1. Introduction

The today’s cost of fossil fuels is constantly evolving. The present economic crisis, combined with political pressures, make the price of oil strongly uncertain. In addition, in recent years, polluting emissions produced by merchant ships have to be contained in increasingly restrictive limits to comply with the new regulations coming in force [

1]. In this changing scenario, the need arises to explore the possibility of using alternative fuels, instead of the traditional oil (heavy fuel oil -HFO) and to increase the whole efficiency of the propulsion system.

From the point of view of alternative fuels, the research points towards fuels with economically sound potentials and with limited impact on the environment. The technology development occurred in large gas engines during the recent years has achieved high thermal efficiency and low emissions utilizing liquefied natural gas (LNG), suggesting this fuel as a potential substitute of HFO [

2,

3,

4]. Modern gas engines abate CO

2 by 30%, NO

x by 85% (without after treatments), ensuring the complete absence of SO

x compared to the correspondent engine, fed by liquid fuel oil [

5]. In order to benefit from these advantages, the major engine manufacturers have designed several set of gas engine for both ship propulsion and land based power generation, like the Wärtsilä 50DF series.

From the point of view of increasing the whole efficiency of the propulsion system, energy recovery can be considered of the waste heat usually dissipated, for both improving the propulsion power or for producing useful heat on board the ship [

6,

7,

8,

9,

10]. In this context, the use of Organic Rankine Cycles (ORC) as bottom power plant of the main propulsion engine appears a very attractive technology, allowing efficiency gains equal, or higher, with respect to other energy saving solutions, like the adoption of more complex exhaust gas boilers, heat pumps [

11,

12], or a bottom Kalina cycle [

13]. Many applications of this technology are made in land-based installations, such as biomass, solar and geothermal energy plant [

14,

15,

16,

17,

18]. Recently, several studies have been conducted on the possible application of ORC groups coupled to diesel engines, for both stationary and propulsion applications [

19,

20,

21]. Specific application to marine propulsion system can be found in [

22], where different hydrocarbons and some refrigerant are considered as working fluids in both recuperated and non-recuperated cycles, in [

23,

24], where different refrigerant are considered as working fluids in simple and superheated cycles, in [

25], where the whole heat exchangers network is designed using the pinch analysis, and in [

26], where an important excess of steam is supposed to be produced by the exhaust gas boiler and the energy recovery can be performed by a cascade, made up by a steam Rankine cycle and a ORC. A similar cascade energy recovery system is presented in [

27], but the ORC is replaced by an absorption refrigeration machine.

This study examines the options of energy recovery from an ICE for ship propulsion by adding a bottom ORC, with the aim of reducing the fuel consumption of the propulsion system during its operation. Different possible bottom ORC configurations are considered and simulated using the Aspen® code, and different working fluids are taken into account, jointly with regenerative and two-temperature levels designs, allowing the identification of the most suitable ORC configuration.

The proposed analysis is based on the real operating data of a marine engine, considering the needs of its cooling system, and on the use of a realistic design/off-design simulator of the heat exchangers, available in Aspen®. In this way the expectation is to obtain very realistic values of the actual performance increase of the propulsion system. Therefore, a robust preliminary economic and environmental evaluation of the real operation of the ship engine can be performed.

The analysis is focused on increasing the efficiency of the on-board propulsion system, without considering the possibility of producing other energy carriers to meet the ship’s requests. A search for optimal solutions to meet the entire energy demand on board of a cruise ship is presented for example in [

28].

2. Options of Waste Heat Recovery from a Naval Engine

In this study a dual fuel engine (model 6L50DF by Wärtsilä) for ship propulsion has been considered. This engine model is a six cylinder in-line, it produces it 5.7 MW with efficiency of about 49%, operating at 514 rpm. It is very flexible from the fuel point of view: it can switch almost instantaneously from gas (LNG) to liquid diesel (LFO-HFO), and vice versa, allowing the choose of the most suitable solution. Because of its complexity, a dual-fuel engine costs up to 30% more than a traditional diesel engine, but it allows an annual saving in term of fuel equal to 5–8% [

5].

The benefits mentioned above can still be enhanced by recovering the thermal energy mainly available in the exhaust gases and in other engine’s fluids, which is discharged to the environment in the traditional propulsion plants.

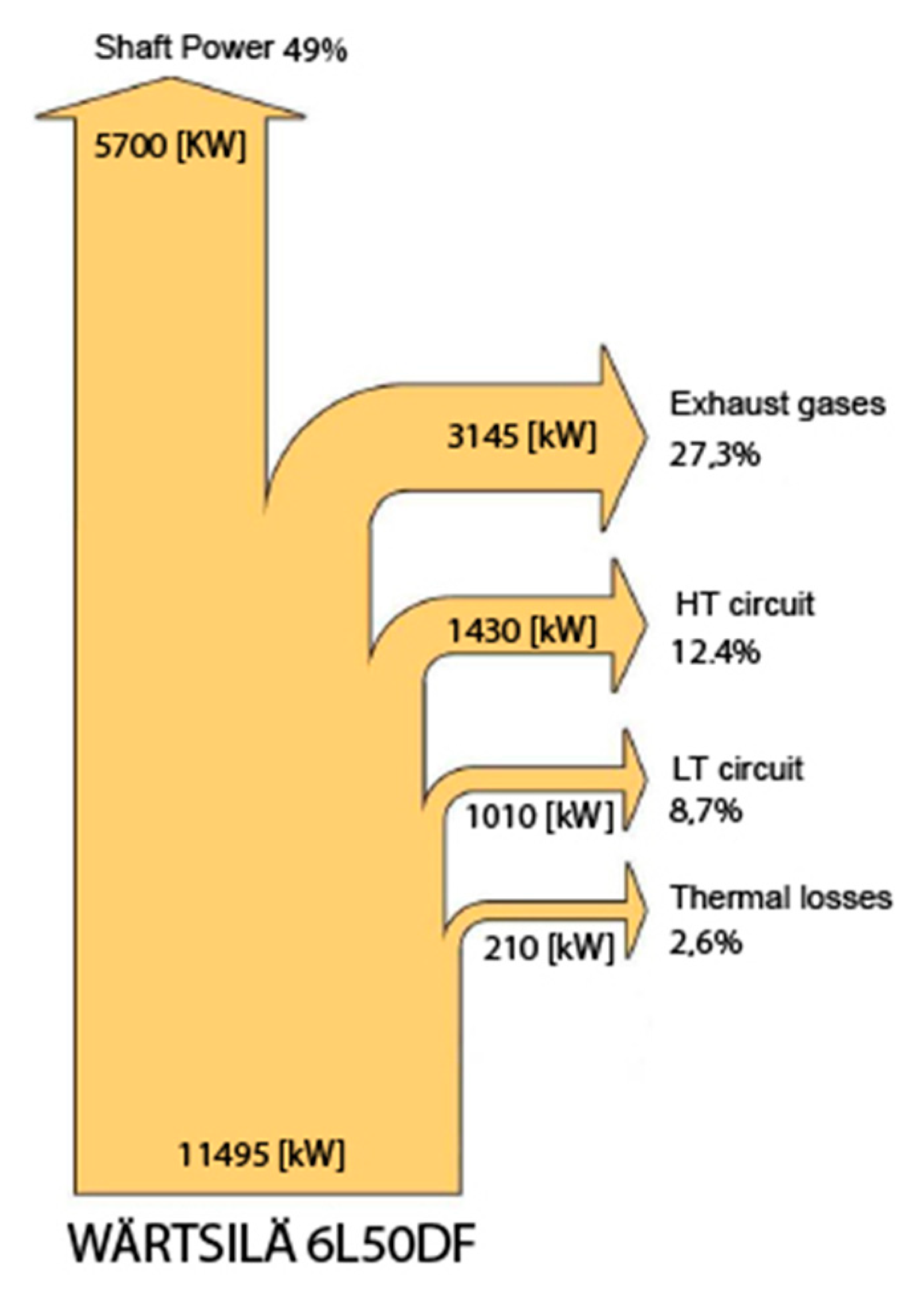

The heat balance of a Wärtsilä 6L50DF engine shows about 11.5 MW of fuel input and a power output of 5.7 MW, at maximum load (

Figure 1). The remaining energy is rejected to the environment by the exhaust gas (about 3.1 MW available at 400 °C) and the cooling circuits (2.4 MW in LT and HT circuits).

The cooling circuit is split in two parts, according to the temperature level: a high temperature circuit (HT, at about 90 °C) and a low temperature circuit (LT, at 50 °C). It is worth nothing that the amount of energy rejected by the engine is about equally split between the exhaust gas and the two cooling circuits HT + LT together (56% and 44%, respectively, at the maximum engine load), but the exergy content of the exhaust gas is three times higher than that of the HT + LT circuits (74% and 26%, respectively, at the maximum engine load). Therefore, it can be inferred that a first selection of possible energy recovery can be based primarily on the availability of high temperature heat sources, namely the exhaust gas and possibly the HT water circuit.

To introduce the feasibility of the heat recovery, a brief description of the cooling circuits and of exhaust gas circuit of the engine W6L50DF is necessary (

Figure 2).

The water of the high temperature fresh-water circuit (HT CIRCUIT) flows through the cylinder jackets, the cylinder heads and the first stage of the air-cooler, from the engine inlet (IM) to the engine outlet (UM). The water in the low temperature fresh-water circuit (LT CIRCUIT) cools the second stage of the air-cooler and then the lubricant oil. The control of the HT circuit is based on the temperature of the water leaving the engine. A three-way thermostatic valve set at 91 °C re-circulates part of the flow (RIC) to keep the water inlet temperature at the right level. The remaining part of the water is then cooled in a central cooler, dissipating heat into the sea water. A heat exchanger, high temperature waste heat recovery (HT WHR) allows the recovery of thermal energy from the HT cooling circuit. The object of this recovery is to allow the maximum power production from the bottom cycle, without preventing the proper operation of the temperature control loop, therefore the extracted thermal power shall be equal to the engine thermal production, at each different load. The water at the outlet of the HT WHR returns to the engine inlet (RIT), with a possible integration from the LT circuit (REINT). In this way, the regulation system of the engine cooling guarantees, for all engine loads, a constant temperature in the high temperature fresh water circuit, while the temperature of the low temperature fresh water circuit does not exceed 50 °C, but it strong depends on the engine load and on the see water temperature. Therefore, an energy recovery from the LT circuit has to be regarded as not feasible in practice.

3. First Plant Modeling and Choice of the Working Fluid

The goal of this study is the identification of the most suitable ORC configuration dedicated to the heat recovery from the engine Wärtsilä 6L50DF. The study is performed in three steps: first step is the choice of the organic working fluid for the cycle, then it comes the thermodynamic analysis to optimize the cycle and finally the component design. For these purposes it is useful the support of a computer software containing an extensive library of fluids, including all their chemical and thermodynamic properties. The different plant solutions have been analyzed with the Aspen Plus

® code, utilizing the standard components of its library [

29].

3.1. Choice of Working Fluid

As it is well known, the convenience of using systems based on ORC cycles lies primarily on favorable characteristics of some organic liquids in comparison with water, i.e., larger molecular mass, lower critical temperature, lower critical pressure, lower condensation entropy and lower solidification temperature [

30,

31,

32]. In fact, the feature that makes water unsuitable to use in applications of small size and low maximum temperature of the cycle, is its large entropy of evaporation, compared with that of organic fluids. By using organic fluids, it is possible to operate with higher mass flow rates and lower expansion pressures, achieving a power output higher than that of a steam cycle working with the same conditions.

In the present study four different pure substances are compared: benzene, cyclohexane, octa-methylsiloxane (MDM) and toluene. Cyclohexane, benzene and toluene are selected as working fluids because they possess efficient thermal performance at high temperature, favorable environmental characteristics and high decomposition temperatures [

33]. MDM and toluene have already found industrial application in ORC cycles [

34,

35,

36] with temperature of the heat source in the range 300–400 °C and electric power output greater than 100 kW. Different kinds of fluids are currently studied and used for lower temperatures of the heat source and small size of the system. In particular some studies consider the option of using refrigerant for waste heat recovery from small size ICEs [

37,

38,

39]. It is worth noting that, for the typical hot source temperature of this application, the fluids considered in the present study (in particular toluene and MDM) always obtain efficiencies close to the maximum achievable value [

34], with small gaps with respect to the best performing fluid, if any. Obviously, different fluids are better suited for lower hot source temperature, like the isobutene introduced in the Two-pressure-levels recovery system, presented further on in this paper.

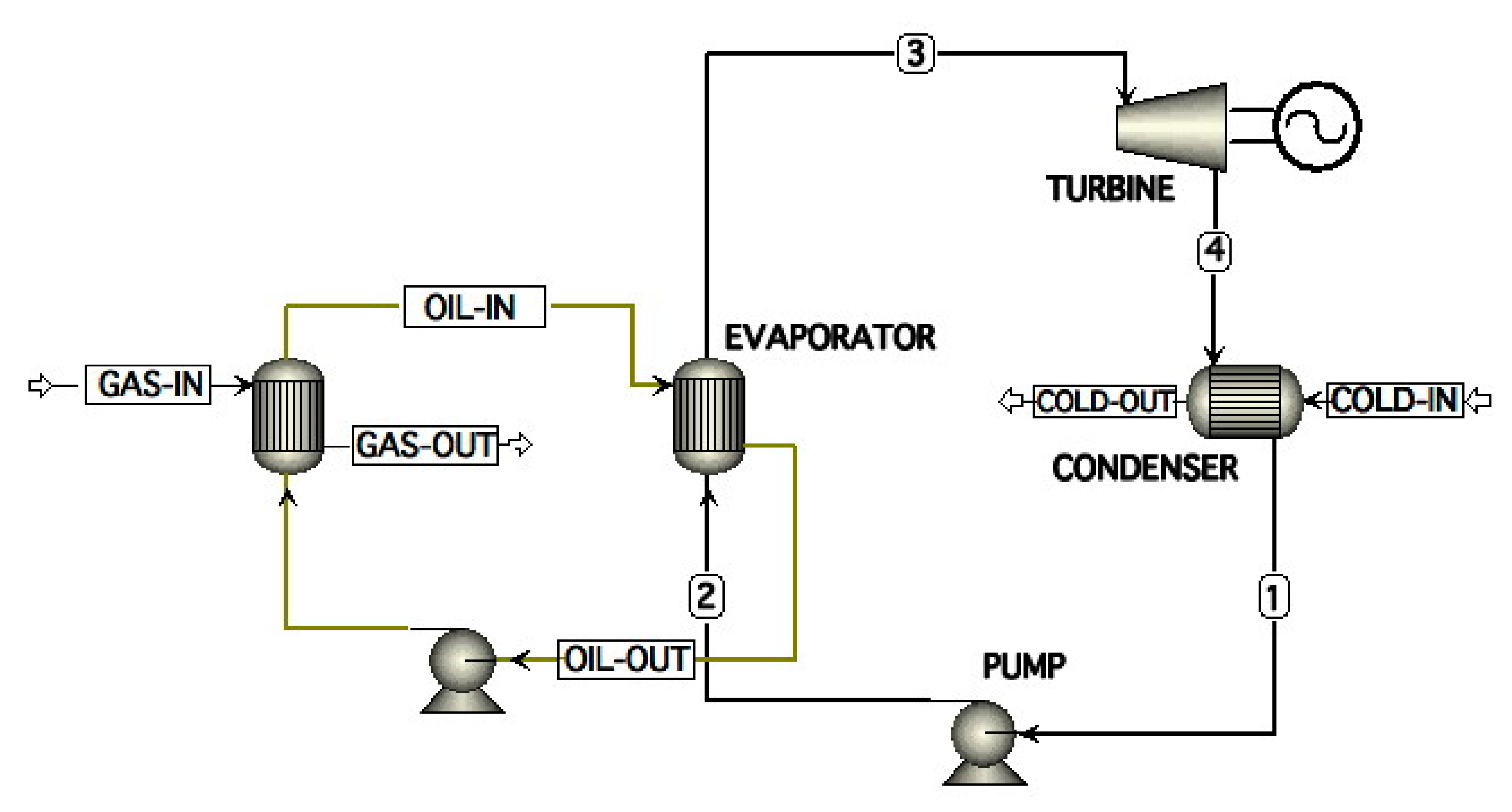

First, a simple Rankine cycle, according to the scheme shown in

Figure 3, has been simulated with the Aspen Plus

® code considering each one of the four organic fluids. In order to assure safe operation on board of the ships, thermal oil is used as intermediate media between the exhaust gasses and the organic fluid. The exhaust gasses flow rate and temperature are 9.2 kg/s and 400 °C, respectively at 100% of the nominal load and they change with load up to 5.3 kg/s and 442 °C, respectively at 50% of the nominal load [

5]. The thermal oil is heated in the heat exchanger at the left hand side in

Figure 3, which is also shown as “Exhaust Gas Recuperator (optional)” at the top of

Figure 2. In this preliminary evaluation, nominal conditions only have been considered and the temperature and mass flow rate of the thermal oil have been fixed, jointly with the maximum and minimum pressures regarded as acceptable for the cycle, in order of obtaining a homogeneous comparison of the four fluids. In the detailed design of the heat exchangers (

Section 5), as well as in the off-design analysis of the ORC regenerated cycle

Section 6), these limitations will be relaxed.

The following operating conditions and mass flow rates are set for all the organic working fluids, consistently with the hypothesis of recovering energy only from the exhaust gas of the engine Wärtsilä 6L50DF:

temperature of hot source (thermal oil Dowtherm-G®): 350 °C;

mass flow rate of hot source (thermal oil Dowtherm-G

® [

40]): 5 kg/s;

maximum evaporating temperature of the organic fluid: 250 °C;

maximum pressure of the organic fluid: 15 bar;

minimum condensing pressure of the organic fluid: 0.3 bar;

The final cold sink is the sea water. Considering a possible intermediate circuit, a precautionary value of 38 °C is assumed for the cooling fluid of the condenser of the energy recovery system. The working fluids flow rates have been determined by the standard Evaporator model of Aspen Plus

® [

29], starting from a tentative value (3 kg/s). The main components of the plant (

Figure 3) have been modeled on the basis of the hypothesis below:

Turbine (3-4): discharge pressure (minimum of the cycle) and isentropic efficiency are set constant.

Condenser (4-1): it allows the condensation of the full amount of the working fluid, with no limits on the maximum temperature reached by the cold fluid.

Circulation pump (1-2): output pressure is set constant (maximum of the cycle).

Evaporator (2-3): the outlet temperature of the working fluid has been fixed (maximum temperature of the cycle); taking the maximum pressure into account, the full amount of the organic fluid may reach the state of dry saturated or superheated vapor.

A comparison of the results obtained for the different working fluids is shown in

Table 1.

This preliminary comparison shows that the most promising fluids appear to be benzene and toluene. Toluene in particular allows to raise the evaporation temperature of the cycle at 290 °C and the maximum cycle pressure to 28 bar. Benzene and cyclohexane have a critical temperature below 290 °C, whilst MDM has a slightly higher critical temperature (291 °C) but its adoption is convenient in internal recuperated ORCs, due to the shape of its saturation curves in the T-s plane [

41]. For toluene in addition, it is possible to further reduce the condensing pressure to 0.1 bar, thanks to the temperature of cold fluid source (see water), and a good resistance to degradation at high temperature (above 300 °C) is also experimentally demonstrated for toluene [

42]; this fluid is also less toxic than benzene.

Then, toluene has been identified as the best working fluid for the considered application. The results obtained in these new conditions are presented in

Table 2. The optimization of the mass flow rate of the chosen fluid allows an even higher maximum power of 611 kW to be obtained from the bottoming cycle, corresponding to a toluene mass flow rate of 3.5 kg/s.

As previously described, the engine releases also a flow of hot water (the HT cooling circuit) that is an additional opportunity of energy recovery. This heat source is at low temperature (about 90 °C), so that the fluids considered in

Table 1 are not suitable for energy recovery in a Rankine cycle, because they are characterized by high boiling temperatures. In this case it would be appropriate using a low temperature boiling fluid, like isobutene, which has an evaporation temperature equal to −12 °C at 1 bar, a T

cr = 135 °C and shows good performance in comparison with other hydrocarbons and refrigerants at maximum cycle temperature of about 90 °C [

43].

Therefore, a simple Rankine cycle with isobutene as the working fluid has been simulated, always according to the scheme in

Figure 3. It has been coupled to the HT water circuit of the ICE, replacing the heat exchanger “HT WHR (optional)” in

Figure 2 with the evaporator of the ORC. The possible output of the latter has been evaluated using a set of thermodynamic parameters consistent with the operating conditions of the engine at maximum load [

5]:

temperature of HT water circuit (hot source): 91 °C;

mass flow rate of HT water circuit: 37.5 kg/s;

evaporating temperature of the working fluid: 81 °C;

maximum pressure of the working fluid: 13 bar;

condensing pressure of the working fluid: 6.5 bar;

tentative working fluid flow rate: 7 kg/s;

temperature of condenser cooling flow: 38 °C.

Under these conditions the additional power of 87 kW has been obtained from the low temperature ORC cycle, with an efficiency of 6.1%.

3.2. Functional Parameters of the ORC at ICE Part Load

A sensitivity analysis has been performed on the main parameters of the cycle at five engine operation points (100%, 85%, 75%, 50%, 25% of nominal load), obtaining information on the maximum expected performance of the ORC, in consequence of changing in the flow rate and temperature of exhaust gases, that change as the engine load varies, modifying the energy available for the bottom cycle. In this sensitivity analysis, the upper and lower temperature and pressure of a simple Rankine cycle with toluene have both been varied, according to the power recovered from the engine exhaust gases.

The cycle’s powers and efficiencies achieved changing the maximum pressure are shown in

Figure 4 and

Figure 5. Increasing the maximum pressure, the efficiency has a monotonous increasing trend, but the power is about constant in the range 20–30 bar, showing that the cycle efficiency increase is compensated by a reduction in the energy recovery from exhaust gas. Therefore, a maximum pressure of 20 bar has been assumed in the further evaluations.

Figure 6 shows that a significant increase in power output can be obtained by considering the engine operating in a cold sea. The condensation pressure, for the considered temperatures range, is from 0.04 to 0.1 bar. The power increases with decreasing the condensation temperature, as it is expected for a Rankine cycle. When condensation temperature can be kept at about 27 °C (as it is possible only if see water temperature is below 20 °C) the power output shows a surplus of about 100 kW, with respect to full load operation with a condensation temperature of 46 °C. The efficiency also increases with decreasing the condensation temperature, varying between 23% and 25.3%, with very limited influence, however, by the engine load.

4. Choice of Optimal Bottoming Cycle Configuration

In the next step of the study, an assessment of different configurations of the ORC bottoming thermodynamic cycle has been made. The criteria used for choosing pressures and temperatures for each configuration are those that allow to maximize the power produced by the cycle for each level of output of the engine. At this stage, the constraints related to the real geometrical dimensions of the heat exchangers are not explicitly taken into account; they will be introduced in the next step, in view of the economic evaluation of the chosen solution.

The following parameters have been kept constant for all engine load:

cycle maximum pressure 20 bar (in order to avoid stressing pipes and components);

cycle maximum temperature 290 °C (in order to obtain a slight overheating above the toluene saturation temperature at 20 bar (260 °C), and below the degradation limit for the same fluid);

condensing mass flow rate 80 kg/s;

maximum oil temperature 350 °C;

maximum gas temperature 468 °C;

overall heat transfer coefficient constant for all exchangers, equal to 850 W/m2K (average value recommended by Aspen® for the used fluid);

no pressure drops in the bottoming cycle components (consistently with a simplified initial analysis).

The performance of the simple cycle, as described in

Section 3, will be compared below (by fixing toluene as working fluid) with those of three other more complex configurations of the energy recovery cycle, obtained by considering a preheating of the working fluid with the water of the HT engine cooling circuit, the internal regeneration for the ORC and two combined ORC cycles in cascade.

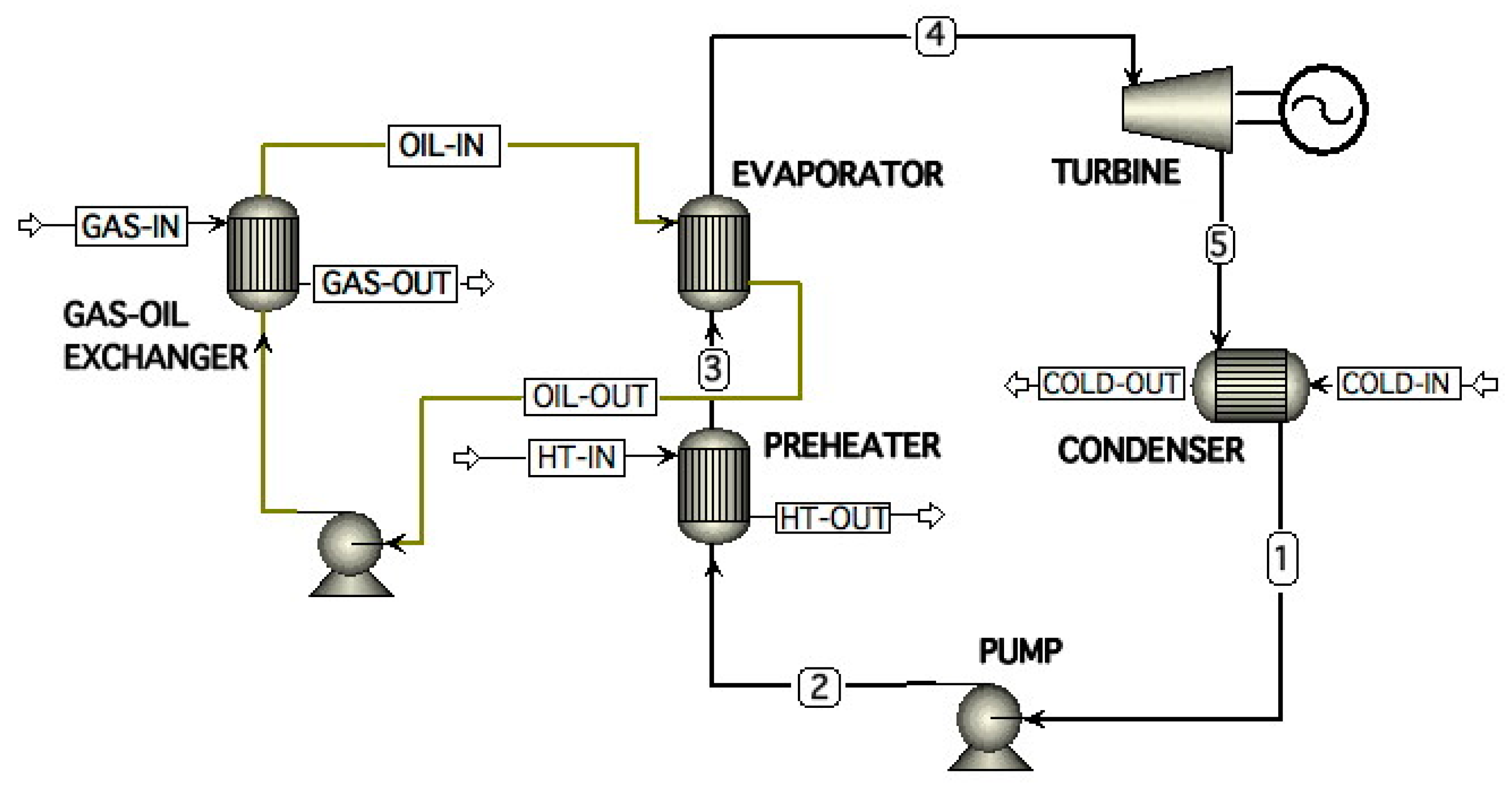

4.1. Cycle with Preheating

A first evolution of the simple cycle is obtained by adding a heat exchanger before the evaporator, which preheats the toluene with the stream of hot water of the engine HT cooling circuit (

Figure 7). This water is produced at 91 °C, so that its preheating can be useful only if the working fluid leaves the pump at a lower temperature. The additional supply energy at low temperature allows operating with a greater mass flow rate of working fluid, increasing the power developed by the turbine. This can be inferred from

Table 3, where the results obtained are compared with those of the simple cycle.

4.2. Regenerative Cycle

The Rankine cycles with dry organic fluids show superheated steam conditions and quite high temperature at the end of expansion, with a limited enthalpy difference across the turbine, so that the enthalpy of the expanding flow is not fully utilized.

The most natural solution, from the thermodynamic point of view, is therefore to realize the internal regeneration of the cycle, by adding a heat exchanger for preheating the organic fluid at the pump outlet (

Figure 8).

As in the previous case, the internal regeneration makes possible to operate with a higher mass flow rates than that of the simple cycle, getting more power from the turbine (

Table 3).

4.3. Two Combined ORC with Different Temperature Levels

Let’s finally consider two combined cycles, operating with different organic fluids at two different thermal levels (

Figure 9). The cycle at higher temperature (toluene) is coupled to the exhaust gas through the thermal oil circuit, as in the ORCs previously shown; the lower temperature cycle (using isobutene as working fluid) receives energy directly from the HT cooling water circuit of the ICE.

As mentioned before, the flow in the HT cooling circuit is adjusted to maintain a constant return temperature to the engine. In case water in the HT cooling circuit is used for the evaporation of the isobutene, the return temperature of the HT water circuit must not drop below the value set in the engine-control system. To avoid this eventuality and to enable the combined cycles to operate with the highest possible flow in the evaporator, an exhaust gas/water recuperator has been introduced to rise the temperature of the water leaving the recovery system (

Figure 9), assuming that the gas at the chimney has not to be cooled below 140 °C. In few words, the heat exchanger “HT WHR (optional)” in

Figure 2 is replaced by the “Evaporator I-butane” and the “Recuperator Gas-Water” in

Figure 9.

The two cycles exchange energy also each other. To take advantage from the high temperature of toluene vapor exiting the turbine, an additional heat exchanger is introduced for superheating the isobutene, allowing the lower temperature cycle to increase its power output (

Table 3).

4.4. Performance Comparison of Different Configurations

The total power obtainable by combining the propulsion ICE and the ORC system is shown in

Figure 10, for different engine loads and the considered configurations of the bottom cycle.

A significant power gain (about 10%) is already achieved with the simple cycle. For the other configurations the increase is slightly higher, at least with reference to the full load of the engine. The corresponding efficiencies are reported in

Figure 11, showing that they grow (up to 8 points) with decreasing engine load. In fact, if the engine efficiency reduces, a bigger fraction of the energy of the fuel input is available as waste heat for the bottom cycle.

The regenerated and the two combined cycles show the bigger efficiency increase, but the latter is affected by the temperature decrease in the HT cooling circuit at low engine loads. Therefore, it can be inferred that the regenerated cycle gives the best performance, without excessive plant complexity. Then, the following design analysis has been carried out on this plant configuration and the sizing and the realistic off-design performance of the required heat exchangers have been obtained.

5. Sizing of the Heat Exchangers for the ORC Regenerated Cycle

The specific design of shell and tube heat exchangers has been performed by using the software Aspen Tasc

®, to address in detail the performance of the regenerative cycle and to perform the economic analysis of the investment. The used software incorporates an extensive library of organic fluids and therefore it has been possible to define in detail the geometry of heat exchangers, according to the prescriptions of the Tubular Exchanger Manufacturers Association (TEMA) [

44], and to calculate accurately the phase transition and the pressure drop in the shell and in the tubes

The heat exchangers in the regenerated cycle are the exhaust gas/thermal oil heat exchanger, the evaporator, the regenerator and the condenser (

Figure 8). During sizing and geometry selection, it has been paid attention to limit the size, in view of a possible installation in a room next to the engine room. The main data obtained for the different heat exchangers are summarized in

Table 4.

To ensure the proper operation of the engine, the pressure drop of the gas stream through the exhaust gas circuit must be below 3 kPa [

4], therefore the maximum loss through the exhaust gas/thermal oil heat exchanger has been set to 1.2 kPa. In this way, an acceptable backpressure is guaranteed for the engine turbocharger, which is just upstream this heat exchanger.

The exhaust gas/thermal oil heat exchanger is a vertical tube bundle (containing the thermal oil), with the direct flow of gases in the shell without support baffles, for reducing losses.

For the evaporator it was used a shell and tube heat exchanger, with geometry type CFU (channel Integral with tube-sheet, Two-pass shell with longitudinal baffle, U-tube bundle [

44]) and two shells in parallel. Taking the toluene pressure (20 bar), it is better to locate it inside the tubes [

45], while the flow of hot thermal oil circulates outside. The losses are not a limit for this heat exchanger, as a sensitivity analysis has shown that fluctuations in the maximum cycle pressure of about few bars lead to negligible power losses. The pinch-point obtained in the oil/toluene exchanger is equal to 5.3 °C, a value that demonstrates a high heat transfer efficiency.

The chosen geometry for the regenerator is a shell-type DFU (Special high pressure closure, Two-Pass shell with longitudinal baffle, U-tube bundle [

44]), with a finned tube bundle in order to obtain a more compact design.

One possible concern is the pressure drop affecting the vapor of toluene coming from the turbine. This loss not only increases the size of the exchanger, but also penalizes the turbine, reducing the available enthalpy drop. By limiting this loss in 0.025 bar, a power penalty of approximately 30 kW only has been obtained for the turbine.

The condenser is cooled by the demineralized water of an intermediate ring, cooled by the sea. The same ring can cool in series the central cooler of the engine HT cooling circuit (see

Figure 2).

It has been verified that a condenser of BIM type (integral cover, split input flow-single output flow, fixed tube-sheet) is the most suitable, allowing better performance while limiting the size and the final cost. In this case, it is also required that the pressure drop in the vapor side is the lowest as possible. In fact, each loss means a pressure increase at the end of the expansion, limiting the power of the turbine. Comprising such loss in 0.013 bar only, it has limited the penalty for the turbine power in about 20 kW.

6. Off Design Analysis of the ORC Regenerated Cycle

Once the geometry of the heat exchangers has been defined, it was possible to switch to the off-design analysis of the bottoming cycle. The simulations have been done at different engine loads, taking into account the actual size of the heat exchangers obtained by the detailed design.

A simplified turbine model has been considered, taking into account the isentropic efficiency reduction vs. mass flow rate [

6].

It should be emphasized that, by using exchangers with fixed characteristics, the performance of the cycle is usually lower compared to those derived from the preliminary analysis of the different possible configurations, presented in

Section 3. The main differences lie in a reduction in the mass flow rate of toluene (3.3 instead of 3.8 kg/s) because the ORC is operated keeping the condenser pressure constant, and controlling the working fluid mass flow rate by changing the speed of the pump, or with a throttle valve placed after the pump itself [

46,

47]. A reduced mass flow rate limits the effectiveness of the heat exchangers, therefore, superheated conditions may not be always reached at turbine inlet. Furthermore, the pressure losses in the heat exchangers reduce the turbine enthalpy drop, with a consequent lower power of about 50 kW at maximum load. Finally, the heat transfer coefficients calculated through the libraries of Aspen Tasc

® have been almost always lower than the default value used in Aspen Plus

®, increasing the area of heat exchangers. This last aspect significantly affects their costs and overall dimensions.

The actual performance obtained by the bottom regenerative Rankine cycle is presented in

Table 5. The gross power gain reaches 520 kW and it is constant for medium and high engine loads, until the organic fluid flow rate can be kept constant. Knowing the real off-design performances of the energy recovery system, it is possible to calculate the real power of the combined engine and ORC system at each load, in order to evaluate the annual achievable fuel saving.

By considering the engine average operation duty equal to 6960 h per year, the fuel saved can be calculated taking the engine load distribution into account, like in [

48,

49]:

100% load is typically used 1.5% of the time for maximum operating speed;

85% load is used to obtain the cruising speed, with the minimum specific consumption of the engine, and is usually kept for 85% of the time;

75% load is used for 5% of the time;

50% load is used in ancillary services, when the ship stops in port, for 7% of the time;

25% load is used for 1.5% of the time in port operation.

Table 6 lists the data obtained for both conventional and combined engine, assuming the LHV of LNG fuel equivalent to 36 MJ/Nm

3 and the price of natural gas of 12

$/Mbtu on the basis of the European average price 2011–2015 [

50]. In the calculations the cost of owning and maintaining the propulsion system has been evaluated as 10% of fuel cost, obtaining a final cost of 0.32 €/Nm

3 for the LNG. It can be appreciated how the ORC gives a significant contribution to fuel savings at the most frequent load used during a year (85% of maximum load).

7. Economic and Environmental Remarks

A first approximation of the installation cost of a ORC group can be evaluated as the sum of turbine, pumps, exchangers and fluids costs. The costs of the heat transfer components have been obtained by means of Aspen Tasc®:

For the other components, the following economic estimates have been considered on the basis of information from manufacturers:

turbine 150,000 €;

electric generator 30,000 €

toluene pump 20,000 €;

thermal oil pump 10,000 €;

toluene 30,000 €;

diathermic oil 15,000 €;

balance of the plant (piping, filters, valves, etc.) 115,500 €.

The expected total cost for the bottom regenerated cycle could be obtained adding to the sum of all these terms (€885,000) a mark-up of 20%, resulting in a total price of 1,062,600 €.

Taking into account the estimation of actual fuel saving for the typical operating year, a simple payback period of the investment equal to 4.9 years has been obtained, while considering a discount rate equal to 3% a dynamic payback period of the investment equal to 5.9 years has been obtained.

The recovery of waste heat downstream of the propulsion engine by means of a bottom ORC has also a good cost/performance ratio, equal to 2214 €/kW.

The adoption of an ORC group as a supplement of the propulsion system, allows saving large amounts of LNG fuel, implying a reduction in atmospheric emissions of pollutant agents, such as carbon dioxide and nitrogen oxides.

To evaluate the quantity of CO2 avoided, the specific average amount of CO2 emitted by the Wärtsilä 6L50DF engine, equal to 430 g/kWh, can be considered. By applying this value to the average power produced by the ORC, and on the basis of the hours of use per year of the propulsion system, 1380 ton/year of CO2 non emitted into the atmosphere can be obtained.

Not emitted into the atmosphere NOx tons can be derived in the same way. Starting from the engine average emission of 2.5 g/kWh, a total amount equal to 8.4 ton/year of avoided NOx emission has been obtained.

8. Conclusions

In the present study various options of energy recovery from an ICE for ship propulsion, by adding bottom ORCs, have been examined. The analysis is based on the real operating data of a marine engine, considering the needs of its cooling system, and on the use of a realistic design/off-design simulator of the heat exchangers, available in Aspen®. In this way, realistic values of the actual performance increase of the propulsion system have been obtained.

Different possible bottom ORC configurations are simulated, and different working fluids are taken into account, jointly with regenerative and two-temperature levels designs, allowing the identification of the most suitable ORC configuration for reducing the fuel consumption of the propulsion system during its operation.

The main results of the study allow to conclude that Toluene confirm the well-match with the engine exhaust gases heat source, even if an intermediate circuit of thermal oil has to be added between exhaust gas and Toluene, because of its high flammability. On the other hand, Isobutene is better suited to be coupled with the HT circuit at about 90 °C and can be used, jointly with Toluene, in a double level bottom ORC. A regenerated cycle bottom ORC is expected to obtain a power increment of about 10%. In the case study, an additional power of 520 kW has been obtained.

A robust preliminary economic evaluation of the real operation of the ship engine has been performed on the basis of the recovered energy flows, showing a payback time equal to about 6 years, thanks to the fuel savings obtained as a result of greater efficiency. Finally, the ORC brings interesting benefits in terms of reducing atmospheric pollutant emissions of both carbon dioxide and nitrogen oxide.