3.1. Numerical Analysis of Cooling Channel

The existing cooling channel patterns can be divided into helical type, paralleling type, axial type, and trapezoidal type. The cooling efficiencies and pressure drop of different spindle cooling channel patterns were obtained in the simulation by ANSYS software.

Figure 7 shows the simulation results of different oil with original cooling channel design in the built-in spindle.

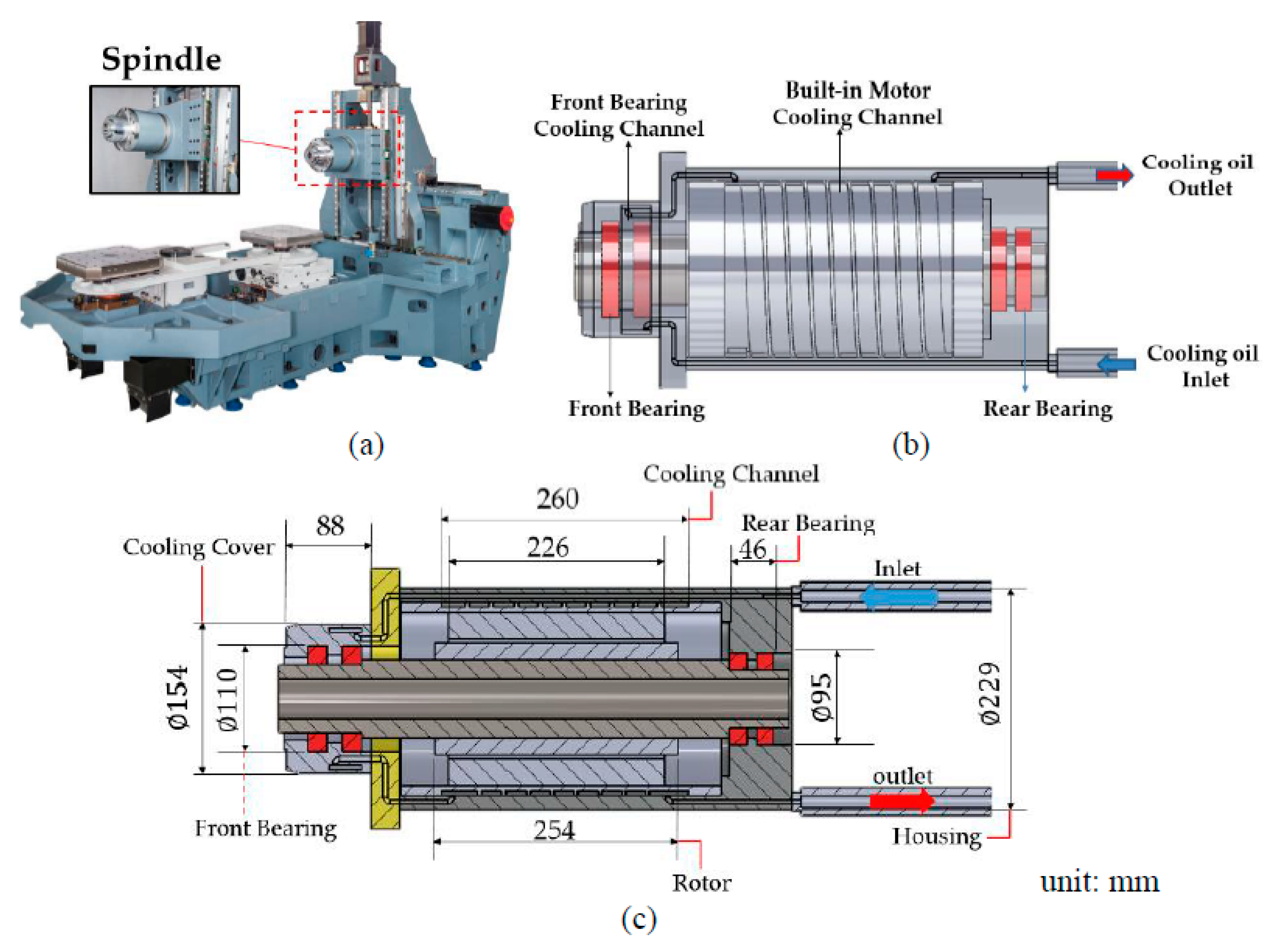

The measured power of the spindle motor by the power meter at 12,500 rpm was 550 W, and the generating heat could be calculated by Equations (13)–(23). In the study, the heat generated by the core loss, copper loss, front bearing and rear bearing were 48.2 W, 14.4 W, 292.4 W, and 194.9 W, respectively. The frictional torque of bearing could be obtained by Equation (13), where the frictional torque of bearing was 420 N-mm.

The generating heat of the spindle can be expressed as

where

W is the heat generated, n is the rotational speed of the spindle, and

n is the rotational speed of spindle.

The physical properties of the different oil types applied in the study are shown in

Table 1. The simulation results of the spindle temperature and deformation with different oil types are shown in

Table 2.

Figure 7 and

Table 2 show a comparison of the cooling efficiency results of VG10 and VG5 oils in the built-in spindle. The average wall temperature of the front bearing cooling channel using VG5 oil was 57.6 °C, which is 3.6 °C lower than using VG10, and the cooling efficiency of the front bearing was improved by 5.9%. The average wall temperature of the motor cooling channel using VG5 oil was 48.4 °C, which is 2.5 °C lower than using VG10, and the motor cooling efficiency was improved by 4.9%. The heat transfer coefficient in the cooling channel can be improved by using the oil type, and the effect of temperature rise can be improved effectively to reduce the thermal deformation. The pressure drop of VG5 oil in the cooling channel is 2.13 bar, which is 1.22 bar lower than using VG10 at the same oil flow rate of 12 L/min, and the pressure drop is reduced by 36.4%. In terms of spindle deformation, the average deformation of the built-in spindle is 118.3 μm by using VG5 oil, which is less than the average deformation 124.6 μm using VG10 oil by 6.3 μm at the same oil flow rate of 12 L/min. The spindle accuracy can be enhanced by 5.1%.

No specification is available for existing cooling channel designs, and the cooling conditions sometimes follow the requirements of the original manufacturer of a motor. The design of a cooling channel influences not only the cooling efficiency inside the spindle but also the accuracy of the spindle and machining results. The simulation results of the cooling efficiency, channel pressure drop, and spindle axial deformation of different front bearing and motor channel designs are compiled in

Figure 8 and

Table 3.

Table 3 illustrates the average temperatures, thermal deformations, and pressure drops with different cooling channel pattern combinations. After the results of combination 1 and combination 2 were compared, the helical type cooling channel was adopted at the motor, and the single-turn cooling channel was adopted at the front bearing. When the VG10 oil was applied at a flow of 12 L/min, the motor and front bearing cooling channel wall temperatures were relatively high, and the cooling channel wall temperature of the front bearing was higher than the cooling channel wall temperature of the motor by 10.3 °C. The heat generated at the front bearing had almost 4.7 times the copper loss and core loss of the motor because most heat concentrates at the front bearing. The deformation of the built-in spindle was 124.6

, and the internal pressure drop of the cooling channel was 3.35 bar. However, when the oil type was changed to VG5, the deformation of the built-in spindle was 118.3 μm (difference is 6.3 μm), which was lower than for VG10, and the pressure drop inside the cooling channel was reduced by 1.22 bar. The results show that the heat transfer coefficient and wall temperature inside the cooling channel can be improved and the thermal deformation can be reduced by selecting the suitable oil type.

To improve the cooling efficiency of the front bearing, the design of the front bearing cooling channel was modified to the paralleling type cooling channel, and the front bearing cooling channel wall temperature of each motor cooling channel type was reduced by 14–15.2 °C. Therefore, the cooling efficiency of the front bearing can be increased effectively by the design. In terms of the pressure drop, after the front bearing of the cooling channel was changed to the paralleling type design, the pressure drop increased due to a longer cooling channel of the front bearing. The cooling channel of the front bearing was designed with the paralleling type design; the temperature of front bearing can be reduced effectively. Therefore, the paralleling type cooling channel was employed for the front bearing in subsequent simulation analysis.

In terms of the design of the motor cooling channel, different cooling channel types—the helical type, paralleling type, axial type, and trapezoidal type—and different channel dimensions were analyzed. The results indicate that the design of the axial type cooling channel can reduce the motor cooling channel wall temperature by 11.1 °C from 48.4 °C to 37.3 °C, followed by the axial cooling channel with larger dimensions. According to the analysis results, the helical type, single-turn paralleling size, and trapezoidal type of motor cooling channel have no obvious effect on reducing the motor temperature, whereas the cooling channel design alteration of the front bearing has a better effect. Because the front bearing has a much higher heat generation rate than the motor, the cooling effect can be improved by increasing the cooling efficiency of the front bearing.

According to the pressure drop results of the cooling channel designs, only if the front bearing has the paralleling type design and the motor has the helical type cooling channel split design, the pressure drop can be minimized to 1.65 bar. However, the axial type cooling channel design achieved the maximum pressure drop of 9.25 bar, followed by the helical type design. For the practical application of the machine tool spindle cooling channel, a lower pressure drop is better. Considering the cost, the larger is the pressure drop, the larger should be the supply pump of the cooling machine and the cooling capacity of the cooling system, which generates a higher cost.

According to the accuracy results of the spindle, the spindle deformation of the motor cooling channel design type of the axial type size (No. 9) was 85.7 μm, which was the smallest among all cooling channel design types, followed by the single-turn paralleling, double turn paralleling, and axial design types with a deformation of 86.2 μm. The third smallest type was the helical type cooling channel split design of motor with a deformation of 86.8 μm.

In

Table 3, the temperature, pressure drop, and deformation in the simulation results are evaluated. The front bearing and the motor adopted the paralleling type cooling channel design and helical type cooling channel design, respectively. The cooling channel temperature of the front bearing was the lowest, followed by the cooling channel wall temperature of the motor. However, the deformation and pressure drop of the cooling channel were the lowest. Comprehensively considering the temperature, pressure drop, deformation, manufacturing cost, and convenience, in the following study of the cooling channel dimension optimization, the paralleling type cooling channel of the front bearing and helical type cooling channel of motor were considered.

3.2. Optimization Analysis of Cooling Channel Dimension

In this study, the optimization module of the analytical software was employed for the dimension optimization. The front bearing cooling channel dimension design was optimized with the same cooling oil conditions and heat transfer coefficient of fluid.

Figure 9 shows the geometrics of the cooling channel, which were imported from Solidworks 3D drawing software into the simulation software for analysis. The optimization simulation of the critical dimensions in the front bearing cooling channel was performed.

The front bearing between the flange facing and the spindle nose had the largest heat contribution to the thermal deformation. Therefore, the thermal deformation of the spindle can be reduced directly by effectively reducing the front bearing temperature. In the design of the cooling channel, direct heat removal from the heating parts is the best method, in which the temperature rise can be improved effectively, and the heat can be prevented from being transferred to other structures, which causes more unforeseeable deformation. Therefore, a front bearing cooling channel design can effectively reduce the front bearing temperature and induce structural deformation.

To obtain the critical dimension of the optimal cooling channel, the optimal design method of software was adopted in this study. First, the front bearing cooling channel of the built-in spindle was drawn by Solidworks, and the model was simplified for analysis. The width and height of the cooling channel were defined as the critical design parameters. The critical dimension of the front bearing cooling channel is shown in

Figure 9a, including the width (W) and height (H) definitions of the paralleling type cooling channel.

In the optimized design for the front bearing cooling channel dimension in this study, the critical dimensions were the cooling channel cross-sectional width (W, denoted as P1) and cooling channel cross-sectional height (H, denoted as P2). In addition, the cooling oil flow rate (Q, set as P3) was applied. The effects of the width (W), height (H), and cooling oil flow rate (Q) on the temperature inside the front bearing cooling channel (T, denoted as P4) were analyzed. The front bearing cooling channel optimization variable settings are shown in

Figure 9b.

The dimension and relevant parameter ranges of the front bearing cooling channel are shown in

Table 4. The width (P1) of the cooling channel was in the range 6.0 mm~9.0 mm; the height (P2) of the cooling channel was in the range 3.5 mm~5.0 mm; and the cooling oil flow rate was in the range 0.1~0.2 kg/s. The temperature of the front bearing is the output of the numerical simulation.

Table 5 shows the results of the front bearing temperatures by the Design of Experiments (DOE) simulation. The Central Composite Design (CCD) method was adopted to automatically generate a combination, and the analytical calculation was performed according to the combination. The front bearing temperature is shown in

Table 5. In the limit range of the dimension and cooling flow rate, the temperature of the front bearing was in the range 308.04–308.97 K. In the limit design space of the cooling channel, the temperature difference in the numerical results was approximately 1 K, which is not substantial. However, even a 1 K temperature difference can produce a considerable effect on structural deformation. Considering the ball-screw as an example, the thermal deformation of a 1-meter-long ball-screw is approximately 12 μm for a 1 K temperature rise.

The sensitivity level of the parameter variations in temperature can be obtained by numerical analysis software (ANSYS), as shown in

Figure 10. The cooling oil flow rate P3 and front bearing temperature P4 have negative sensitivity levels, which means that the front bearing temperature drops obviously as the flow rate of the cooling oil increases. Second, the cooling channel height P2 and front bearing temperature P4 present positive sensitivity levels, which means that the front bearing temperature can be reduced by reducing the channel height and the heat transfer efficiency will improve. Last, in terms of the cooling channel width P1, an increase or decrease in the cooling channel width has a slight effect on the front bearing temperature P4.

According to the correlation matrix in

Figure 11 and the response surface diagram in

Figure 12, the front bearing temperature P4 is highly correlated with the cooling oil flow rate P3, and the cooling channel width P1 and channel height P2 are correlated with the front bearing temperature P4. As shown in

Figure 11, a slight interaction between the cooling channel width P1 and the cooling oil flow rate P3 was observed. Generally, the cooling oil flow rate P3 is inversely proportional to the front bearing temperature P4, and the cooling channel height P2 is proportional to the front bearing temperature.

The response surface in

Figure 12a indicates the effect of the cooling channel width P1 and cooling oil flow rate P3 on the front bearing temperature P4. When the cooling channel width P1 is 7.5 mm, the optimal front bearing temperature is 308 K. When the cooling oil flow rate P3 is 0.2 kg/s, the most significant effect on the front bearing cooling is observed. However, when the cooling channel width P1 is 6.0 mm and 9.0 mm, the front bearing temperature is 309 K and the cooling oil flow rate P3 of 0.1 kg/s has the worst cooling effect on the front bearing.

The response surface in

Figure 12b shows the effect of the channel height P2 and cooling oil flow rate P3 on front bearing temperature P4. According to the analysis results, when the channel height P2 is approximately 4.0 mm, the optimal front bearing temperature is approximately 308 K. When the cooling oil flow rate P3 is 0.2 kg/s, the most significant effect on the front bearing cooling is observed. However, when the channel height P2 is 5.0 mm, the front bearing temperature is approximately 309 K and the cooling oil flow rate P3 of 0.1 kg/s has the worst cooling effect on the front bearing.

The response surface in

Figure 12c shows the effect of the relation between channel width P1 and the channel height P2 on the front bearing temperature P4. The match dimension between the channel width P1 and the channel height P2 can be evaluated by the analysis results of the response surface diagram. The selection principle is that the front bearing temperature P4, which is approximately 308 K, is the preferred design dimension reference frame. Thus, the blue region in the diagram is employed as the selection region, the channel width P1 is 7.0 mm~8.0 mm, and the channel height is 3.5–4.5 mm. The convenience of machining and the cost must be considered in the selection of the final channel width P1 and channel width P2.

Three preferred dimension parameter combinations can be obtained by the optimization simulation, as shown in

Table 6 and

Figure 13. The cooling channel can be evaluated based on the actual design constraints. The lowest front bearing temperature can be obtained with the three groups of parameters.

This optimal design is admitted into the initial stage of design; the time and cost of trial and error can be substantially reduced, and the relative relationships among variables can be obtained from the simulation results. The design is based on a systematic method. The optimal dimensions of the front bearing cooling channel are shown in

Table 7. Considering the design convenience, the first group of parameters is selected as the optimal dimension design, and the cooling channel wall temperature is lower than the original design channel (

Figure 3a) by 25.9 °C. Use of the optimal design can reduce the wall temperature by 7.1 °C compared with sole use of the cooling channel simulation.

3.3. Validation of Cooling Channel Optimization Design

From the dimension optimization of the front bearing by simulation, the cooling channel width of 7.5 mm and height of 4.5 mm have the best effect on the cooling efficiency. In this study, thermal deformation measurement experiments were performed to verify the optimized design of the front bearing cooling channel.

To verify the cooling channel optimization design for the front bearing, the thermal deformation measurement was performed for the original design and optimized design of the cooling channel. The experimental conditions include: (1) the rotational speed of spindle was 12,500 rpm, and the measurement experiment was completed when the horizontal machine tool reached the thermal steady state; (2) the coolant system of the machine tool operated simultaneously with the machine tool, and the cooling method of the coolant system was temperature tracking cooling. The temperature was adjusted by the preset temperature, which was set to 2 °C lower than the environment temperature in this study. In the measurement experiments, the main data that were measured include the front bearing temperature, rear bearing temperature, environment temperature, cooling oil temperature, and thermal deformation of spindle. The front bearing temperature and rear bearing temperature are the data that can be obtained by the controller of the horizontal machine tool. However, the temperature sensor and thermal deformation measurement system had slight steady-state errors due to external factors. To accurately define the steady state of the horizontal machine tool, the difference was calculated every 5 min and then the average was calculated. The total experimental time was 300 min, and 60 intervals were utilized for analyzing the thermal deformation trend. The thermal stability was defined by the following equation.

where

TDR is the thermal deformation rate,

TD is the thermal deformation,

is the time interval, and

n indicates the

nth time step. The thermal deformation rate represents the difference in thermal deformation between the (

n + 1)-th time step and the

nth time step with a time interval of

. To determine the thermal steady state of the spindle, a criterion of 0.01 µm/min was defined. While the thermal deformation rate was less than this criterion value, the spindle was considered to attain a thermal steady thermal state.

The measurement results of the cooling channel before the dimension optimization was performed are shown in

Figure 14. The environment temperature rose from 29.6 °C to 31.3 °C, the temperature difference was ±0.85 °C, and the average rate of variation in environment temperature was 0.0055 °C/min. During the 300 min of experimental time, the initial cooling oil temperature of the coolant system was 28.9 °C, the maximum oil temperature was 31.5 °C, the minimum was 27.4 °C, and the difference was 4.1 °C. Because the coolant system supplied a constant oil flow rate to the cooling channel of the rotating spindle, the bearing, and motor generating heat during operation, the cooling oil flow rate of the coolant system was insufficient for effectively cooling the heating source. Therefore, a large temperature difference is probable. The maximum temperature of the cooling oil occurred at 185 min, which was close to the steady-state time of the spindle. The minimum temperature of the cooling oil occurred at 2.6 min. During the initial operation of the spindle, the heat generation was not high. When the initial supply temperature of the cooling oil was lower than the bearing temperature by 0.5 °C and the coolant system continuously cooled the cooling oil, the temperature of the cooling oil dropped after the spindle was in operation for a period of time. The machine tool reached a steady state at 185.3 min, and the variation rate in the thermal deformation was within ±0.01 μm/min. The maximum thermal deformation after the steady state was 53.8 μm.

The initial temperature of the front bearing before the operation of the spindle was 29.4 °C. In the initial operation of the spindle, due to the cooling effect of the coolant system, the front bearing temperature at 0.4 min of spindle operation was reduced from 29.4 °C to 29.1 °C, which was reduced by 0.3 °C and 1.02%. From 0 to 0.4 min of spindle operation, the temperature variation of the front bearing was 0.3 °C, and the thermal deformation of the spindle increased from 0 μm to 7.6 μm. However, the thermal deformation of the spindle was 6.8 μm at 29.1 °C of the front bearing temperature, which means that the thermal deformation of the spindle was reduced as the front bearing temperature drops. When the machine tool reached a steady state, the maximum temperature of the front bearing was 35.2 °C, and the temperature was increased by 5.8 °C. The initial temperature of the rear bearing before the operation of the spindle was 29.6 °C, and the difference between this temperature and the front bearing temperature was 0.2 °C. The rear bearing of the horizontal machine tool was sealed inside the spindle, no environmental convection occurred, and the measurement errors are summed. Because the rear bearing was not designed with a cooling channel, during the initial operation of the spindle, the rear bearing was not cooled, and the initial temperature of the rear bearing increased from 30 °C to 45.5 °C, i.e., the temperature increased by 15.5 °C (51.7%). Based on these results, the rear bearing without a cooling channel required a longer thermal steady-state time than the front bearing, and the maximum temperature of the rear bearing occurred at 300.5 min.

In this study, the experiments were performed with the original cooling channel design (refer to

Figure 3a). The required steady state time of the horizontal machine tool was approximately 3 h at a spindle rotational speed of 12,500 rpm. In addition, the thermal deformation was 53.8 μm, and the maximum temperature of the front bearing was 35.2 °C, which is an increase of 5.8 °C.

To validate the benefit of cooling channel dimension optimization, the experiments were performed with the same spindle operating condition; the results are shown in

Figure 15. The results indicate that the ambient temperature rose from an initial temperature of 30.2 °C to 30.9 °C. The temperature difference was ±0.35 °C, and the average rate of change in the ambient temperature was 0.0017 °C/min. The maximum temperature of the cooling oil occurred at 129.4 min, which is close to the required spindle steady-state time. The minimum temperature of the cooling oil occurred at 1.9 min. In the initial operation of the spindle, the heat generation was not high. When the initial supply temperature of the cooling oil was lower than the bearing temperature by 0.5 °C and the coolant system continuously cooled the cooling oil, the temperature of the cooling oil dropped after the spindle was in operation for a period of time. The machine tool reached a steady state at 132.6 min, and the variation rate in thermal deformation was within ±0.01 μm/min. The maximum thermal deformation was 30.9 μm. The optimal design of a cooling channel can shorten the required steady-state time of the machine tool by 52.7 min from 185.3 min to 132.6 min. The steady-state time of a machine tool can be reduced by 28.4%. The spindle thermal deformation decreased by 22.9 μm from 53.8 μm to 30.9 μm, and the accuracy of the spindle was enhanced by 42.6%.

The initial temperature of the front bearing before the operation of the spindle was 30.3 °C. During the initial operation of the spindle, due to the cooling effect of the coolant system, the front bearing temperature at 0.2 min of spindle operation decreased from 30.3 °C to 30.1 °C, which is a reduction of 0.2 °C (decrement of 0.7%). From 0 to 0.2 min of spindle operation, the temperature variation of the front bearing was 0.2 °C. The thermal deformation of the spindle increased from 0 μm to 7.1 μm, but the thermal deformation of the spindle was 6.9 μm at 30.1 °C of the front bearing temperature. The thermal deformation of the spindle decreased as the front bearing temperature decreased. When the machine tool reached a steady state, the maximum temperature of the front bearing was 32.9 °C, and the temperature was increased by 1.8 °C. The initial temperature of the rear bearing before operation of the spindle was 30.7 °C, and the difference between this temperature and the front bearing temperature was 0.4 °C, which is the same as the result of the original cooling channel design (

Figure 3a). Because the rear bearing was not designed with a cooling channel, during the initial operation of the spindle, the rear bearing was not cooled, the initial temperature of the rear bearing increased from 30.7 °C to 38.8 °C, and the temperature increased by 8.1 °C (26.4%). The rear bearing temperature rise was less than half of the original cooling channel design, and the temperature rise was reduced from 15.5 °C to 8.1 °C. The results indicate that the rear bearing without a cooling channel requires a longer thermal steady-state time than the front bearing, and the maximum temperature of the rear bearing occurred at 177.2 min.

Based on the results, the built-in spindle with the optimal design of the cooling channel dimensions can reduce the required thermal steady-state time. The cooling efficiency inside the spindle is enough, and the heat generated by the bearing or motor can be rapidly carried away. Therefore, the heat transfer can be avoided from the internal structure of the spindle to the spindle nose and from the spindle nose to the upright column and base of the machine tool to ensure that the thermal steady state can be rapidly reached and the thermal deformation can be effectively decreased. According to the temperature variations of the front and rear bearings, the temperature of the cooling channel with dimension optimization can be reduced by more than 50%. The cooling efficiency by the cooling channel with dimension optimization can be enhanced, and the spindle thermal deformation can be reduced. In addition, the required steady-state time of the machine can be reduced, which decreases the warm-up time. The productivity of the machine tool spindle with cooling channel dimension optimization can be improved effectively.

In addition,

Table 8 shows the experimental results of the cooling channel dimension optimization.

3.4. Practical Machining Accuracy Validation

In previous experimental results, the cooling efficiency of the cooling channel, spindle thermal deformation, and required steady-state time of the machine tool were improved by the cooling channel dimension optimization design. However, the experimental results were obtained in static experiments, which cannot represent the dynamic conditions in the actual machining process. Therefore, the actual machining verification was conducted to understand the effect of the cooling channel with optimization on the practical machining accuracy.

The verification experiment aims to discuss the errors in the flatness and surface roughness of a workpiece after 3 h of machining time. Due to the increase in thermal deformation, the flatness and surface roughness of machining may be reduced to verify the machining effect of the cooling channel dimension optimization. The flatness and surface roughness of the machining experiment was conducted on the workpiece by a 6 mm end mill tool with a spindle rotational speed of 10,000 rpm. The dimension of the workpiece is 100 mm × 50 mm, and the material of the workpiece is S45C steel, as shown in

Figure 16.

The machining error results are shown in

Table 9. The flatness machined by the original cooling channel design was 9.3 μm, whereas the flatness by the cooling channel dimension optimization was 3.6 μm, and the cooling channel dimension optimization can be enhanced with a flatness error of 5.7 μm. The flatness of a workpiece with cooling channel dimension optimization can be improved effectively by 61.3% compared with the original cooling channel design. The centerline average roughness

, maximum height roughness

, and ten-point average roughness

with cooling channel dimension optimization were 0.24 μm, 6.11 μm, and 1.25 μm, respectively. Compared with the original cooling channel design,

,

, and

with cooling channel dimension optimization are lower than 0.26 μm, 2.83 μm, and 0.72 μm, respectively.

,

, and

can be effectively enhanced by 52%, 31.7%, and 36.5%, respectively.

In the practical machining verification, the improved spindle cooling channel increased the cooling efficiency, reduced spindle thermal deformation, shortened the complete machine warm-up time, increased the machine operating rate, and in an actual cutting application, substantially improved the flatness and surface roughness of a workpiece. To summarize the findings, the improvement in the spindle cooling channel can improve the actual machining accuracy and shorten the required warm-up time of machine tools.