High-k Polymer Nanocomposite Materials for Technological Applications

Abstract

Featured Application

Abstract

1. Background

2. High-k Dielectric Polymers

3. High-k Dielectric Nanoparticles

4. High-k Dielectric Nanocomposites

5. Future Perspectives and Challenges

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| BNNs | Boron nitride nano-sheets |

| CNF | Cellulose nanofibrils |

| CNTs | Carbon nanotubes |

| DGE-BA | Diglycidyl ether - Bisphenol-A |

| MOSFETs | Metal–oxide–semiconductor field-effect transistors |

| MWCNTs | Multi-walled carbon nanotubes |

| OFETs | Organic field-effect transistors |

| PC | Polycarbonate |

| PDMS | Polydimethylsiloxane |

| PET | Polyethylene terephthalate |

| PP | Polypropylene |

| PPC | Polypropylene carbonate |

| PTFE | Polytetrafluoroethylene |

| PVC | Polyvinyl chloride |

| PVA | Polyvinyl alcohol |

| P(VDF-TrFE-CFE) | Poly(vinylidene fluoride-trifluoroethylene chlorofluoroethylene) |

| PVDF | Polyvinylidene fluoride |

| PVPy | Polyvinylpyrrolidone |

| RAFT | Reversible addition–fragmentation chain transfer |

| RF | Radio frequency |

| SMECH | Sigma mixing, extrusion, calendering, followed by hot pressing |

| TFTs | Thin-film transistors |

References

- Panyukov, S. Theory of Flexible Polymer Networks: Elasticity and Heterogeneities. Polymers 2020, 12, 767. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Peng, L.; Ding, Y.; Zhao, Y.; Yu, G. Nanostructured conductive polymers for advanced energy storage. Chem. Soc. Rev. 2015, 44, 6684–6696. [Google Scholar] [CrossRef] [PubMed]

- Lopez, J.; Mackanic, D.G.; Cui, Y.; Bao, Z. Designing polymers for advanced battery chemistries. Nat. Rev. Mater. 2019, 4, 312–330. [Google Scholar] [CrossRef]

- Carothers, W.H. Polymerization. Chem. Rev. 1931, 8, 353–426. [Google Scholar] [CrossRef]

- Qiu, Z.; Hammer, B.A.G.; Müllen, K. Conjugated polymers—Problems and promises. Prog. Polym. Sci. 2020, 100, 101179. [Google Scholar] [CrossRef]

- Chang, A.B.; Bates, F.S. The ABCs of Block Polymers. Macromolecules 2020, 53, 2765–2768. [Google Scholar] [CrossRef]

- Tran, H.; Feig, V.R.; Liu, K.; Zheng, Y.; Boa, Z. Polymer Chemistries Underpinning Materials for Skin-Inspired Electronics. Macromolecules 2019, 52, 3965–3974. [Google Scholar] [CrossRef]

- Zhu, T.; Zheng, L.; Yi, C.; Yu, T.; Cao, Y.; Liu, L.; Gong, X. Two-Dimensional Conjugated Polymeric Nanocrystals for Organic Electronics. ACS Appl. Electron. Mater. 2019, 1, 1458–1464. [Google Scholar] [CrossRef]

- Kwon, Y.-T.; Yune, S.-J.; Song, Y.; Yeo, W.-H.; Choa, Y.-H. Green Manufacturing of Highly Conductive Cu2O and Cu Nanoparticles for Photonic-Sintered Printed Electronics. ACS Appl. Electron. Mater. 2019, 1, 2069–2075. [Google Scholar] [CrossRef]

- Chon, J.; Ye, S.; Cha, K.J.; Lee, S.C.; Koo, Y.S.; Jung, J.H.; Kwon, Y.K. High-κ Dielectric Sol−Gel Hybrid Materials Containing Barium Titanate Nanoparticles. Chem. Mater. 2010, 22, 5445–5452. [Google Scholar] [CrossRef]

- Lu, J.; Moon, K.; Wong, C.P. High-k Polymer Nanocomposites as Gate Dielectrics for Organic Electronics Applications. In Proceedings of the 2007 Proceedings 57th Electronic Components and Technology Conference, Reno, NV, USA, 29 May–1 June 2007; pp. 453–457. [Google Scholar] [CrossRef]

- Billah, S.M. Dielectric Polymers. In Functional Polymers; Jafar Mazumder, M., Sheardown, H., Al-Ahmed, A., Eds.; Polymers and Polymeric Composites: A Reference Series; Springer: Cham, Swizerland, 2018. [Google Scholar] [CrossRef]

- Li, Y.; Wang, H.; Shi, Z.; Mei, J.; Wang, X.; Yan, D.; Cui, Z. Novel high-k polymers as dielectric layers for organic thin-film transistors. Polym. Chem. 2015, 6, 6651–6658. [Google Scholar] [CrossRef]

- Clark, R.D. Emerging Applications for High K Materials in VLSI Technology. Materials (Basel) 2014, 7, 2913–2944. [Google Scholar] [CrossRef] [PubMed]

- You, Y.; Zhan, C.; Tu, L.; Wang, Y.; Hu, W.; Wei, R.; Liu, X. Polyarylene Ether Nitrile-Based High- κ Composites for Dielectric Applications. Int. J. Polym. Sci. 2018, 2018, 5161908. [Google Scholar] [CrossRef]

- Chiang, C.K.; Popielarz, R. Polymer Composites with High Dielectric Constant. Ferroelectrics 2002, 275, 1–9. [Google Scholar] [CrossRef]

- Wallace, R.M. Dielectric Materials for Microelectronics. In Springer Handbook of Electronic and Photonic Materials; Kasap, S., Capper, P., Eds.; Springer Handbooks; Springer: Cham, Swizerland, 2017. [Google Scholar] [CrossRef]

- Dutta, K.; De, S.K. Electrical conductivity and dielectric properties of SiO2 nanoparticles dispersed in conducting polymer matrix. J. Nanopart. Res. 2007, 9, 631–638. [Google Scholar] [CrossRef]

- Kumar, B.; Kaushik, B.K.; Negi, Y.S. Perspectives and challenges for organic thin film transistors: Materials, devices, processes and applications. J. Mater. Sci. Mater. Electron. 2014, 25, 1–30. [Google Scholar] [CrossRef]

- Liu, S.; Xiu, S.; Shen, B.; Zhai, J.; Kong, L.B. Dielectric Properties and Energy Storage Densities of Poly(vinylidenefluoride) Nanocomposite with Surface Hydroxylated Cube Shaped Ba0.6Sr0.4TiO3 Nanoparticles. Polymers 2016, 8, 45. [Google Scholar] [CrossRef]

- Li, B.; Salcedo-Galan, F.; Xidas, P.I.; Xidas, E. Improving Electrical Breakdown Strength of Polymer Nanocomposites by Tailoring Hybrid-Filler Structure for High-Voltage Dielectric Applications. ACS Appl. Nano Mater. 2018, 1, 4401–4407. [Google Scholar] [CrossRef]

- Campo, E.A. 4—Electrical Properties of Polymeric Materials. In Selection of Polymeric Materials; Plastics Design Library: William Andrew Inc.; Elsevier: Norwich, NY, USA, 2008; pp. 141–173. [Google Scholar] [CrossRef]

- Song, Y.; Shen, Y.; Liu, H.; Lin, Y.; Li, M.; Nan, C.-W. Improving the dielectric constants and breakdown strength of polymer composites: Effects of the shape of the BaTiO3 nanoinclusions, surface modification and polymermatrix. J. Mater. Chem. 2012, 22, 16491–16498. [Google Scholar] [CrossRef]

- Henes, G. 6—Metal–polymer nanocomposites. In Advances in Polymer Nanocomposites; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2012; pp. 164–177. [Google Scholar] [CrossRef]

- Carpi, F.; Gallone, G.; Galantine, F.; Rossi, D.D. Chapter 6—Enhancing the Dielectric Permittivity of Elastomers. In Dielectric Elastomers as Electromechanical Transducers: Fundamentals, Materials, Devices, Models and Applications of an Emerging Electroactive Polymer Technology; Elsevier: Amsterdam, The Netherlands, 2008; pp. 51–68. [Google Scholar] [CrossRef]

- Karlsson, M. Investigation of the Dielectric Breakdown Strength of Polymer Nanocomposites. Master’s Thesis, Uppasala University, Uppsala, Sweden, June 2014. UPTEC Q14 009. Available online: https://www.diva-portal.org/smash/get/diva2:731544/FULLTEXT01.pdf (accessed on 1 May 2020).

- Zulkifli, A. Polymer Dielectric Materials. Dielectric Material; Silaghi, M.A., Ed.; IntechOpen: London, UK, 2012. [Google Scholar] [CrossRef]

- Fiorenza, P.; Giannazzo, F.; Roccaforte, F. Characterization of SiO2/4H-SiC Interfaces in 4H-SiC MOSFETs: A Review. Energies 2019, 12, 2310. [Google Scholar] [CrossRef]

- Bieniek, T.; Wojtkiewicz, A.; Lukasiak, L.; Beck, R.B. Silicon dioxide as passivating, ultrathin layer in MOSFET gate stacks. In Proceedings of the 3rd International Conference ‘Novel Applications of Wide Bandgap Layers’ Abstract Book (Cat. No.01EX500), Zakopane, Poland, 26–30 June 2001; pp. 163–164. [Google Scholar] [CrossRef]

- Liou, J.J.; Ortiz-Conde, A.; Garcia-Sanchez, F. MOSFET physics and modeling. In Analysis and Design of Mosfets; Springer: Boston, MA, USA, 1998. [Google Scholar] [CrossRef]

- Dubey, P.K. Chapter 1—Tunnel FET: Devices and Circuits. Nanoelectronics, Devices, Circuits and Systems, Advanced Nanomaterials; Elsevier: Amsterdam, The Netherlands, 2019; pp. 3–25. [Google Scholar] [CrossRef]

- Lucovsky, G.; Misra, V. Deposited Gate Dielectrics. Encyclopedia of Materials: Science and Technology, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2001; pp. 2070–2077. [Google Scholar]

- Tan, D.Q. Review of Polymer-Based Nanodielectric Exploration and Film Scale-Up for Advanced Capacitors. Adv. Funct. Mater. 2019, 1808567. [Google Scholar] [CrossRef]

- Thakur, V.K.; Gupta, R.K. Recent Progress on Ferroelectric Polymer-Based Nanocomposites for High Energy Density Capacitors: Synthesis, Dielectric Properties, and Future Aspects. Chem. Rev. 2016, 116, 4260–4317. [Google Scholar] [CrossRef]

- Luo, H.; Zhou, X.; Ellingford, C.; Zhang, Y.; Chen, S.; Zhou, K.; Zhang, D.; Bowen, C.R.; Wan, C. Interface design for high energy density polymer nanocomposites. Chem. Soc. Rev. 2019, 48, 4424–4465. [Google Scholar] [CrossRef] [PubMed]

- Siddabattuni, S.; Scuman, T.P.; Dogan, F. Dielectric Properties of Polymer–Particle Nanocomposites Influenced by Electronic Nature of Filler Surfaces. ACS Appl. Mater. Interfaces 2013, 5, 1917–1927. [Google Scholar] [CrossRef] [PubMed]

- Popielarz, R.; Chiang, C.K.; Nozaki, R.; Obrzut, J. Dielectric Properties of Polymer/Ferroelectric Ceramic Composites from 100 Hz to 10 GHz. Macromolecules 2001, 34, 5910–5915. [Google Scholar] [CrossRef]

- Li, L. Dielectric properties of aged polymers and nanocomposites. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2011. 12128. Available online: https://lib.dr.iastate.edu/etd/12128 (accessed on 1 May 2020).

- Tang, D.; Zhang, J.; Zhou, D.; Zhao, L. Influence of BaTiO3 on damping and dielectric properties of filled polyurethane/unsaturated polyester resin interpenetrating polymer networks. J. Mater. Sci. 2005, 40, 3339–3345. [Google Scholar] [CrossRef]

- Yazdanian, S.M.; Marohn, J.A.; Loring, R.F. Dielectric fluctuations in force microscopy: Noncontact friction and frequency jitter. J. Chem. Phys. 2008, 128, 224706. [Google Scholar] [CrossRef]

- Joshi, S.; Hung, S.; Vengallatore, S. Design strategies for controlling damping in micromechanical and nanomechanical resonators. EPJ Tech. Instrum. 2014, 1, 5. [Google Scholar] [CrossRef]

- Zhou, Y.; Han, S.-T.; Xu, Z.-X.; Yang, X.-B.; Ng, H.-P.; Huang, L.-B.; Roy, V.A.L. Functional high-k nanocomposite dielectrics for flexible transistors and inverters with excellent mechanical properties. J. Mater. Chem. 2012, 22, 14246–14253. [Google Scholar] [CrossRef]

- Ambrosio, R.; Carrillo, A.; Mota, M.L.; de la Torre, K.; Torrealba, R.; Moreno, M.; Vazquez, H.; Flores, J.; Vivaldo, I. Polymeric Nanocomposites Membranes with High Permittivity Based on PVA-ZnO Nanoparticles for Potential Applications in Flexible Electronics. Polymers (Basel) 2018, 10, 1370. [Google Scholar] [CrossRef]

- Cook, B.S.; Cooper, J.R.; Tentzeris, M. Multi-layer RF capacitors on flexible substrates utilizing inkjet printed dielectric polymers. IEEE Microw. Wirel. Compon. Lett. 2013, 23, 353–355. [Google Scholar] [CrossRef]

- Mikolajek, M.; Reinheimer, T.; Bohn, N.; Kohler, C.; Hoffmann, M.J.; Binder, J.R. Fabrication and Characterization of Fully Inkjet Printed Capacitors Based on Ceramic/Polymer Composite Dielectrics on Flexible Substrates. Sci. Rep. 2019, 9, 13324. [Google Scholar] [CrossRef] [PubMed]

- Michler, G.H.; Balta-Calleja, F.J. Mechanical Properties of Polymers based on Nanostructure and Morphology, 1st ed.; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar] [CrossRef]

- Prosa, M.; Bolognesi, M.; Fornasari, L.; Grasso, G.; Lopez-Sanchez, L.; Marabelli, F.; Toffanin, S. Nanostructured Organic/Hybrid Materials and Components in Miniaturized Optical and Chemical Sensors. Nanomaterials 2020, 10, 480. [Google Scholar] [CrossRef] [PubMed]

- Shih, C.-C.; Lee, W.-Y.; Chen, W.-C. Nanostructured materials for non-volatile organic transistor memory applications. Mater. Horiz. 2016, 3, 294–308. [Google Scholar] [CrossRef]

- Zeraati, A.S.; Mirkhani, S.A.; Sundararaj, U. Enhanced Dielectric Performance of Polymer Nanocomposites Based on CNT/MnO2 Nanowire Hybrid Nanostructure. J. Phys. Chem. C 2017, 121, 8327–8334. [Google Scholar] [CrossRef]

- Meng, X. An overview of molecular layer deposition for organic and organic–inorganic hybrid materials: Mechanisms, growth characteristics, and promising applications. J. Mater. Chem. A 2017, 5, 18326–18378. [Google Scholar] [CrossRef]

- Helgee, B.; Bjellheim, P. Electric breakdown strength of aromatic polymers: Dependence on film thickness and chemical structure. IEEE Trans. Electr. Insul. 1991, 26, 1147–1152. [Google Scholar] [CrossRef]

- Ieda, M. Dielectric Breakdown Process of Polymers. IEEE Trans. Electr. Insul. 1980, EI-15, 206–224. [Google Scholar] [CrossRef]

- Artbauer, J. Electric strength of polymers. J. Phys. D Appl. Phys. 1996, 29, 446. [Google Scholar] [CrossRef]

- Elanseralathan, K.; Thomas, M.J.; Nagabhushana, G.R. Breakdown of solid insulating materials under high frequency high voltage stress. In Proceedings of the 6th International Conference on Properties and Applications of Dielectric Materials, Xi’an, China, 21–26 June 2000; Volume 2, pp. 999–1001, (Cat. No.00CH36347). [Google Scholar] [CrossRef]

- Gadoum, A.; Gosse, B.; Gosse, J.P. Breakdown strength of impregnated polypropylene films aged under high a.c. fileds. Eur. Polym. J. 1997, 33, 1161–1166. [Google Scholar] [CrossRef]

- Dang, Z.-M.; Fan, L.-Z.; Shen, Y.; Nan, C.-W. Dielectric behavior of novel three-phase MWNTs/BaTiO3/PVDF composites. Mater. Sci. Eng. B 2003, 103, 140–144. [Google Scholar] [CrossRef]

- Dang, Z.-M.; Wu, J.-B.; Fan, L.-Z.; Nan, C.-W. Dielectric behavior of Li and Ti co-doped NiO/PVDF composites. Chem. Phys. Lett. 2003, 376, 389–394. [Google Scholar] [CrossRef]

- Zhou, W.; Zuo, J.; Ren, W. Thermal conductivity and dielectric properties of Al/PVDF composites. Compos. Part A Appl. Sci. Manufac. 2012, 43, 658–664. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, Y.; Xiang, Y.; Wang, G.; Xu, H. Bi2S3–BaTiO3/PVDF three-phase composites with high dielectric permittivity. J. Mater. Chem. 2009, 19, 2058–2061. [Google Scholar] [CrossRef]

- Bottino, A.; Capannelli, G.; Comite, A. Preparation and characterization of novel porous PVDF-ZrO2 composite membranes. Desalination 2002, 146, 35–40. [Google Scholar] [CrossRef]

- Xu, P.; Fu, W.; Luo, X.; Ding, Y. Enhanced dc conductivity and conductivity relaxation in PVDF/ionic liquid composites. Mater. Lett. 2017, 206, 60–63. [Google Scholar] [CrossRef]

- Lorenz, H.; Despont, M.; Fahrni, N.; LaBianca, N.; Renaud, P.; Vettiger, P. SU-8: A low-cost negative resist for MEMS. J. Micromech. Microeng. 1997, 7, 121. [Google Scholar] [CrossRef]

- Del Campo, A.; Greiner, C. SU-8: A photoresist for high-aspect-ratio and 3D submicron lithography. J. Micromech. Microeng. 2007, 17, R81. [Google Scholar] [CrossRef]

- Juodkazis, S.; Mizeikis, V.; Seet, K.K.; Miwa, M.; Misawa, H. Two-photon lithography of nanorods in SU-8 photoresist. Nanotechnology 2005, 16, 846. [Google Scholar] [CrossRef]

- Xia, H.; Ueki, T.; Hirai, T. Electrical Response and Mechanical Behavior of Plasticized PVC Actuators. Adv. Mater. Res. 2009, 79–82, 2063–2066. [Google Scholar] [CrossRef]

- Ogawa, N.; Hashimoto, M.; Takasaki, M.; Hirai, T. Characteristics evaluation of PVC gel actuators. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, St. Louis, MO, USA, 11–15 October 2009; pp. 2898–2903. [Google Scholar] [CrossRef]

- Bae, J.W.; Yeo, M.; Shin, E.-J.; Park, W.-H.; Lee, J.E.; Nam, B.-U.; Kim, S.-Y. Eco-friendly plasticized poly(vinyl chloride)–acetyl tributyl citrate gels for varifocal lens. RSC Adv. 2015, 5, 94919–94925. [Google Scholar] [CrossRef]

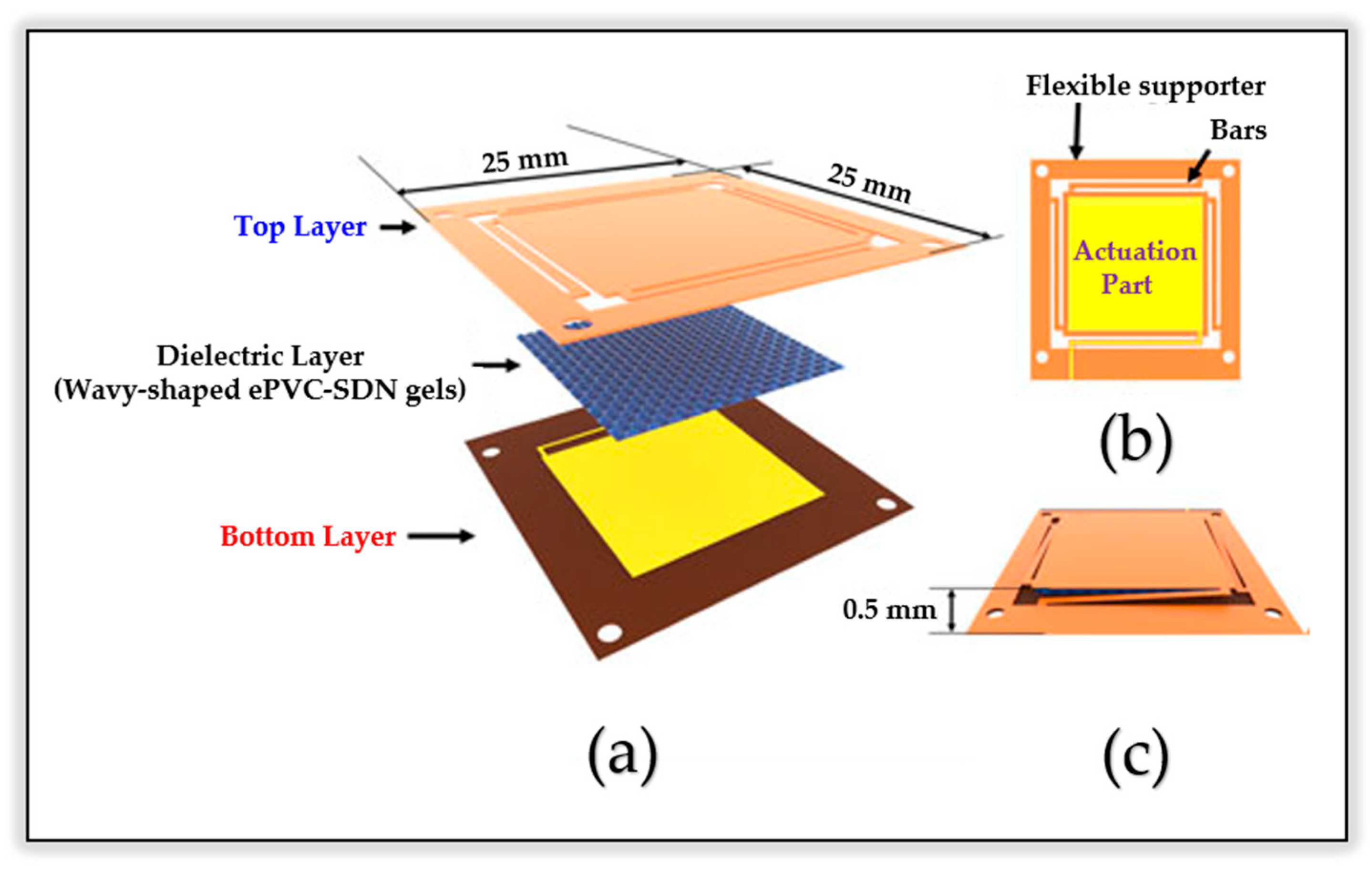

- Park, W.-H.; Shin, E.-J.; Yoo, Y.; Choi, S.; Kim, S.-H. Soft Haptic Actuator Based on Knitted PVC Gel Fabric. IEEE Trans. Ind. Electron. 2020, 67, 677–685. [Google Scholar] [CrossRef]

- Shin, E.-J.; Park, W.-H.; Kim, S.-Y. Fabrication of a High-Performance Bending Actuator Made with a PVC Gel. Appl. Sci. 2018, 8, 1284. [Google Scholar] [CrossRef]

- Park, W.-H.; Shin, E.-J.; Yun, S.; Kim, S.-Y. An Enhanced Soft Vibrotactile Actuator Based on ePVC Gel with Silicon Dioxide Nanoparticles. IEEE Trans. Haptics 2018, 11, 22–29. [Google Scholar] [CrossRef] [PubMed]

- Hasan, S.M.; Thompson, R.S.; Emery, H.; Nathan, A.L.; Weems, A.C.; Zhou, F.; Monroe, M.B.B.; Maitland, D.J. Modification of shape memory polymer foams using tungsten, aluminum oxide, and silicon dioxide nanoparticles. RSC Adv. 2016, 6, 918–927. [Google Scholar] [CrossRef] [PubMed]

- Ahmadi, M.; Phonthammachai, N.; Shuan, T.H.; White, T.J.; Mathews, N.; Mhaisalkar, S.G. Solution processable nanoparticles as high-k dielectric for organic field effect transistors. Org. Electron. 2010, 11, 1660–1667. [Google Scholar] [CrossRef]

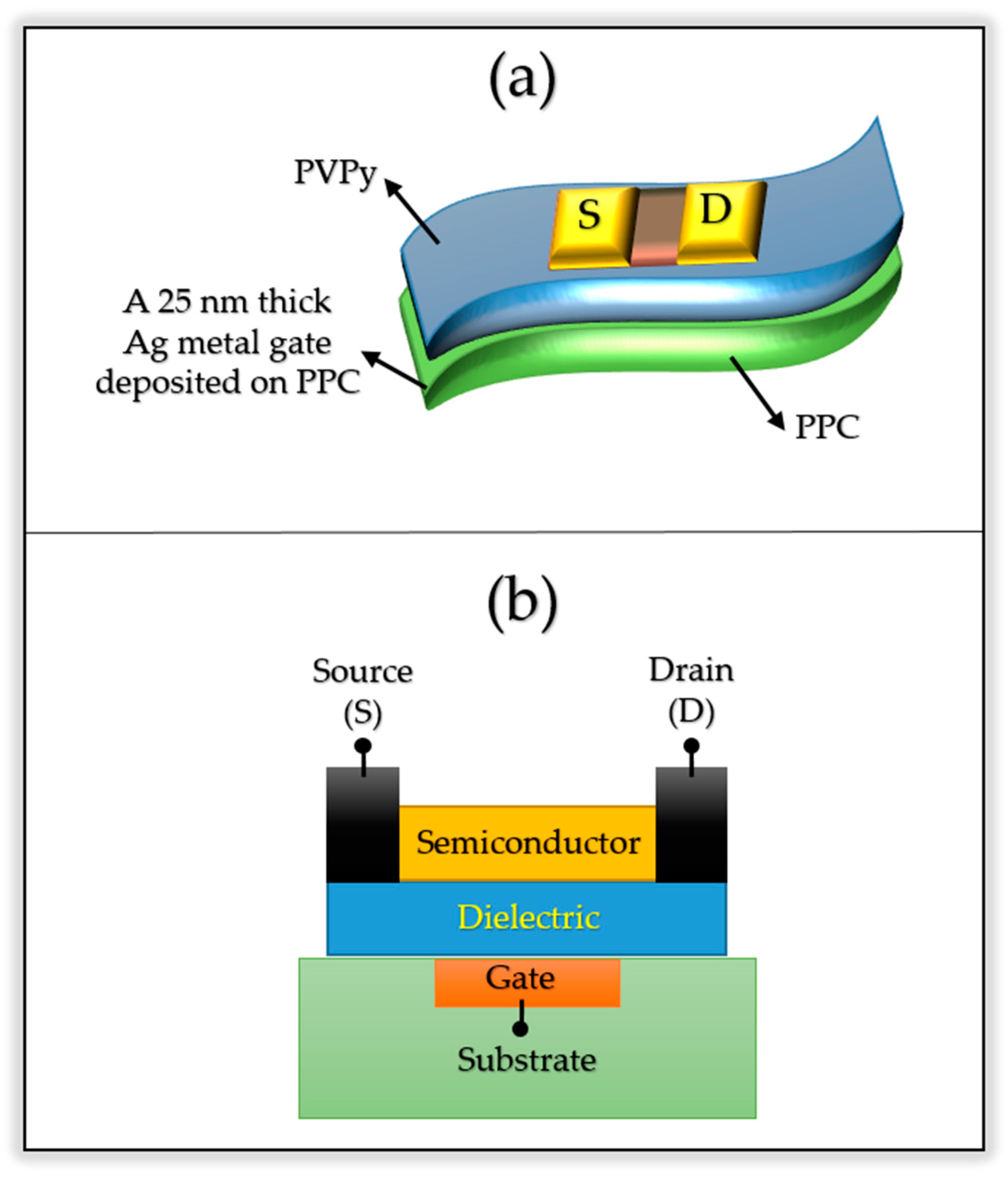

- Jeong, J.W.; Hwang, H.S.; Choi, D.; Ma, B.C.; Jung, J.; Chang, M. Hybrid Polymer/Metal Oxide Thin Films for High Performance, Flexible Transistors. Micromachines 2020, 11, 264. [Google Scholar] [CrossRef]

- Ellingford, C.; Zhang, R.; Wemyss, A.M.; Bowen, C.; McNally, T.; Figiel, Ł.; Wan, C. Intrinsic Tuning of Poly(styrene–butadiene–styrene)-Based Self-Healing Dielectric Elastomer Actuators with Enhanced Electromechanical Properties. ACS Appl. Mater. Interfaces 2018, 10, 38438–38448. [Google Scholar] [CrossRef]

- Kang, B.; Song, E.; Lee, S.B.; Chae, B.-G.; Ahn, H.; Cho, K. Stretchable Polymer Gate Dielectric with Segmented Elastomeric Network for Organic Soft Electronics. Chem. Mater. 2018, 30, 6353–6360. [Google Scholar] [CrossRef]

- Lee, D.; Yung, Y.; Ha, M.; Ahn, H.; Lee, K.H.; Seo, M. High-conductivity electrolyte gate dielectrics based on poly(styrene-co-methyl methacrylate)/ionic liquid. J. Mater. Chem. C 2019, 7, 6950–6955. [Google Scholar] [CrossRef]

- Schröder, S.; Strunskus, T.; Rehders, S.; Gleason, K.K.; Faupel, F. Tunable polytetrafluoroethylene electret films with extraordinary charge stability synthesized by initiated chemical vapor deposition for organic electronics applications. Sci. Rep. 2019, 9, 2237. [Google Scholar] [CrossRef] [PubMed]

- Murali, K.P.; Rajesh, S.; Prakash, O.; Kulkarni, A.R.; Ratheesh, R. Preparation and properties of silica filled PTFE flexible laminates for microwave circuit applications. Compos. Part A 2009, 40, 1179–1185. [Google Scholar] [CrossRef]

- Rajesh, S.; Nisa, V.S.; Murali, K.P.; Ratheesh, R. Microwave dielectric properties of PTFE/rutile nanocomposites. J. Alloys Compd. 2009, 477, 677–682. [Google Scholar] [CrossRef]

- Rullyani, C.; Sung, C.-F.; Lin, H.-C.; Chu, C.-W. Flexible Organic Thin Film Transistors Incorporating a Biodegradable CO2-Based Polymer as the Substrate and Dielectric Material. Sci. Rep. 2018, 8, 8146. [Google Scholar] [CrossRef] [PubMed]

- Gray, B.L. Polymer Nanocomposites for Flexible and Wearable Fluidic and Biomedical Microdevices. In Proceedings of the IEEE 13th Nanotechnology Materials and Devices Conference (NMDC), Portland, OR, USA, 14–17 October 2018; pp. 1–2. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, L.; Wang, C.; Yang, F.; Ren, X.; Zhang, X.; Dong, H.; Hu, W. Organic crystalline materials in flexible electronics. Chem. Soc. Rev. 2019, 48, 1492–1530. [Google Scholar] [CrossRef]

- Silva, S.R.P.; Beliatis, M.J.; Jayawardena, I.; Mills, C.; Rhodes, R.; Rozanski, L. Hybrid and nanocomposite materials for flexible organic electronics applications. In Handbook of Flexible Organic Electronics; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Zhang, X.; Yan, X.; He, X.; Wei, H.; Long, J.; Guo, J.; Gu, H.; Yu, J.; Liu, J.; Ding, D.; et al. Electrically Conductive Polypropylene Nanocomposites with Negative Permittivity at Low Carbon Nanotube Loading Levels. ACS Appl. Mater. Interfaces 2015, 7, 6125–6138. [Google Scholar] [CrossRef]

- Wang, Y.; Xing, C.; Guan, J.; Li, Y. Towards Flexible Dielectric Materials with High Dielectric Constant and Low Loss: PVDF Nanocomposites with both Homogenously Dispersed CNTs and Ionic Liquids Nanodomains. Polymers 2017, 9, 562. [Google Scholar] [CrossRef]

- Shehzad, K.; Haq, A.U.; Ahmad, S.; Mumtaz, M.; Hussain, T.; Mujahid, A.; Shah, A.T.; Choudhry, M.Y.; Khokhar, I.; Hassan, S.U.; et al. All-organic PANI–DBSA/PVDF dielectric composites with unique electrical properties. J. Mater. Sci. 2013, 48, 3737–3744. [Google Scholar] [CrossRef]

- Arshad, A.N.; Wahid, M.H.M.; Rusop, M.; Majid, W.H.A.; Subban, R.H.Y.; Rozana, M.D. Dielectric and Structural Properties of Poly(vinylidene fluoride) (PVDF) and Poly(vinylidene fluoride-trifluoroethylene) (PVDFTrFE) Filled with Magnesium Oxide Nanofillers. J. Nanomater. 2019, 2019, 5961563. [Google Scholar] [CrossRef]

- Thomas, P.; Satapathy, S.; Dwarakanath, K.; Varma, K.B.R. Dielectric properties of poly(vinylidene fluoride)/CaCu3Ti4O12 nanocrystal composite thick films. eXPRESS Polym. Lett. 2010, 4, 632–643. [Google Scholar] [CrossRef]

- MacDonald, W.A.; Looney, M.K.; MacKerron, D.; Eveson, R.; Rakos, K. Designing and manufacturing substrates for flexible electronics. Plast. Rubber Compos. 2007, 37, 41–45. [Google Scholar] [CrossRef]

- Malik, A.; Kandasubramanian, B. Flexible Polymeric Substrates for Electronic Applications. Polym. Rev. 2018, 58, 630–667. [Google Scholar] [CrossRef]

- Kang, J.; Park, J.H.; Choi, D.-S.; Kim, D.H.; Kim, S.-Y.; Cho, J.H. Design of Wavy Ag Microwire Array for Mechanically Stable, Multimodal Vibrational Haptic Interface. Adv. Funct. Mater. 2019, 29, 1902703. [Google Scholar] [CrossRef]

- Mi, H.; Liu, C.-H.; Chang, T.-H.; Seo, J.-H.; Zhang, H.; Cho, S.J.; Behdad, N.; Ma, Z.; Yao, C.; Cai, Z.; et al. Characterizations of biodegradable epoxy-coated cellulose nanofibrils (CNF) thin film for flexible microwave applications. Cellulose 2016, 23, 1989–1995. [Google Scholar] [CrossRef]

- Zhang, Y.-H.; Karthikeyan, S.; Zhang, J. Polymer-Sandwich Ultra-Thin Silicon Platform for Flexible Electronics. Chin. Phys. Lett. 2016, 33, 066201. [Google Scholar] [CrossRef]

- Matarèse, B.F.E.; Feyen, P.L.C.; Falco, A.; Benfenati, F.; Lugli, P.; deMello, J.C. Use of SU8 as a stable and biocompatible adhesion layer for gold bioelectrodes. Sci. Rep. 2018, 8, 5560. [Google Scholar] [CrossRef]

- Yeo, H.G.; Jung, J.; Sim, M.; Jang, J.E.; Choi, H. Integrated Piezoelectric AlN Thin Film with SU-8/PDMS Supporting Layer for Flexible Sensor Array. Sensors 2020, 20, 315. [Google Scholar] [CrossRef]

- Shah, B.L.; Shertukde, V.V. Effect of Plasticizers on Mechanical, Electrical, Permanence, and Thermal Properties of Poly(vinyl chloride). J. Appl. Polym. Sci. 2003, 90, 3278–3284. [Google Scholar] [CrossRef]

- Mallakpour, S.; Shafiee, E. The synthesis of poly(vinyl chloride) nanocomposite films containing ZrO2 nanoparticles modified with vitamin B1 with the aim of improving the mechanical, thermal and optical properties. Des. Monomers Polym. 2017, 20, 378–388. [Google Scholar] [CrossRef]

- Ali, I.; Weimin, Y.; Xudong, L.; Ali, A.; Zhiwei, J.; Xie, P.; Dias, O.A.T.; Pervaiz, M.; Li, H.; Sain, M. Highly Electro-responsive Plasticized PVC/FMWCNTs Soft Composites: A Novel Flex Actuator with Functional Characteristics. Eur. Polym. J. 2020, 126, 109556. [Google Scholar] [CrossRef]

- Hwang, T.; Frank, Z.; Neubauer, J.; Kim, K.J. High-performance polyvinyl chloride gel artificial muscle actuator with graphene oxide and plasticizer. Sci. Rep. 2019, 9, 9658. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Hashimoto, M. PVC Gel based Artificial Muscles: Characterizations and Actuation Modular Constructions. Sens. Actuators A Phys. 2015, 233, 246–258. [Google Scholar] [CrossRef]

- Li, Y.; Guo, M.; Li, Y. Recent advances in plasticized PVC gels for soft actuators and devices: A review. J. Mater. Chem. C 2019, 7, 12991–13009. [Google Scholar] [CrossRef]

- Helps, T.; Taghavi, M.; Rossiter, J. Thermoplastic electroactive gels for 3D-printable artificial muscles. Smart Mater. Struct. 2018, 28, 085001. [Google Scholar] [CrossRef]

- Dong, T.Y.; Zhang, X.L.; Liu, T. Artificial muscles for wearable assistance and rehabilitation. Front. Inf. Technol. Electronic. Eng. 2018, 19, 1303–1315. [Google Scholar] [CrossRef]

- Li, Y.; Hashimoto, M. PVC Gel Soft Actuator-Based Wearable Assist Wear for Hip Joint Support during Walking. Smart Mater. Struct. 2017, 26, 125003. [Google Scholar] [CrossRef]

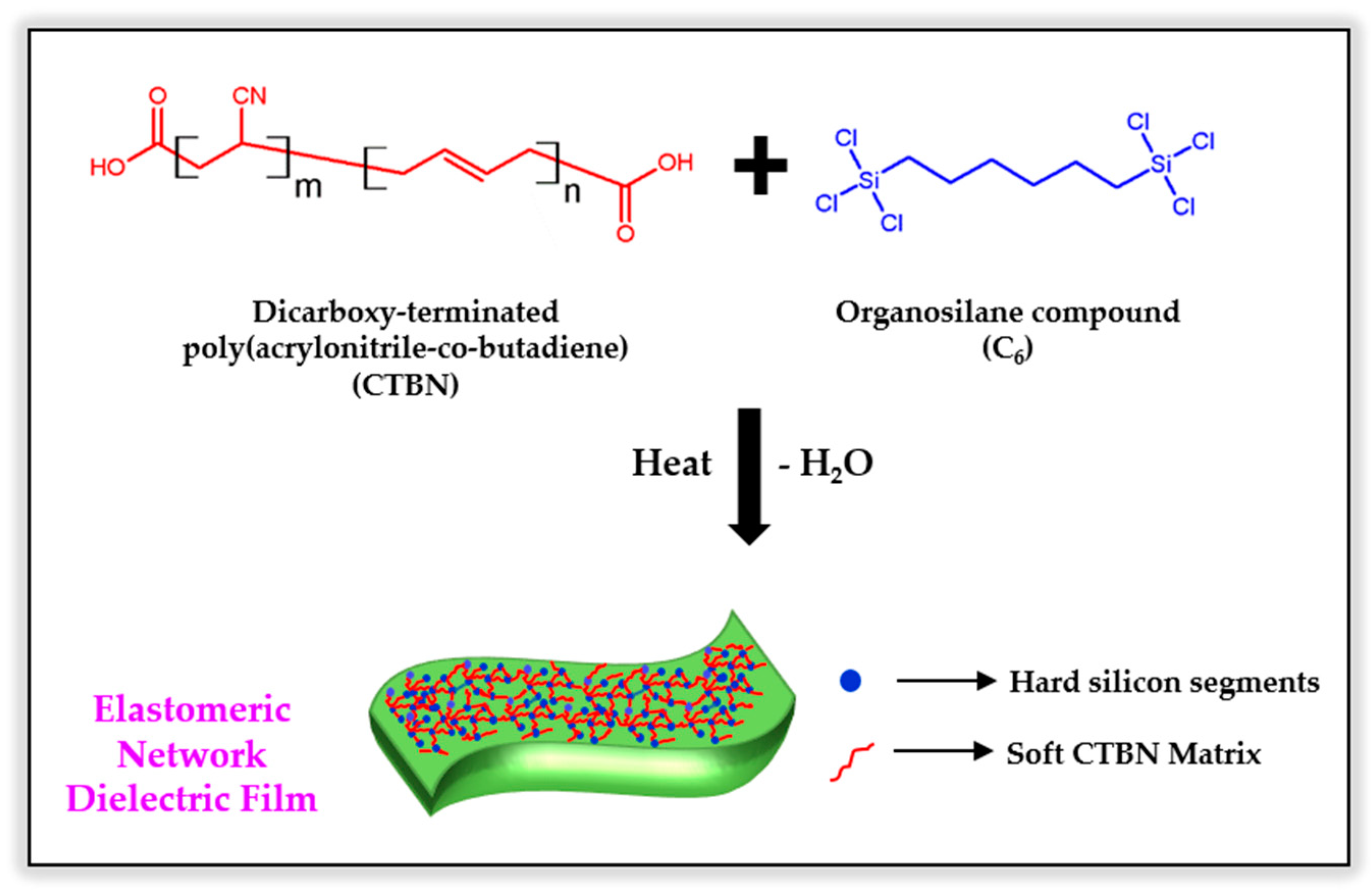

- Shi, L.; Yang, R.; Lu, S.; Jia, K.; Xiao, C.; Lu, T.; Wang, T.; Wei, W.; Tan, H.; Ding, S. Dielectric gels with ultra-high dielectric constant, low elastic modulus, and excellent transparency. NPG Asia Mater. 2018, 10, 821–826. [Google Scholar] [CrossRef]

- Jiang, J.; Li, Y.; Liu, J.; Huang, X.; Yuan, C.; Lou, X.W. Recent Advances in Metal Oxide-based Electrode Architecture Design for Electrochemical Energy Storage. Adv. Mater. 2012, 24, 5166–5180. [Google Scholar] [CrossRef]

- Yan, J.; Pietrasik, J.; Wypych-Puszkarz, A.; Ciekanska, M.; Matyjaszewski, K. Synthesis of High k Nanoparticles by Controlled Radical Polymerization (Chapter 3). In Solution-Processable Components for Organic Electronic Devices; Ulanski, J., Luszczynska, B., Matyjaszewski, K., Eds.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2019. [Google Scholar] [CrossRef]

- Jena, A.K.; Kulkarni, A.; Miyasaka, T. Halide Perovskite Photovoltaics: Background, Status, and Future Prospects. Chem. Rev. 2019, 119, 3036–3103. [Google Scholar] [CrossRef]

- Bhalla, A.S.; Guo, R.; Roy, R. The perovskite structure—a review of its role in ceramic science and technology. Mater. Res. Innov. 2000, 4, 3–26. [Google Scholar] [CrossRef]

- Karmaoui, M.; Ramana, E.V.; Tobaldi, E.M.; Lajaunie, L.; Graça, M.P.; Arenal, R.; Seabra, M.P.; Labrincha, J.A.; Pullar, R.C. High dielectric constant and capacitance in ultrasmall (2.5 nm) SrHfO3 perovskite nanoparticles produced in a low temperature non-aqueous sol-gel route. RSC Adv. 2016, 6, 51493–51502. [Google Scholar] [CrossRef]

- Manikantan, J.; Ramalingam, H.B.; Shekar, B.C.; Murugan, B.; Kumar, R.R.; Santhoshi, J.S. Wide band gap of Strontium doped Hafnium oxide nanoparticles for opto-electronic device applications—Synthesis and characterization. Mater. Lett. 2017, 186, 42–46. [Google Scholar] [CrossRef]

- Schenk, T.; Mueller, S.; Schroeder, U.; Materlik, R.; Kersch, A.; Popovici, M.; Adelmann, C.; Elshocht, S.V.; Mikolajick, T. Strontium doped hafnium oxide thin films: Wide process window for ferroelectric memories. In Proceedings of the European Solid-State Device Research Conference (ESSDERC), Bucharest, Romania, 16–20 September 2013; pp. 260–263. [Google Scholar] [CrossRef]

- Pokhriyal, S.; Biswas, S. Doping dependent high-frequency dielectric properties of Hf1-xTixO2 Nanoparticles. Mater. Today Proc. 2016, 3, 1311–1319. [Google Scholar] [CrossRef]

- Lee, J.C.; Cho, H.J.; Kang, C.S.; Rhee, S.; Kim, Y.H.; Choi, R.; Knag, C.Y.; Choi, C.; Abkar, M. High-k dielectrics and MOSFET characteristics. In Proceedings of the IEEE International Electron. Devices Meeting, Washington, DC, USA, 8–10 December 2003; pp. 4.4.1–4.4.4. [Google Scholar] [CrossRef]

- Kawanago, T. A Study on High-k/Metal Gate Stack MOSFETs with Rare Earth Oxides. Ph.D. Thesis, Interdisciplinary Graduate School of Science and Engineering, Tokyo Institute of Technology, Tokyo, Japan, 2011. 08D36028. Available online: http://www.iwailab.ep.titech.ac.jp/pdf/201103dthesiskawanago.pdf (accessed on 1 May 2020).

- Lin, Y.; Watson, K.A.; Fallbach, M.J.; Ghose, S., Jr.; Smith, J.G.; Delozier, D.M.; Cao, W.; Crooks, R.E.; Connell, J.W. Rapid, solventless, bulk preparation of metal nanoparticle-decorated carbon nanotubes. ACS Nano 2009, 3, 871–884. [Google Scholar] [CrossRef] [PubMed]

- Dhaouadi, H.; Ghodbane, O.; Hosni, F.; Touati, F. Mn3O4 Nanoparticles: Synthesis, Characterization, and Dielectric Properties. ISRN Spectrosc. 2012, 2012, 706398. [Google Scholar] [CrossRef]

- Samuel, M.S.; Koshy, J.; Chandran, A.; George, K.C. Electrical charge transport and dielectric response in ZnO nanotubes. Curr. Appl. Phys. 2011, 11, 1094–1099. [Google Scholar] [CrossRef]

- Sharmila, P.P.; Tharayil, N.J. Synthesis and Dielectric Properties of Zinc Oxide Nanoparticles Using a Biotemplate. AIP Conf. Proc. 2014, 1620, 462. [Google Scholar] [CrossRef]

- Prabaharan, D.M.D.M.; Sadaiyandi, K.; Mahendran, M.; Sagadevan, S. Structural, Optical, Morphological and Dielectric Properties of Cerium Oxide Nanoparticles. Mater. Res. 2016, 19, 478–482. [Google Scholar] [CrossRef]

- Khan, Z.R.; Shkir, M.; Ganesh, V.; Yahia, I.S.; AlFaify, S. A facile microwave-assisted synthesis of novel ZnMn2O4 nanoparticles and their structural, morphological, optical, surface area, and dielectric studies. Indian J. Phys. 2020. [Google Scholar] [CrossRef]

- Kumar, D.S.; Naidu, K.C.B.; Rafi, M.M.; Nazeer, K.P.; Begam, A.A.; Kumar, G.R. Structural and dielectric properties of superparamagnetic iron oxide nanoparticles (SPIONs) stabilized by sugar solutions. Mater. Sci.-Pol. 2018, 36, 123–133. [Google Scholar] [CrossRef]

- Suresh, S. Studies on the dielectric properties of CdS nanoparticles. Appl. Nanosci. 2014, 4, 325–329. [Google Scholar] [CrossRef]

- Raghavender, A.T.; Jadhav, K.M. Dielectric properties of Al-substituted Co ferrite nanoparticles. Bull. Mater. Sci. 2009, 32, 575–578. [Google Scholar] [CrossRef]

- Al-Hartomy, O.A.; Ubaidullah, M.; Kumar, D.; Madani, J.H.; Ahmad, T. Dielectric properties of Ba1-xSrxZrO3 (0 ≤ x ≤ 1) nanoceramics developed by citrate precursor route. J. Mater. Res. 2013, 26, 1070–1077. [Google Scholar] [CrossRef]

- Shen, Y.; Lin, Y.; Li, M.; Nan, C.-W. High Dielectric Performance of Polymer Composite Films Induced by a Percolating Interparticle Barrier Layer. Adv. Mater. 2007, 19, 1418–1422. [Google Scholar] [CrossRef]

- Zamiri, R.; Ahangar, H.A.; Kaushal, A.; Zakaria, A.; Zamiri, G.; Tobaldi, D.; Ferreira, J.M.F. Dielectrical Properties of CeO2 Nanoparticles at Different Temperatures. PLoS ONE 2015, 10, e0122989. [Google Scholar] [CrossRef]

- Kamran, M.; Shoukat, W.; Nadeem, K.; Hussain, S.S.; Zeb, F.; Hussain, S. Magnetic and Dielectric Properties of NiCrxFe2-xO4 Nanoparticles. Mater. Res. Express 2019, 6, 076106. [Google Scholar] [CrossRef]

- Xiang, P.-H.; Dong, X.-L.; Feng, C.-D.; Liang, R.-H.; Wang, Y.-L. Dielectric behavior of lead zirconate titanate/silver composites. Mater. Chem. Phys. 2006, 97, 410–414. [Google Scholar] [CrossRef]

- Kaur, S.; Kumar, A.; Sharma, A.L.; Singh, D.P. Dielectric and energy storage behavior of CaCu3Ti4O12 nanoparticles for capacitor application. Ceram. Int. 2019, 45, 7743–7747. [Google Scholar] [CrossRef]

- Chaudhuri, R.G.; Paria, S. Core/Shell Nanoparticles: Classes, Properties, Synthesis Mechanisms, Characterization, and Applications. Chem. Rev. 2012, 112, 2373–2433. [Google Scholar] [CrossRef]

- Gawande, M.B.; Goswami, A.; Asefa, T.; Gua, H.; Biradar, A.V.; Peng, D.-L.; Zboril, R.; Varma, R.S. Core–shell nanoparticles: Synthesis and applications in catalysis and electrocatalysis. Chem. Soc. Rev. 2015, 44, 7540. [Google Scholar] [CrossRef]

- Mahadevegowda, A.; Young, N.P.; Grant, P.S. Core–shell nanoparticles and enhanced polarization in polymer based nanocomposite dielectrics. Nanotechnology 2014, 25, 475706. [Google Scholar] [CrossRef]

- Hu, P.; Jia, Z.; Shen, Z.; Wang, P.; Liu, X. High dielectric constant and energy density induced by the tunable TiO2 interfacial buffer layer in PVDF nanocomposite contained with core–shell structured TiO2@BaTiO3 nanoparticles. Appl. Surf. Sci. 2018, 441, 824–831. [Google Scholar] [CrossRef]

- Fang, X.; Wang, S.; Li, Y.; Liu, X.; Li, X.; Lin, S.; Cui, Z.-K.; Zhunag, Q. NH2-functionalized carbon-coated Fe3O4 core-shell nanoparticles for in situ preparation of robust polyimide composite films with high dielectric constant, low dielectric loss, and high breakdown strength. RSC Adv. 2016, 6, 107533–107541. [Google Scholar] [CrossRef]

- Ling, W.; Hongxia, L.; Peihai, J.; Ting, W.; Lizhu, L. The effects of TiC@AlOOH core–shell nanoparticles on the dielectric properties of PVDF based nanocomposites. RSC Adv. 2016, 6, 25015–25022. [Google Scholar] [CrossRef]

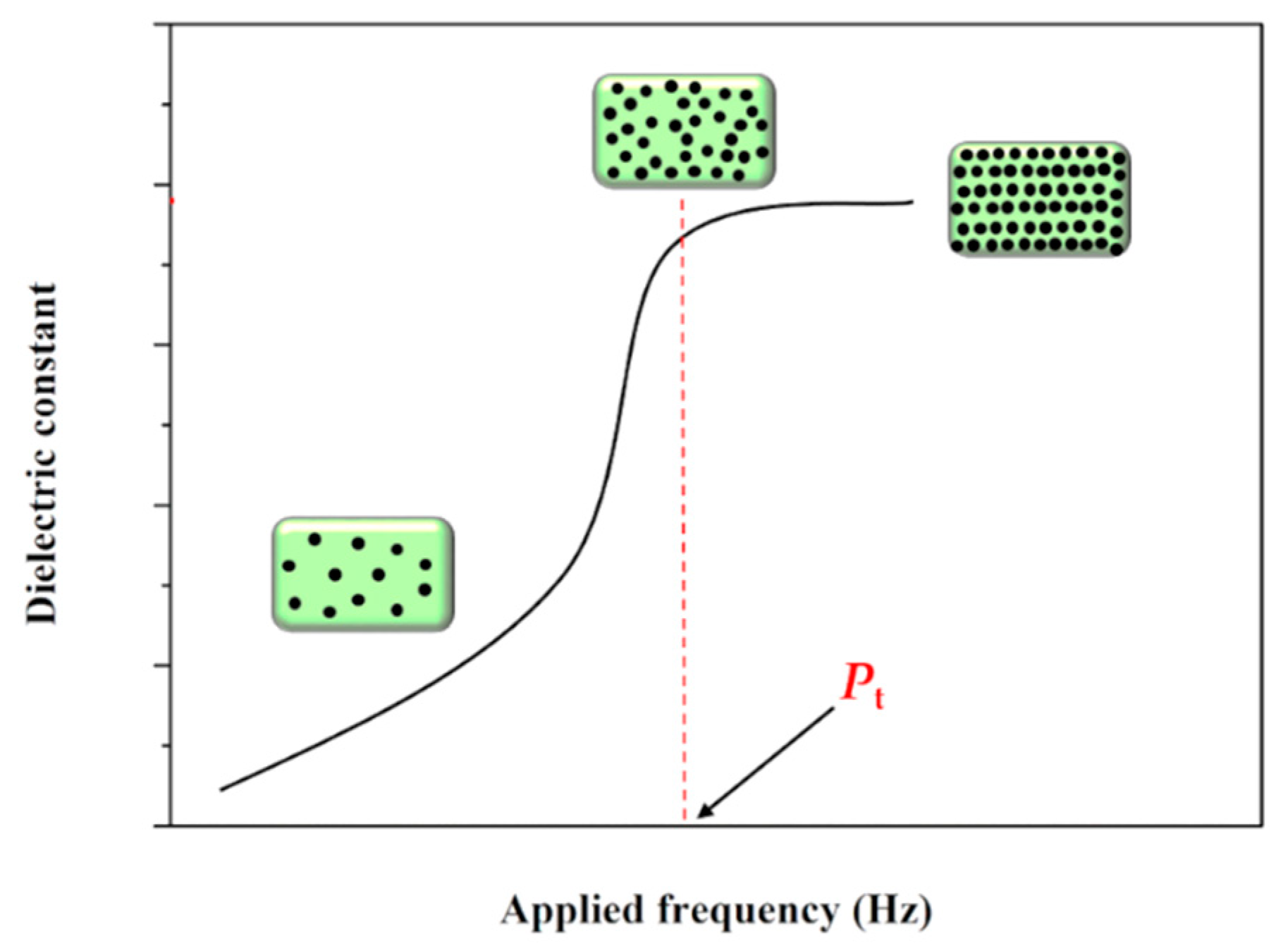

- Nadiv, R.; Shtein, M.; Shachar, G.; Verinik, M.; Regev, O. Optimal nanomaterial concentration: Harnessing percolation theory to enhance polymer nanocomposite performance. Nanotechnology 2017, 28, 305701. [Google Scholar] [CrossRef] [PubMed]

- Francis, E.; Ko, H.U.; Kim, J.W.; Kim, H.C.; Kalarikkal, N.; Varughese, K.; Kim, J.; Thomas, S. High-k Dielectric Percolative Nanocomposites Based on Multiwalled Carbon Nanotubes and Polyvinyl Chloride. J. Mater. Chem. C 2018, 6, 8152–8159. [Google Scholar] [CrossRef]

- Vidor, F.F.; Wirth, G.I.; Hilleringmann, U. Low temperature fabrication of a ZnO nanoparticle thin-film transistor suitable for flexible electronics. Microelectronics Reliability 2014, 54, 2760–2765. [Google Scholar] [CrossRef]

- Iacob, M.; Tugui, C.; Tiron, V.; Bele, A.; Vlad, S.; Vasiliu, T.; Cazacu, M.; Vasiliu, A.-L.; Racles, C. Iron oxide nanoparticles as dielectric and piezoelectric enhancers for silicone elastomers. Smart Mater. Struct. 2017, 26, 105046. [Google Scholar] [CrossRef]

- Ramazanov, M.A.; Hajiyeva, F.V. Copper and copper oxide nanoparticles in polypropylene matrix: Synthesis, characterization, and dielectric properties. Compos. Interfaces 2020. [Google Scholar] [CrossRef]

- Cheng, L.; Zheng, L.; Li, G.; Yao, Z.; Yin, Q. Manufacture of epoxy-silica nanoparticle composites and characterisation of their dielectric behavior. Int. J. Nanopart. 2008, 1. [Google Scholar] [CrossRef]

- Canimkurbey, B.; Çakirlar, Ç.; Mucur, S.P.; Yasin, M.; Berber, S. Influence of Al2O3 nanoparticles incorporation on the dielectric properties of solution processed PVA films for organic field effect transistor applications. J. Mater. Sci. Mater. Electron. 2019, 30, 18384–18390. [Google Scholar] [CrossRef]

- Tang, H.; Sodano, H.A. Ultra High Energy Density Nanocomposite Capacitors with Fast Discharge Using Ba0.2Sr0.8TiO3 Nanowires. Nano Lett. 2013, 13, 1373–1379. [Google Scholar] [CrossRef] [PubMed]

- Feng, P.; Zhong, M.; Zhao, W. Stretchable Multifunctional Dielectric Nanocomposites based on Polydimethylsiloxane Mixed with Metal Nanoparticles. Mater. Res. Express 2020, 7, 015007. [Google Scholar] [CrossRef]

- Dai, Y.; Zhu, X. Improved dielectric properties and energy density of PVDF composites using PVP engineered BaTiO3 nanoparticles. Korean J. Chem. Eng. 2018, 35, 1570–1576. [Google Scholar] [CrossRef]

- Tang, H.; Lin, Y.; Sodano, H.A. Synthesis of High Aspect Ratio BaTiO 3 Nanowires for High Energy Density Nanocomposite Capacitors. Adv. Energy Mater. 2013, 3, 451–456. [Google Scholar] [CrossRef]

- Yosuf, Y.; Ng, Z.Y.; Wong, Y.H.; Johan, M.R. The tunable permittivity of multi-walled carbon nanotubes/silver nanoparticles reinforced polyvinyl alcohol (PVA) nanocomposites at low frequency. Mater. Res. Express 2018, 5, 085604. [Google Scholar] [CrossRef]

- Dang, Z.-M.; Shen, Y.; Nan, C.-W. Dielectric behavior of three-phase percolative Ni-BaTiO3/polyvinylidene fluoride composites. Appl. Phys. Lett. 2002, 81, 4814. [Google Scholar] [CrossRef]

- Liu, X.; Liu, C.-F.; Lai, W.-Y.; Huang, W. Porous Organic Polymers as Promising Electrode Materials for Energy Storage Devices. Adv. Mater. Technol. 2020, 2000154. [Google Scholar] [CrossRef]

- Gao, M.; Shih, C.-C.; Pan, S.-Y.; Chueh, C.-C.; Chen, W.-C. Advances and challenges of green materials for electronics and energy storage applications: From design to end-of-life recovery. J. Mater. Chem. A 2018, 6, 20546–20563. [Google Scholar] [CrossRef]

- Friebe, C.; Lex-Balducci, A.; Schubert, U.S. Sustainable Energy Storage: Recent Trends and Developments toward Fully Organic Batteries. ChemSusChem 2019, 12, 4093–4115. [Google Scholar] [CrossRef]

- Lu, J.; Wong, C.P. Recent Advances in High-k Nanocomposite Materials for Embedded Capacitor Applications. IEEE Trans. on Dielectr. Electr. Insul. 2008, 15, 1322–1328. [Google Scholar] [CrossRef]

- Anju, V.P.; Narayanankutty, S.K. High dielectric constant polymer nanocomposite for embedded capacitor applications. Mater. Sci. Eng. B 2019, 249, 114418. [Google Scholar] [CrossRef]

- Li, Q.; Han, K.; Gadinski, M.R.; Zhang, G.; Wang, Q. High Energy and Power Density Capacitors from Solution-Processed Ternary Ferroelectric Polymer Nanocomposites. Adv. Mater. 2014, 26, 6244–6249. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Zhang, G.; Liu, F.; Han, K.; Gadinski, M.R.; Xiong, C.; Wang, Q. Solution-processed ferroelectric terpolymer nanocomposites with high breakdown strength and energy density utilizing boron nitride nanosheets. Energy Environ. Sci. 2015, 8, 922–931. [Google Scholar] [CrossRef]

- Zhu, Y.; Yao, H.; Jiang, P.; Wu, J.; Zhu, X.; Huang, X. Two-Dimensional High-k Nanosheets for Dielectric Polymer Nanocomposites with Ultrahigh Discharged Energy Density. J. Phys. Chem. C 2018, 122, 18282–18293. [Google Scholar] [CrossRef]

- Li, Q.; Liu, F.; Yang, T.; Gadinski, M.R.; Zhang, G.; Chen, L.-Q.; Wang, Q. Sandwich-structured polymer nanocomposites with high energy density and great charge–discharge efficiency at elevated temperatures. PNAS 2016, 113, 9995–10000. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.; Zhang, T.; Chen, H.; Wang, F.; Pu, Y.; Goa, C.; Li, S. Mini Review on Flexible and Wearable Electronics for Monitoring Human Health Information. Nanoscale Res. Lett. 2019, 14, 263. [Google Scholar] [CrossRef]

- Zou, M.; Ma, Y.; Yuan, X.; Hu, Y.; Liu, J.; Jin, Z. Flexible devices: From materials, architectures to applications. J. Semicond. 2018, 39, 011010. [Google Scholar] [CrossRef]

- Wu, W. Stretchable electronics: Functional materials, fabrication strategies and applications. Science and Technol. Adv. Mater. 2019, 20, 187–224. [Google Scholar] [CrossRef]

- Huang, S.; Liu, Y.; Zhao, Y.; Ren, Z.; Guo, C.F. Flexible Electronics: Stretchable Electrodes and Their Future. Adv. Funct. Mater. 2019, 29, 1805924. [Google Scholar] [CrossRef]

| Polymers | Breakdown Strength (MV/m) |

|---|---|

| Polytetrafluoroethylene (PTFE) | 600–700 |

| Polypropylene (PP) | 640 |

| Polyvinylidene fluoride (PVDF) | 590 |

| Polyethylene terephthalate (PET) | 570 |

| Polycarbonate (PC) | 528 |

| SU-8 | 440 |

| Polyvinyl chloride (PVC) | 140–210 |

| Nanoparticles | Dielectric Constant | References |

|---|---|---|

| Cerium oxide (CeO2) | 4.1 | [120] |

| ZnMn2O4 | 16.5 | [121] |

| a Strontium hafnium oxide (SrHfO3) | 17.0 | [110] |

| b Iron oxide (Fe3O4) | 130.0 | [122] |

| Cadmium sulfide (CdS) | 163.0 | [123] |

| CoFe1.6Al0.4O4 | 200.0 | [124] |

| Ba0.9Sr0.1ZrO3 | 290.0 | [125] |

| Carbon coated silver (Ag@C) | 320.0 | [126] |

| Cerium oxide (CeO2) | 370.0 d | [127] |

| NiCr2FeO4 | 900.0 | [128] |

| Pb(Zr0.97Ti0.03)O3 coated silver | 1700.0 c | [129] |

| CaCu3Ti4O12 | 9000.0 e | [130] |

| Nano-Fillers | Dielectric Matrix | Weight % of Nano-Fillers | Dielectric Constant | References |

|---|---|---|---|---|

| Iron oxide (Fe3O4) | Polydimethylsiloxane | 60.0 | 9.0 | [140] |

| Copper/copper oxide (Cu/CuO) | Polypropylene | 3.0 | 9.0 | [141] |

| a Silicon dioxide | DGE-BA † | 3.0 | 11.4 | [142] |

| Aluminum oxide (Al2O3) | Polyvinyl alcohol | 70.0 | 12.0 | [143] |

| b Ba0.2Sr0.8TiO3 | Polyvinylidene fluoride | 7.5 | 18.0 | [144] |

| Silver and Nickel (Ag/Ni) | Polydimethylsiloxane | 30.0 | 35.0 c | [145] |

| d BaTiO3 | Polyvinylidene fluoride | 50.0 | 80.4 | [146] |

| b BaTiO3 | P(VDF-TrFE-CFE) † | 50.0 | 108.0 | [147] |

| MWCNT/AgNP | Polyvinyl alcohol | 1.0 | 620.0 e | [148] |

| Ni/BaTiO3 | Polyvinylidene fluoride | 0.22 f | 800.0 | [149] |

| MWCNT | Polyvinyl chloride | 4.0 | 13066.0 | [138] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shimoga, G.; Kim, S.-Y. High-k Polymer Nanocomposite Materials for Technological Applications. Appl. Sci. 2020, 10, 4249. https://doi.org/10.3390/app10124249

Shimoga G, Kim S-Y. High-k Polymer Nanocomposite Materials for Technological Applications. Applied Sciences. 2020; 10(12):4249. https://doi.org/10.3390/app10124249

Chicago/Turabian StyleShimoga, Ganesh, and Sang-Youn Kim. 2020. "High-k Polymer Nanocomposite Materials for Technological Applications" Applied Sciences 10, no. 12: 4249. https://doi.org/10.3390/app10124249

APA StyleShimoga, G., & Kim, S.-Y. (2020). High-k Polymer Nanocomposite Materials for Technological Applications. Applied Sciences, 10(12), 4249. https://doi.org/10.3390/app10124249