Experimental Characterization of Plasmonic Sensors Based on Lab-Built Tapered Plastic Optical Fibers

Abstract

:1. Introduction

2. Lab-Built System to Make TPOFs

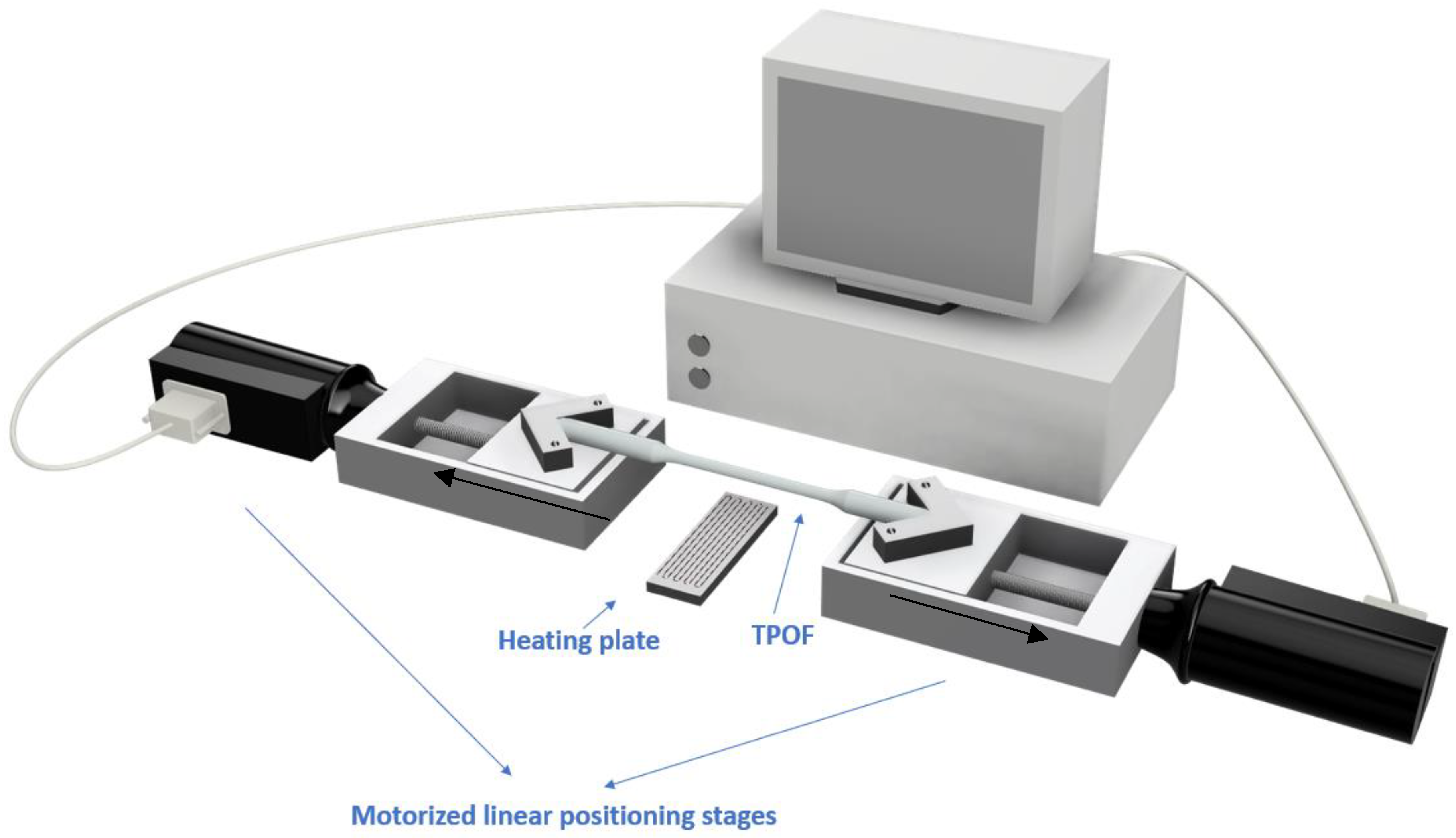

3. SPR-TPOF Sensors

4. Experimental Setup

5. Experimental Results

5.1. Preliminary Test Exploiting SPR-TPOFs Sensors with and without a Buffer Layer

5.2. SPR-TPOF Sensors without Buffer Layer and with Different Taper Ratios

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Homola, J. Present and future of surface plasmon resonance biosensors. Anal. Bioanal. Chem. 2003, 377, 528–539. [Google Scholar] [CrossRef] [PubMed]

- Singh, P. SPR Biosensors: Historical Perspectives and Current Challenges. Sens. Actuators B Chem. 2016, 229, 110–130. [Google Scholar] [CrossRef]

- Abbas, A.; Linman, M.J.; Cheng, Q. New trends in instrumental design for surface plasmon resonance-based biosensors. Biosens. Bioelectron. 2011, 26, 1815–1824. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Homola, J.; Yee, S.S.; Gauglitz, G. Surface plasmon resonance sensors: Review. Sens. Actuators B Chem. 1999, 54, 3–15. [Google Scholar] [CrossRef]

- Jorgenson, R.C.; Yee, S.S. A fiber-optic chemical sensor based on surface plasmon resonance. Sens. Actuators B Chem. 1993, 12, 213–220. [Google Scholar] [CrossRef]

- Caucheteur, C.; Guo, T.; Albert, J. Review of plasmonic fiber optic biochemical sensors: Improving the limit of detection. Anal. Bioanal. Chem. 2015, 407, 3883–3897. [Google Scholar] [CrossRef]

- Anuj, K.; Sharma, R.J.; Gupta, B.D. Fiber-optic sensors based on surface Plasmon resonance: A comprehensive review. IEEE Sens. J. 2007, 7, 1118–1129. [Google Scholar]

- Allsop, T.; Neal, R. A Review: Evolution and Diversity of Optical Fibre Plasmonic Sensors. Sensors 2019, 19, 4874. [Google Scholar] [CrossRef] [Green Version]

- Trouillet, A.; Ronot-Trioli, C.; Veillas, C.; Gagnaire, H. Chemical sensing by surface plasmon resonance in a multimode optical fibre. Pure Appl. Opt. 1996, 5, 227–237. [Google Scholar] [CrossRef]

- Zhaoa, Y.; Tongb, R.; Xiab, F.; Peng, Y. Current status of optical fiber biosensor based on surface plasmon resonance. Biosens. Bioelectron. 2019, 142, 111505. [Google Scholar] [CrossRef]

- Wang, X.D.; Wolfbeis, O.S. Fiber-Optic Chemical Sensors and Biosensors (2013–2015). Anal. Chem. 2016, 88, 203–227. [Google Scholar] [CrossRef] [PubMed]

- Wanga, Q.; Jianga, X.; Niua, L.Y.; Fana, X.-C. Enhanced sensitivity of bimetallic optical fiber SPR sensor based on MoS2 nanosheets. Opt. Laser Eng. 2020, 128, 105997. [Google Scholar] [CrossRef]

- Liu, L.; Liu, Z.; Zhang, Y.; Liu, S. V-shaped micro-structure optical fiber surface plasmon resonance sensor for the simultaneous measurement of the refractive index and temperature. Opt. Lett. 2019, 44, 5093–5096. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Cheng, T.; Chen, J.; Yan, X. Graphene-Enhanced Surface Plasmon Resonance Liquid Refractive Index Sensor Based on Photonic Crystal Fiber. Sensors 2019, 19, 3666. [Google Scholar] [CrossRef] [Green Version]

- Cennamo, N.; Zeni, L.; Arcadio, F.; Catalano, E.; Minardo, A. A Novel Approach to Realizing Low-Cost Plasmonic Optical Fiber Sensors: Light-Diffusing Fibers Covered by Thin Metal Films. Fibers 2019, 7, 34. [Google Scholar] [CrossRef] [Green Version]

- Wei, Y.; Hu, J.; Wu, P.; Su, Y.; Liu, C.; Wang, S.; Nie, X.; Liu, L. Optical Fiber Cladding SPR Sensor Based on Core-Shift Welding Technology. Sensors 2019, 19, 1202. [Google Scholar] [CrossRef] [Green Version]

- Cennamo, N.; Massarotti, D.; Conte, L.; Zeni, L. Low Cost Sensors Based on SPR in a Plastic Optical Fiber for Biosensor Implementation. Sensors 2011, 11, 11752–11760. [Google Scholar] [CrossRef]

- Cennamo, N.; D’Agostino, G.; Porto, G.; Biasiolo, A.; Perri, C.; Arcadio, F.; Zeni, L. A Molecularly Imprinted Polymer on a Plasmonic Plastic Optical Fiber to Detect Perfluorinated Compounds in Water. Sensors 2018, 18, 1836. [Google Scholar] [CrossRef] [Green Version]

- Cennamo, N.; Pasquardini, L.; Arcadio, F.; Vanzetti, L.E.; Bossi, A.M. D-shaped plastic optical fibre aptasensor for fast thrombin detection in nanomolar range. Sci. Rep. 2019, 9, 18740. [Google Scholar] [CrossRef]

- Cennamo, N.; Zeni, L.; Ricca, E.; Isticato, R.; Marzullo, V.M.; Capo, A.; Staiano, M.; D’Auria, S.; Varriale, A. Detection of naphthalene in sea-water by a label-free plasmonic optical fiber biosensor. Talanta 2019, 194, 289–297. [Google Scholar] [CrossRef]

- Cennamo, N.; D’Agostino, G.; Pesavento, M.; Zeni, L. High selectivity and sensitivity sensor based on MIP and SPR in tapered plastic optical fibers for the detection of L-nicotine. Sens. Actuators B Chem. 2014, 191, 529–536. [Google Scholar] [CrossRef]

- Verma, R.K.; Sharma, A.K.; Gupta, B.D. Modeling of Tapered Fiber-Optic Surface Plasmon Resonance Sensor With Enhanced Sensitivity. IEEE Photonic. Technol. Lett. 2007, 19, 1786–1788. [Google Scholar] [CrossRef]

- Verma, R.K.; Sharma, A.K.; Gupta, B.D. Surface plasmon resonance based tapered fiber optic sensor with different taper profiles. Opt. Commun. 2008, 281, 1486–1491. [Google Scholar] [CrossRef]

- Kumar, S.; Sharma, G.; Singh, V. Sensitivity of tapered optical fiber surface plasmon resonance sensors. Opt. Fiber Technol. 2014, 20, 333–335. [Google Scholar] [CrossRef]

- Cennamo, N.; Massarotti, D.; Galatus, R.; Conte, L.; Zeni, L. Performance Comparison of Two Sensors Based on Surface Plasmon Resonance in a Plastic Optical Fiber. Sensors 2013, 13, 721–735. [Google Scholar] [CrossRef]

- Cennamo, N.; Coelho, L.; Santos, D.F.; Baptista, J.M.; Guerreiro, A.; Jorge, P.A.S.; Zeni, L. Modal filtering for optimized surface plasmon resonance sensing in multimode plastic optical fibers. IEEE Sens. J. 2015, 15, 6306–6312. [Google Scholar] [CrossRef]

- Gasior, K.; Martynkien, T.; Urbanczyk, W. Effect of constructional parameters on the performance of a surface plasmon resonance sensor based on a multimode polymer optical fiber. Appl. Opt. 2014, 53, 8167–8174. [Google Scholar] [CrossRef] [PubMed]

- Kanso, M.; Cuenot, S.; Louarn, G. Sensitivity of Optical Fiber Sensor Based on Surface Plasmon Resonance: Modeling and Experiments. Plasmonics 2008, 3, 49–57. [Google Scholar] [CrossRef]

- Dwivedi, Y.S.; Sharma, A.K.; Gupta, B.D. Influence of design parameters on the performance of a SPR based fiber optic sensor. Plasmonics 2008, 3, 79–86. [Google Scholar] [CrossRef]

| Configuration | B2 | B1 | Intercept | Adj. R-Square |

|---|---|---|---|---|

| A | 11,301.90 | −29,023.40 | 18,607.20 | 0.9997 |

| B | 11,819.05 | −30,274.00 | 19,355.60 | 0.9995 |

| C | 12,665.17 | −32,483,31 | 20,797.75 | 0.9977 |

| Configuration | Taper Ratio | Sensitivity [nm/RIU] | FWHM [nm] | SNR |

|---|---|---|---|---|

| “A” | 1.3 | 1450 | 67 | 7.4 |

| “B” | 1.4 | 1600 | 76 | 3 |

| “C” | 1.5 | 1700 | 90 | 2.6 |

| D-shaped POF (250 µm) [25] | 1 (non-tapered) | 550 | ~70 | 1.75 |

| D-shaped POF (1000 µm) [25] | 1 (non-tapered) | 1325 | ~200 | 0.85 |

| D-shaped POF (1000 µm) without buffer layer [17] | 1 (non-tapered) | ~2400 | ~180 | 0.98 |

| D-shaped POF (1000 µm) with buffer layer [17] | 1 (non-tapered) | ~2500 | ~150 | 2.33 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cennamo, N.; Arcadio, F.; Minardo, A.; Montemurro, D.; Zeni, L. Experimental Characterization of Plasmonic Sensors Based on Lab-Built Tapered Plastic Optical Fibers. Appl. Sci. 2020, 10, 4389. https://doi.org/10.3390/app10124389

Cennamo N, Arcadio F, Minardo A, Montemurro D, Zeni L. Experimental Characterization of Plasmonic Sensors Based on Lab-Built Tapered Plastic Optical Fibers. Applied Sciences. 2020; 10(12):4389. https://doi.org/10.3390/app10124389

Chicago/Turabian StyleCennamo, Nunzio, Francesco Arcadio, Aldo Minardo, Domenico Montemurro, and Luigi Zeni. 2020. "Experimental Characterization of Plasmonic Sensors Based on Lab-Built Tapered Plastic Optical Fibers" Applied Sciences 10, no. 12: 4389. https://doi.org/10.3390/app10124389

APA StyleCennamo, N., Arcadio, F., Minardo, A., Montemurro, D., & Zeni, L. (2020). Experimental Characterization of Plasmonic Sensors Based on Lab-Built Tapered Plastic Optical Fibers. Applied Sciences, 10(12), 4389. https://doi.org/10.3390/app10124389