China Communications Press: Beijing, China, 2011. [Google Scholar]

| Parameters (Unit) | Test Results | Technical Requirements | Test Methods |

|---|---|---|---|

| Penetration @ 25 °C (0.1 mm) | 72.9 | 60~80 | T 0604 |

| Penetration index | 1.6 | ≥0.5 | T 0604 |

| Ductility @ 5 °C (cm) | 50.1 | ≥30 | T 0605 |

| Softening point (°C) | 90.5 | ≥80 | T 0606 |

| Fraas breaking point (°C) | −28 | ≤−25 | T 0613 |

| Dynamic viscosity @ 175 °C (Pa·s) | 1.12 | ≤1.5 | T 0625 |

| Flash point (°C) | 280 | ≥260 | T 0611 |

| Asphalt– Aggregate Ratio (%) | Bulk Density (g/cm3) | Void Ratio (%) | VMA (%) | VFA (%) | Stability (kN) | Flow Values (dmm) |

|---|---|---|---|---|---|---|

| 4.0 | 2.473 | 7.1 | 14.71 | 51.99 | 14.57 | 3.77 |

| 4.5 | 2.506 | 5.1 | 14.00 | 63.38 | 15.12 | 2.79 |

| 5.0 | 2.530 | 3.5 | 13.57 | 74.33 | 16.23 | 3.66 |

| 5.5 | 2.525 | 3.0 | 14.18 | 78.85 | 14.64 | 4.52 |

| 6.0 | 2.516 | 2.6 | 14.87 | 82.31 | 13.35 | 5.12 |

| Functionality | Parameter (Unit) | Test Result | Technical Requirement | Test Method |

|---|---|---|---|---|

| Waterproofing | Water permeability coefficient (mL/min) | 0 | ≤60 | T 0730 |

| Void ratio (%) | 1.67 | ≤4 | T 0711 | |

| Bearing capacity | Compressive strength @ 20 °C (MPa) | 5.37 | ≥4 | T 0713 |

| Dynamic stability @ 60 °C (cycle/mm) | 3060 | ≥2400 | T 0719 | |

| Dynamic modulus @ 10 Hz, 15 °C (MPa) | 8112 | ≥6000 | T 0738 | |

| Low-temperature cracking resistance | Failure stiffness @ −10 °C (MPa) | 13.26 | ≥8 | T 0715 |

| Failure strain (με) | 3356 | ≥3000 | ||

| Water damage resistance | Resilient stability (%) | 95 | ≥85 | T 0709 |

| Tensile strength ratio (%) | 95 | ≥80 | T 0729 | |

| Fatigue resistance | Fatigue life @ 10 Hz, 500 με, 15 °C (×104 cycle) | 122.5 | ≥20 | T 0739 |

| Test Group | Parameters of the Vibration Exciter | Parameters of the Train | |||

|---|---|---|---|---|---|

| Vibration Frequency (Hz) | Amplitude of the Vibration Force (kN) | Loading Cycle (×104) | Train Speed (km/h) | Train Axle Load (ton) | |

| Test-1 | 12.3 | 58.8 | 200 | 350 | 17 |

| Test-2 | 12.3 | 105.2 | 200 | 350 | 19 |

| Test-3 | 19.0 | 155.8 | 200 | 450 | 19 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, Q.; Chen, X.; Cai, D.; Lou, L. Mechanical Characteristics and Failure Mode of Asphalt Concrete for Ballastless Track Substructure Based on In Situ Tests. Appl. Sci. 2020, 10, 3547. https://doi.org/10.3390/app10103547

Fu Q, Chen X, Cai D, Lou L. Mechanical Characteristics and Failure Mode of Asphalt Concrete for Ballastless Track Substructure Based on In Situ Tests. Applied Sciences. 2020; 10(10):3547. https://doi.org/10.3390/app10103547

Chicago/Turabian StyleFu, Qinghong, Xianhua Chen, Degou Cai, and Liangwei Lou. 2020. "Mechanical Characteristics and Failure Mode of Asphalt Concrete for Ballastless Track Substructure Based on In Situ Tests" Applied Sciences 10, no. 10: 3547. https://doi.org/10.3390/app10103547

APA StyleFu, Q., Chen, X., Cai, D., & Lou, L. (2020). Mechanical Characteristics and Failure Mode of Asphalt Concrete for Ballastless Track Substructure Based on In Situ Tests. Applied Sciences, 10(10), 3547. https://doi.org/10.3390/app10103547