Abstract

When B and V are added to CoFe material, the mechanical strength and spin tunneling polarization of a CoFe alloy can be improved and enhanced by the high tunneling magnetoresistance (TMR) ratio. Based on these reasons, it is worthwhile investigating Co40Fe40V10B10 films. In this work, X-ray diffraction (XRD) showed that Co40Fe40V10B10 thin films have some distinct phases including CoFe (110), CoFe (200), FeB (130), and V (110) diffracted peaks with the strongest diffracted peak for 30 nm. The lowest low-frequency alternate-current magnetic susceptibility (χac) was detected at 30 nm because the large grain distribution inducing that high coercivity (Hc) enhances the spin coupling strength and low χac. The external field (Hext) had difficulty rotating in the spin state, hence, the spin sensitivity was reduced and the χac value decreased due to increased surface roughness. The 20 mm thickness had the highest χac 1.96 × 10−2 value at 50 Hz of an optimal resonance frequency (fres). The surface energy increased from 34.2 mJ/mm2 to 51.5 mJ/mm2 for Co40Fe40V10B10 films. High surface energy had corresponding strong adhesive performance. According to the magnetic and surface energy results, the optimal thickness is 20 nm due as it had the highest χac and strong adhesion.

1. Introduction

The unique magnetic properties of CoFeB films have attracted wide attention in recent years [1,2,3,4,5,6,7,8]. In spin-valve magnetic tunneling junctions (MTJs), CoFeB thin films can be sputtered into free or pinned layers, resulting in apparent tunneling magnetoresistance (TMR), perpendicular magnetic anisotropy (PMA), and soft ferromagnetic properties. The films can be applied for magnetoresistance random access memory (MRAM) and sensor components [9,10,11,12,13,14,15]. According to these properties, CoFeB films can be used to many kinds of spintronic devices. In 2010, Ohno et al. found that the PMA of the CoFeB/MgO system can combine with the perpendicular MTJ and produce a tremendous TMR effect [16]. Therefore, increasing the thickness of the PMA CoFeB layer has become a very important goal in research. In previous research by our group, the Co40Fe40V20 film has been only studied with regard to its structural and magnetic properties [17]. CoFeV is also compatible with other seed layers or semiconductor processes to improve physical performance. For example, Ru/CoFeV and Ta/CoFeV can be useful in magnetics and semiconductor applications [18]. Adding B and V elements to the CoFe material has advantages. When V is added to the CoFe alloy, the mechanical strength and magnetic properties can be improved to a high durability of materials, which could increase its ductility and decrease its coercivity (Hc) and brittleness [19,20,21,22,23]. Adding B to the CoFe alloy can improve spin tunneling polarization and increase the high TMR ratio. Nevertheless, due to the low coercivity and high TMR properties of CoFeB films at room temperature (RT), most of the studies have focused on the CoFeB magnetic films [6,7,8]. According to above reasons, it is worthwhile investigating the specific properties of CoFeVB in this study where V was added to the CoFeB alloy to form a new Co40Fe40V10B10 material. Based on the magnetic and mechanical properties, the CoFeVB has low Hc and high strength, which can be suitable as a free layer of spin-value MTJ. CoFeVB is generally inserted as a seed layer, buffer layer, capping layer, and protective layer in a multilayered structure, which can be used extensively in MRAM and semiconductor applications. It is compatible with the semiconductor process and can also be used as a free or pinned layer in spin-value MTJ. Therefore, the surface energy and adhesion are relatively important in this investigation and it is a worthwhile cause to detect the structure, magnetic characteristics, and adhesive property.

2. Materials and Methods

Under the condition of 50 W power, CoFeVB was deposited on a Si(100) structure by the sputtering method, and the thickness of CoFeVB was 10–40 nm. The deposited temperature (Ts) of CoFeVB was maintained at RT. The power density was 1.09 W/cm2 and the deposition rate was 1.2 nm/min. The sputtering chamber was square, and the distance between target and substrate was about 15 cm. The substrate faced the target. The target composition of the CoFeVB alloy was 40 at% Co, 40 at% Fe, 10 at% V, and 10 at% B. The typical base chamber pressure was 1 × 10−7 Torr, and the Ar working chamber pressure was 2 × 10−3 Torr. The structure of the Co40Fe40V10B10 thin films was detected by X-ray diffraction (XRD) (Philips, Amsterdam, The Netherlands) of CuKα1 (Philips X’pert). The field emission scanning electron microscopy (FESEM) (JEOL, Tokyo, Japan) equipped with energy dispersive spectrometer (EDX) spectrometer was used for surface morphology and determination of the elemental composition of films. In addition, the in-plane low-frequency alternate-current magnetic susceptibility (χac) of Co40Fe40V10B10 was studied using a χac analyzer. The model, manufacturer, and country of manufacture of the χac analyzer were XacQuan, MagQu Co. Ltd. New Tapei City, and Taiwan, respectively. First, the χac analyzer with an external magnetic field was used to calibrate the reference standard sample. Then, the tested sample was inserted into the χac analyzer. The driving frequency was between 10 and 25,000 Hz. The χac was determined by magnetization measurement. All tested samples had the same shape and size to eliminate demagnetization factors. The χac valve is an arbitrary unit (a.u.), because the alternating current result corresponds to the reference standard sample and is a comparative value. The χac analyzer measured the relationship between susceptibility and frequency. The optimal resonance frequency (fres) is measured by the χac analyzer, which represents the frequency of the maximum χac. The surface roughness and morphology of CoFeVB films were studied by atomic force microscopy (AFM) (NT-MDT, Moscow, Russia). The in-plane hysteresis loop of the Co40Fe40V10B10 films was obtained by alternating gradient magnetometer (AGM) (PMC, Ohio, USA). Finally, using deionized (DI) water and glycerol as the experimental liquids, the surface energy of the Co40Fe40V10B10 thin films was calculated by measuring the contact angle [24,25,26], which is defined as the surface excess free energy of a specific crystal surface area [27].

3. Results

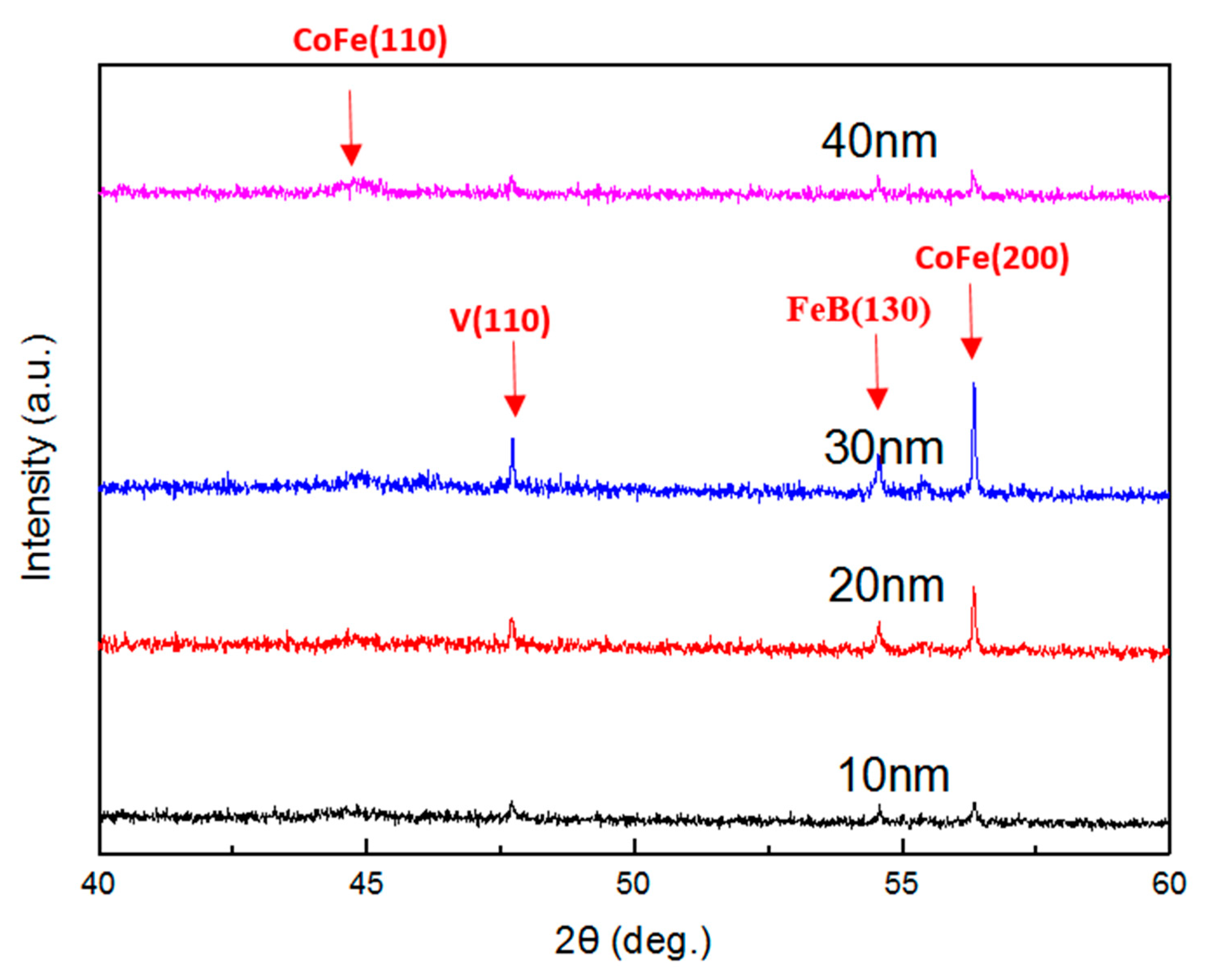

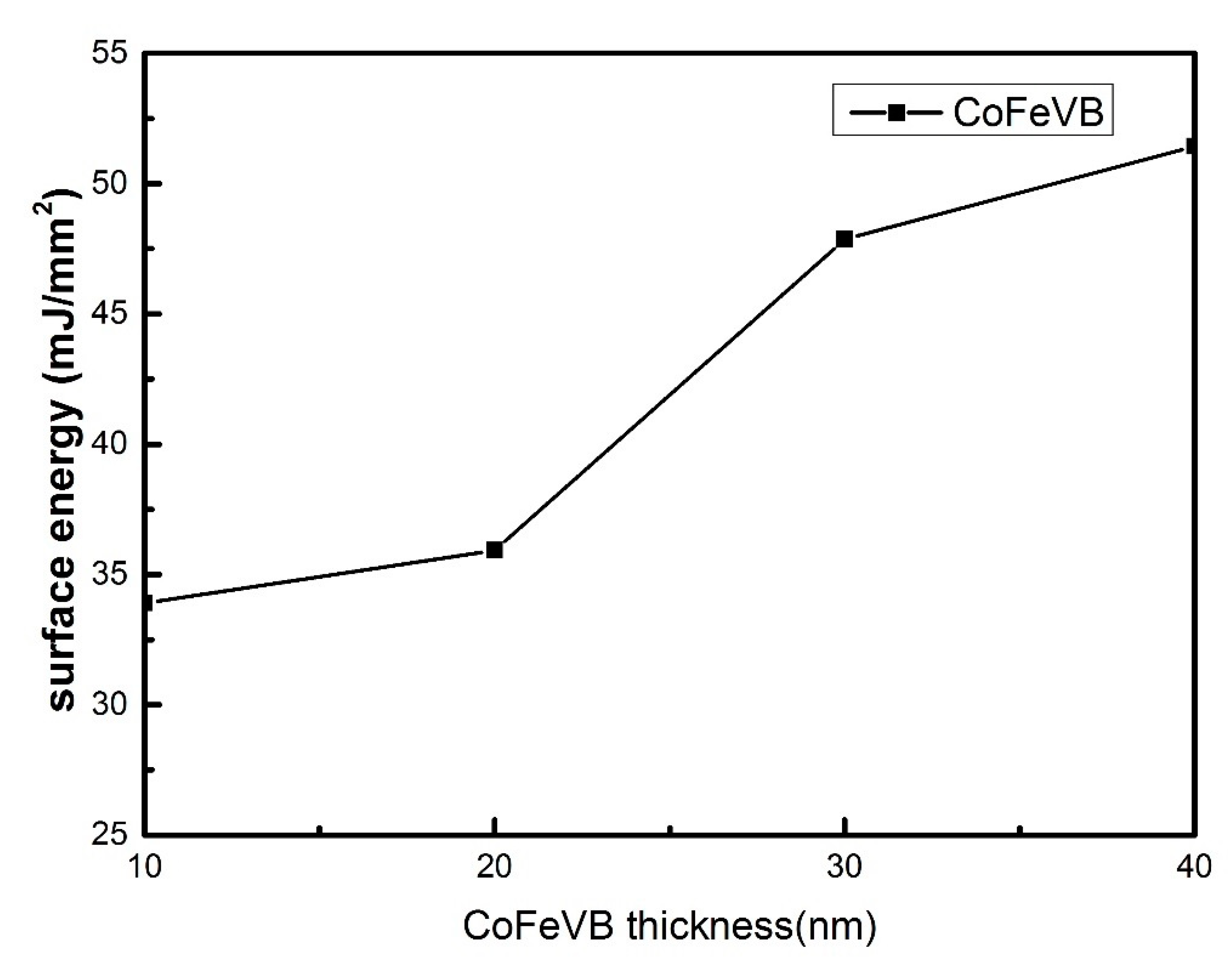

The X-ray diffraction (XRD) patterns are displayed in Figure 1. From the results in Figure 1, the Co40Fe40V10B10 demonstrated diffracted peaks in all Co40Fe40V10B10 thin films, indicating that there are distinct phases including CoFe (110) at about 2θ with 46°, V (110) at 2θ with 48°, FeB (130) at 2θ with about 54°, and the signal CoFe (200) at 2θ with 57°. The XRD intensities increased from 10 nm up to 30 nm and then drastically decreased for the 40 nm film. It can be reasonably concluded that the 40 nm is not a homogeneous and discontinuous film, thus inducing a weak crystalline peak. Apparently, a distinct high crystalline XRD peak occurred at 30 nm. According to Scherrer’s formula (1), the average grain size (D) can be estimated by measuring the full width of the half-height width (FWHM, B) of the 30-nm diffraction peak. Scherrer’s formula is [28,29],

where k (0.89) is Scherrer’s constant; λ is the X-ray wavelength of the Cu Kα1 line; B is the FWHM of the 30-nm diffraction peak; and θ is the half angle of the diffraction peak. This formula shows that D is proportional to 1/B, so the smaller B corresponds to larger grains. The 30 nm of the Co40Fe40V10B10 thin film has a smaller B and can induce larger grains to be deposited.

D = kλ/Bcosθ

Figure 1.

X-ray diffraction patterns of the Co40Fe40V10B10 films.

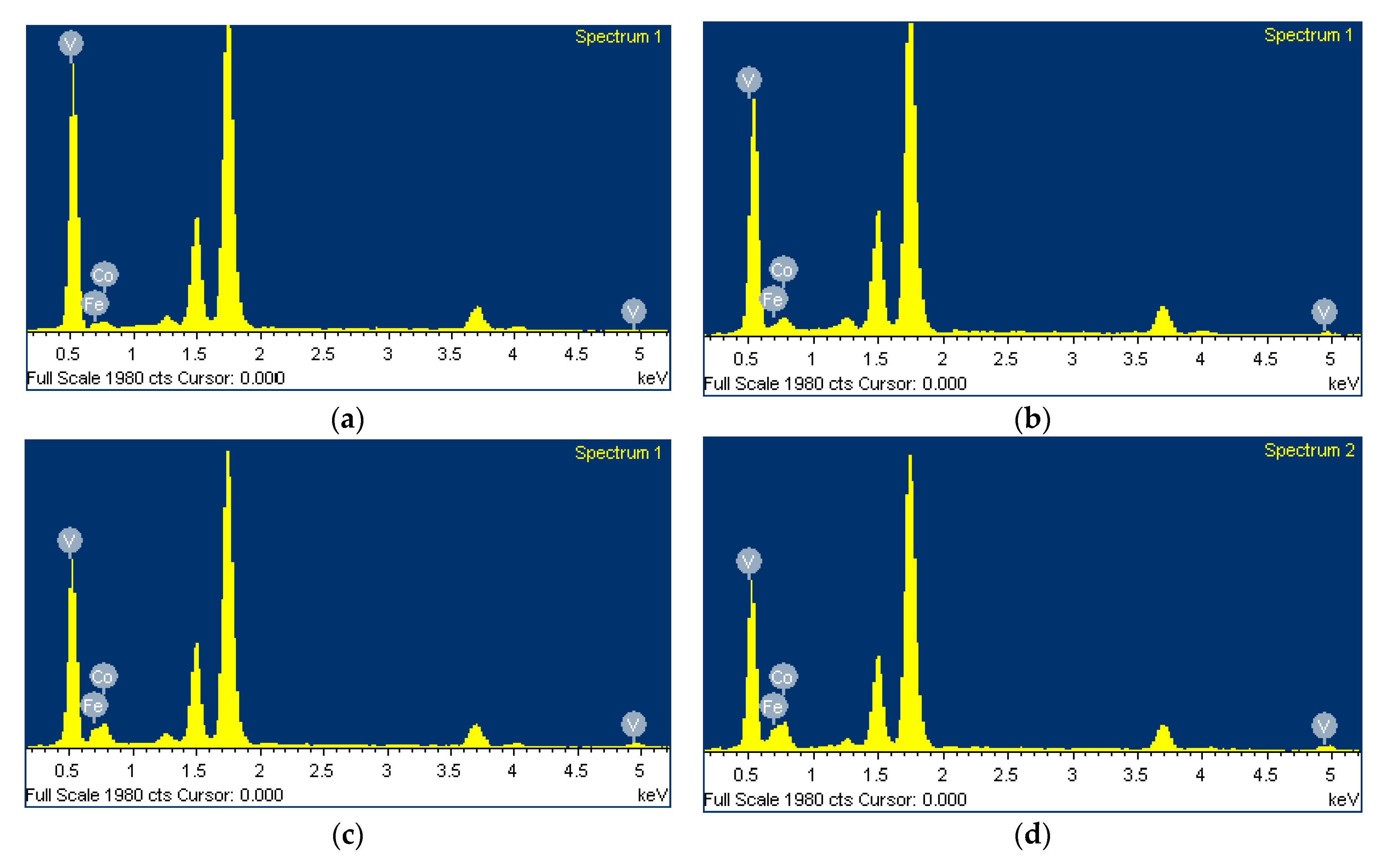

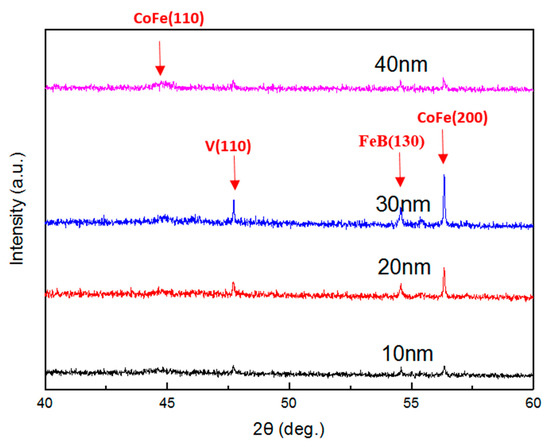

The composition of the CoFeVB alloy films was determined. The composition data for CoFeVB films by FESEM equipped with an EDX spectrometer was shown in Table 1. The corresponding EDX patterns of the Co40Fe40V10B10 films are shown in Figure 2. However, the B content could not be measured in the EDX measurement, because the boron atom is too light. According to the result, it was found that the 40 nm film was not a homogeneous composition. Non-uniform composition is caused by the multi-directional and multi-angle scattering of the sputtered atoms [30,31].

Table 1.

EDX analysis data for the alloy films.

Figure 2.

EDX patterns of the Co40Fe40V10B10 thin films with various thicknesses. (a) 10 nm, (b) 20 nm, (c) 30 nm, and (d) 40 nm.

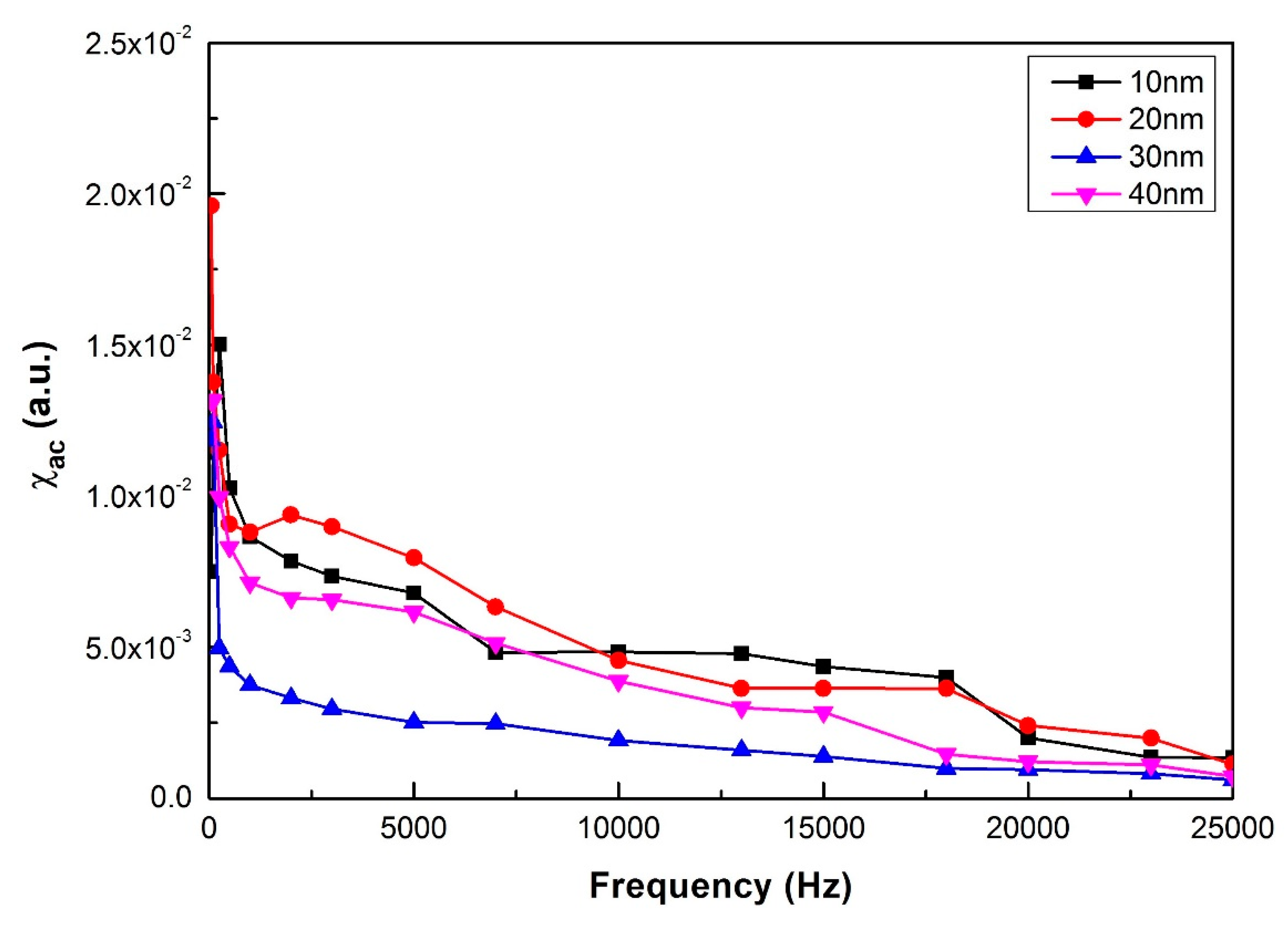

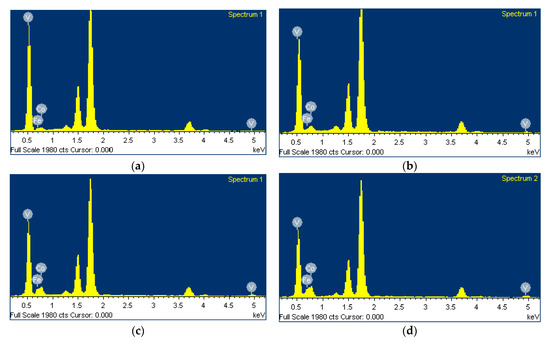

Figure 3 presents the low-frequency alternate-current magnetic susceptibility (χac) results in the CoFeVB films. When the thickness increased from 10 nm to 40 nm, χac decreased sharply with the increase in frequency. According to Equation (2) [29,32,33,34,35],

where Pc is the order constant of unity; D is the grain size; K1 is the magneto-crystalline anisotropy; μ0 is the free space permeability; Ms is the saturation magnetization; A is the exchange stiffness constant; and Hc is the coercivity. By Equation (2), it can be reasonably concluded that Hc is proportional to crystalline grain size D6 and demonstrates that large grain size distribution has a higher Hc. The lowest χac was detected at 30 nm due to the large grain distribution and high coercivity, which enhanced the spin coupling strength [17,36,37]. The range of the external field (Hext) used was not sufficient to rotate the spin state, consequently, the spin sensitivity was reduced and the χac value was decreased.

Hc = PcD6K14/μ0MsA3,

Figure 3.

For samples with a thickness of 10 nm to 40 nm, the low-frequency alternate-current magnetic susceptibility (χac) as a function of the frequency from 10 to 25,000 Hz.

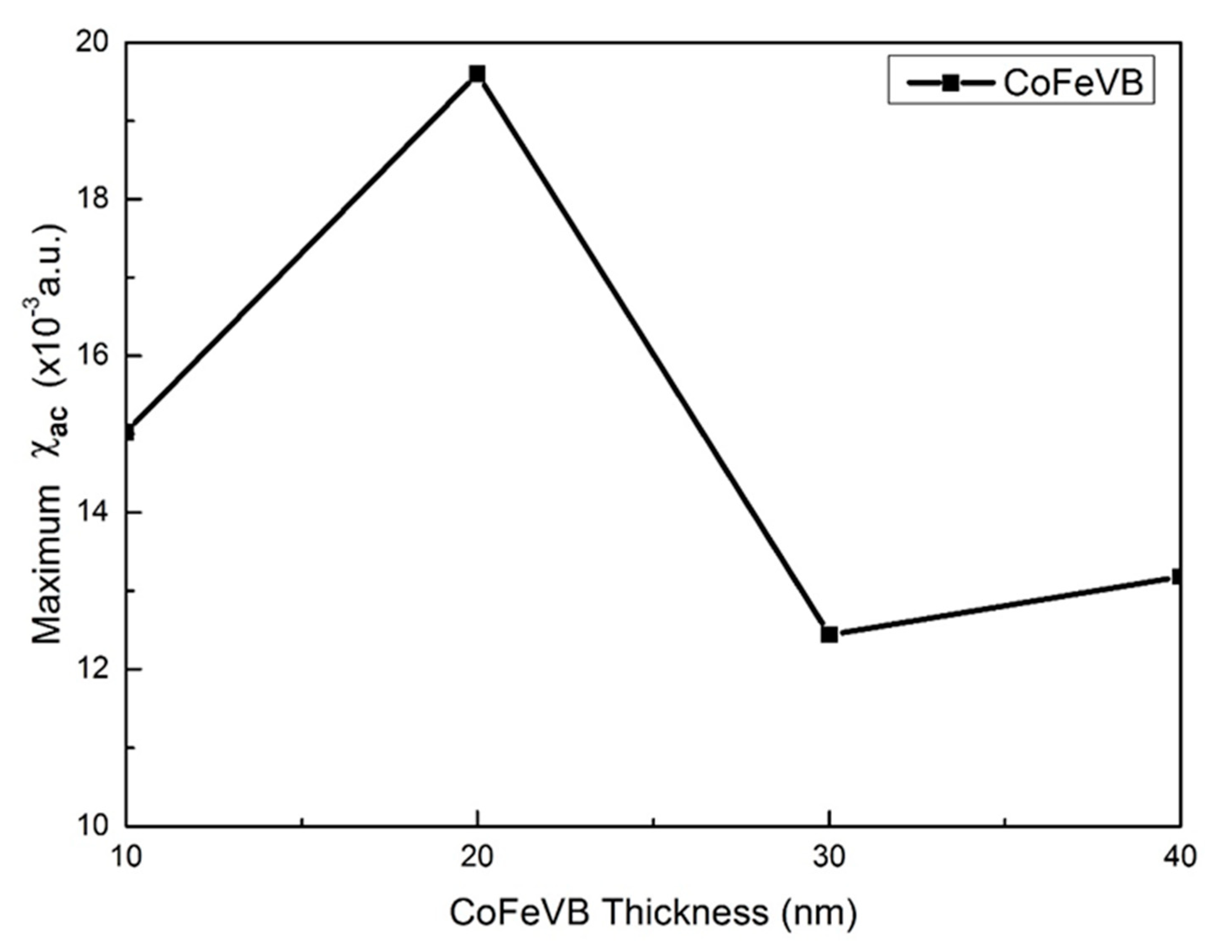

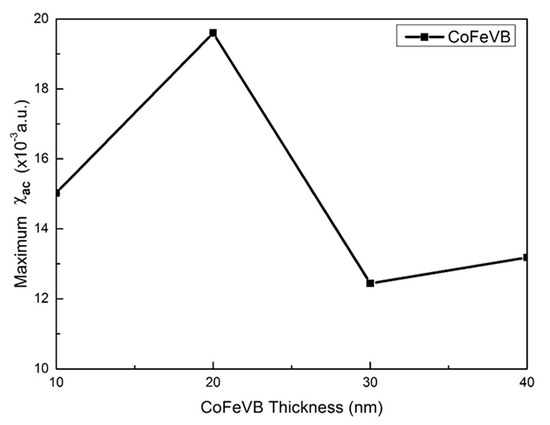

Figure 4 shows the maximum χac value associated with the thickness of the CoFeVB. For CoFeVB films with a thickness of 20 mm, the maximum χac value of 1.96 × 10−2 was obtained. When the thickness increased from 10 to 20 nm, the maximum χac was increased from 1.5 × 10−2 to 1.96× 10−2. In addition, the maximum χac decreased from 1.96 × 10−2 to 1.31 × 10−2 as the thickness ranged from 20 to 40 nm. The results show that the spin sensitivity is the strongest at the optimal resonance frequency (fres). The maximum χac at the optimal resonance frequency has the following physical significance. At low frequencies, the alternating-current dipole moment is caused by the oscillation of the volume dipole moment in each domain. The external alternating current magnetic field plays a driving role. The recovery of magnetic interaction is between domains. There is a resonance frequency as the driving force acting on the system. Therefore, the peak frequency of the low frequency susceptibility corresponds to the resonance frequency of the magnetic dipole moment oscillation in the domain. At frequency, the χac peak represents the spin exchange coupling interaction and domain dipole moment [38]. As shown in Figure 4, the best magnetic properties were achieved on the CoFeVB film with a thickness of 20 nm.

Figure 4.

Maximum alternate-current magnetic susceptibility for the CoFeVB films.

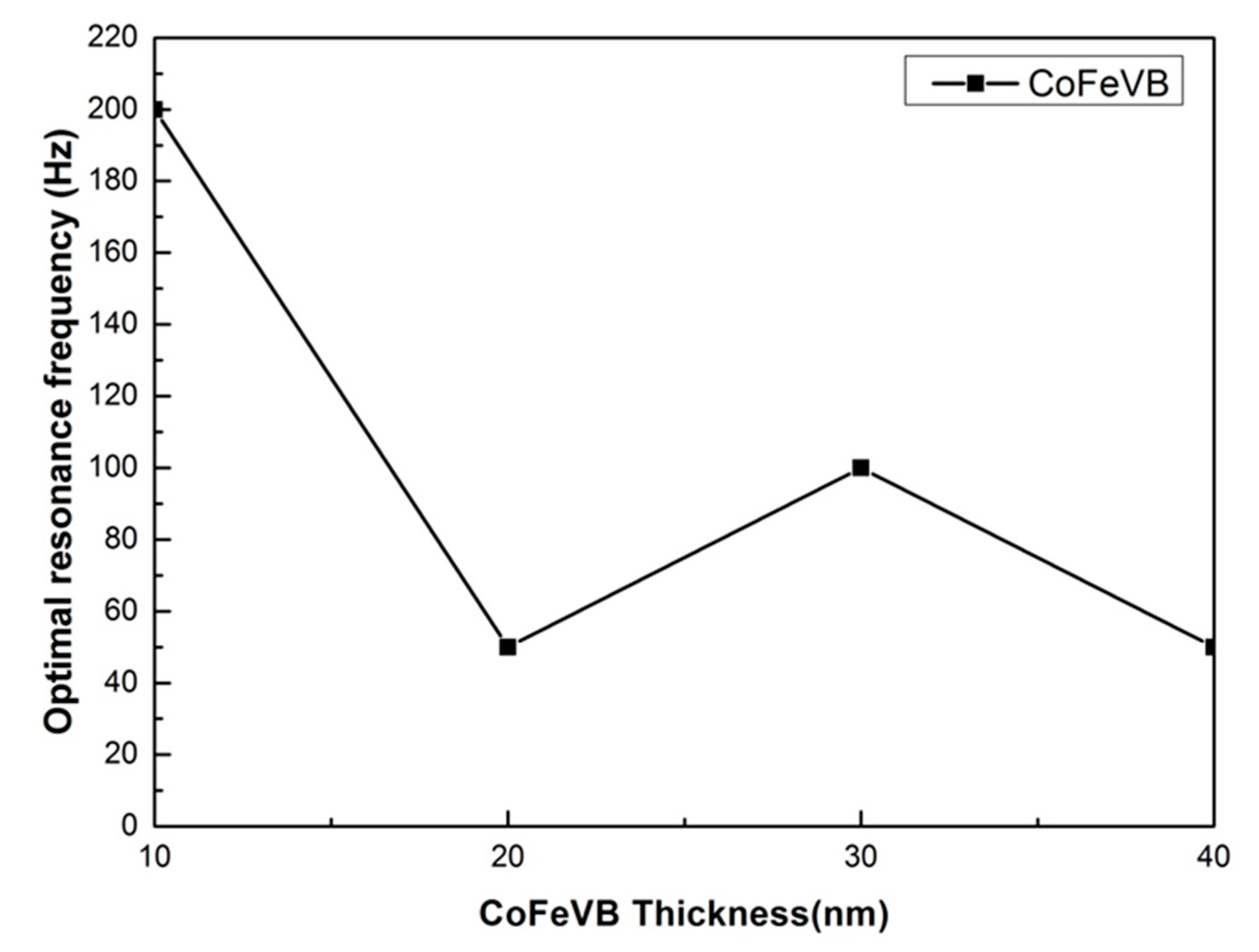

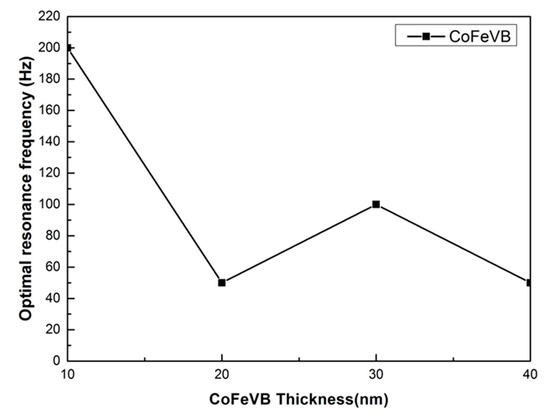

The optimal resonance frequency of CoFeVB films is shown in Figure 5. According to the fres value, the maximum χac value is measured with the strongest spin sensitivity at this frequency [38,39]. The fres presented an oscillating trend with a minimum critical frequency of 50 Hz. For all CoFeVB thicknesses, the fres value of all CoFeVB thicknesses was less than 200 Hz, which indicates that the films are beneficial to the application of sensors, transformers, and magnetic recording media at low frequencies.

Figure 5.

Optimal resonance frequency for films of various thicknesses.

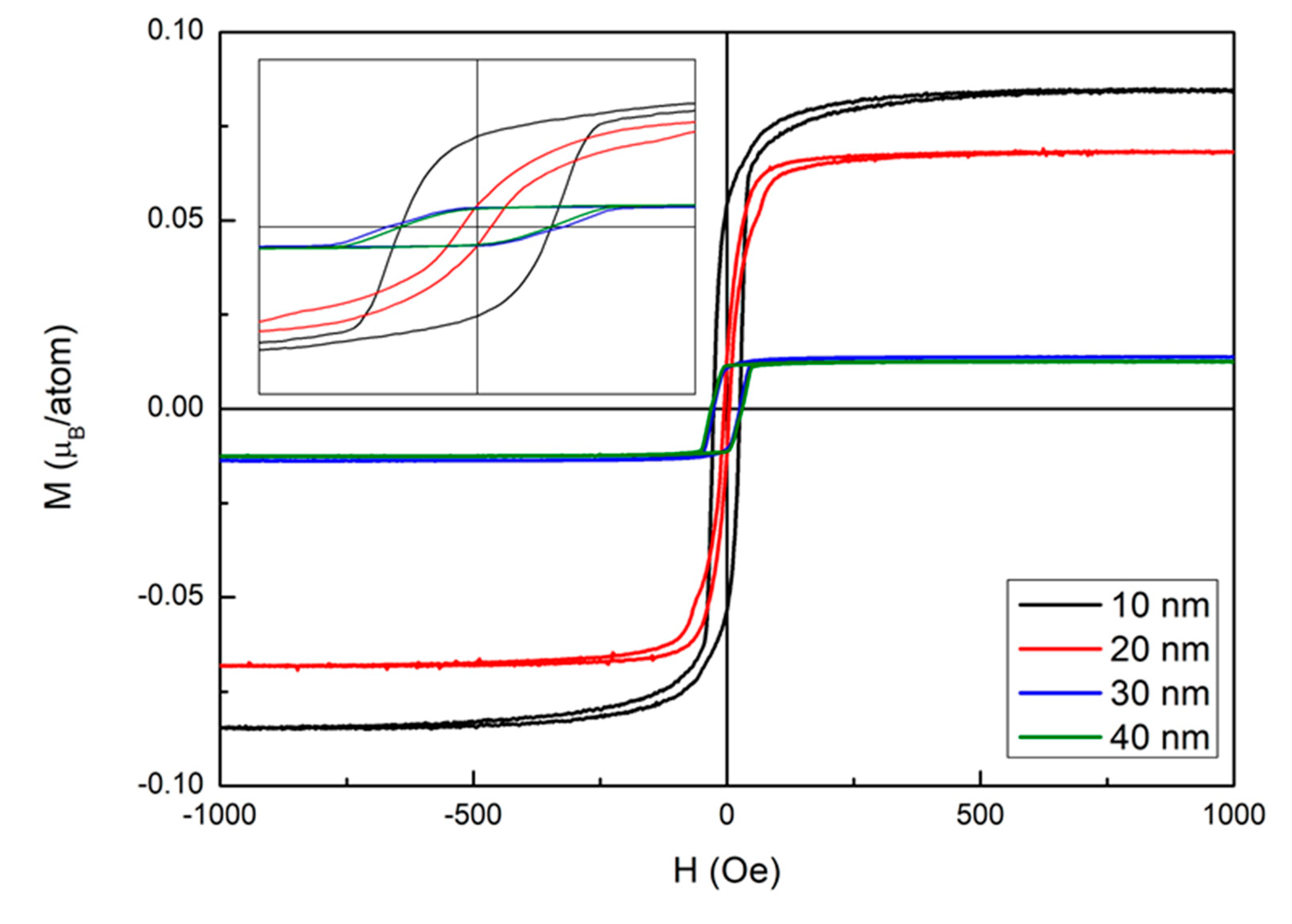

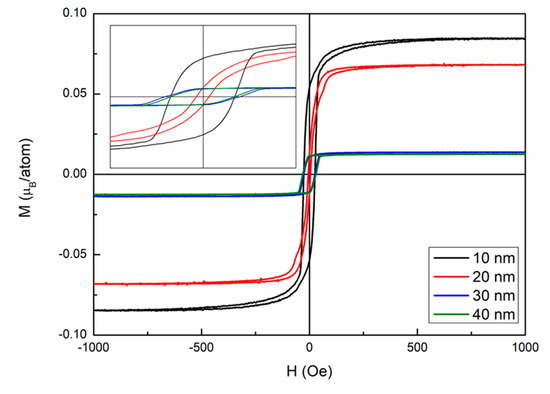

Figure 6 shows the hysteresis loop of the films with an in-plane external field (Hext) for various CoFeVB thicknesses, as determined through AGM. The external field (Hext) was 1000 Oe in the AGM measurement, which was enough to observe the saturated magnetic spin status of the Co40Fe40V10B10 films. While the magnetization for the 10 nm and 20 nm films was very close to each other, the magnetization for the 30 nm and 40 nm was lower. It can be reasonably concluded that the 40 nm film was not homogeneous and was a discontinuous film, inducing weak magnetization. Table 1, which presents the EDX analysis, also indicates that the 40 nm film was not a homogeneous composition. The enlarged illustration of Figure 6 shows that the largest Hc was achieved at 30 nm. The external field (Hext) used had difficulty rotating the spin state, consequently reducing the magnetization and decreasing the χac value. From Figure 6, the results indicate that the in-plane hysteresis loop of the CoFeVB films was an easy axis. Moreover, the hysteresis loops also indicate that the CoFeVB films are magnetically soft.

Figure 6.

In-plane magnetic hysteresis loop of the Co40Fe40V10B10 thin films.

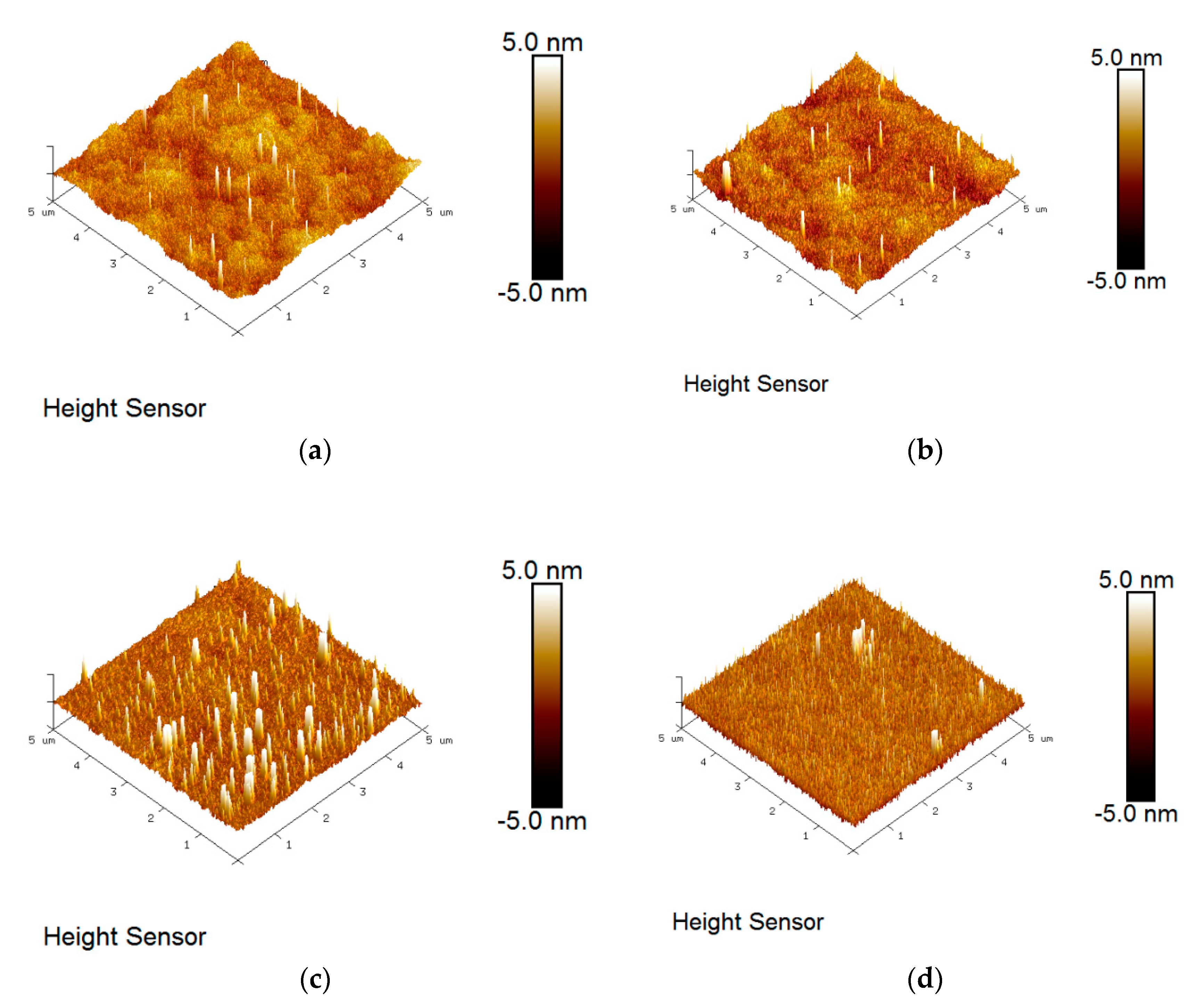

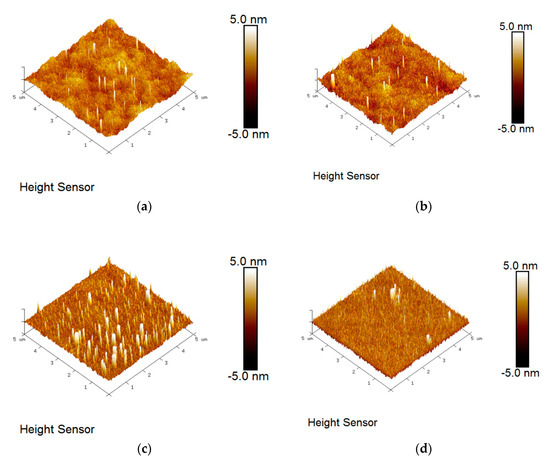

The surface roughness and morphology of the CoFeVB films were investigated by AFM, as shown in Figure 7a–d. When the thickness was increased from 10 nm to 40 nm, the root-mean-square values (Rq) of surface roughness were 0.57 nm, 0.39 nm, 1.07 nm, and 0.69 nm, respectively. The increased surface roughness can lead to the pinning effect of the domain wall, which is not easy to move, resulting in an increase in coercivity and a decrease in the χac value [40,41]. In Figure 4 and Figure 7, the maximum alternate-current magnetic susceptibility and surface roughness had a relation, which indicates that the increased surface roughness can lead to the pinning effect of the domain wall, which has difficulty moving, resulting in the increase in coercivity and the decrease in the χac value.

Figure 7.

AFM 3D images showing different surface roughness of the Co40Fe40V10B10 thin films with various thicknesses: (a) 10 nm, (b) 20 nm, (c) 30 nm, and (d) 40 nm.

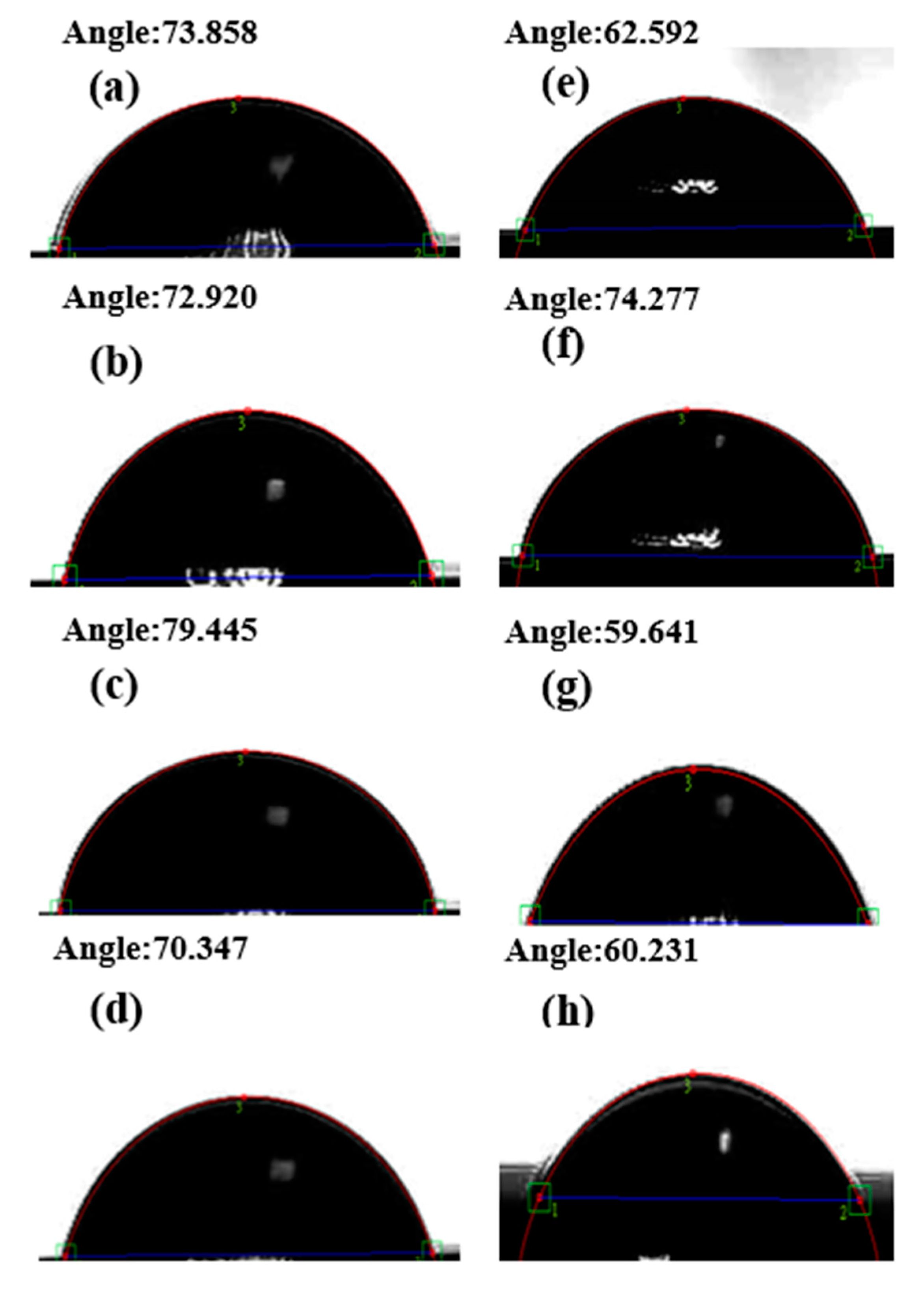

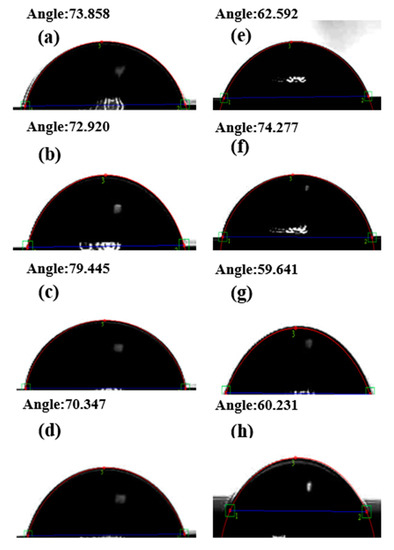

Figure 8a–d showed the contact angles (θ) with DI water: 73.85°, 72.92°, 79.44°, and 70.34° for the 10, 20, 30, and 40 nm films, respectively. Figure 8e–h shows the contact angles (θ) with glycerol as 62.59°, 74.27°, 59.64°, and 60.23° for 10, 20, 30, and 40 nm films, respectively. The contact angle results from DI water and glycerin are shown in Figure 8. The CoFeVB films can be used as a seed or buffer layer, so the surface energy and adhesion are very important. The results show that the water drops of CoFeVB film are almost spherical. The contact angles of the Co40Fe40V10B10 film were less than 90°, which indicates that the film has a good wetting effect and is hydrophilic. When the surface free energy is high, the liquid absorption is large and the liquid absorption area is also large, which leads to the decrease in contact angle [24,25,42].

Figure 8.

Contact angles of the Co40Fe40V10B10 thin films with DI water: (a) 10 nm, (b) 20 nm, (c) 30 nm, and (d) 40 nm. Contact angles of the Co40Fe40V10B10 thin films with glycerol: (e) 10 nm, (f) 20 nm, (g) 30 nm, and (h) 40 nm.

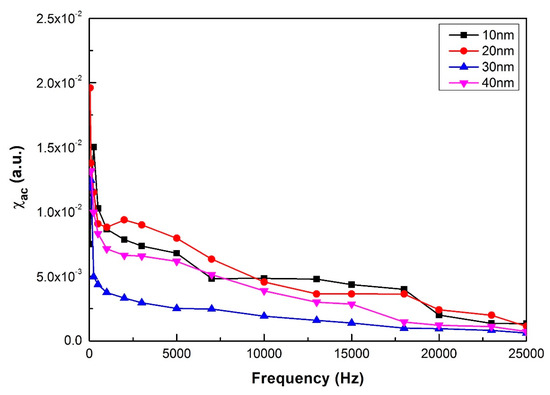

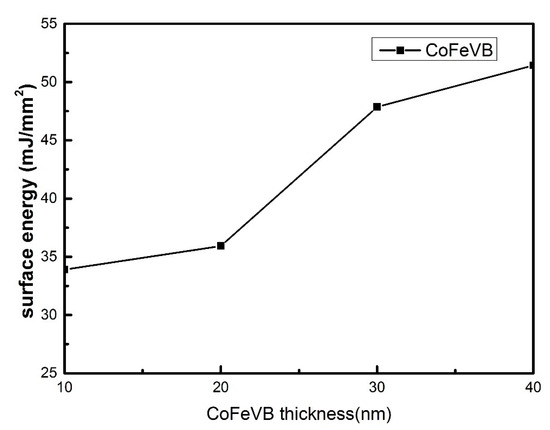

The surface energy of the Co40Fe40V10B10 films was obtained by measured contact angles, as shown in Figure 9 [24,25,26,27,28,29,32]. High surface energy corresponds to strong adhesion [43]. It was found that the surface energy tended to increase with the increase in thickness. Figure 9 shows that when the thickness increased from 10 nm to 40 nm, the surface energy range increased from 34.2 mJ/mm2 to 51.5 mJ/mm2, which indicates that the surface energy is larger and the adhesion is enhanced. The surface energy is the key factor affecting the adhesion of the film. As CoFeVB is compatible with MTJ applications, it can also be used as a free layer and in combination with other layers.

Figure 9.

Surface energy results for the Co40Fe40V10B10 films.

4. Conclusions

XRD demonstrated that a high significant crystalline peak was achieved at 30 nm because it could be reasonably concluded that it had a large grain distribution. As the frequency increased, the χac decreased sharply. The lowest χac was detected at 30 nm due to the large grain distribution inducing high coercivity, resulting in an enhanced spin coupling strength. The increased surface roughness could be the induced domain wall pinning effect and also indicated the same tendency. The range of the external field used was not sufficient to rotate the spin state, consequently reducing the spin sensitivity and decreasing the χac value. The results showed that the maximum 1.96 × 10−2 amplitude was obtained at a fres of 50 Hz for the 20 nm film. The contact angles of the Co40Fe40V10B10 thin films were less than 90°, which indicates that the films are hydrophilic. The surface energy is closely related to the adhesion of the film. When the thickness increased from 10 to 40 nm, the surface energy changed from 34.2 mJ/mm2 to 51.5 mJ/mm2, indicating that the larger the surface energy, the stronger the adhesion. It can be seen that the surface energy tends to increase with an increase in the thickness. The magnetic properties and surface energy efficiency showed that the optimal thickness of the Co40Fe40V10B10 film was 20 nm, which had the highest χac value and strong adhesion.

Author Contributions

Conceptualization, S.-L.O. and Y.-T.C.; Methodology, Y.-T.C., W.-H.L., Y.-T.W., T.-H.W., and P.-W.C.; Validation, formal analysis, Y.-H.C. and J.-Y.T.; Investigation, Y.-T.C. and W.-J.L.; Resources, C.-L.C.; Writing—original draft preparation, Y.-T.C.; Writing—review and editing, Y.-T.C. and S.-L.O.; Supervision, Y.-T.C. and S.-L.O.; Project administration, Y.-T.C. and Y.-T.W.; Funding acquisition, W.-J.L. and Y.-H.C. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Ministry of Science and Technology (grant No. MOST108-2221-E-224-015-MY3 and MOST105-2112-M-224-001), and the National Yunlin University of Science and Technology (grant No. 109T01).

Conflicts of Interest

The authors declare that there are no conflict of interest regarding the publication of this paper. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Ohshima, N.; Sato, H.; Kanai, S.; Llandro, J.; Fukami, S.; Matsukura, F.; Ohno, H. Current-induced magnetization switching in a nano-scale CoFeB-MgO magnetic tunnel junction under in-plane magnetic field. AIP Adv. 2017, 7, 055927. [Google Scholar] [CrossRef]

- Siripongsakul, T.; Naganuma, H.; Kovacs, A.; Kohn, A.; Oogane, M.; Ando, Y. Observation of single-spin transport in an island-shaped CoFeB double magnetic tunnel junction prepared by magnetron sputtering. Philos. Mag. 2016, 96, 310–319. [Google Scholar] [CrossRef]

- Hamada, T.; Ohno, T.; Maekawa, S. First-principles study of electronic and magnetic structures of CoFeB|Ta and CoFe|TaB heterostructures. Mol. Phys. 2015, 113, 314–318. [Google Scholar] [CrossRef]

- Sun, J.Z. Resistance-area product and size dependence of spin-torque switching efficiency in CoFeB-MgO based magnetic tunnel junctions. Phys. Rev. B. 2017, 96, 064437. [Google Scholar] [CrossRef]

- Lu, J.W.; Chen, E.; Kabir, M.; Stan, M.R.; Wolf, S.A. Spintronics technology: Past, present and future. Int. Mater. Rev. 2016, 61, 456–472. [Google Scholar] [CrossRef]

- Meo, A.; Chureemart, P.; Wang, S.; Chepulskyy, R.; Apalkov, D.; Chantrell, R.W.; Evans, L.R.F. Thermally nucleated magnetic reversal in CoFeB/MgO nanodots. Sci. Rep. 2017, 7, 16729. [Google Scholar] [CrossRef] [PubMed]

- Xiong, R.; Fang, B.; Li, G.; Xiao, Y.; Tang, M.; Li, Z. Electric-field tuning of ferromagnetic resonance in CoFeB/MgO magnetic tunnel junction on a piezoelectric PMN-PT substrate. Appl. Phys. Lett. 2017, 111, 062401. [Google Scholar] [CrossRef]

- Okada, A.; Kanai, S.; Fukami, S.; Sato, H.; Ohno, H. Electric-field effect on the easy cone angle of the easy-cone state in CoFeB/MgO investigated by ferromagnetic resonance. Appl. Phys. Lett. 2018, 112, 172402. [Google Scholar] [CrossRef]

- Cao, J.; Chen, Y.; Jin, T.; Gan, W.; Wang, Y.; Zheng, Y.; Lv, H.; Cardoso, S.; Wei, D.; Lew, W.S. Spin orbit torques induced magnetization reversal through asymmetric domain wall propagation in Ta/CoFeB/MgO structures. Sci. Rep. 2018, 8, 1355–1359. [Google Scholar] [CrossRef]

- Bibes, M.; Villegas, J.E.; Barthélémy, A. Ultrathin oxide films and interfaces for electronics and spintronics. Adv. Phys. 2011, 60, 5–84. [Google Scholar]

- Igarashi, J.; Llandro, J.; Sato, H.; Matsukura, F.; Ohno, H. Magnetic-field-angle dependence of coercivity in CoFeB/MgO magnetic tunnel junctions with perpendicular easy axis. Appl. Phys. Lett. 2017, 111, 132407. [Google Scholar] [CrossRef]

- Dohi, T.; Kanai, S.; Matsukura, F.; Ohno, H. Electric-field effect on spin-wave resonance in a nanoscale CoFeB/MgO magnetic tunnel junction. Appl. Phys. Lett. 2017, 111, 072403. [Google Scholar] [CrossRef]

- Lattery, D.M.; Zhang, D.; Zhu, J.; Hang, X.; Wang, J.P.; Wang, X. Low Gilbert Damping Constant in Perpendicularly Magnetized W/CoFeB/MgO Films with High Thermal Stability. Sci. Rep. 2018, 8, 13395–13399. [Google Scholar] [CrossRef] [PubMed]

- Ichikawa, N.; Dohi, T.; Okada, A.; Sato, H.; Fukami, S.; Ohno, H. Non-linear variation of domain period under electric field in demagnetized CoFeB/MgO stacks with perpendicular easy axis. Appl. Phys. Lett. 2018, 112, 202402. [Google Scholar] [CrossRef]

- Huai, Y.; Gan, H.; Wang, Z.; Xu, P.; Hao, X.; Yen, B.K.; Malmhall, R.; Pakala, N.; Wang, C.; Zhang, J.; et al. High performance perpendicular magnetic tunnel junction with Co/Ir interfacial anisotropy for embedded and standalone STT-MRAM applications. Appl. Phys. Lett. 2018, 112, 092402. [Google Scholar] [CrossRef]

- Ikeda, S.; Miura, K.; Yamamoto, H.; Mizunuma, K.; Gan, H.D.; Endo, M.; Kanai, S.; Hayakawa, J.; Matsukura, F.; Ohno, H. A perpendicular-anisotropy CoFeB–MgO magnetic tunnel junction. Nat. Mater. 2010, 9, 721–724. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.J.; Chen, Y.T.; Chang, Y.H.; Chiang, M.R.; Li, W.H.; Tseng, J.Y.; Chi, P.W.; Wu, T.H. Structure and Magnetic Properties of Co40Fe40V20 Thin Films. J. Nanosci. Nanotechnol. 2019, 19, 5974–5978. [Google Scholar] [CrossRef]

- Chen, Y.T.; Chang, Y.H.; Liu, W.J.; Liang, W.C.; Chan, W.H.; Wang, Y.T.; Wu, T.H. Ta and Ru seed layers effect on the magnetic and optical properties of Ru/ Co60Fe20V20 and Ta/Co60Fe20V20 films. J. Magn. Magn. Mater. 2018, 464, 112–115. [Google Scholar] [CrossRef]

- Zheng, C.; Li, X.; Shull, R.D.; Chen, P.J.; Pong, P.W.T. Comprehensive noise characterisation of magnetic tunnel junction sensors for optimising sensor performance and temperature detection. Mater. Res. Innov. 2015, 19, 553–557. [Google Scholar] [CrossRef]

- Morón, C.; Cabrera, C.; Morón, A.; Garcia, A.; González, M. Magnetic sensors based on amorphous ferromagnetic materials: A review. Sensors 2015, 15, 28340–28366. [Google Scholar] [CrossRef]

- Kantar, E. Composition, temperature and geometric dependent hysteresis behaviours in Ising-type segmented nanowire with magnetic and diluted magnetic, and its soft/hard magnetic characteristics. Philos. Mag. B 2017, 97, 431–450. [Google Scholar] [CrossRef]

- Chen, C.W. Metallurgy and Magnetic Properties of an Fe-Co-V Alloy. J. Appl. Phys. 1961, 32, S348–S355. [Google Scholar] [CrossRef]

- George, E.P.; Gubbi, A.N.; Baker, I.; Robertson, L. Mechanical properties of soft magnetic FeCo alloysMater. Sci. Eng. A 2002, 329, 325–333. [Google Scholar] [CrossRef]

- Ma, K.; Chung, T.S.; Good, R.J. Surface energy of thermotropic liquid crystalline polyesters and polyesteramide. J. Polym. Sci. 1998, 36, 2327–2337. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Kaelble, D.H.; Uy, K.C. A Reinterpretation of Organic Liquid-Polytetrafluoroethylene Surface Interactions. J. Adhens. 1970, 2, 50–60. [Google Scholar] [CrossRef]

- Maruyama, S.; Kurashige, T.; Matsumoto, S.; Yamaguchi, Y.; Kimura, T. Liquid droplet in contact with a solid surface. Microscale Thermophys. Eng. 1998, 2, 49–62. [Google Scholar]

- Cullity, B.D. Elements of X-ray Diffraction, 2nd ed.; Addison-Wesley: Boston, MA, USA, 1978. [Google Scholar]

- Ghaferi, Z.; Sharafi, S.; Bahrololoom, M.E. The role of electrolyte pH on phase evolution and magnetic properties of CoFeW codeposited films. Appl. Sur. Sci. 2016, 375, 35–41. [Google Scholar] [CrossRef]

- Ikeda, H.; Iwai, M.; Nakajima, D.; Kikuchi, T.; Natsui, S.; Sakaguchi, N.; Suzuki, R.O. Nanostructural characterization of ordered gold particle arrays fabricated via aluminum anodizing, sputter coating, and dewetting. Appl. Sur. Sci. 2019, 465, 747–753. [Google Scholar] [CrossRef]

- Yamazaki, T.; Ikeda, N.; Tawara, H.; Sato, M. Investigation of composition uniformity of MoSix sputtering films based on measurement of angular distribution of sputtered atoms. Thin Solid Films 1993, 235, 71–75. [Google Scholar] [CrossRef]

- Sakita, A.M.P.; Passamani, E.C.; Kumar, H.; Cornejo, D.R.; Fugivara, C.S.; Noce, R.D.; Benedetti, A.V. Influence of current density on crystalline structure and magnetic properties of electrodeposited Co-rich CoNiW alloys. Mater. Chem. Phys. 2013, 141, 576–581. [Google Scholar] [CrossRef]

- Mehrizi, S.; Sohi, M.H.; Ebrahimi, S.A.S. Study of microstructure and magnetic properties of electrodeposited nanocrystalline CoFeNiCu thin films. Surf. Coat. Technol. 2011, 205, 4757–4763. [Google Scholar] [CrossRef]

- Sharifati, A.; Sharafi, S. Structure and magnetic properties of mechanically alloyed (Fe70Co30)91Cu9 powder. Mater. Des. 2012, 36, 35–40. [Google Scholar] [CrossRef]

- Khajepour, M.; Sharafi, S. Structural and magnetic properties of nanostructured Fe50(Co50)–6.5 wt% Si powder prepared by high energy ball milling. J. Alloys Compd. 2011, 509, 7729–7737. [Google Scholar] [CrossRef]

- Xu, S.T.; Ma, Y.Q.; Zheng, G.H.; Dai, Z.X. Simultaneous effects of surface spins: Rarely large coercivity, high remanence magnetization and jumps in the hysteresis loops observed in CoFe2O4 nanoparticles. Nanoscale 2015, 7, 6520–6526. [Google Scholar] [CrossRef]

- Muroi, M.; Street, R.; McCormick, P.G.; Amighian, J. Magnetic properties of ultrafine MnFe2O4 powders prepared by mechanochemical processing. Phys. Rev. B 2001, 63, 184414. [Google Scholar] [CrossRef]

- Yang, S.Y.; Chien, J.J.; Wang, W.C.; Yu, C.Y.; Hing, N.S.; Hong, H.E.; Hong, C.Y.; Yang, H.C.; Chang, C.F.; Lin, H.Y. Magnetic nanoparticles for high-sensitivity detection on nucleicacidsvia superconducting quantum-interference device basedimmunomagnetic reduction assay. J. Magn. Magn. Mater. 2011, 323, 681–685. [Google Scholar] [CrossRef]

- Chen, Y.T.; Xie, S.M.; Jheng, H.Y. The low-frequency alternative-current magnetic susceptibility and electrical properties of Si(100)/Fe40Pd40B20(X Å)/ZnO(500 Å) and Si(100)/ZnO(500 Å)/Fe40Pd40B20(Y Å) systems. J. Appl. Phys. 2013, 113, 17B303. [Google Scholar] [CrossRef]

- Choe, G.; Steinback, M. Surface roughness effects on magnetoresistive and magnetic properties of NiFe thin films. J. Appl. Phys. 1999, 85, 5777–5779. [Google Scholar] [CrossRef]

- Bhatia, G.; Srivastava, A.; Srivastava, C.P. Effect of ion irradiation on magnetic property of exchange coupled interfacial structures of Fe/NiO and NiO/Fe on Si substrates. Radiat. Eff. Defects Solids 2014, 169, 529–537. [Google Scholar]

- Kong, S.H.; Okamoto, T.; Nakagawa, S. [Ni-Fe/Si] double seedlayer with low surface energy for Fe-Co-B soft magnetic underlayer with high Hk for perpendicular magnetic recording media. IEEE Trans. Magn. 2004, 40, 2389–2391. [Google Scholar] [CrossRef]

- Porter, D.A.; Easterling, K.E. Phase Transformations in Metals and Alloy, 2nd ed.; CRC Press: London, UK, 1992. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).