1. Introduction

Air pollution, carbon dioxide emissions, and fine dust problems have attracted attention due to the use of fossil fuels. Proton exchange membrane water electrolysis (PEMWE) can produce hydrogen without emitting pollutants such as carbon dioxide, in contrast to fossil fuels [

1]. If electricity is produced by renewable energy technology, hydrogen from water electrolysis can be stored in an environmentally friendly manner [

2]. PEMWE consists of an end plate, current collector, bipolar plate (BP), porous transport layer (PTL), and membrane electrode assembly (MEA) [

3]. The end plates—ones of the components of the PEMWE—are located at both ends of the stack to maintain a constant pressure for lower electrical resistance and tight gas sealing [

4]. Thick end plates are produced to withstand the high pressure, resulting in heavy weight and unnecessary material consumption. In contrast, using thin plates can produce non-uniform clamping pressure, thus deteriorating the performance of PEMWE due to leakage and large electrical contact resistance [

5].

Chang et al. [

6] examined the effect of clamping pressure on the performance of a proton exchange membrane fuel cell (PEMFC). Clamping pressure can reduce the interfacial resistance between the BP and the gas diffusion layer (GDL). This study focuses on fuel cell performance based on the diffusion path for mass transfer in the GDL, not in the end plates. Furthermore, Wen et al. [

7] conducted an experimental study of the clamping effects on the performance of a single PEMFC, and a 10-cell stack was studied with a pressure-sensitive film. The linear relationship of combinations of bolts and clamping torque was investigated experimentally. The pressure distribution in a 10-cell stack was not simulated in detail.

Wang et al. [

5] conducted an experimental study on clamping pressure distribution with performance tests and pressure-sensitive films. Newly designed end plates provide uniform stress to MEA. The new design was convenient to use in the laboratory for the uniform clamping pressure, but not in practice because of its bulky system with the built-in hydraulically pressurizing devices. Bates et al. [

8] applied an endplate with center holes and hex-head screws in single-cell and 16-cell stacks. Simulation and experimental analyses of single-cell and 16-cell stacks and components of the stack were performed by finite element analysis (FEA) and pressure-sensitive film. The stress on the GDL is simulated at 1.6 MPa for the 16-cell stack and 4 MPa in single-cell. Experimental results demonstrated nearly zero pressure at the center of the stack, regardless of the clamping pressure. Pushing pins through center holes compensate for the deficient clamping pressure of end plates, which needs additional devices for the stacks.

Lin et al. [

9] investigated the multi-objective topology optimization of end plates with nonlinear contact boundary conditions. The 5-cell and 10-cell stacks have different response forces to end plates, which optimize the different shapes of end plates. The stiff end plates press the cells uniformly, but the parametric study of various end plates was not investigated further. Lee et al. [

10] used FEA and a pressure film test to study end plate assembly pressure distribution. The quantitative comparison of simulation and experimental results are essential for obtaining consistent fuel cell performance with stacking parameters such as stacking design, BP thickness, sealing size, and assembly pressure. Asghar et al. [

11] designed and manufactured end plates for a 5 kW PEMFC that provided uniform pressure distribution between the fuel cell components (e.g., BPs, GDLs, and current collectors) and, consequently, reduced the contact resistance, which was measured by electrochemical impedance spectroscopy. The thickness of the end plates was optimized, minimizing deflections. The clamping torque, end plate thickness, and number of bolts were optimally combined for the appropriate assembly pressure distribution. Montanini et al. stated that higher torque does not ensure the uniform pressure distribution because of the bending of end plates [

12].

For PEMWE, Al Shakhshir et al. [

3] studied the in situ experimental characterizations of clamping pressure effects. A graphite block is stiffer than a titanium block for loading uniform pressure to the MEAs, which results in homogeneous local current density [

13]. Similar to the additional hydraulic compression in PEMFC, the pneumatical compression of the end plates in PEMWE stacks enhances the uniformity of local current density [

14]. Non-uniform distribution of current density can result in a temperature difference and significant degradation of MEAs [

15]. Wilson et al. [

16] have an end plate design patent for a high-pressure electrolytic module that maintains a uniform pressure with the backing plate. Verdin et al. investigated the relationship between pressure distribution and local current density with the operando method [

17]. The highly compressed region exhibits a high current density with low ohmic resistance. Selamet et al. compared circular PEMWE stacks with 5 and 10 cells [

18].

The further analysis of clamping pressure distribution in the stacks with different cell numbers is necessary to investigate the performance difference between the stacks. Although the previous studies conducted PEMFC and PEMWE end plate research, few papers have studied high pressure sealing end plates with weight reduction. Comparing the square and the circular end plates is necessary to ensure the uniform pressure distribution at each cell in the stacks.

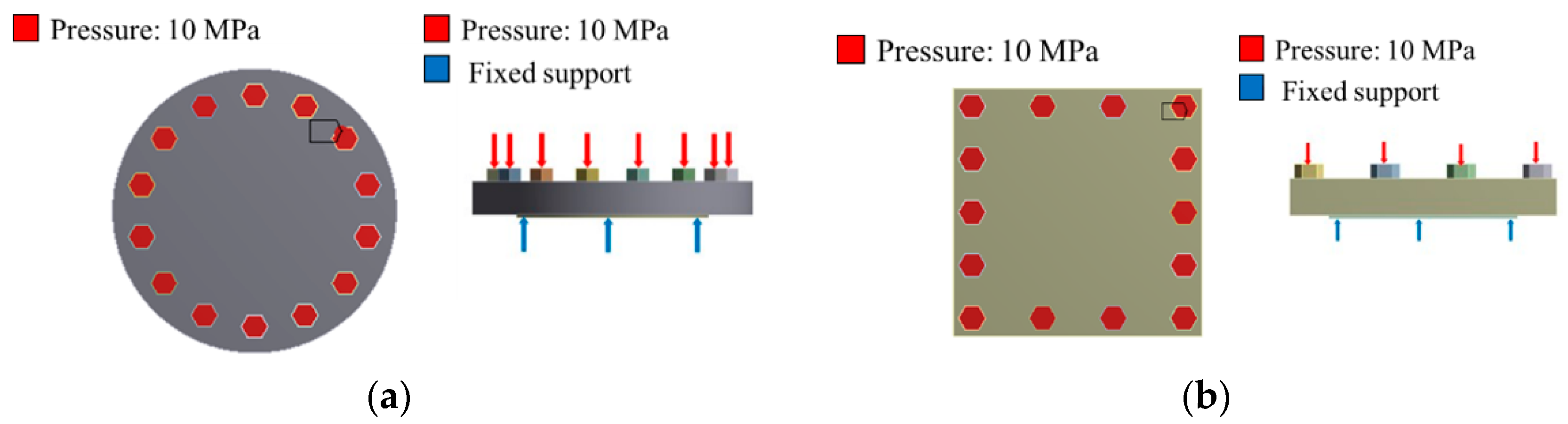

In this study, stress, deformation analysis, and topology optimization are performed to reduce the weight of circular and square end plates. After the topology optimization, design parameters, such as removing the regions of upper, lower, or side parts, were derived. Stress and deformation analyses were conducted with newly designed end plates. Strain simulation and validating experiments of dummy cells was performed to verify clamping pressure uniformity between cells by insertion of pressure sensing films into the middle and end cells of the stack. The square end plate experiences more stress than the circular end plate in topology optimization with weight reduction. In contrast, the clamping pressure between cells in the square end plate stacks is uniform similarly to cells of the circular end plate stacks based on FEA.

4. Results and Discussion

4.1. Topology Optimization and Design Parameters

Figure 3 illustrates the results of the conventional end plate stress and deformation analysis. As depicted in

Figure 3a,b, the maximum stress of the circular end plate was 62.248 MPa, the total deformation was 0.015193 mm, and the weight was 50.766 kg (end plate + current collector + bolt head). The maximum deformation occurred at the outer edge of the end plate due to the stress concentration in the bolt. As depicted in

Figure 3c,d, the maximum stress of the square end plate was 239.08 MPa, the total deformation was 0.029516 mm, and the weight was 47.308 kg (end plate + current collector + bolt heads). The maximum deformation occurred at each vertex of the end plate due to the stress concentration in the bolt.

From the topology optimization conducted using the Ansys 18.1 bundle, cut regions were suggested in each end plate: the side region between bolt locations (

Figure 4a top), the groove of the bottom side (

Figure 4a bottom), and the top center region (

Figure 4c). For the topology region, whereas

Figure 4a,c illustrates which exclusion region was applied only to bolts that were similar to the boundary condition,

Figure 4b illustrates which exclusion region was applied to upper and lower sides of the end plate. Both sides remained after the topology optimization; therefore, the side-cut shape differs from that in

Figure 4a.

Based on the topology optimization depicted in

Figure 4, the four parameters were derived as follows: (1) volume removal between the bolts, (2) volume removal at the bottom, (3) round of sector form at the top, and (4) top center cut depth.

The designation of the end plates consists of six letters. The order of the removed parameters is as follows: the first letter from the left is the bolt, the second letter is the bottom side, the third and fourth digits are the round radius, and the fifth and sixth digits are the thickness. The first letter is the symbol “C” in

Figure 4a with a red circle when completely removed, the symbol “I” with a red square at the bottom in

Figure 4b when partially removed, and the symbol “N” when nothing has been removed. The second letter is the symbol “B” with a red square at the bottom left of

Figure 4a, and the symbol “N” is the portion where nothing has been removed. Furthermore, the part where nothing has been removed for the third and fourth digits is indicated by the symbol “00”, the part where a round R5 has been applied is indicated by the symbol “05”, and the part where a round R15 has been applied is indicated by the symbol “15”. The part where nothing has been removed for the fifth and sixth digits was designated “00”, the portion to be removed to a depth of 10 mm was designated “10”, and the portion to be removed to a depth of 20 mm was designated “20”.

Based on the topology optimization of the square end plate depicted in

Figure 4c, three parameters were derived: (1) volume removal between the bolts, (2) fillet formation, and (3) thickness reduction of the top region. Before proceeding with the parametric stress and strain analysis derived from the topology optimization of the square end plate, seven types were designed like the circular end plate, as illustrated in

Figure 5b. The designed square end plate consists of four letters in total, in the order of removed parameters: the first letter from the left is the bolt, the second letter is the fillet, and the third and fourth digits are the thickness. The first letter is depicted in

Figure 4c as a red circle, where the symbol “C” was completely removed, and the part where nothing was removed is indicated by the symbol “N”. The second digit is indicated by the symbol “F” in the part where the symbol fillet is formed and the symbol “N” in the part where nothing is removed. Finally, the third and fourth digits are marked with the symbol “00” where nothing was removed, “10” where the part to be removed is 10 mm deep, and “20” where the part to be removed is 20 mm deep.

4.2. Parametric Study of Various End Plates

As depicted in

Table 3, NB0000 with the ring-type groove at the bottom of the end plate exhibits small deformation; it also exhibits small stress because of the removal of the concentrated stress region (i.e., the groove). For NN0510, the total deformation was increased by 23.5%, and the weight was decreased by 5.6%, which is a relatively greater weight reduction with a smaller total deformation. For CN0000, the total deformation increased by 14.7%, and the weight decreased by 17.4%, compared with the conventional circular end plate. The total deformation increased as the weight decreased; CN0510 modeling was derived by adding CN0000, which had the lowest total deformation of the circular end plate parameters. For CN0510, the results imply a light circular end plate after confirming a 40.5% increase in total deformation and a 22.9% decrease in weight compared with the conventional circular end plate.

As depicted in

Table 4, the stress and strain behaviors were confirmed by modeling the square end plate. The maximum deformation was observed at the outer edge of the end plate due to the stress concentration in the bolt, similar to the conventional square end plate. The stress of the square end plates is much larger than that of the circular end plates by one order of the magnitude. The fillet of the end plates (NF00) does not affect the weight reduction significantly.

In contrast, NF10, NF20, NN10, and NN20 contribute to weight reduction from the center cut of the upper side of the end plates. For NN10, the total deformation decreased by 4.4%, and the weight decreased by 5.8%. For CN00, the total deformation increased by 39.4%, and the weight decreased by 17.5% compared with the conventional square end plate. The total deformation increased as the weight decreased; CN10 modeling was derived by adding CN00, which had the largest weight reduction among square end plate parameters. The results imply a light square end plate after confirming an increase of 38.5% and a decrease of 23.3% in weight, similar to the results in CN10.

For the circular end plate—as depicted in

Figure 6a—when the weight of the circular end plate is reduced, the tendency of the removal portion can be confirmed. The effect of removing the outer edge of the end plate is the largest, and the effect of removing the bottom of the end plate is the smallest. Consequently, when the weight of the circular end plate is reduced, it becomes possible to derive a light end plate design with less deformation by removing it in the order of bottom, round, thickness, and outer edges. The weight reduction and strain data set have a linear relationship because the circular end plate, which is a symmetric rotating body, distributes the stress uniformly to the plate.

In contrast to the circular end plate, in

Figure 6b, the relationship between the strain and the weight reduction of the square end plates illustrates nonlinearity, which indicates the optimized combination of the weight reduction and the shape should be calculated on a case-by-case basis. The effect of removing the outer edge of the square end plate is the largest, and the effect of the removal parameter only applied to the end plate fillet is the smallest, as depicted in

Figure 6b. Consequently, when the square end plate’s weight is reduced, if the fillet, thickness, and outer edge are removed in order, the light end plate design can be derived with less deformation.

Furthermore, upon comparing the circular and square end plates as presented in

Table 3 and

Table 4, the square end plates had greater stress concentration and deformation than the circular end plates. Moreover, as depicted in

Figure 6b, the square end plates can deteriorate cells.

4.3. Dummy Cell Stack Simulation and Experimental Results

Table 5 illustrates the strains of the end and middle cells of the 21-cell stacks to which the conventional circular end plate and CN0510 end plate, which was optimized by the parametric study, were applied. The strain ranges are similar at the end and the middle cells of the stacks, respectively, between the conventional and CN0510 end plates. The wavy shape inside on the end cell occurred because the upper cut of the sector formed, which disappeared on the middle cell with CN0510 end plates. The outside of the cell was bent and appeared severely deformed with more than 0.001 of strain. Experimental results of pressure sensing films for circular end plate dummy cells have similar distribution of pressure. Both end plates pressed inside (pink) of the dummy cells lighter than outside (strong red).

Furthermore, after comparing the cells located in the middle of the stacks to which the conventional circular end plate had been applied and those to which the CN0510 end plate had been applied, the strain was smaller, and the color was more uniform than for the end cells. The clamping pressure was uniformly applied to the end plates; thus, the CN0510 end plate and uniform clamping pressure were equivalent to that of a conventional circular end plate.

The strain of the end and the middle cells of the stacks in which the conventional square end plate and those in which the CN10 end plate, which was selected from the parametric study, were applied, can be confirmed from

Table 6. The strain of the end and the middle cells of the stacks with the conventional square end plates and those with the CN10 end plate are at the same level, while the strains of the square end plates are 10 times larger than those of the circular end plates. The outside of the cell was bent and appeared severely deformed similar to the circular end plates.

Furthermore, for cells located in the middle of the stacks with the conventional square end plate and those with the CN10 end plate, after comparing the end cells with rectangle contour inside, the strain was smaller, and the contour was circular. Evidently, the clamping pressure was applied uniformly, and so the square end plate with less weight and uniform clamping pressure was equivalent to that of the conventional square end plate. The contour distribution and color uniformity were confirmed by the experimental results with pressure sensing films.

Figure 7 is a graph comparing each of the four types of stacks in which conventional circular, CN0510, conventional square, and CN10 end plates had been applied. For the middle cell, the deviation of the strain is much smaller than at the end cells. The minimum strains of the middle cells are nearly zero, which can result in high ohmic resistance.

Figure 8 confirms the strain tendencies for each cell. In

Figure 8, the stack applied with the conventional circular and CN0510 end plates had less strain at both ends of the cell compared with the stack with the conventional and CN10 end plates. The strains of the newly designed end plates (CN0510, CN10) are slightly lower than those of the conventional end plates. The cell strain is higher at both ends of the stack with all kinds of end plates.

5. Conclusions

Stress and deformation analysis and topology optimization were performed in this paper to solve the deterioration of PEMWE performance caused by deformation—a problem for the end plate—and reduce the weight of the two types of conventional circular and square end plates. Thus, light end plates were designed using the derived parameters. The weights of the light circular and square end plates were reduced compared with conventional end plates by 22.9% and 23.3%, respectively. Furthermore, strain analysis was performed to confirm the uniformity of the clamping pressure between cells. The stacks with the light circular and square end plates had confirmed strains similar to the stack applied with the conventional end plates.

Furthermore, even if the square end plates have large stress distributions compared with the circular end plates, the cell clamping pressure was distributed uniformly in each cell because of the nonlinearity of the square end plate pressure distribution. The results verified that structural strength was required and that the square end plates exhibited reduced strain due to the large stress concentration compared with the circular end plates. Thus, FEA was performed to examine the end plate weight reduction and the uniformity of the clamping pressure between the stack cells. The pressure sensing experiments validated simulation results qualitatively. The comparative analysis of the circular and the square end plates with dummy cell simulation can improve the performance of the high-pressure PEMWE by using end plates to provide gas-tight sealing and uniform clamping pressure.