The Influence of Radial Stress on Mechanical Properties of Anchorage Structure

Abstract

:1. Introduction

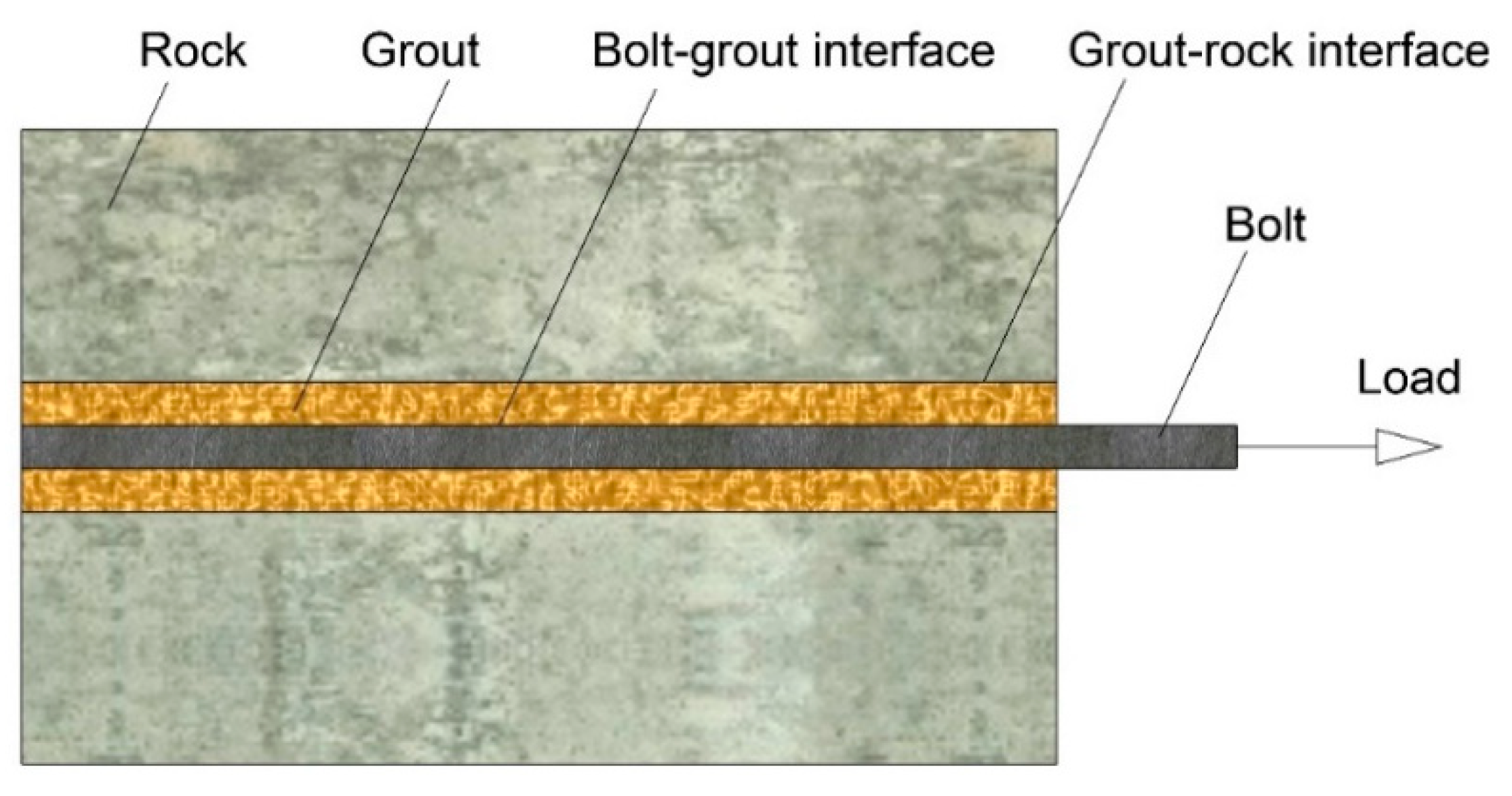

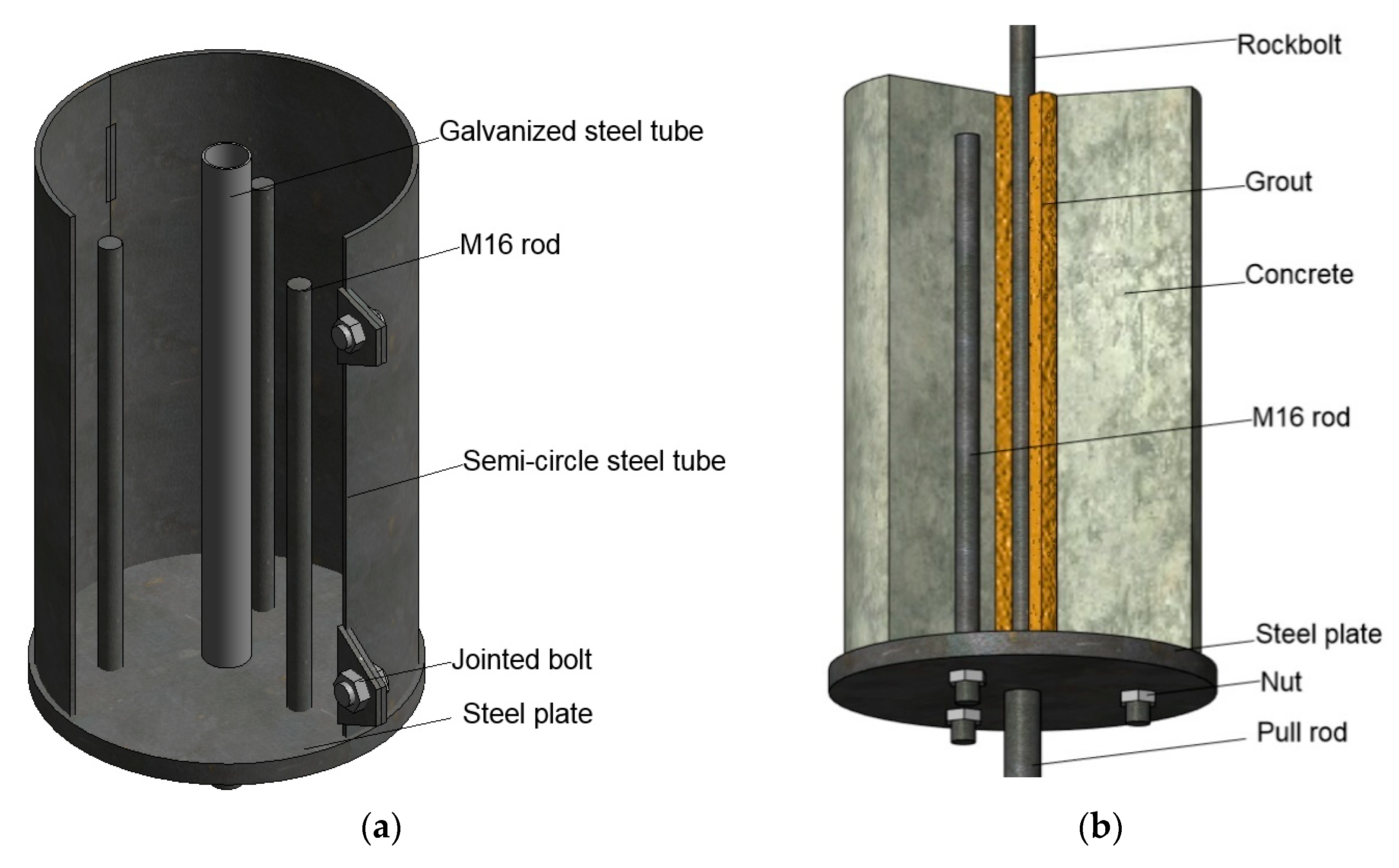

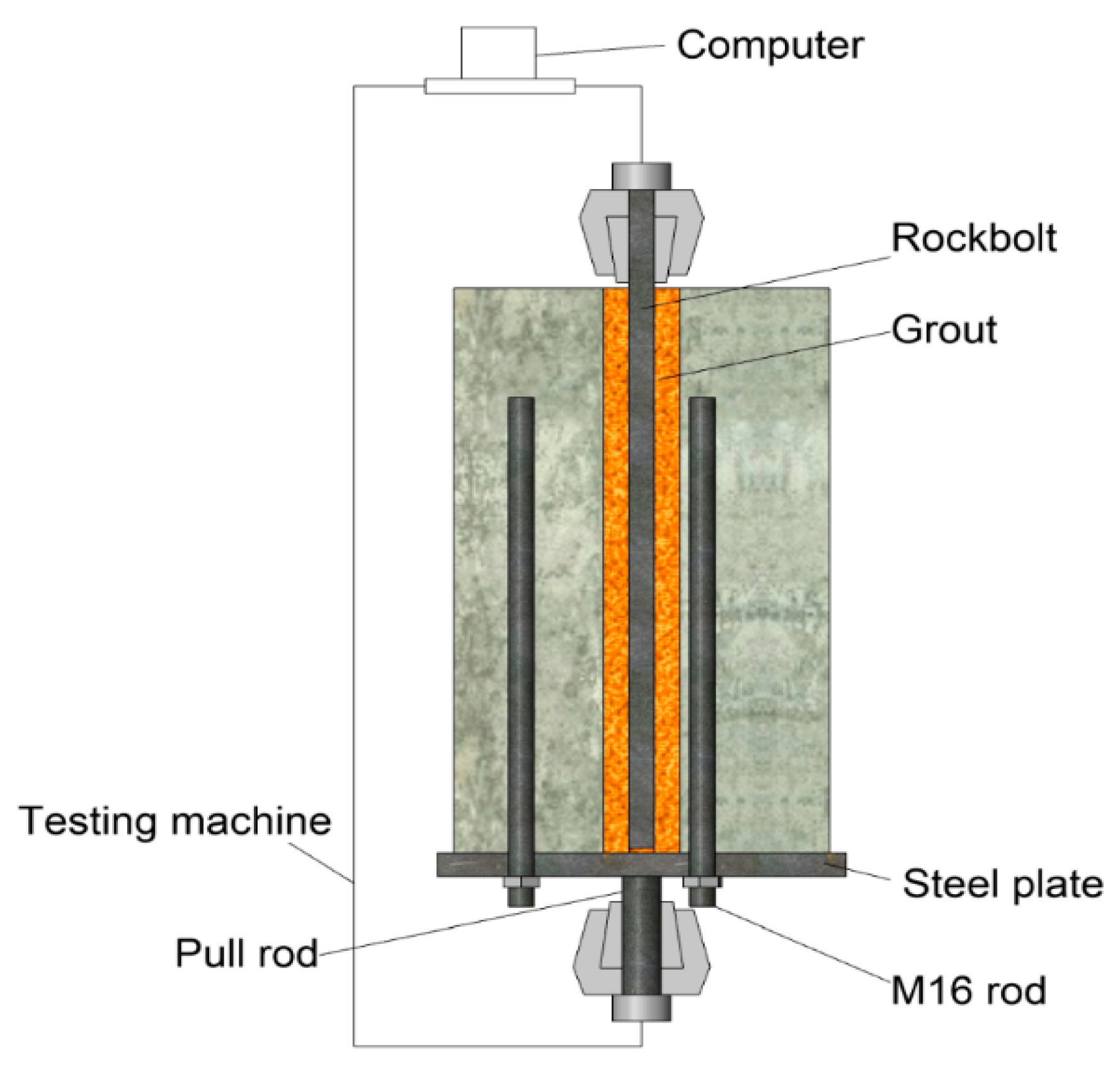

2. Experimental Programs

2.1. Samples Preparation

2.2. Testing Procedure

2.3. Results of the Tests

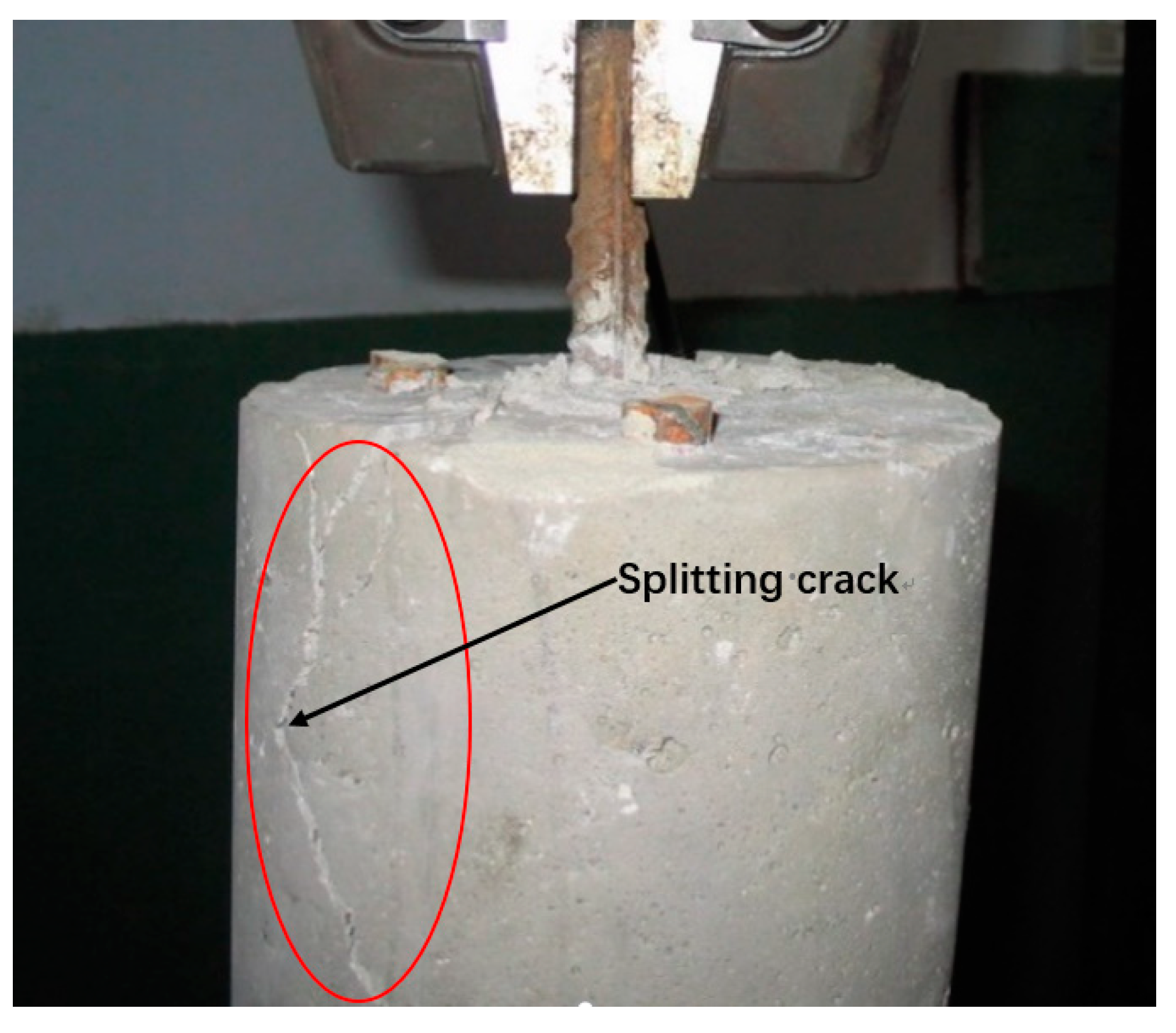

2.3.1. The Failure Modes of Samples

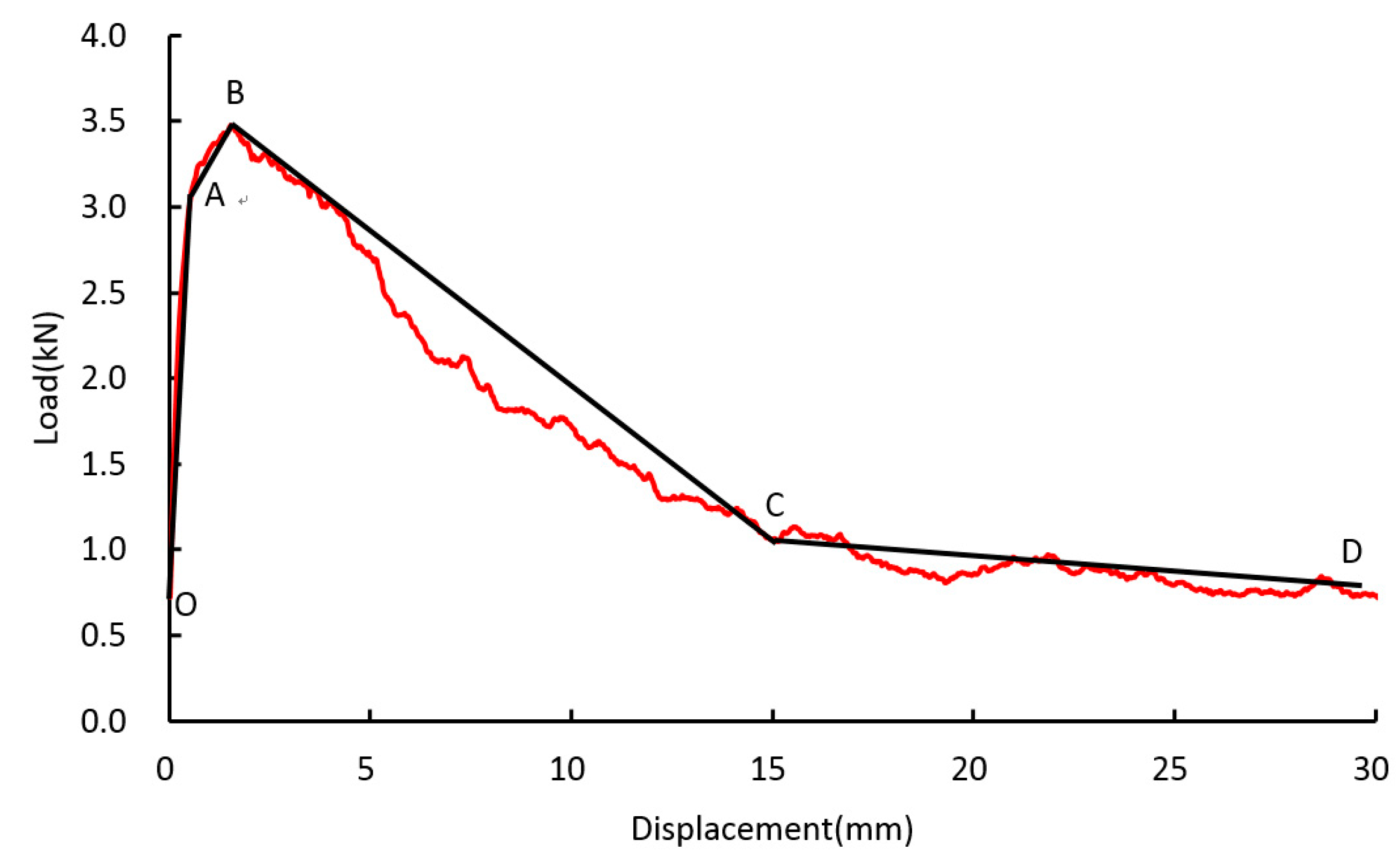

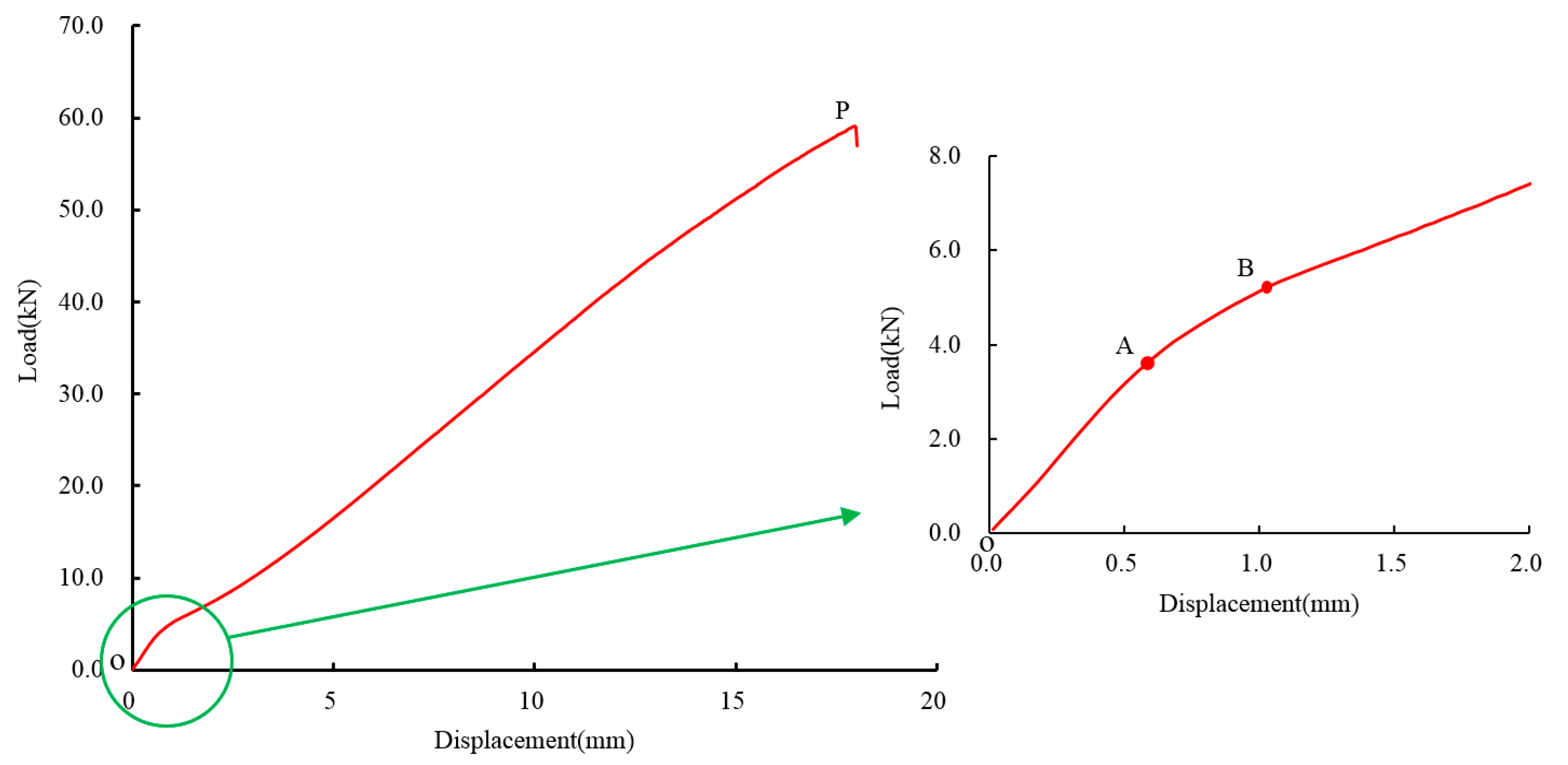

2.3.2. Typical Load-Displacement Curves

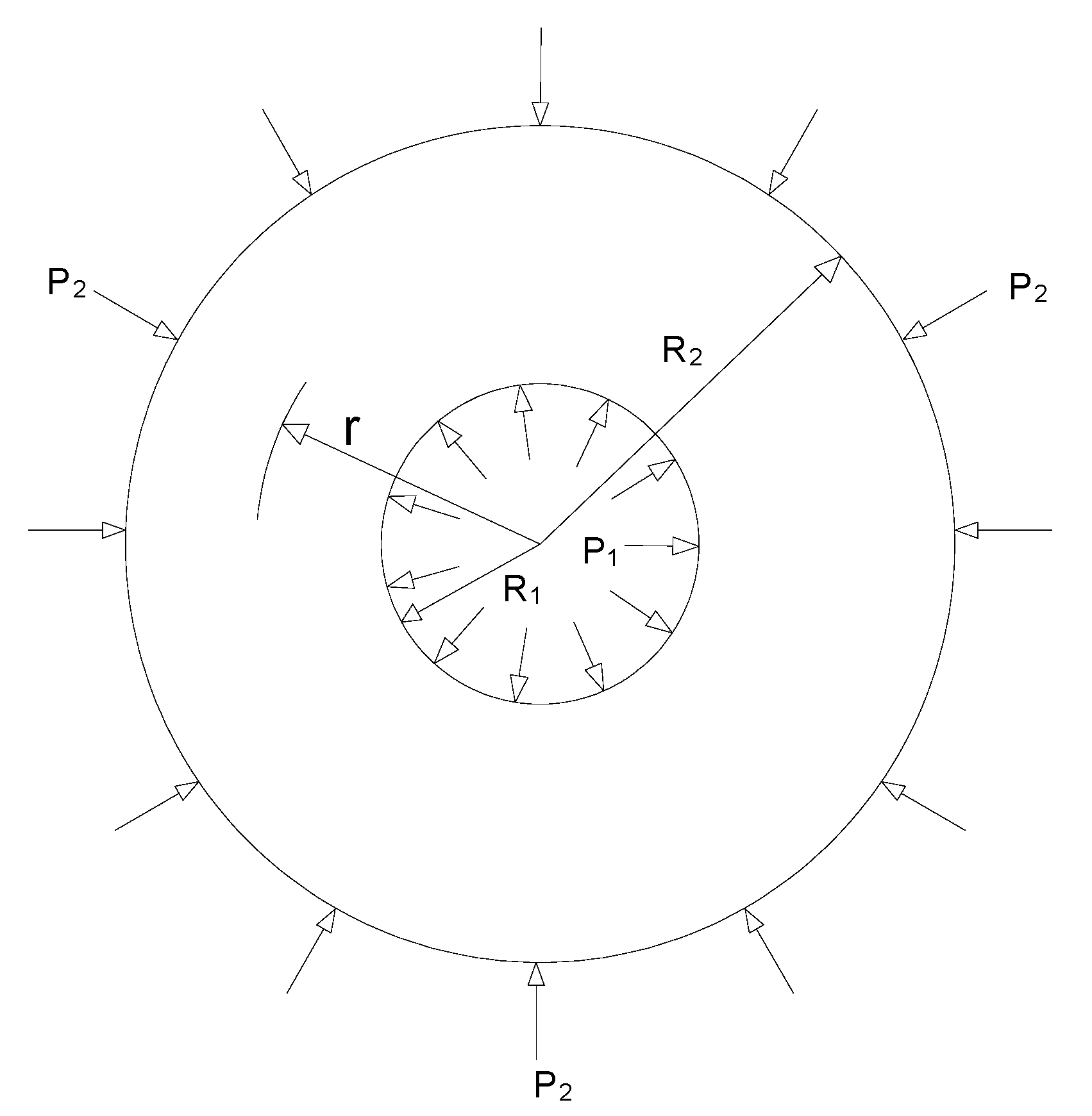

3. Theoretical Methods

3.1. Analysis Using the Criteria of Maximum Tensile Stress

3.2. Analysis Using the Mohr–Coulomb Criterion

- When , , the radial stress and tangential stress of the rock are shown in Figure 9 at the inner wall of the borehole. Since there is no shear stress, is the first principal stress, i.e., , and is the third principal stress, i.e., . And then the Mohr’s circle corresponding to and can be drawn in the coordinate system. The relative relationship between the Mohr’s circle and the Mohr–Coulomb strength line is shown in Figure 9. Under the conditions of and , if the rock strength is good, Mohr’s circle is neither tangent to nor intersecting with the strength line, indicating that the rock has not been damaged. If the rock is of low strength, the Mohr’s circle may be tangent to or intersect with the strength line under this condition, and the rock will break down.

- If a certain confining pressure is applied to the anchorage section, that is, and . According to Equations (2) and (4), , , and the Mohr’s circle under this condition is , as shown in Figure 9. Compared with , the position of is fixed, the value of moves to the positive direction of axis, and the diameter of decreases obviously. Therefore, the Mohr’s circle is gradually away from the strength line of the rock. In this case, compared with the stress state of Mohr’s circle , the rock is less likely to be damaged.

- Continue to increase the confining pressure of anchorage section, when increases to a value that makes . According to Equation (4), , . In this stress state, since both principal stresses are greater than zero, the Mohr’s circle M3 as a whole has been in the positive axis range of the -axis. In this case, the Mohr’s circle M3 is far away from the rock strength line, the two main stresses on the rock around the borehole wall are all compressive stresses. The mechanical properties of the rock are obviously improved, and it is more difficult to damage.

- The confining pressure acting on the anchorage section can be transferred to the interface of anchorage structure. The increase of normal stress will inevitably greatly improve the interfacial shear stress, which will definitely increase the bearing capacity of anchorage structure;

- The existence of the confining pressure in the anchorage section improves the mechanical properties of the rock around the borehole obviously. When the dilatancy occurs at the interface of anchorage structure, the rock is not easy to split. The radial stress produced by the shear expansion acts directly on the normal direction of the interface, which greatly improves the shear stress strength of the interface, thus greatly improving the ultimate bearing capacity of anchorage structure.

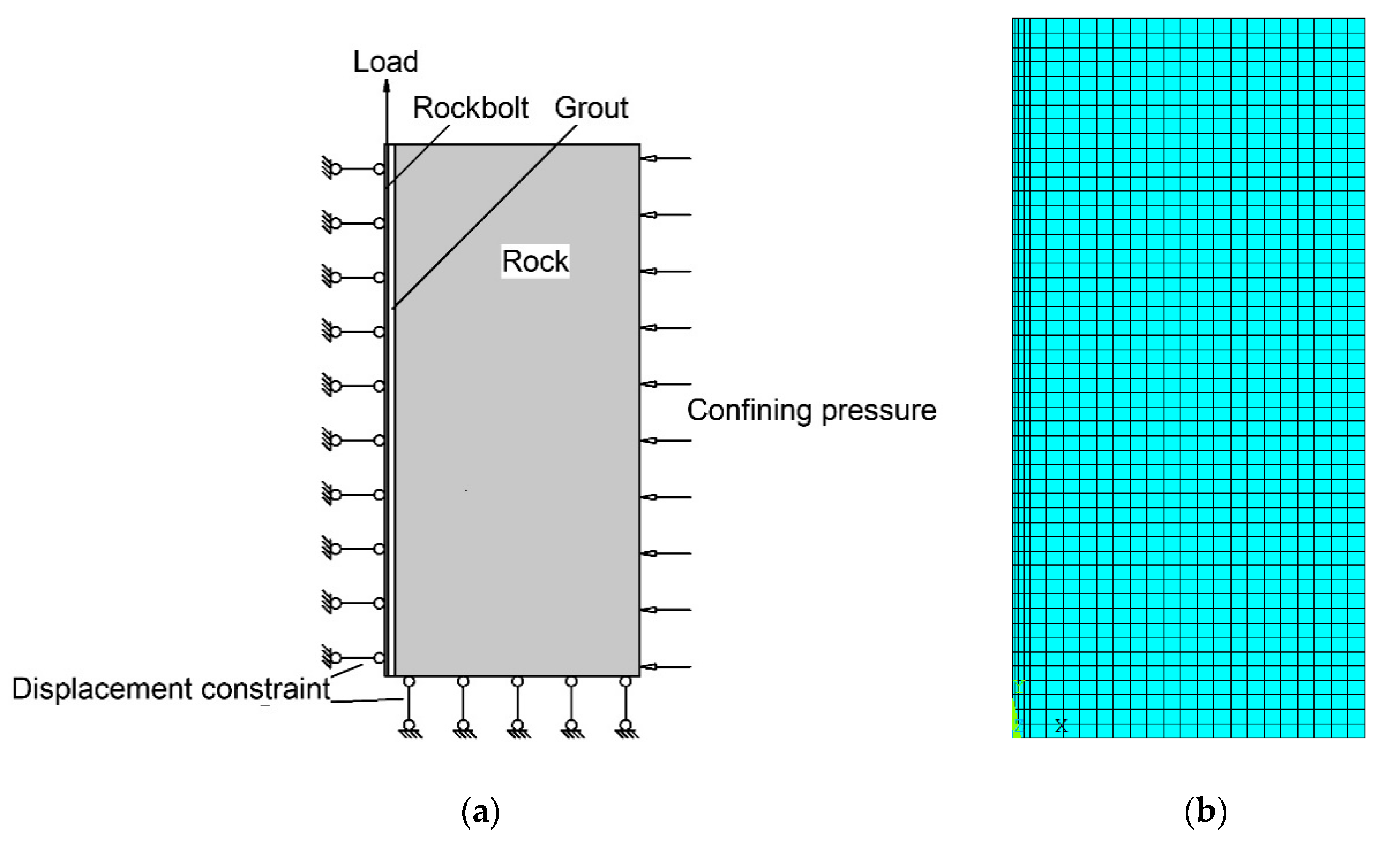

4. Numerical Simulation

4.1. Numerical Model

4.2. Material Modeling

4.3. Influence of Different Confining Pressure on the Interfacial Shear Stress

4.4. Ultimate Anchorage Force under Different Confining Pressures

- With the increasing of confining pressure in the anchorage section of the anchorage structure, the maximum displacement of anchorage structure is increasing, which indicates that the anchorage structure will not be damaged even if it has a large deformation under the action of high confining pressure;

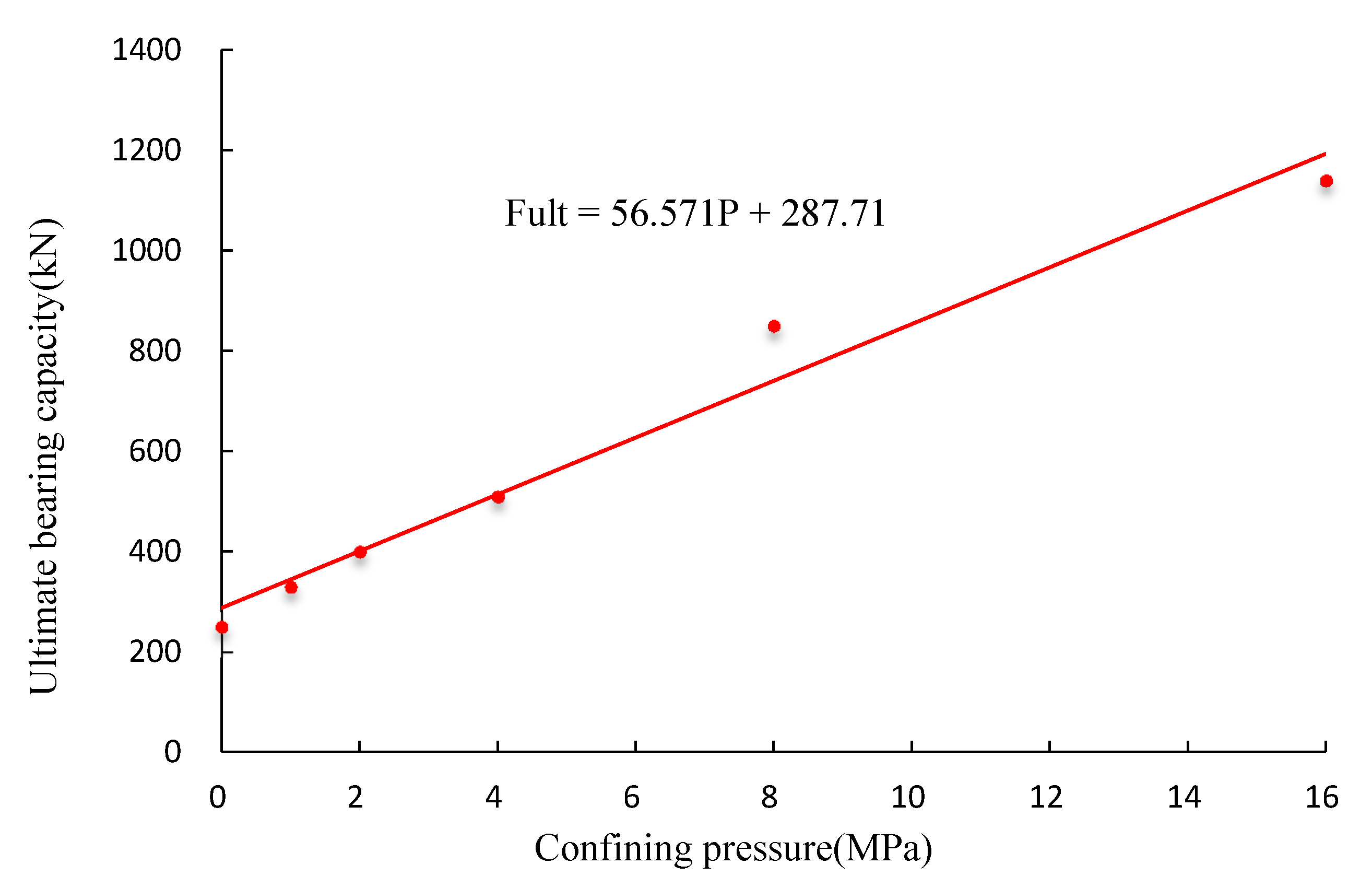

- By analyzing the relationship between confining pressure and ultimate bearing capacity, the ultimate bearing capacity increases linearly with the increase of confining pressure. Through the curve fitting method, the linear relationship between the confining pressure of the anchorage section and ultimate bearing capacity of anchorage structure is obtained, as shown in Equation (6). In this paper, when there is no confining pressure, the ultimate bearing capacity of the anchorage structure is 250 kN. When the confining pressure increases to 4 MPa, the ultimate bearing capacity reaches 510 kN, increasing by more than one time. When the confining pressure increased to 16 MPa, the ultimate bearing capacity of the anchorage structure reached 1140 kN, and the increasing range of the ultimate bearing capacity is amazing. This is clearly shows that the influence of confining pressure on the ultimate bearing capacity of anchorage structure is significant.where, is the ultimate bearing capacity of anchorage structure, kN; is the confining pressure of the anchorage section, MPa.

5. Conclusions

- The radial stress of anchorage section had a significant effect on the mechanical properties of anchorage structure, and the influence on the mechanical properties of the rock around the borehole cannot be ignored;

- The confining pressure had little effect on the distribution of interfacial shear stress, but with the increase of confining pressure, the maximum value of interfacial shear stress increased obviously;

- With the increasing of confining pressure, the anchorage structure was more adaptable to deformation and less prone to failure. The ultimate bearing capacity of anchorage structure increased linearly with the increase of confining pressure, and the effect of confining pressure on the ultimate bearing capacity was very significant;

- According to the results of numerical analysis, the relationship between the confining pressure and the ultimate bearing capacity of anchorage structure was obtained. Although the specific values in the fitting curve needed to be further studied, it could be seen from the relationship between the two that the confining pressure on the anchorage section had a significant impact on the mechanical properties of anchorage structure.

Author Contributions

Funding

Conflicts of Interest

References

- Martín, L.B.; Tijani, M.; Hadj-Hassen, F.; Noiret, A. Assessment of the bolt-grout interface behaviour of fully grouted rockbolts from laboratory experiments under axial loads. Int. J. Rock Mech. Min. Sci. 2013, 63, 50–61. [Google Scholar] [CrossRef]

- Teymen, A.; Kilic, A. Effect of grout strength on the stress distribution (tensile) of fully-grouted rockbolts. Tunn. Undergr. Space Technol. 2018, 77, 280–287. [Google Scholar] [CrossRef]

- Li, C.C.; Kristjansson, G.; Høien, A.H. Critical embedment length and bond strength of fully encapsulated rebar rockbolts. Tunn. Undergr. Space Technol. 2016, 59, 16–23. [Google Scholar] [CrossRef] [Green Version]

- Kilic, A.; Yasar, E.; Celik, A.G. Effect of grout properties on the pull-out load capacity of fully grouted rock bolt. Tunn. Undergr. Space Technol. 2002, 17, 355–362. [Google Scholar] [CrossRef]

- Wang, H.T.; Li, S.C.; Wang, Q.; Wang, D.C.; Li, W.T.; Liu, P.; Li, X.J.; Chen, Y.J. Investigating the supporting effect of rock bolts in varying anchoring methods in a tunnel. Geomech. Eng. 2019, 19, 485–498. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, C.; Zheng, P.Q.; Zhao, W.J.; Li, N. A combined supporting system based on filled-wall method for semi coal-rock roadways with large deformations. Tunn. Undergr. Space Technol. 2020, 99, 103382. [Google Scholar] [CrossRef]

- Akisanya, A.R.; Ivanović, A. Debonding along the fixed anchor length of a ground anchorage. Build. Struct. 2014, 74, 23–31. [Google Scholar] [CrossRef] [Green Version]

- Durham, R.K. Anchorage tests on strain gauged resin bonded bolts. Tunn. Tunn. 1976, 8, 73–76. [Google Scholar]

- Yap, L.P.; Rodger, A.A. A study of the behaviour of vertical rock anchors using the finite element method. Int. J. Rock Mech. Min. Sci. 1984, 21, 47–61. [Google Scholar] [CrossRef]

- Benmokrane, B.; Chennouf, A.; Mitri, H.S. Laboratory evaluation of cement-based grouts and grouted rock anchors. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1995, 32, 633–642. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China and the State Administration for Market Regulation. Technical Code for Building Slope Engineering; Architecture & Building Press: Beijing, China, 2013.

- Ministry of Railways of the People’s Republic of China. Code for Design of Retaining Structures of Railway Earthworks; Railway Press Co., Ltd.: Beijing, China, 2019.

- Freeman, T.J. The behaviour of fully-bonded rock bolts in the Kielder experimental tunnel. Tunn. Tunn. 1978, 10, 37–40. [Google Scholar]

- Moosavi, M.; Jafari, A.; Khosravi, A. Bond of cement grouted reinforcing bars under constant radial pressure. Cem. Concr. Compos. 2005, 27, 103–109. [Google Scholar] [CrossRef]

- Ivanović, A.; Neilson, R.D. Modelling of debonding along the fixed anchor length. Int. J. Rock Mech. Min. Sci. 2009, 46, 699–707. [Google Scholar] [CrossRef]

- Ren, F.F.; Yang, Z.J.; Chen, J.F.; Chen, W.W. An analytical analysis of the full-range behaviour of grouted rockbolts based on a tri-linear bond-slip model. Constr. Build. Mater. 2010, 24, 361–370. [Google Scholar] [CrossRef]

- Li, C.; Stillborg, B. Analytical models for rock bolts. Int. J. Rock Mech. Min. Sci. 1999, 36, 1013–1029. [Google Scholar] [CrossRef]

- Szu, W.; Fragaszy, R.J. Uplift testing of model anchors. J. Geotech. Eng. 1988, 114, 961–983. [Google Scholar]

- Yazici, S.; Kaiser, P.K. Bond strength of grouted cable bolts. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1992, 29, 279–292. [Google Scholar] [CrossRef]

- Bazant, Z.P.; Sener, S. Size effect in pull out tests. ACI Mater. J. 1988, 85, 347–351. [Google Scholar]

- Akisanya, A.R.; Meng, C.S. Initiation of fracture at the interface corner of bi-material joints. J. Mech. Phys. Solids 2003, 51, 27–46. [Google Scholar] [CrossRef]

- Suzuki, Y. Adhesive tensile strength of scarf and butt joints of steel plates. Int. J. JSME Ser. A 1987, 30, 1042–1051. [Google Scholar] [CrossRef] [Green Version]

- Kaiser, P.K.; Yazici, S.; Nosé, J. Effect of stress change on the bond strength of fully grouted cables. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1992, 29, 293–306. [Google Scholar] [CrossRef]

- Martin, L.B.; Tijani, M.; Hadj-Hassen, F. A new analytical solution to the mechanical behaviour of fully grouted rockbolts subjected to pull-out tests. Constr. Build. Mater. 2011, 25, 749–755. [Google Scholar] [CrossRef] [Green Version]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical Specification for Retaining and Protection of Building Foundation Excavations; China Architecture & Building Press: Beijing, China, 2012.

- China Association for Engineering Construction Standardization. Technical Specification for Ground Anchors; China Planning Press: Beijing, China, 2005. [Google Scholar]

- Rong, G.; Zhu, H.; Zhou, C. Testing study on working mechanism of fully grouted bolts of thread steel and smooth steel. Chin. J. Rock Mech. Eng. 2004, 23, 469–475. [Google Scholar]

| Compressive Strength (MPa) | Elastic Modulus (GPa) | Poisson’s Ratio |

|---|---|---|

| 45.3 | 35.6 | 0.23 |

| Sample Number | 1-0 | 2-0 | 3-0 | 4-0 | 1-1 | 2-1 | 3-1 | 4-1 | 1-3 | 2-3 | 3-3 | 4-3 |

| Cement-Sand Ratio | 1:0 | 1:0 | 1:0 | 1:0 | 1:1 | 1:1 | 1:1 | 1:1 | 1:3 | 1:3 | 1:3 | 1:3 |

| Anchorage Length (mm) | 300 | 250 | 200 | 150 | 300 | 250 | 200 | 150 | 300 | 250 | 200 | 150 |

| Failure Modes | Debonding Failure | Splitting Failure |

|---|---|---|

| Sample number | 1-0, 2-0, 3-0, 4-0, 2-1, 3-1, 4-1, 4-3 | 1-1, 1-3, 2-3, 3-3 |

| Anchorage Length (Mm) | 300 | 200 | 150 | |

|---|---|---|---|---|

| Cement-Sand Ratio | ||||

| 1:0 | 14.0 | 8.1 | 4.7 | |

| 1:1 | 20.4 | 9.8 | 12.0 | |

| 1:3 | 48.9 | 41.9 | 21.9 | |

| Materials | (GPa) | (MPa) | (°) | (°) | |

|---|---|---|---|---|---|

| Bolt | 200 | 0.3 | |||

| Grout | 26 | 0.24 | 1 | 35 | 20 |

| Rock | 5 | 0.32 | 2.5 | 60 | 35 |

| Confining pressures (MPa) | 0 | 1 | 2 | 4 | 8 | 16 |

| Ultimate bearing capacity (kN) | 250 | 330 | 400 | 510 | 850 | 1140 |

| Maximum displacement (mm) | 4.2 | 14.7 | 18.5 | 23.5 | 38.7 | 51.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhan, Y.; Zheng, P.; Wang, H.; Wang, Q. The Influence of Radial Stress on Mechanical Properties of Anchorage Structure. Appl. Sci. 2020, 10, 7029. https://doi.org/10.3390/app10207029

Zhan Y, Zheng P, Wang H, Wang Q. The Influence of Radial Stress on Mechanical Properties of Anchorage Structure. Applied Sciences. 2020; 10(20):7029. https://doi.org/10.3390/app10207029

Chicago/Turabian StyleZhan, Yubao, Pengqiang Zheng, Hui Wang, and Qingbiao Wang. 2020. "The Influence of Radial Stress on Mechanical Properties of Anchorage Structure" Applied Sciences 10, no. 20: 7029. https://doi.org/10.3390/app10207029

APA StyleZhan, Y., Zheng, P., Wang, H., & Wang, Q. (2020). The Influence of Radial Stress on Mechanical Properties of Anchorage Structure. Applied Sciences, 10(20), 7029. https://doi.org/10.3390/app10207029