An Experimental Approach on Beating in Vibration Due to Rotational Unbalance

Abstract

:1. Introduction

2. A Theoretical Approach

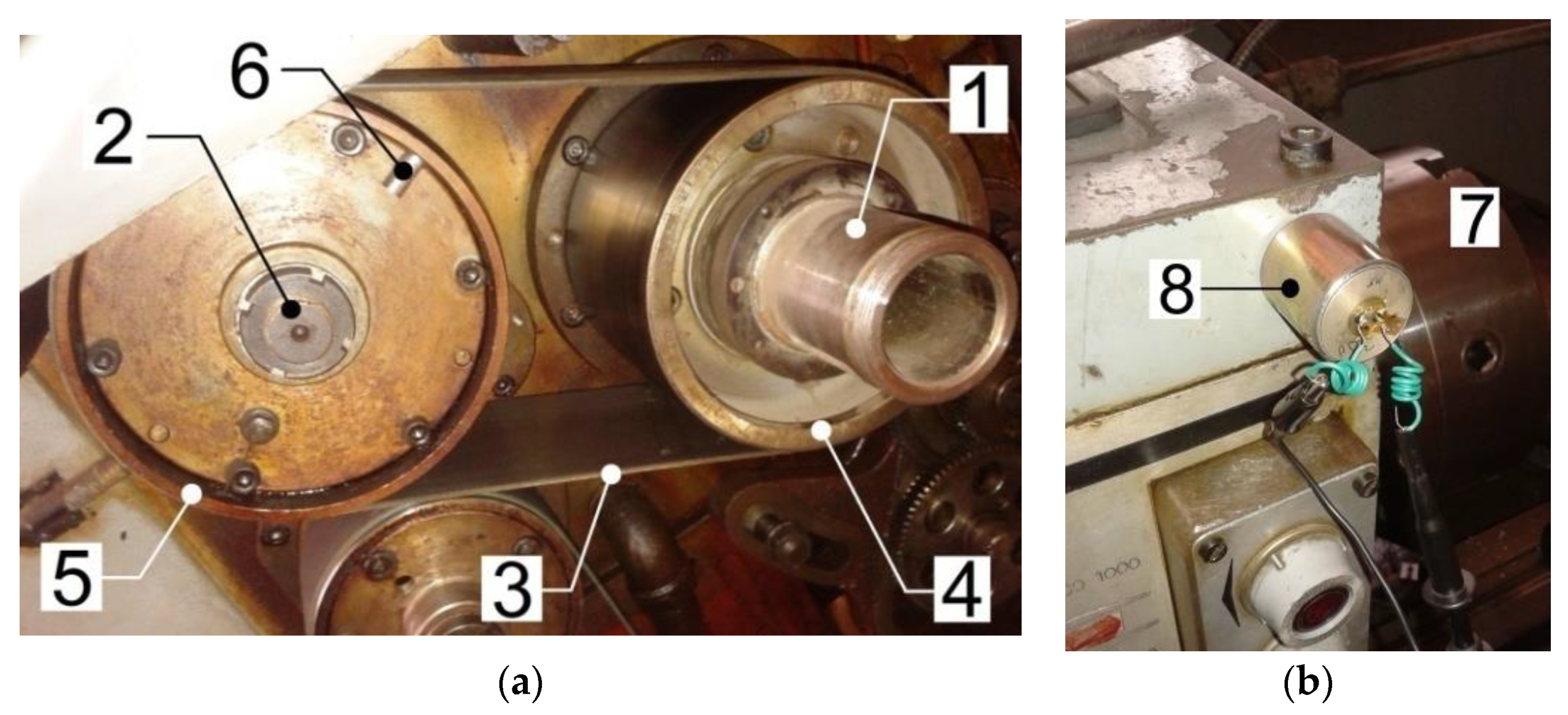

3. Experimental Setup

4. Experimental Results and Discussion

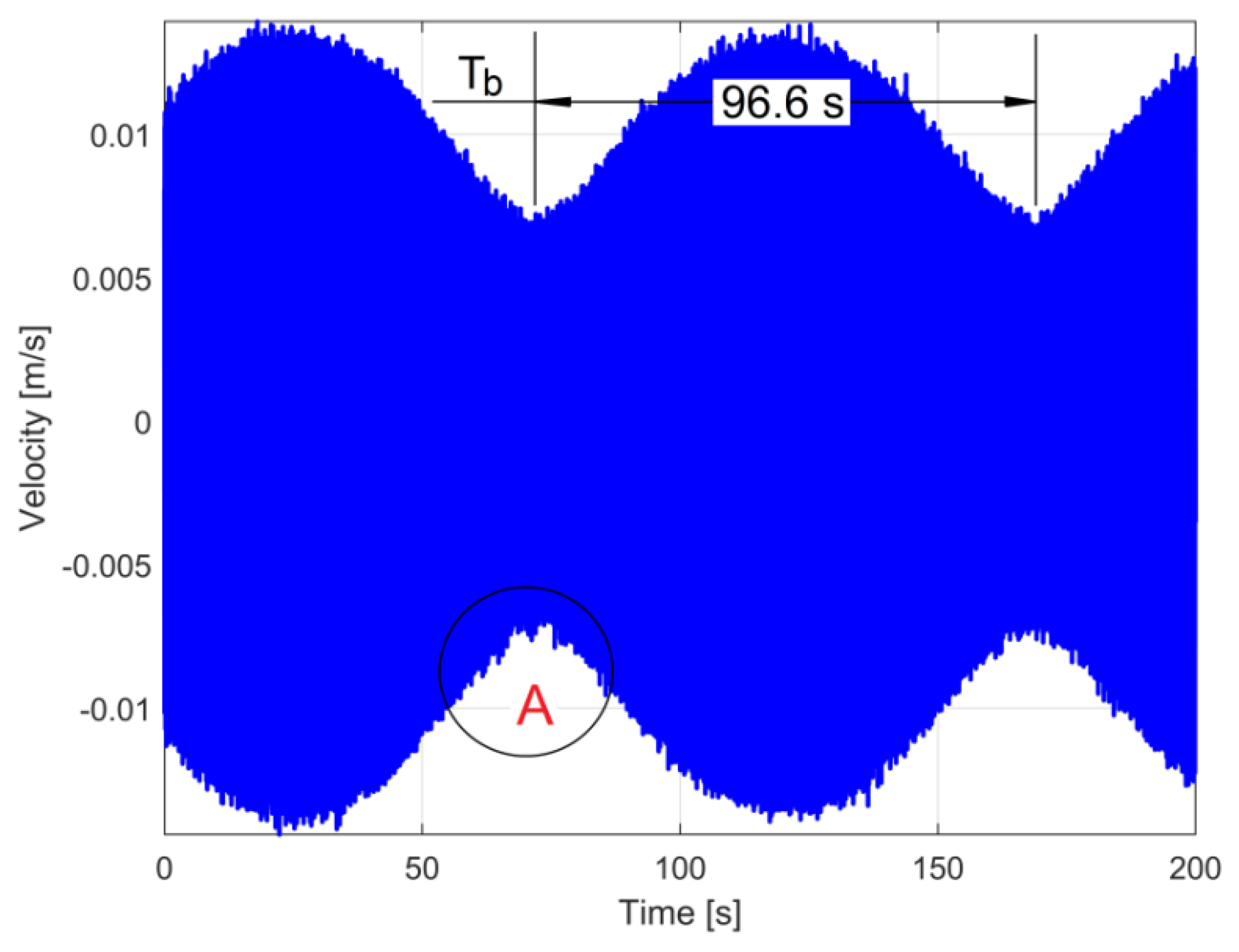

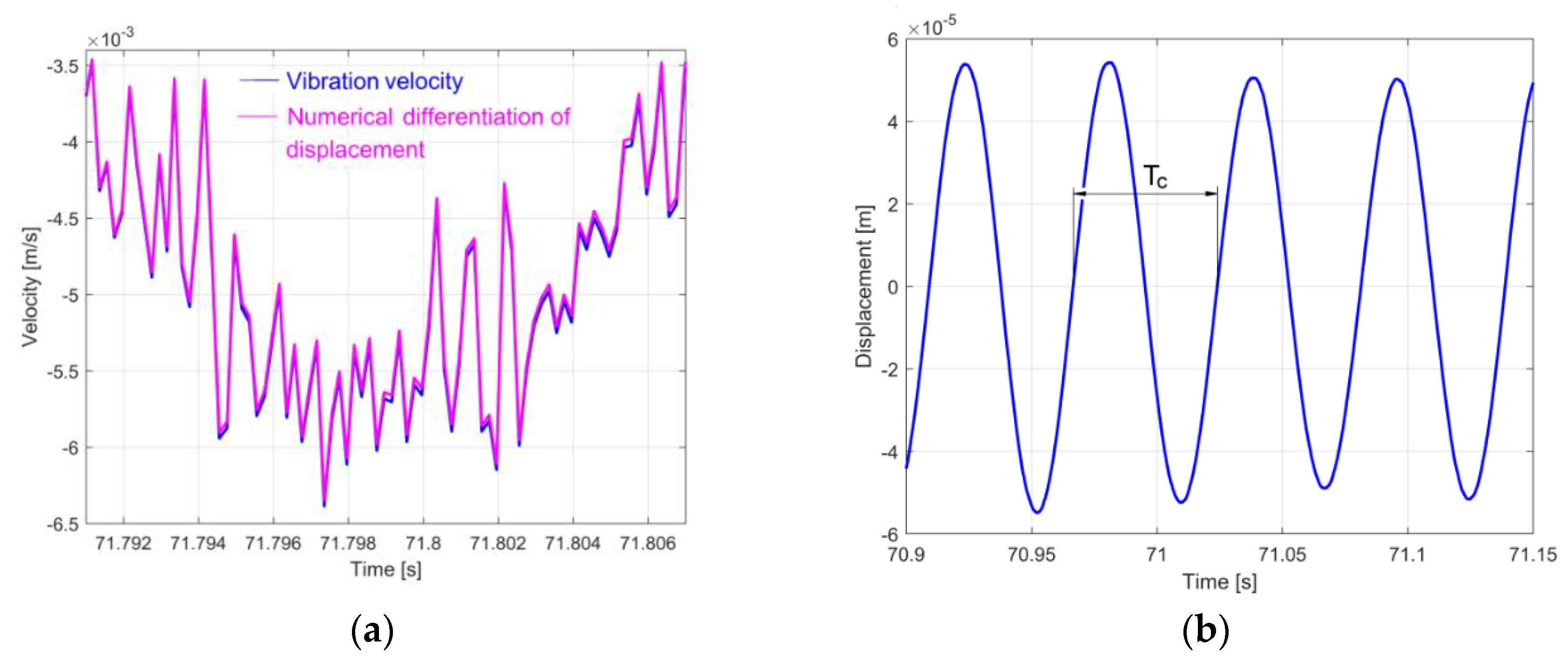

4.1. A Beating Phenomenon Described in Vibration Velocity

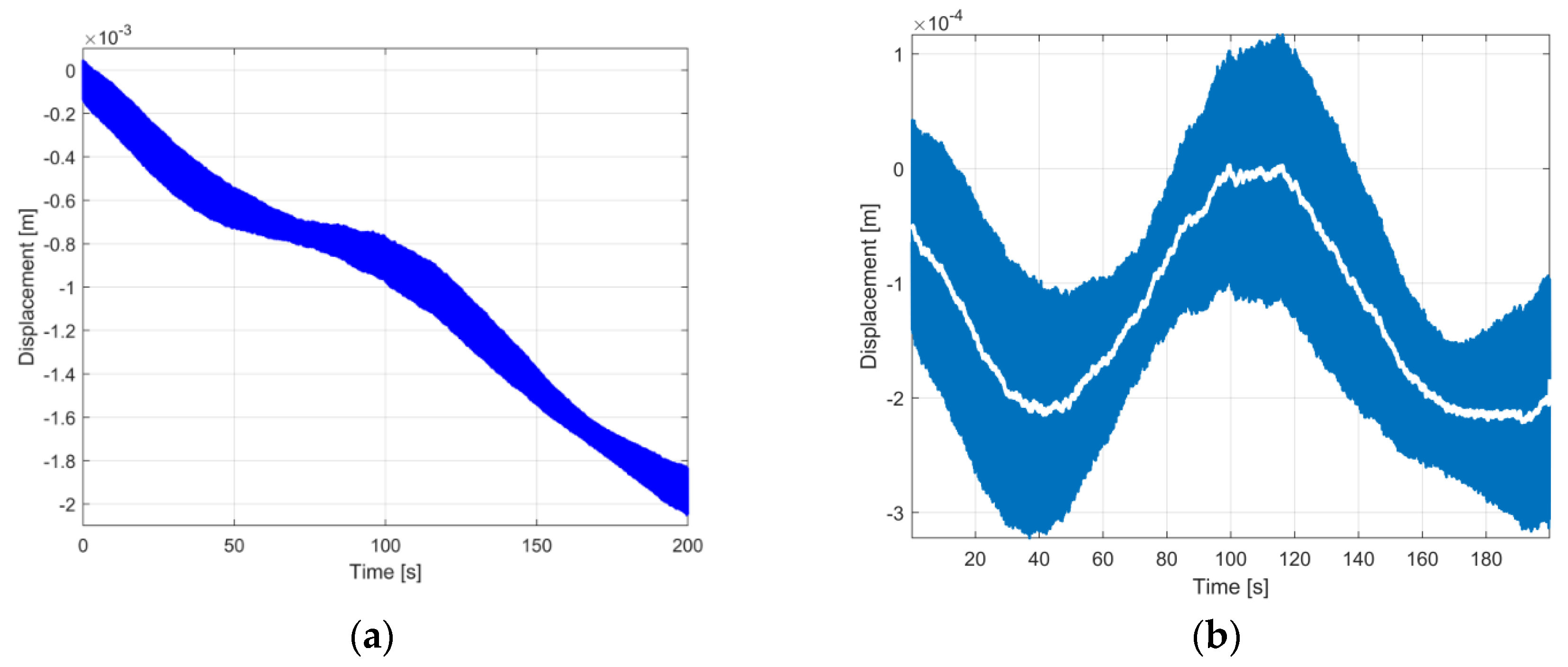

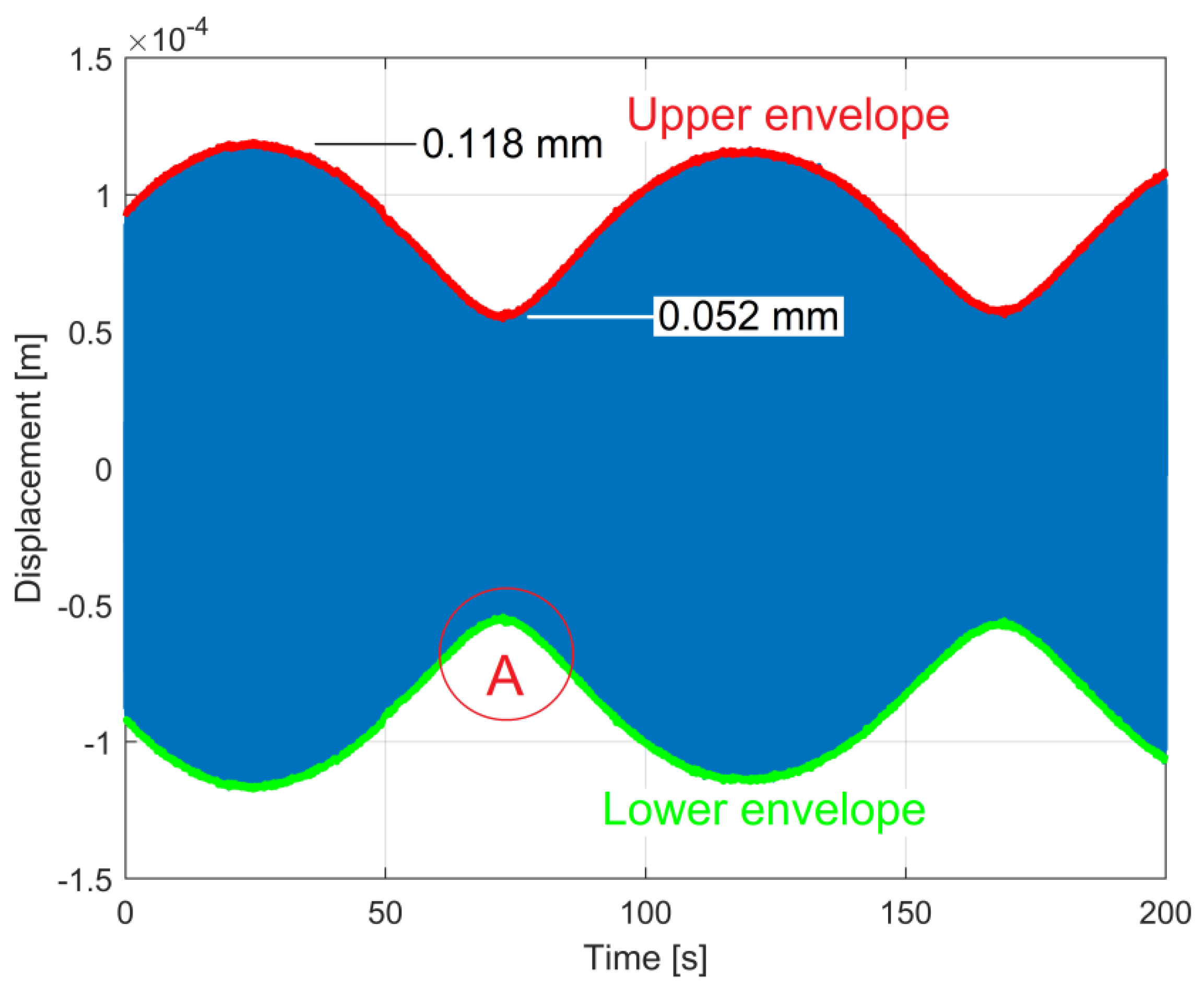

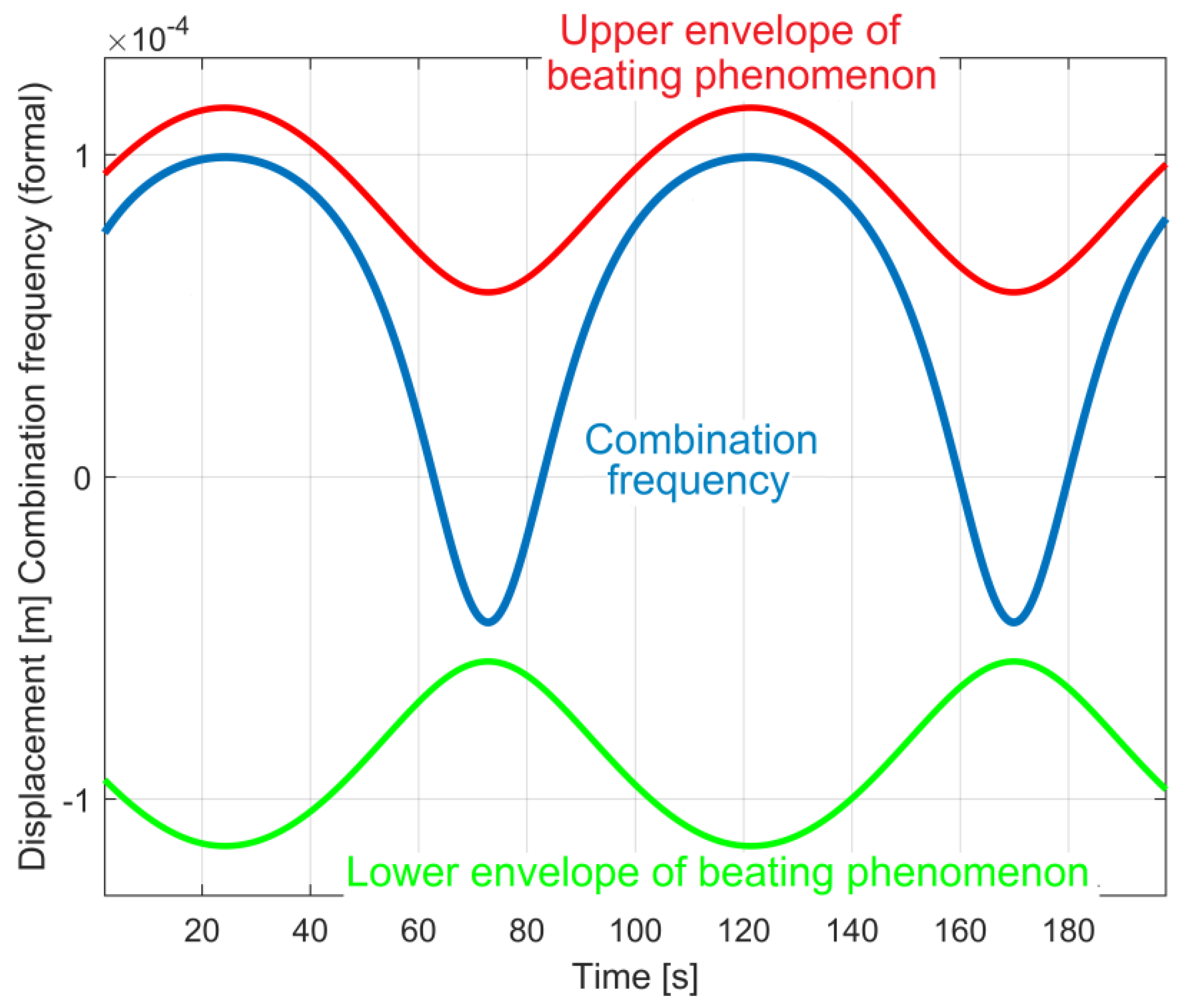

4.2. The Description of the Beating Phenomenon in Vibration Displacement by Numerical Integration

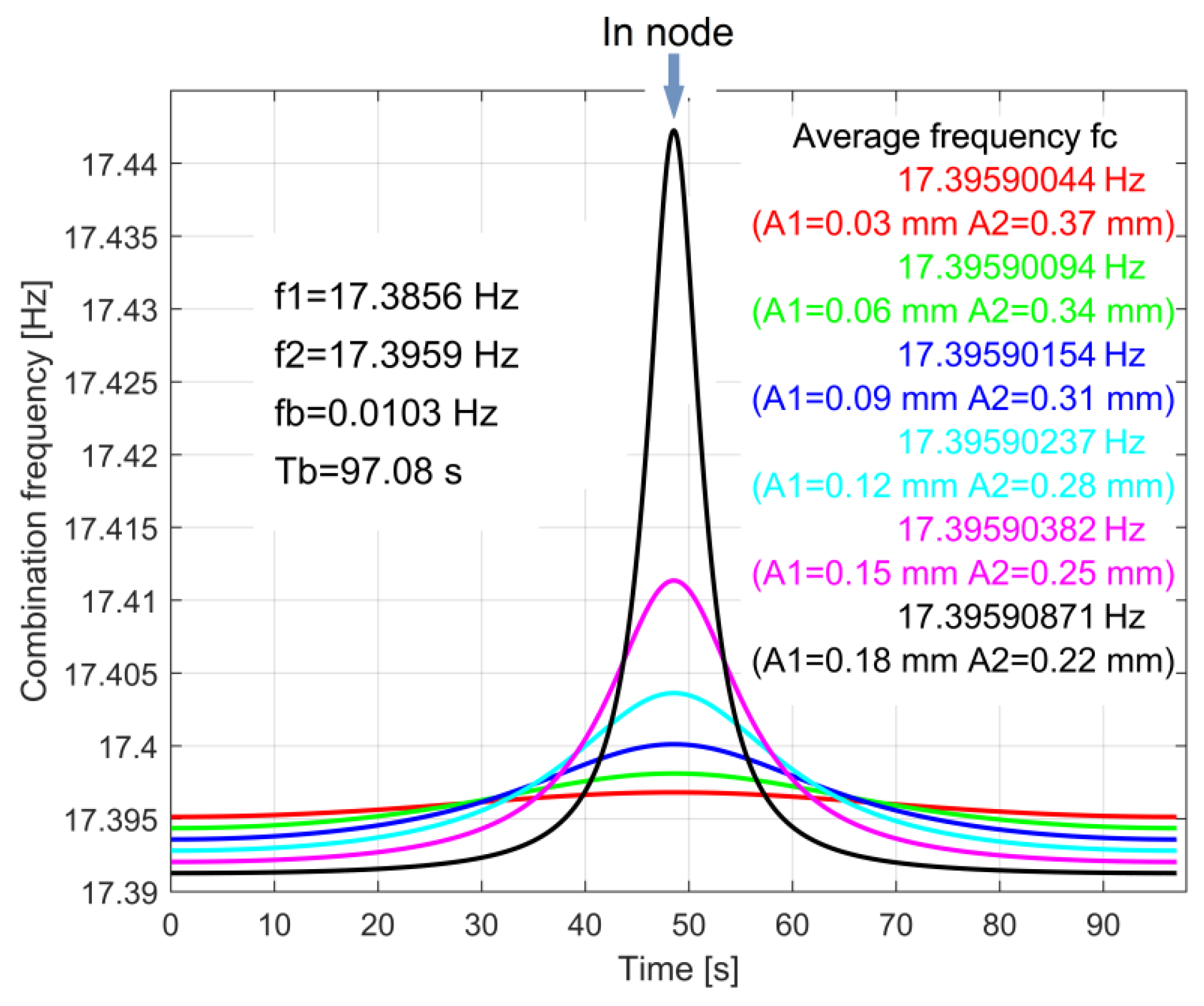

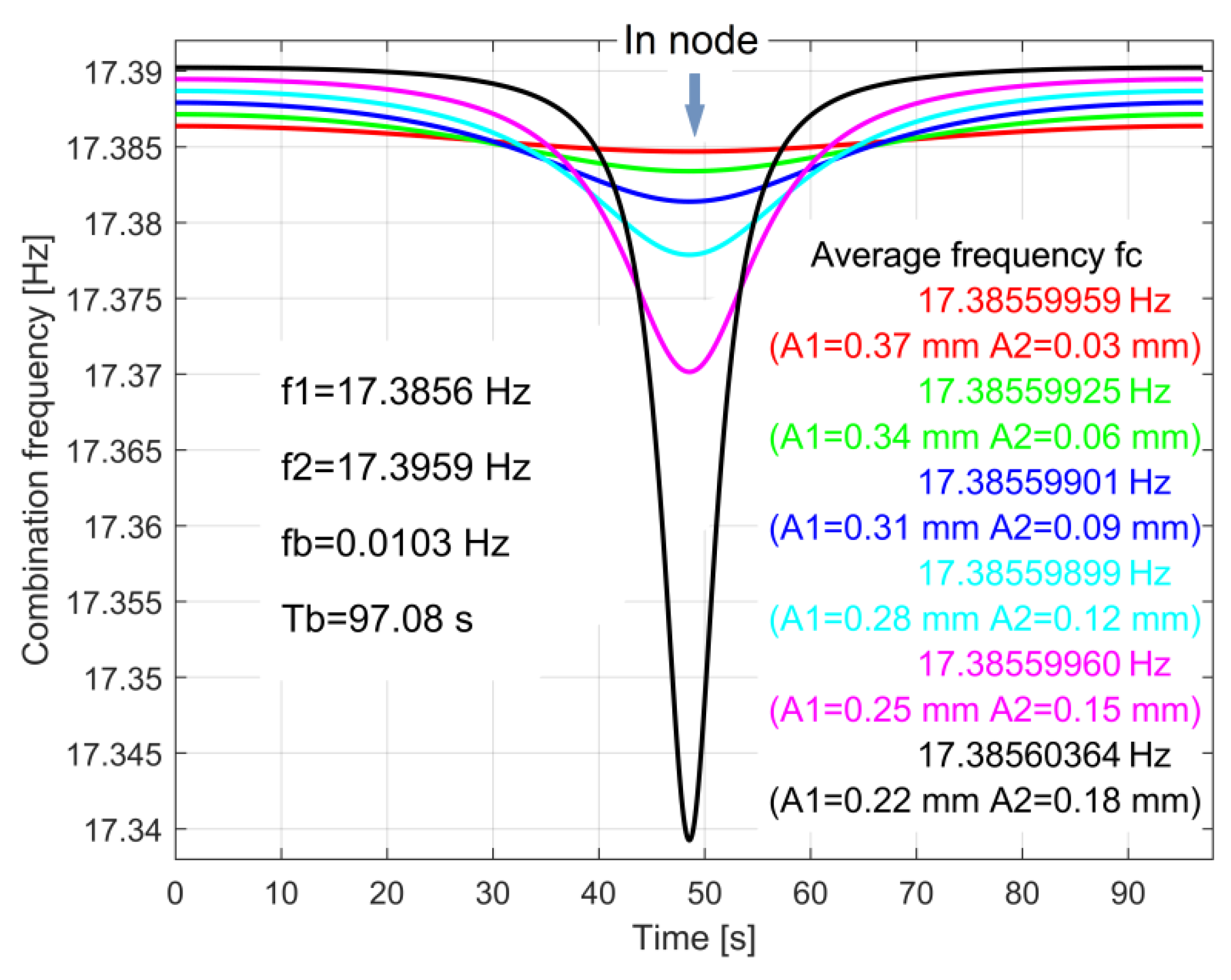

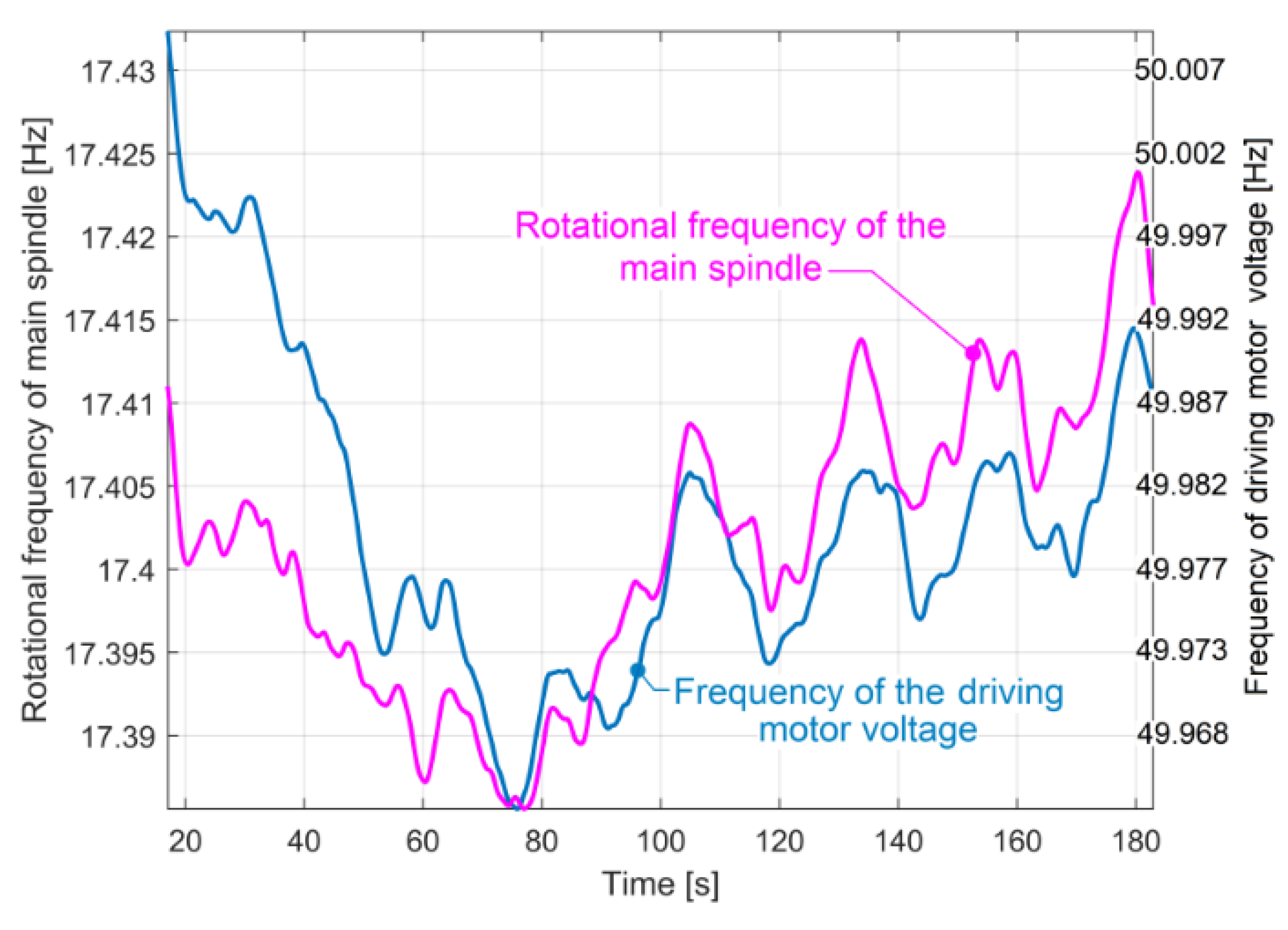

4.3. The Evolution of Frequency for Resultant Vibration in Beating Phenomenon

- -

- The combination frequency fc is not constant over a period Tb (even if its variation is not significant);

- -

- The average value of the combination frequency fc over a period Tb is practically the same as the frequency of the input vibration in the beating phenomenon (y1s(A1,f1) or y2s(A2,f2)), whose amplitudes are higher (e.g., if A2 > A1 then the average fc ≈ f2).

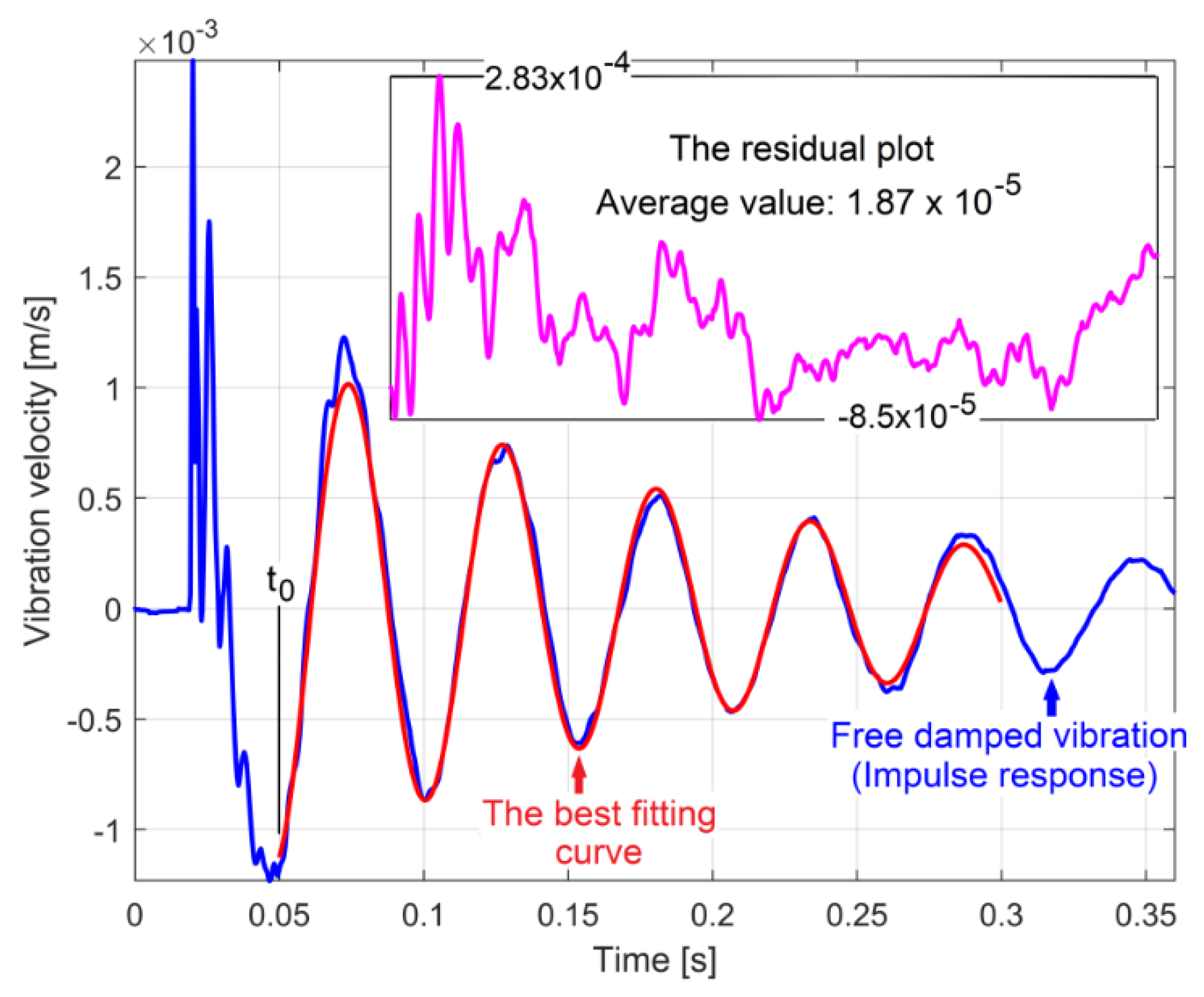

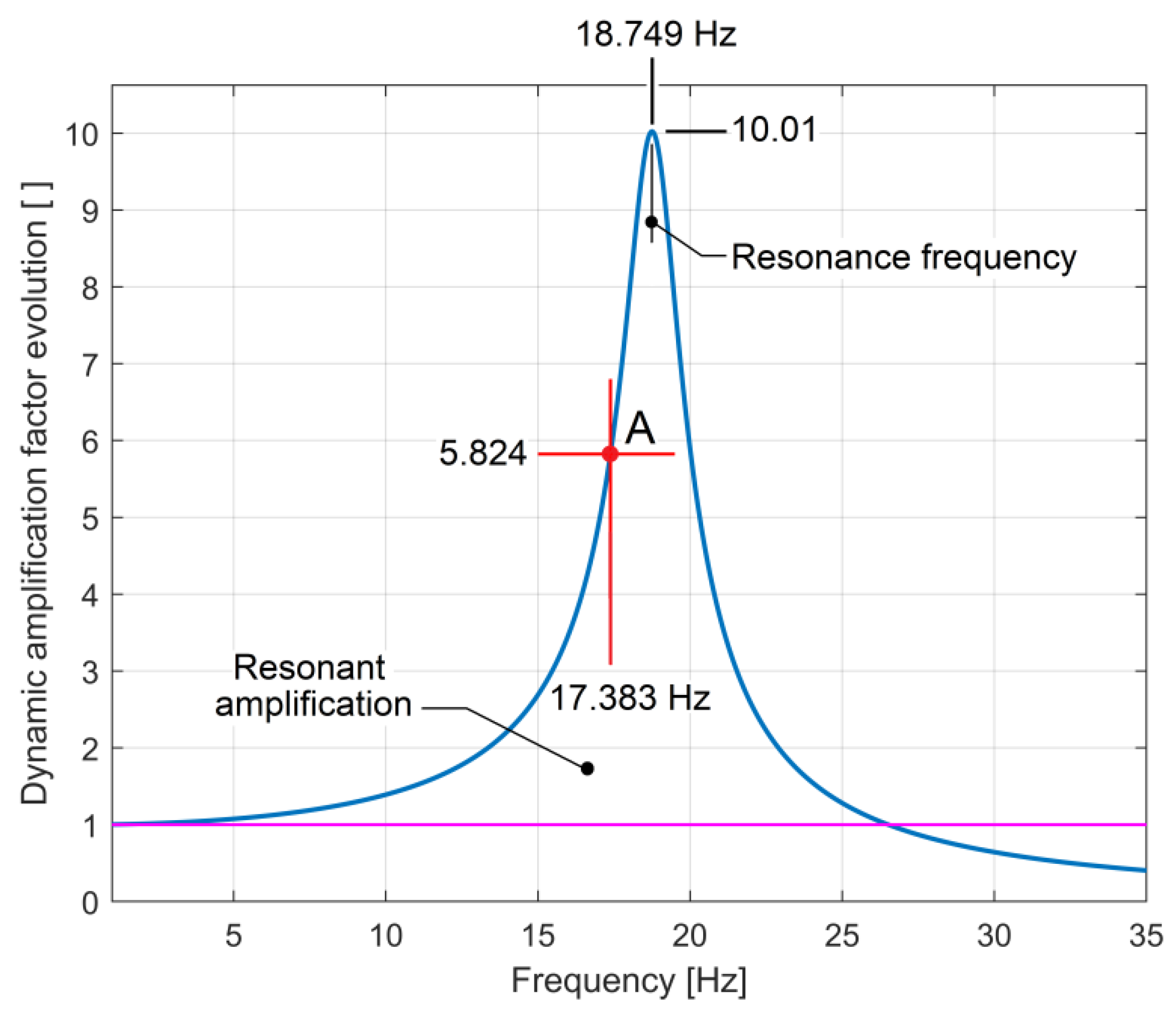

4.4. The Influence of the Lathe Suspension Dynamics on Beating Vibrations Amplitude

5. Conclusions and Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| A1 , A2 | The amplitudes of vibrations y1, y2 [m] |

| ae-bt | The envelope of free viscous damped vibration velocity response [m/s] |

| b | The damping constant [s−1] |

| C | The constant of velocity signal integration [m] |

| Daf | Theoretical dynamic amplification factors of vibrations [ ] |

| Daf1,Daf2 | Dynamic amplification factors of vibrations y1, y2 produced by shafts 1, 2 [ ] |

| Dafc | Dynamic amplification factor of resultant vibration y1 + y2 at average frequency fc [ ] |

| dy1 /dt, dy2 /dt | The derivative of vibration displacements y1, y2 (vibration velocities) [m/s] |

| f | The frequency of harmonic excitation of the lathe headstock [Hz] |

| F1 , F2 | The horizontal projection of the rotary unbalance forces generated by shafts 1 and 2 [N] |

| f1 , f2 | The frequency of vibrations y1, y2 [Hz] |

| fb | The beat frequency [Hz] |

| fc | The frequency of the resultant vibration y1 + y2, or combination frequency [Hz] |

| IAS | Instantaneous angular speed [rad/s] |

| k | The stiffness of headstock and lathe foundation [N/m] |

| m1 , m2 | Unbalance mass on rotary shafts 1, 2 [Kg] |

| n | A natural number involved in the definition of the beat period Tb |

| p | The natural angular frequency [rad/s] |

| p1 | The angular frequency of damped harmonic vibration [rad/s] |

| r1 , r2 | The distance between the center of the unbalance mass and the rotation axis on shafts 1, 2 [m] |

| s | The addition of vibration displacements s = y1 + y2 [m] |

| si, si+1 | Two successive displacement samples of vibration [m] |

| si+h, si+h-1 | Two successive displacement samples of vibration [m] |

| t | Time [s] |

| t0 | The origin of time for the theoretical model of free damped vibration velocity [s] |

| tzcj, tzcj+1 | Two successive zero-crossing moments of the displacement vibration signal involved in frequency measurement [s] |

| Δt | Sampling interval for a numerically described signal [s] |

| T1 , T2 | The periods of vibrations y1, y2 [s] |

| Tb | The beat period, with Tb = 1/fb [s] |

| Tc | The period of the resultant vibration y1 + y2, with Tc = 1/ fc [s] |

| v | The velocity of the resultant vibration in beating [m/s] |

| vfd | The vibration velocity of the headstock during a free damped response [m/s] |

| vi | A sample of the vibration velocity [m/s] |

| y1 , y2 | The vibration displacement generated by shafts 1, 2 [m] |

| y1s , y2s | Simulated vibration displacement signals [m] |

| α | The phase angle at the origin of time t0 for a theoretical model of free damped vibration velocity [rad/s] |

| εf | The error in the frequency measurement [Hz] |

| εj, εj+1 | The calculus errors for two successive zero-crossing moments [s] |

| γ | The shift of phase between the excitation force and the vibration displacement in the free damped response [rad] |

| θ1 , θ2 | The instantaneous value of the angle of centrifugal forces to the horizontal direction [rad] |

| φ1 , φ2 | The values of θ1 and θ2 at the origin of time, t = 0 [rad] |

| ω | The angular frequency of harmonic excitation of the lathe headstock [rad/s] |

| ω1 , ω2 | The instantaneous angular speed of the rotary shafts 1, 2 [rad/s] |

References

- Muszyńska, A. Rotordynamics; CRC Press: Boca Raton, FL, USA, 2005; ISBN 978-0-8247-2399-6. [Google Scholar]

- Wang, Y.; Yuan, X.; Sun, R. Critical techniques of design for large scale centrifugal shakers. World Inf. Earthq. Eng. 2011, 27, 113–123. [Google Scholar]

- Anekar, N. Design and testing of unbalanced mass mechanical vibration exciter. IJRET 2014, 3, 107–112. [Google Scholar]

- Conley, K.; Foyer, A.; Hara, P.; Janik, T.; Reichard, J.; D’Souza, J.; Tamma, C.; Ababei, C. Vibration alert bracelet for notification of the visually and hearing impaired. J. Open Hardw. 2019, 3, 4. [Google Scholar] [CrossRef]

- Fontana, F.; Papetti, S.; Jarvelainen, H.; Avanzini, F. Detection of keyboard vibrations and effects on perceived piano quality. J. Acoust. Soc. Am. 2017, 142, 2953–2967. [Google Scholar] [CrossRef]

- Ippolito, R.; Settineri, L.; Sciamanda, M. Vibration monitoring and classification in centerless grinding. In International Centre for Mechanical Sciences (Courses and Lectures); Kuljanic, E., Ed.; Springer: Vienna, Austria, 1999; p. 406. [Google Scholar] [CrossRef]

- Merino, R.; Barrenetxea, D.; Munoa, J.; Dombovari, Z. Analysis of the beating frequencies in dressing and its effect in surface waviness. CIRP Annal. Manuf. Technol. 2019, 68, 353–356. [Google Scholar] [CrossRef]

- Mayoof, F.N. Beating phenomenon of multi-harmonics defect frequencies in a rolling element bearing: Case study from water pumping station. World Acad. Sci. Eng. Technol. 2009, 57, 327–331. [Google Scholar]

- Pham, M.T.; Kim, J.-M.; Kim, C.H. Accurate bearing fault diagnosis under variable shaft speed using convolutional neural networks and vibration spectrogram. Appl. Sci. 2020, 10, 6385. [Google Scholar] [CrossRef]

- Park, J.; Lee, J.; Ahn, S.; Jeong, W. Reduced ride comfort caused by beating idle vibrations in passenger vehicles. Int. J. Ind. Ergon. 2017, 57, 74–79. [Google Scholar] [CrossRef]

- Huang, P.; Lee, W.B.; Chan, C.Y. Investigation of the effects of spindle unbalance induced error motion on machining accuracy in ultra-precision diamond turning. IJMTM 2015, 94, 48–56. [Google Scholar] [CrossRef]

- Norfield, D. Practical Balancing of Rotating Machinery; Elsevier Science: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Thearle, E.L.; Schenectady, N.Y. Dynamic balancing of rotating machinery in the field. ASME Trans. 1934, 56, 745–775. [Google Scholar]

- Kelm, R.; Kelm, W.; Pavelek, D. Rotor Balancing Tutorial. In Proceedings of the 45th Turbomachinery and 32th Pump Symposia, Houston, TX, USA, 12–16 September 2016. [Google Scholar]

- Wijk, V.; Herder, J.L.; Demeulenaere, B. Comparison of various dynamic balancing principles regarding additional mass and additional inertia. J. Mech. Robot. 2009, 1, 4. [Google Scholar] [CrossRef] [Green Version]

- Isavand, J.; Kasaei, A.; Peplow, A.; Afzali, B.; Shirzadi, E. Comparison of vibration and acoustic responses in a rotary machine balancing process. Appl. Acoust. 2020, 164, 107258. [Google Scholar] [CrossRef]

- Bertoneri, M.; Forte, P. Turbomachinery high speed modal balancing: Modelling and testing of scale rotors. In Proceedings of the 9th IFToMM International Conference on Rotor Dynamics. Mechanisms and Machine Science, Milan, Italy, 22–25 September 2017; Pennacchi, P., Ed.; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Caoa, H.; Dörgelohb, T.; Riemerb, O.; Brinksmeier, E. Adaptive separation of unbalance vibration in air bearing spindles. Proc. CIRP 2017, 62, 357–362. [Google Scholar] [CrossRef]

- Majewski, T.; Szwedowicz, D.; Melo, M.A.M. Self-balancing system of the disk on an elastic shaft. J. Sound Vib. 2015, 359, 2–20. [Google Scholar] [CrossRef]

- Hashimoto, F.; Gallego, I.; Oliveira, J.F.G.; Barrenetxea, D.; Takahashi, M.; Sakakibara, K.; Stalfelt, H.O.; Staadt, G.; Ogawa, K. Advances in centerless grinding technology. CIRP Annal. 2012, 61, 747–770. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Wang, L.Z.; Jin, Z.J.; Zhang, Q.; Li, X.L. Non-whole beat correlation method for the identification of an unbalance response of a dual-rotor system with a slight rotating speed difference. MSSP 2013, 39, 452–460. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Zhang, Q.; Li, X.L.; Qian, T.L. The whole-beat correlation method for the identification of an unbalance response of a dual-rotor system with a slight rotating speed difference. MSSP 2011, 25, 1667–1673. [Google Scholar] [CrossRef]

- Lee, Y.J. 8.03SC Physics III: Vibrations and Waves. Fall 2016. Massachusetts Institute of Technology: MIT Open CourseWare. 2016. Available online: https://ocw.mit.edu (accessed on 17 September 2020).

- Kim, S.H.; Lee, C.W.; Lee, J.M. Beat characteristics and beat maps of the King Seong-deok Divine Bell. JSV 2005, 281, 21–44. [Google Scholar] [CrossRef]

- Yuan, L.; Järvenpää, V.M. On paper machine roll contact with beating vibrations. Appl. Math. Mech. 2006, 6, 343–344. [Google Scholar] [CrossRef]

- Gao, H.; Meng, X.; Qian, K. The Impact analysis of Beating vibration for active magnetic bearing. IEEE Access 2019, 7, 134104–134112. [Google Scholar] [CrossRef]

- Preumont, A. Twelve lectures on Structural Dynamics; Université Libre de Bruxelles: Brussels, Belgium, 2012. [Google Scholar]

- Horodinca, M.; Seghedin, N.; Carata, E.; Boca, M.; Filipoaia, C.; Chitariu, D. Dynamic characterization of a piezoelectric actuated cantilever beam using energetic parameters. Mech. Adv. Mater. Struct. 2014, 21, 154–164. [Google Scholar] [CrossRef]

- Endo, H.; Suzuki, H. Beating vibration phenomenon of a very large floating structure. J. Mar. Sci. Technol. 2018, 23, 662–677. [Google Scholar] [CrossRef]

- Carrino, S.; Nicassio, F.; Scarselli, G. Subharmonics and beating: A new approach to local defect resonance for bonded single lap joints. J. Sound Vib. 2019, 456, 289–305. [Google Scholar] [CrossRef]

- Cattarius, J.; Inman, D.J. Experimental verification of intelligent fault detection in rotor blades. Int. J. Syst. Sci. 2000, 31, 1375–1379. [Google Scholar] [CrossRef]

- Morrone, A. Seismic vibration testing with sine beats. Nucl. Eng. Des. 1973, 24, 344–356. [Google Scholar] [CrossRef]

- Huang, H.H.; Chen, K.S. Design, analysis, and experimental studies of a novel PVDF–based piezoelectric energy harvester with beating mechanisms. Sens. Actuators A Phys. 2016, 238, 317–328. [Google Scholar] [CrossRef]

- Basovich, S.; Arogeti, S. Identification and robust control for regenerative chatter in internal turning with simultaneous compensation of machining error. Mech. Syst. Sign. Process. 2021, 149, 107208. [Google Scholar] [CrossRef]

- Li, D.; Cao, H.; Liu, J.; Zhang, X.; Chen, X. Milling chatter control based on asymmetric stiffness. Int. J. Mach. Tools Manuf. 2019, 147, 103458. [Google Scholar] [CrossRef]

- Yana, Y.; Xub, J.; Wiercigrochc, M. Influence of work piece imbalance on regenerative and frictional grinding chatters. Proc. IUTAM 2017, 22, 146–153. [Google Scholar] [CrossRef] [Green Version]

- Kimmelmann, M.; Stehle, T. Measuring unbalance-induced vibrations in rotating tools. MATEC Web Conf. 2017, 121, 03012. [Google Scholar] [CrossRef]

- Gohari, M.; Eydi, A.M. Modelling of shaft unbalance: Modelling a multi discs rotor usingK-nearest neighbor and decision tree algorithms. Measurement 2020, 151, 107253. [Google Scholar] [CrossRef]

- Hui, S.; Xiaoqiang, H.; Zhiqiang, D.; Lichang, X.; Haishui, J. Research on Low Frequency Noise Caused by Beat Vibration of Rotary Compressor. In Compressor Engineering Conference, Proceedings of the 24th International Compressor Engineering Conference, Purdue, Italy, 9–12 July 2018; Purdue University: Purdue, Italy, 2018; p. 2528. [Google Scholar]

- Available online: http://hgsindia.com/www.hgsproducts.nl/Pdf/196216HG-4%20V%201.1.pdf (accessed on 17 September 2020).

- Available online: https://www.picotech.com/oscilloscope/4224-4424/picoscope-4224-4424-overview (accessed on 17 September 2020).

- Horodinca, M.; Ciurdea, I.; Chitariu, D.F.; Munteanu, A.; Boca, M. Some approaches on instantaneous angular speed measurement using a two-phase n poles AC generator as sensor. Measurement 2020, 157, 107636. [Google Scholar] [CrossRef]

- Chapra, S.C.; Canale, R.P. Numerical Methods for Engineers, 7th ed.; McGraw Hill Education: New York, NY, USA, 2015. [Google Scholar]

- Arlinghaus, S. Practical Handbook of Curve Fitting, 1st ed.; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Shabanna, A.A. Theory of Vibrations. An introduction; Springer: New York, NY, USA, 1991. [Google Scholar]

- Schmitz, T. Modal interactions for spindle, holders, and tools. Proc. Manuf. 2020, 48, 457–465. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chitariu, D.-F.; Negoescu, F.; Horodinca, M.; Dumitras, C.-G.; Dogan, G.; Ilhan, M. An Experimental Approach on Beating in Vibration Due to Rotational Unbalance. Appl. Sci. 2020, 10, 6899. https://doi.org/10.3390/app10196899

Chitariu D-F, Negoescu F, Horodinca M, Dumitras C-G, Dogan G, Ilhan M. An Experimental Approach on Beating in Vibration Due to Rotational Unbalance. Applied Sciences. 2020; 10(19):6899. https://doi.org/10.3390/app10196899

Chicago/Turabian StyleChitariu, Dragos-Florin, Florin Negoescu, Mihaita Horodinca, Catalin-Gabriel Dumitras, Gures Dogan, and Mehmet Ilhan. 2020. "An Experimental Approach on Beating in Vibration Due to Rotational Unbalance" Applied Sciences 10, no. 19: 6899. https://doi.org/10.3390/app10196899

APA StyleChitariu, D.-F., Negoescu, F., Horodinca, M., Dumitras, C.-G., Dogan, G., & Ilhan, M. (2020). An Experimental Approach on Beating in Vibration Due to Rotational Unbalance. Applied Sciences, 10(19), 6899. https://doi.org/10.3390/app10196899