WEEE Recycling and Circular Economy Assisted by Collaborative Robots †

Abstract

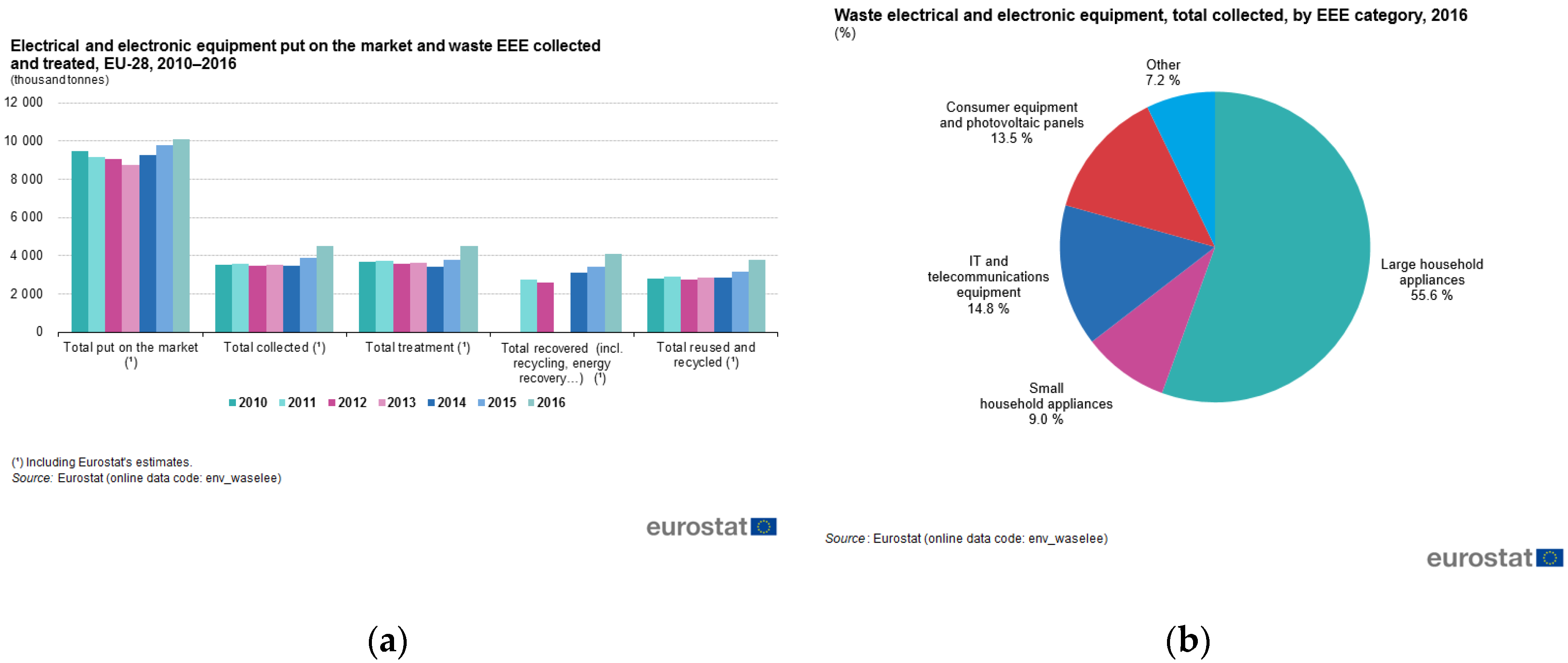

:1. Introduction

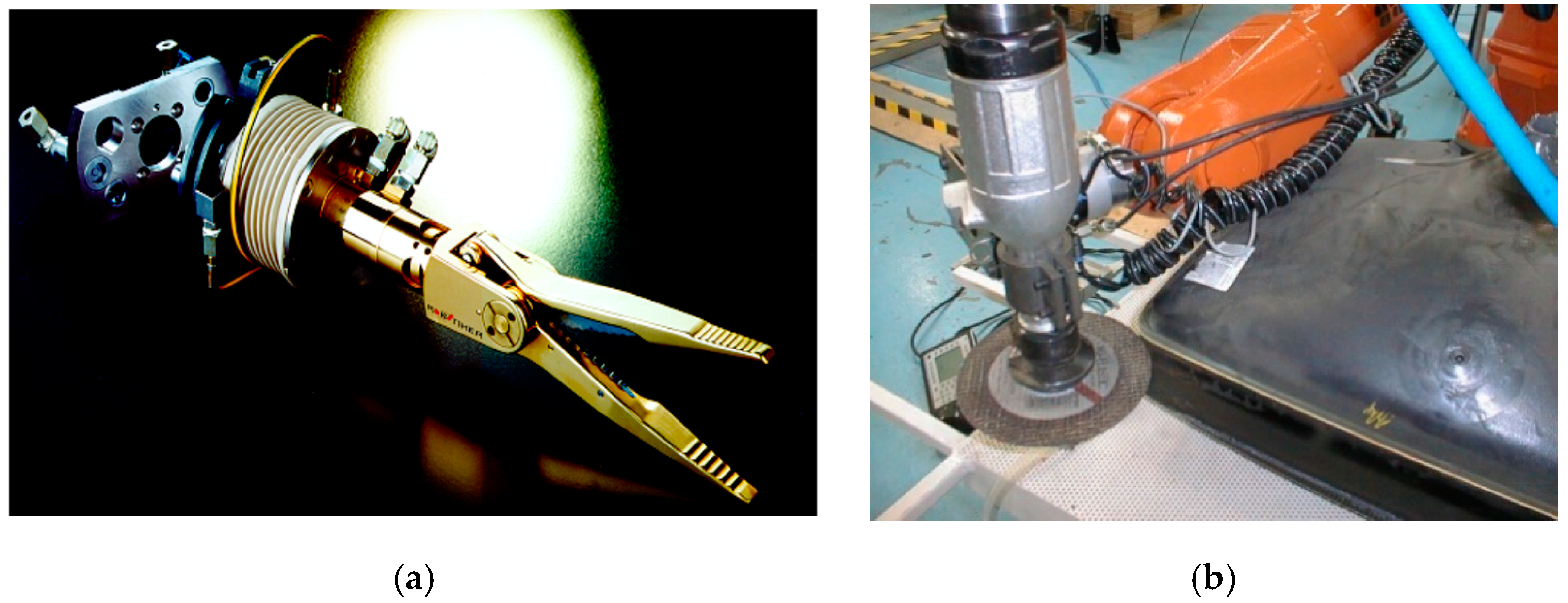

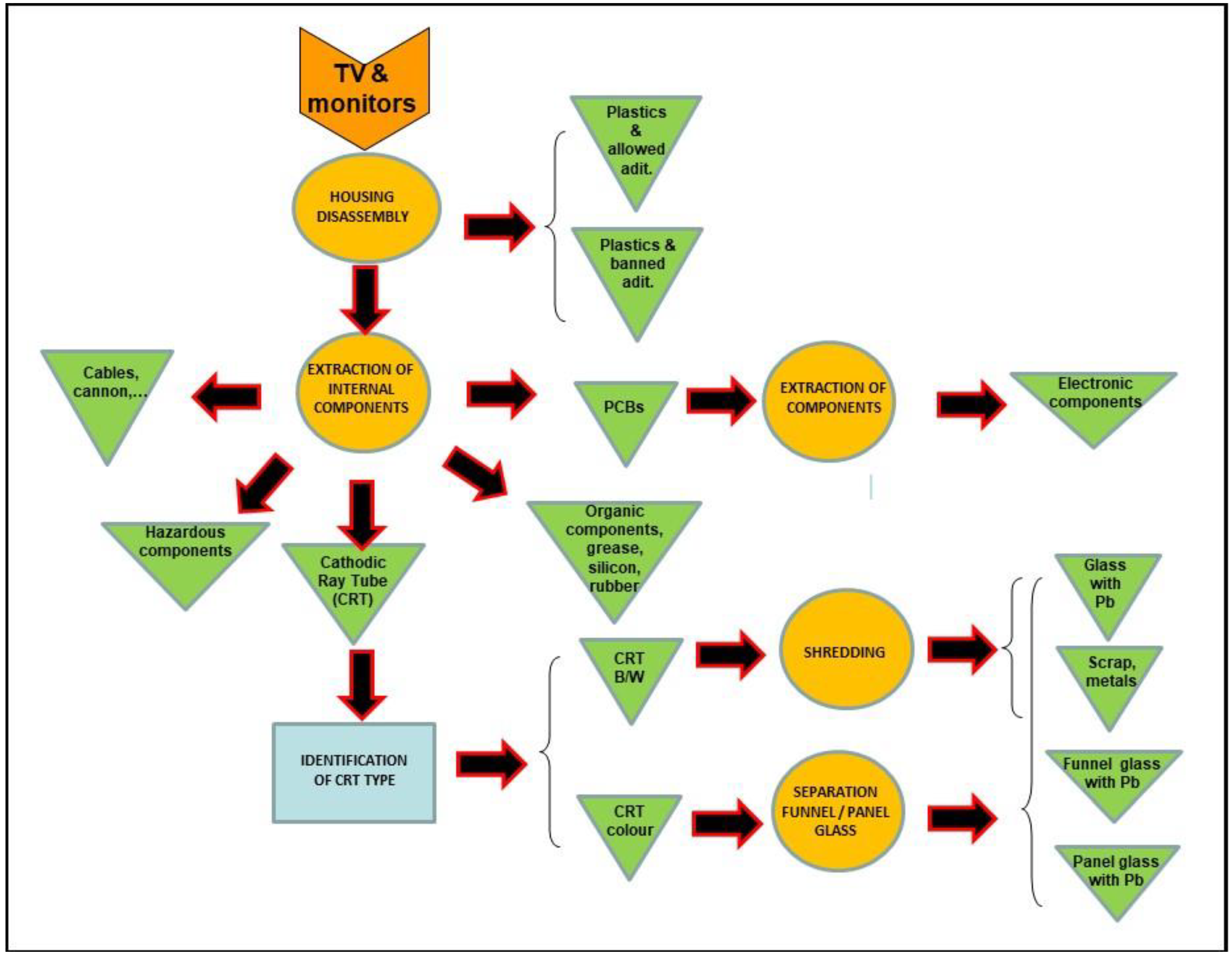

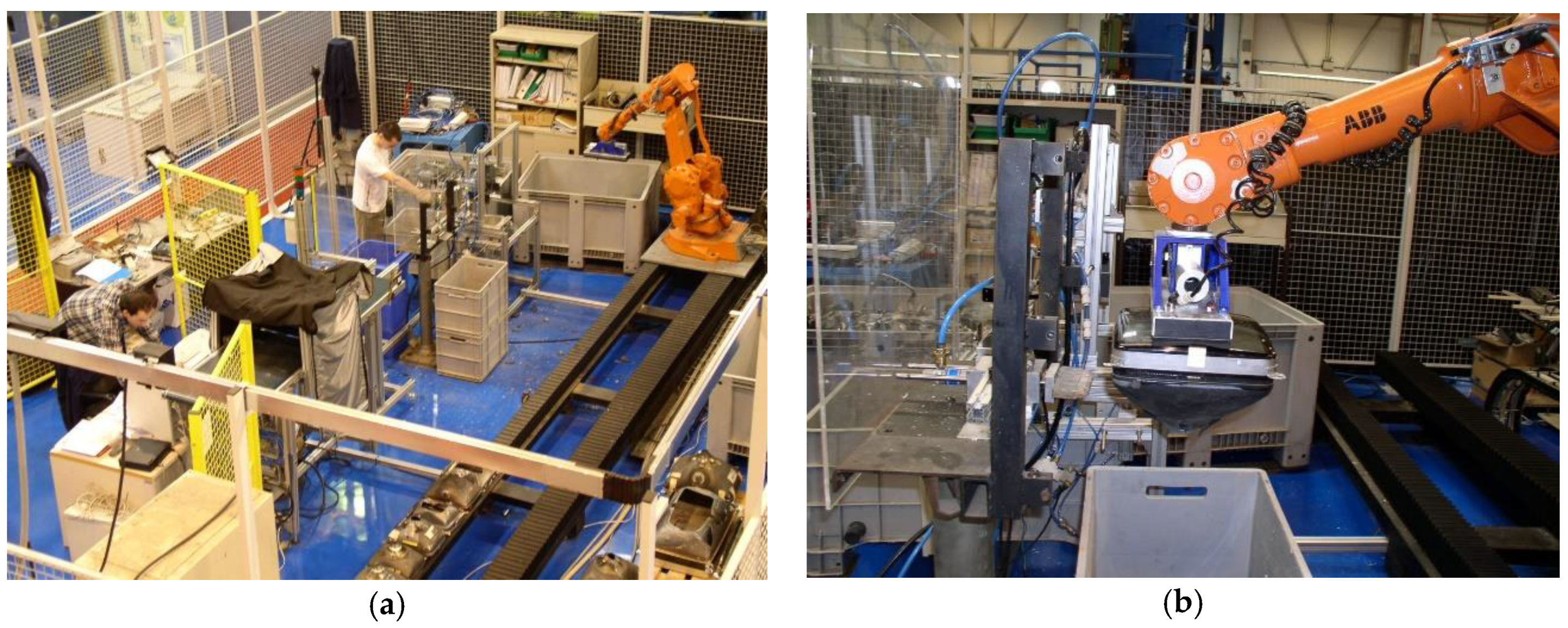

2. Materials and Methods

3. Results

Proposal of a Disassembly Process Using Collaborative Robots

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- ECOS. Available online: http:www.ecostandard.org (accessed on 18 December 2019).

- Waste Electrical & Electronic Equipment (WEEE). Available online: http://ec.europa.eu/environment/waste/weee/index_en.htm (accessed on 10 January 2019).

- Renteria, A. Simulation Method and Operational and Economic Strategies for Optimization in Processes of Automated Recycling of Electronic Devices. Ph.D. Thesis, University of Deusto, Bilbao, Spain, 2010. [Google Scholar]

- EU Circular Economy Package. Available online: https://www.gs1.org/sites/default/files/eu_circular_economy_package.pdf (accessed on 16 January 2020).

- COM (2019) 640 final. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions. In The European Green Deal; Publications Office of the European Union: Brussels, Belgium, 2019.

- McIntyre, K. Delivering sustainability through supply chain management. In Global Logistics. New Directions in Supply Chain Management, 7th ed.; Waters, D., Rinsler, S., Eds.; Kogan Page: London, UK, 2014; pp. 244–258. [Google Scholar]

- Waste Statistics—Electrical and Electronic Equipment—Eurostat. Statistics Explained. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics_-_electrical_and_electronic_equipment#EEE_put_on_the_market_and_WEEE_collected_in_the_EU (accessed on 15 May 2020).

- Waste Targets. Eurostat. Available online: https://ec.europa.eu/eurostat/web/waste/targets (accessed on 15 May 2020).

- Waste Electrical and Electronic Equipment (WEEE) by Waste Management Operations. Eurostat. Available online: https://appsso.eurostat.ec.europa.eu/nui/show.do?dataset=env_waselee&lang=en (accessed on 15 May 2020).

- Report on the WEEE Recovery Targets, European Commission. 2017. Available online: http://ec.europa.eu/environment/waste/weee/pdf/report_re-examination_recovery_targets_calculation_en.pdf (accessed on 19 February 2019).

- OECD (2018). Improving Plastics Management: Trends, Policy Responses, and the Role of International Co-Operation and Trade; Background Report; OECD Publishing: Paris, France, 2018. [Google Scholar]

- DRAFT REPORT on a European Strategy for Plastics in a Circular Economy. Available online: http://www.europarl.europa.eu/doceo/document/A-8-2018-0262_EN.html (accessed on 29 September 2019).

- Esmailzadeh Davani, A. Impacts of Increased Plastic Recycling in Sweden, A Quantitative Study of the Environmental, Social and Economic Impacts of Increased Plastic Recycling in Sweden. Bachelor’s Thesis, Lund University, Lund, Sweden, 2018. [Google Scholar]

- Vanegas, P.; Peeters, J.R.; Devoldere, T.; Cattrysse, D.; Duflou, J.R. Closed loop recycling of Philips TV housing plastics. In Proceedings of the International Conference “Innovation for Sustainable Production”, Bruges, Belgium, 6−9 May 2012. [Google Scholar]

- Mathieux, F.; Ardente, F.; Bobba, S.; Nuss, P.; Blengini, G.; Alves Dias, P.; Blagoeva, D.; Torres De Matos, C.; Wittmer, D.; Pavel, C.; et al. Critical Raw Materials and the Circular Economy—Background Report; JRC Science-for-policy report, EUR 28832 EN; Publications Office of the European Union: Luxembourg, 2017. [Google Scholar]

- Buchert, M.; Manhart, A.; Bleher, D.; Pingel, D. Recycling critical raw materials from waste electronic equipment. In Report of Oeko-Institut e.V., Freiburg (Germany), Commissioned by the North Rhine-Westphalia State Agency for Nature; Environment and Consumer Protection: Darmstadt, Germany, 2012. [Google Scholar]

- BioRefineries Blog. Available online: https://biorrefineria.blogspot.com/2020/03/profile-nantek-nanomaterials-as-reagent-key-take-chemical-recycling-next-level-pyrolysis.html (accessed on 2 June 2020).

- Brochure Responsible Recycling for CRT Screens. Available online: https://www.eera-recyclers.com/news/brochure-responisble-recycling-of-crt (accessed on 22 June 2019).

- Alvarez de los Mozos, E.; Rentería, A. Human-Robot collaboration as a new paradigm in circular economy for WEEE. Procedia Manuf. 2020, 38, 375–382. [Google Scholar]

- Graça Martinho, A.P.; Luanha Saraiva, R.R. Composition of plastics from waste electrical and electronic equipment (WEEE) by direct sampling. Waste Manag. 2012, 32, 1213–1217. [Google Scholar] [CrossRef] [PubMed]

- Dimitrakakis, E.; Janz, A.; Bilitewski, B.; Gidarakos, E. Small WEEE: Determining recyclables and hazardous substances in plastics. J. Hazard. Mater. 2009, 161, 913–919. [Google Scholar] [CrossRef] [PubMed]

- Schlummer, M.; Gruber, L.; Mäurer, A.; Wolz, G.; van Eldik, R. Characterisation of polymer fractions from waste electrical and electronic equipment (WEEE) and implications for waste management. Chemosphere 2007, 67, 1866–1876. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Wang, L. An AR-based worker support system for human-robot collaboration. Procedia Manuf. 2017, 11, 22–30. [Google Scholar] [CrossRef]

- Bauer, A.; Wollherr, D.; Buss, M. Human–Robot Collaboration: A Survey. Int. J. Hum. Robot. 2012, 5, 47–66. [Google Scholar] [CrossRef]

- Hentout, A.; Aouache, M.; Maoudj, A.; Akli, I. Human–robot interaction in industrial collaborative robotics: A literature review of the decade 2008–2017. Adv. Robot. 2019, 33, 764–799. [Google Scholar] [CrossRef]

- Gerbers, R.; Mücke, M.; Dietrich, F.; Dröder, K. Simplifying robot tools by taking advantage of sensor integration in human collaboration robots. In Proceedings of the 6th CIRP Conference on Assembly Technologies and Systems (CATS). Procedia CIRP 44, Gothenburg, Sweden, 16–18 May 2016; pp. 287–292. [Google Scholar]

- Mendes, N.; Ferrer, J.; Vitorino, J.; Safeea, M.; Neto, P. Human behaviour and hand gesture classification for smart human-robot interaction. Procedia Manuf. 2017, 11, 91–98. [Google Scholar] [CrossRef]

- Tsarouchi, P.; Makris, S.; Chryssolouris, G. Human–Robot Interaction Review and Challenges on Task Planning and Programming. Int. J. Comput. Integr. Manuf. 2016, 29, 916–931. [Google Scholar] [CrossRef]

- Coupeté, E.; Moutarde, F.; Manitsaris, S. Multi-users online recognition of technical gestures for natural Human-Robot Collaboration in manufacturing. In Autonomous Robots; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Kalverkamp, M.; Pehlken, A.; Wuest, T. Cascade Use and the Management of Product Lifecycles. Sustainability 2017, 9, 1540. [Google Scholar] [CrossRef] [Green Version]

- COGLABORATION Project. Available online: https://cordis.europa.eu/project/rcn/101415/factsheet/es (accessed on 16 May 2019).

- Hengstebeck, A.; Weisner, K.; Klöckner, M.; Deuse, J.; Kuhlenkötter, B.; Roßmann, J. Formal Modelling of Manual Work Processes for the Application of Industrial Service Robotics. In Proceedings of the 48th CIRP Conference on Manufacturing Systems—CIRP CMS 2015, Naples, Italy, 24–26 June 2015; Volume 41, pp. 364–369. [Google Scholar]

- Aiyar, S.; Ebeke, C.; Shao, X. The Impact of Workforce Aging on European Productivity; International Monetary Fund Working Paper; IMF Publications: Washington, DC, USA, 2016. [Google Scholar]

- Kroon, A.C.; van Selm, M.; ter Hoeven, C.; Vliegenthart, R. Dealing with an aging workforce: Locating threats and opportunities in corporate media. Educ. Gerontol. 2016, 42, 818–834. [Google Scholar] [CrossRef] [Green Version]

- Nilsson, C.H.; Nordahl, H.; Persson, I. Analysis and evaluation of flexible capital investment. In Economics of Advanced Manufacturing Systems; Parsaei, H.R., Mital, A., Eds.; Chapman & Hall: London, UK, 1992; pp. 239–253. [Google Scholar]

- Macleod, D.; Clarke, N. Engaging for Success: Enhancing Performance through Employee Engagement, A Report to Government; Department for Business Innovation & Skills (BIS) Crown Copyright; Office of Public Sector Information: Richmond, UK, 2012. [Google Scholar]

- Kahn, W.A. Psychological Conditions of Personal Engagement and Disengagement at Work. Acad. Manag. J. 1990, 33, 692–724. [Google Scholar]

- Clark, A.E. What Really Matters in a Job? Hedonic Measurement Using Quit Data. Labour Econ. 2001, 8, 223–242. [Google Scholar] [CrossRef]

- Helliwell, J.; Huang, H. Well-Being and Trust in the Workplace. J. Happiness Stud. 2011, 12, 747–767. [Google Scholar] [CrossRef]

- Yamamoto, I. The Impact of AI and Information Technologies on Worker Stress. Available online: https://voxeu.org/article/impact-ai-and-information-technologies-worker-stress (accessed on 1 June 2020).

| Number of CRTs | 2015 | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|---|

| CRTs collected (kg) | 1,699,000 | 2,129,000 | 1,805,000 | 1,870,000 | 1,273,727 |

| Fraction Recovered after Treatment | % |

|---|---|

| Metallic fraction | 23.85 |

| Plastic fraction | 16.00 |

| Glass fraction | 57.60 |

| Wood fraction | 1.50 |

| Condenser | 0.06 |

| Others | 0.98 |

| Fluorescent Screen Coat | 0.01 |

| TOTAL | 100 |

| Material | Quantity | Unit | Sale Price (€/t) |

|---|---|---|---|

| Copper | 0.441 | kg | 5.771 |

| Iron/Steel | 1.620 | kg | 280 |

| Aluminum and other metals | 1.080 | kg | 1.690 |

| PVC | 0.700 | kg | 1.290 |

| Funnel glass | 2.430 | kg | 30 |

| Screen glass | 5.130 | kg | 30 |

| Condensers | 0.008 | kg | 240 |

| Plastics for mechanical recycling | 1.000 | kg | 717 |

| Plastics for concrete manufacturers | 0.666 | kg | 25 |

| Polypropylene (plastics) | 0.250 | kg | 400 |

| Others | 0.211 | kg | 0 |

| TOTAL | 13.54 | kg | |

| Percentage of recovery (in weight) | 90.24% | ||

| Parameter | Quantity | Units |

|---|---|---|

| Productivity | ||

| Number of TV/monitors processed | 48 | devices/h |

| Capacity of the recycling line | 76,800 | CRT/year |

| Total weight of the separated and recovered material | 13.54 | kg/unit |

| Percentage of recovery (in weight) | 90.24 | % |

| Revenues and operating costs | ||

| Sales revenue | 6.79 | €/unit |

| Required workforce | 6 | workers |

| Number of shifts | 1 | shifts |

| Hourly workforce cost | 15 | €/h |

| Required investment | 258,056 | € |

| Annual operating expenses | 146,080 | € |

| Annual revenue from obtained material | 521,187 | € |

| Average treatment cost | 2.57 | €/unit |

| Indicator | Value | Unit |

|---|---|---|

| Net Present Value | 1,677,970 | € |

| Internal Rate of Return | 153,11 | % |

| Pay-Back Period | 0.69 | years |

| Capital-Back | 0.72 | years |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Álvarez-de-los-Mozos, E.; Rentería-Bilbao, A.; Díaz-Martín, F. WEEE Recycling and Circular Economy Assisted by Collaborative Robots. Appl. Sci. 2020, 10, 4800. https://doi.org/10.3390/app10144800

Álvarez-de-los-Mozos E, Rentería-Bilbao A, Díaz-Martín F. WEEE Recycling and Circular Economy Assisted by Collaborative Robots. Applied Sciences. 2020; 10(14):4800. https://doi.org/10.3390/app10144800

Chicago/Turabian StyleÁlvarez-de-los-Mozos, Esther, Arantxa Rentería-Bilbao, and Fernando Díaz-Martín. 2020. "WEEE Recycling and Circular Economy Assisted by Collaborative Robots" Applied Sciences 10, no. 14: 4800. https://doi.org/10.3390/app10144800