Prediction of Damage Level of Slab-Column Joints under Blast Load

Abstract

:1. Introduction

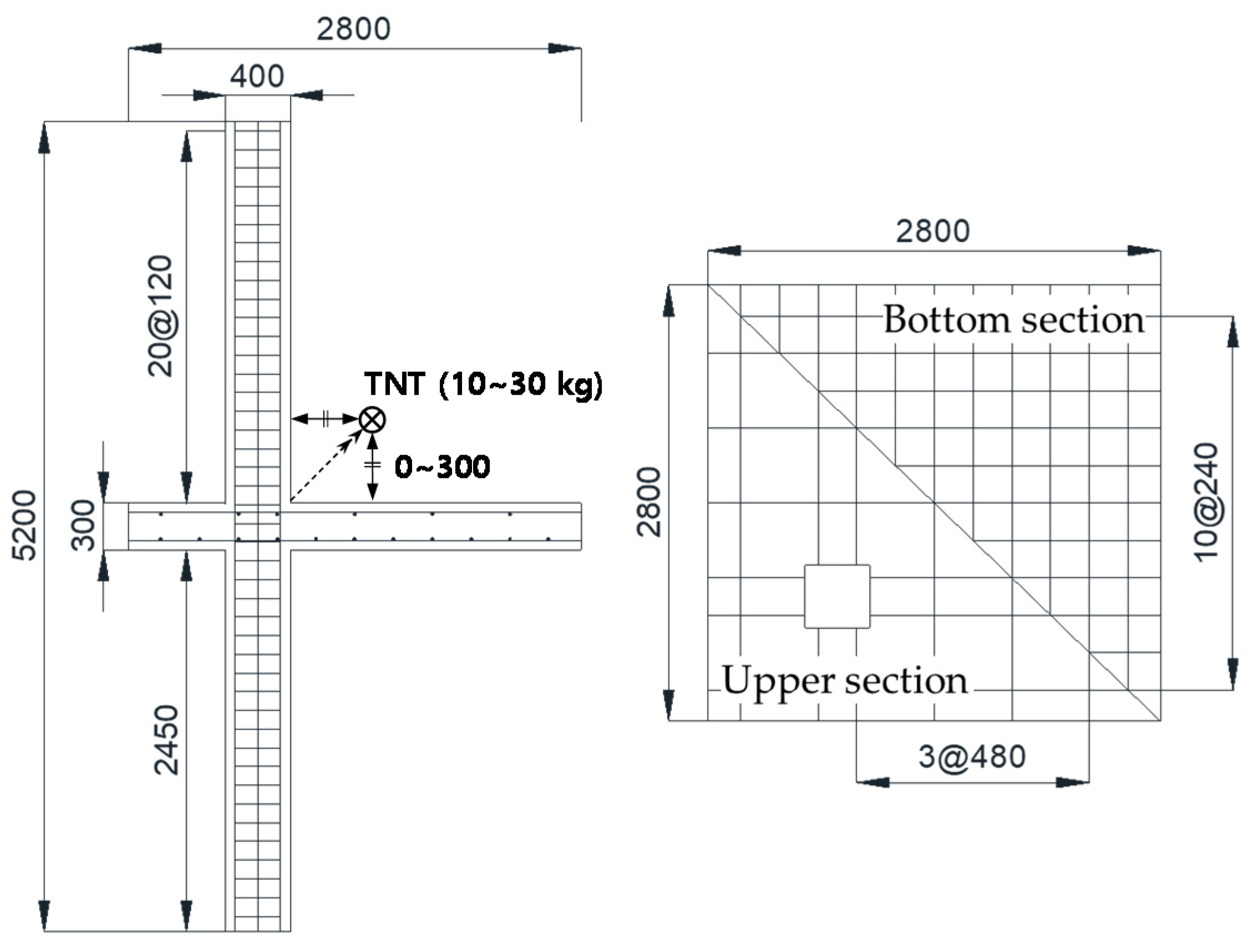

2. Modeling of Slab-Column Joints

2.1. Analysis Variables

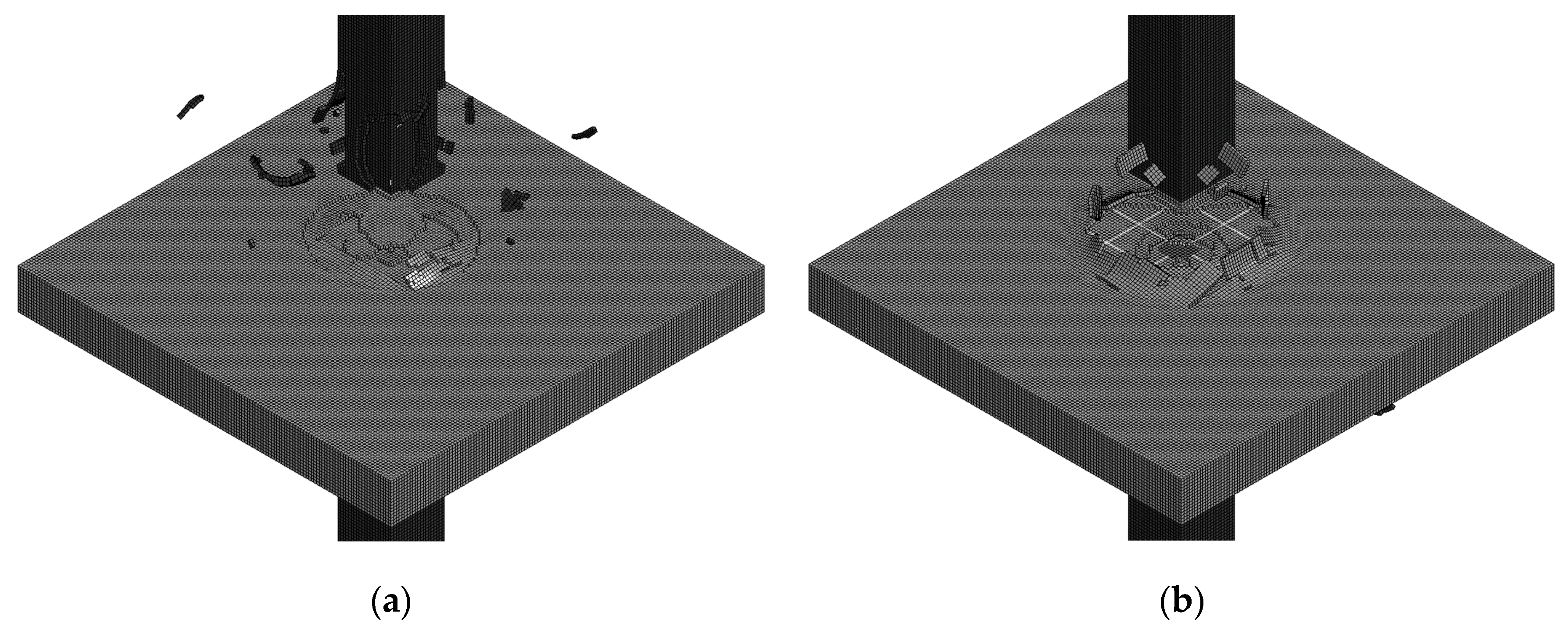

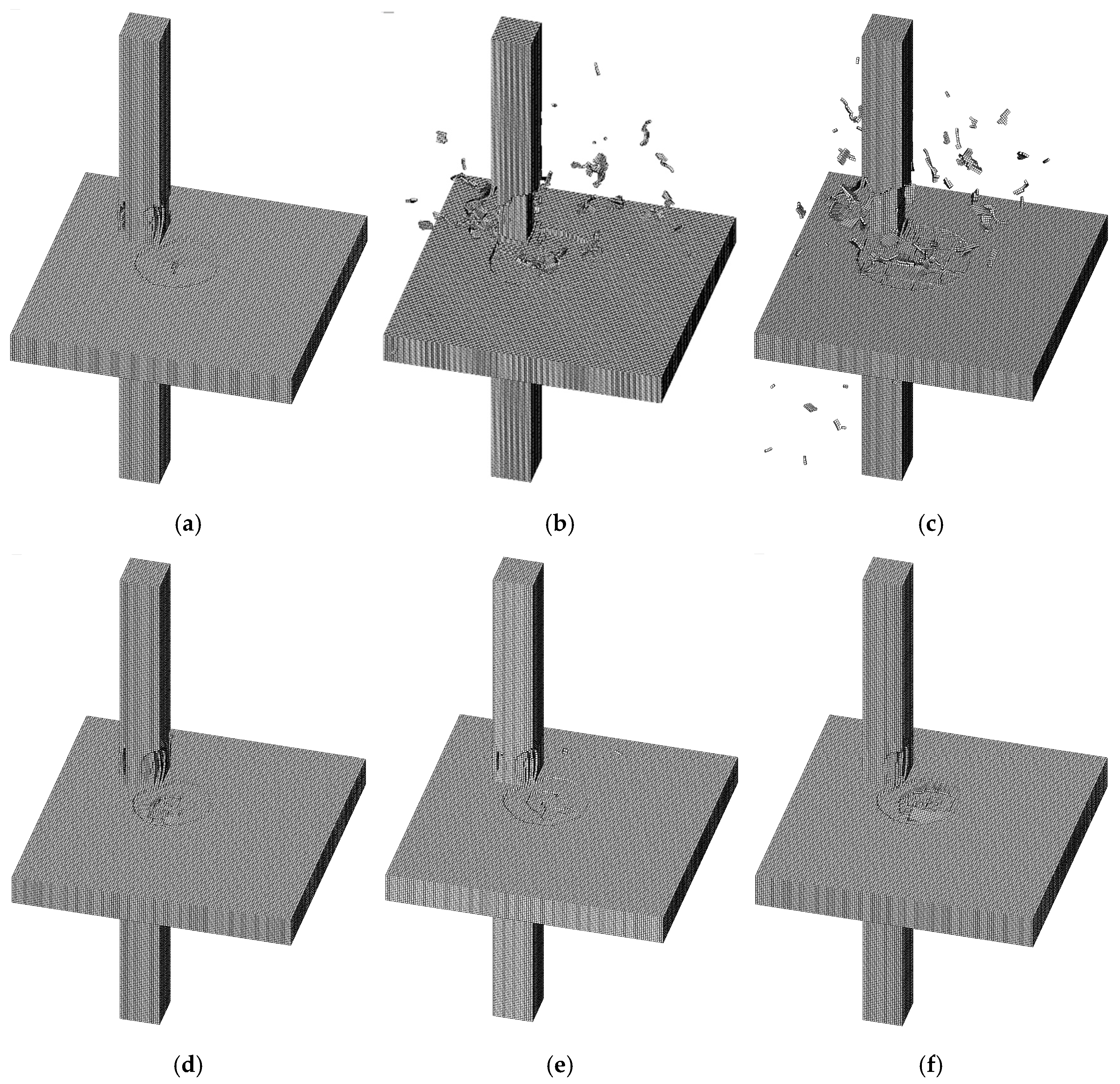

2.2. Modeling of Slab-Column Joints

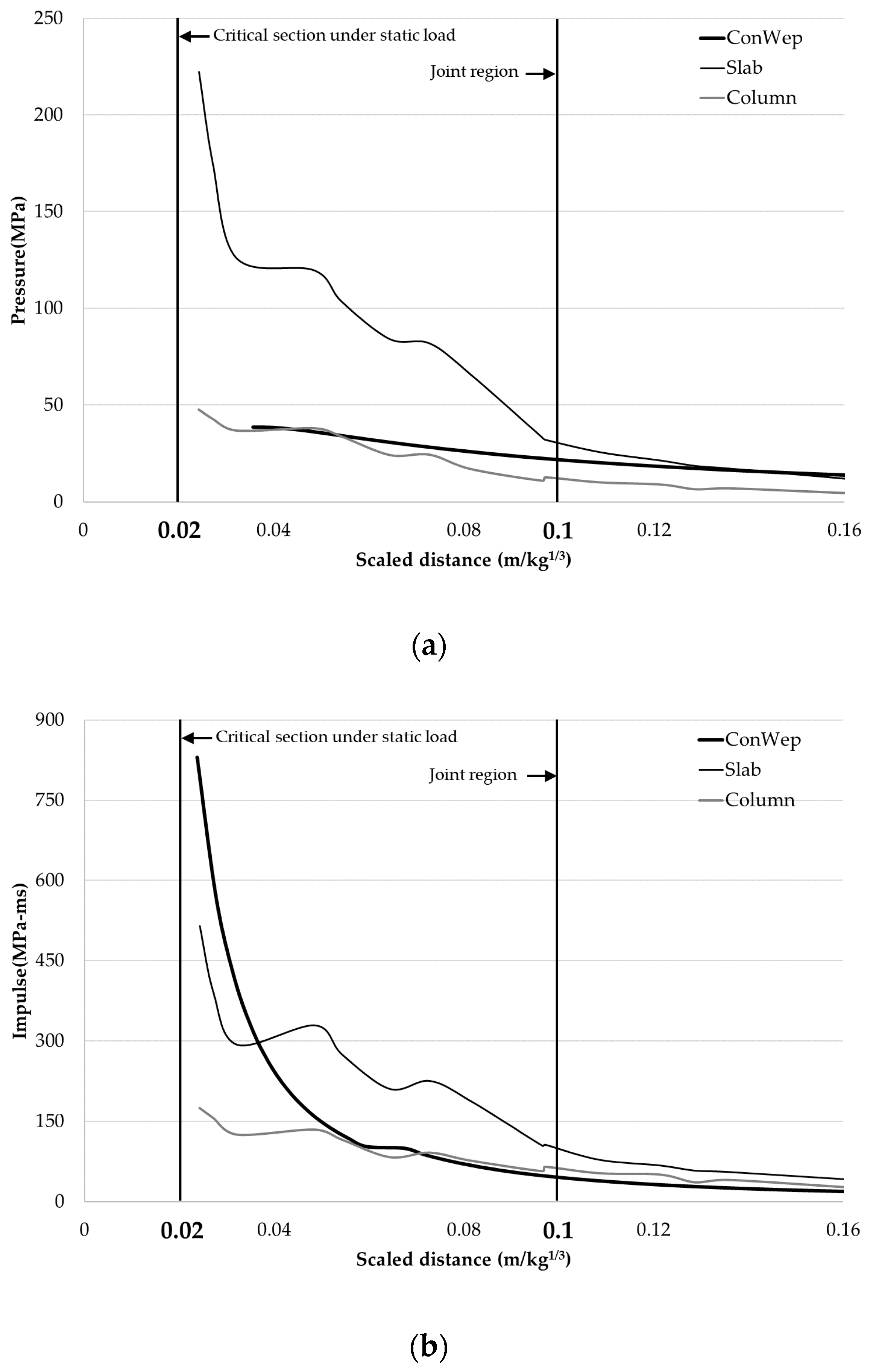

3. Defining a Joint Region under Blast Load

4. Numerical Analysis Results and Discussion

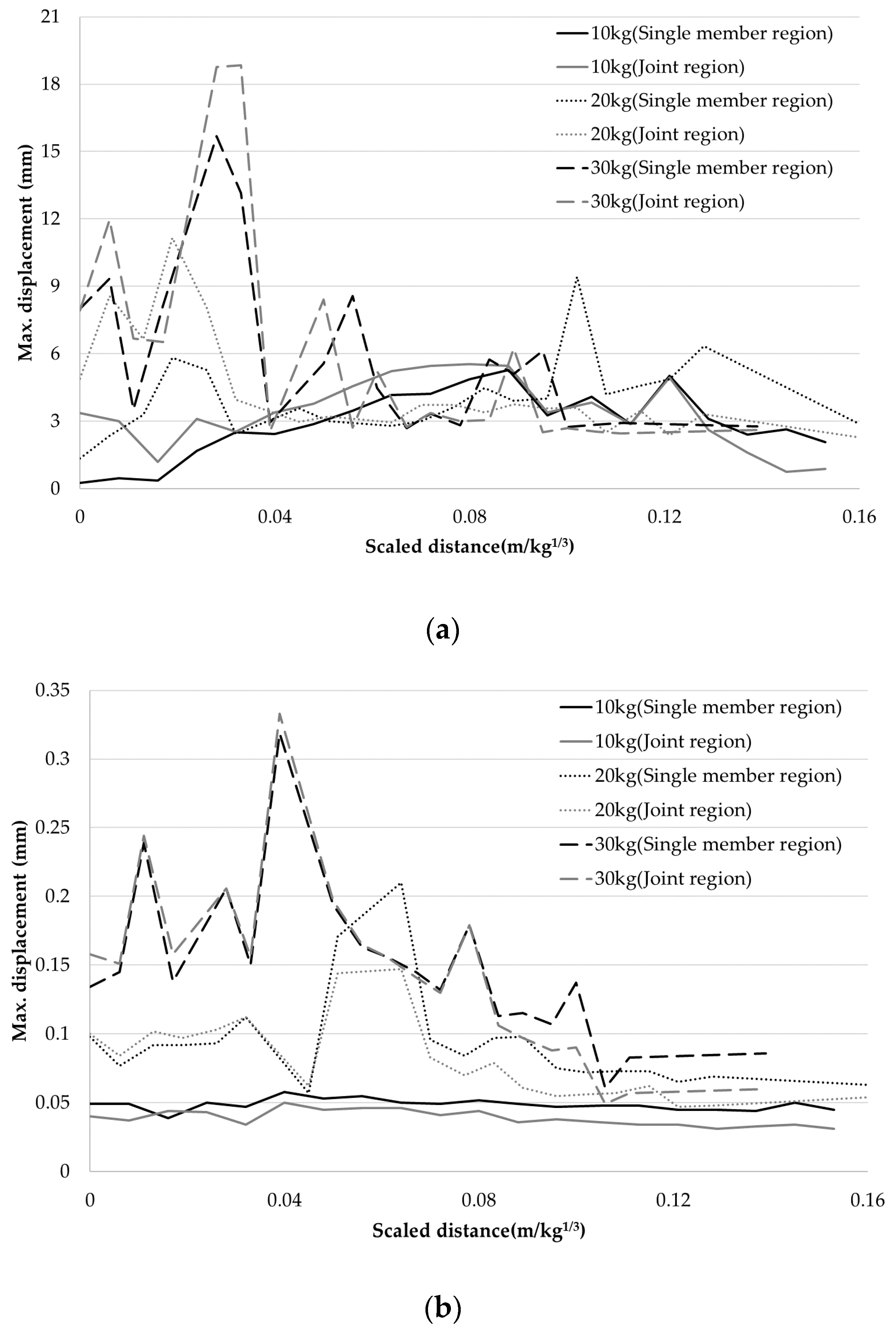

4.1. Displacement

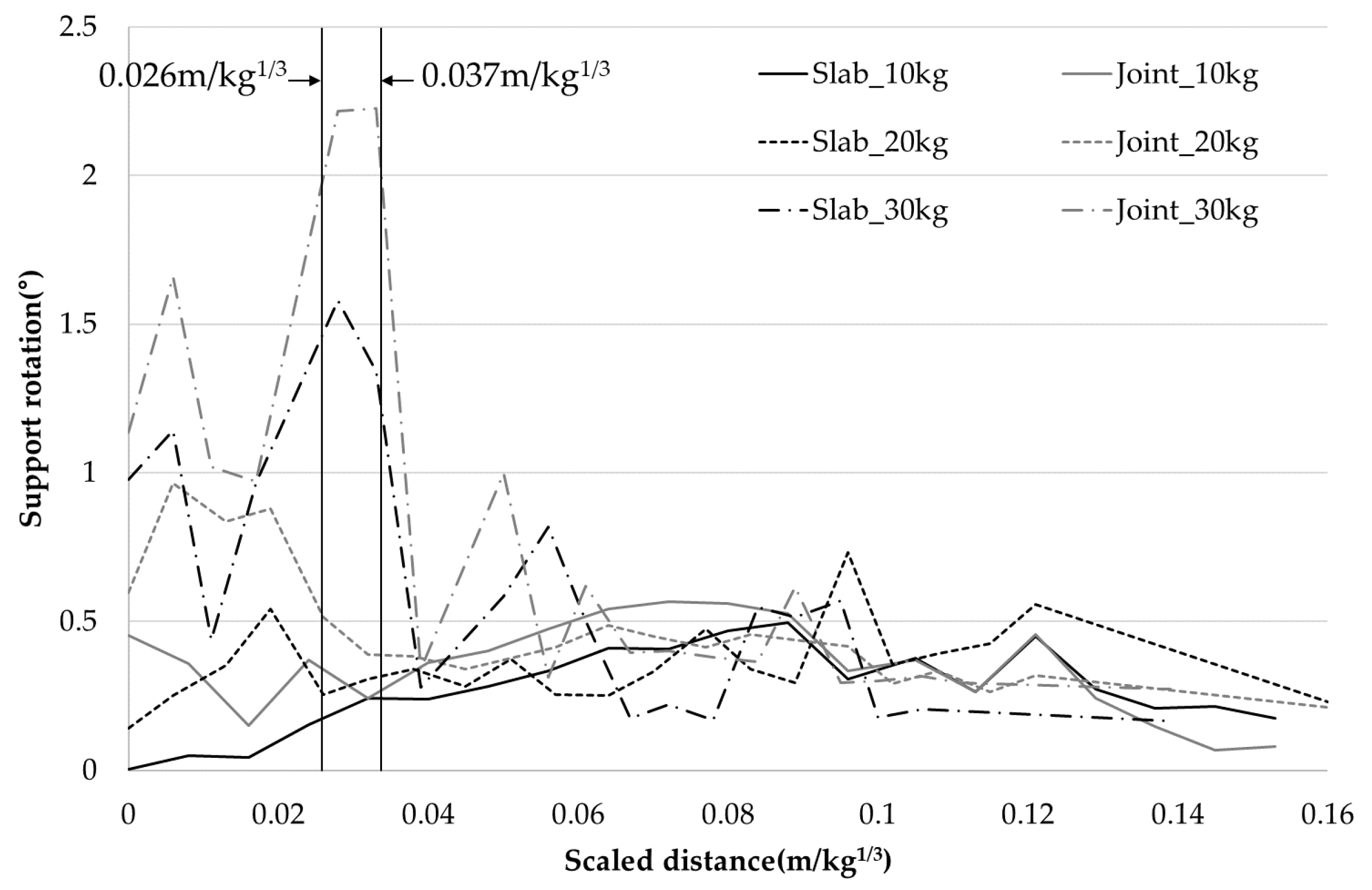

4.2. Support Rotation

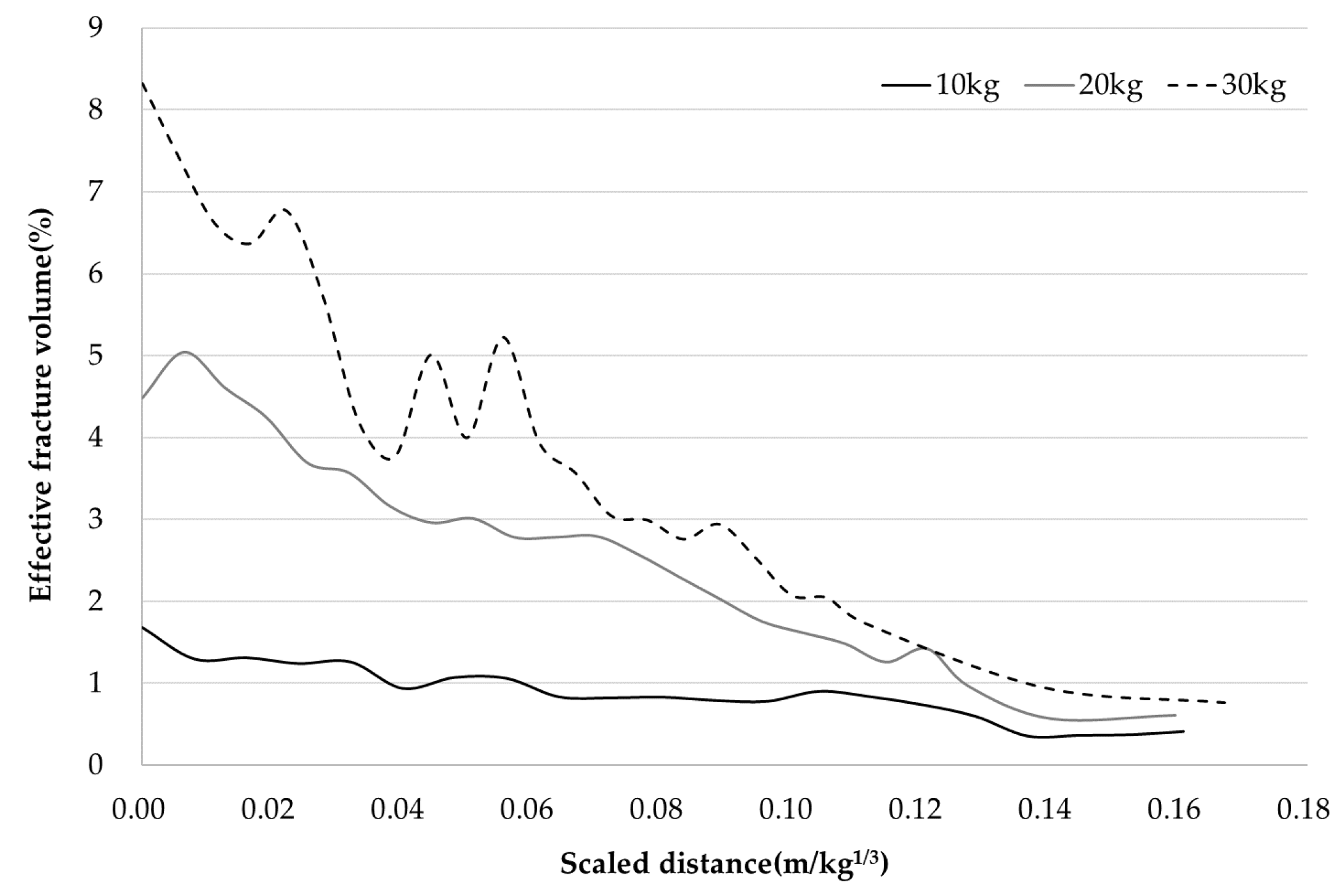

4.3. Fracture Volume

5. Prediction Model

5.1. The Suggestion of Prediction Model

5.2. Verification of Prediction Model

6. Conclusions

- (1)

- ConWep’s empirical values for shock wave parameters of a single member, such as a slab and a column, were compared with the pressure and impulse of a slab-column joint by numerical analysis. As a result, a region with a scaled distance of less than 0.1 m/kg1/3 was defined as a joint region.

- (2)

- The explosion created more pressure and impact on the slab than the column, thereby causing a larger displacement in the slab. In addition, it was observed that the damage of the member decreased sharply as the explosion position moved away from the member.

- (3)

- Even if the support rotation of the slab after the explosion was less than the limit of 2 degrees, it was observed that serious damage, such as spalling, occurred over a wide range of slab. Therefore, in addition to the support rotation and displacement, which are mainly used to evaluate blast-resistant performance, other evaluation factors are required.

- (4)

- Effective fracture volume was proposed as an evaluation factor for blast-resistant performance. Effective fracture volume was a good indication of the actual degree of damage to the member depending on the TNT weight and the explosive distance.

- (5)

- A prediction equation for the damage level of the slab-column joints through the TNT weight and the standoff distance of explosives was proposed. The reliability and accuracy of the proposed equation were verified through additional numerical analysis.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Brun, A.; Batti, A.; Limam, A.; Gravouil, A. Explicit/implicit multi-time step co-computations for blast analyses on a reinforced concrete frame structure. Finite Elem. Anal. Des. 2012, 52, 41–59. [Google Scholar] [CrossRef]

- Hajek, R.; Fladr, J.; Pachman, J.; Stoller, J.; Foglar, M. An experimental evaluation of the blast resistance of heterogeneous concrete-based composite bridge decks. Eng. Struct. 2019, 179, 204–210. [Google Scholar] [CrossRef]

- Kumar, V.; Kartik, K.V.; Iqbal, M.A. Experimental and numerical investigation of reinforced concrete slabs under blast loading. Eng. Struct. 2020, 206, 110–125. [Google Scholar] [CrossRef]

- Abdulsamee, M.H.; Yazan, B.A.T.; Amin, H.A.; George, Z.V. The effect of shape memory alloys on the ductility of exterior reinforced concrete beam-column joints using the damage plasticity model. Eng. Struct. 2019, 200, 109676. [Google Scholar]

- Cumhur, C.; Ahmet, M.T.; Atakan, M.; Turgay, C.; Guven, K. Experimental behavior and failure of beam-column joints with plain bars, low-strength concrete and different anchorage details. Eng. Fail. Anal. 2020, 109, 104247. [Google Scholar]

- Yim, H.C.; Krauthammer, T. Load-impulse characterization for steel connections in monolithic reinforced concrete structures. Int. J. Impact Eng. 2009, 36, 737–745. [Google Scholar] [CrossRef]

- Yoon, Y.S. Mechanics & Design of Reinforced Concrete; CIR: Seoul, Korea, 2013. [Google Scholar]

- Park, J.Y. Modern Protective Structures; CIR: Seoul, Korea, 2011. [Google Scholar]

- ASCE/SEI. ASCE/SEI 59-11: Blast Protection of Buildings; American Society of Civil Engineers, American Society of Civil Engineers/Structural Engineering Institute: Reston, VA, USA, 2011. [Google Scholar]

- Department of Defense. UFC 3-340-02: Structures to Resist the Effects of Accidental Explosions; Department of Defense: Arlington, VA, USA, 2008.

- Lim, K.M.; Shin, H.O.; Kim, D.J.; Yoon, Y.S.; Lee, J.H. Numerical assessment of reinforcing details in beam-column joints on blast resistance. Int. J. Concr. Struct. Mater. 2016, 10, 87–96. [Google Scholar] [CrossRef] [Green Version]

- Yandzio, E.; Gough, M. Protection of Buildings against Explosions; The Steel Construction Institute: Ascot, UK, 1999. [Google Scholar]

- Homeland Security. Improvised Explosive Devices; The National Academies and the Department of Homeland Security: Washington, DC, USA, 2019.

- Giversen, S. Blast Testing and Modelling of Composite Structures; DCAMM Special Report, No. S167; DTU Mechanical Engineering: Kongens Lyngby, Denmark, 2014. [Google Scholar]

- Andrew, R.; Nicola, B.; Giuseppe, C.; Stefano, D.M.; Gianluca, I.; Sonia, M.; Elio, S.; Sara, S.; Gabriel, T. Full scale experimental tests and numerical model validation of reinforced concrete slab subjected to direct contact explosion. Int. J. Impact Eng. 2019, 132, 103309. [Google Scholar]

- Azer, M.; Stijn, M.; Bachir, B.; David, L.; John, V. Blast response of retrofitted reinforced concrete hollow core slabs under a close distance explosion. Eng. Struct. 2019, 191, 447–459. [Google Scholar]

- Brannon, R.M.; Leelavanichkul, S. Survey of Four Damage Models for Concrete; Sandia National Laboratories: Albuquerque, NM, USA, 2009; SAND2009-5544.

- Crawford, J.E.; Wu, Y.; Choi, H.J.; Magallanes, J.M.; Lan, S. Use and Validation of the Release III K&C Concrete Material Model in LS-DYNA; Karagozian & Case technical report, TR-11-36.5; Karagozian & Case, Inc.: Glendale, CA, USA, 2012. [Google Scholar]

- LSTC (Livermore Software Technology Corporation). LS-DYNA Keyword User’s Manual Volume II Material Models; Livermore Software Technology Corporation: Livermore, CA, USA, 2013. [Google Scholar]

- Ling, L. Local Damages and Blast Resistance of RC Slabs Subjected to Contact Detonation. Master’s Thesis, Korea University, Seoul, Korea, 2013. [Google Scholar]

- Gonzalez, H.A.; Zapatero, J. Influence of minimum element size to determine crack closure stress by the finite element method. Eng. Fract. Mech. 2005, 72, 337–355. [Google Scholar] [CrossRef]

- Krauthammer, T. Mesh, gravity and load effects on finite element simulations of blast loaded reinforced concrete structures. Comput. Struct. 1997, 63, 1113–1120. [Google Scholar] [CrossRef]

- Foglar, M.; Kovar, M. Conclusions for experimental testing of blast resistance of FRC and RC bridge decks. Int. J. Impact Eng. 2013, 59, 18–28. [Google Scholar] [CrossRef]

- Thiagarajan, G.; Kadambi, A.V.; Robert, S.; Johnson, C.F. Experimental and finite element analysis of doubly reinforced concrete slabs subjected to blast loads. Int. J. Impact Eng. 2015, 75, 162–173. [Google Scholar] [CrossRef]

- Shi, Y.; Stewart, M.G. Damage and risk assessment for reinforced concrete wall pannels subjected to explosive blast loading. Int. J. Impact Eng. 2015, 85, 5–19. [Google Scholar] [CrossRef]

- Bae, D.M.; Zakki, A.F. Comparisons of multi material ALE and single material ALE in LS-DYNA for estimation of acceleration response of free-fall lifeboat. J. Soc. Nav. Archit. Korea 2011, 48, 552–559. [Google Scholar] [CrossRef] [Green Version]

- Jang, I.H. Sloshing Response Analysis of LNG Carrier Tank Using Fluid Structure Interaction Analysis Technique of LS-DYNA3D. Master’s Thesis, Korea Maritime and Ocean University, Busan, Korea, 2007. [Google Scholar]

- Zahra, S.T.; Jeffery, S.V. A comparison between three different blast methods in LS-DYNA: LBE, MM-ALE, Coupling of LBE and MM-ALE. In Proceedings of the 12th International LS-DYNA User Conference, Dearborn, MI, USA, 3–5 June 2012. [Google Scholar]

- Huh, Y.C.; Chung, T.Y.; Kim, K.C.; Jung, H.J.; Choi, H.H. A study on the modeling techniques of air blast load using LS-DYNA. In Proceedings of the Korean Society for Noise and Vibration Engineering Conference, Jeju Island, Daejeon, Korea, 26–28 April 2012; pp. 375–376. [Google Scholar]

- ACI-ASCE Committee 352. ACI352.1R-11: Guide for Design of Slab-Column Connections in Monolithic Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 2012. [Google Scholar]

| Bomblet | Loaded Weight (kg) | Material Type |

|---|---|---|

| Small briefcase | 2~4 | Military and commercial explosives (such as Trinitrotoluene (TNT)) |

| Large briefcase | 4~12 | |

| Suitcase | 12~22 | |

| Bicycle | 30 |

| TNT Weight (kg) | Standoff Distance (m) * | Scaled Distance (m/kg1/3) |

|---|---|---|

| 10 | 0~0.19 | 0~0.153 |

| 20 | 0~0.25 | 0~0.160 |

| 30 | 0~0.30 | 0~0.163 |

| Properties | Slab | Column | Reinforcements |

|---|---|---|---|

| Compressive strength (MPa) | 30 | 50 | - |

| Yield strength (MPa) | - | - | 475 |

| Tensile strength (MPa) | - | - | 751 |

| Density (kg/m3) | 2400 | 2500 | 7850 |

| Poisson’s ratio | 0.18 | 0.18 | 0.3 |

| Analysis Conditions | Value | |

|---|---|---|

| Number of elements | Solids | 392,000 ea (20 × 20 × 20 mm) |

| Beam | 10,648 ea (20 mm) | |

| Time step | 0.1 ms | |

| Analysis of end time | 2000 ms | |

| Analysis of running time | 6 h 45 m | |

| Case | Column Strength (MPa) | Slab Strength (MPa) | Slab Thickness(mm) | TNT Weight (kg) | Scaled Distance (m/kg1/3) | Effective Fracture Volume (%) | Prediction Differences (%) | |

|---|---|---|---|---|---|---|---|---|

| Verification Analysis | Prediction Model | |||||||

| 1 | 50 | 30 | 300 | 6 | 0.03 | 0.73 | 1.00 | 0.27 |

| 2 | 12 | 0.06 | 1.21 | 1.40 | 0.19 | |||

| 3 | 18 | 0.09 | 1.84 | 1.47 | 0.37 | |||

| 4 | 24 | 0.12 | 1.55 | 1.38 | 0.17 | |||

| 5 | 24 | 0.03 | 4.19 | 4.00 | 0.19 | |||

| 6 | 40 | 6.39 | 6.66 | 0.27 | ||||

| 7 | 50 | 8.07 | 8.33 | 0.26 | ||||

| 8 | 30 | 12 | 0.06 | 1.72 | 1.40 | 0.32 | ||

| 9 | 40 | 1.63 | 0.23 | |||||

| 10 | 50 | 20 | 1.92 | 0.52 | ||||

| 11 | 40 | 0.90 | 0.50 | |||||

| 12 | 50 | 30 | 320 | 1.41 | 0.01 | |||

| 13 | 340 | 1.43 | 0.03 | |||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, K.M.; Yoo, D.G.; Lee, B.Y.; Lee, J.H. Prediction of Damage Level of Slab-Column Joints under Blast Load. Appl. Sci. 2020, 10, 5837. https://doi.org/10.3390/app10175837

Lim KM, Yoo DG, Lee BY, Lee JH. Prediction of Damage Level of Slab-Column Joints under Blast Load. Applied Sciences. 2020; 10(17):5837. https://doi.org/10.3390/app10175837

Chicago/Turabian StyleLim, Kwang Mo, Do Guen Yoo, Bo Yeon Lee, and Joo Ha Lee. 2020. "Prediction of Damage Level of Slab-Column Joints under Blast Load" Applied Sciences 10, no. 17: 5837. https://doi.org/10.3390/app10175837

APA StyleLim, K. M., Yoo, D. G., Lee, B. Y., & Lee, J. H. (2020). Prediction of Damage Level of Slab-Column Joints under Blast Load. Applied Sciences, 10(17), 5837. https://doi.org/10.3390/app10175837