Environmental Impacts Associated to Different Stages Spanning from Harvesting to Industrialization of Pineapple through Life Cycle Assessment

Abstract

1. Introduction

2. Materials and Methods

2.1. Definition of Objectives and Scope

2.2. Life Cycle Inventory

2.3. Life Cycle Impact Assessment

2.4. Interpretation of Life Cycle

3. LCA of Pineapple Cultivation and Processing

3.1. Objectives and Scope

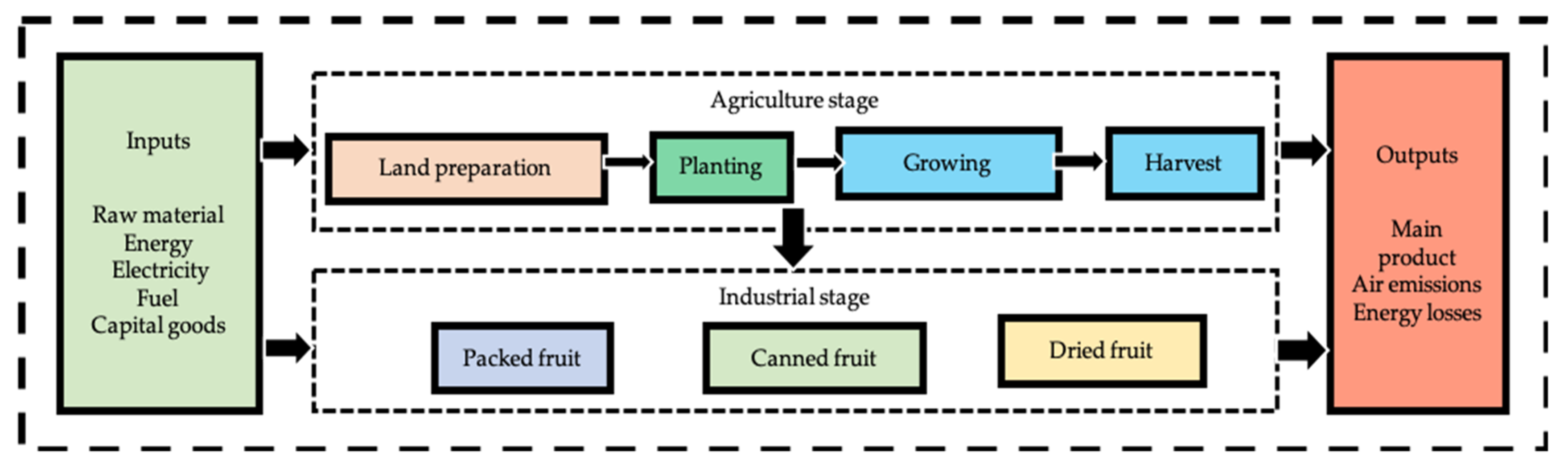

3.2. System Boundary Description

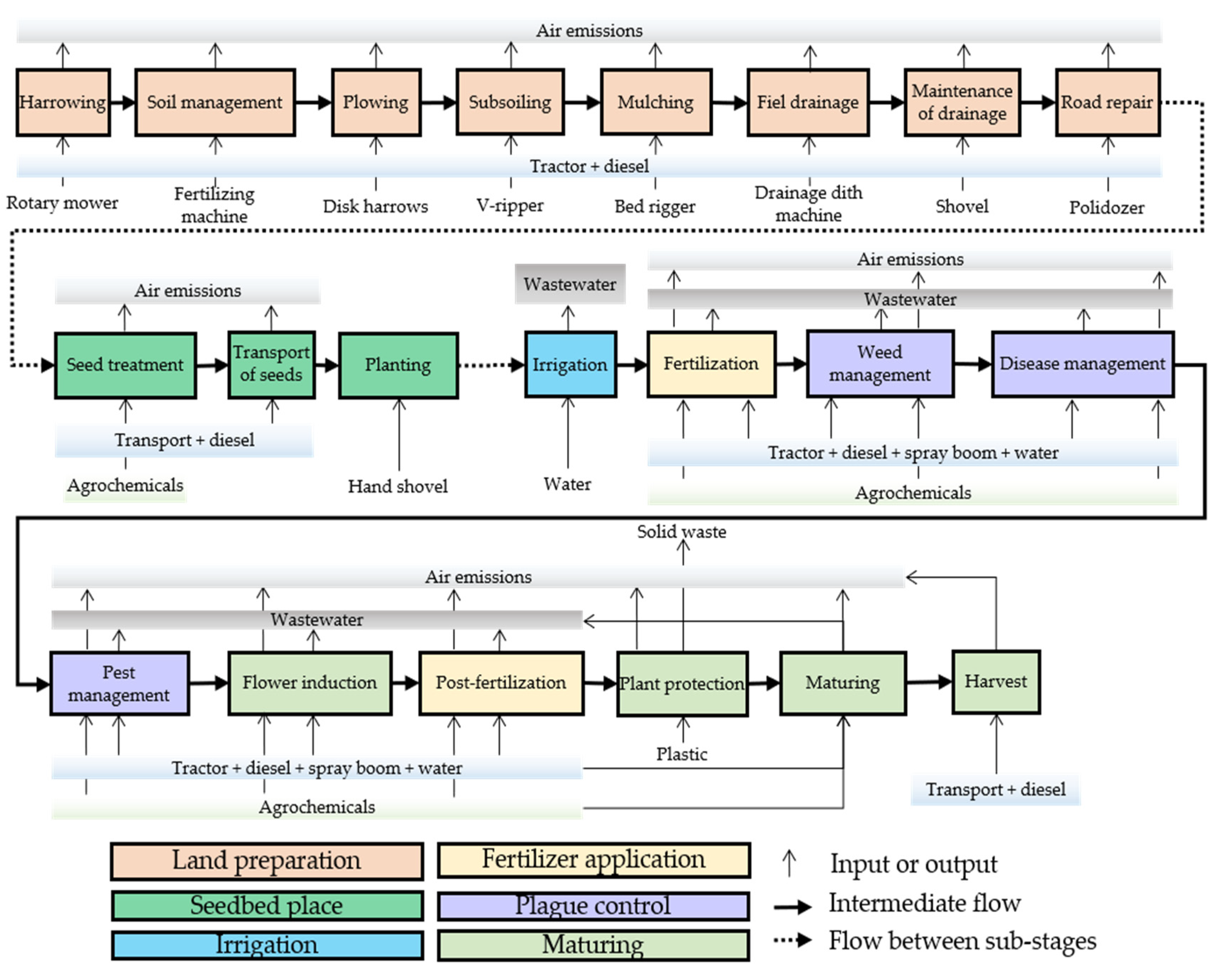

3.2.1. Agricultural Stage

3.2.2. Industrial Stage

3.3. Life Cycle Inventory

- EPG: electric power generation, GWh.

- PFS: primary fuel supplied, kg, L or m3.

- NCV: Net calorific value conversion factor, units according to the fuel supplied.

- η: net thermal efficiency from the overall cycle of electric power generation, fraction.

- PES: primary energy share, fraction.

- TPE: total primary energy for electric power generation (in the national grid), MJ

- FC: conversion factor, 1 GWh/3.6E+06MJ.

3.4. Life Cycle Impact Assessment

4. Results and Discussion

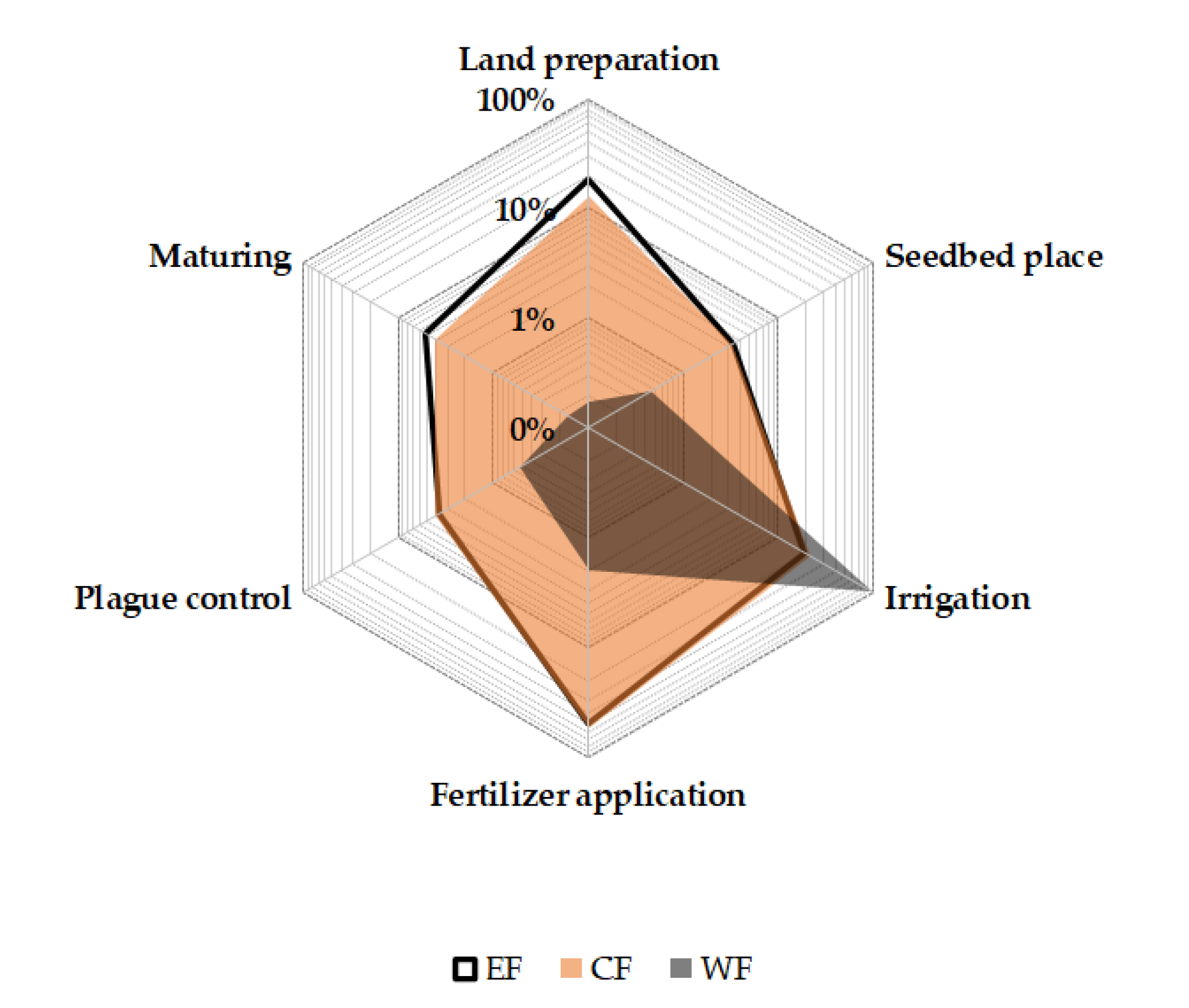

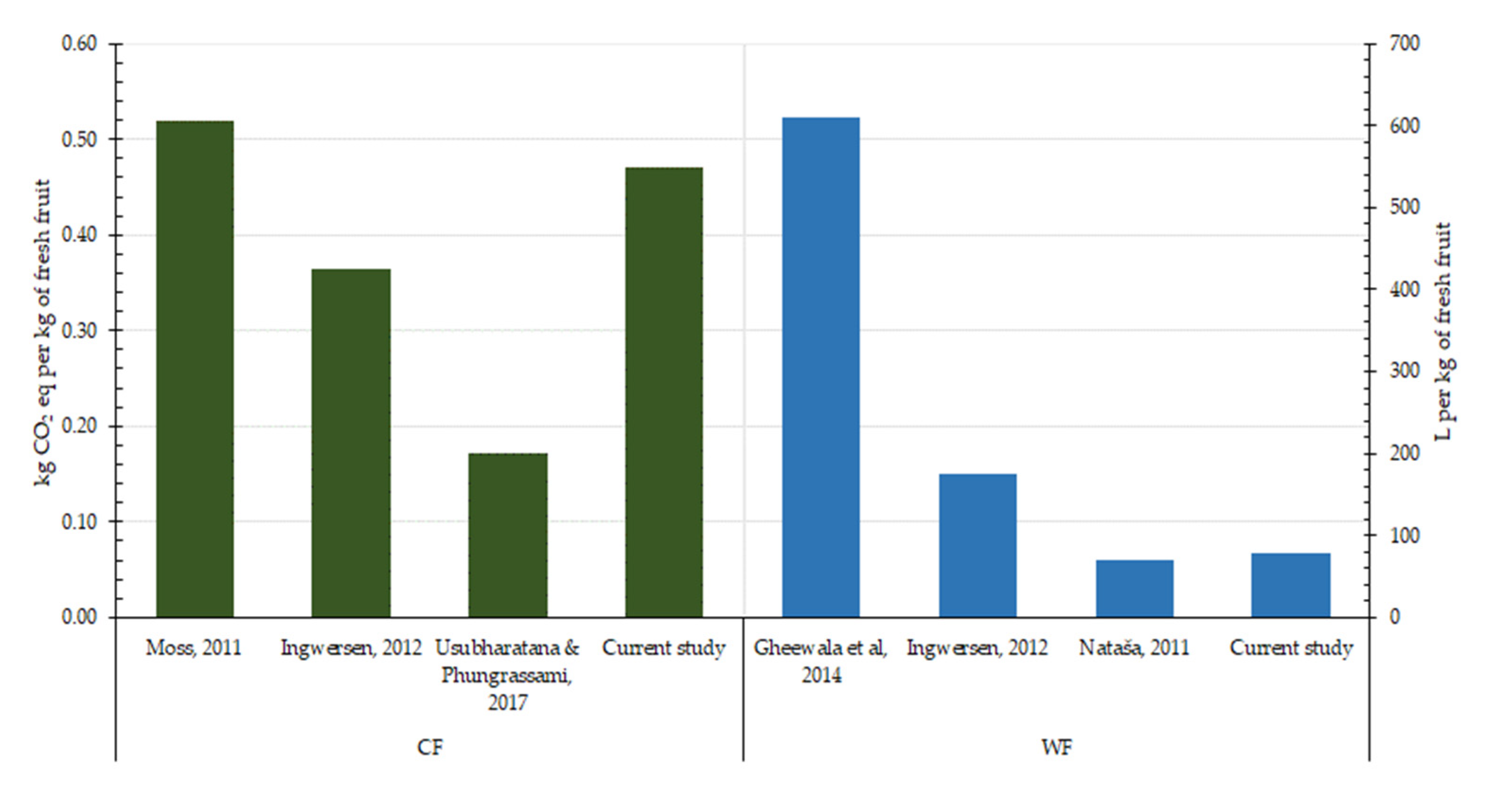

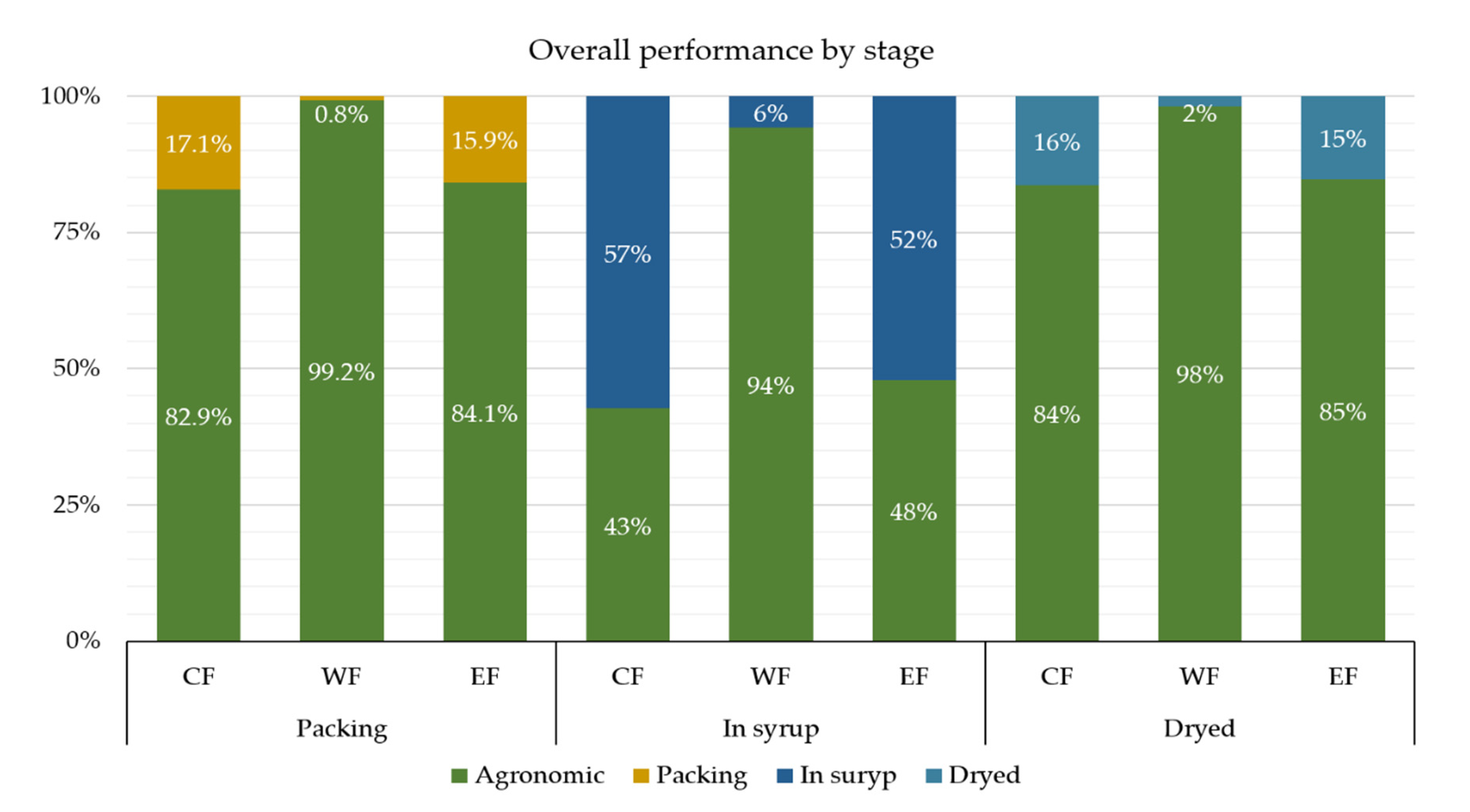

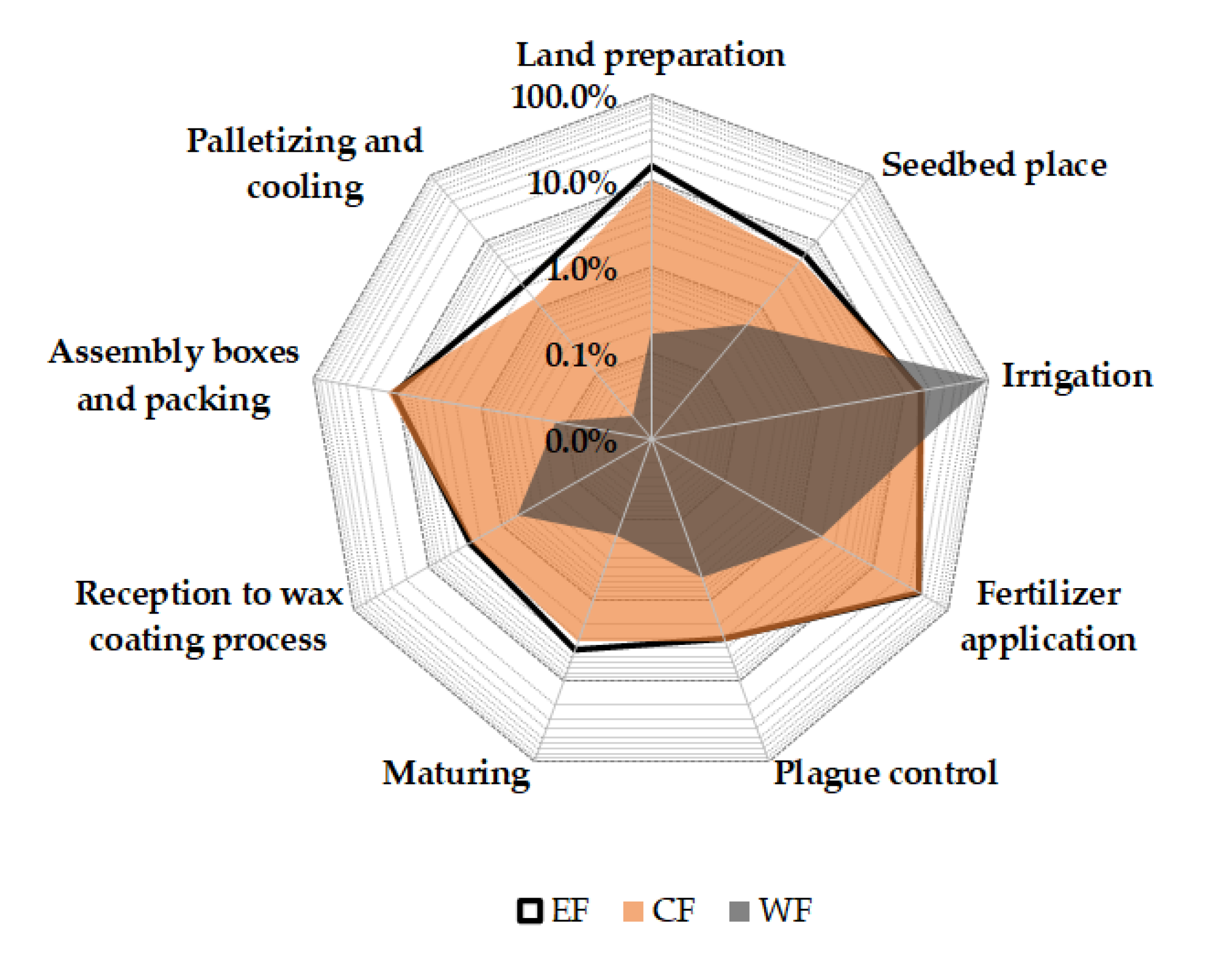

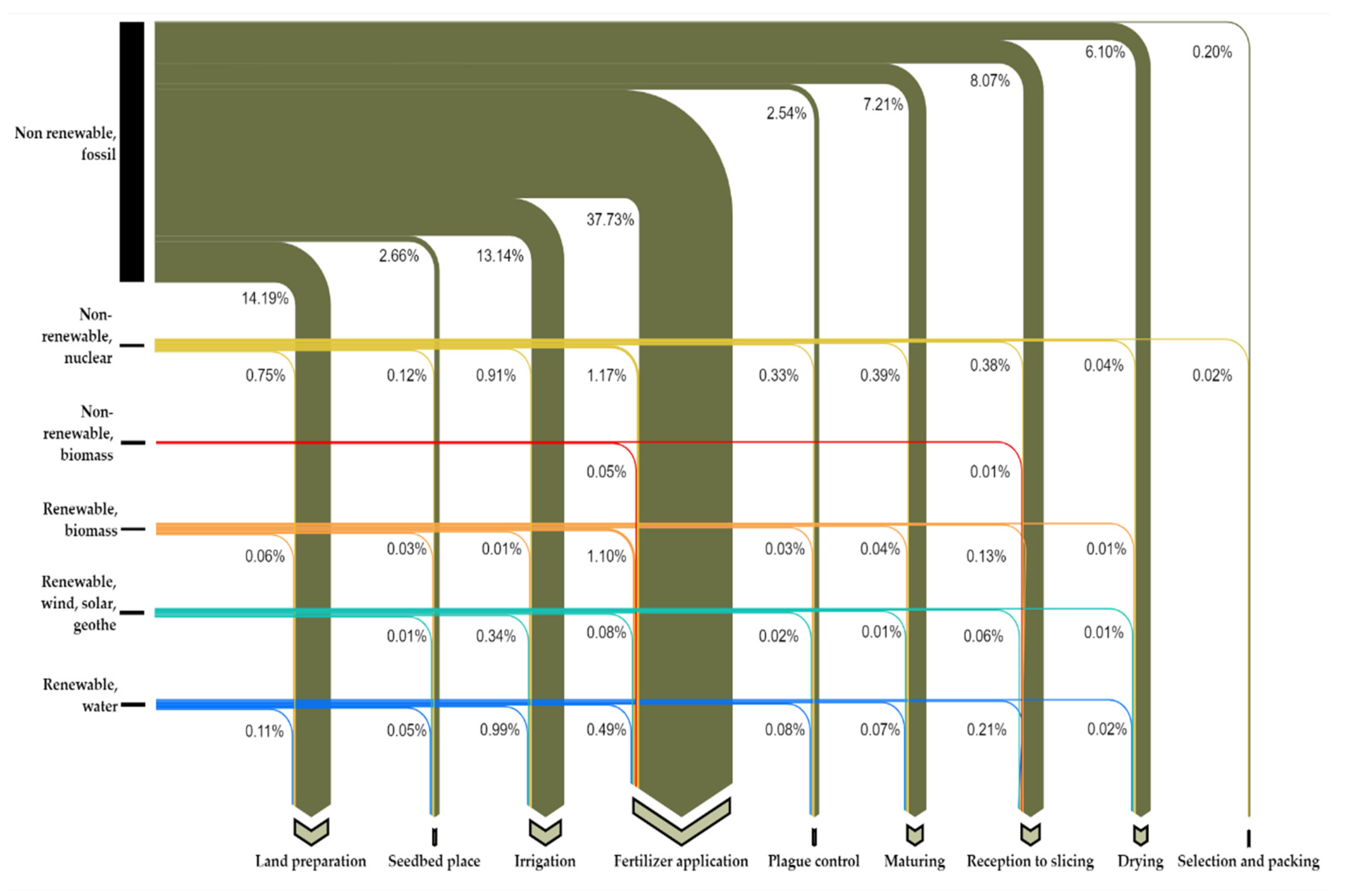

4.1. Agricultural Stage

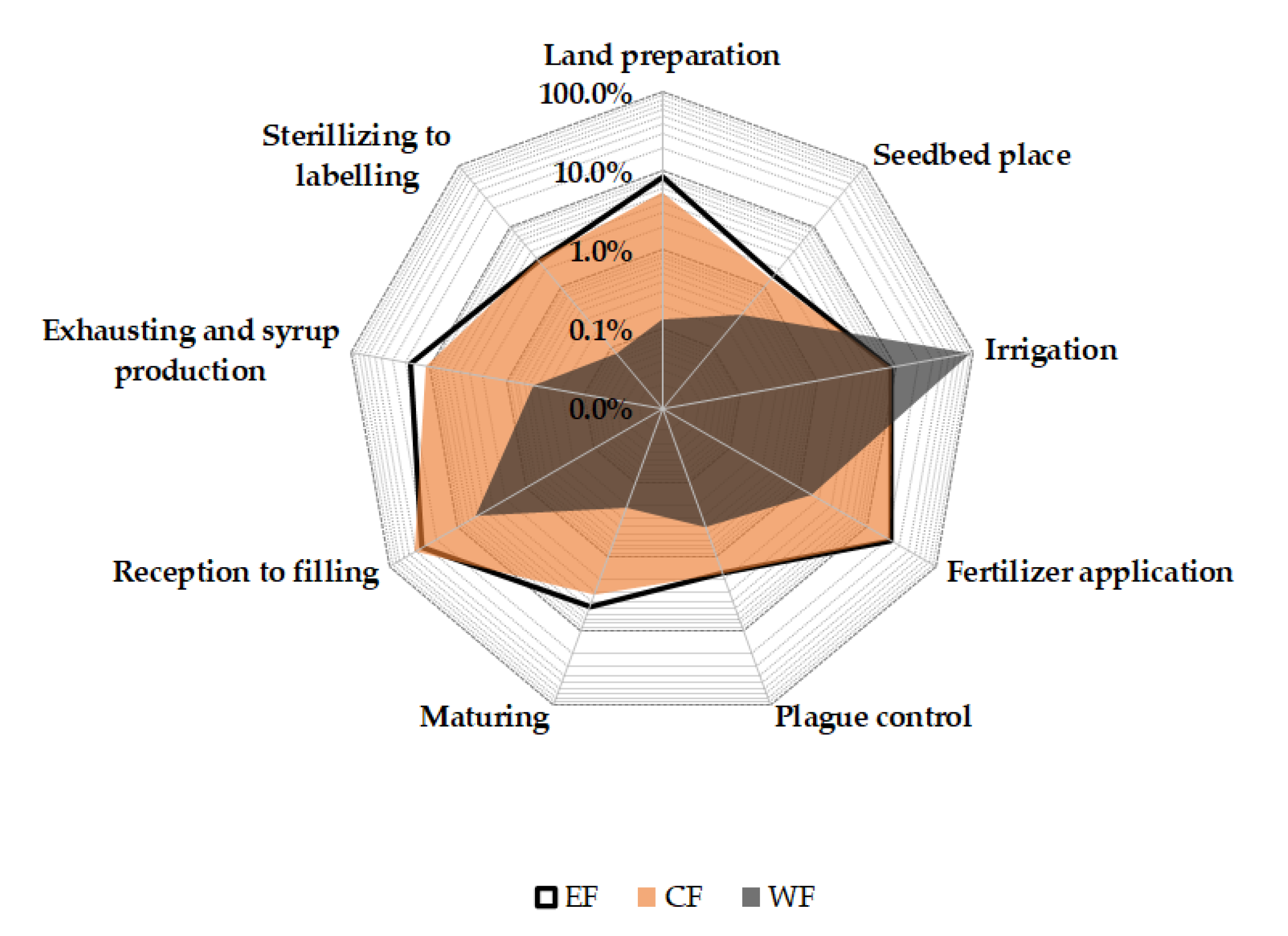

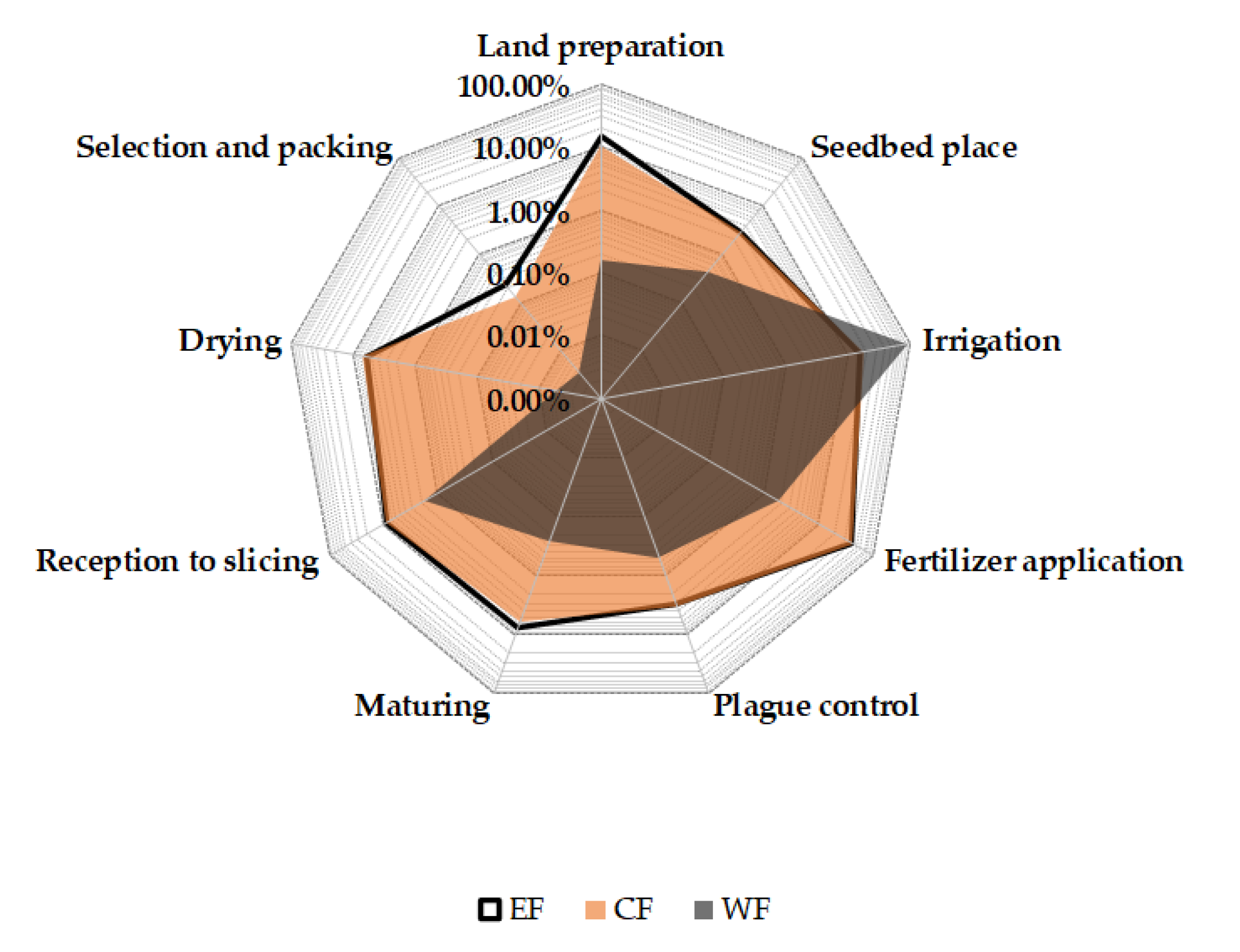

4.2. Pineapple Fruit Processing

4.2.1. Pineapple Packing Process

4.2.2. Pineapple Process in Syrup

4.2.3. Pineapple Dehydration Process

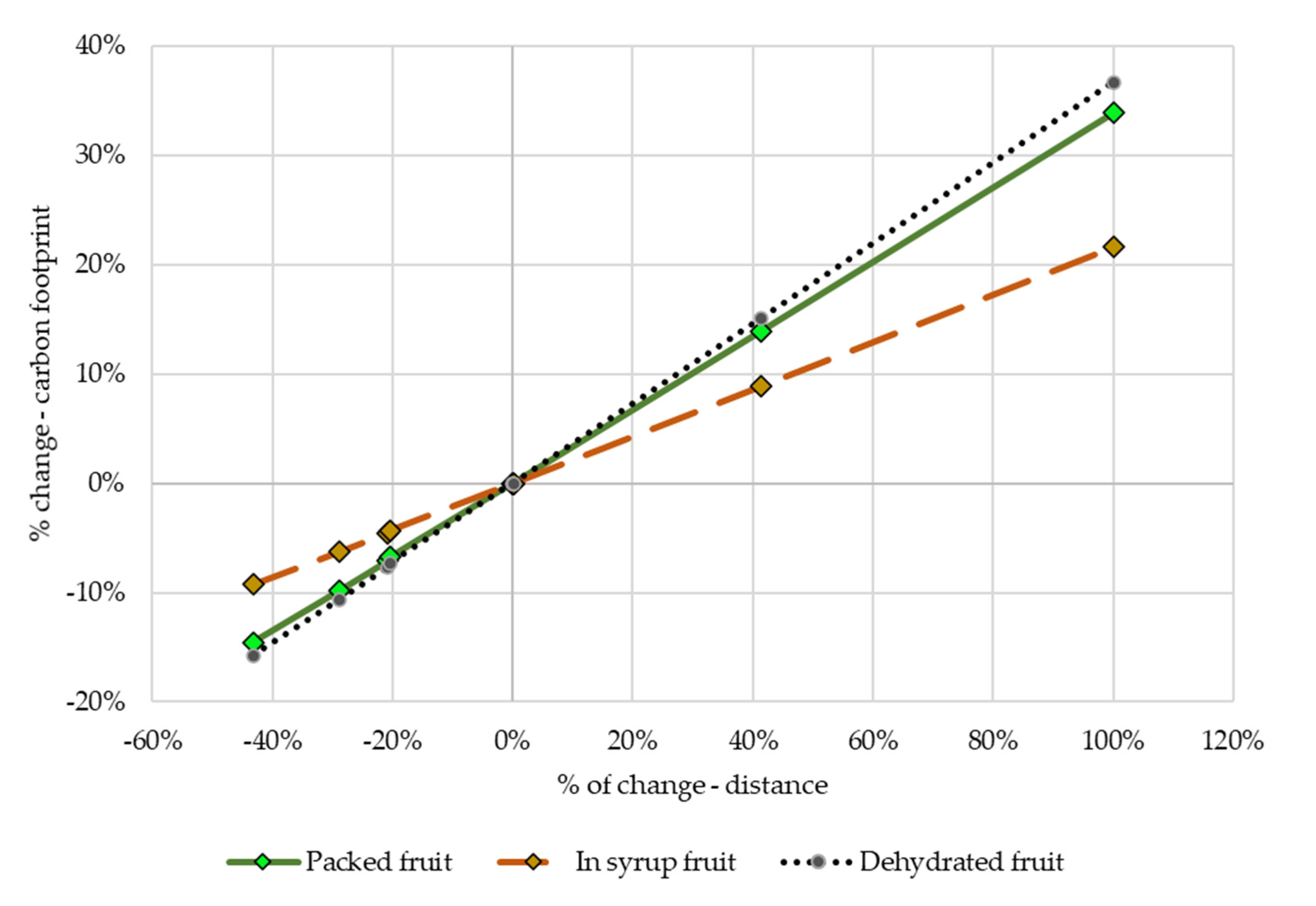

4.3. Sensitivity Analysis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Water for Sustainable Food and Agriculture: A Report Produced for the G20 Presidency of Germany; FAO: Rome, Italy, 2017.

- International Energy Agency CO2 Emissions from Fuel Combustion 2019; Organisation for Economic Co-Operation and Development (OECD): Paris, France, 2019.

- Pfister, S.; Bayer, P.; Koehler, A.; Hellweg, S. Projected water consumption in future global agriculture: Scenarios and related impacts. Sci. Total Environ. 2011, 409, 4206–4216. [Google Scholar] [CrossRef] [PubMed]

- Pfister, S.; Bayer, P. Monthly water stress: Spatially and temporally explicit consumptive water footprint of global crop production. J. Clean. Prod. 2014, 73, 52–62. [Google Scholar] [CrossRef]

- FAO; WWC. Towards a Water and Food Secure Future: Critical Perspectives for Policy-Makers; FAO & WWC: Roma, Italy, 2015. [Google Scholar]

- Pandey, D.; Agrawal, S.B. Carbon Footprint Estimation in the Agriculture Sector. In Sustainable Urban Logistics: Concepts, Methods and Information Systems; Springer: Singapore, 2014; Volume 1, pp. 25–47. [Google Scholar]

- Rebolledo-Leiva, R.; Meza, L.A.; Iriarte, A.; González-Araya, M.C. Joint carbon footprint assessment and data envelopment analysis for the reduction of greenhouse gas emissions in agriculture production. Sci. Total Environ. 2017, 593, 36–46. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Hellweg, S.; Frischknecht, R.; Hendriks, H.W.M.; Hungerbühler, K.; Hendriks, A.J. Cumulative Energy Demand As Predictor for the Environmental Burden of Commodity Production. Environ. Sci. Technol. 2010, 44, 2189–2196. [Google Scholar] [CrossRef] [PubMed]

- Puig, R.; Fullana-I-Palmer, P.; Baquero, G.; Riba, J.-R.; Gala, A.B. A Cumulative Energy Demand indicator (CED), life cycle based, for industrial waste management decision making. Waste Manag. 2013, 33, 2789–2797. [Google Scholar] [CrossRef]

- Jefferies, D.; Muñoz, I.; Hodges, J.; King, V.J.; Aldaya, M.M.; Ercin, A.E.; I Canals, L.M.; Hoekstra, A.Y. Water Footprint and Life Cycle Assessment as approaches to assess potential impacts of products on water consumption. Key learning points from pilot studies on tea and margarine. J. Clean. Prod. 2012, 33, 155–166. [Google Scholar] [CrossRef]

- D’Ambrosio, E.; De Girolamo, A.M.; Rulli, M.C. Assessing sustainability of agriculture through water footprint analysis and in-stream monitoring activities. J. Clean. Prod. 2018, 200, 454–470. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO 14044 Environmental Management-Life Cycle Assessment-Requirements and Guidelines. Available online: https://www.iso.org/obp/ui/#iso:std:iso:14044:ed-1:v1:es (accessed on 31 August 2020).

- Joy, P.P. Benefits and Uses of Pineapple. Available online: https://www.researchgate.net/profile/Pp_Joy/publication/306017037_Benefits_and_uses_of_pineapple/links/57aad02f08ae3765c3b63025/Benefits-and-uses-of-pineapple.pdf (accessed on 31 August 2020).

- Crops, Mexico, Pineapple, Official Data (2018). Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 31 August 2020).

- Piña Mexicana. Available online: https://www.gob.mx/cms/uploads/attachment/file/257084/Potencial-Pi_a.pdf (accessed on 15 May 2020).

- Crivelli, C. Análisis del Ciclo de Vida de dos sistemas de manejo para la producción de piña en México. Master’s Thesis, Universitat Politècnica de Catalunya. Departament d’Enginyeria Civil i Ambiental, Barcelona, Spain, 2017. [Google Scholar]

- Silvetti, F.; Cáceres, D. La expansión de monocultivos de exportación en Argentina y Costa Rica. In Conflictos Socioambientales y Lucha Campesina Por la Justicia Ambiental; Mundo Agrar: Córdoba, Argentina, 2015; p. 16. [Google Scholar]

- Usubharatana, P.; Phungrassami, H. Evaluation of Opportunities to Reduce the Carbon Footprint of Fresh and Canned Pineapple Processing in Central Thailand. Pol. J. Environ. Stud. 2017, 26, 1725–1735. [Google Scholar] [CrossRef]

- Frankowska, A.; Jeswani, H.K.; Azapagic, A. Life cycle environmental impacts of fruits consumption in the UK. J. Environ. Manag. 2019, 248, 109111. [Google Scholar] [CrossRef]

- Marius de Ramos, Q.R.; Toboada, E.B. Cradle-to-Gate Life Cycle Assessment of Fresh and Processed Pineapple in the Philippines. Nat. Environ. Poll. Tech. 2018, 17, 783–790. [Google Scholar]

- Ingwersen, W.W. Life cycle assessment of fresh pineapple from Costa Rica. J. Clean. Prod. 2012, 35, 152–163. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO 14040 Environmental Management-Life Cycle Assessment-Principles and Framework. Available online: https://www.iso.org/obp/ui#iso:std:iso:14040:ed-2:v1:es (accessed on 31 August 2020).

- Aguayo, F.; Peralta, M.E.; Lama, J.R.; Soltero, V.M. Ecodiseño Ingeniería Sostenible de la Cuna a la Tumba (C2C), 1st ed.; RC Libros: Madrid, Spain, 2011; pp. 65–85. [Google Scholar]

- Bribián, I.Z.; Aranda-Usón, A.; Scarpellini, S. Life cycle assessment in buildings: State-of-the-art and simplified LCA methodology as a complement for building certification. Build. Environ. 2009, 44, 2510–2520. [Google Scholar] [CrossRef]

- Besnier, A.; Bosque, F.; Farrant, L.; Labau, M.; Lempereur, V.; Penavayre, S. Analyse de cycle de vie de filières agro-alimentaires. Available online: https://www.vignevin.com/wp-content/uploads/2019/03/ACYDU_Synth%C3%A8seAcvEnviro.pdf (accessed on 28 August 2019).

- Fonction, Unité Fonctionnelle et flux de référence. Available online: http://stockage.univ-valenciennes.fr/MenetACVBAT20120704/acvbat/chap03/co/ch03_160_3-2-1.html (accessed on 3 April 2020).

- Haya, E. Análisis de Ciclo de Vida. Available online: https://www.eoi.es/es/file/66611/download?token=BTXaL249 (accessed on 3 April 2020).

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F. ReCiPe2016: A harmonized life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO 14067 Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification. Available online: https://www.iso.org/obp/ui#iso:std:iso:14067:ed-1:v1:es (accessed on 31 August 2019).

- Berger, M.; Van Der Ent, R.; Eisner, S.; Bach, V.; Finkbeiner, M. Water Accounting and Vulnerability Evaluation (WAVE): Considering Atmospheric Evaporation Recycling and the Risk of Freshwater Depletion in Water Footprinting. Environ. Sci. Technol. 2014, 48, 4521–4528. [Google Scholar] [CrossRef] [PubMed]

- International Organization for Standardization (ISO). ISO 14046 Environmental management—water footprint—Principles, requirements and guidelines. Available online: https://www.iso.org/obp/ui#iso:std:iso:14046:ed-1:v1:es (accessed on 31 August 2020).

- Análisis de Ciclo de Vida y Huella de Carbono. Available online: http://www.comunidadism.es/wp-content/uploads/downloads/2012/10/PUB-2009-033-f-C-001_analisis-ACV-y-huella-de-carbonoV2CAST.pdf (accessed on 13 May 2020).

- Life Cycle Environmental Impacts Study for Europe, Middle East and Africa (AMEA). Available online: https://www8.hp.com/h20195/v2/getpdf.aspx/c05876603.pdf (accessed on 20 May 2020).

- Stranddfort, H.K.; Hoffmann, L.; Schmidt, A. Impact Categories, Normalization and Weighting in LCA; Danish Ministry of the Environment: Odense, Denmark, 2005; pp. 77–79.

- Lovarelli, D.; Bacenetti, J.; Fiala, M. Water Footprint of crop productions: A review. Sci. Total Environ. 2016, 548, 236–251. [Google Scholar] [CrossRef]

- Bockel, L.T.; Jönsson, O.M. Carbon Footprinting Across the Food Value Chain: A New Profitable Low Carbon Initiative? A Review of the Main Benefits for Businesses, Public Bodies and Issues for Developing Countries; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2011. [Google Scholar]

- Hoesktra, A.Y.; Chapagain, A.K.; Aldaya, M.M.; Mekonnen, M.M. The Water Footprint Assessment Manual: Setting the Global Standard, 1st ed.; Earthscan: London, UK, 2011. [Google Scholar]

- Hischier, R.; Althaus, H.-J.; Doka, G.; Frischknecht, R.; Humbert, S.; Koellner, T.; Margni, M.; Weidema, B.P.; Bauer, C.; Dones, R.; et al. Implementation of Life Cycle Impact Assessment Methods, 3rd ed.; Swiss Centre for Life Cycle Inventories: St. Gallen, Switzerland, 2013. [Google Scholar]

- SENER (Secretaría de Energía). Balance Nacional de Energía 2018. Available online: https://www.gob.mx/cms/uploads/attachment/file/528054/Balance_Nacional_de_Energ_a_2018.pdf (accessed on 18 April 2020).

- International Energy Agency. World Energy Balances 2019; OECD Publishing: Paris, France, 2019. [Google Scholar]

- International Energy Agency. Electricity Information 2000; OECD Publishing: Paris, France, 2019. [Google Scholar]

- Secretaría de Energía (SENER). Programa de Desarrollo del Sistema Eléctrico Nacional 2018–2032. Available online: https://base.energia.gob.mx/prodesen/PRODESEN2018/PRODESEN18.pdf (accessed on 18 April 2020).

- Huijbregts, M.A.J.; Rombouts, L.J.A.; Hellweg, S.; Frischknecht, R.; Hendriks, A.J.; Van De Meent, D.; Ragas, A.M.J.; Reijnders, L.; Struijs, J. Is Cumulative Fossil Energy Demand a Useful Indicator for the Environmental Performance of Products? Environ. Sci. Technol. 2006, 40, 641–648. [Google Scholar] [CrossRef]

- Frischknecht, R.; Wyss, F.; Knöpfel, S.B.; Lützkendorf, T.; Balouktsi, M. Cumulative energy demand in LCA: The energy harvested approach. Int. J. Life Cycle Assess 2015, 20, 957–969. [Google Scholar] [CrossRef]

- Wiesen, K.; Wirges, M. From cumulated energy demand to cumulated raw material demand: The material footprint as a sum parameter in life cycle assessment. Energy Sustain. Soc. 2017, 7, 25. [Google Scholar] [CrossRef]

- Martínez, P.; Escudero, M.; Romero, A.; Hernández, A.; (Fieldwork in the Pineapple Farm Sector, Juan Rodriguez Clara, Veracruz, México). Personal communication, 2019.

- Buendía, L.; Domínguez, C.; Sánchez, O.; (Fieldwork in the Pineapple Industrial Sector, Juan Rodriguez Clara, Veracruz, México). Personal communication, 2019.

- Secretaría de Energía (SENER). Sistema de Información de Energía. Available online: http://sie.energia.gob.mx (accessed on 18 April 2020).

- Brogaard, L.K.; Christensen, T.H. Life cycle assessment of capital goods in waste management systems. Waste Manag. 2016, 56, 561–574. [Google Scholar] [CrossRef]

- D3.5 Report on the LCA of the Solution. Available online: http://www.digesmart.eu/documentos/D3.5%20Report%20on%20the%20life%20cycle%20assessment%20study%20of%20the%20solution_(public)_EN.pdf (accessed on 25 May 2020).

- Henry, B.; Ledgard, S.; Nebel, B.; Wiedemann, S. Guidelines for Conducting Life Cycle Assessment of the Environmental Performance of Wool Textiles, 1st ed.; International Wool Textile Organization: Brussels, Belgium, 2016. [Google Scholar]

- Cuadernillo municipal de Juan Rodríguez Clara, Ver 2019. Available online: http://ceieg.veracruz.gob.mx/wp-content/uploads/sites/21/2019/06/Juan-Rodr%C3%ADguez-Clara_2019.pdf (accessed on 19 August 2020).

- Ecoinvent Database. Available online: https://www.ecoinvent.org/database/database.html (accessed on 29 February 2020).

- Jeswani, H.K.; Azapagic, A. Water footprint: Methodologies and a case study for assessing the impacts of water use. J. Clean. Prod. 2011, 19, 1288–1299. [Google Scholar] [CrossRef]

- Nazri, A.M.; Pebrian, D.E. Analysis of Energy Consumption in Pineapple Cultivation in Malaysia: A Case Study Pertanika. J. Sci. Technol. 2017, 1, 17–28. [Google Scholar]

- Moss, R. Summary of Studies on Environmental Performance of Fresh Pineapple Produced in Ghana for Export to Europe 2011. Available online: https://www.twinn.com.au/pdf/C-footprint-of-pineapple-production-and-transport-WAFF.pdf (accessed on 31 August 2020).

- Nataša, S. Water Footprint Assessment Bananas and Pineapples; Soil & More International: Thousand Oaks, CA, USA, 2011. [Google Scholar]

- Gheewala, S.H.; Silalertruksa, T.; Nilsalab, P.; Mungkung, R.; Perret, S.R.; Chaiyawannakarn, N. Water Footprint and Impact of Water Consumption for Food, Feed, Fuel Crops Production in Thailand. Water 2014, 6, 1698–1718. [Google Scholar] [CrossRef]

- Rincón, L.E.; Becerra, L.A.; Moncada, J.; Cardona, C.A. Techno-Economic Analysis of the Use of Fired Cogeneration Systems Based on Sugar Cane Bagasse in South Eastern and Mid-Western Regions of Mexico. Waste Biomass-Valoriz. 2013, 5, 189–198. [Google Scholar] [CrossRef]

- García, C.A.; Fuentes, A.; Hennecke, A.; Riegelhaupt, E.; Manzini, F.; Masera, O. Life-cycle greenhouse gas emissions and energy balances of sugarcane ethanol production in Mexico. Appl. Energy 2011, 88, 2088–2097. [Google Scholar] [CrossRef]

- Aguilar-Rivera, N.; Rodríguez, D.; Enríquez, V.; Castillo, A.; Herrera, A. The Mexican Sugarcane Industry: Overview, Constraints, Current Status and Long-Term Trends. Sugar Tech 2012, 14, 207–222. [Google Scholar] [CrossRef]

- Alemán-Nava, G.S.; Casiano-Flores, V.H.; Cárdenas-Chávez, D.L.; Diaz-Chavez, R.; Scarlat, N.; Mahlknecht, J.; Dallemand, J.-F.; Parra-Saldivar, R. Renewable energy research progress in Mexico: A review. Renew. Sustain. Energy Rev. 2014, 32, 140–153. [Google Scholar] [CrossRef]

- Lozano-García, D.F.; Santibañez-Aguilar, J.E.; Lozano, F.J.; Flores-Tlacuahuac, A. GIS-based modeling of residual biomass availability for energy and production in Mexico. Renew. Sustain. Energy Rev. 2020, 120, 109610. [Google Scholar] [CrossRef]

- Honorato-Salazar, J.A.; Sadhukhan, J. Annual biomass variation of agriculture crops and forestry residues, and seasonality of crop residues for energy production in Mexico. Food Bioprod. Process. 2020, 119, 1–19. [Google Scholar] [CrossRef]

- Islam, S.; Ponnambalam, S.G.; Lam, H.L. A novel framework for analyzing the green value of food supply chain based on life cycle assessment. Clean Technol. Environ. Policy 2016, 19, 93–103. [Google Scholar] [CrossRef]

- Konieczny, P.; Dobrucka, R.; Mroczek, E. Using carbon footprint to evaluate environmental issues of food transportation. Int. J. Logist. Manag. 2013, 9, 3–10. [Google Scholar]

- Goodarzi, S.; Fahimnia, B.; Sarkis, J. Supply Chain Carbon Management; Institute of Transport and Logistics Studies: Sydney, Australia, 2019. [Google Scholar]

| Category | Description | Unit |

|---|---|---|

| Carbon footprint (CF) | It accounts for the GHG emission, which is expressed in kg CO2 eq., emitted throughout the supply chain for a product or service. It takes into account the production of raw material, transport, and transformation, up to the final disposal of the waste generated. | kg CO2 eq |

| Water footprint (WF) | The category that quantifies the volume of water consumed in all stages of production to manufacture a product. It includes the source and use of “freshwater”, “green water”, and “gray water”. It is represented according to the water resource available to the human population. | L |

| Energy footprint (EF) | Energy consumed in obtaining raw materials, manufacturing, distribution, use, and end of life of the analyzed element. It includes the direct energy used, as well as indirect energy. | MJ |

| Supplies | Energy Consumption by Source (%) | ||||||

|---|---|---|---|---|---|---|---|

| Coke | Diesel | Fuel Oil | LP Gas | Natural Gas | Biomass | Electricity | |

| Cans | 21.71 | 0.31 | 0.22 | 0.004 | 69.32 | - | 8.44 |

| Cardboard | - | 2.87 | 5.11 | 0.90 | 68.18 | - | 22.94 |

| Fertilizers and pesticides | - | 12.87 | - | - | 25.73 | - | 61.40 |

| Glue | 5.12 | 3.32 | 0.63 | 0.67 | 76.43 | - | 13.83 |

| Plastic and Wax | - | 21.23 | 2.73 | 0.20 | 57.59 | - | 18.25 |

| Sugar | - | 0.02 | 0.75 | - | - | 91.33 | 7.90 |

| Type of Energy | PFS (2018) | NCV Factor | PES b | η | PF c | EPG | |||

|---|---|---|---|---|---|---|---|---|---|

| % | % | % | GWh | % | |||||

| Natural gas | 15.6 × 109 | m3 | 38.13 | MJ/m3 | 40.48 | 38.6 | 56 | 63779 | 37.27 |

| Coal | 16.3 × 109 | kg | 19.43 | MJ/kg | 21.59 | 32.6 | 61 | 28680 | 16.76 |

| Fuel oil | 6.4 × 109 | L | 40.23 | MJ/L | 17.53 | 37.6 | 33 | 26892 | 15.71 |

| Diesel | 687.6 × 106 | L | 38.12 | MJ/L | 1.79 | 31.3 | 10 | 2279 | 1.33 |

| Uranium | 47.4 × 103 | kg | 3.29 | GJ/g | 10.63 | 31.5 | 77 | 13645 | 7.97 |

| Hydro-energy | 7.97 | 93.9 | 40 | 30496 | 17.82 | ||||

| Geothermal | 7.72 | 16.6 | 73 | 5222 | 3.05 | ||||

| Wind | 0.03 | 99.6 | 27 | 122 | 0.07 | ||||

| Solar (photovoltaic) | 0.003 | 99.2 | 16 | 12 | 0.007 | ||||

| Process | Flow | Quantity, kg | Price, USD/kg | Flow Value, USD | Allocation |

|---|---|---|---|---|---|

| Q1 or Q2 | P1 or P2 | Q1 × P1 | |||

| Packed pineapple | Accepted fruit | 1.00 | 0.23 | 0.23 | 0.968 |

| Rejected fruit | 0.08 | 0.10 | 0.008 | 0.032 | |

| Pineapples in syrup | Accepted fruit | 1.23 | 0.17 | 0.21 | 0.970 |

| Rejected fruit | 0.06 | 0.10 | 0.006 | 0.030 | |

| Dehydrated pineapple | Accepted fruit | 9.85 | 0.17 | 1.66 | 0.994 |

| Rejected fruit | 0.10 | 0.10 | 0.010 | 0.006 |

| Agricultural Stage (FU: 1 kg of Fresh Pineapple) | |||

|---|---|---|---|

| Sub-Stage | Material | Quantity | Unit |

| Nursery maintenance | Water | 1.94 × 10−1 | L |

| Transport | 3.82 × 10 | kgkm | |

| NPK | 4.09 × 10−4 | kg | |

| Pesticides | 7.06 × 10−5 | kg | |

| Land preparation | Diesel | 2.86 × 10−6 | kg |

| Machinery | 7.01 × 10−6 | kg | |

| Plastic | 1.79 × 10−2 | kg | |

| Sowing | Water | 1.47 × 10−2 | L |

| Transport | 9.88 × 10−1 | kgkm | |

| Pesticides | 9.82 × 10−5 | kg | |

| Plant growth | Water | 8.08 × 10 | L |

| Diesel | 6.32 × 10−7 | kg | |

| Transport | 8.82 × 102 | kgkm | |

| Machinery | 4.45 × 10−6 | kg | |

| NPK | 6.91 × 10−2 | kg | |

| Pesticides | 1.70 × 10−3 | kg | |

| Plastic | 3.34 × 10−3 | kg | |

| Steel | 1.79 × 10−3 | kg | |

| Industrial Stage (FU: 1 kg of Packed Pineapple) | |||

| Sub-Stage | Material | Quantity | Unit |

| Packaging | Cardboard | 8.04 × 10−2 | kg |

| Electric energy | 8.09 × 10−3 | kWh | |

| Wax | 5.51 × 10−4 | kg | |

| Water | 1.67 × 10−1 | L | |

| Industrial Stage (FU: 1 kg of in Syrup Pineapple) | |||

| In syrup | Cans | 1.78 × 10−1 | kg |

| Fuel oil | 3.17 | MJ | |

| Electric energy | 5.91 × 10−3 | kWh | |

| Sugar | 1.43 × 10−2 | kg | |

| Water | 4.55 × 10−1 | L | |

| Glue | 1.05 × 10−3 | kg | |

| Industrial Stage (FU: 1 kg of Dehydrated Pineapple) | |||

| Dehydrated | Water | 1.25 × 10−1 | L |

| Electric energy | 6.73 × 10−2 | kWh | |

| Plastic bags | 2.72 × 10−3 | kg | |

| L.P. Gas | 4.56 | MJ | |

| CF | WF | EF | |

|---|---|---|---|

| kg CO2 eq | L | MJ | |

| Agriculture stage (1 kg of fresh pineapple) | 0.47 | 78.60 | 9.09 |

| Packaging (1 kg of packed pineapple) | 0.58 | 82.28 | 11.03 |

| In Syrup (1 kg of in syrup pineapple) | 1.12 | 103.19 | 19.28 |

| Dehydrated (1 kg of dehydrated pineapple) | 5.12 | 782.66 | 97.04 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castillo-González, E.; Giraldi-Díaz, M.R.; De Medina-Salas, L.; Velásquez-De la Cruz, R. Environmental Impacts Associated to Different Stages Spanning from Harvesting to Industrialization of Pineapple through Life Cycle Assessment. Appl. Sci. 2020, 10, 7007. https://doi.org/10.3390/app10197007

Castillo-González E, Giraldi-Díaz MR, De Medina-Salas L, Velásquez-De la Cruz R. Environmental Impacts Associated to Different Stages Spanning from Harvesting to Industrialization of Pineapple through Life Cycle Assessment. Applied Sciences. 2020; 10(19):7007. https://doi.org/10.3390/app10197007

Chicago/Turabian StyleCastillo-González, Eduardo, Mario Rafael Giraldi-Díaz, Lorena De Medina-Salas, and Raúl Velásquez-De la Cruz. 2020. "Environmental Impacts Associated to Different Stages Spanning from Harvesting to Industrialization of Pineapple through Life Cycle Assessment" Applied Sciences 10, no. 19: 7007. https://doi.org/10.3390/app10197007

APA StyleCastillo-González, E., Giraldi-Díaz, M. R., De Medina-Salas, L., & Velásquez-De la Cruz, R. (2020). Environmental Impacts Associated to Different Stages Spanning from Harvesting to Industrialization of Pineapple through Life Cycle Assessment. Applied Sciences, 10(19), 7007. https://doi.org/10.3390/app10197007