Multi-Scale Probabilistic Analysis for the Mechanical Properties of Plain Weave Carbon/Epoxy Composites Using the Homogenization Technique

Abstract

:1. Introduction

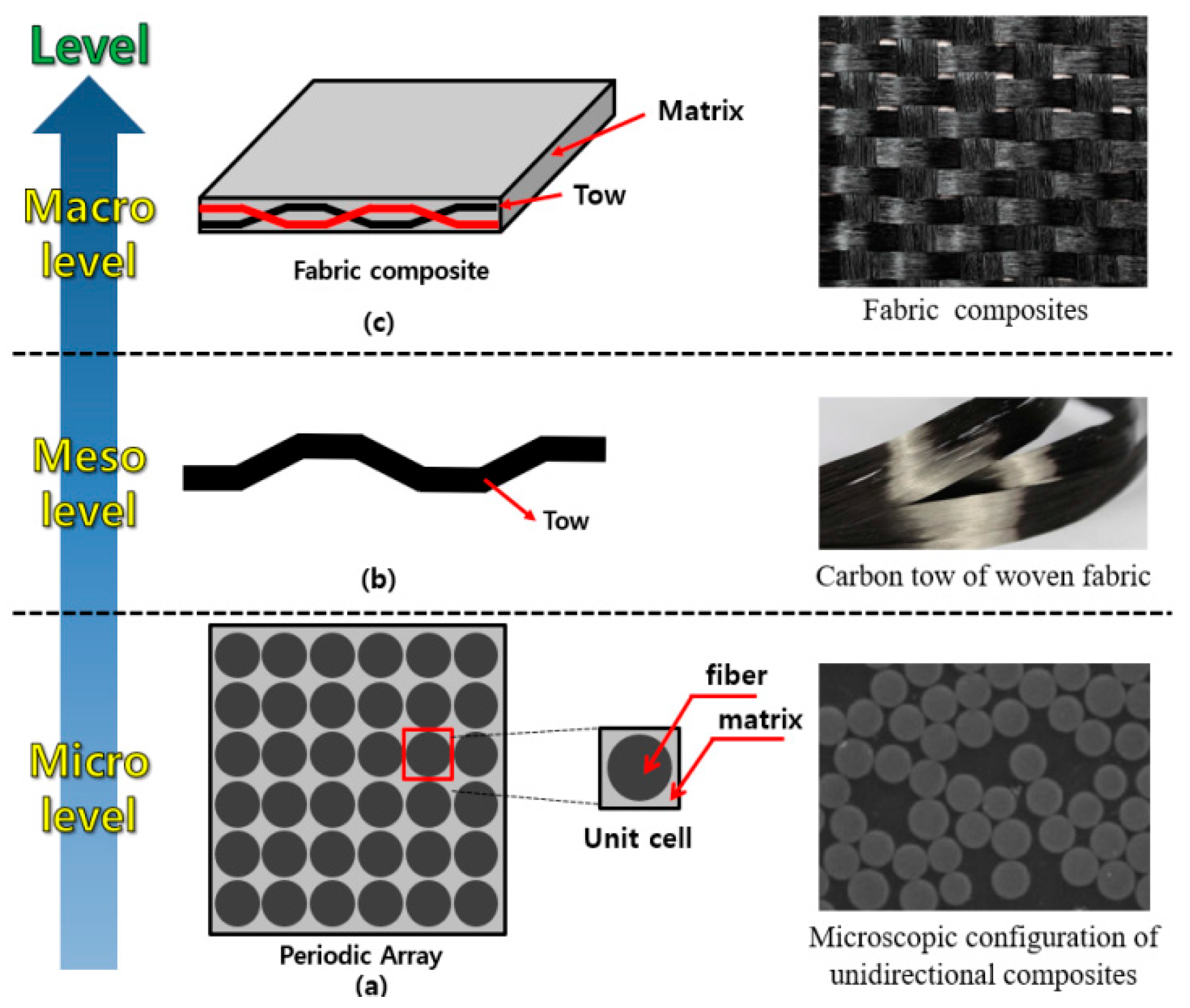

2. Verification of Homogenization Analysis for Unidirectional Composites

2.1. Material and Specimen

2.2. Homogenization Analysis Technique

2.3. Homogenization Analysis and Experimental Results

3. Probabilistic Homogenization Analysis at the Micro-Level for Plain-Weave Composites

3.1. Random Variables for the Probabilistic Homogenization Technique at the Micro-Level

3.2. Effective Properties at the Micro-Level

4. Probabilistic Homogenization Analysis at the Macro-Level for Plain Weave Composites

4.1. Homogenization Analysis Technique at the Macro-Level

4.2. Effective Properties at the Macro-Level

4.3. Sensitivity Analysis

5. Conclusions

- To verify the effective properties of the homogenization technique applied in this study, the analysis results of the effective properties at the micro-level with the combination of the carbon fiber and epoxy were compared with the ROM theory. In addition, the UD composites with the same geometry of the micro-level was fabricated and compared with the tensile test results to experimentally verify the homogenization technique.

- The MCS based on the homogenization analysis technique was performed at the micro-level to evaluate the uncertainties in the mechanical properties of the composites. The results showed that the effective properties of the micro-level followed the normal distribution same as those of the carbon fiber and epoxy.

- The MCS was performed based on the homogenization technique for the fabric composite (macro-level) combined with the tow and matrix was performed based on the effective properties of the micro-level. The effective properties of the macro-level had the same distribution characteristics as those of the tow and matrix.

- The sensitivity analysis between the properties of constituents (carbon fiber and epoxy) and the effective properties of the macro-level exhibits that the fabric composite is ultimately dependent on the mechanical properties of the carbon fiber and epoxy.

Author Contributions

Funding

Conflicts of Interest

References

- Lee, D.W.; Song, J.I. Research on simple joint method using fiber-metal laminate design for improved mechanical properties of CFRP assembly structure. Compos. Part B Eng. 2019, 164, 358–367. [Google Scholar] [CrossRef]

- Muflikhun, M.A.; Yokozeki, T.; Aoki, T. The strain performance of thin CFRP-SPCC hybrid laminates for automobile structures. Compos. Struct. 2019, 220, 11–18. [Google Scholar] [CrossRef]

- Tang, E.; Li, W.; Han, Y. Research on the interacting duration and microscopic characteristics created by high-velocity impact on CFRP/Al HC SP structure. J. Mater. Res. Technol. 2019, 9, 1640–1651. [Google Scholar] [CrossRef]

- Golewski, P.; Sadowski, T. Description of thermal protection against heat transfer of carbon fiber reinforced plastics (CFRP) coated by stiffened ceramic mat (TBC). Compos. Struct. 2019, 229, 111489. [Google Scholar] [CrossRef]

- Behera, A.; Dupare, P.; Thawre, M.M.; Ballal, A. Effects of hygrothermal aging and fiber orientations on constant amplitude fatigue properties of CFRP Multidirectional composite laminates. Int. J. Fatigue 2020, 136, 105590. [Google Scholar] [CrossRef]

- Tian, W.; Qi, L.; Liang, J.; Chao, X.; Zhou, J. Evaluation for elastic properties of metal matrix composites with randomly distributed fibers: Two-step mean-field homogenization procedure versus FE homogenization method. J. Alloys Compd. 2016, 658, 241–247. [Google Scholar] [CrossRef]

- Adumitroaie, A.; Barbero, E.J. Beyond plain weave fabrics–I. Geometrical model. Compos. Struct. 2011, 93, 1424–1432. [Google Scholar] [CrossRef]

- Gilioli, A.; Manes, A.; Giglio, M. Evaluation of the effects of the numerical modelling choices on the simulation of a tensile test on CFRP composite. Procedia Struct. Integr. 2018, 8, 33–42. [Google Scholar] [CrossRef]

- Hale, P.; Ng, E.G. Non-linear material characterization of CFRP with FEM utilizing cohesive surface considerations validated with effective tensile test fixturing. Mater. Today Commun. 2020, 23, 100872. [Google Scholar] [CrossRef]

- Li, H.X. Limit analysis of composite materials with anisotropic microstructures: A homogenization approach. Mech. Mater. 2011, 43, 574–585. [Google Scholar] [CrossRef]

- Muflikhun, M.A.; Chua, A.Y. Load-displacement experimental data from axial tensile loading of CFRP-SPCC hybrid laminates. Data Brief 2020, 29, 105306. [Google Scholar] [CrossRef] [PubMed]

- Babu, K.P.; Mohite, P.M.; Upadhyay, C.S. Development of an RVE and its stiffness predictions based on mathematical homogenization theory for short fibre composites. Int. J. Solids Struct. 2018, 130, 80–104. [Google Scholar] [CrossRef]

- Qi, Z.; Liu, Y.; Chen, W. An approach to predict the mechanical properties of CFRP based on cross-scale simulation. Compos. Struct. 2019, 210, 339–347. [Google Scholar] [CrossRef]

- Gao, J.; Shakoor, M.; Domel, G.; Merzkirch, M.; Zhou, G.; Zeng, D.; Su, X.; Liu, W.K. Predictive multiscale modeling for Unidirectional Carbon Fiber Reinforced Polymers. Compos. Sci. Technol. 2020, 186, 107922. [Google Scholar] [CrossRef]

- Mustafa, G.; Suleman, A.; Crawford, C. Probabilistic micromechanical analysis of composite material stiffness properties for a wind turbine blade. Compos. Struct. 2015, 131, 905–916. [Google Scholar] [CrossRef]

- Lee, S.P.; Jin, J.W.; Kang, K.W. Probabilistic analysis for mechanical properties of glass/epoxy composites using homogenization method and Monte Carlo simulation. Renew. Energy 2014, 65, 219–226. [Google Scholar] [CrossRef]

- Kamiński, M.; Kazimierczak, M. 2D versus 3D probabilistic homogenization of the metallic fiber-reinforced composites by the perturbation-based stochastic Finite Element Method. Compos. Struct. 2014, 108, 1009–1018. [Google Scholar] [CrossRef]

- Goda, I.; Assidi, M.; Ganghoffer, J.F. Equivalent mechanical properties of textile monolayers from discrete asymptotic homogenization. J. Mech. Phys. Solids 2013, 61, 2537–2565. [Google Scholar] [CrossRef]

- Chen, Z.; Yang, F.; Meguid, S.A. Multi-level modeling of woven glass/epoxy composite for multilayer printed circuit board applications. Int. J. Solids Struct. 2014, 51, 3679–3688. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.Y.; Gosling, P.D.; Pearce, C.J.; Ullah, Z.; Kaczmarczyk, L. Perturbation-based stochastic multi-scale computational homogenization method for woven textile composites. Int. J. Solids Struct. 2016, 80, 368–380. [Google Scholar] [CrossRef] [Green Version]

- Hayat, K.; Lei, X.; Ali, H.T. Prediction of elastic behavior of woven fabric reinforced plastics composites using two-step homogenization. In Proceedings of the 2018 15th International Bhurban Conference on Applied Sciences and Technology (IBCAST), Islamabad, Pakistan, 9–13 January 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 36–42. [Google Scholar]

- COMPOSITES PLAZA. Available online: https://compositesplaza.com/ (accessed on 6 July 2020).

- FIBRE GLAST. Available online: https://www.fibreglast.com/ (accessed on 6 July 2020).

- Ostapiuk, M.; Surowska, B.; Bienias, J. Interface analysis of fiber metal laminates. Compos. Interfaces 2014, 21, 309–318. [Google Scholar] [CrossRef]

- Choi, H.; Huang, H.; Kim, D.U.; Joe, C.R. Fracture behavior of carbon/epoxy laminated composite reinforced by iron powder. Korean J. Chem. Eng. 2008, 25, 1208–1211. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M-17. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Hu, A.; Li, X.; Ajdari, A.; Jiang, B.; Burkhart, C.; Chen, W.; Catherine Brinson, L. Computational analysis of particle reinforced viscoelastic polymer nanocomposites–statistical study of representative volume element. J. Mech. Phys. Solids 2018, 114, 55–74. [Google Scholar] [CrossRef]

- Bayat, M.; Aghdam, M.M. A micromechanics-based analysis of effects of square and hexagonal fiber arrays in fibrous composites using DQEM. Eur. J. Mech. A Solids 2012, 32, 32–40. [Google Scholar] [CrossRef]

- Macedo, R.Q.; Ferreira, R.T.L.; Guedes, J.M.; Donadon, M.V. Intraply failure criterion for unidirectional fiber reinforced composites by means of asymptotic homogenization. Compos. Struct. 2017, 159, 335–349. [Google Scholar] [CrossRef]

- Abaqus Documentation. Available online: https://abaqus-docs.mit.edu/2017/English/SIMACAEEXCRefMap/simaexc-c-docproc.htm (accessed on 17 September 2020).

- Tan, H.; Huang, Y.; Liu, C.; Geubelle, P.H. The Mori–Tanaka method for composite materials with nonlinear interface debonding. Int. J. Plast. 2005, 21, 1890–1918. [Google Scholar] [CrossRef]

- Klusemann, B.; Svendsen, B. Homogenization methods for multi-phase elastic composites. Tech. Mech. Sci. J. Fundam. Appl. Eng. Mech. 2010, 30, 374–386. [Google Scholar]

- Hyer, M.W.; Waas, A.M. Micromechanics of Linear Elastic Continuous Fiber Composites; Elsevier: Amsterdam, The Netherlands, 2000. [Google Scholar]

- Halpin, J.C. Effects of Environmental Factors on Composite Materials; Air Force Materials Lab Wright-Patterson AFB OH: Greene, OH, USA, 1969. [Google Scholar]

- Kang, K.W.; Lim, D.M.; Kim, J.K. Probabilistic analysis for the fatigue life of carbon/epoxy laminates. Compos. Struct. 2008, 85, 258–264. [Google Scholar] [CrossRef]

- Isight. Available online: https://www.3ds.com/fileadmin/PRODUCTS-SERVICES/SIMULIA/RESOURCES/DS_SIMULIA_IsightV40_GettingStartedGuide.pdf (accessed on 17 September 2020).

- Carvelli, V.; Poggi, C. A homogenization procedure for the numerical analysis of woven fabric composites. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1425–1432. [Google Scholar] [CrossRef]

- Jiang, Y.; Tabiei, A.; Simitses, G.J. A novel micromechanics-based approach to the derivation of constitutive equations for local/global analysis of a plain-weave fabric composite. Compos. Sci. Technol. 2000, 60, 1825–1833. [Google Scholar] [CrossRef]

- Obert, E.; Daghia, F.; Ladeveze, P.; Ballere, L. Micro and meso modeling of woven composites: Transverse cracking kinetics and homogenization. Compos. Struct. 2014, 117, 212–221. [Google Scholar] [CrossRef]

| Fiber (Carbon) | Matrix (Epoxy) | |

|---|---|---|

| Young’s modulus (GPa) | 240.00 | 2.45 |

| Shear modulus (GPa) | 93.39 | 0.91 |

| Poisson’s ratio | 0.285 | 0.350 |

| VF 10% | VF 20% | VF 30% | VF 40% | VF 50% | VF 60% | VF 70% | |

|---|---|---|---|---|---|---|---|

| E11,tow (GPa) | 27.20 | 49.80 | 72.40 | 97.20 | 120.90 | 144.75 | 168.47 |

| E22,tow (GPa) | 5.84 | 6.74 | 7.80 | 6.62 | 9.06 | 13.19 | 22.42 |

| E33,tow (GPa) | 5.84 | 6.74 | 7.80 | 6.62 | 9.06 | 13.19 | 22.42 |

| G12,tow (GPa) | 1.95 | 2.24 | 2.57 | 2.09 | 2.71 | 3.75 | 6.14 |

| G13,tow (GPa) | 1.95 | 2.24 | 2.57 | 2.09 | 2.71 | 3.75 | 6.14 |

| G23,tow (GPa) | 1.90 | 2.12 | 2.35 | 1.63 | 1.96 | 2.51 | 3.79 |

| ν12,tow | 0.342 | 0.324 | 0.307 | 0.320 | 0.313 | 0.306 | 0.298 |

| ν13,tow | 0.342 | 0.324 | 0.307 | 0.320 | 0.313 | 0.306 | 0.298 |

| ν23,tow | 0.504 | 0.496 | 0.472 | 0.392 | 0.326 | 0.252 | 0.170 |

| VF (%) | SROM (GPa) | Result of Homogenization Analysis (GPa) | Error (%) |

|---|---|---|---|

| 10 | 26.21 | 27.20 | 3.78 |

| 20 | 49.96 | 49.80 | 0.32 |

| 30 | 73.71 | 72.40 | 1.78 |

| 40 | 97.47 | 97.20 | 0.28 |

| 50 | 121.23 | 120.90 | 0.27 |

| 60 | 144.98 | 144.75 | 0.16 |

| 70 | 168.74 | 168.47 | 0.16 |

| Result of Homogenization Analysis | Result of Tensile Test | Error (%) | |

|---|---|---|---|

| E11,tow (GPa) | 144.75 | 146.40 | 1.13 |

| v12,tow | 0.30 | 0.32 | 6.25 |

| Design Variable | Type | Mode | Distribution | Mean | COV |

|---|---|---|---|---|---|

| Ef | real | continuous | normal | 240 GPa | 0.05 |

| Em | real | continuous | normal | 2.45 GPa | 0.05 |

| Gf | real | continuous | normal | 93.40 GPa | 0.05 |

| Gm | real | continuous | normal | 0.91 GPa | 0.05 |

| vf | real | continuous | normal | 0.285 | 0.05 |

| vm | real | continuous | normal | 0.350 | 0.05 |

| No. | Ef | Em | Gf | Gm | vf | vm |

|---|---|---|---|---|---|---|

| 1 | 216.79 | 2.56 | 98.53 | 0.95 | 0.292 | 0.366 |

| 2 | 247.96 | 2.51 | 105.71 | 866.32 | 0.287 | 0.334 |

| ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ |

| 999 | 249.48 | 2.56 | 91.49 | 0.92 | 0.284 | 0.359 |

| 1000 | 244.37 | 2.44 | 93.29 | 0.83 | 0.310 | 0.353 |

| Size (mm) | |

|---|---|

| H (Overall height) | 0.225 |

| W (Overall width) | 0.9 |

| L (Overall length) | 0.9 |

| TL (Tow length) | 0.99 |

| TW (Tow width) | 0.376 |

| TT (Tow thickness) | 0.093 (VF 60%) |

| No. | E11,tow | E22,tow | E33,tow | G12,tow | G13,tow | G23,tow | v12,tow | v13,tow | v23,tow | Em | Gm | vm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 130.90 | 14.30 | 14.30 | 3.94 | 3.94 | 2.64 | 0.317 | 0.317 | 0.275 | 2.56 | 0.95 | 0.366 |

| 2 | 149.55 | 12.91 | 12.91 | 3.61 | 3.61 | 2.41 | 0.301 | 0.301 | 0.234 | 2.51 | 866.32 | 0.334 |

| ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ |

| 999 | 150.47 | 14.13 | 14.13 | 3.80 | 3.80 | 2.56 | 0.310 | 0.310 | 0.260 | 2.56 | 0.92 | 0.359 |

| 1000 | 147.37 | 13.24 | 13.24 | 3.44 | 3.44 | 2.32 | 0.324 | 0.324 | 0.258 | 2.44 | 0.83 | 0.353 |

| VF 40% | VF 50% | VF 60% | VF 70% | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Average | Std. Dev | COV | Average | Std. Dev | COV | Average | Std. Dev | COV | Average | Std. Dev | COV | |

| E11,eq,macro | 21.23 | 0.698 | 0.033 | 24.88 | 0.828 | 0.033 | 26.70 | 0.877 | 0.033 | 29.67 | 0.969 | 0.033 |

| E33,eq,macro | 5.183 | 0.368 | 0.071 | 6.00 | 0.432 | 0.072 | 7.04 | 0.501 | 0.071 | 8.64 | 0.601 | 0.070 |

| G12,eq,macro | 1.90 | 0.091 | 0.048 | 2.14 | 0.101 | 0.047 | 2.35 | 0.111 | 0.047 | 2.56 | 0.121 | 0.047 |

| G23,eq,macro | 1.29 | 0.062 | 0.048 | 1.48 | 0.071 | 0.048 | 1.72 | 0.081 | 0.047 | 2.09 | 0.097 | 0.046 |

| v12,eq,macro | 0.096 | 0.006 | 0.063 | 0.087 | 0.006 | 0.069 | 0.082 | 0.006 | 0.073 | 0.075 | 0.006 | 0.080 |

| v23,eq,macro | 0.407 | 0.027 | 0.066 | 0.386 | 0.025 | 0.065 | 0.364 | 0.023 | 0.063 | 0.342 | 0.021 | 0.061 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, J.-W.; Jeon, B.-W.; Choi, C.-W.; Kang, K.-W. Multi-Scale Probabilistic Analysis for the Mechanical Properties of Plain Weave Carbon/Epoxy Composites Using the Homogenization Technique. Appl. Sci. 2020, 10, 6542. https://doi.org/10.3390/app10186542

Jin J-W, Jeon B-W, Choi C-W, Kang K-W. Multi-Scale Probabilistic Analysis for the Mechanical Properties of Plain Weave Carbon/Epoxy Composites Using the Homogenization Technique. Applied Sciences. 2020; 10(18):6542. https://doi.org/10.3390/app10186542

Chicago/Turabian StyleJin, Ji-Won, Byung-Wook Jeon, Chan-Woong Choi, and Ki-Weon Kang. 2020. "Multi-Scale Probabilistic Analysis for the Mechanical Properties of Plain Weave Carbon/Epoxy Composites Using the Homogenization Technique" Applied Sciences 10, no. 18: 6542. https://doi.org/10.3390/app10186542

APA StyleJin, J.-W., Jeon, B.-W., Choi, C.-W., & Kang, K.-W. (2020). Multi-Scale Probabilistic Analysis for the Mechanical Properties of Plain Weave Carbon/Epoxy Composites Using the Homogenization Technique. Applied Sciences, 10(18), 6542. https://doi.org/10.3390/app10186542