Finite Element Analysis of Grain Size Effects on Curvature in Micro-Extrusion

Abstract

1. Introduction

2. Materials and Methods

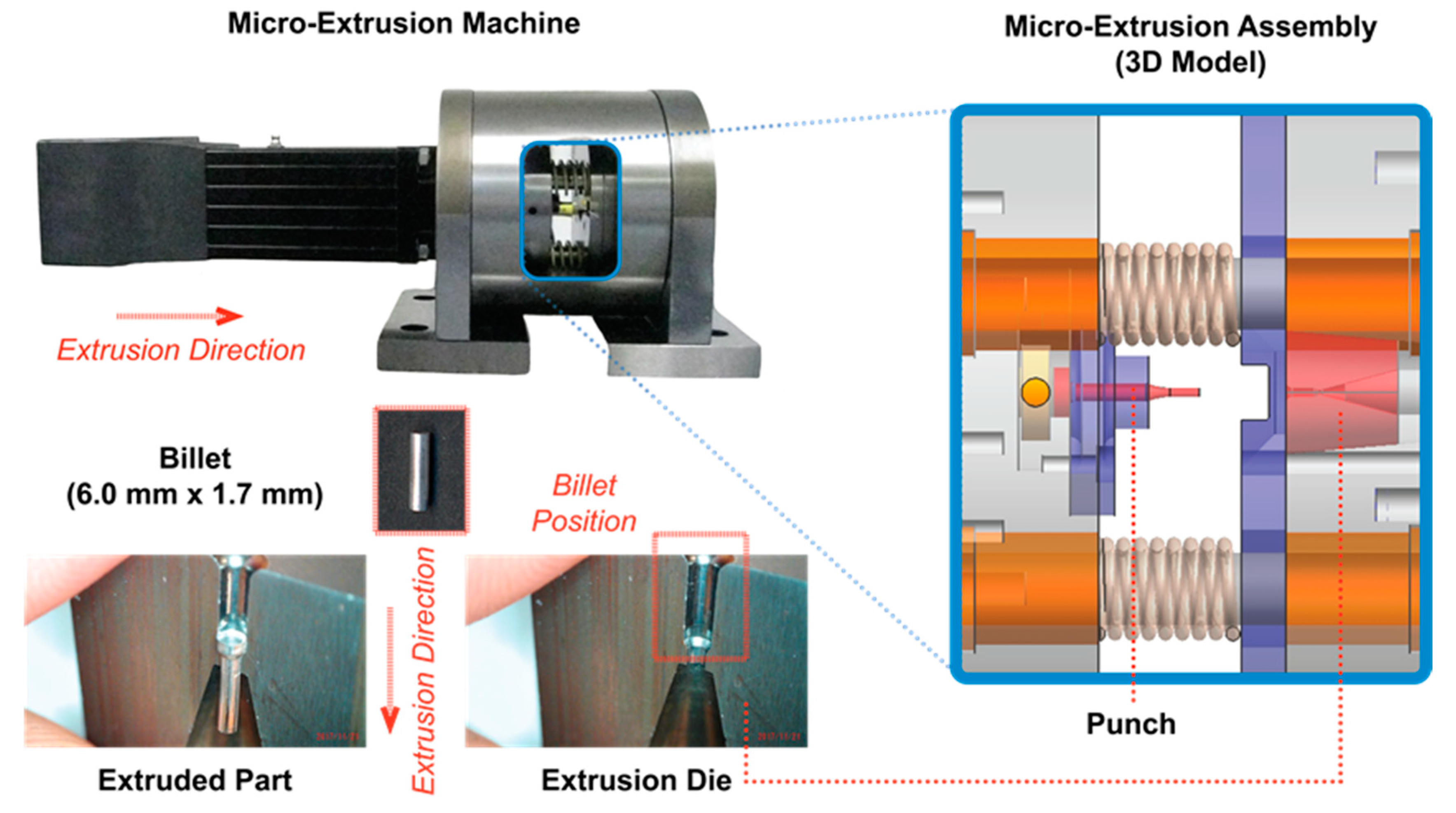

2.1. Micro-Extrusion Experiment and Simulation

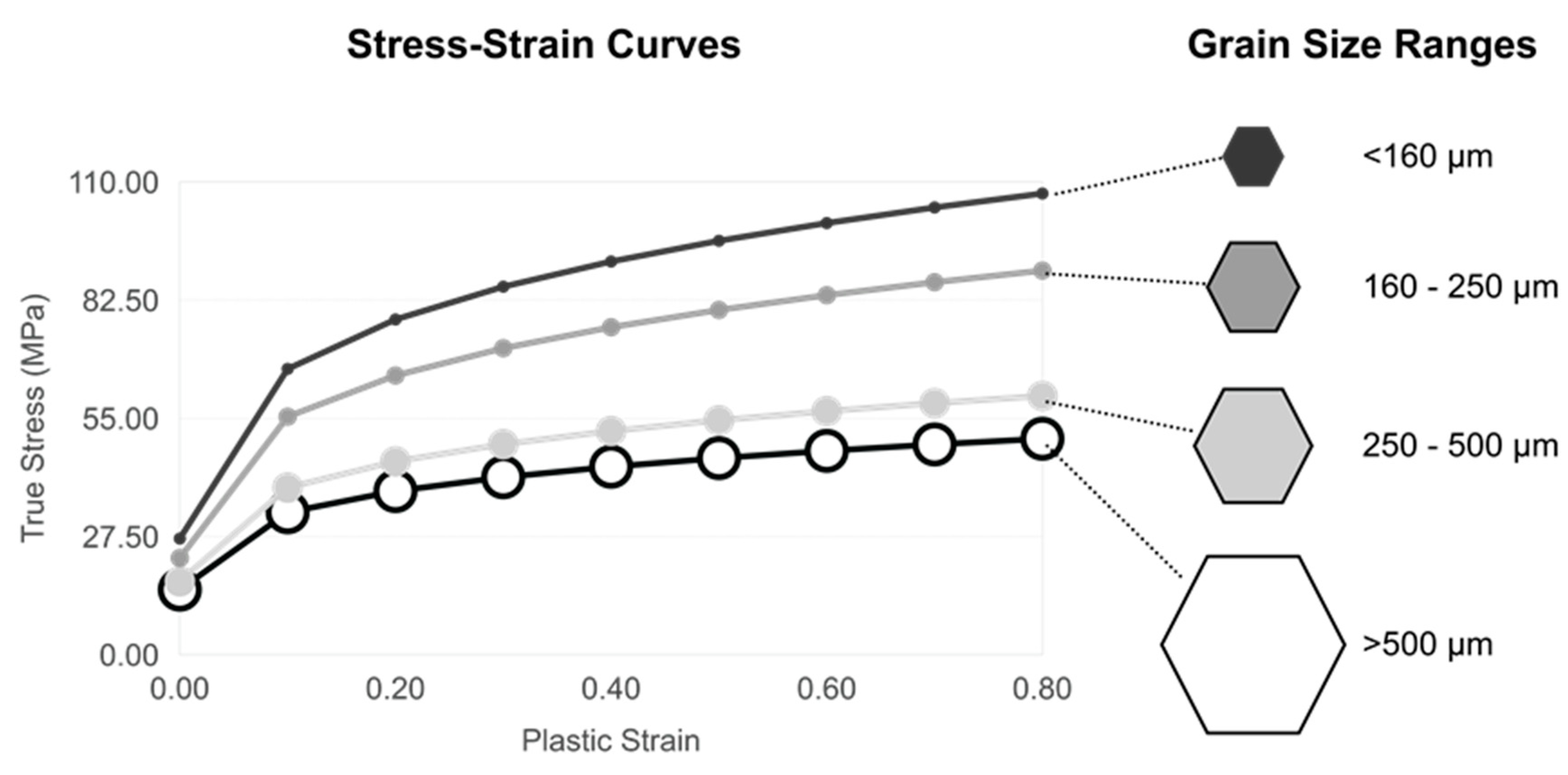

2.2. Considered Grain Sizes, Grain Boundaries, and Grain Orientations

2.2.1. Grain Orientations

2.2.2. Grain Boundaries and Grain Orientations

2.2.3. Grain Sizes and Grain Boundaries

2.2.4. Bearing Lengths

2.2.5. Extrusion Curvature Index

3. Results and Discussion

3.1. Effects of Grain Orientations

3.2. Effects of Grain Boundaries and Grain Orientations

3.3. Effects of Grain Sizes and Grain Boundaries

3.4. Effects of Bearing Lengths

- -

- For single-grain conditions (GR = 0.75), if the grain sizes and grain boundaries were symmetric along the extrusion direction, the grain orientation was the dominating factor for the curvature. If the grain sizes and grain boundaries were not symmetric along the extrusion direction, the grain boundary at the high strain and die opening area was the dominating factor for the curvature. The interactive influences of the grain boundary and grain orientation also affected the curvature.

- -

- For poly-grain conditions (GR < 0.75), if the number of grains across the specimen increased up to 2.7, the curvature effects were dramatically reduced. The influences of the grain boundaries and grain orientations were not significant.

- -

- For all conditions, if the bearing lengths (BL) were extended beyond the exit diameter (DE), the micro-extrusion pins were straightened.

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cullen, J.M.; Allwood, J.M. Mapping the Global Flow of Aluminum: From Liquid Aluminum to End-Use Goods. Environ. Sci. Technol. 2013, 47, 3057–3064. [Google Scholar] [CrossRef] [PubMed]

- Alting, L.; Kimura, F.; Hansen, H.N.; Bissacco, G. Micro Engineering. CIRP Ann. 2003, 52, 635–657. [Google Scholar] [CrossRef]

- Dong, X.; Chen, F.; Chen, S.; Liu, Y.; Huang, Z.; Chen, H.; Feng, S.; Zhao, L.; Wu, Z.; Zhang, X. Microstructure and microhardness of hot extruded 7075 aluminum alloy micro-gear. J. Mater. Process. Technol. 2015, 219, 199–208. [Google Scholar] [CrossRef]

- Cowley, A.; Woodward, B. A Healthy Future: Platinum in Medical Applications. Platin. Met. Rev. 2011, 55, 98–107. [Google Scholar] [CrossRef]

- Geiger, M.; Kleiner, M.; Eckstein, R.; Tiesler, N.; Engel, U. Microforming. CIRP Ann. 2001, 50, 445–462. [Google Scholar] [CrossRef]

- Qin, Y. Micro-forming and miniature manufacturing systems—Development needs and perspectives. J. Mater. Process. Technol. 2006, 177, 8–18. [Google Scholar] [CrossRef]

- Gronostajski, Z.; Pater, Z.; Madej, L.; Gontarz, A.; Lisiecki, L.; Łukaszek-Sołek, A.; Łuksza, J.; Mróz, S.; Muskalski, Z.; Muzykiewicz, W.; et al. Recent development trends in metal forming. Arch. Civ. Mech. Eng. 2019, 19, 898–941. [Google Scholar] [CrossRef]

- Jeswiet, J.; Geiger, M.; Engel, U.; Kleiner, M.; Schikorra, M.; Duflou, J.; Neugebauer, R.; Bariani, P.; Bruschi, S. Metal forming progress since 2000. CIRP J. Manuf. Sci. Technol. 2008, 1, 2–17. [Google Scholar] [CrossRef]

- Parasız, S.A.; Kinsey, B.L.; Mahayatsanun, N.; Cao, J. Effect of specimen size and grain size on deformation in microextrusion. J. Manuf. Process. 2011, 13, 153–159. [Google Scholar] [CrossRef]

- Rosochowski, A.; Presz, W.; Olejnik, L.; Richert, M. Micro-extrusion of ultra-fine grained aluminium. Int. J. Adv. Manuf. Technol. 2007, 33, 137–146. [Google Scholar] [CrossRef]

- Fann, K.-J.; Chen, C.-C. Grain Size in Aluminum Alloy 6061 under Hot Ring Compression Test and after T6 Temper. Appl. Sci. 2017, 7, 372. [Google Scholar] [CrossRef]

- Justinger, H.; Hirt, G. Estimation of grain size and grain orientation influence in microforming processes by Taylor factor considerations. J. Mater. Process. Technol. 2009, 209, 2111–2121. [Google Scholar] [CrossRef]

- Hansen, N. The effect of grain size and strain on the tensile flow stress of aluminium at room temperature. Acta Metall. 1977, 25, 863–869. [Google Scholar] [CrossRef]

- Li, Y.; Bushby, A.J.; Dunstan, D.J. The Hall–Petch effect as a manifestation of the general size effect. Proc. R. Soc. A Math. Phys. Eng. Sci. 2016, 472, 20150890. [Google Scholar] [CrossRef]

- Kim, G.-Y.; Ni, J.; Koç, M. Modeling of the Size Effects on the Behavior of Metals in Microscale Deformation Processes. J. Manuf. Sci. Eng. 2006, 129, 470–476. [Google Scholar] [CrossRef]

- Wang, C.-J.; Guo, B.; Shan, D.-B.; Sun, L.-N. Effects of specimen size on flow stress of micro rod specimen. Trans. Nonferrous Met. Soc. China 2009, 19, s511–s515. [Google Scholar] [CrossRef]

- Parasiz, S.A.; Kinsey, B.; Krishnan, N.; Cao, J.; Li, M. Investigation of Deformation Size Effects During Microextrusion. J. Manuf. Sci. Eng. 2006, 129, 690–697. [Google Scholar] [CrossRef]

- Engel, U. Tribology in microforming. Wear 2006, 260, 265–273. [Google Scholar] [CrossRef]

- Krishnan, N.; Cao, J.; Dohda, K. Study of the Size Effect on Friction Conditions in Microextrusion—Part I: Microextrusion Experiments and Analysis. J. Manuf. Sci. Eng. 2006, 129, 669–676. [Google Scholar] [CrossRef]

- Mori, L.F.; Krishnan, N.; Cao, J.; Espinosa, H.D. Study of the Size Effects and Friction Conditions in Microextrusion—Part II: Size Effect in Dynamic Friction for Brass-Steel Pairs. J. Manuf. Sci. Eng. 2007, 129, 677–689. [Google Scholar] [CrossRef]

- Vollertsen, F.; Biermann, D.; Hansen, H.N.; Jawahir, I.S.; Kuzman, K. Size effects in manufacturing of metallic components. CIRP Ann. 2009, 58, 566–587. [Google Scholar] [CrossRef]

- Chan, W.L.; Fu, M.W.; Yang, B. Study of size effect in micro-extrusion process of pure copper. Mater. Des. 2011, 32, 3772–3782. [Google Scholar] [CrossRef]

- Deng, J.H.; Fu, M.W.; Chan, W.L. Size effect on material surface deformation behavior in micro-forming process. Mater. Sci. Eng. A 2011, 528, 4799–4806. [Google Scholar] [CrossRef]

- Lin, J.-F.; Li, F.; Zhang, J.-F. A new approach to investigate real flow stress in micro-extrusion. Trans. Nonferrous Met. Soc. China 2012, 22, s232–s238. [Google Scholar] [CrossRef]

- Xinyun, W.; Mao, Z.; Na, T.; Ning, L.; Lin, L.; Jianjun, L. A Forming Load Prediction Model in BMG Micro Backward Extrusion Process Considering Size Effect. Phys. Proced. 2013, 48, 146–151. [Google Scholar] [CrossRef][Green Version]

- Ghassemali, E.; Tan, M.-J.; Wah, C.B.; Jarfors, A.E.W.; Lim, S.C.V. Grain size and workpiece dimension effects on material flow in an open-die micro-forging/extrusion process. Mater. Sci. Eng. A 2013, 582, 379–388. [Google Scholar] [CrossRef]

- Ghassemali, E.; Tan, M.-J.; Jarfors, A.E.W.; Lim, S.C.V. Optimization of axisymmetric open-die micro-forging/extrusion processes: An upper bound approach. Int. J. Mech. Sci. 2013, 71, 58–67. [Google Scholar] [CrossRef]

- Ghassemali, E.; Tan, M.-J.; Wah, C.B.; Lim, S.C.V.; Jarfors, A.E.W. Effect of cold-work on the Hall–Petch breakdown in copper based micro-components. Mech. Mater. 2015, 80, 124–135. [Google Scholar] [CrossRef]

- Rajenthirakumar, D.; Sridhar, R.; Abenethiri, R.; Kartik, R.; Bagri, D. Experimental investigations of grain size effects in forward microextrusion. Int. J. Adv. Manuf. Technol. 2016, 85, 2257–2264. [Google Scholar] [CrossRef]

- Wang, C.; Wang, C.; Xu, J.; Zhang, P.; Shan, D.; Guo, B. Interactive effect of microstructure and cavity dimension on filling behavior in micro coining of pure nickel. Sci. Rep. 2016, 6, 23895. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Lin, J.; Dean, T.A.; Wang, L. A novel application of sideways extrusion to produce curved aluminium profiles: Feasibility study. Procedia Eng. 2017, 207, 2304–2309. [Google Scholar] [CrossRef]

- Zhou, W.; Lin, J.; Dean, T.A.; Wang, L. Feasibility studies of a novel extrusion process for curved profiles: Experimentation and modelling. Int. J. Mach. Tools Manuf. 2018, 126, 27–43. [Google Scholar] [CrossRef]

- Zhang, B.; Dodaran, M.; Ahmed, S.; Shao, S.; Meng, W.J.; Juul, K.J.; Nielsen, K.L. Grain-size affected mechanical response and deformation behavior in microscale reverse extrusion. Materialia 2019, 6, 100272. [Google Scholar] [CrossRef]

- Truong, T.-T.; Hsu, Q.-C.; Tong, V.-C. Effects of Solid Die Types in Complex and Large-Scale Aluminum Profile Extrusion. Appl. Sci. 2020, 10, 263. [Google Scholar] [CrossRef]

- Ye, T.; Li, L.; Guo, P.; Xiao, G.; Chen, Z. Effect of aging treatment on the microstructure and flow behavior of 6063 aluminum alloy compressed over a wide range of strain rate. Int. J. Impact Eng. 2016, 90, 72–80. [Google Scholar] [CrossRef]

- Roters, F.; Eisenlohr, P.; Bieler, T.R.; Raabe, D. Crystal Plasticity Finite Element Methods: In Materials Science and Engineering; Wiley-VCH: Weinheim, Germany, 2011. [Google Scholar]

- Funazuka, T.; Takatsuji, N.; Dohda, K.; Aizawa, T. Effect of Grain Size on Formability in Micro-extrusion-Research on Forward-Backward Micro-extrusion of Aluminum Alloy 1st Report-. J. Jpn. Soc. Technol. Plast. 2018, 59, 8–13. [Google Scholar] [CrossRef][Green Version]

- Pan, D.; Xu, Q.; Liu, B.; Li, J.; Yuan, H.; Jin, H. Modeling of grain selection during directional solidification of single crystal superalloy turbine blade castings. JOM 2010, 62, 30–34. [Google Scholar] [CrossRef]

- Dai, H.J.; D’Souza, N.; Dong, H.B. Grain Selection in Spiral Selectors During Investment Casting of Single-Crystal Turbine Blades: Part I. Experimental Investigation. Metall. Mater. Trans. A 2011, 42, 3430–3438. [Google Scholar] [CrossRef]

- Dai, H.J.; Dong, H.B.; D’Souza, N.; Gebelin, J.C.; Reed, R.C. Grain Selection in Spiral Selectors During Investment Casting of Single-Crystal Components: Part II. Numerical Modeling. Metall. Mater. Trans. A 2011, 42, 3439–3446. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, Q. Simulation and Experimental Studies on Grain Selection and Structure Design of the Spiral Selector for Casting Single Crystal Ni-Based Superalloy. Materials 2017, 10, 1236. [Google Scholar] [CrossRef]

| Condition | Lubrication | Tool Coating | Coefficient of Friction | Extrusion Speed |

|---|---|---|---|---|

| Test A | PAO Lubricant (2.6 mm2/s Kinematic Viscosity) | Uncoated | 0.45 | 0.10 mm/s |

| Test B | PAO Lubricant (428.6 mm2/s Kinematic Viscosity) | Uncoated | 0.25 | 0.10 mm/s |

| Test C | Dry (No Lubricant) | DLC (PVD) | 0.11 | 100 mm/s |

| Average Grain Size | Material Constant (k) | Strain Hardening Exponent (n) | Source of Data [37] |

|---|---|---|---|

| 47 μm | 265.30 MPa | 0.27 | Compression Test |

| 66 μm | 168.40 MPa | 0.30 | Compression Test * |

| 97 μm | 163.10 MPa | 0.25 | Compression Test |

| 150 μm | 113.00 MPa | 0.23 | Prediction |

| 200 μm | 94.12 MPa | 0.23 | Prediction |

| 375 μm | 63.13 MPa | 0.21 | Prediction |

| 500 μm | 52.58 MPa | 0.20 | Prediction |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Preedawiphat, P.; Mahayotsanun, N.; Sucharitpwatskul, S.; Funazuka, T.; Takatsuji, N.; Bureerat, S.; Dohda, K. Finite Element Analysis of Grain Size Effects on Curvature in Micro-Extrusion. Appl. Sci. 2020, 10, 4767. https://doi.org/10.3390/app10144767

Preedawiphat P, Mahayotsanun N, Sucharitpwatskul S, Funazuka T, Takatsuji N, Bureerat S, Dohda K. Finite Element Analysis of Grain Size Effects on Curvature in Micro-Extrusion. Applied Sciences. 2020; 10(14):4767. https://doi.org/10.3390/app10144767

Chicago/Turabian StylePreedawiphat, Pavaret, Numpon Mahayotsanun, Sedthawatt Sucharitpwatskul, Tatsuya Funazuka, Norio Takatsuji, Sujin Bureerat, and Kuniaki Dohda. 2020. "Finite Element Analysis of Grain Size Effects on Curvature in Micro-Extrusion" Applied Sciences 10, no. 14: 4767. https://doi.org/10.3390/app10144767

APA StylePreedawiphat, P., Mahayotsanun, N., Sucharitpwatskul, S., Funazuka, T., Takatsuji, N., Bureerat, S., & Dohda, K. (2020). Finite Element Analysis of Grain Size Effects on Curvature in Micro-Extrusion. Applied Sciences, 10(14), 4767. https://doi.org/10.3390/app10144767