Energy and Exergy Analyses of a Combined Infrared Radiation-Counterflow Circulation (IRCC) Corn Dryer

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

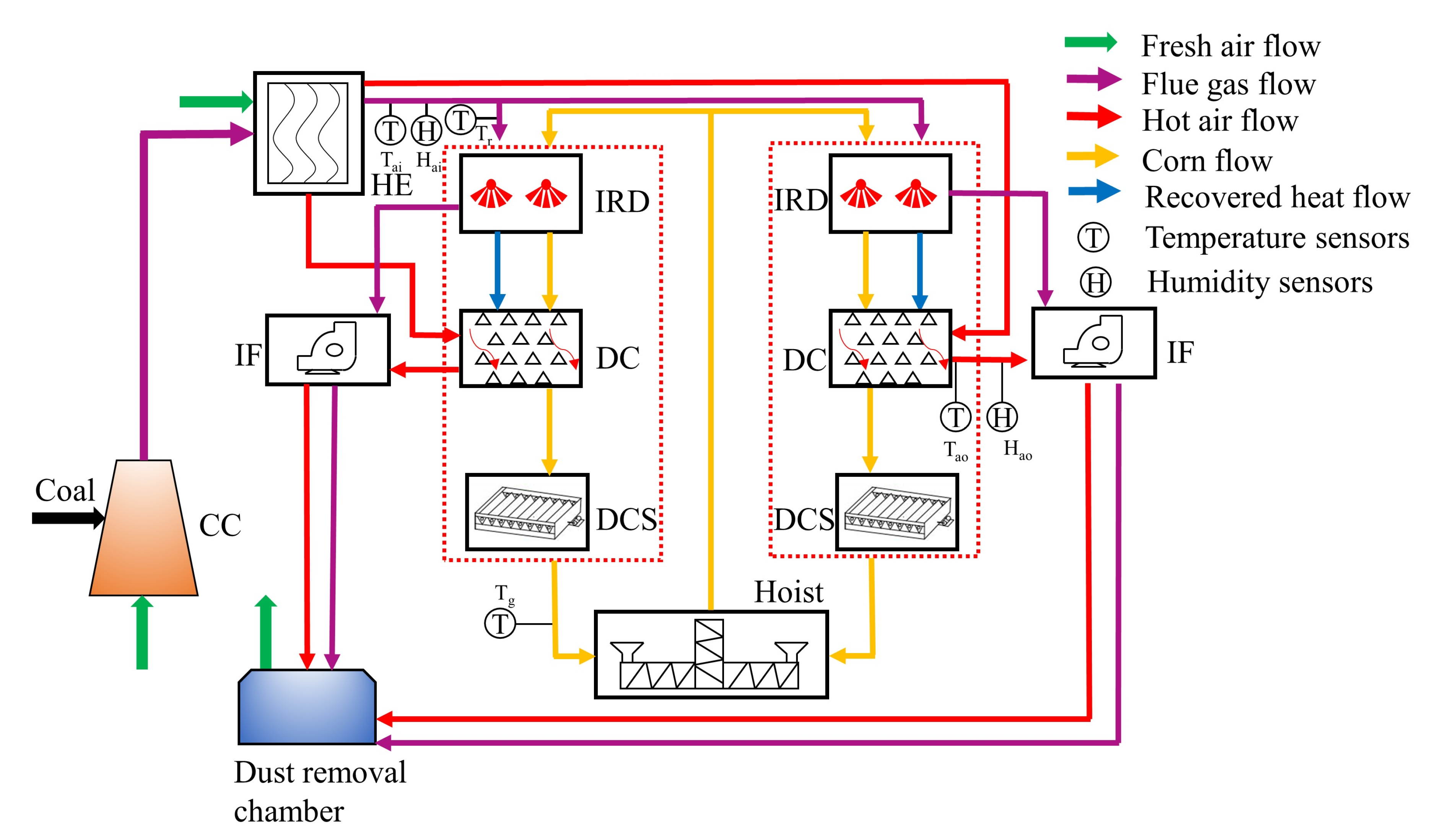

2.2. Principle and Process of Equipment

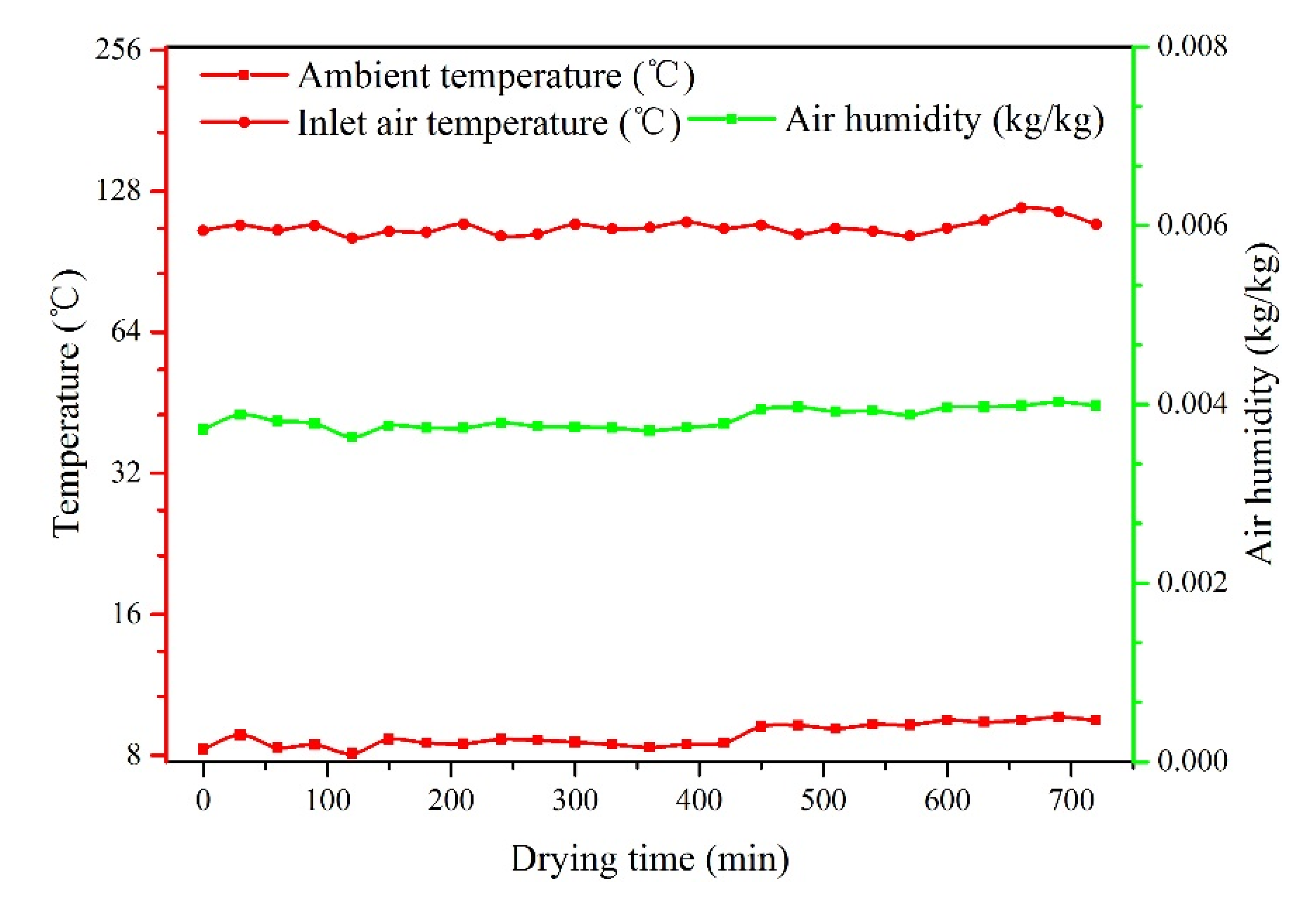

2.3. Drying Procedure and Data Collection

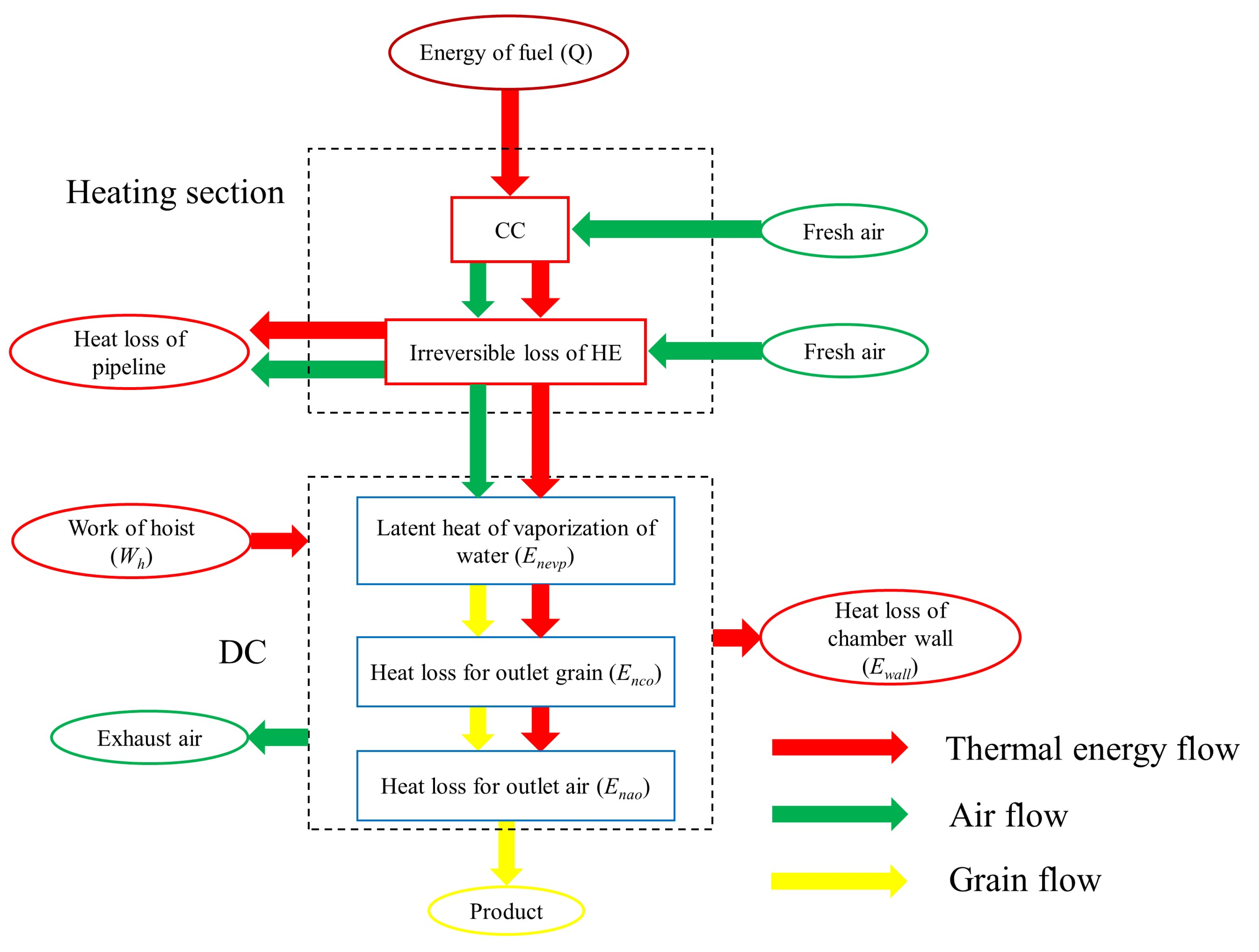

2.4. Theoretical Principle Used for Energy and Exergy Analyses

- The initial total weight of the corn in the dryer was regarded as 50 t;

- All components of the dryer were assumed to be operating in a stable state;

- The moisture of corn diffuses to the drying medium in the form of gas;

- The temperature potential inside a single corn kernel was ignored;

- The loss of heat stemming from inertia, convection and radiation in the drying chamber was ignored;

- The moisture (Mar), oxygen (Oar), ash (Aar) content and low heat value (LHV) of coal used in the present project were assumed to be 8.0%, 3.19%, 19.02% and 28.073 MJ/kg, respectively [34].

2.4.1. Energy Analysis

2.4.2. Exergy Analysis

2.5. Performance Indicators

2.6. Uncertainty Analysis

3. Results and Discussions

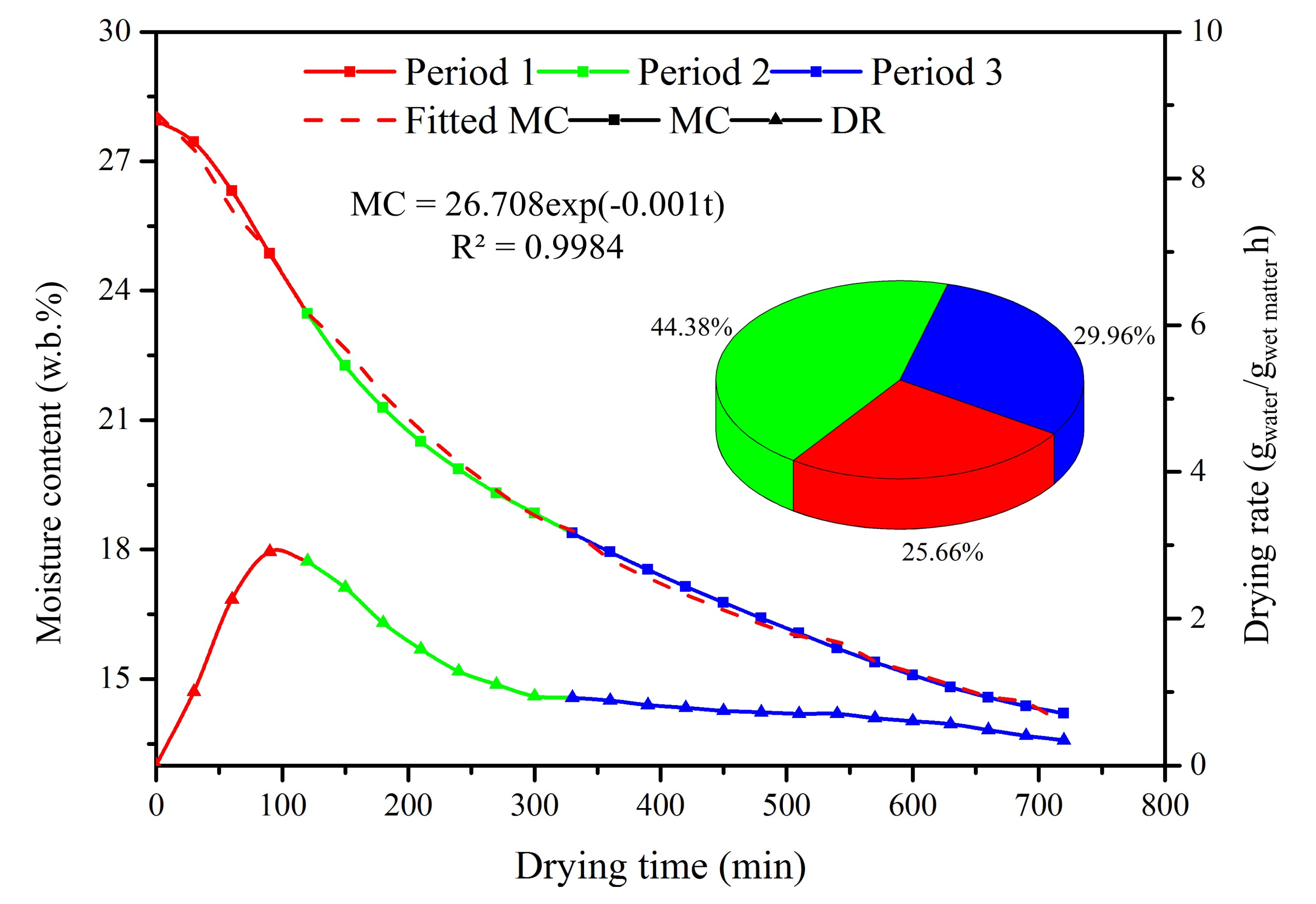

3.1. Drying Kinetics of the IRCC Corn Dryer

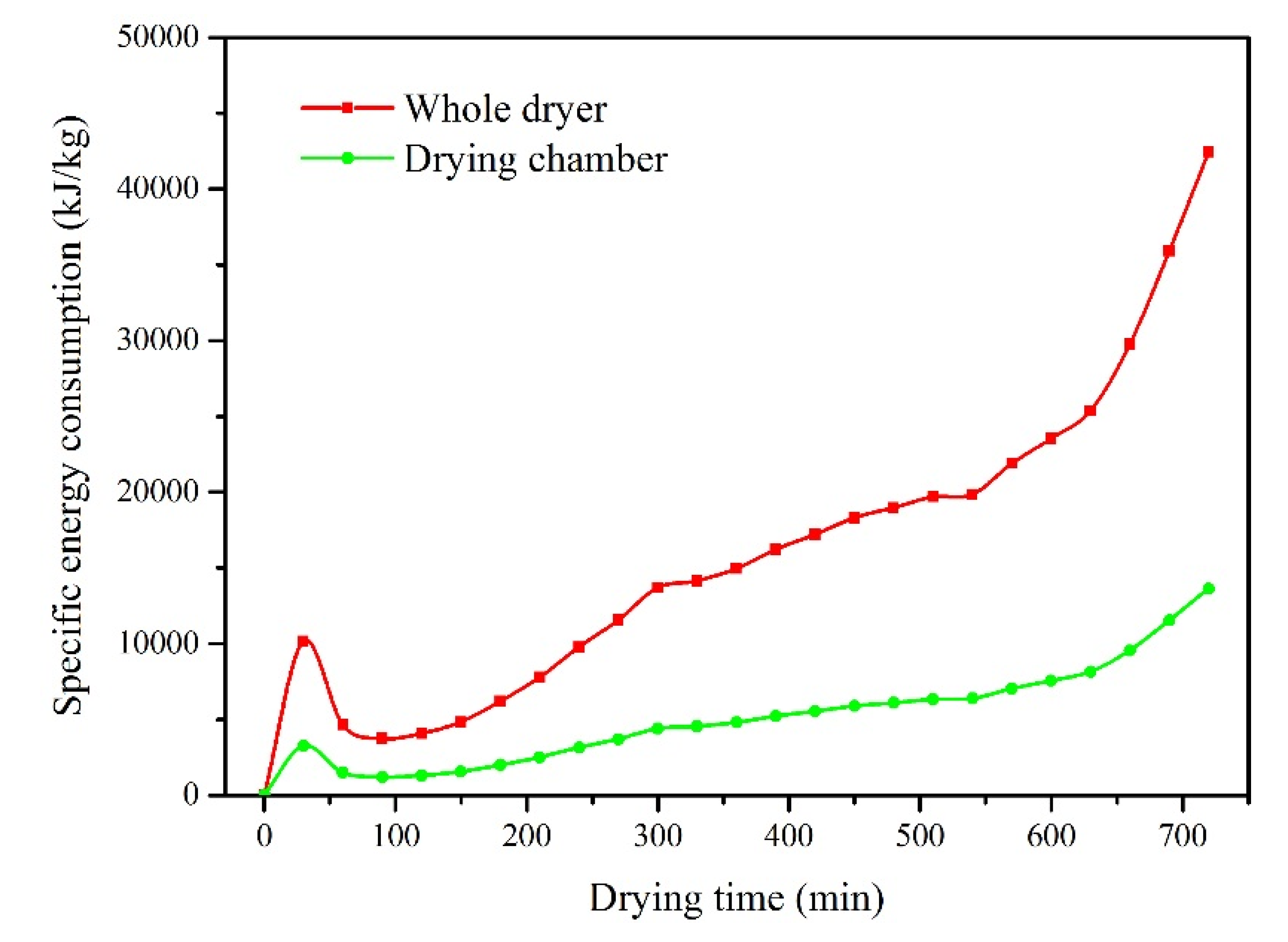

3.2. Energy Analysis of Corn Drying with the IRCC Corn Dryer

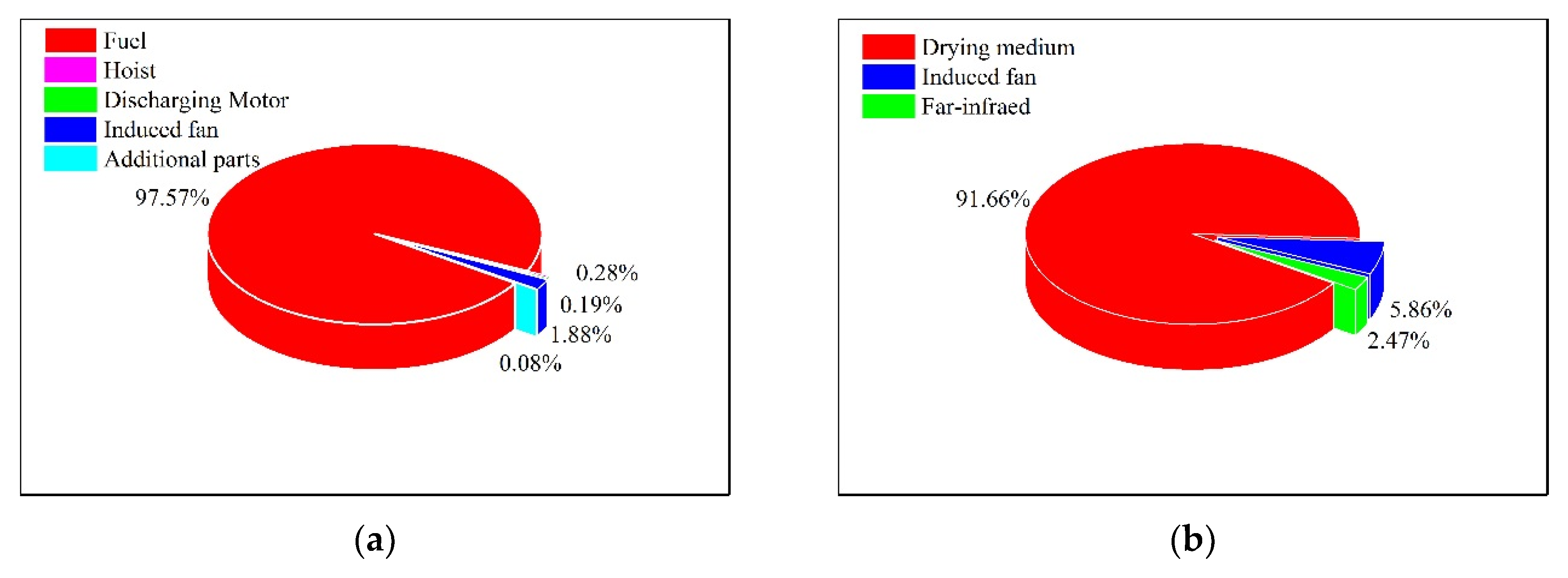

3.2.1. General View of Energy Structure

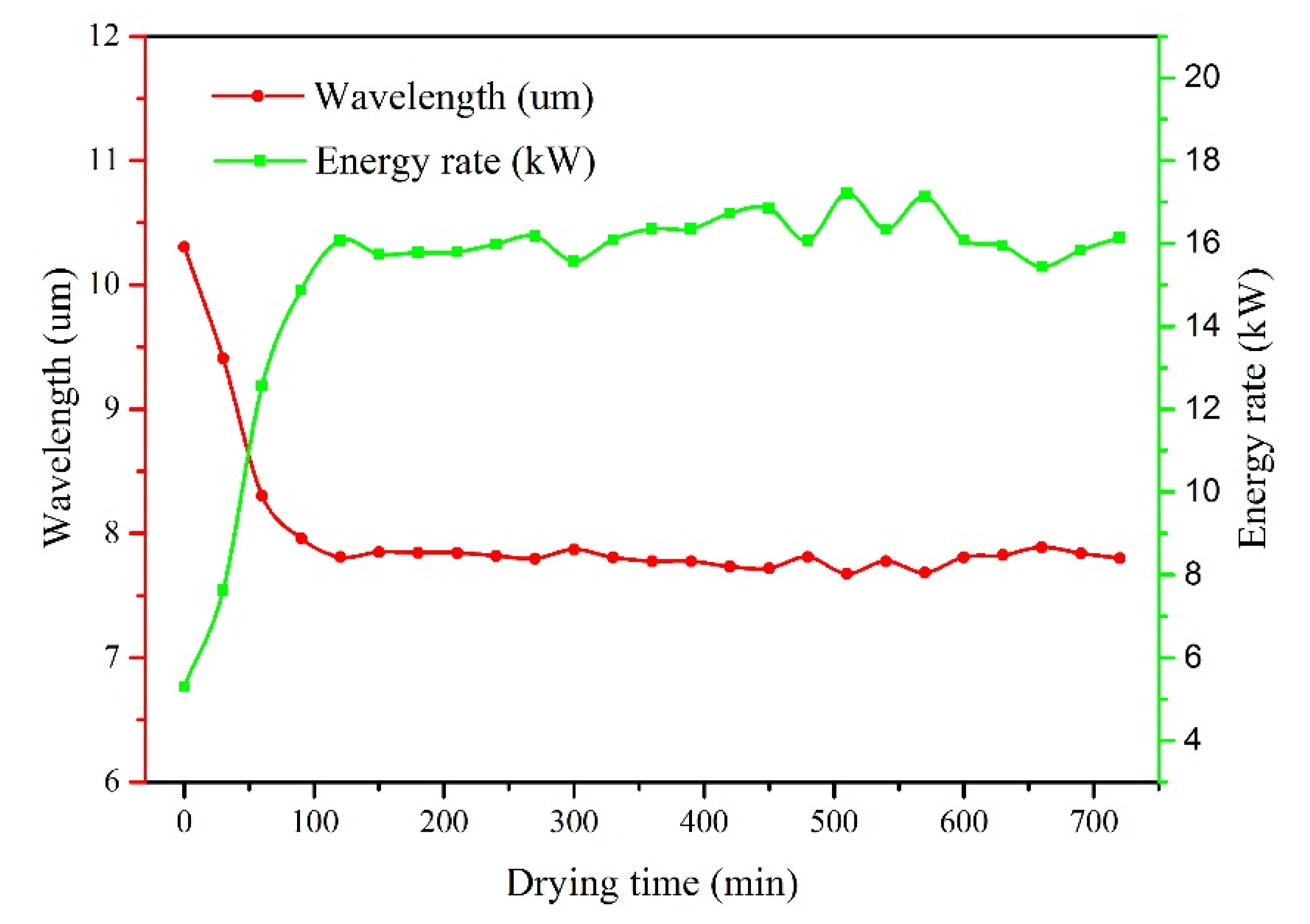

3.2.2. Radiant Energy Recovery

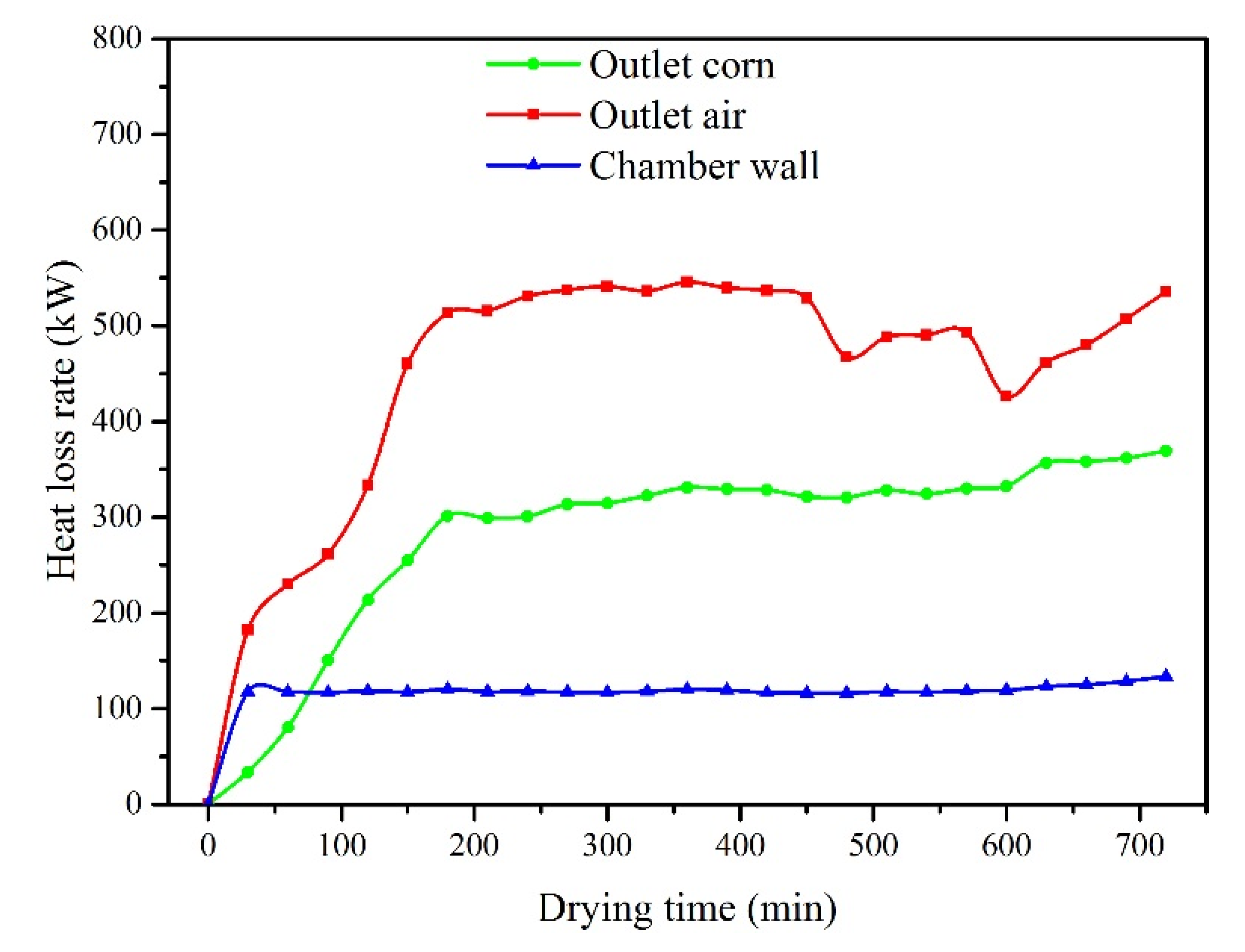

3.2.3. Heat Loss Characteristics

3.3. Exergy Analysis of Corn Drying with the IRCC Corn Dryer

3.3.1. General View of Exergy Structure

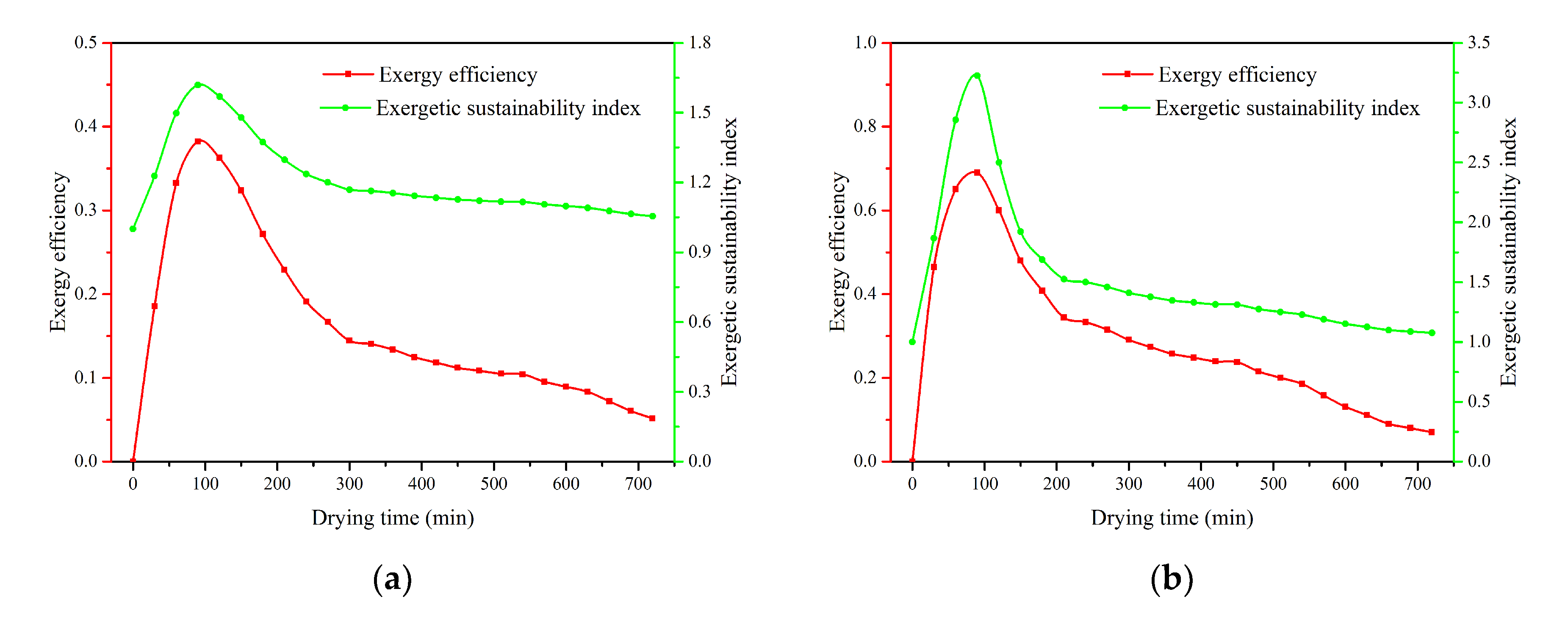

3.3.2. Exergetic Performance

4. Conclusions

- (1)

- The average drying rate of corn drying system in the current dryer was 1.1 gwater/gwet matter h. According to the drying rate, the drying process of corn can be divided into three stages; he dehydration of each stage accounts for 25.66%, 44.38% and 29.96% of total, respectively;

- (2)

- The energy efficiency of the entire drying system ranged from 2.16% to 35.21%. Additionally, the SEC of the whole drying system increases rapidly (19,844.52–42,425.59 kJ/kg) due to the effect of the binding energy after 540 min, indicating that energy efficiency ought to be optimized in this period;

- (3)

- The overall recovered radiant energy and the average radiant exergy rate were 674,339.3 kJ and 3.54 kW, respectively. Moreover, the wavelength range of the radiator with slight fluctuation (between 7.68 μm and 8.3 μm) indicated that the corn quality has been improved correspondingly under the suitable far-infrared radiation absorption rate;

- (4)

- Heat loss in the outlet air, the corn kernels and to the chamber wall were found to be 20,045.23 MJ, 12,547.16 MJ and 5151.52 MJ, accounting for 53.11%, 33.24% and 13.65% of the total, respectively. It is of great significance to design a waste-heat recovery device in view of reducing exhaust heat-loss and energy-consumption costs—especially in the later stages of the drying process.

- (5)

- The average exergy rate for dehydration was 462 kW; the exergy efficiency of the whole drying system varied from 5.16% to 38.21%, indicating that the IRCC corn dryer had a productive exergy performance;

- (6)

- Measures should primarily be put in place to optimize the CC, below by the DC, HE and RA according to the contribution level to the total exergy destruction.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| c | specific heat (J·kg−1·K−1) |

| humidity ratio of air (kg water vapor/kg dry air) | |

| mass flow rate (kg·s−1) | |

| energy rate (kW) | |

| exergy rate (kW) | |

| heat transfer rate (kW) | |

| power rate (kW) | |

| work rate (kW) | |

| R | gas constant (kJ·kg−1·K−1) |

| Afir | cross-sectional area of the drying chamber (m2) |

| v | velocity (m·s−1) |

| g | gravity acceleration (m·s−2) |

| hfg | latent heat (kJ·kg−1) |

| T | temperature (K or °C) |

| m | mass (kg) |

| md | dry weight (kg) |

| pi | pressure (Pa) |

| specific enthalpy (kJ·kg−1) |

Abbreviations

| IRCC | infrared radiation–counterflow circulation |

| IR | infrared radiation |

| TP | tempering section |

| IRD | infrared radiation section |

| DC | drying chamber |

| DCS | discharging section |

| HE | heat exchanger |

| CC | combustion chamber |

| MC | moisture content |

| RA | Radiators |

Greek Symbols

| Ɛ | emissivity |

| ρ | density (kg·m3) |

| μ | dynamic viscosity (kg·m−1·s−1) |

| γ | thermal conductivity (W·m−1·K−1) |

| δ | thickness (m) |

| λ | wavelength (um) |

Subscripts

| a | air |

| g | corn kernels |

| in | inlet |

| out | outlet |

| v | vapor |

| c | chamber |

| ∞ | ambient |

| r | radiator |

| wall | dryer wall |

| h | hoist |

| dm | discharging motor |

| if | induced fan |

| ap | additional parts |

| evap | evaporation |

| (∆t) | time |

| da | dry air |

References

- Aviara, N.A.; Onuoha, L.N.; Falola, O.E.; Igbeka, J.C. Energy and exergy analyses of native cassava starch drying in a tray dryer. Energy 2014, 73, 809–817. [Google Scholar] [CrossRef]

- Midilli, A.; Kucuk, H. Energy and exergy analyses of solar drying process of pistachio. Energy 2003, 28, 539–556. [Google Scholar] [CrossRef]

- Defraeye, T. Advanced computational modelling for drying processes–A review. Appl. Energy 2014, 131, 323–344. [Google Scholar] [CrossRef]

- Beigi, M.; Tohidi, M.; Torki-Harchegani, M. Exergetic Analysis of Deep-Bed Drying of Rough Rice in a Convective Dryer. Energy 2017, 140. [Google Scholar] [CrossRef]

- Tohidi, M.; Sadeghi, M.; Torki-Harchegani, M. Energy and quality aspects for fixed deep bed drying of paddy. Renew. Sustain. Energy Rev. 2017, 70, 519–528. [Google Scholar] [CrossRef]

- Ozgen, F.; Celik, N. Evaluation of Design Parameters on Drying of Kiwi Fruit. Appl. Sci. 2019, 9, 10. [Google Scholar] [CrossRef]

- Zheng, X.; Liu, H.; Shen, L.; Wang, J.; Wang, L.; Zhu, Y. Hot-air Drying Technology of Changing Temperature for Paddy Rice Based on Glass Transition Theory. Trans. Chin. Soc. Agric. Mach. 2020, 51, 331–340. [Google Scholar] [CrossRef]

- Romuli, S.; Schock, S.; Somda, M.K.; Müller, J. Drying Performance and Aflatoxin Content of Paddy Rice Applying an Inflatable Solar Dryer in Burkina Faso. Appl. Sci. 2020, 10, 3533. [Google Scholar] [CrossRef]

- Taechapairoj, C.; Dhuchakallaya, I.; Soponronnarit, S.; Wetchacama, S.; Prachayawarakorn, S. Superheated steam fluidised bed paddy drying. J. Food Eng. 2003, 58, 67–73. [Google Scholar] [CrossRef]

- Li, C.; Mai, Z.; Fang, Z.; Zhang, Y. Design and test on energy-saving drying system for paddy with high moisture content. Trans. Chin. Soc. Agric. Eng. 2014, 30, 1–9. [Google Scholar] [CrossRef]

- Xie, Y.; Zhang, Y.; Xie, Y.; Li, X.; Liu, Y.; Gao, Z. Radio frequency treatment accelerates drying rates and improves vigor of corn seeds. Food Chem. 2020, 319, 126597. [Google Scholar] [CrossRef] [PubMed]

- Faria, R.Q.D.; Santos, A.R.P.D.; Gariepy, Y.; Silva, E.A.A.D.; Maria, M.P.S.; Raghavan, V. Optimization of the process of drying of corn seeds with the use of microwaves. Dry. Technol. 2020, 38, 676–684. [Google Scholar] [CrossRef]

- Li, S.; Chen, S.; Liang, Q.; Ma, Z.; Han, F.; Xu, Y.; Jin, Y.; Wu, W. Low temperature plasma pretreatment enhances hot-air drying kinetics of corn kernels. J. Food Process Eng. 2019, e13195. [Google Scholar] [CrossRef]

- Vera, I.; Langlois, L. Energy indicators for sustainable development. Energy 2007, 32, 875–882. [Google Scholar] [CrossRef]

- Li, C.; Ma, X.; Fang, Z.; Zhang, Y. Thermal energy structure of grain hot air drying and analytical method. Trans. Chin. Soc. Agric. Eng. 2014, 30, 220–228. [Google Scholar] [CrossRef]

- Khanali, M.; Aghbashlo, M.; Rafiee, S.; Jafari, A. Exergetic performance assessment of plug flow fluidised bed drying process of rough rice. Int. J. Energy 2013, 13, 387–408. [Google Scholar] [CrossRef]

- Dincer, I. On energetic, exergetic and environmental aspects of drying systems. Int. J. Energy Res. 2002, 26, 717–727. [Google Scholar] [CrossRef]

- Moran, M.J.; Shapiro, H.N. Fundamentals of Engineering Thermodynamics, 6th ed.; John Wiley and Sons Inc.: Chichester, UK, 2000. [Google Scholar] [CrossRef]

- Yildirim, N.; Genc, S. Energy and exergy analysis of a milk powder production system. Energy Convers. Manag. 2017, 149, 698–705. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Mobli, H.; Rafiee, S.; Madadlou, A. Energy and exergy analyses of the spray drying process of fish oil microencapsulation. Biosyst. Eng. 2012, 111, 229–241. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Kianmehr, M.H.; Arabhosseini, A. Energy and exergy analyses of thin-layer drying of potato slices in a semi-industrial continuous band dryer. Dry. Technol. 2008, 26, 1501–1508. [Google Scholar] [CrossRef]

- Li, B.; Li, C.; Li, T.; Zeng, Z.; Ou, W.; Li, C. Exergetic, Energetic, and Quality Performance Evaluation of Paddy Drying in a Novel Industrial Multi-Field Synergistic Dryer. Energies 2019, 12, 4588. [Google Scholar] [CrossRef]

- Yogendrasasidhar, D.; Setty, Y.P. Drying kinetics, exergy and energy analyses of kodo millet grains and fenugreek seeds using wall heated fluidized bed dryer. Energy 2018, 151, 799–811. [Google Scholar] [CrossRef]

- Delgado-Plaza, E.; Peralta-Jaramillo, J.; Quilambaqui, M.; Gonzalez, O.; Reinoso-Tigre, J.; Arevalo, A.; Arancibia, M.; Paucar, M.; Velázquez-Martí, B. Thermal Evaluatiown of a Hybrid Dryer with Solar and Geothermal Energy for Agroindustry Application. Appl. Sci. 2019, 9, 4079. [Google Scholar] [CrossRef]

- Darvishi, H.; Zarein, M.; Farhudi, Z. Energetic and exergetic performance analysis and modeling of drying kinetics of kiwi slices. J. Food Sci. Technol. 2016, 53, 2317–2333. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Li, B.; Huang, J.; Li, C. Developing an online measurement device based on resistance sensor for measurement of single grain moisture content in drying process. Sensors 2020, 20, 4102. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z. Agricultural Materials Science; Agriculture Press: Beijing, China, 1994. (In Chinese) [Google Scholar]

- Li, C.; Mai, Z.; Fang, Z. Analytical study of grain moisture binding energy and hot air drying dynamics. Trans. Chin. Soc. Agric. Eng. 2014, 30, 236–242. [Google Scholar] [CrossRef]

- Khir, R.; Pan, Z.; Salim, A.; Hartsough, B.R.; Mohamed, S. Moisture diffusivity of rough rice under infrared radiation drying. LWT Food Sci. Technol. 2011, 44, 1126–1132. [Google Scholar] [CrossRef]

- Sharma, G.P.; Verma, R.C.; Pathare, P.B. Thin-layer infrared radiation drying of onion slices. J. Food Eng. 2005, 67, 361–366. [Google Scholar] [CrossRef]

- Li, C.Y. Hot Blast Stove Burning Chaff and its Operation Method. Patent No. CN105757650B, 27 October 2017. [Google Scholar]

- Li, C.Y.; Fang, Z.D.; Zheng, F. A lossless grain discharging and cleaning device. Patent NO CN105707224A, 29 June 2016. [Google Scholar]

- National Standards of People’s Republic of China; GB 1353-2018; Maize; State Administration for Market Regulation: Bejing, China, 2017.

- Li, B.; Li, C.; Huang, J.; Li, C. Exergoeconomic analysis of corn drying in a novel industrial drying system. Entropy 2020, 22, 689. [Google Scholar] [CrossRef]

- Akpinar, E.K.; Midilli, A.; Bicer, Y. The first and second law analyses of thermodynamic of pumpkin drying process. J. Food Eng. 2006, 72, 320–331. [Google Scholar] [CrossRef]

- Li, C.Y. Engineering Thermodynamics and Heat Transfer; China Agricultural University Press: Beijing, China, 2012. (In Chinese) [Google Scholar]

- Stepanov, V.S. Chemical energies and exergies of fuels. Energy 1995, 20, 235–242. [Google Scholar] [CrossRef]

- Soufiyan, M.M.; Dadak, A.; Hosseini, S.S.; Nasiri, F.; Dowlati, M.; Tahmasebi, M. Comprehensive exergy analysis of a commercial tomato paste plant with a double-effect evaporator. Energy 2016, 111, 910–922. [Google Scholar] [CrossRef]

- Lima, J.A.S.; Santos, J. Generalized Stefan-Boltzmann law. Int. J. Ther. Phys. 1995, 34, 127–134. [Google Scholar] [CrossRef]

- Li, C.Y. Analysis of Grain Drying; Science Press: Beijing, China, 2018. (In Chinese) [Google Scholar]

- Syahrul, S.; Hamdullahpur, F.; Dincer, I. Thermal analysis in fluidized bed drying of moist particles. Appl. Therm. Eng. 2002, 22. [Google Scholar] [CrossRef]

- Torki-Harchegani, M.; Ghanbarian, D.; Ghasemi-Pirbalouti, A.; Sadeghi, M. Dehydration behaviour, mathematical modelling, energy efficiency and essential oil yield of peppermint leaves undergoing microwave and hot air treatments. Renew. Sust. Energy Rev. 2016, 58, 407–418. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Rosen, M.A. Exergoeconoenvironmental analysis as a new concept for developing thermodynamically, economically, and environmentally sound energy conversion systems. J. Clean. Prod. 2018, 187, 190–204. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Tabatabaei, M.; Jazini, H. Exergoeconomic and exergoenvironmental co-optimization of continuous fuel additives (acetins) synthesis from glycerol esterification with acetic acid using Amberlyst 36 catalyst. Energy Convers. Manag. 2018, 65, 183–194. [Google Scholar] [CrossRef]

- Zhu, W.X. Principle and Technology of Food Drying; Science Press: Beijing, China, 2009. (In Chinese) [Google Scholar]

- Ding, Z.; Zhu, D.; Tao, C.; Sun, L. Study on Hot Air Drying Characteristic of High–Moisture Wheat and its Mathematical Model. Agric. Mech. Res. 2012, 9, 55–60. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Q.; Xiao, B.; Yang, D.; Liu, X. Modeling Simulation of Combined Convective and Infrared radiation in rice Drying Process. Trans. Chin. Soc. Agric. Mach. 2013, 44, 145–151. [Google Scholar] [CrossRef]

- Wang, D.; Li, H.; Yu, F.; Wang, Z. Studies on factors effecting thin-layer drying rate of corn. Trans. Chin. Soc. Agric. Eng. 1993, 9, 102–108. [Google Scholar]

- Xiong, S.; Sun, W.; Zhao, L. Optimization of three-stage drying of paddy. Food Sci. 2017, 38, 274–281. [Google Scholar] [CrossRef]

- Zare, D.; Naderi, H.; Ranjbaran, M. Energy and quality attributes of combined hot-air/infrared drying of paddy. Dry. Technol. 2015, 33, 570–582. [Google Scholar] [CrossRef]

- Sarker, M.S.H.; Ibrahim, M.N.; Aziz, N.A.; Punan, M.S. Energy and exergy analysis of industrial fluidized bed drying of paddy. Energy 2015, 84, 131–138. [Google Scholar] [CrossRef]

- Zhu, W.; Zhang, Z. Research on characteristics of infrared absorption of grain. Grain Storage 2003, 32, 38–41. [Google Scholar]

- Syahrul, S.; Hamdullahpur, F.; Dincer, I. Exergy analysis of fluidized bed drying of moist particles. Exergy Int. J. 2002, 2, 87–98. [Google Scholar] [CrossRef]

- Mujumdar, A.S. An Overview of innovation in industrial drying: Current status and R&D needs. Trans. Porous Media. 2007, 6, 3–18. [Google Scholar] [CrossRef]

- Li, T.; Li, C.; Li, C.; Xu, F.; Fang, Z. Porosity of flowing rice layer: Experiments and numerical simulation. J. Biosyst. Eng. 2019, 179, 1–12. [Google Scholar] [CrossRef]

- Li, T.; Li, C.; Li, B.; Li, C.; Fang, Z.; Zeng, Z.; Ou, W.; Huang, J. Characteristic analysis of heat loss in multistage counter-flow paddy drying process. Energy Rep. 2020, 6, 2153–2166. [Google Scholar] [CrossRef]

- Ma, X.; Fang, Z.; Li, C. Energy efficiency evaluation and experiment on grain counter-flow drying system based on exergy analysis. Trans. Chin. Soc. Agric. Eng. 2017, 33, 285–291. [Google Scholar] [CrossRef]

- Zhu, M. Exergy Analysis of Energy System; Tsinghua University Press: Beijing, China, 1988. (In Chinese) [Google Scholar]

- Li, C.; Mai, Z.; Fang, Z.; Li, J.; Zhang, Y. Development of Seed Circulation Drying System. Trans. Chin. Soc. Agric. Eng. 2014, 45, 242–248. [Google Scholar] [CrossRef]

| Instruments | Model | Measurement Scope | Accuracy |

|---|---|---|---|

| Temperature resistance | PT100 | −200–450 °C | ±0.1 °C |

| Pyrometer couple | WRN-130/230 | 0–1300 °C | ±0.1 °C |

| Anemograph | DT-8893 | 0.001–45 m/s | 0.01 m/s |

| Temperature and humidity sensor | AM2301 | 0–100%/−40–80 °C | ±3%/±0.5 °C |

| Data-acquisition system | Self-developed | – | – |

| Equipment | Power |

|---|---|

| Hoist | 5.5 kW |

| Discharging motor | 3.75 kW |

| Induced fan | 37 kW |

| Additional parts | 1.5 kW |

| Parameter | Value/Equation | Unit | Reference |

|---|---|---|---|

| Afir | 16.6 | m2 | – |

| σ | 5.67 × 10−8 | W·m−2·K−4 | [27] |

| Ɛr | 0.9 | – | [39] |

| S | 0.126 | m2 | – |

| As | 8.3 | m2 | – |

| δ | 0.05 | m | – |

| γ | 1 | W·m−1·K−1 | – |

| Cc | 1.465 + 0.036 M | kJ·kg−1·K−1 | [40] |

| Ca | 1.004 | kJ·kg−1·K−1 | [16] |

| Cv | 1.872 | kJ·kg−1·K−1 | [16] |

| Ra | 0.287 | kJ·kg−1·K−1 | [5] |

| Rv | 0.462 | kJ·mol−1·K−1 | [5] |

| 9.26 | kg·s−1 | – |

| Components | Exin (kW) | Exout (kW) | Exdes (kW) | ηex (%) | SI | rd (%) | Improvement Priority |

|---|---|---|---|---|---|---|---|

| CC | 2077.65 | 1213.38 | 864.27 | 58.40 | 2.40 | 56.11 | 1 |

| HE | 1213.38 | 1034.72 | 178.66 | 82.28 | 5.64 | 11.60 | 3 |

| RA | 36.34 | 17.39 | 18.95 | 9.74 | 1.11 | 1.23 | 4 |

| DC | 1001.92 | 523.56 | 478.36 | 46.11 | 1.86 | 31.06 | 2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Li, B.; Huang, J.; Li, C. Energy and Exergy Analyses of a Combined Infrared Radiation-Counterflow Circulation (IRCC) Corn Dryer. Appl. Sci. 2020, 10, 6289. https://doi.org/10.3390/app10186289

Li C, Li B, Huang J, Li C. Energy and Exergy Analyses of a Combined Infrared Radiation-Counterflow Circulation (IRCC) Corn Dryer. Applied Sciences. 2020; 10(18):6289. https://doi.org/10.3390/app10186289

Chicago/Turabian StyleLi, Chengjie, Bin Li, Junying Huang, and Changyou Li. 2020. "Energy and Exergy Analyses of a Combined Infrared Radiation-Counterflow Circulation (IRCC) Corn Dryer" Applied Sciences 10, no. 18: 6289. https://doi.org/10.3390/app10186289

APA StyleLi, C., Li, B., Huang, J., & Li, C. (2020). Energy and Exergy Analyses of a Combined Infrared Radiation-Counterflow Circulation (IRCC) Corn Dryer. Applied Sciences, 10(18), 6289. https://doi.org/10.3390/app10186289