Effect of High-Temperature Pavement Paving on Fatigue Durability of Bearing-Supported Steel Decks

Abstract

:1. Introduction

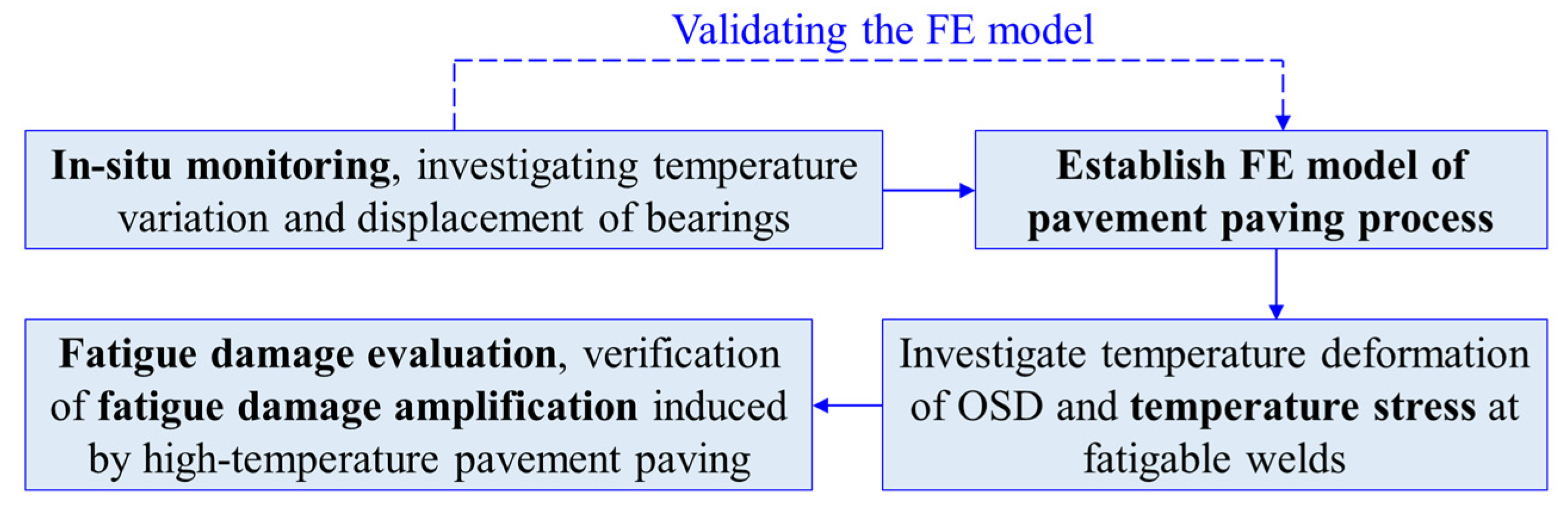

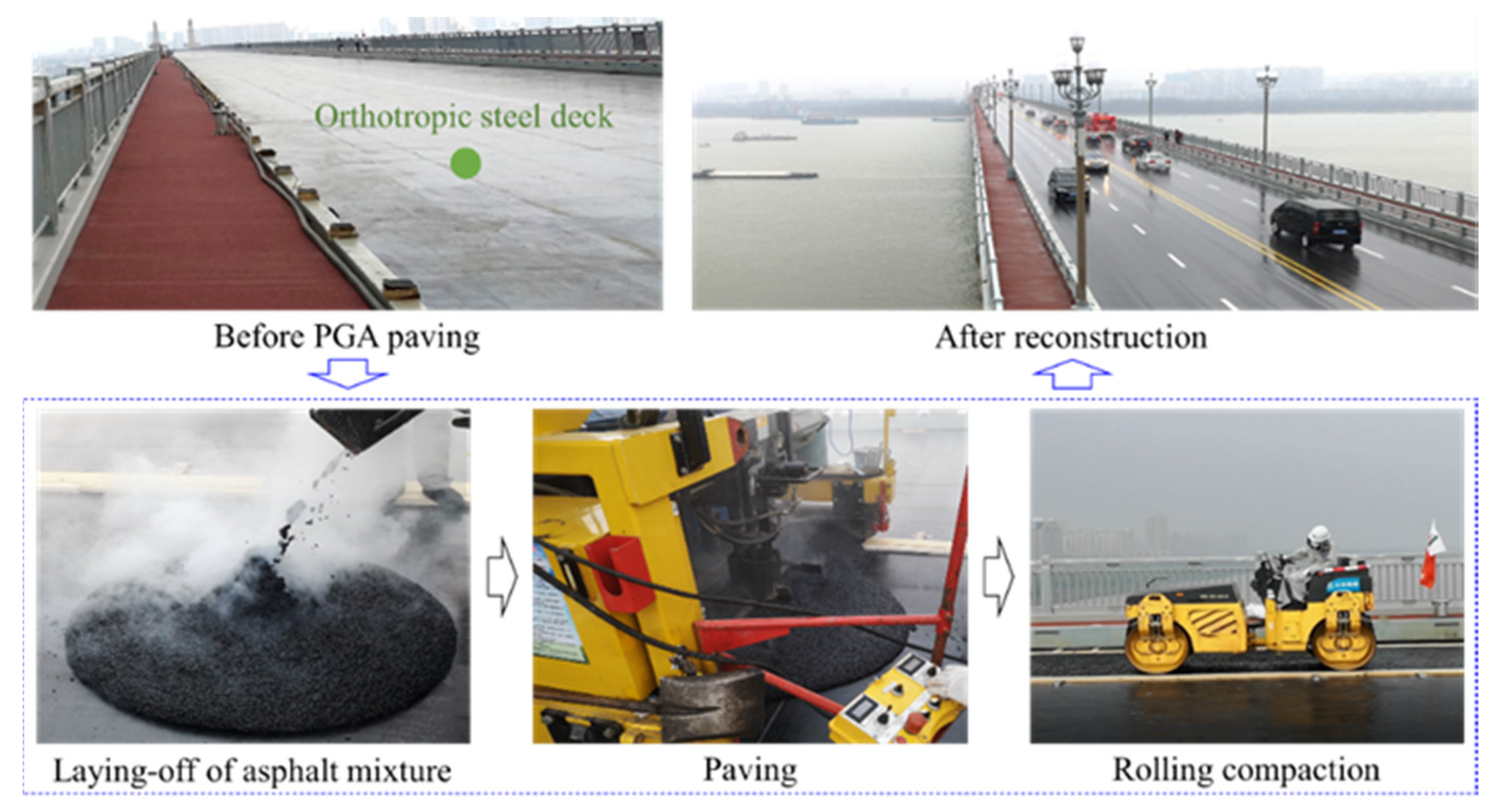

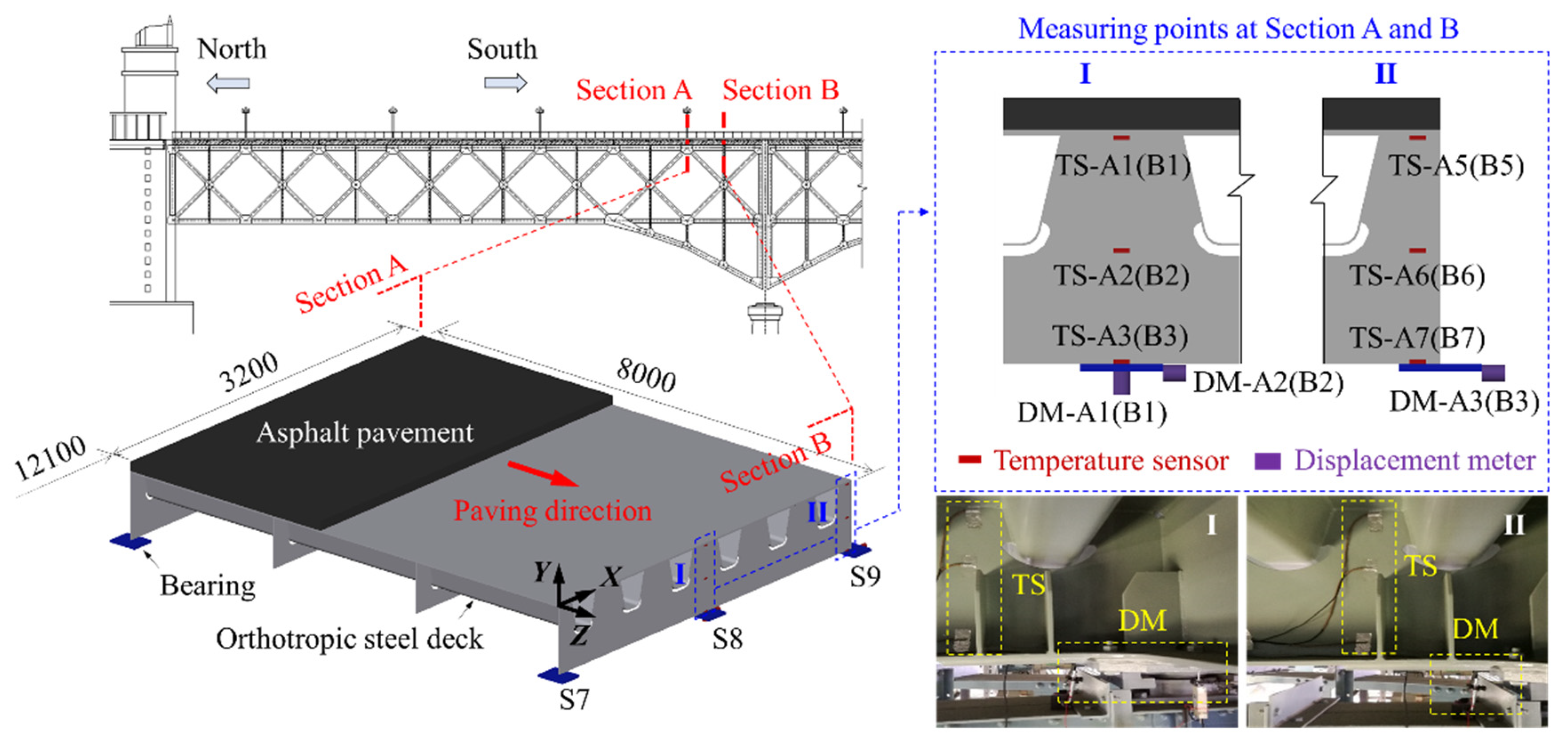

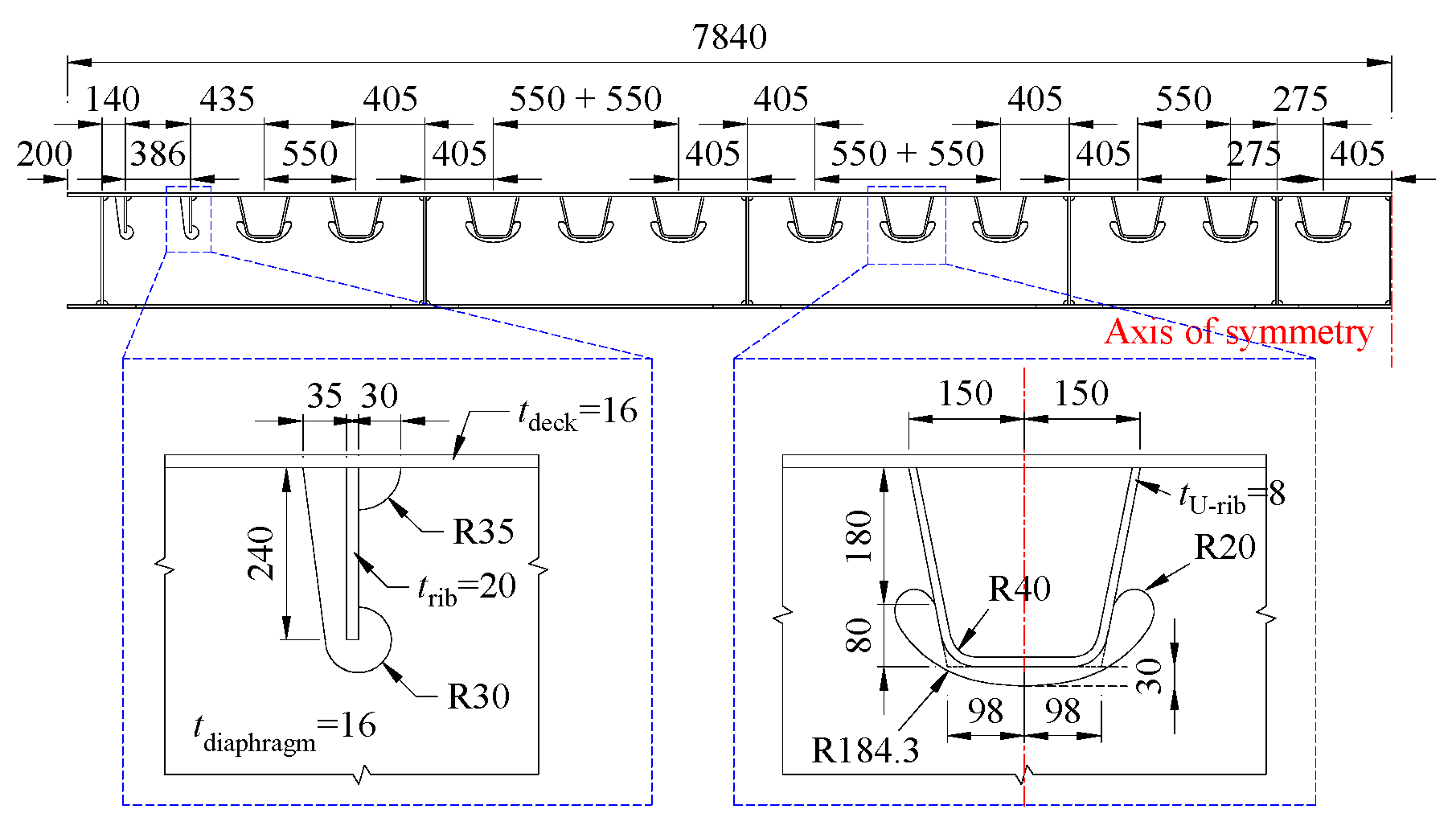

2. Background of Project

3. Field Monitoring

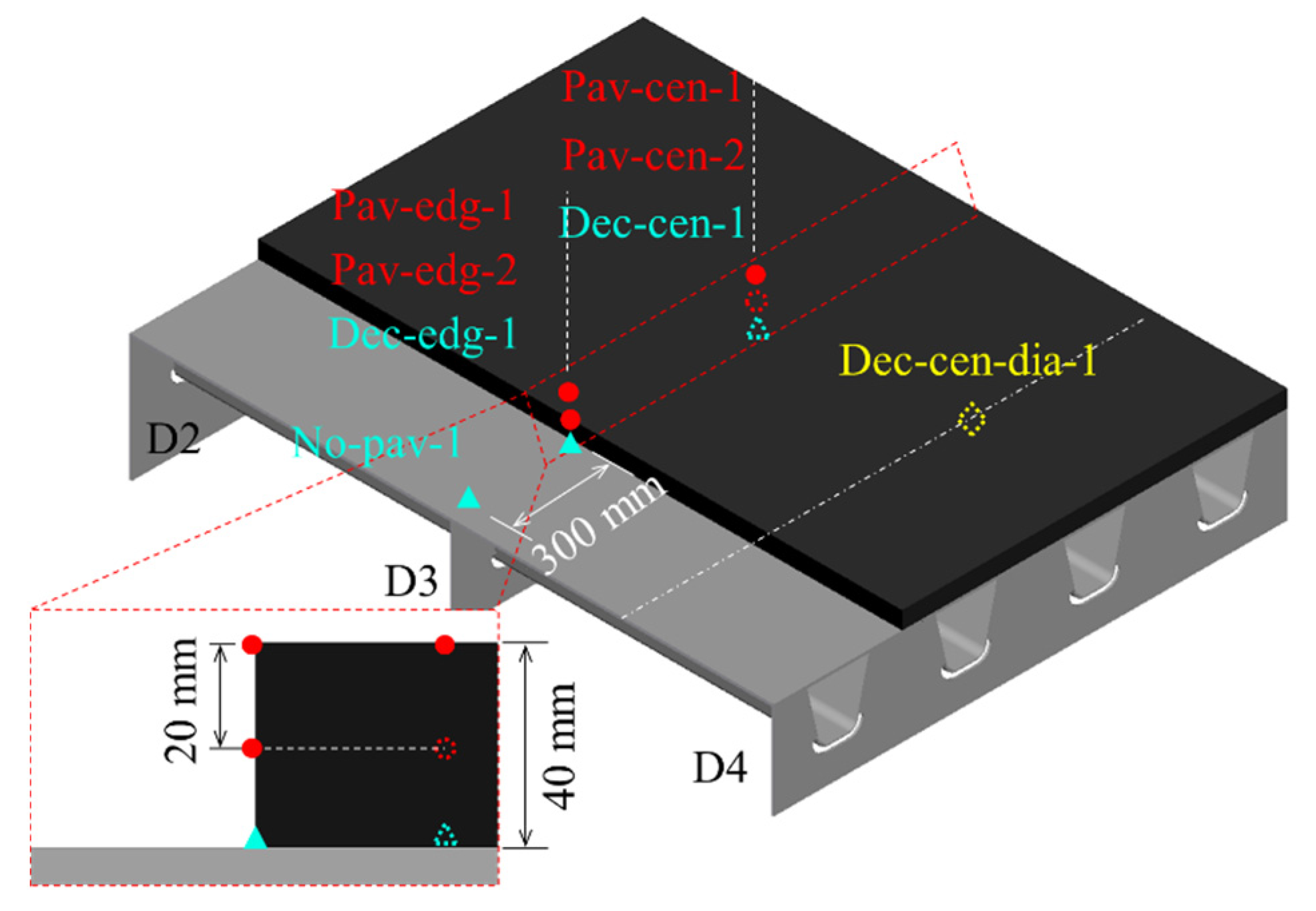

3.1. Layout of Measuring Points

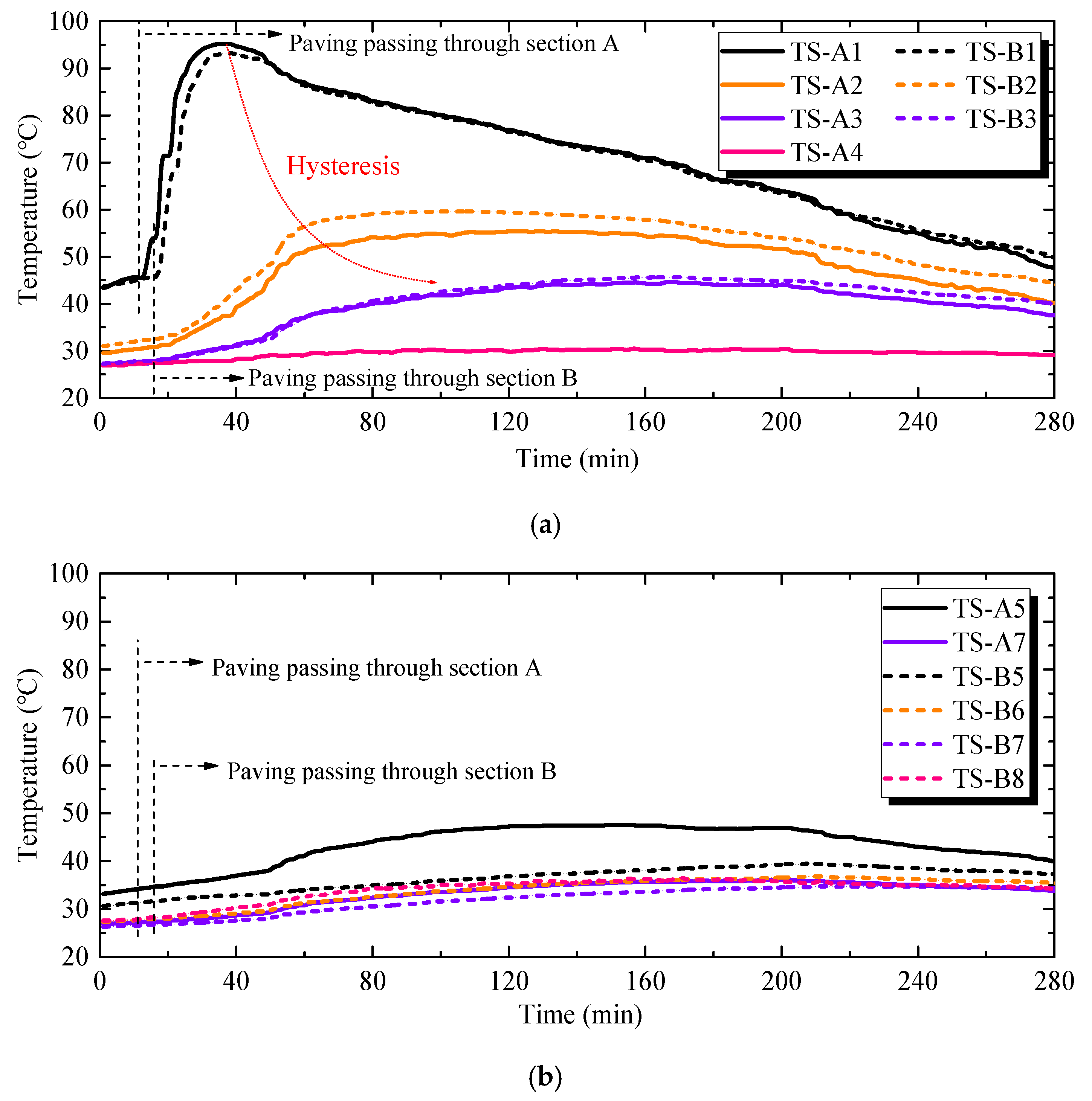

3.2. Temperature Variation during the Paving Process

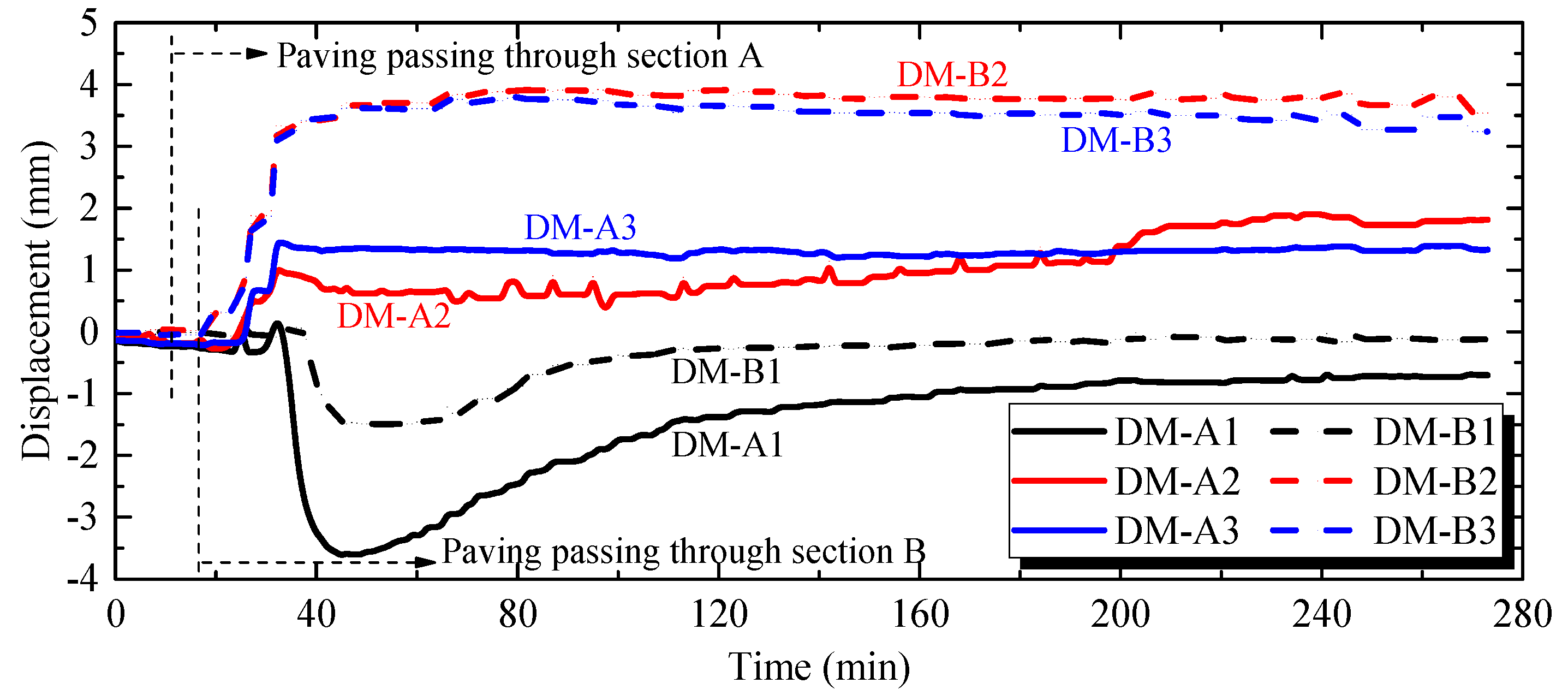

3.3. Displacement of the Bearings

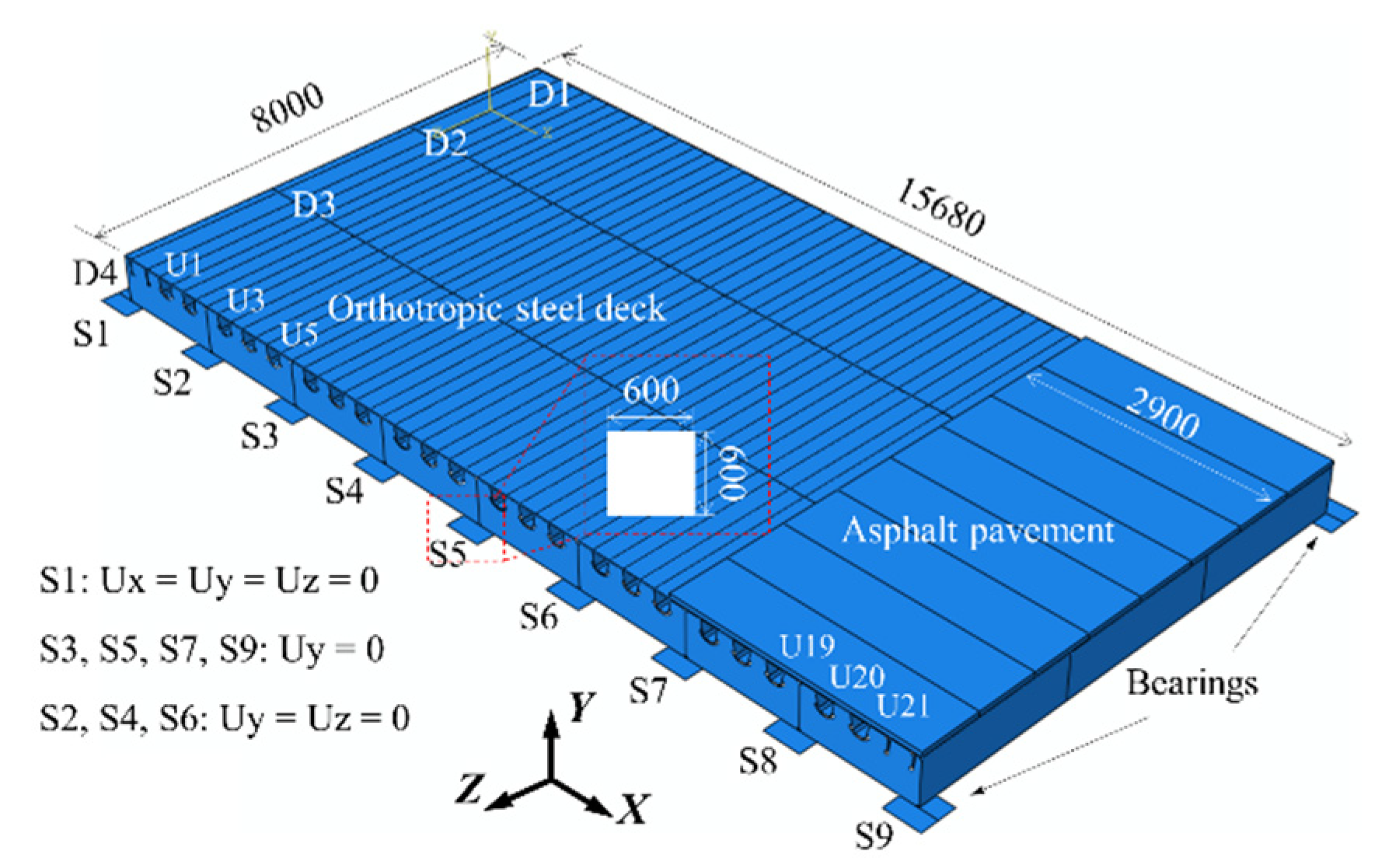

4. Modeling of High-Temperature Pavement Paving

4.1. Coupled Thermal-Structural Analysis

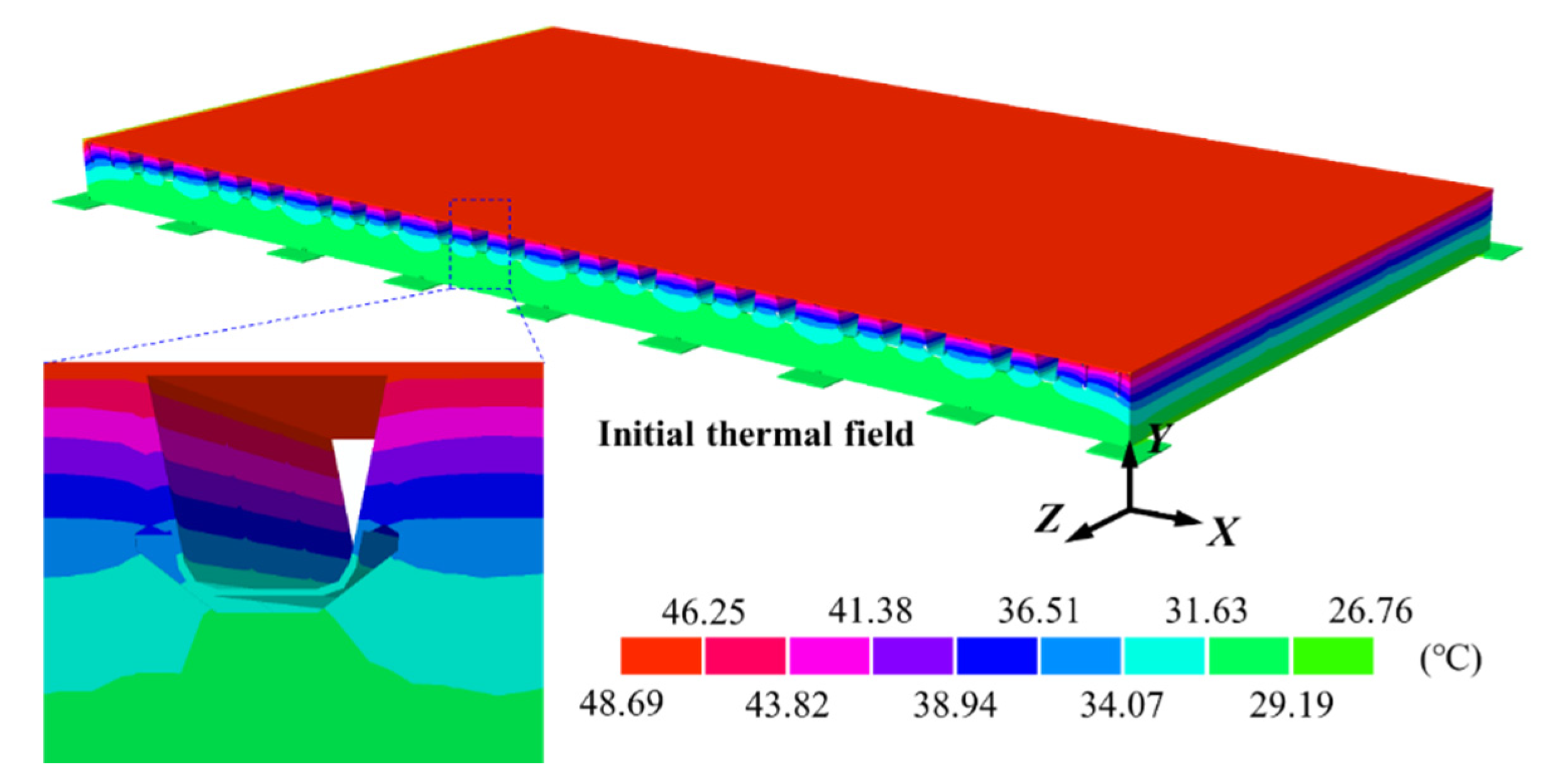

4.2. Initial Thermal Field

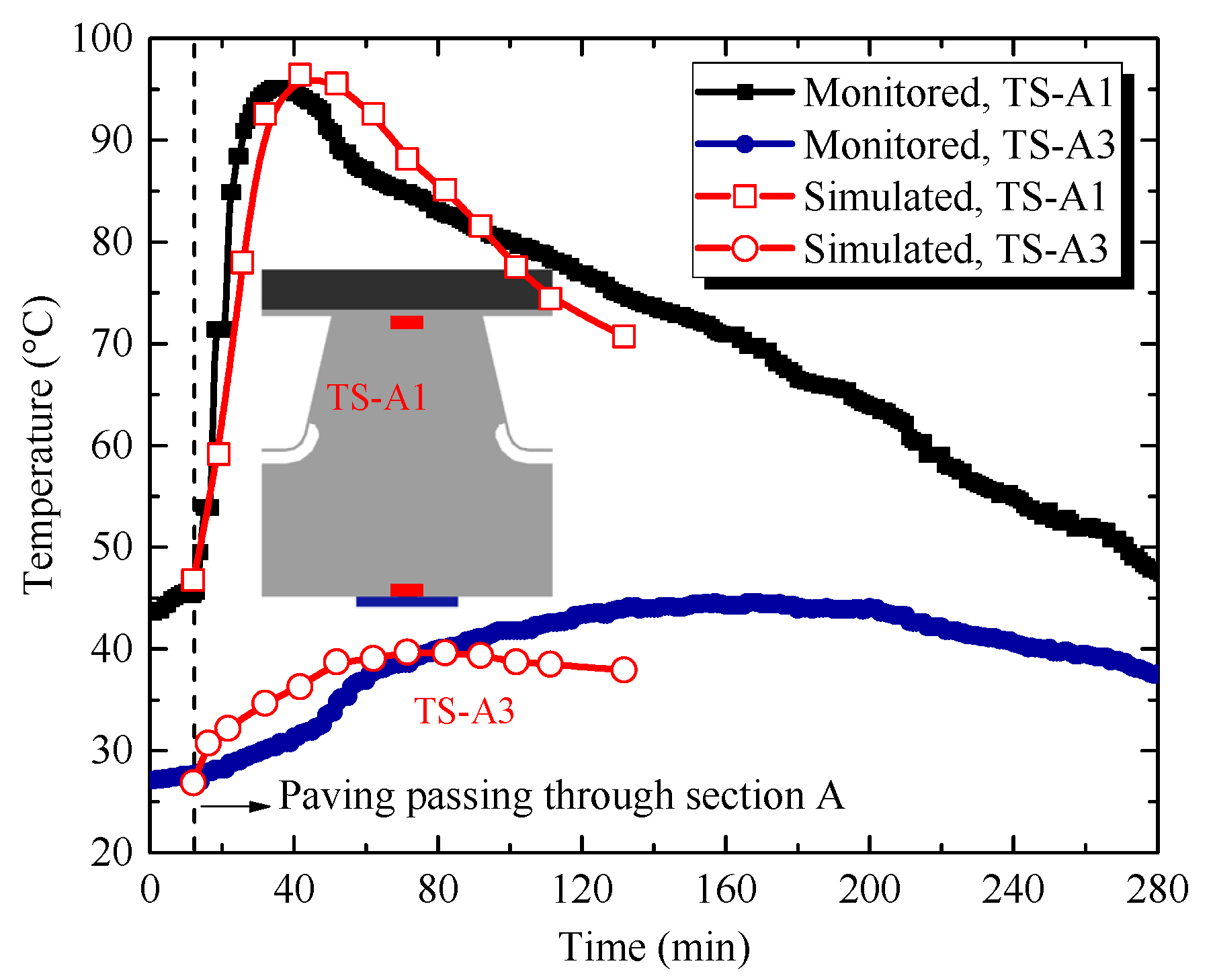

4.3. Validation of the Model

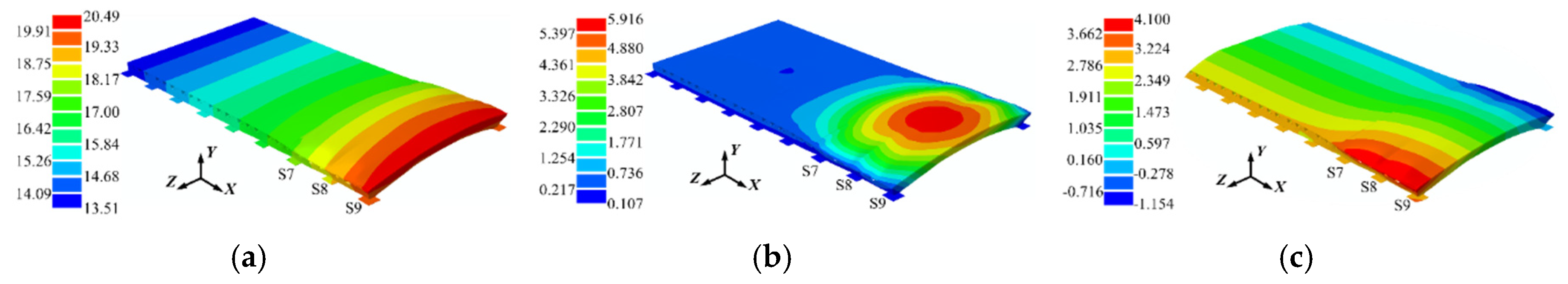

5. Temperature Deformation and Stress

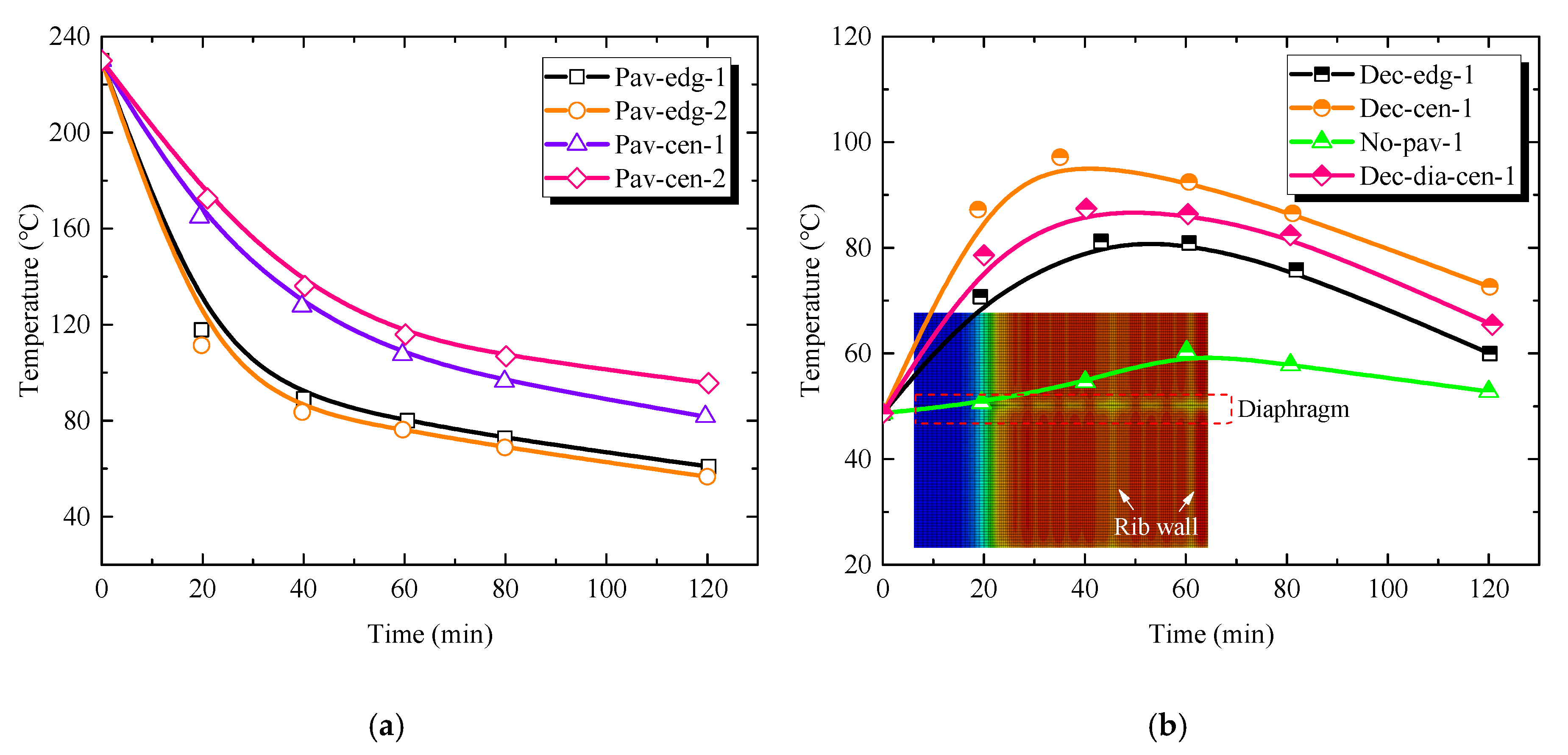

5.1. Temperature Variation at Pavement and Deck Plate

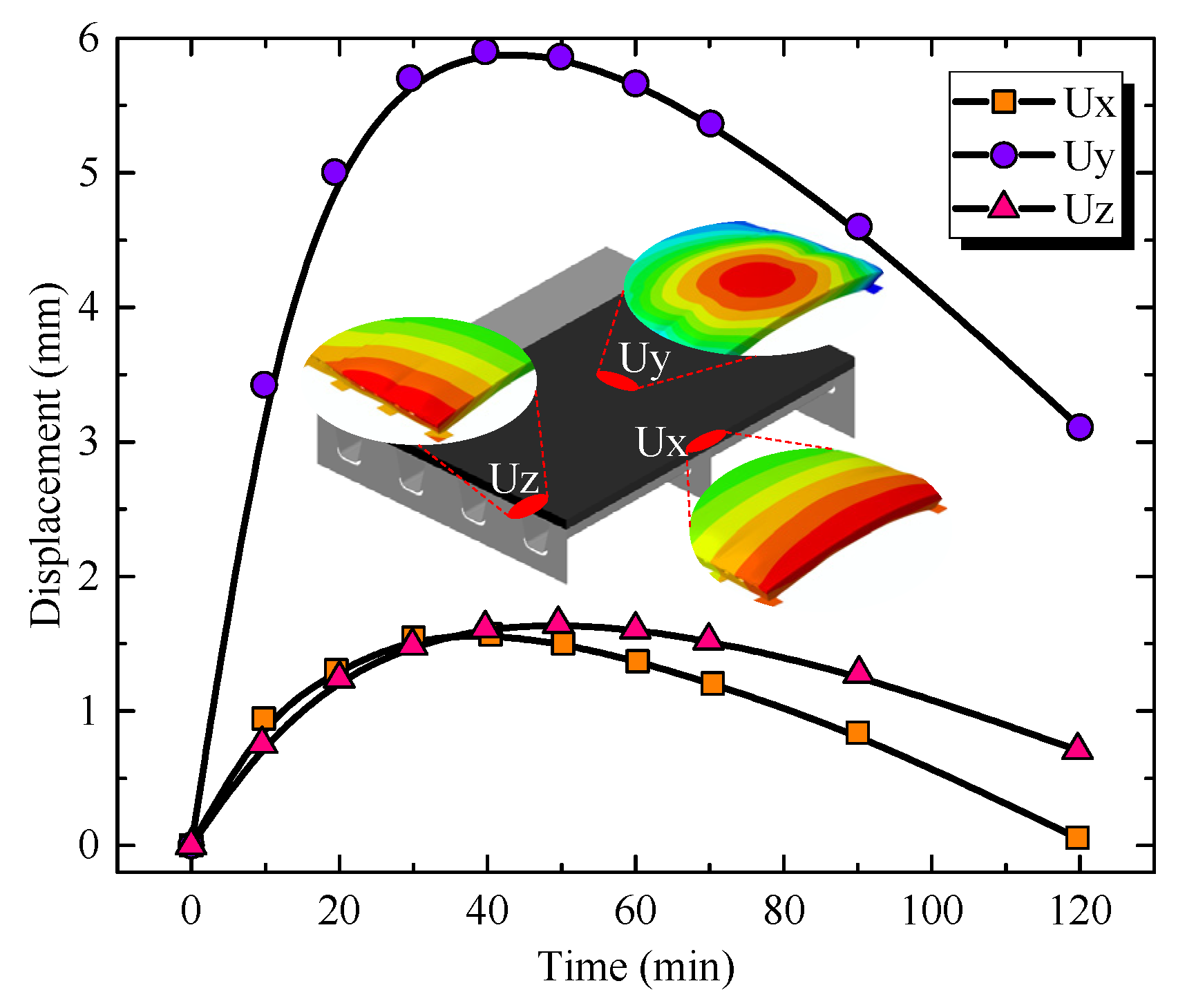

5.2. Deformation of the OSD

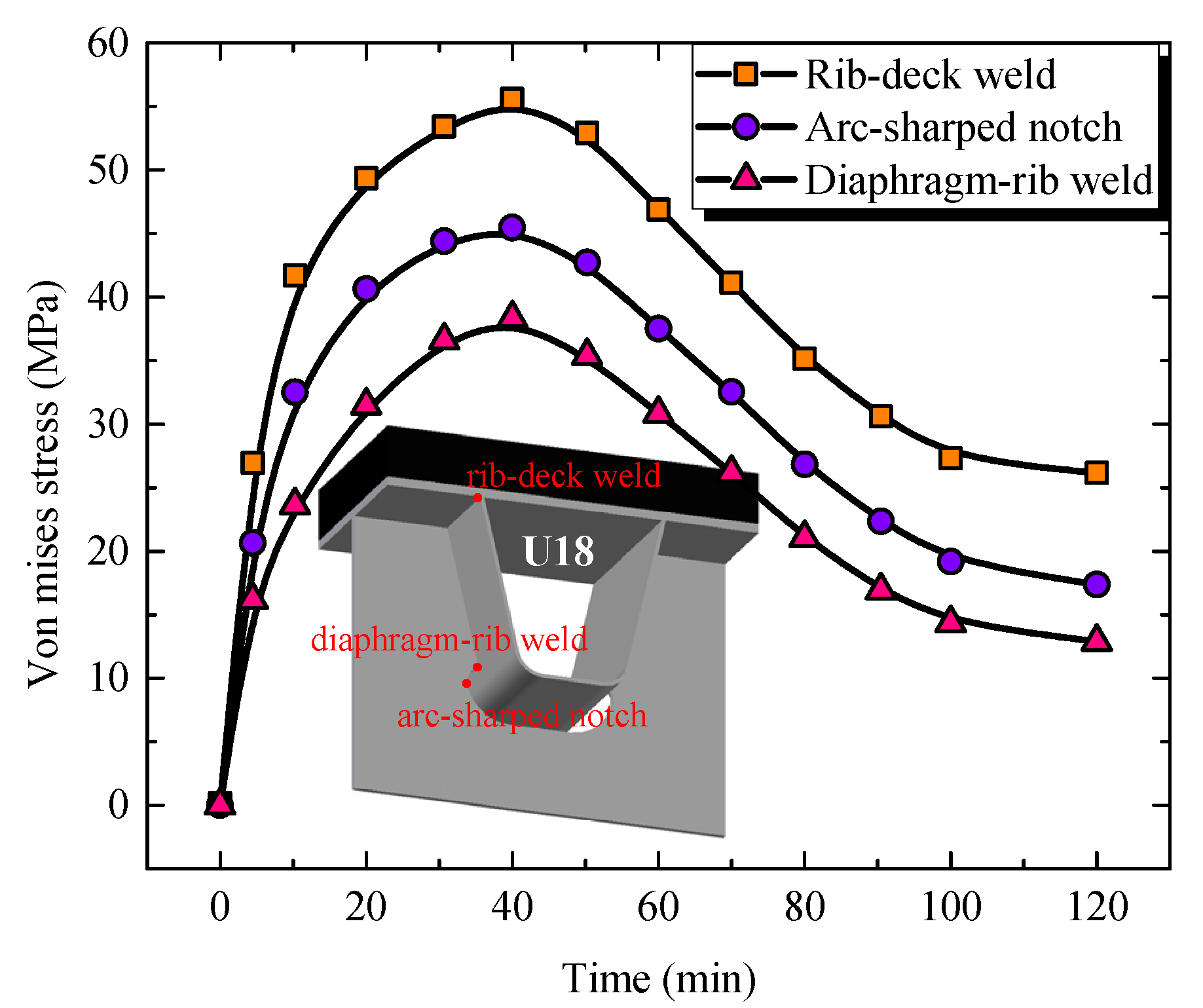

5.3. Temperature Stress at Fatigable Details

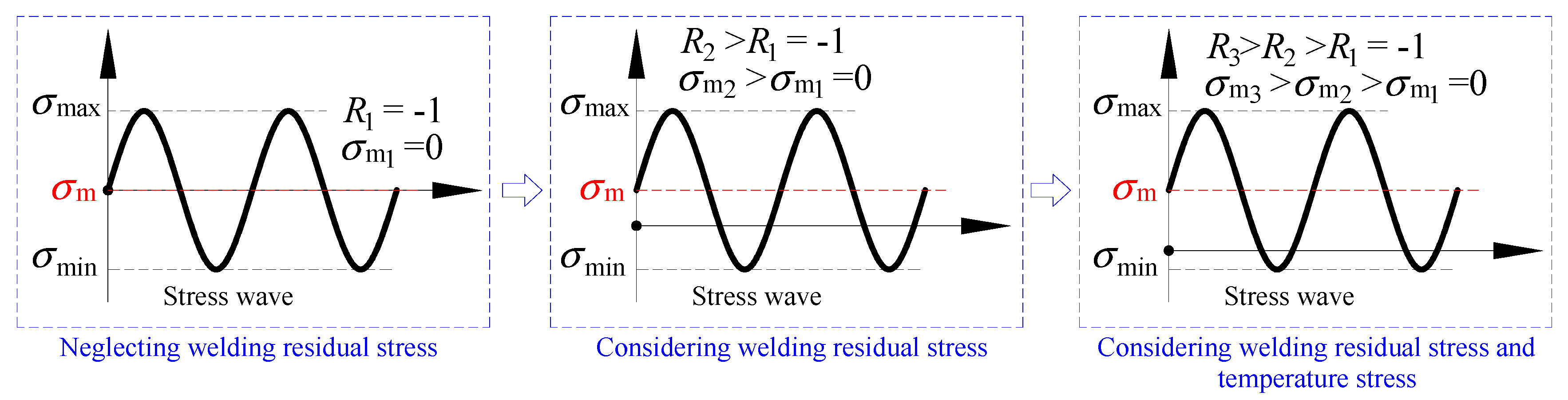

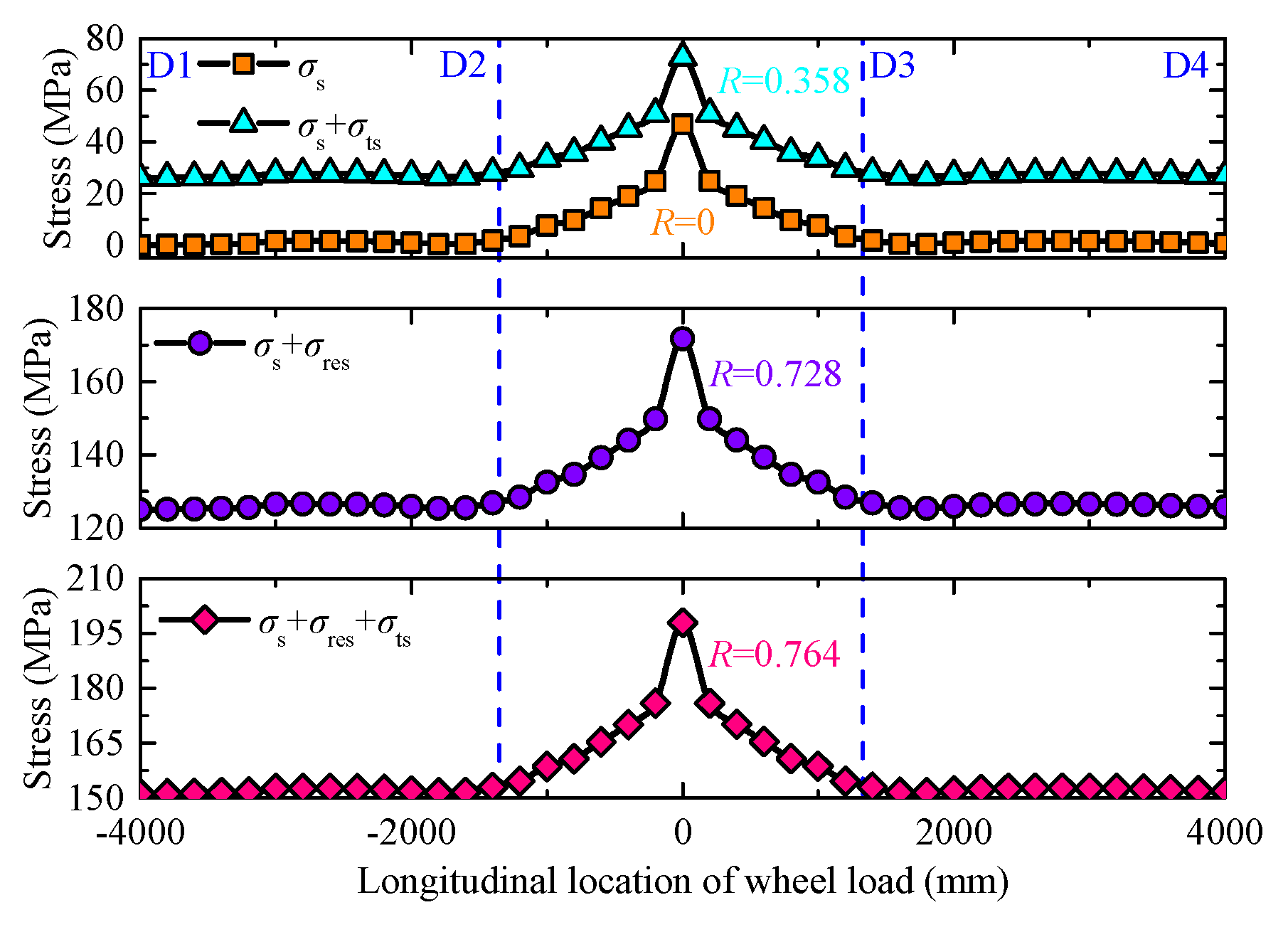

6. Fatigue Damage Evaluation Considering Residual Temperature Stress

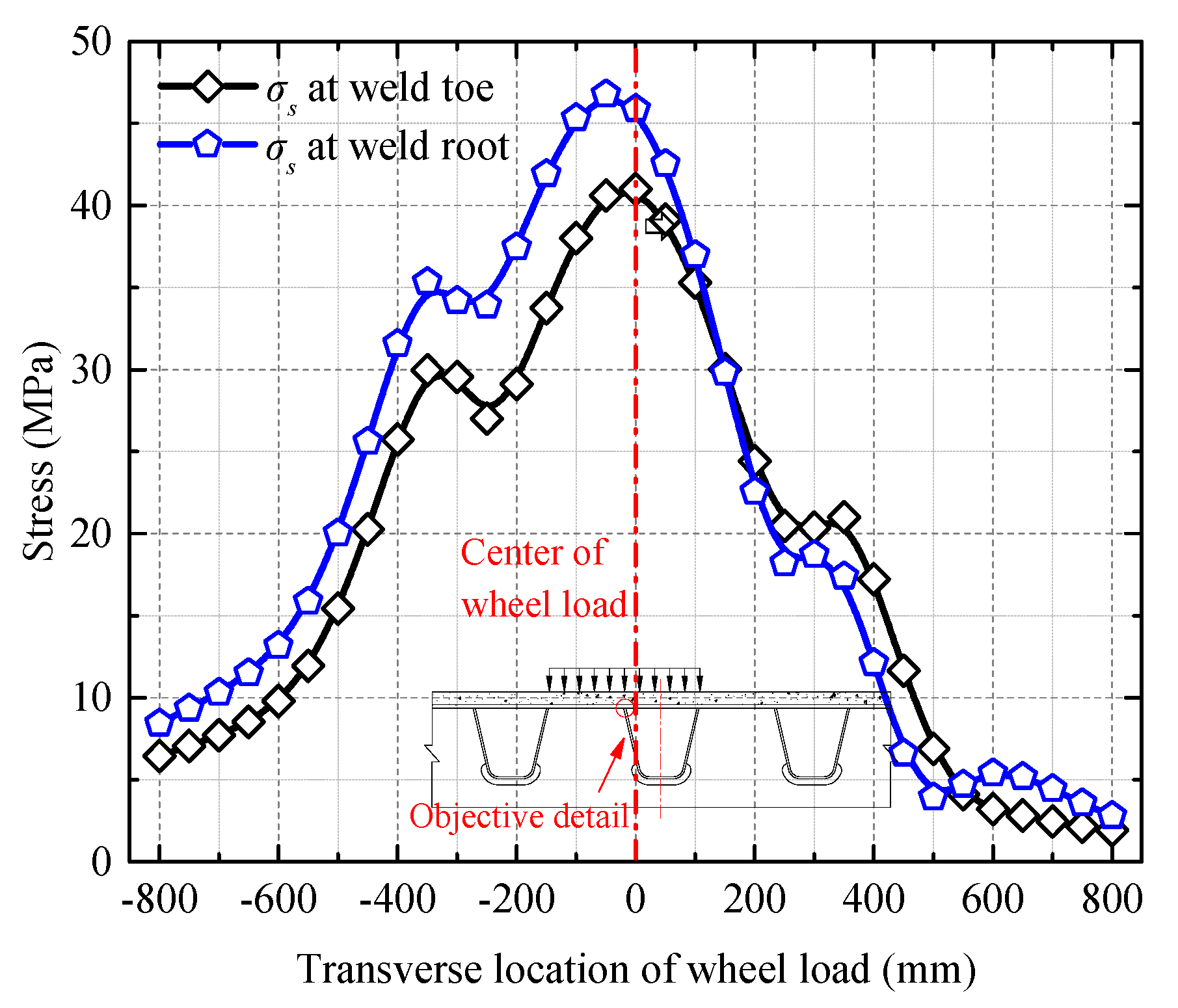

6.1. Refining the FE Model

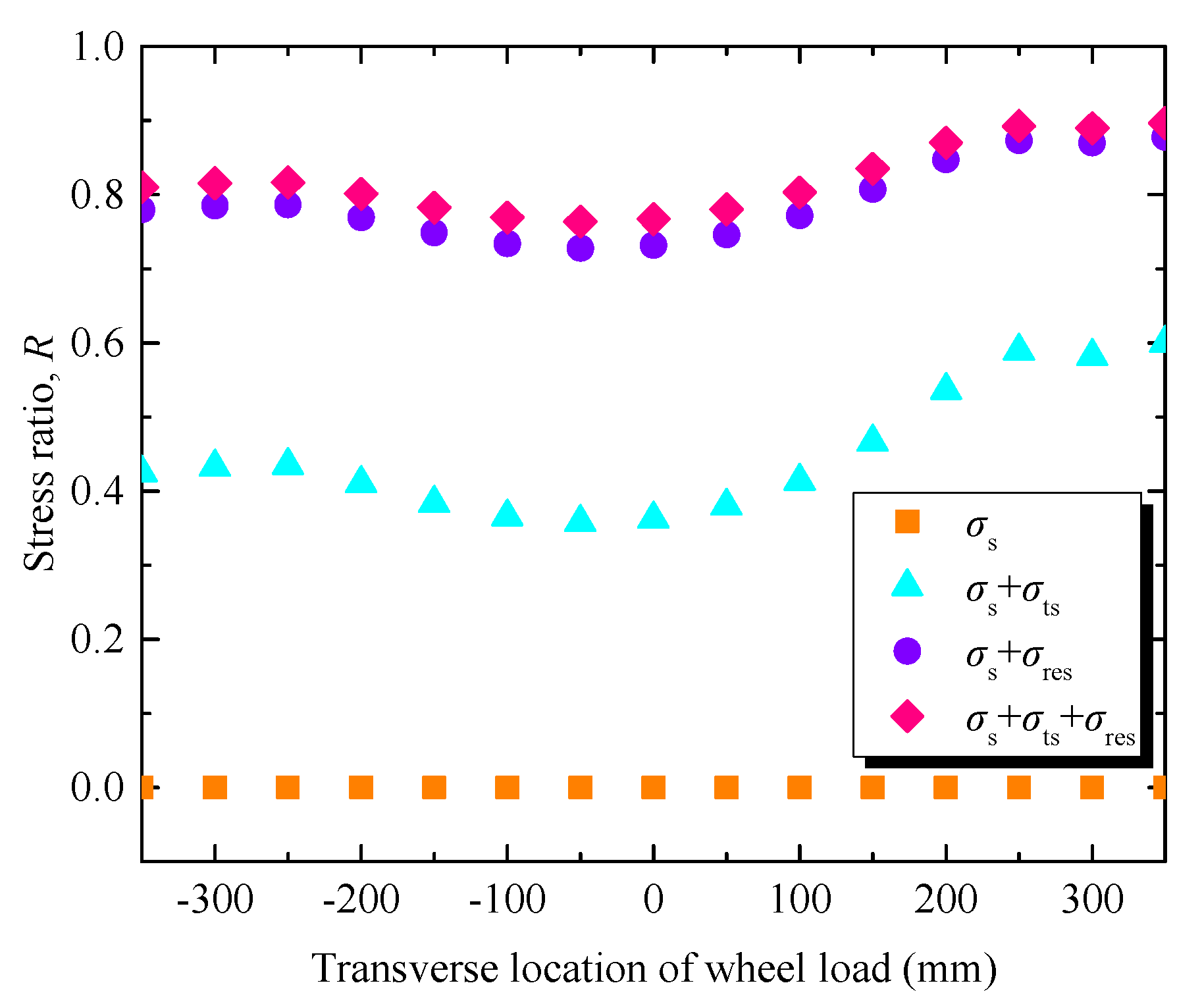

6.2. Consideration of Transverse Distribution of Wheel Load

6.3. Consideration of Residual Temperature Stress

6.4. Fatigue Damage Evaluation and Comparison

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xiao, Z.G.; Yamada, K.; Ya, S.; Zhao, X.L. Stress analyses and fatigue evaluation of rib-deck joints in steel orthotropic decks. Int. J. Fatigue 2008, 30, 1387–1397. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, Z.D.; Hu, J.; Jin, L. Temperature behavior and stability analysis of orthotropic steel bridge deck during gussasphalt PGA paving. J. Bridge Eng. 2017, 23, 04017117. [Google Scholar] [CrossRef]

- Memari, M.; Mahmoud, H. Performance of steel moment resisting frames with RBS connections under fire loading. Eng. Struct. 2014, 75, 126–138. [Google Scholar] [CrossRef]

- Skriko, T.; Ghafouri, M.; Björk, T. Fatigue strength of TIG-dressed ultra-high-strength steel fillet weld joints at high stress ratio. Int. J. Fatigue 2017, 94, 110–120. [Google Scholar] [CrossRef]

- Cao, B.Y.; Ding, Y.L.; Song, Y.S.; Zhong, W. Fatigue life evaluation for deck-rib welding details of orthotropic steel deck integrating mean stress effects. J. Bridge Eng. 2019, 24, 04018114. [Google Scholar] [CrossRef]

- Ding, Y.L.; Zhou, G.D.; Li, A.Q.; Wang, G.X. Thermal field characteristic analysis of steel box girder based on long-term measurement data. Int. J. Steel Struct. 2012, 12, 219–232. [Google Scholar] [CrossRef]

- Tong, M.; Tham, L.G.; Au, F.T.K.; Lee, P.K.K. Numerical modelling for temperature distribution in steel bridges. Comput. Struct. 2001, 79, 583–593. [Google Scholar] [CrossRef]

- Kim, S.H.; Cho, K.I.; Won, J.H.; Kim, J.H. A study on thermal behaviour of curved steel box girder bridges considering solar radiation. Arch. Civ. Mech. Eng. 2009, 9, 59–76. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, Z.D.; Hu, H.Z. Thermal field characteristic analysis of steel bridge deck during high-temperature asphalt PGA paving. KSCE J. Civ. Eng. 2016, 20, 2811–2821. [Google Scholar] [CrossRef]

- Zhou, L.R.; Xia, Y.; Brownjohn, J.M.W.; Koo, K.Y. Temperature analysis of a long-span suspension bridge based on field monitoring and numerical simulation. J. Bridge Eng. 2016, 22, 04015027. [Google Scholar] [CrossRef]

- Xu, X.; Huang, Q.; Ren, Y.; Zhao, D.Y. Modeling and separation of thermal effects from cable-stayed bridge response. J. Bridge Eng. 2019, 24, 04019028. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.J.; Jiang, L.; Zhang, N. Long-term field test of temperature gradients on the composite girder of a long-span cable-stayed bridge. Adv. Struct. Eng. 2019, 22, 2785–2798. [Google Scholar] [CrossRef]

- Rajbongshi, P.; Das, A. Estimation of residual temperature stress and low-temperature crack spacing in asphalt surfacing. J. Transp. Eng. 2009, 135, 745–752. [Google Scholar] [CrossRef]

- Wang, Q.D.; Ji, B.H.; Chen, X.; Ye, Z. Dynamic response analysis-based fatigue evaluation of rib-to-deck welds considering welding residual stress. Int. J. Fatigue 2019, 129, 105249. [Google Scholar] [CrossRef]

- JTG D64-2015. Specifications for Design of Highway Steel Bridge; China Communications Press: Beijing, China, 2015. (In Chinese) [Google Scholar]

- Fu, Z.Q.; Wang, Y.X.; Ji, B.H.; Jiang, F. Effects of multiaxial fatigue on typical details of orthotropic steel bridge deck. Thin Walled Struct. 2019, 135, 137–146. [Google Scholar] [CrossRef]

- Wang, Q.D.; Ji, B.H.; Fu, Z.Q.; Yao, Y. Effective notch stress approach-based fatigue evaluation of rib-to-deck welds including pavement surfacing effects. Int. J. Steel Struct. 2020, 20, 272–286. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Solar radiation intensity (W/m2) | 800 | Paving temperature (°C) | 230 |

| Ambient temperature (°C) | 40 | Pavement thickness (mm) | 40 |

| Wind speed (m/s) | 1 | Paving speed (m/min) | 2.0 |

| Measuring Point | Measured Result, tm (°C) | Numerical Result, tn (°C) | (tn − tm)/ tm × 100% |

|---|---|---|---|

| TS-A1 | 43.44 | 46.77 | 7.67% |

| TS-A2 | 29.71 | 30.88 | 3.94% |

| TS-A3 | 27.44 | 26.87 | −2.08% |

| Case | D1 | D2 | D3 | D4 | (D2 − D1)/D1 | (D4 − D3)/D3 |

|---|---|---|---|---|---|---|

| Fatigue damage | 7.88 × 10−5 | 1.09 × 10−4 | 1.97 × 10−4 | 2.17 × 10−4 | 38.3% | 10.2% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Ji, B.; Fu, Z.; Wang, H. Effect of High-Temperature Pavement Paving on Fatigue Durability of Bearing-Supported Steel Decks. Appl. Sci. 2020, 10, 7196. https://doi.org/10.3390/app10207196

Wang Q, Ji B, Fu Z, Wang H. Effect of High-Temperature Pavement Paving on Fatigue Durability of Bearing-Supported Steel Decks. Applied Sciences. 2020; 10(20):7196. https://doi.org/10.3390/app10207196

Chicago/Turabian StyleWang, Qiudong, Bohai Ji, Zhongqiu Fu, and Hao Wang. 2020. "Effect of High-Temperature Pavement Paving on Fatigue Durability of Bearing-Supported Steel Decks" Applied Sciences 10, no. 20: 7196. https://doi.org/10.3390/app10207196