Experimental Study of Entrainment and Mixing of Renewable Active Particles in Fluidized Beds

Abstract

1. Introduction

2. Materials and Methods

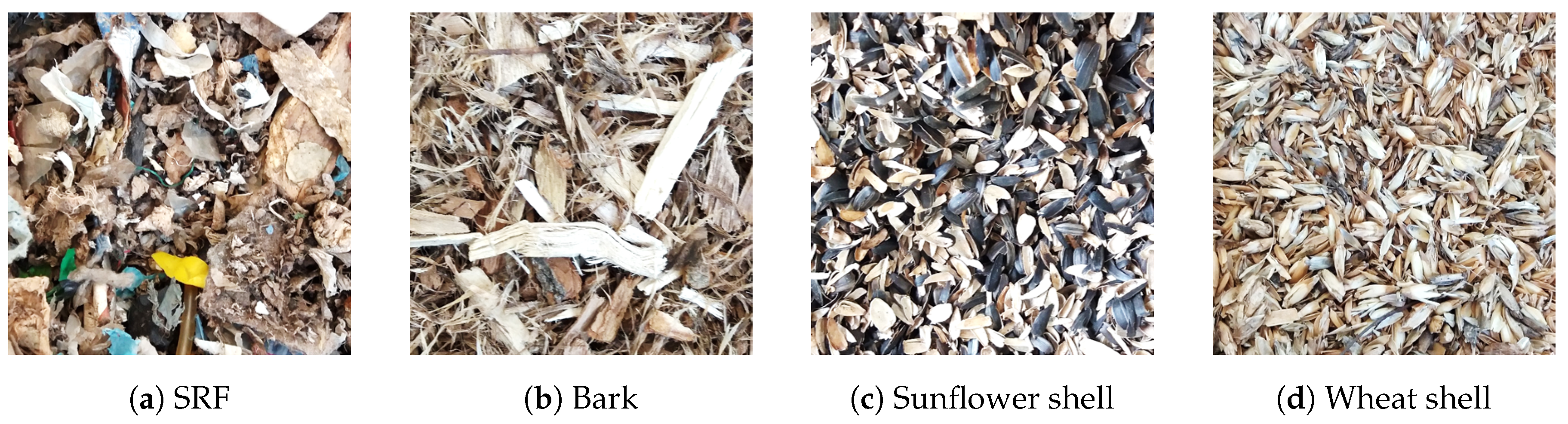

2.1. Biomass Fuels and Bed Material

2.2. Particle Size Analysis

2.3. Particle Entrainment Measurements

- –

- Filling the riser with about 50 g of the investigated particles.

- –

- Increasing the fluidization air velocity.

- –

- Measuring the entrained fuel amount in the filter at five fluidization velocities within the range of 1–3 m/s.

- –

- Plotting the entrainment curve between the normalized entrained mass and the fluidization velocity.

2.4. Particle Mixing Measurements

- –

- Filling the plexi tube with a mixture of about 50 g fuel and 1500 g sand.

- –

- Fluidizing the mixture with air of a velocity of 1.2 times the minimum fluidization velocity of the sand till the steady state is achieved (2 –20 min).

- –

- Sudden closing of the fluidization air.

- –

- Slicing the bed into three vertical partitions with copper separators, at heights of 2 and 8 cm.

- –

- Evacuating the sliced partitions using a vacuum pump.

- –

- Measuring the fuel mass after sieving.

- –

- Repeating the measurement at other fluidization velocities, at 1.4, 1.6, 1.8, and 2.0 times the minimum fluidization velocity of the sand.

- –

- Plotting the measured fuel mass fraction with the dimensionless fluidization velocity.

3. Results and Discussion

3.1. Particle Size Distribution

3.2. Particle Entrainment

3.3. Mixing in Binary-Mixture Fluidized Beds

4. Conclusions

- –

- The sunflower shell entrained at the highest degree.

- –

- At very low velocity, the entrainment of the wheat shells is the most intensive.

- –

- SRF and bark has similar entrainment behavior, but with a less steep gradient.

- –

- SRF has relatively high mass fraction in the bottom and center regions of the fluidized bed at low superficial velocities.

- –

- Unlike all the biomass fuels, SRF tends to shift upwards at elevated velocities.

- –

- The nonspherical active particles have higher concentrations at the bottom region than spherical ones.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yang, W.C. (Ed.) Handbook of Fluidization and Fluid-Particle Systems; Number 91 in Chemical Industries; OCLC: ocm52260128; Marcel Dekker: New York, NY, USA, 2003. [Google Scholar]

- ECN-Netherlands. RDF (ID-Number: 849). Available online: https://phyllis.nl/Biomass/View/84 (accessed on 27 April 2020).

- ECN-Netherlands. Bark (ID-Number: 51). Available online: https://phyllis.nl/Biomass/View/51 (accessed on 27 April 2020).

- Demirbaş, A. Fuel Characteristics of Olive Husk and Walnut, Hazelnut, Sunflower, and Almond Shells. Energy Sour. 2002, 24, 215–221. [Google Scholar] [CrossRef]

- Fryda, L. Wheat Straw (ID-Number: 3563). Available online: https://phyllis.nl/Biomass/View/356 (accessed on 27 April 2020).

- ECN-Netherlands. Coal, Lignite (ID-Number: 2847). Available online: https://phyllis.nl/Biomass/View/2847 (accessed on 27 April 2020).

- Estejab, B.; Battaglia, F. Modeling of Coal-Biomass Fluidization Using Computational Fluid Dynamics. In Volume 7A: Fluids Engineering Systems and Technologies; American Society of Mechanical Engineers: San Diego, CA, USA, 2013; p. V07AT08A058. [Google Scholar] [CrossRef]

- Mätzing, H.; Gehrmann, H.J.; Seifert, H.; Stapf, D. Modelling grate combustion of biomass and low rank fuels with CFD application. Waste Manag. 2018, 78, 686–697. [Google Scholar] [CrossRef]

- Haaf, M.; Peters, J.; Hilz, J.; Unger, A.; Ströhle, J.; Epple, B. Combustion of Solid Recovered Fuels within the Calcium Looping Process—Experimental Demonstration at 1 MWth Scale. Exp. Therm. Fluid Sci. 2019, 113, 110023. [Google Scholar] [CrossRef]

- Vonk, G.; Piriou, B.; Felipe Dos Santos, P.; Wolbert, D.; Vaïtilingom, G. Comparative analysis of wood and solid recovered fuels gasification in a downdraft fixed bed reactor. Waste Manag. 2019, 85, 106–120. [Google Scholar] [CrossRef] [PubMed]

- Valin, S.; Ravel, S.; Pons de Vincent, P.; Thiery, S.; Miller, H. Fluidized bed air gasification of solid recovered fuel and woody biomass: Influence of experimental conditions on product gas and pollutant release. Fuel 2019, 242, 664–672. [Google Scholar] [CrossRef]

- De Gisi, S.; Chiarelli, A.; Tagliente, L.; Notarnicola, M. Energy, environmental and operation aspects of a SRF-fired fluidized bed waste-to-energy plant. Waste Manag. 2017, 73, 271–286. [Google Scholar] [CrossRef]

- Hervy, M.; Remy, D.; Dufour, A.; Mauviel, G. Air-blown gasification of Solid Recovered Fuels (SRFs) in lab-scale bubbling fluidized-bed: Influence of the operating conditions and of the SRF composition. Energy Convers. Manag. 2019, 181, 584–592. [Google Scholar] [CrossRef]

- Morris, J.D.; Daood, S.S.; Chilton, S.; Nimmo, W. Mechanisms and mitigation of agglomeration during fluidized bed combustion of biomass: A review. Fuel 2018, 230, 452–473. [Google Scholar] [CrossRef]

- Behainne, J.J.R.; Martinez, J.D. Performance analysis of an air-blown pilot fluidized bed gasifier for rice husk. Energy Sustain. Dev. 2014, 18, 75–82. [Google Scholar] [CrossRef]

- Szentannai, P.; Szücs, B. Vertical arrangement of SRF particles in a stationary fluidized bed. Powder Technol. 2018, 325, 209–217. [Google Scholar] [CrossRef]

- Zhou, T.; Yang, S.; Wei, Y.; Hu, J.; Wang, H. Impact of wide particle size distribution on the gasification performance of biomass in a bubbling fluidized bed gasifier. Renew. Energy 2019, 148, 534–547. [Google Scholar] [CrossRef]

- Yang, S.; Zhou, T.; Wei, Y.; Hu, J.; Wang, H. Influence of size-induced segregation on the biomass gasification in bubbling fluidized bed with continuous lognormal particle size distribution. Energy Convers. Manag. 2019, 198, 111848. [Google Scholar] [CrossRef]

- Kraft, S.; Kirnbauer, F.; Hofbauer, H. Investigations using a cold flow model of char mixing in the gasification reactor of a dual fluidized bed gasification plant. Powder Technol. 2017, 316, 687–696. [Google Scholar] [CrossRef]

- Köhler, A.; Rasch, A.; Pallarès, D.; Johnsson, F. Experimental characterization of axial fuel mixing in fluidized beds by magnetic particle tracking. Powder Technol. 2017, 316, 492–499. [Google Scholar] [CrossRef]

- Win, K.K.; Nowak, W.; Matsuda, H.; Hasatani, M.; Bis, Z.; Krzywanski, J.; Gajewski, W. Transport Velocity of Coarse Particles in Multi-Solid Fluidized Bed. J. Chem. Eng. Jpn. 1995, 28, 535–540. [Google Scholar] [CrossRef]

- Liang, Z.; Nie, Z.; An, A.; Gong, J.; Wang, X. A particle shape extraction and evaluation method using a deep convolutional neural network and digital image processing. Powder Technol. 2019, 353, 156–170. [Google Scholar] [CrossRef]

- Wu, L.C.; Yu, C. Powder Particle Size Measurement with Digital Image Processing Using Matlab. Adv. Mater. Res. 2012, 443-444, 589–593. [Google Scholar] [CrossRef]

- Lu, Z.; Hu, X.; Lu, Y. Particle Morphology Analysis of Biomass Material Based on Improved Image Processing Method. Int. J. Anal. Chem. 2017, 2017, 5840690. [Google Scholar] [CrossRef]

- Huilin, L.; Yurong, H.; Gidaspow, D.; Lidan, Y.; Yukun, Q. Size segregation of binary mixture of solids in bubbling fluidized beds. Powder Technol. 2003, 134, 86–97. [Google Scholar] [CrossRef]

- Wu, S.; Baeyens, J. Segregation by size difference in gas fluidized beds. Powder Technol. 1998, 98, 139–150. [Google Scholar] [CrossRef]

- Olivieri, G.; Marzocchella, A.; Salatino, P. Segregation of fluidized binary mixtures of granular solids. AIChE J. 2004, 50, 3095–3106. [Google Scholar] [CrossRef]

- Zhang, Y.; Jin, B.; Zhong, W. Experimental investigation on mixing and segregation behavior of biomass particle in fluidized bed. Chem. Eng. Process. Process. Intensif. 2009, 48, 745–754. [Google Scholar] [CrossRef]

- Haider, A.; Levenspiel, O. Drag coefficient and terminal velocity of spherical and nonspherical particles. Powder Technol. 1989, 58, 63–70. [Google Scholar] [CrossRef]

- Szücs, B.; Szentannai, P. Experimental Investigation on Mixing and Segregation Behavior of Oxygen Carrier and Biomass Particle in Fluidized Bed. Period. Polytech. Mech. Eng. 2019, 63, 188–194. [Google Scholar] [CrossRef]

- Wirsum, M.; Fett, F.; Bausch, T.; Lütge, C. Über die Eignung von Feuerungsanlagen mit Wirbelschicht zur Verbrennung von kommunalem Klärschlamm. VDI Berichte 1996, 1280, 209–224. [Google Scholar]

- Wirsum, M.; Fett, F.; Iwanowa, N.; Lukjanow, G. Particle mixing in bubbling fluidized beds of binary particle systems. Powder Technol. 2001, 120, 63–69. [Google Scholar] [CrossRef]

- Fotovat, F.; Chaouki, J.; Bergthorson, J. Distribution of large biomass particles in a sand-biomass fluidized bed: Experiments and modeling. AIChE J. 2014, 60, 869–880. [Google Scholar] [CrossRef]

- Cluet, B.; Mauviel, G.; Rogaume, Y.; Authier, O.; Delebarre, A. Segregation of wood particles in a bubbling fluidized bed. Fuel Process. Technol. 2015, 133, 80–88. [Google Scholar] [CrossRef]

| SRF | Bark | Sunflower Shell | Wheat Straw | Lignite | |

|---|---|---|---|---|---|

| Calorific value, MJ/kg | 13.6–14.9 [2] | 16.0–17.5 [3] | 17.4–18.8 [4] | 18.5–19.8 [5] | 23.6–24.6 [6] |

| Moisture | Ash | Volatile | S | C | H | HHV | LHV | Cl | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| (wt.%) | (wt.%) | (wt.%) | (wt.%) | (wt.%) | (wt.%) | (MJ/kg) | (MJ/kg) | (wt.%) | (wt.%) | |

| SRF | Analysis data in wet (raw) state | |||||||||

| 13.20 | 34.90 | – | 0.160 | – | – | 14.40 | 12.60 | 0.510 | – | |

| – | – | – | – | – | – | – | – | – | – | |

| Analysis data in dry state | ||||||||||

| 3.37 | 74.7 | – | 0.28 | – | – | 24.20 | 22.20 | 0.870 | – | |

| – | – | – | – | – | – | – | – | – | – | |

| Bark | Analysis data in wet (raw) state | |||||||||

| 15.83 | 4.07 | 61.5 | 0.057 | 41.81 | 6.89 | 15.94 | 14.05 | 0.076 | 0.384 | |

| EN 14774 | EN 14775 | EN 15148 | – | – | – | ISO 1928 | ISO 1928 | ISO 587 | – | |

| Analysis data in dry state | ||||||||||

| – | 4.84 | 73.1 | 0.067 | 49.68 | 8.18 | 18.94 | 17.15 | 0.090 | 0.456 | |

| – | EN 14775 | EN 15148 | – | – | – | ISO 1928 | ISO 1928 | ISO 587 | – | |

| Sunflower shell | Analysis data in wet (raw) state | |||||||||

| 8.47 | 2.28 | 69.1 | 0.180 | 46.81 | 7.87 | 19.16 | 17.24 | 0.058 | 0.884 | |

| EN 14774 | EN 14775 | EN 15148 | – | – | – | ISO 1928 | ISO 1928 | ISO 587 | – | |

| Analysis data in dry state | ||||||||||

| – | 2.49 | 75.5 | 0.190 | 51.14 | 8.60 | 20.94 | 19.06 | 0.063 | 0.966 | |

| – | EN 14775 | EN 15148 | – | – | – | ISO 1928 | ISO 1928 | ISO 587 | – | |

| Wheat shell | Analysis data in wet (raw) state | |||||||||

| 12.97 | 9.90 | 64.4 | 0.347 | 40.95 | 8.09 | 17.01 | 14.93 | 0.085 | 1.808 | |

| EN 14774 | EN 14775 | EN 15148 | – | – | – | ISO 1928 | ISO 1928 | ISO 587 | – | |

| Analysis data in dry state | ||||||||||

| – | 11.38 | 74.0 | 0.399 | 47.05 | 9.29 | 19.54 | 17.52 | 0.098 | 2.077 | |

| – | EN 14775 | EN 15148 | – | – | – | ISO 1928 | ISO 1928 | ISO 587 | – | |

| SRF | Bark | Sunflower Shell | Wheat Shell | |

|---|---|---|---|---|

| Skeleton density, kg/m | 1400 | 1253 | 1876 | 1446 |

| Apparent density, kg/m | 325 | 600 | 338 | 415 |

| Particle shape, – | diverse irregular shapes | stringy and chips-like | half-ellipsoidal shell-like | ellipsoidal shell-like |

| Particle structure, – | ductile (big-sizes), hard (small-sizes) | ductile (stringy), hard (chips) | hard | elastic |

| Source, – | waste (textile, plastic, etc) | wood industry | sunflower seeds | wheat crop |

| Cumulative Fraction, | |||

|---|---|---|---|

| : Equivalent Particle Diameter, mm | |||

| Mean Diameter | Spread Parameter | Regression | |

| , mm | n, – | , % | |

| SRF | 23.69 | 1.61 | 98.98 |

| Bark | 13.30 | 1.55 | 98.96 |

| Sunflower shell | 7.26 | 7.00 | 99.75 |

| Wheat shell | 6.99 | 4.00 | 99.30 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szucs, B.; Alagha, M.S.; Szentannai, P. Experimental Study of Entrainment and Mixing of Renewable Active Particles in Fluidized Beds. Appl. Sci. 2020, 10, 4268. https://doi.org/10.3390/app10124268

Szucs B, Alagha MS, Szentannai P. Experimental Study of Entrainment and Mixing of Renewable Active Particles in Fluidized Beds. Applied Sciences. 2020; 10(12):4268. https://doi.org/10.3390/app10124268

Chicago/Turabian StyleSzucs, Botond, Mohamed Sobhi Alagha, and Pal Szentannai. 2020. "Experimental Study of Entrainment and Mixing of Renewable Active Particles in Fluidized Beds" Applied Sciences 10, no. 12: 4268. https://doi.org/10.3390/app10124268

APA StyleSzucs, B., Alagha, M. S., & Szentannai, P. (2020). Experimental Study of Entrainment and Mixing of Renewable Active Particles in Fluidized Beds. Applied Sciences, 10(12), 4268. https://doi.org/10.3390/app10124268