Abstract

Electronic waste (e-waste) has become one of the fastest-growing waste, leading a globe issue. Reverse supply chain (RSC) is considered a potential way for e-waste management. Over the last two decades, RSC has received significant attention from industries, governments, experts, and researchers. A large number of studies have been published in the field of e-waste RSC. Most of the existing review papers concentrated on the general RSC models for all types of returned products. However, the review papers focusing on specific products, such as e-waste, are quite limited. To fill this gap published papers in the area of RSC for a specific product, e-waste, from 1999 to 2019 have been selected for review and analysis in this study. E-waste RSC studies have been divided into four main groups, namely, factors of implementation, performance evaluation and decision making, foresting product returns, and network design. Finally, some potential directions for e-waste RSC models have been suggested for future research.

1. Introduction

Companies are currently challenged in globally competitive markets due to resource scarcity, environmental regulations, and economic pressure [1]. In addition, customers are becoming more demanding in terms of environmental and social issues [2]. Further, firms should take into account environmental regulations from governments to take responsibility for their end-of-life products. Some environmental regulations have been introduced such as the Waste Electrical and Electronic Equipment (WEEE) Directive, and the Restriction of Use of Certain Hazardous Substances Directive (RoHS) [3]. RoHS was introduced in the European Union and aims to restrict the use of specific hazardous materials found in electrical and electronic products, while the WEEE Directive focuses on reducing the disposal of waste and contributes to the efficient use of resources by re-using, recycling, and refurbishing [3]. These vital challenges are forcing companies to pay attention to reverse supply chain (RSC) management. RSCs or reverse logistics are terms used interchangeably in some literature [4]. An RSC consists of various activities to reuse or recycle a used product from a consumer or dispose of it properly.

RSCs can be considered as one of the most vital ways to implement circular economy practices at an inter-organisational level [5]. An RSC is also part of a closed-loop supply chain which is the combination of forward and reverse flows of products and information in the supply chain that circulates an on-going flow of products.

With the significant amount of upgrading of electronic devices, electronic waste (e-waste) is one of the fastest-growing types of waste. For example, 80% of mobile phones have been upgraded every two years, which leads to a large number of discard products [6]. E-waste RSC systems require a unique system from general RSC systems due to e-waste containing some special characteristics and features, such as a short product lifecycle, and the large amount of precious and hazardous materials involved [7]. The complicated processes of RSC for e-waste comes from the disposal of e-waste. It is a dynamic system with a high level of uncertainties in quantity, quality, and time of returned products [8]. Firstly, there are three main sources of e-waste generation, including households, industries, and institutional sources (i.e., schools, hospitals, and governmental agencies) [7]. Secondly, e-waste collection is derived from municipality collection points, electronic industries, retailers, and informal and formal recycling sectors. Informal recycling activities are common in developing countries, such as India and South Africa, where recycling methods are rudimentary, and a significant proportion of e-waste components end up in uncontrolled landfills.

To mitigate the amount of product disposal, industries have been carrying out 6R concepts (namely, Reduce, Reuse, Recycle, Recover, Redesign, and Remanufacture) to improve recovery implementation and minimize non-value added activities within end-of-life (EoL) management [9]. Companies gain many benefits by implementing product EoL treatment, such as financial benefits to companies, product usage, increasing market share, improved public reputation, and competitive advantage.

The amount of published research in the field of reverse supply chains focusing on electronic waste is significantly increasing. However, the number of review papers on e-waste RSCs is still limited. To fill the research gap, this research aims to provide a comprehensive picture of the area by reviewing the literature and classifying it into four key research types: factors of implementation, performance evaluation and decision making, foresting product returns, and network design. After reviewing the published articles, research gaps and the potential works were then identified and suggested for future researchers.

The rest of the paper is organized as follows. Section 2 describes the current issues of electronic waste while the detailed explanation of reverse supply chain is discussed in Section 3. Section 4 examines the detailed analysis of the collected papers, whereas Section 5 focuses on the research gaps and the potential future works. Section 6 ends with the conclusion.

2. Electronic Waste Issues

In today’s business world with a competitive electronics market, the production of electronic equipment is rapidly growing because customers are likely to own the latest models with more advanced functions and attractive designs. This leads to the amount of e-waste growing speedily, reaching around 41.8 million tonnes in 2014 [3]. The quantity of e-waste produced is approximately three times faster in comparison with other wastes [10]. The amount of e-waste is estimated to reach 52 million tonnes or 6.8 kg per capita in 2021. However, around 20% of all e-waste generated is officially collected and recycled [11]. For example, the average lifespan of a new computer in India has reduced from seven years to four years [12]. Most e-waste was generated in Asia (16 million tonnes) whereas the least e-waste generation (0.6 million tonnes) was in Australia in 2016. The highest e-waste per resident (15.6 kg per capita) was in Europe, while Africa produced the lowest quantity of e-waste per capita (1.7 kg per capita). Both North and South Americas released around 11.7 million tonnes, which was equal to 12.2 kg per capita [13].

E-waste has no standard definition but, in general, e-waste refers to all types of electrical and electronic products and its components that have been discarded by the owner as waste without the intention of re-use [14]. E-waste can be divided into six main categories: large devices, small devices, small IT and telecommunications equipment, temperature exchange equipment, lamps, and screens and monitors. According to the information of [11,13], Table 1 presents the examples of these categories and the amount of each category generated. Each category has different functions, and materials used, which causes various influences on the environment and human health if they are not strictly managed and treated.

Table 1.

Different categories of e-waste and the amount of each category generated.

E-waste contains a wide range of valuable substances such as gold, platinum, silver, zinc, copper, plastic and palladium, which can be recycled to become potential new raw materials [11]. The total value of all raw materials contained e-waste is approximately 55 billion euros in 2016, which is higher than the 2016 Gross Domestic Product of most countries in the world [11]. For example, the highest average value comes from three valuable metals (platinum: 37,607 €/kg; gold: 34,070 €/kg; and palladium: €23,214/kg) [15]. However, e-waste also includes a large number of dangerous substances like lead (Pb), hexavalent chromium (Cr6), mercury (Hg), cadmium (Cd), and flame retardants (i.e., polybrominated biphenyls and polybrominated diphenylethers) [16]. These chemicals assorted with solid wastes are posing a great risk for environmental deterioration especially in developing nations, like China and Bangladesh, where the appropriate technology for recycling is limited and non-formal recyclers are handling precious metals through crude ways due to an economic aspect [17]. Transboundary shipment of e-waste is strictly regulated by the Basel Convention. The developed countries have been banned the export of e-waste to developing countries. Unlawful activities are going leading to severe damage on health and the environment in some developing countries. With the lack of suitable treatment strategies, a large amount of e-waste ends up in landfills, leading to dangerous impacts on the environment and society [18].

There are many regulations developed and implemented by different governments and non-government organizations worldwide to prevent the growth and illegal movements of the e-waste between nations and, hence, restrict the pollution generated.

In the European Union, there are two directives in e-waste handling, namely the Waste Electronic and Electrical Equipment (WEEE) directive and Restriction of Hazardous Substances (RoHS). The recycling rate of e-waste in the European Union is around 35% higher than the e-waste recycling rate in the US since the management of e-waste in the EU is implemented by these two directives [19]. The purpose of the WEEE directive is to increase the collection percentage for EoL electronic products from 65% by 2012 to 85% in 2016. In addition, the RoHS Directive aims to reduce the use of harmful materials in electronics, such as mercury, cadmium, lead, and polybrominated biphenyls (PBB). Moreover, some other European countries not part of the European Union have also been successfully handling e-waste. Switzerland, for example, has two different e-waste systems: SWICO for office, and SENS for home products. The recycling companies related to both systems have recycled approximately 75,000 metric tons of e-waste in 2004, which is 11 kg of e-waste per person in comparison with a minimum rate of 4 kg per capital guided by WEEE directive in 2002.

In Japan, Home Appliance Recycling Law was passed in 1998 to collect four types of household appliances: televisions, refrigerators, washing machines and air conditioners. A proportion of the recycling and transportation fee is covered by consumers. This fee varies from US$27 to US$65 depending on different types of electronic devices [11]. Consumers are encouraged to send e-waste to the store where they bought the product. Retailers then transfer the used product to established collection centres, and companies are required to recycle e-waste. The recycling rate of e-waste in Japan is around 75% under this law because consumers have a greater finical responsibility [19]. Until 2004, more than 40 e-waste recycling centres in Japan have been established and they are partially supported by the local governments or electronic companies.

Many states in the US have made efforts to collect and recycle e-waste from private houses and business sectors. For example, a law in California State has passed to charge consumer fees, namely advanced recycling fees (ARFs), when products are purchased. The ARFs is between US$6 and US$10 for collecting monitors, televisions, and laptops [20]. In 2006, the Electronic Product Recycling Law was introduced by Washington State. This law aims to require producers of computer and television products to implement a recycling system throughout the state with no fee to residential, local businesses, local municipalities, charitable organizations, and schools. Moreover, more than 800 local communities have created e-waste collection events, which is an essential role in e-waste management in private houses [21]. Some e-waste collection methods are implemented in the US, such as curbside, particular drop-off places, persistent drop-off, and takeback and purchasing centres [22]. According to Kahhat et al. [21], the actions of all states and main companies do play a vital role in sustainable development, but they are still limited in e-waste management in the US. The government should work together with company approaches to establish a regulatory framework to achieve an efficient solution.

The process of e-waste treatment is still quite slow in Southeast Asian nations, although many e-waste laws have been introduced and implemented [23]. The e-waste management regulations were published by the Government of India in October 2016. These regulations have been applied to manufacturer, producer, consumer, collection centres, dealers, e-retailers, refurbishers, dismantlers and recyclers involved in the manufacture, sale, transfer, purchase, collection, storage and processing of e-waste [24]. Thailand, Indonesia, Philippines Malaysia are in the final stage to develop their e-waste regulations [25].

If e-waste is properly treated, it would offer great benefits for urban mining in terms of the recovery of precious metals with the estimated value of €48 billion [26]. Therefore, handling e-waste is really a challenge for the related parties including customers, electronic industries and governments. RSCs offer a chance for the enhancement of legally collected and recycled e-waste.

3. Reverse Supply Chain

3.1. Definition of Reverse Supply Chain

RSCs comprise a number of activities needed to recover, reuse or dispose of a discarded product from a user [27]. Although the term RSC is sometimes used synonymously with reverse logistics (RL) by various researchers in their studies, there is a slight difference between them [28]. Prahinski and Kocabasoglu [29] clarified that the scope of RSC is somehow wider than RL. While the former concept includes coordination and collaboration with partners, additionally, the latter concentrates on the activities regarding transportation, warehouse and inventory management. In short, RL can be considered as one of the components in RCS. From a business perspective, RSC operation requires a large number of investments, but it can create economic benefits and strategic importance to companies [30].

3.2. Reverse Supply Chain Processes

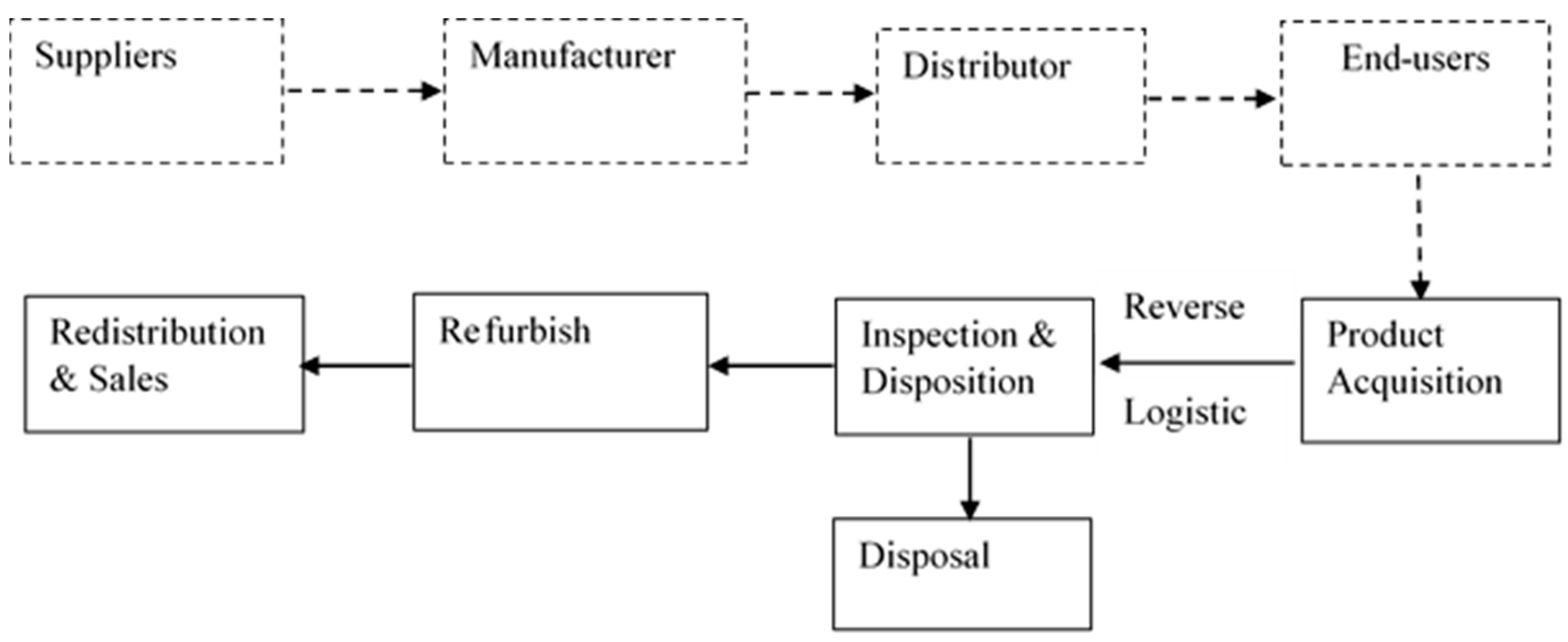

A closed-loop supply chain consists of both forward and reverse supply chains as shown in Figure 1. The flow of a forward supply chain starts with the purchasing of raw materials from different suppliers. Manufacturing plants are well designed with the necessary technology and responsible for producing various parts that are then assembled into finished products. After that, distribution centres deliver these products to end users [31] (seen in the dashed line). In contrast, the flow of reverse supply chain begins with product acquisition to redistribution and sales (seen in the solid line). The reverse supply chain is arranged by five primary steps: product acquisition, reverse logistics, inspection and disposition, refurbish, and distribution and sales. These five steps are further detailed as follows:

Figure 1.

A closed-loop supply chain for e-waste.

3.2.1. Product Acquisition

Product acquisition is a step of collecting returned products from the end-users for further treatment [26]. Returned products can be collected from three main ways: from the forward supply chain, from an existing RSC, or from the waste stream. Typical cases of collection from the forward chain consist of product returns or recalls. These returned products are normally damaged due to pushing upstream through the same chain members. In contrast, if used products are collected through established RSC, they are pulled upstream by incentive policies such as deposits or rebates for product returns. Used products are acquired by waste stream sources which can be sent to landfills or reused [29].

3.2.2. Reverse Logistics

When used products are collected, components and materials will be delivered to the next stage, namely reverse logistics. In this step, returned products are sent to the facilities for inspecting, sorting and disposition [32]. Transportation activity, inventory, distribution management are included in this process. Transportation cost usually accounts for the largest proportion of the total cost of reverse logistics operation. If the total cost related to renewable practices exceeds the total cost of purchasing new materials or products, firms might have insufficient finances for applying an RSC system. Therefore, it is important to manage reverse logistics activities effectively [29].

3.2.3. Inspection and Disposition

There are various reasons why customers return used products [33]. These reasons include end-of-life products, faulty items, customer returns, and obsoleted products [4]. Inspection and disposition steps aim to identify the quality of a used product and a suitable strategy for recovering each product in the RSC system.

3.2.4. Refurbish

After inspection and disposition stage, if a product is identified to be upgraded or repaired, it will be delivered to a refurbishing practice like repair, or remanufacturing centres.

3.2.5. Redistribution and Sales

The process of redistribution and sales in the RSC is quite similar to the process in the forward supply chain. While the latter deals with the new products, the former sell the reconditioned or recovery materials or components to the market. The potential consumers of these components or materials are original customers in the traditional market or new customers in different markets who do not want or cannot afford the new equipment [27].

3.3. Differences between Forward and Reverse Supply Chains

A reverse supply chain differs significantly from a forward supply chain in a wide range of aspects [26,34]. Table 2 shows a summary of these main differences. Reducing cost and increasing profit are considered as two vital goals in forward supply chains, while reverse supply chains focus on environmental regulations, cost minimization as well as profit maximization.

Table 2.

Differences between forward and reverse supply chains.

In forward supply chains, the demand for a product can be forecasted by using conventional forecasting techniques. However, these techniques might not be applied directly in reverse supply chains due to the high level of uncertainty regarding returned products [29,35]. In addition, a new product, in forward supply chains, is produced in a manufacturing facility that is transferred to many distributors. In RSC operations, product returns are collected from many resources, such as consumers, collection centres, etc., which are delivered to one treatment facility, such as recycling, remanufacturing or disposal facilities. In other words, the shipping flows in the former are one-to-many, whereas the shipping flows in the latter are normally many-to-one.

New products are generally packaged carefully to prevent damage during transportation processes and ensure ease of treatment and identification. On the other hand, product returns do not have complete packaging, which can lead to some important issues in shipping, treatment and identification. Another aspect of the difference is the delivery speed. If a customer cannot receive a new product on time from a company, the customer can change to the competitors of the company. This is a reason why forward supply chains should offer fast delivery to prevent stock-outs. In RSC, returned products can be collected from the company itself. Thus, these products can be delivered slower to the company, which does not cause any stock-outs or loss of customer satisfaction.

A new product normally has a fixed structure decided based on the bill of materials. The product should pass quality inspections to make sure the conformance to quality standards. In RSC, however, returned products are collected with different qualities, such as damaged products, missing components or nonworking products. Hence, the inspection stage consumes more time, and the estimation of the reusable component yield is challenging. Further, processing stages and times are generally different based on the quality of returned products.

Inventory management models in forward supply chains mainly assume that unlimited supply and demand known in advance. These models are unable to be applied in RSC systems since returned products are a high level of fluctuation with uncertainties. Thus, inventory management systems are demanding and inconsistent.

Information system infrastructure is usually installed to track the movement of products in forward supply chains. However, such infrastructure is not available in RSC systems, so it is difficult to establish operational planning due to the lack of critical information of returned products in the RSC networks.

In forward supply chains, delivering a new product to a customer is considered as a final disposition option of a product. However, this decision in RSC systems varies depending on the characteristics of returned products. A returned product can be reused, recycled, reprocessed or disposed based on its characteristic [36].

4. E-Waste Reverse Supply Chains

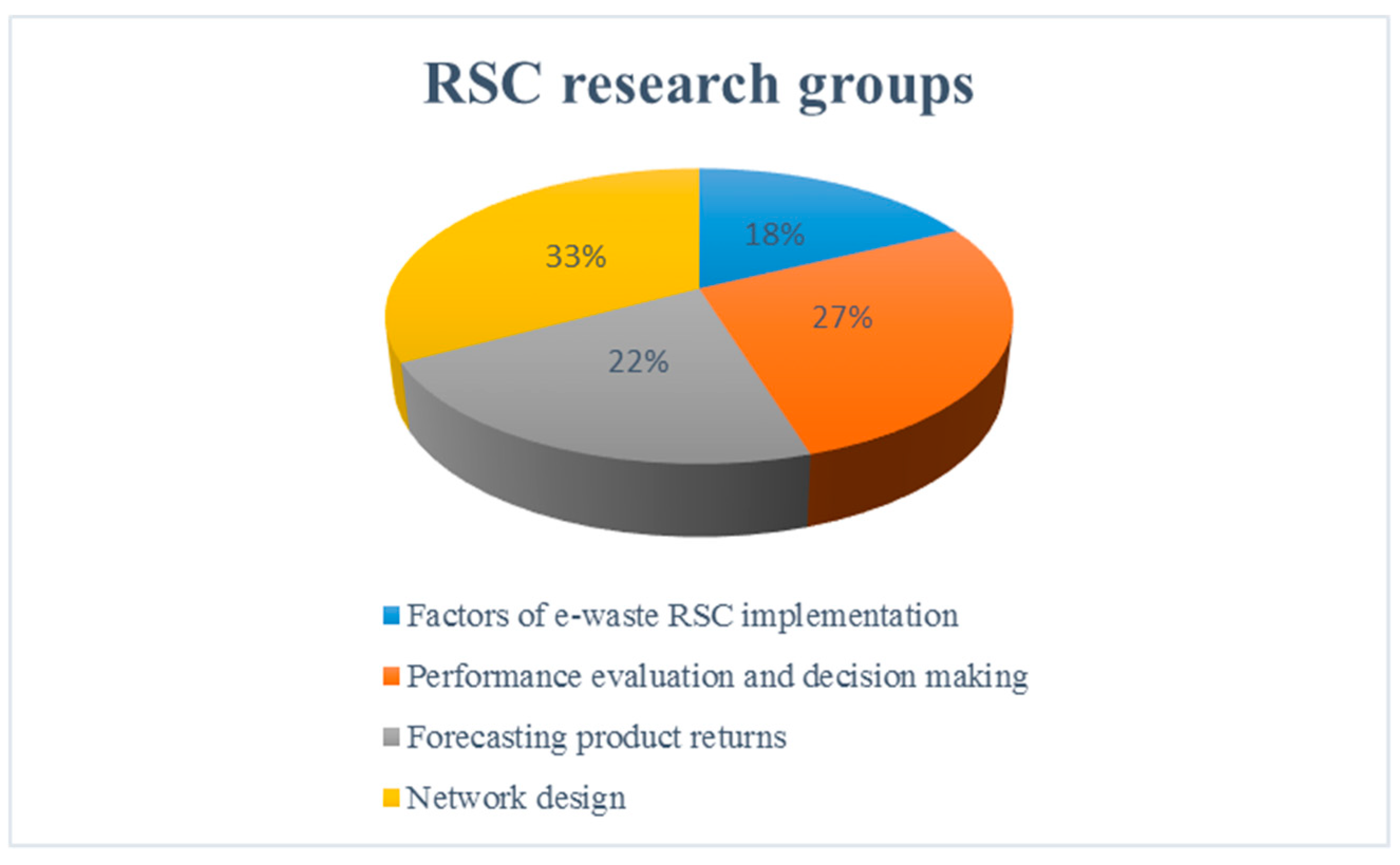

Due to the growing environmental issues, resource scarcity and limited landfill capacities in many nations, e-waste RSC operations have received growing attention from governments, industries and researchers. Based on the literature review, the key issues in the field of the reverse supply chain for e-waste can be divided into four main research groups: (1) factors of implementation; (2) performance evaluation and decision making; (3) Forecasting product returns; and (4) network design.

Figure 2 shows the percentage of research groups focusing on e-waste RSC and e-waste RSC network design has got the highest attention from researchers. The detailed analysis of these groups will be presented in the following subsections.

Figure 2.

E-waste RSC research groups.

4.1. Factors of Implementation

There are several factors that need to be considered before making decisions about RSC implementation. Analysing factors influencing RSC practices can suggest useful guidelines for top management in RSC implementation since this practice can affect the performance of the company in long-term goals. The summary of different factors of e-waste RSC implementation is shown in Table 3. Hung Lau and Wang [22] presented a conceptual model considering both external and internal elements which can affect the implementation of RSC practices in electronic companies in China. The internal factors consist of strategic consideration, financial issues, management skills and technical issues while external factors include public awareness, environmental regulations, economic evaluation, systems and collaboration. The research found that financial support and better tax policies can assist electronic companies with the investment cost of RSC operation. Ravi et al. [37] proposed key four determinants (i.e., economic elements, regulations, corporate citizenship, and environmental and green issues) considered in implementing RSC operation for end-of-life computers by using an analytic network process (ANP) technique. A study was conducted by Chiou et al. [38] investing and ranking three key factors (financial needs, environmental needs and social requirements) affecting RSC implementation in Taiwanese electronic companies by utilizing the fuzzy analytic hierarchy process (FAHP). They found that financial needs is the most important criteria while environmental and social needs place the second and third priorities, respectively.

Table 3.

Factors of e-waste RSC implementation.

In Brazil, Guarnieri et al. [39] applied an integrated approach between strategic analysis and problem structuring method to determine four main actions, such as strategic consideration, environmental awareness, economic concerns and social awareness considered in e-waste RSC practice. The study suggested that apart from the responsibility of government and electronic companies in RSC implementation, it is important to educate consumers to return or dispose of their end-of-life products in a proper place. A framework for EoL computer recycling in RSC operation in Australia was obtained by Rahman and Subramanian [40]. They investigated the key factors influencing the implementation of computer recycling through the mapping process and indicated that the available resource, the quantity and quality of recyclable items and the coordination of recycling activities are vital for the recycling operation.

Further, other factors, like government regulations, incentives and the demand of customers are considered as key drivers. Research regarding important factors influencing the incentive dependency of residents to involve in e-waste RSC practice in Iran was conducted by Jafari et al. [41]. The primary data were collected through the interview of 148 residents in Iran. The results indicated that 58.7% of inhabitants would take part in e-waste RSC practice without any incentive. The income and size of household, education background, level of e-waste awareness and marital status are key elements that affect the incentive dependency of residents. To determine the consumers to return e-waste in European nations, a research was conducted by Janse et al. [42]. In the research, the integrated method including quantitative (implementing a survey) and qualitative (visiting electronics industries and interviews) approaches have been applied. Similarly, a survey of 750 customers using mobile phones in India was implemented by Dixit and Badgaiyan [43]. The research found that return purpose is considered as a mediator variable in the estimation of return habit. In addition, the perception of behaviour, willingness, and social and moral norms were recognized as vital factors for return intention. Pandebesie et al. [44] conducted a study regarding the management of electronic waste in Surabaya city in Indonesia. The results found that behaviour of community, knowledge and attitudes are the key factors influencing the willingness to manage electronic waste.

4.2. Performance Evaluation and Decision Making

Keh et al. [48] proposed an integrated RL model to answer three critical questions: (1) what are the financial benefits received through RL activity? (2) What is environmental improvement? (3) What are the advantages of social factors? A real case study of IBM in France was conducted to validate the model. Lin et al. [49] evaluated the e-waste recycling performance in Taiwan focusing on 15 potential electronic devices. The study applied the analytic hierarchy process (AHP) to determine the priority of the new compulsory recycled wastes, namely due recycled wastes. To evaluate the overall quality of recycling operation, Ravi [50] proposed a conceptual framework using the multi-attribute global inference of quality (MAGIQ) approach. The study combined various types of recycling processes into an integrated value which represents the overall quality of recycling operations. The research can assist logistic managers to have a clear picture of selecting appropriate recycling systems. Bereketli et al. [51] introduced a systematic model for evaluating e-waste treatment strategies including reuse, recycling and disposal. They utilized the fuzzy linear programming technique for multidimensional analysis of preference (fuzzy LINMAP) method to determine the weight of alternatives. The result found that reuse and recycling methods are safer than the disposal method and contribute the resource conservation in the long run although these methods require a higher investment cost and technological facilities. To evaluate the capability of the e-waste RL model, Liu et al. [52] considered eight critical factors and used the index system and quantitative approaches. The study provided a new framework for decision-makers to evaluate and improve the RL capability in an effective way.

Collection points are a crucial part of RSC practice since they are established to collect and sort used products for proper treatment processes. This step significantly affects the whole chain process [53]. Ponce-Cueto et al. [54] introduced an analytic model using AHP approach to evaluate key criteria for selecting appropriate locations for collection points in the RL model. Some aspects considered to choose collection points included the number of inhabitants, legal concerns, accessibility and public awareness. The model was validated through a case study of used batteries in Spain. Tsai and Hung [55] proposed a new framework with a two-stage decision to optimize the treatment and recycling systems of e-waste RL. Firstly, in the treatment stage, different treatment suppliers were selected by the manufacturer through a multi-objective model (i.e., environmental goals and activity-based costing goals). This stage is considered as a non-profit stage. Secondly, the recycling stage aims to achieve profit maximization with consideration of environmental issues by applying some methods (e.g., single-objective model, activity-based costing constraints, and environmental constraints). A case study of an electronic company was conducted to validate the effectiveness of the proposed model. To evaluate the sustainable performance of e-waste RSC management in Tunisia, Dhib et al. [56] introduced a collaborative strategy by applying an integrated method (with entropic approach and fuzzy set theory). Aidonis et al. [57] aimed to evaluate the alternative e-waste management plans at the national level with a case study of Greece. They considered 12 criteria with four main dimensions, such as financial, technical, social and environmental aspects. A binary linear programming was applied to find the maximum performance of nine alternative scenarios of e-waste management. The study suggested that the joint collaboration of all partners, including political willing, consumer, industry and government are necessary for integrated e-waste management. Some studies focus on the performance valuation and decision making on the RSC of e-waste shown in Table 4.

Table 4.

Performance evaluation and decision making studies on the RSC for e-waste.

4.3. Forecasting Product Returns

The design and planning for RSC are more challenging than forward supply chain due to uncertain factors including quantity, cost, time, and quality of e-waste [68]. Forecasting for the number of product returns is vital for the optimal level of RSC performance since it is a key step for collection, recovery strategies and transportation activities [28,69]. The design of the RSC network, the layouts of treatment facilities and planning of the treatment processes are significantly affected by the estimation of product returns [70]. Hence, the way forecasts such returns are crucial in RSC, some of the existing forecasting models are presented in Table 5.

Table 5.

The summary of forecasting models.

Hanafi, Kara and Kaebernick [69] applied a fuzzy coloured Petri net method to estimate the number of mobile phone returns in different regions in Australia. Input data used in this study include income distribution, demographics, sales data and the lifespan of mobile phones. Their result showed that this method could reach 90% accuracy in forecasting the returns of mobile phones. Araújo et al. [71] proposed a model for estimating the quantity of e-waste generation in Brazil. They used a variety of methods such as an average lifetime, the number of sales and stock which can apply for the mature as well as non-mature market products. The study found that it is important to estimate the lifespan of products which are normally based on the understanding of customer’s behaviour. To estimate the computer waste produced in Chile, Steubing et al. [72] utilized a material flow analysis (MFA) approach. The data of sales and imports were collected from two sources, customs databases and publications. The result showed that LCD monitors and laptops in 2020 would rapidly increase due to the replacement of CRT monitors. The MFA method was also used by Andarani and Goto [73] for estimating the amount of e-waste from household generation in Indonesia. They found that the overall e-waste from households produced in the years 2015–2025 will grow to 3.75–4.98 million tonnes. By using different forecasting approaches, Petridis et al. [74] proposed a model for estimating computer waste quantities in different regions (i.e., Europe, Asia, Australia, Americas). Seven forecasting techniques used in the study including Bass, Gompertz, logistic, trend model, level model, auto regressive moving average and exponential smoothing. The findings showed that computer waste generation in USA and United Kingdom would rapidly increase in the period 2014–2030 since the lifetime of a computer is decreasing and the consumption is increasing. It requires the need for effective recycling systems and initiatives for reuse or recover. In United States, the future trends of e-waste generation were also conducted by Chang et al. [75]. The factors for forecasting were historical data on sales and the lifetime of electronic products. The decreasing rate and polynomial regression analysis methods were used. The results showed that approximately 1.0835 million units of e-waste of thirteen selected products would be generated in 2025 while mobile phones will account for the highest proportion.

In the research of Rahmani et al. [76], the amount of EoL mobile phones and computers produced in the past and future in Iran was also investigated. This study applied the time-series lifespan and logistic function models. The outflows of obsolete products were firstly estimated through the time-series lifespan approach. At the next step, the logistic function was employed to forecast the values of end-of-life electronic appliances. Finally, the results showed that around 90 million obsolete computers will be generated in 2035 while about 50 million obsolete mobile phones will be generated in 2040 in Iran.

Ikhlayel [77] compared the benefits and drawbacks of five common methods (i.e., Consumption and Use, Simple Delay, Time Step, Mass Balance, and Approximation 2) to estimate the amount of e-waste generation in Jordan. The research concluded that the Consumption and Use approach is widely used in developing nations since variables are required little data and straightforwardly obtained or modified. The Simple Delay approach can be employed to market saturation while the Time Step and Mass Balance approaches are suitable for both saturated and unsaturated markets. The overestimation of e-waste generation is the drawback of the Approximation 2 method but it is suitable for market saturation. The Delay method was utilized in the study of Polák and Drápalová [78] which aimed to estimate the obsolete mobile phone generation in the years 2010–2020 in the Czech Republic. Their research found that only around 3–6% of obsolete mobile phones in the Czech Republic were collected for recycling and recovery processes. In addition, the amount of obsolete mobile phones in this country will climb up to 26.3 million units in the period 2010–2020. Alavi et al. [79] estimated the quantity of e-waste in Ahvaz City, Iran through the Consumption and Use method. They found that air conditioners had the highest percentage of e-waste generation followed by refrigerators, freezers.

Nguyen et al. [80] used combined techniques (such as Weibull distribution, the logistic function, and the population balance model) to forecast the waste quantities of five large household equipment (i.e., TVs, washing machines, air conditioners, refrigerators and personal computers) in Vietnam in the period 2010–2025. The factors for forecasting in this study involve the rate of the disposal using Weibull distribution, the lifespan of electronic equipment, the family size and the sales. The population balance model was also applied in the study of Kim et al. [81] aimed to forecast the waste quantities of eight selected electronic equipment in South Korea. Weibull distribution was also employed to analyse a survey of 1000 families to estimate the average lifespan of electronic appliances. Further, the study estimated the e-waste collection rates for five selected products in the period 2003–2009 and found that in 2009 washing machines had the highest percentage of the collection (28%) whereas the lowest collection rate (7%) was air conditioners. Islam and Huda [82] conducted research regarding the estimation of e-waste generation, e-waste put-on-market and the stock in the period 2000–2047 in Australia. Holt’s double exponential smoothing and Weibull distribution were utilized to calculate e-waste generation in the past and future. The research found that the generation of e-waste, especially large and small household appliances and consumer electronics will increase approximately 3% every year in 2018–2047. This study will assist useful insights for policymakers, local governments in future regulations and recycling industry in the country.

4.4. Research on E-Waste Reverse Supply Chain Network Design Models

RSC network design problems have attracted the most attention from companies and experts since it is one of the vital and challenging issues in the RSC environment [86]. The design of RSC network is great potential as an effective strategy to achieve the goals of companies [87]. RSC network design is strategic planning which is of key importance for the finical ability of product recovery activities. Hence, the implementation of RSC network design aims to determine a proper network configuration for the flows of returned products [88]. The reverse chain of the used product normally comes from several locations and is incorporated at a few locations or even one destination. General RSC network structure, the proper physical locations, the number of necessary tiers, the number of centres needed, their maximum capacities, and transportation between nodes in the network need to be decided to transfer returned products from consumers to treatment facilities and to potential markets [89].

Several studies on the design of RSC network have been conducted for various sectors, such as sand [90], paper [89,91,92], plastic [93], vehicles [86,94], carpet recycling [95], electronic waste [36,96,97]. There are two main types of objective function (i.e., cost minimization and profit maximization) considered in RSC models. Most studies investigated cost minimization as an objective function [36,86,90,91,96,98,99,100,101,102,103,104,105] while a few research investigated profit maximization in their studies [89,97,106].

According to Pochampally and Gupta [107], there are at least three key parties in any RSC network. The first one is collection facilities where customers can return their used products while the second party should be recovery centres including recycling and remanufacturing centres to process these used products. The last one is demand markets where can sell recovery materials. Based on the different types of returned products and various network designs, there are some other parties that participate in RSC networks, such as disassembly and disposal centres.

In the literature of e-waste RSC modelling (as seen in Table 6), mixed integer linear programming (MILP) formulation is one of the common tools used [108,109]. One of the early research was conducted by Krikke et al. [110] which aims to determine the way the used products being processed as well as minimize the total costs of the RSC network design using MILP. The model conducted a real case of a copier industry (especially HV02-machine) in Venlo in the Netherlands to demonstrate the usefulness of the model. Two candidate locations namely in Venlo (The Netherlands) and in Prague (Czech Republic) were examined. The study showed that there is a slight difference in costs incurred so the building of recovery operations in Prague should be selected from the view of the company. Two years later, Shih [111] also optimized the design of RSC network for electrical devices and computers in Taiwan by utilizing MILP model. The overall costs considered in the model include shipping, operating, fixed, and disposal costs and the revenue from recovery materials. The quantity and the locations of storage areas, disassembly and recycling facilities were identified based on different take-back rates. The research found that the expansion of disassembly facilities for computers is not necessary whereas there is a need for a new disassembly facility for electronic devices as the returned rate increases by 20%. Similarity, Deng and Shao [112] proposed a recycling network design model for e-waste which aims to minimize the total cost of the recycling model under the capacity constraints. The study suggested that at pre-processing facilities, waste compression should be implemented since it is crucial for the whole recycling system. In addition, the uncertainty of the quality and quantity of used products should be considered in future research. A research regarding a national recovery network for e-waste in Portugal was conducted by Gomes, Barbosa-Povoa and Novais [101]. MILP model was applied to select suitable locations for collection and sorting centres with total cost minimization. Results from the case study showed that recycling and shipping costs are the key elements in the design of an RSC network. To eliminate the variance from the actual RSC network problem, these costs should be carefully estimated.

Table 6.

E-waste RSC network design models.

Alumur et al. [109] proposed an RSC network design for multi-products by applying MILP to maximize the profit. Washing machines and tumble dryers in Germany were conducted to validate the model. The research found that to reduce transportation costs, inspection and remanufacturing centres can be co-located. However, this model did not consider uncertain parameters in the model. Dat et al. [36] suggested an e-waste RL model with different treatment options (i.e., reuse, recycling, repair) by using an MILP approach which was modelled by utilizing a mathematical programming language (AMPL) and then solved with CPLEX software. The research can assist decision-makers to select the optimal locations to build centres and the flow of materials in the RL network. Kilic, Cebeci and Ayhan [96] examined an e-waste RL system with 10 different scenarios of collecting rates in Turkey. An MILP model was also applied to minimize the overall cost of the RL system. Compared to the other existing researches, different categories of storage and recycling centres were investigated in the model. The authors suggested that the model can be enhanced by integrating reuse and remanufacture options in further studies. To consider risk elements in RSC models, Linh et al. [104] proposed a new model integrating collection risks, transportation risks and operating risks. The study concluded that the RSC network design has been obviously modified with risk factors considered.

The uncertainty of RSC network design is also one of the key problems to be considered [113]. To address uncertain parameters including the quantity, quality, the return rate of used products and related costs in e-waste RSC network design studies, stochastic programming is considered as a common approach [89,114]. To deal with the uncertainty of demand and return rate in RSC network design model, Lee and Dong [114] developed a two-stage stochastic programming model that was enhanced from a deterministic model. The solution approach incorporated a sample average approximation approach with simulated annealing. The research concluded that compared to the deterministic optimization approach, the stochastic approach could provide a closer true network design problem. Ayvaz et al. [115] also proposed a multi-tiers, multi-products RSC network design for e-waste to optimize the profit maximization by using a stochastic programming model. The research examined the quantity and quality of returned products and transportation costs as uncertainties. A recycling industry for e-waste in Turkey was conducted to demonstrate the possible application of the model. The sample average approximation method was utilized in order to solve the model. The study showed that the model provided appropriate solutions in making efficient decisions regarding the uncertainties of the quantity and quality of used products, and transportation cost. The summary of e-waste RSC network design models can be seen in Table 6.

5. Research Gaps and Potential Research Directions

After carefully reviewing and analysing research in the field of e-waste RSC, some research gaps have been identified for the scope of future studies as follows:

- -

- It is important to establish an integrated approach (combining field trips, literature review, and quantitative data analysis) to manage e-waste in developing countries (i.e., India, Pakistan, Vietnam, the Philippines) since informal recycling practices are common in these countries. Recycling methods normally use larger labour force and low-level technology so a significant number of e-waste components are heading to landfills.

- -

- There are some challenges in the implementation of e-waste management for developing countries. Firstly, setting up formal processing of e-waste requires significant investment at the initial stage so informal collectors are popular in these countries. Secondly, since the regulations of e-waste management in developed countries are extremely stringent, these countries export their waste to developing countries, such as India, where costs of management are lower and the rules are not as tough [24]. Hence, Extended Producer Responsibility (EPR) is considered as a useful practice for e-waste management. This practice can share the responsibility with companies, consumers, and smaller waste collectors and expand the reach of waste clean-up operations and creates a formal structure for a profitable and efficient e-waste management program. EPR can be implemented well in the long term only if effective monitoring of the collection process and roles of all the stakeholders are clearly defined in an integrated manner. This would be an interesting topic in the future.

- -

- Implementing proper e-waste management is not only a practical and technical issue but also political and financial aspects. In the future study, decision-makers should align proposed improvements with regional priorities and with a mechanism for monitoring and evaluate changes to a management system.

- -

- Evaluation of the existing e-waste practices is primary and it leads to prioritizing actions that start by regulating aspects of e-waste. Future work should include legislations of e-waste disposal and product imports.

- Research group 1: factors affected e-waste RSC implementation

- -

- In the category of factors affecting e-waste RSC implementation, although there are various factors to be considered, such as regulations, top management, environmental issues, financial concerns and etc., consumers’ behaviour is one of the most vital factors which contributes to the success of e-waste RSC implementation. Their return intention is a crucial variable for the prediction of the quantity of e-waste, and as a result, this will become important inputs for electronic firms in implementing the design of their RSC systems. Even though a few studies examined customers’ behaviour and residents’ awareness for returning e-waste issues, their research just focused on some particular products such as mobile phones or computers. Hence, further studies can enhance the behaviour of customers for a variety of electronic products, like household devices or IT and telecommunications equipment.

- -

- Most studies in this category try to improve the awareness of inhabitants about e-waste by the public media, educational programmes, etc. The roles of government and industry through incentive campaigns to encourage consumers to return their end-of-life products can be an interesting topic in the future.

- -

- There is a lack of studies focusing on e-waste RSC implementations in rural areas. The residents and local governments in the countryside, especially in developing countries have less awareness of e-waste recycling and environmental protection [46]. Hence, research on factors affected e-waste RSC implementations in rural areas can be conducted in future studies.

- -

- Extended producer responsibility (EPR) policy aims to manage and treat their end-of-life products. This plays an important role in e-waste RSC implementations at an industry perspective, which can be enhanced to the implementation at the national level. More practical research specifying on EPR implementation for e-waste would be potential future studies.

- -

- Risk assessment is also an important factor in RSC operation but it has been not examined by existing studies. In future research, risk assessment will be an interesting topic to explore.

- Research group 2: Performance evaluation and decision making

- -

- E-waste is normally recognized as a complex issue to make a proper decision. The complexity is influenced by various elements such as various sources of collection, the flow of returned products, the numbers of decision-makers. Hence, it requires an appropriate decision to improve the RSC performance which should be based on the collective decision. In this context, focusing on the vagueness of different decision-makers using Fuzzy Technique for Order Performance by Similarity to Ideal Solution (FTOPSIS) and more criteria to interpret their interaction on the RSC performance would be potential topics in future.

- -

- To comply with governmental regulations and create a competitive advantage, there is a need for electronics industries to collaborate with third-party reverse supply chain providers to effectively manage their returned products [67]. Although some existing studies conducted the evaluation and selection of third-party RSC providers, the limited number of studies focused on multiple attribute evaluation of electronics companies for RSC collaborations. Hence, more research on this issue by considering the vagueness of the decision-making process could be a promising study direction in the future.

- -

- Another potential topis could be conducting game theory to examine the strategic interactions in the decision-making process among different partners in RSC operations for e-waste.

- -

- Some recent research has considered three suitable dimensions such as social, economic and environmental aspects. It would be an interesting direction if future studies could integrate the technology dimension into the sustainable RSC system. The applications of radio-frequency identification, the internet of things can implement for inventory management, tracking the flows of materials, the management of recovery information could be a new study direction in this category.

- Research group 3: Forecasting product returns

- -

- Most existing studies estimate the number of product returns by examining different variables such as data sales, the lifespan of products, material composition, etc. However, other factors like customs and culture, regulations, demographics and consumer’s income might affect the prediction of product returns. There is no study analysing these factors for estimating returned products, which might create potential future research.

- -

- Previous research estimated the data of weight and e-waste composition based on the literature. However, these data might not accurate or vary over the years due to technological innovations. This might create some level of uncertainty. Further, other data such as lifespan, market share and value of unit which were normally collected and analysed by consumer survey, official government statistics or stakeholders. This also leads to fuzzy or uncertain data. Hence, in such a context, uncertainty analysis could be possible research in future implementation.

- -

- Although different forecasting techniques were applied for recycling or remanufacturing products, the study for forecasting returned products until disposition level is quite limited.

- Research group 4: e-waste RSC network designs

- -

- Network design is a strategic issue and has received great attention from researchers. Existing research mainly focused on transportation, fixed, operating, and disposal costs in the total cost of RSC. They ignore risk factors involved RSC operation which has a significant influence on RSC costs [104,127]. Risks can be seen at treatment centres and transportation activities due to a variety of dangerous materials contained in e-waste [128,129,130]. Therefore, integrating risk factors in an RSC network design model can be an interesting topic for future direction.

- -

- Regarding uncertain issues, most of the existing studies assumed that all parameters in the RSC system are deterministic or known in advanced. However, RSC operation is generally recognized as dynamic in nature with a high degree of uncertain parameters, such as return rate, processing cost, transportation cost, capacity and so on [8,94,131,132,133]. To handle uncertain parameters, stochastic approaches have been proposed [89,104,114,115,134]. Nevertheless, there are two main issues in applying a stochastic method. The first one is that, in some practical cases, there is insufficient historical data to be used for uncertain parameters, so it is difficult to acquire the exact random distributions of these parameters. The second reason is that in most of the existing studies on RSC under uncertainty environment, a stochastic approach is applied through different scenarios for modelling the uncertainty which might result in heavily computational burdens [135]. Therefore, to deal with these issues, the fuzzy approach has emerged as a potential option because it can be flexible to cope with imprecise information and various kinds of uncertainty simultaneously with high computational efficiency [136]. A few studies [137,138,139] used the fuzzy approach in the field of supply chain management. However, current studies on the e-waste RSC model with the fuzzy approach are still in their infancy.

- -

- Most articles in this group neglect to specify the source of e-waste which normally comes from three main sources: households, industries, government sectors. This factor should be cooperated in the design phase of RSC network to provide better policy management for e-waste in terms of economic and environmental aspects.

- -

- RSC consists of a set of activities including disassembly, repair and recycling to recover returned products. Selecting partners in the RSC network is crucial to achieving optimal outcomes. In this regard, partner selections can be addressed as a multi-criteria decision-making problem. This step can be implemented prior to considering a network design problem. There is a clear deficit of applying an integrated model (e.g., fuzzy AHP and MILP) which comprises the selection of RSC partners and network design.

- -

- The number of research which considers a specific product of e-waste RSC network modelling is still limited. Only a few studies examined some specific products such as refrigerators, conditioners [1,97], mobile phones, cameras [123]. More product-oriented research, such as IT products, computers, medical devices, etc., should be investigated in future studies.

- -

- To solve a large scale of problems, meta-heuristic or heuristic algorithms like Genetic Algorithms, Ant Colony Optimization and Tabu search can be applied for obtaining better computational performance.

6. Conclusions

E-waste has received a great deal of attention from government, industry, policymakers, and consumers due to environmental issues, economic benefits, sustainable development, and competitive advances. This forces companies to put more effort to implement e-waste RSC practices to make them more effective. E-waste issues and the differences between forward and reverse supply chains have been discussed in this study. This paper then focuses on four main issues in e-waste RSC, including factors of implementation, performance evaluation and decision making, forecasting product returns, and network design. Published articles in this field have been selected and reviewed to identify the research gaps and suggest potential future research. The suggestions for future research direction would help researchers, policymakers, and practitioners to consider these topics in their work.

Author Contributions

In this study, L.T.T.D. wrote the original draft; Y.A. and S.-H.L. supervised and reviewed the paper; P.N.K.P. provided research direction, and reviewed and edited the paper; L.Q.D. provided data curation and funding acquisition.

Funding

This research received no external funding.

Acknowledgments

Linh Thi Truc Doan would like to thank the Australian Government for sponsoring her Ph.D. program at the University of South Australia, Australia under an Endeavour Award.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Doan, L.T.T.; Amer, Y.; Lee, S.-H.; Phuc, P.N.K.; Dat, L.Q. A comprehensive reverse supply chain model using an interactive fuzzy approach-a case study on the vietnamese electronics industry. Appl. Math. Model. 2019, 76, 87–108. [Google Scholar] [CrossRef]

- Doan, L.T.T.; Amer, Y.; Lee, S.-H.; Phuc, P.N.K. Optimizing the total cost of an e-waste reverse supply chain considering transportation risk. Oper. Supply Chain Manag. Int. J. 2018, 11, 151–160. [Google Scholar] [CrossRef]

- Namias, J. The Future of Electronic Waste Recycling in the United States: Obstacles and Domestic Solutions; Columbia University: Broadway, NY, USA, 2013. [Google Scholar]

- Gurtu, A.; Searcy, C.; Jaber, M. An analysis of keywords used used in the literature on green supply chain management. Manag. Res. Rev. 2015, 38, 166–194. [Google Scholar] [CrossRef]

- Mokhtar, A.R.M.; Genovese, A.; Brint, A.; Kumar, N. Improving reverse supply chain performance: The role of supply chain leadership and governance mechanisms. J. Clean. Prod. 2019, 216, 42–55. [Google Scholar] [CrossRef]

- Shi, J.; Liu, Z.; Tang, L.; Xiong, J. Multi-objective optimization for a closed-loop network design problem using an improved genetic algorithm. Appl. Math. Model. 2017, 45, 14–30. [Google Scholar] [CrossRef]

- Islam, M.T.; Huda, N. Reverse logistics and closed-loop supply chain of waste electrical and electronic equipment (weee)/e-waste: A comprehensive literature review. Resour. Conserv. Recycl. 2018, 137, 48–75. [Google Scholar] [CrossRef]

- Pishvaee, M.S.; Razmi, J. Environmental supply chain network design using multi-objective fuzzy mathematical programming. Appl. Math. Model. 2012, 36, 3433–3446. [Google Scholar] [CrossRef]

- Kuik, S.S. Development of an Integrated Performance Evaluation Framework for Product Returns and Recovery Operations. Ph.D. Thesis, University of South Australia, Adelaide, Australia, 2013. [Google Scholar]

- Singh, N.; Li, J.; Zeng, X. Global responses for recycling waste crts in e-waste. Waste Manag. 2016, 57, 187–197. [Google Scholar] [CrossRef]

- Balde, C.P.; Forti, V.; Gray, V.; Kuehr, R.; Stegmann, P. The Global E-Waste Monitor 2017: Quantities, Flows and Resources; United Nations University, International Telecommunication Union, and International Solid Waste Association: Geneva, Switzerland, 2017. [Google Scholar]

- Dwivedy, M.; Mittal, R.K. Future trends in computer waste generation in india. Waste Manag. 2010, 30, 2265–2277. [Google Scholar] [CrossRef]

- Kumar, A.; Holuszko, M.; Espinosa, D.C.R. E-waste: An overview on generation, collection, legislation and recycling practices. Resour. Conserv. Recycl. 2017, 122, 32–42. [Google Scholar] [CrossRef]

- Widmer, R.; Oswald, H.; Sinha-Khetriwal, D.; Schnellmann, M.; Böni, H. Global perspectives on e-waste. Environ. Impact Assess. Rev. 2005, 25, 436–458. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I.; Koh, S.L.; Rosa, P. Recycling of weees: An economic assessment of present and future e-waste streams. Renew. Sustain. Energy Rev. 2015, 51, 263–272. [Google Scholar] [CrossRef]

- Gaidajis, G.; Angelakoglou, K.; Aktsoglou, D. E-waste: Environmental problems and current management. J. Eng. Sci. Technol. Rev. 2010, 3, 193–199. [Google Scholar] [CrossRef]

- Alam, M.; Bahauddin, K.M. Electronic waste in Bangladesh: Evaluating the situation, legislation and policy and way forward with strategy and approach. Present Environ. Sustain. Dev. 2015, 9, 81–101. [Google Scholar] [CrossRef]

- Lundgren, K. The Global Impact of E-Waste: Addressing the Challenge; International Labour Office: Genève, Switzerland, 2012. [Google Scholar]

- Wäger, P.A.; Hischier, R. Life cycle assessment of post-consumer plastics production from waste electrical and electronic equipment (weee) treatment residues in a central European plastics recycling plant. Sci. Total Environ. 2015, 529, 158–167. [Google Scholar] [CrossRef] [PubMed]

- Gregory, J.R.; Kirchain, R.E. A comparison of North American electronics recycling systems. In Proceedings of the 2007 IEEE International Symposium on Electronics and the Environment, Orlando, FL, USA, 7–10 May 2007; IEEE: Piscataway, NJ, USA, 2007; pp. 227–232. [Google Scholar]

- Kahhat, R.; Kim, J.; Xu, M.; Allenby, B.; Williams, E.; Zhang, P. Exploring e-waste management systems in the united states. Resour. Conserv. Recycl. 2008, 52, 955–964. [Google Scholar] [CrossRef]

- Hung Lau, K.; Wang, Y. Reverse logistics in the electronic industry of china: A case study. Supply Chain Manag. Int. J. 2009, 14, 447–465. [Google Scholar] [CrossRef]

- Afroz, R.; Masud, M.M.; Akhtar, R.; Duasa, J.B. Survey and analysis of public knowledge, awareness and willingness to pay in Kuala Lumpur, Malaysia—A case study on household weee management. J. Clean. Prod. 2013, 52, 185–193. [Google Scholar] [CrossRef]

- Chaudhary, M.; Shalender, K.; Mishra, A.K. Issues and challenges in e-waste management in India: A gap between theory and practice. IUP J. Bus. Strategy 2018, 15, 54–63. [Google Scholar]

- Manomaivibool, P.; Vassanadumrongdee, S. Buying back household waste electrical and electronic equipment: Assessing Thailand’s proposed policy in light of past disposal behavior and future preferences. Resour. Conserv. Recycl. 2012, 68, 117–125. [Google Scholar] [CrossRef]

- Agrawal, S.; Singh, R.K.; Murtaza, Q. A literature review and perspectives in reverse logistics. Resour. Conserv. Recycl. 2015, 97, 76–92. [Google Scholar] [CrossRef]

- Van Wassenhove, L. The reverse supply chain. Harv. Bus. Rev. 2002, 80, 25–26. [Google Scholar]

- Gupta, S.M. Reverse Supply Chains Issues and Analysis; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Prahinski, C.; Kocabasoglu, C. Empirical research opportunities in reverse supply chains. Omega 2006, 34, 519–532. [Google Scholar] [CrossRef]

- Yin, W. Reverse supply chain management. Master Thesis, University of Gothenburg, Gothenburg, Sweden, 2011. [Google Scholar]

- Garg, K.; Kannan, D.; Diabat, A.; Jha, P.C. A multi-criteria optimization approach to manage environmental issues in closed loop supply chain network design. J. Clean. Prod. 2015, 100, 297–314. [Google Scholar] [CrossRef]

- Blackburn, J.D.; Guide, V.D.R.; Souza, G.C.; Van Wassenhove, L.N. Reverse supply chains for commercial returns. Calif. Manag. Rev. 2004, 46, 6–22. [Google Scholar] [CrossRef]

- Rogers, D.S.; Tibben-Lembke, R.S. Going Backwards: Reverse Logistics Trends and Practices; Reverse Logistics Executive Council Pittsburgh: Pittsburgh, PA, USA, 1999; Volume 2. [Google Scholar]

- Tibben-Lembke, R.S.; Rogers, D.S. Differences between forward and reverse logistics in a retail environment. Supply Chain Manag. Int. J. 2002, 7, 271–282. [Google Scholar] [CrossRef]

- Marx-Gomez, J.; Rautenstrauch, C.; Nürnberger, A.; Kruse, R. Neuro-fuzzy approach to forecast returns of scrapped products to recycling and remanufacturing. Knowl. Based Syst. 2002, 15, 119–128. [Google Scholar] [CrossRef]

- Dat, L.Q.; Truc Linh, D.T.; Chou, S.-Y.; Yu, V.F. Optimizing reverse logistic costs for recycling end-of-life electrical and electronic products. Expert Syst. Appl. 2012, 39, 6380–6387. [Google Scholar] [CrossRef]

- Ravi, V.; Shankar, R.; Tiwari, M. Analyzing alternatives in reverse logistics for end-of-life computers: Anp and balanced scorecard approach. Comput. Ind. Eng. 2005, 48, 327–356. [Google Scholar] [CrossRef]

- Chiou, C.Y.; Chen, H.C.; Yu, C.T.; Yeh, C.Y. Consideration factors of reverse logistics implementation -a case study of taiwan’s electronics industry. Procedia Soc. Behav. Sci. 2012, 40, 375–381. [Google Scholar] [CrossRef]

- Guarnieri, P.; e Silva, L.C.; Levino, N.A. Analysis of electronic waste reverse logistics decisions using strategic options development analysis methodology: A Brazilian case. J. Clean. Prod. 2016, 133, 1105–1117. [Google Scholar] [CrossRef]

- Rahman, S.; Subramanian, N. Factors for implementing end-of-life computer recycling operations in reverse supply chains. Int. J. Prod. Econ. 2012, 140, 239–248. [Google Scholar] [CrossRef]

- Jafari, A.; Heydari, J.; Keramati, A. Factors affecting incentive dependency of residents to participate in e-waste recycling: A case study on adoption of e-waste reverse supply chain in Iran. Environ. Dev. Sustain. 2017, 19, 325–338. [Google Scholar] [CrossRef]

- Janse, B.; Schuur, P.; de Brito, M.P. A reverse logistics diagnostic tool: The case of the consumer electronics industry. Int. J. Adv. Manuf. Technol. 2010, 47, 495–513. [Google Scholar] [CrossRef]

- Dixit, S.; Badgaiyan, A.J. Towards improved understanding of reverse logistics – examining mediating role of return intention. Resour. Conserv. Recycl. 2016, 107, 115–128. [Google Scholar] [CrossRef]

- Pandebesie, E.S.; Indrihastuti, I.; Wilujeng, S.A.; Warmadewanthi, I. Factors influencing community participation in the management of household electronic waste in West Surabaya, Indonesia. Environ. Sci. Pollut. Res. 2019, 26, 27930–27939. [Google Scholar] [CrossRef]

- Nduneseokwu, C.; Qu, Y.; Appolloni, A. Factors influencing consumers’ intentions to participate in a formal e-waste collection system: A case study of Onitsha, Nigeria. Sustainability 2017, 9, 881. [Google Scholar] [CrossRef]

- Cao, J.; Lu, B.; Chen, Y.; Zhang, X.; Zhai, G.; Zhou, G.; Jiang, B.; Schnoor, J.L. Extended producer responsibility system in china improves e-waste recycling: Government policies, enterprise, and public awareness. Renew. Sustain. Energy Rev. 2016, 62, 882–894. [Google Scholar] [CrossRef]

- Thi Thu Nguyen, H.; Hung, R.-J.; Lee, C.-H.; Thi Thu Nguyen, H. Determinants of residents’ e-waste recycling behavioral intention: A case study from Vietnam. Sustainability 2019, 11, 164. [Google Scholar] [CrossRef]

- Keh, P.; Rodhain, F.; Meissonier, R.; Llorca, V. Financial performance, environmental compliance, and social outcomes: The three challenges of reverse logistics. Case Study IBM Montp. Supply Chain Forum Int. J. 2012, 13, 26–38. [Google Scholar] [CrossRef]

- Lin, C.-H.; Wen, L.; Tsai, Y.-M. Applying decision-making tools to national e-waste recycling policy: An example of analytic hierarchy process. Waste Manag. 2010, 30, 863–869. [Google Scholar] [CrossRef] [PubMed]

- Ravi, V. Evaluating overall quality of recycling of e-waste from end-of-life computers. J. Clean. Prod. 2012, 20, 145–151. [Google Scholar] [CrossRef]

- Bereketli, I.; Erol Genevois, M.; Esra Albayrak, Y.; Ozyol, M. Weee treatment strategies’ evaluation using fuzzy linmap method. Expert Syst. Appl. 2011, 38, 71–79. [Google Scholar] [CrossRef]

- Liu, J.; Zhong, H.; Wei, W. Composition and evaluation of waste electric and electronic equipment reverse logistics capability. In Proceedings of the 2010 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Macao, China, 7–10 December 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 1199–1203. [Google Scholar]

- Govindan, K.; Popiuc, M.N. Reverse supply chain coordination by revenue sharing contract: A case for the personal computers industry. Eur. J. Oper. Res. 2014, 233, 326–336. [Google Scholar] [CrossRef]

- Ponce-Cueto, E.; Manteca, J.Á.G.; Carrasco-Gallego, R. Reverse logistics for used portable batteries in Spain: An analytical proposal for collecting batteries. In Information Technologies in Environmental Engineering: New Trends and Challenges; Golinska, P., Fertsch, M., Marx-Gómez, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 593–604. [Google Scholar]

- Tsai, W.-H.; Hung, S.-J. Treatment and recycling system optimisation with activity-based costing in weee reverse logistics management: An environmental supply chain perspective. Int. J. Prod. Res. 2009, 47, 5391–5420. [Google Scholar] [CrossRef]

- Dhib, S.; Addouche, S.-A.; El Mhamdi, A.; Loukil, T. Performance Study for a Sustainable Strategy: Case of Electrical and Electronic Equipments Waste; Springer International Publishing: Cham, Switzerland, 2016; pp. 572–587. [Google Scholar]

- Aidonis, D.; Achillas, C.; Folinas, D.; Keramydas, C.; Tsolakis, N. Decision support model for evaluating alternative waste electrical and electronic equipment management schemes—A case study. Sustainability 2019, 11, 3364. [Google Scholar] [CrossRef]

- Duygan, M.; Meylan, G. Strategic management of weee in Switzerland—Combining material flow analysis with structural analysis. Resour. Conserv. Recycl. 2015, 103, 98–109. [Google Scholar] [CrossRef]

- Jayant, A.; Gupta, P.; Garg, S.; Khan, M. Topsis-ahp based approach for selection of reverse logistics service provider: A case study of mobile phone industry. Procedia Eng. 2014, 97, 2147–2156. [Google Scholar] [CrossRef]

- Sahu, A.K.; Narang, H.K.; Rajput, M.S. A grey-dematel approach for implicating e-waste management practice: Modeling in context of indian scenario. Grey Syst. Theory Appl. 2018, 8, 84–99. [Google Scholar] [CrossRef]

- Tran, H.P.; Schaubroeck, T.; Nguyen, D.Q.; Ha, V.H.; Huynh, T.H.; Dewulf, J. Material flow analysis for management of waste tvs from households in urban areas of Vietnam. Resour. Conserv. Recycl. 2018, 139, 78–89. [Google Scholar] [CrossRef]

- Bahers, J.-B.; Kim, J. Regional approach of waste electrical and electronic equipment (weee) management in france. Resour. Conserv. Recycl. 2018, 129, 45–55. [Google Scholar] [CrossRef]

- Agrawal, S.; Singh, R.K.; Murtaza, Q. Reverse supply chain issues in Indian electronics industry: A case study. J. Remanufacturing 2018, 8, 115–129. [Google Scholar] [CrossRef]

- Shokohyar, S.; Mansour, S. Simulation-based optimisation of a sustainable recovery network for waste from electrical and electronic equipment (weee). Int. J. Comput. Integr. Manuf. 2013, 26, 487–503. [Google Scholar] [CrossRef]

- De Meester, S.; Nachtergaele, P.; Debaveye, S.; Vos, P.; Dewulf, J. Using material flow analysis and life cycle assessment in decision support: A case study on weee valorization in belgium. Resour. Conserv. Recycl. 2019, 142, 1–9. [Google Scholar] [CrossRef]

- Isernia, R.; Passaro, R.; Quinto, I.; Thomas, A. The reverse supply chain of the e-waste management processes in a circular economy framework: Evidence from Italy. Sustainability 2019, 11, 2430. [Google Scholar] [CrossRef]

- Govindan, K.; Jha, P.; Agarwal, V.; Darbari, J.D. Environmental management partner selection for reverse supply chain collaboration: A sustainable approach. J. Environ. Manag. 2019, 236, 784–797. [Google Scholar] [CrossRef] [PubMed]

- Phuc, P.N.K.; Yu, V.F.; Chou, S.-Y. Optimizing the fuzzy closed-loop supply chain for electrical and electronic equipments. Int. J. Fuzzy Syst. 2013, 15, 9–21. [Google Scholar]

- Hanafi, J.; Kara, S.; Kaebernick, H. Generating Fuzzy Coloured Petri Net Forecasting Model to Predict the Return of Products. In Proceedings of the 2007 IEEE International Symposium on Electronics and the Environment, Orlando, FL, USA, 7–10 May 2007. [Google Scholar]

- Xiaofeng, X.; Tijun, F. Forecast for the Amount of Returned Products Based on Wave Function. In Proceedings of the 2009 International Conference on Information Management, Innovation Management and Industrial Engineering, Xi’an, China, 26–27 December 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 324–327. [Google Scholar]

- Araújo, M.G.; Magrini, A.; Mahler, C.F.; Bilitewski, B. A model for estimation of potential generation of waste electrical and electronic equipment in Brazil. Waste Manag. 2012, 32, 335–342. [Google Scholar] [CrossRef]

- Steubing, B.; Böni, H.; Schluep, M.; Silva, U.; Ludwig, C. Assessing computer waste generation in chile using material flow analysis. Waste Manag. 2010, 30, 473–482. [Google Scholar] [CrossRef]

- Andarani, P.; Goto, N. Potential e-waste generated from households in indonesia using material flow analysis. J. Mater. Cycles Waste Manag. 2014, 16, 306–320. [Google Scholar] [CrossRef]

- Petridis, N.E.; Stiakakis, E.; Petridis, K.; Dey, P. Estimation of computer waste quantities using forecasting techniques. J. Clean. Prod. 2016, 112, 3072–3085. [Google Scholar] [CrossRef]

- Chang, S.-Y.; Assumaning, G.A.; Abdelwahab, Y. Estimation of future generated amount of e-waste in the United States. J. Environ. Prot. 2015, 6, 902. [Google Scholar] [CrossRef]

- Rahmani, M.; Nabizadeh, R.; Yaghmaeian, K.; Mahvi, A.H.; Yunesian, M. Estimation of waste from computers and mobile phones in Iran. Resour. Conserv. Recycl. 2014, 87, 21–29. [Google Scholar] [CrossRef]

- Ikhlayel, M. Differences of methods to estimate generation of waste electrical and electronic equipment for developing countries: Jordan as a case study. Resour. Conserv. Recycl. 2016, 108, 134–139. [Google Scholar] [CrossRef]

- Polák, M.; Drápalová, L. Estimation of end of life mobile phones generation: The case study of the Czech Republic. Waste Manag. 2012, 32, 1583–1591. [Google Scholar] [CrossRef]

- Alavi, N.; Shirmardi, M.; Babaei, A.; Takdastan, A.; Bagheri, N. Waste electrical and electronic equipment (weee) estimation: A case study of Ahvaz City, Iran. J. Air Waste Manag. Assoc. 2015, 65, 298–305. [Google Scholar] [CrossRef]

- Nguyen, D.-Q.; Yamasue, E.; Okumura, H.; Ishihara, K.N. Use and disposal of large home electronic appliances in Vietnam. J. Mater. Cycles Waste Manag. 2009, 11, 358. [Google Scholar] [CrossRef]

- Kim, S.; Oguchi, M.; Yoshida, A.; Terazono, A. Estimating the amount of weee generated in south korea by using the population balance model. Waste Manag. 2013, 33, 474–483. [Google Scholar] [CrossRef]

- Islam, M.T.; Huda, N. E-waste in Australia: Generation estimation and untapped material recovery and revenue potential. J. Clean. Prod. 2019, 237, 117787. [Google Scholar] [CrossRef]

- Gusukuma, M.; Kahhat, R. Electronic waste after a digital tv transition: Material flows and stocks. Resour. Conserv. Recycl. 2018, 138, 142–150. [Google Scholar] [CrossRef]

- Lau, W.K.-Y.; Chung, S.-S.; Zhang, C. A material flow analysis on current electrical and electronic waste disposal from Hong Kong households. Waste Manag. 2013, 33, 714–721. [Google Scholar] [CrossRef] [PubMed]

- Abbondanza, M.; Souza, R. Estimating the generation of household e-waste in municipalities using primary data from surveys: A case study of Sao Jose dos Campos, Brazil. Waste Manag. 2019, 85, 374–384. [Google Scholar] [CrossRef] [PubMed]

- Demirel, E.; Demirel, N.; Gökçen, H. A mixed integer linear programming model to optimize reverse logistics activities of end-of-life vehicles in Turkey. J. Clean. Prod. 2016, 112 Part 3, 2101–2113. [Google Scholar] [CrossRef]

- Özceylan, E.; Paksoy, T. Reverse supply chain optimisation with disassembly line balancing. Int. J. Prod. Res. 2013, 51, 5985–6001. [Google Scholar] [CrossRef]

- Jalili Ghazi Zade, M.; Noori, R. Prediction of municipal solid waste generation by use of artificial neural network: A case study of Mashhad. Int. J. Environ. Res. 2008, 2, 13–22. [Google Scholar]

- Kara, S.S.; Onut, S. A stochastic optimization approach for paper recycling reverse logistics network design under uncertainty. Int. J. Environ. Sci. Technol. 2010, 7, 717–730. [Google Scholar] [CrossRef]

- Barros, A.I.; Dekker, R.; Scholten, V. A two-level network for recycling sand: A case study. Eur. J. Oper. Res. 1998, 110, 199–214. [Google Scholar] [CrossRef]

- Fleischmann, M.; Beullens, P.; Bloemhof-Ruwaard, J.M.; Wassenhove, L.N. The impact of product recovery on logistics network design. Prod. Oper. Manag. 2001, 10, 156–173. [Google Scholar] [CrossRef]

- Pati, R.K.; Vrat, P.; Kumar, P. A goal programming model for paper recycling system. Omega 2008, 36, 405–417. [Google Scholar] [CrossRef]

- Nakatani, J.; Konno, K.; Moriguchi, Y. Variability-based optimal design for robust plastic recycling systems. Resour. Conserv. Recycl. 2017, 116, 53–60. [Google Scholar] [CrossRef]

- Phuc, P.N.K.; Yu, V.F.; Tsao, Y.-C. Optimizing fuzzy reverse supply chain for end-of-life vehicles. Comput. Ind. Eng. 2016, 113, 757–765. [Google Scholar] [CrossRef]

- Louwers, D.; Kip, B.J.; Peters, E.; Souren, F.; Flapper, S.D.P. A facility location allocation model for reusing carpet materials. Comput. Ind. Eng. 1999, 36, 855–869. [Google Scholar] [CrossRef]

- Kilic, H.S.; Cebeci, U.; Ayhan, M.B. Reverse logistics system design for the waste of electrical and electronic equipment (weee) in turkey. Resour. Conserv. Recycl. 2015, 95, 120–132. [Google Scholar] [CrossRef]

- John, S.T.; Sridharan, R.; Ram Kumar, P.N.; Krishnamoorthy, M. Multi-period reverse logistics network design for used refrigerators. Appl. Math. Model. 2018, 54, 311–331. [Google Scholar] [CrossRef]

- Jayaraman, V.; Patterson, R.A.; Rolland, E. The design of reverse distribution networks: Models and solution procedures. Eur. J. Oper. Res. 2003, 150, 128–149. [Google Scholar] [CrossRef]

- Min, H.; Jeung Ko, H.; Seong Ko, C. A genetic algorithm approach to developing the multi-echelon reverse logistics network for product returns. Omega 2006, 34, 56–69. [Google Scholar] [CrossRef]

- Cruz-Rivera, R.; Ertel, J. Reverse logistics network design for the collection of end-of-life vehicles in Mexico. Eur. J. Oper. Res. 2009, 196, 930–939. [Google Scholar] [CrossRef]

- Gomes, M.I.; Barbosa-Povoa, A.P.; Novais, A.Q. Modelling a recovery network for weee: A case study in portugal. Waste Manag. 2011, 31, 1645–1660. [Google Scholar] [CrossRef]