1. Introduction

The continued use of industrial products has caused permanent pollution. Permanent pollution is environmental pollution caused by industrial waste without recycling or the continuous use of raw materials from nature without renewal. The use of bamboo as a renewable building material can reduce pollution and maintain a healthy environment [

1]. Bamboo is a grass plant with cavities and nodes in its stems [

2]. Bamboo is a renewable building material, such as wood. Bamboo has the advantage of being economical, growing fast, and does not take long to achieve mechanical resistance. Mechanical resistance of bamboo, such as tensile strength, flexural strength, and other mechanical properties, can be achieved in a relatively fast time, namely at the age of bamboo ranging from 3–4 years [

3]. Bamboo is also very abundant in tropical and subtropical areas around the world [

1]. Indonesia is a country with a tropical climate. One of the plants that can thrive in Indonesia is bamboo. Bamboo is scattered throughout Indonesia. Bamboo has been widely used as a material for simple structures, such as warehouses, bridges, and village traditional houses, and for handicrafts for rural communities. In Indonesia, there are more than 100 species of bamboo. Around the world, there are ±1500 species of bamboo [

4]. In terms of its potential, in 2000 the total area of bamboo plants in Indonesia was 2,104,000 ha, consisting of 690,000 ha of bamboo planted in forest areas and 1,414,000 ha of bamboo plant areas outside forest areas [

5]. Arsad (2015) [

5] revealed that in the Hulu Sungai Selatan Regency, the bamboo area was estimated to be around 22,158 ha, with a production of about 3000 stems/ha. The description of the potential for bamboo production in East Java is 29,950,000 stems/year, Yogyakarta 2,900,000 stems/year, Central Java 24,730,000 stems/year, and West Java 14,130,000 stems/year [

6]. With such a large production potential, efforts must be made to increase its economic value, including being used as an alternative to concrete reinforcement. The best bamboos that are widely used as structural elements are the petung bamboo (

Dendrocalamus asper) and ori bamboo (

Bambusa blumeana), because these two bamboos have the best technical specifications with a high tensile strength. The use of bamboo as concrete reinforcement for simple construction is applied specifically in underdeveloped village areas that have a lot of bamboo.

Bamboo for concrete reinforcement is because it has a relatively high tensile strength. The tensile strength of bamboo can reach 370 MPa in its outer fibers [

1]. The failure of the elements of the bridge frame or roof truss usually occurs in the tensile stem elements. Bamboo has a high enough tensile strength suitable for use in tensile elements. Bamboo is suitable for use in tensile elements, simple construction, such as roof trusses, simple bridge trusses, simple house construction elements, and so on. Muhtar et al. (2018) [

7] tested the pull-out of bamboo reinforcement with a layer of Sikadur

®-752 and hose clamps embedded in a concrete cylinder, showing an increase in tensile stress of up to 240% compared to untreated bamboo reinforced concrete (BRC). A single BRC beam with a bamboo reinforcing area ratio of 4% exceeds the ultimate load of a steel-reinforced concrete (SRC) beam by 38.54% with a steel reinforcement area ratio of 0.89% [

8]. However, bamboo also has weaknesses, which are being easily attacked by insects and having high water absorption. This study did not test for fungal and insect attacks, but the technology to prevent fungus and insect attack was based on the opinion and research of Ridley (1911) [

2] and Stebbings (1904) [

9], namely that soaking in water for two months is sufficient to prevent insect attack. Soaking and drying aim to remove the starch or sugar content in bamboo. The criterion for sufficient soaking is that the bamboo smells bad. The soaking causes the bamboo’s water content to increase and decrease its strength; however, after drying it undergoes a transition from a brittle behavior to a very resilient behavior [

10]. The effect of alkaline cement does not cause the bamboo to decrease in strength. According to Ming Li (2017) [

11], the content of bamboo fiber (BF) treated with the right alkaline can effectively increase toughness, flexural strength, and tensile strength. Moe Thwe (2003) [

12] conducted a study on the durability of bamboo with treatment using calcium hydroxide (CaOH2) to increase flexibility and durability.

In this study, the technology used to prevent decay and absorption, and the effect of a high pH, is to provide a Sikadur adhesive that is also a waterproof layer, and the basis is previous research that has been conducted by several researchers, including (1) Ghavami (2005) [

1], who researched the attachment of bamboo reinforcement with several adhesives applied to the pull-out test and beam test. From the results of his research concluded that the best adhesive is Sicadur 32 Gel; (2) Agarwal et al. (2014) [

13], who researched bamboo reinforcement treated with Araldite adhesive, Tepecrete P-151, Anti Corr RC, and Sikadur 32 Gel. From the sticky strength test, it was found that the best adhesive was the Sikadur 32 Gel; (3) Lima Jr et al. (2008) [

14], who experimented on the

Dendrocalamus giganteus bamboo species, showing that bamboo with 60 cycles of wetting and drying in a calcium hydroxide solution and tap water did not reduce its tensile strength or Young’s Modulus; (4) Javadian et al. (2016) [

15], who did research on several types of epoxy coatings to determine the bonding behavior between concrete and bamboo-composite reinforcement. The results showed that the bamboo-composite reinforcement without bonding layers was adequate with the concrete matrix, but with an epoxy base layer and sand particles, it could provide extra protection without losing bond strength. However, tests for decay resistance, absorption, and the effect of a high pH on the strength properties will be carried out in future studies; and (5) Muhtar et al. (2019) [

8], who processed bamboo reinforcement by immersing in water for 1 month, coating with Sikadur

®-752, and applying a hose clamp. The pull-out test results show that the bond-stress increases by 200% when compared to untreated bamboo. Sikadur

®-752 adhesive is quite effective in preventing the occurrence of hygroscopic and hydrolysis processes between bamboo and concrete. The non-adhesive hose-clamp does not affect bond stress.

Several researchers who have concluded that bamboo is suitable for use as concrete reinforcement include (1) Ghavami (2005) [

1], who concluded that bamboo can be used as a structural concrete element, including beams, windows, frames, and elements that experience bending stress; (2) Agarwal et al. (2014) [

13], who conducted tests of treated bamboo reinforced columns and beams and concluded that all tests indicated that bamboo has the potential to replace steel as reinforcing beam and column elements; (3) Sakaray et al. (2012) [

16], who conducted a feasibility test for the moso-type bamboo as a reinforcing material for concrete and the conclusion was that bamboo could be used as a substitute for steel in concrete; (4) Nayak et al. (2013) [

17], who conducted a study to analyze the effect of replacing steel reinforcement with bamboo reinforcement. One of the conclusions wrote that bamboo reinforcement is three times cheaper than steel reinforcement and that the engineering technique is cheaper than steel reinforcement; (5) Kaware et al. (2013) [

18], who reviewed bamboo as a reinforcing material for concrete and one conclusion was that bamboo exhibits ductile behavior like steel; (6) Khan (2014) [

19], who researched bamboo as an alternative material to substitute for reinforcing steel and one of the results of his study revealed that bamboo reinforced concrete can be used successfully for structural and non-structural elements in building construction; (7) Rahman et al. (2011) [

3], who conducted tests on bamboo reinforced concrete beams and one of the conclusions wrote that bamboo is a potential reinforcing material in concrete; (8) Sethia and Baradiya (2014) [

20], who in one conclusion revealed that bamboo can be used as an alternative to steel reinforcement in beams; (9) Terai and Minami (2011) [

21], who conducted a study on 11 bamboo reinforced concrete beams and tested them to check for flexural cracks and shear cracks, and concluded that the crack pattern of bamboo reinforced concrete (BRC) beams resembles the fracture pattern of steel-reinforced concrete (RCC) beams so that the fracture behavior of bamboo reinforced concrete (BRC) beams can be evaluated with the existing formula on RCC steel-reinforced concrete beams; and (10) Muhtar (2020) [

22], who conducted a flexural test on four beams with untreated bamboo reinforcement and treated with Sikadur

®-752 and a hose clamp. The test results showed that the beam treated with Sikadur

®-752 increased the load capacity by 164% when compared to the untreated reinforced bamboo. With the first treatment, bamboo is suitable for use as a simple construction concrete reinforcement.

Bamboo as a concrete reinforcement must be treated beforehand, such as immersion in water [

8,

23], drying in free air [

3,

13], applying a waterproof layer [

24], and sprinkled with sand, to modify the roughness of the bamboo reinforcement. Usage of the adhesive or waterproof coating can be done in various ways, such as paint [

25], Sikadur 32 Gel [

1,

13], and Sikadur

®-752 [

7,

22,

23,

24,

26,

27]. Strengthening of bamboo reinforcement with adhesive or waterproof coating can increase the bond stress of bamboo reinforcement [

23]. Bamboo as reinforcement for concrete construction elements has been widely researched, including bamboo as beam reinforcement [

28,

29,

30,

31], bamboo as column reinforcement [

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30,

31,

32,

33,

34], bamboo as slab reinforcement or panel reinforcement [

35,

36,

37], and bamboo as a bridge frame reinforcement [

38,

39].

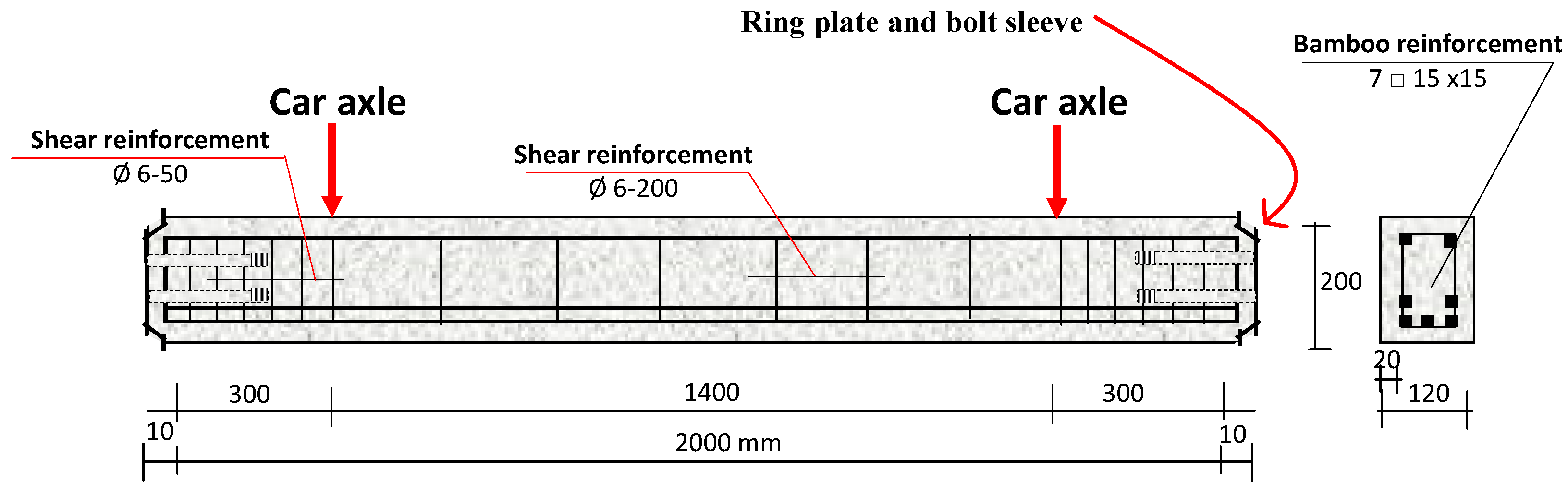

Muhtar [

22] tested the flexural properties of four types of bridge beams with different treatments. The size of the bridge beam is 120 mm × 200 mm × 2100 mm with the area of tensile reinforcement ρ = 4.68% and compressive reinforcement ρ′ = 1.88%. Strengthening of bamboo reinforcement is done by applying adhesive as a waterproof layer. Modification of the roughness of the bamboo reinforcement is done by sprinkled sand and installing hose clamps on the tensile reinforcement. The test was carried out using the four-point load method. The position of the loading point is adjusted to the distance of the minibus car axle. The test results show that the bridge beam with bamboo reinforcement can reach the ultimate load of 98.3 kN with an initial crack load of 20 kN. Modification of the roughness of the bamboo reinforcement with adhesive, sand, and hose clamp can increase the bond stress and capacity of the bamboo reinforced concrete beam (BRC beam) [

22]. The relationship between load vs. displacement is shown in

Figure 1.

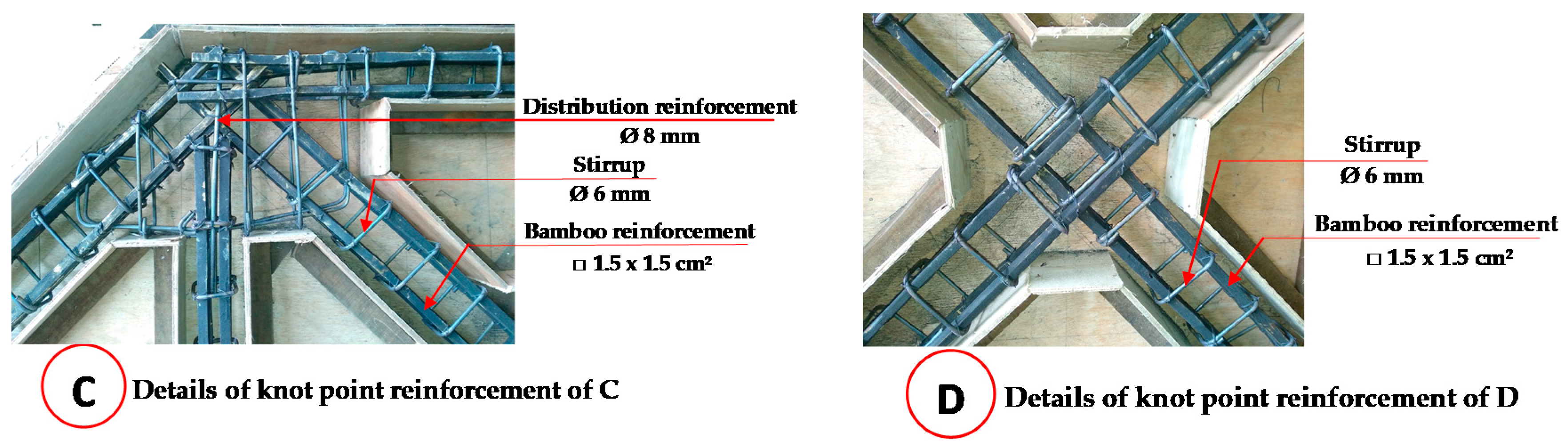

Testing of bridge trusses has been carried out by several researchers, including bamboo as reinforcement for a truss easel [

39] and as reinforcement for a bridge frame with a span of 3 m [

38]. Dewi and Wonlele [

39] concluded that the collapse of the frame structure was caused by a combination of compressive and shear forces at the positioning of the support knot points. Failure at the knot placement causes the tensile and compressive rods to be unable to develop the maximum tensile and compressive strength; however, the collapse pattern still shows a bending effect [

39].

Muhtar et al. [

38] tested two bridge frame models, namely one frame with symmetry reinforcement as the joint frame model or “truss model”, and one frame with flexural reinforcement as the rigid portal model or “frame model”. The test results show that the rigid portal model or “frame model” has a higher rigidity and load capacity than the joint frame model or “truss model”. The rigid portal model or “frame model” has an initial crack load capacity of 8700 kg or 87 kN and the joint frame model or “truss model” has an initial crack load capacity of 5500 kg or 55 kN. The relationship pattern of the load (

P) vs. deflection (Δ) of the two bridge frames is shown in

Figure 2.

The dimensions and reinforcement of the bridge beams used in this study are the same as Muhtar’s (2020) research [

22]. In this study, strengthening of the reinforcement with hose clamps is only for tensile reinforcement, whereas in previous studies it was carried out for all reinforcements. Hose-clamp strengthening when the distance is too close together can reduce the elastic properties of the bamboo and reduce its capacity. The bridge frame model used in this study is a rigid frame model or “frame model” as in the experiment conducted by Muhtar et al. (2020) [

38]. The reinforcement model on the lower side frame stem is installed with the concept of flexural reinforcement, whereas in previous studies it was carried out with the concept of truss reinforcement or symmetry, and their behavior shows flexural behavior. The basis for using the results of previous laboratory research is to control the results of the direct tests in the field. The novelty that is expected is (1) obtaining a prototype of the precast concrete reinforced concrete bridge; and (2) increasing the stiffness and capacity of the precast bridge elements when assembled into a complete unit. The expected benefits are that the research results can be used as the basis for the use of bamboo as a substitute for steel reinforcement, which could be applied to a simple frame bridge structure in underdeveloped village areas with local materials that are cheap, environmentally friendly, and acceptable.

The targets to apply this research to are underdeveloped villages with lots of bamboos. Bamboo is a new and renewable energy from natural resources that are very abundant in rural areas. Bamboo needs to be used, including for reinforced concrete. The use of bamboo is one of the real efforts to increase the economic strength of the community. Based on previous research and the abundant potential of bamboo, it is necessary to use it as a reinforcing element for simple precast reinforced concrete bridges, especially in rural areas with lots of bamboos.

3. Results

Specifications for precast bridges of the bamboo reinforced concrete frame are shown in

Table 6. The precast bridges were tested with a minibus car full of passengers. The test was carried out after several stages of work were done, including making river stone foundations, making support plates, setting the frame on two supports, installing bridge beams and joints, casting bridge plates, and completing or finishing the bridge. Recording of the test results started when the front axle of the minibus car was right on the hinge support and ended when the rear axle of the minibus car was right on the support of the roller. The test result data are shown in

Table 7.

The security measure during the test was to place the support poles and scaffolding under the bridge. The support poles and scaffolding under the bridge also function as a place and safety for the LVDT tool. Besides, the bridge was planned using the “Service Load Planning” method with the assumption that the structure has linear elastic behavior and the load test was carried out with elastic loads or under the initial crack load of the most critical bridge components. Observation of deflection and the deformation that occurred was deflection and elastic deformation. The critical load (Pcr) or initial crack load was 2.1 tons and the maximum test load for the minibuses was 1.55 tons.

Figure 20,

Figure 21,

Figure 22,

Figure 23,

Figure 24 and

Figure 25 show the beam displacement and the bridge frame with the minibus Brio car, the Brio full of passengers, and the AVANZA full of passengers. The maximum displacement with the load of the Brio car occurred when the position of the front axle was at coordinates 150 cm and the rear axle was at a distance of 85 cm from the pedestal, with a displacement of 0.2 mm for the frame and 0.14 mm for the beam displacement. While, the maximum displacement with a full passenger Brio car occurred when the position of the front axle was at coordinates 200 cm and the rear axle was at a distance of 35 cm from the pedestal, with a displacement of 0.2 mm for the frame and 0.17 mm for the beam displacement. The maximum displacement with a full passenger AVANZA car load occurred when the front axle position was outside the bridge coordinates, which was 115 cm from the roller support, and the rear axle was at 150 cm coordinates, with a displacement of 0.25 mm for the frame and 0.21 mm for the displacement beam.

Based on the AASHTO [

48] and RSNI T-12-2004 standards [

49], the maximum allowable displacement limit of the bridge is Δ

max = L/800 or equal to 3.75 mm. Thus, the maximum displacement that occurs in the element of the bamboo reinforced concrete frame bridge meets the requirements based on the AASHTO [

48] and RSNI T-12-2004 standards [

49].

Figure 26 shows the deformation of the bridge beam of the bamboo reinforced concrete with a load of Brio minibuses, the Brio car full of passengers, and the Avanza car full of passengers. From

Figure 26 and

Table 7, we see that the maximum deformation occurs in the beam with the load of the Avanza car with a full passenger load, which is when the position of the front axle is outside the coordinates of the bridge, which is 65 cm from the roller support, and the rear axle is at coordinates 100 cm, with the deformation of the beam being 0.20 mm.

Figure 27,

Figure 28 and

Figure 29 show the deformation of the bridge frame with the load of the Brio minibus, Brio car full of passengers, and the Avanza car full of passengers. The maximum deformation with the brio car load occurs when the position of the front axle is outside the coordinates of the bridge, which is 85 cm from the roller support, and the rear axle is at coordinates 150 cm, with a frame deformation of 0.04 mm.

The maximum frame deformation with the load of the brio car full of passengers occurred when the position of the front axle was at coordinates 150 cm and the rear axle was at a distance of 85 cm from the hinge support, with a deformation of 0.05 mm. The maximum deformation of the frame with the load of the Avanza car full of passengers occurred when the position of the front axle was at the coordinates of the bridge of 150 cm, and the rear axle was at a distance of 115 cm from the hinge support, with a deformation of 0.13 mm.

4. Discussion

Deformation usually occurs due to shrinkage of concrete, deformation of precast connections, foundation settlement, or due to a static load or dynamic loads on the bridge. In this study, deformation or elastic deformation is a change in shape or change in the angle of the cross-section of the beam or frame due to the distribution of the vehicle loads within the elastic limit measured in the horizontal direction of the cross section. Measurements were made by installing LVDTs (Linear Variable Displacement Transducers) with inductive transducers of type PR 9350 on the horizontal side of the frame and bridge beams, as shown in

Figure 30.

The accuracy of the deformation measurement is very much determined by the calibration of the equipment, the accuracy of the load point of the observation, the conditions of the test site, such as near roads, and human error.

Figure 26 shows that the minimum beam deformation occurs when the car axle is right on the neutral line of the beam; this shows that the coupling moment or torque due to the load is a factor that greatly affects the size of the beam deformation. Gravity loads right on the neutral line can reduce the deformation and increase the deflection of the bridge beams.

Figure 21 and

Figure 26 at the 200 cm coordinates show that when the beam deformation is minimum, the beam displacement is maximum. As shown in

Figure 17, Beam 1 is at the coordinates 100 cm and Beam 2 is at coordinates 200 cm. The deformation of the beam increases in line with the track of the car axle; that is, the deformation continues to increase, respectively, at the front car axle and rear car axle. However, the accuracy of the deformation measurements needs attention as to the many determinants of accuracy that exist.

Figure 27 and

Figure 28 shows that the minimum frame deformation or deformation = 0 occurs when the car axle is directly above the pedestal or approaching the pedestal. Meanwhile, the maximum frame deformation occurs when the car axle is in the middle of the bridge span, which is at coordinates 150 cm. There is a difference in the deformation of the bridge beam and the bridge frame, namely the maximum beam deformation occurs when the load is outside the beam coordinates, while the maximum frame deformation occurs when the load is in the middle of the bridge span or at the 150 cm coordinates. It must be remembered that careful preparation at the time of testing or measurement must be considered so that the data obtained is truly accurate; as shown in

Figure 27, the coordinates at 250 cm convey inconsistent deformation data even though the car axle is close to the support.

Table 7 shows that the maximum deformation of the bridge frame is 0.13 mm and the maximum displacement of the bridge beam is 0.20 mm. According to the AASHTO [

48] and RSNI T-12-2004 standards [

49], the allowable limit for the maximum displacement is Δ

max = L/800 = 3.75 mm and the maximum deformation of the bridge is

δmax = L/800 = 3.75 mm. Thus, the maximum deformation and displacement that occurs in the precast bridge elements of the bamboo reinforced concrete frame meet the requirements based on AASHTO [

48] and RSNI T-12-2004 standards [

49]. However, the relationship of load vs. displacement of the beam and the frame results from the field experiments need to be validated or controlled with the relationship of load vs. displacement of laboratory experimental results and simulation results of numerical methods. The simulation in this study used the finite element method (FEM).

The simulation of the bridge frame test using the finite element method (FEM) was carried out using the Fortran PowerStation 4.0 program and Surfer 9.8 software [

50] based on laboratory test results. Simulations were carried out as control and validation of the experimental data. The bridge frame test simulation was carried out at the first crack load stage, which was 87 kN based on the frame loading capacity of only 100 kN. The discretization of the bamboo reinforced concrete bridge frame for the finite element method (FEM) is shown in

Figure 31. The Y-direction and X-direction displacement are shown in

Figure 32 and

Figure 33. The loading stages and Y-direction displacement of the finite element method simulation results are combined with the load vs. displacement laboratory test results [

38], and with the field test results as shown in

Figure 34.

Figure 33 shows displacement in the X-direction; the green color shows the minimum displacement, and the orange and blue colors show the maximum positive and negative displacement, respectively. FEM analysis modeling on the bamboo reinforced concrete frames can be seen in Item 2.3 of the numerical method used.

Bridge integrity is the ability of a bridge structure or bridge components to withstand the designed load, preventing structural collapse due to cracks or fractures, deformation, and structural fatigue. Structural integrity is a concept used for the design plan and designing service load. Stiffness is the main parameter of the resistance of a bridge structure to get good bridge integrity [

24]. The stiffness of the elements of the bridge structure needs to be controlled to prevent sudden collapse due to cracking and excessive deformation. Stiffness control of the beams and bridge frames was analyzed through a combination of load vs. displacement from the simulation results of the finite element method (FEM), the results of laboratory experiments [

22,

38], and the results of field experiments as shown in

Figure 34. Control was carried out at the maximum load point of the bamboo reinforced concrete precast frame bridge test in the field, which was 15.5 kN, as shown in

Figure 35 and

Figure 36. Documentation of the direct test of the bamboo reinforced concrete precast bridges can be seen at the following link:

https://bit.ly/3gzaW30.

Calculation of the aerodynamic effects due to wind loads and dynamic analysis on precast concrete bamboo bridges were not carried out. Based on the Earthquake Resistance Standard for Bridges, the SNI SNI-07-SE-2015 [

51] dynamic analysis needed to be carried out for bridge types with a complex behavior, one of which was the main span exceeding 200 m. In this study, the bridge width is 2.24 m and the bridge span is 3.20 m, and the ratio of the bridge width to the bridge span of 0.7 is still stable against aerodynamic effects due to wind loads according to Leondhart’s requirements (

B ≥

L/25) and still meets the maximum deflection requirements of AASHTO [

48] and RSNI T-12-2004 [

49], which is Δ

max = L/800 = 3.75 mm.

The next step was validating the stiffness of the beam and bridge trusses. The main principle is that the bridge must be in a service condition, with a Serviceability Limit State (SLS) load. The elements of the bridge structure should not be subjected to cracks, deflection, or vibrations causing user discomfort. The allowable deflections are those that are elastic deflection and do not cause the crack. Stiffness is the main parameter of structural resistance. Therefore, the stiffness of the field test results needs to be validated by the stiffness of the laboratory test results. Load–displacement relationship diagrams of the experimental results, laboratory results, and FEM analysis results are combined into one graph. The maximum test load of the bridge becomes the stiffness control limit, which is 15.50 kN. Based on the displacement of the laboratory test results, and the displacement of the field experiments results of the bamboo reinforced concrete frame precast bridge at a stop load of 15.50 kN, the displacement ratio of the laboratory test results to the displacement of the field experiment results (Δ

Exp/Δ

LAB) = 2.6 for the bridge frame and 4.07 for the bridge beam.

Figure 35 and

Figure 36 shows that the stiffness of the precast bridge beam and precast bridge frame increases ± 80% for the beam stiffness and increases ± 60% for the frame stiffness if it is used as an integral part of other bridge elements.

5. Conclusions

Based on the results of the laboratory tests and field experiments, it appears that the bridge displacement is quite small and comfortable for the user. The maximum beam displacement occurs when the rear wheel is at the center of the span at the 150 cm coordinates and the front wheel is at the 415.5 cm coordinates (the front wheel is outside the bridge). While, the maximum displacement of the frame occurs when the rear wheel is at the 100 cm coordinates and the front wheel is at the 365.5 cm coordinates (the front wheel is outside the bridge).

The minimum beam deformation occurs when the car axle is right on the neutral line of the beam; this shows that the coupling moment or torque due to the load is a factor that greatly affects the size of the beam deformation. Gravity load right on the neutral line can reduce deformation and increase the deflection of the beam and bridge frame, and the size of the torque moment can affect the size of the deformation.

There is a difference in the maximum deformation occurrence between the beam and the bridge frame, namely, the maximum beam deformation occurs when the load is outside the beam coordinates, while the maximum frame deformation occurs when the load is in the middle of the bridge span and outside the frame coordinates.

Precast bamboo reinforced concrete frame bridges have sufficiently good integrity; that is, they can distribute loads with deflection and deformation that do not exceed their permits. The maximum displacement of 0.25 mm meets the requirements based on the AASTHO and RSNI T-12-2004 standards, which is not more than Δmax = L/800 = 3.75 mm. The maximum deformation occurs in the bridge beam of 0.20 mm, and the bridge frame of 0.13 mm meets the requirements based on the AASTHO and RSNI T-12-2004 standards, which is not more than δmax = L/800 = 3.75 mm.

At the stop load of P = 15.5 kN, the stiffness of the bridge beam increased ±80% during the bridge test when compared with the beam stiffness of the laboratory results. Likewise, the stiffness of the bridge frame increased ±60% during the bridge test when compared to the frame stiffness of the laboratory results.