Improving a Cable Robot Recovery Strategy by Actuator Dynamics

Abstract

1. Introduction

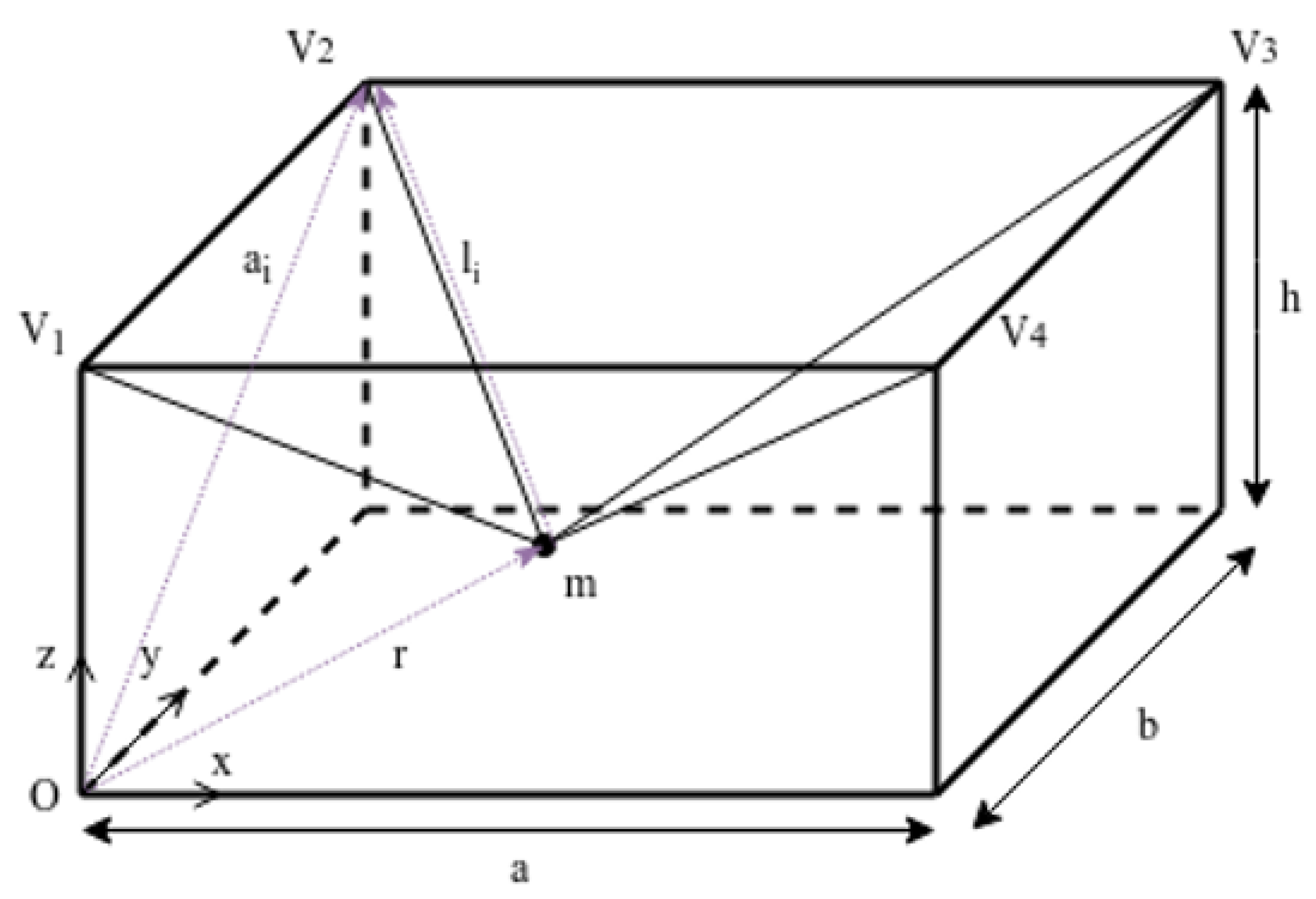

2. Cable Robot Model

2.1. Robot Dynamics

2.2. Actuator Dynamics

3. After Failure Strategy Approach

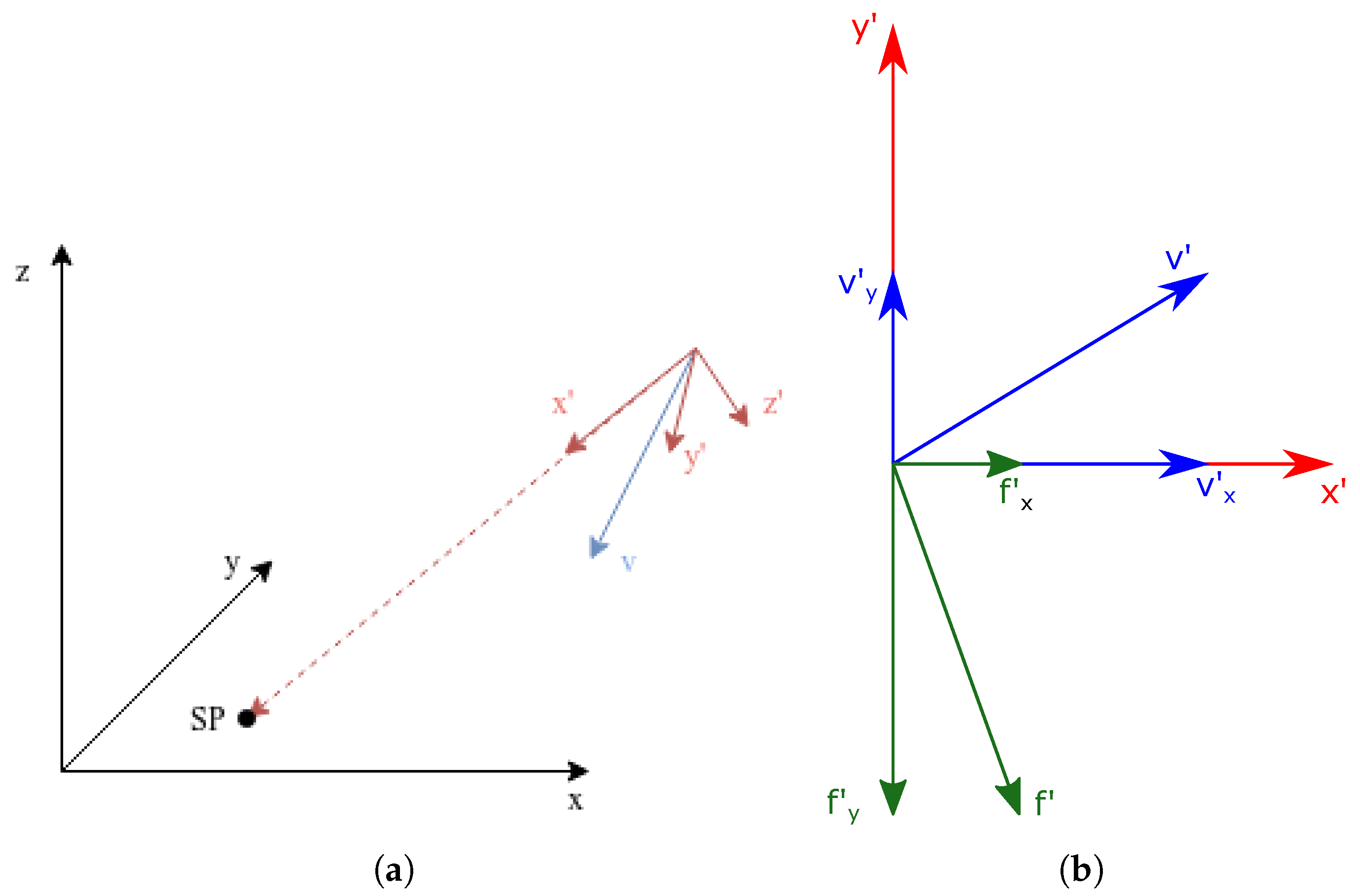

3.1. Connecting Path

3.1.1. Linear Programming Problem

- The first two rotations and are applied to align the x-axis with the direction d of the desired velocity component;

- The third rotation is such that the undesired velocity component (i.e., the orthogonal one) is aligned with the y-axis.

3.1.2. Real-Time Approach

- In the first iteration, the algorithm rotates the mobile reference frame of along the z-axis, in order to align the x-axis with the direction opposing ;

- The WEC index geometric formulation is used to evaluate the maximum and minimum force along the new x-axis;

- The evaluated force limits are verified in terms of cable tensions and actuator torques, i.e., the constraints in (18) must be satisfied;

- If the constraints are not satisfied, a new iteration is carried out, rotating the initial mobile frame along the z-axis of an angle lower than the previous one, i.e., <90, until the constraints are fulfilled.

3.2. Motion Planning along a Straight Path

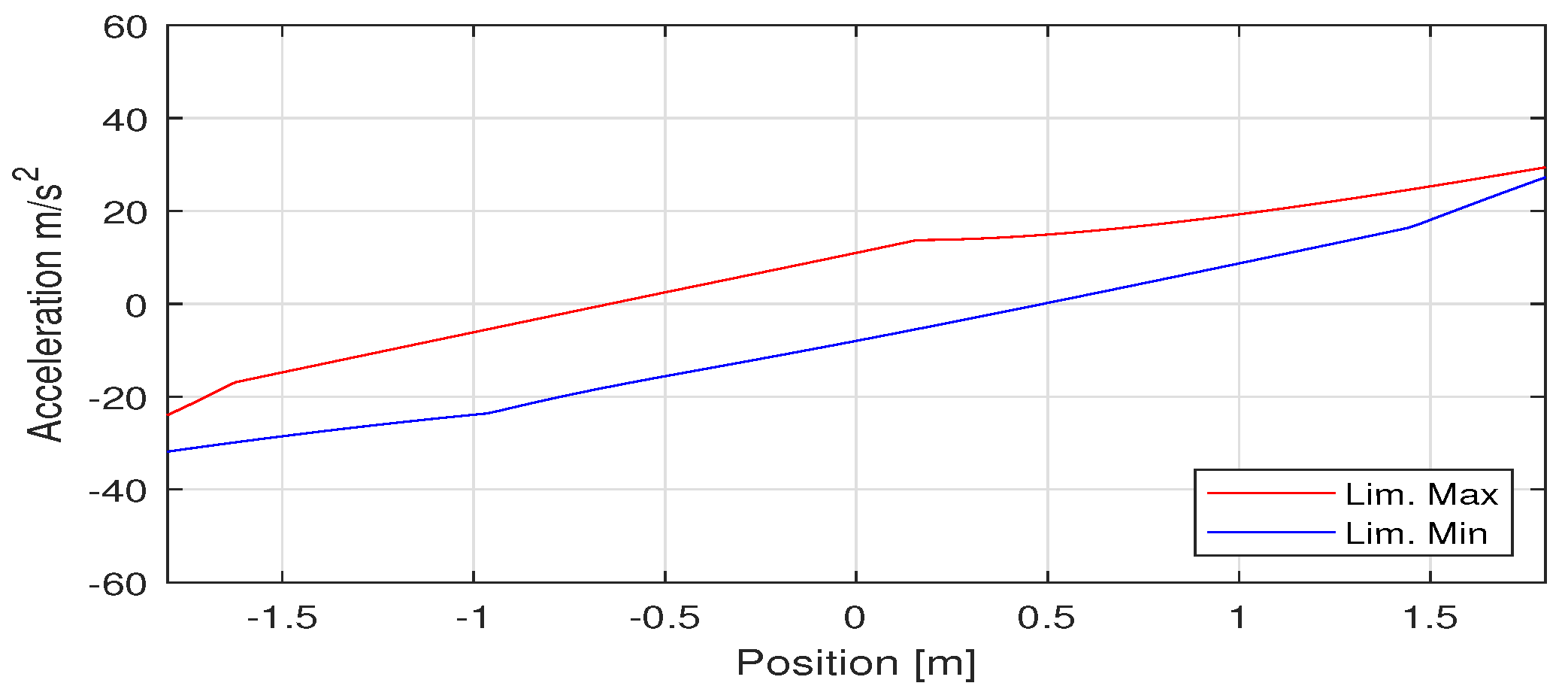

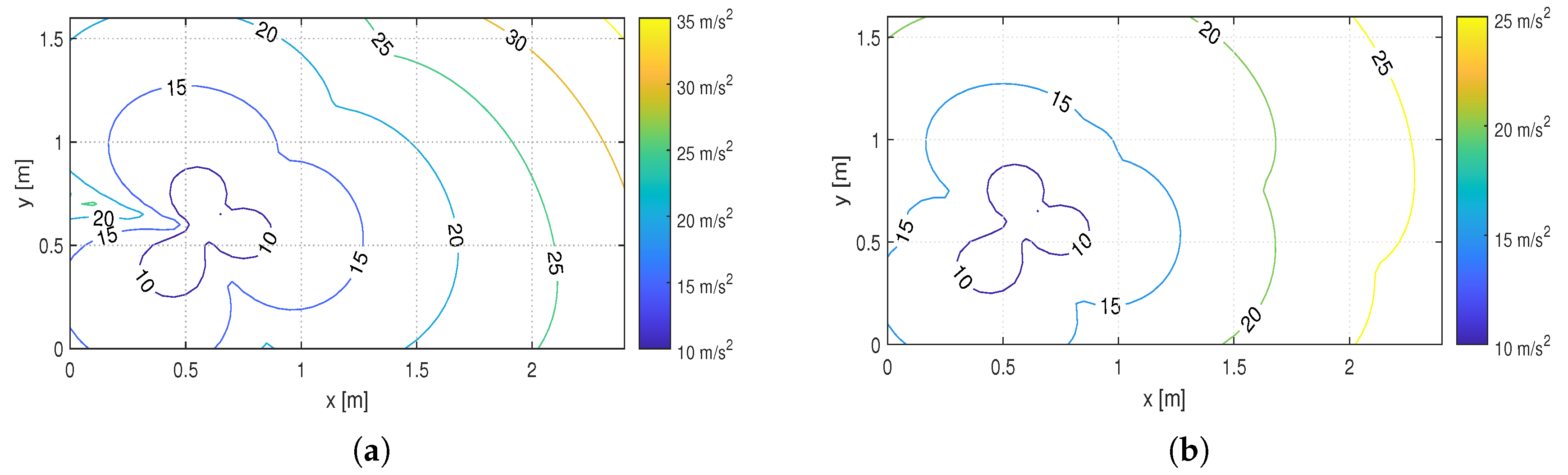

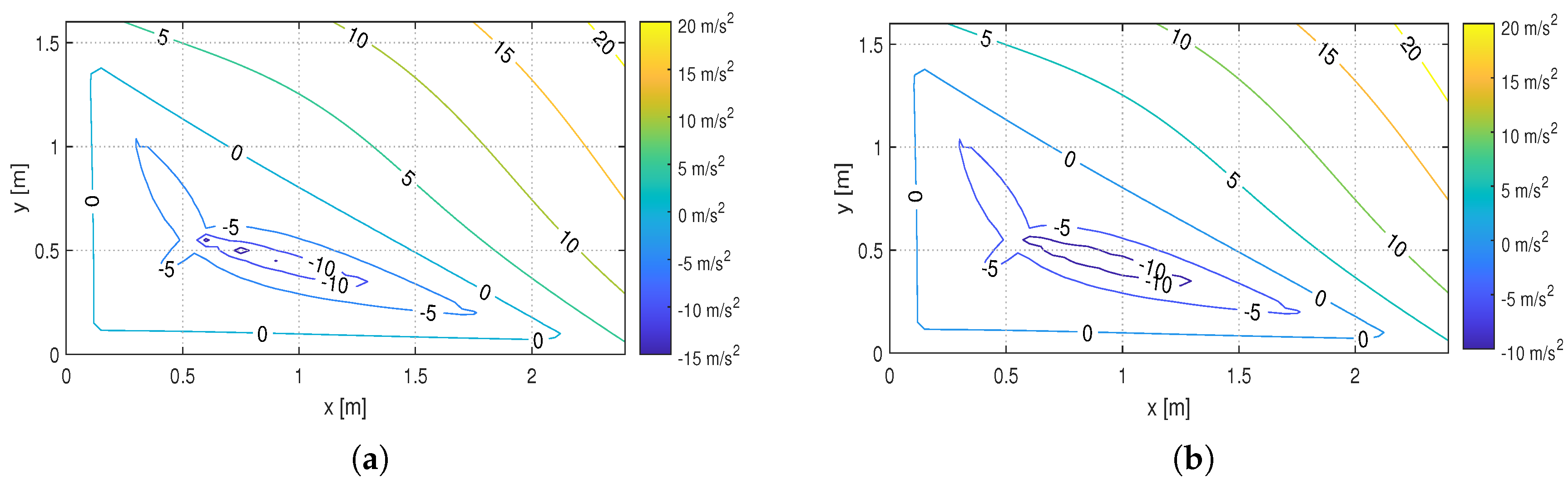

3.2.1. Wec Analysis

3.2.2. Real Time Approach

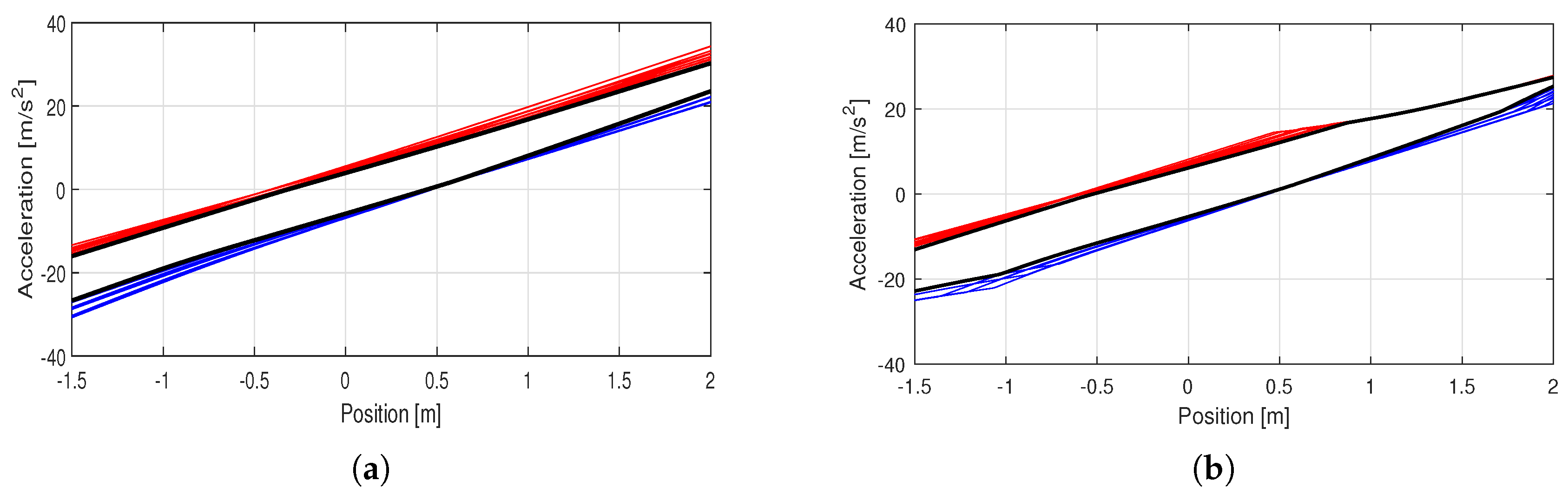

- Evaluation of the fast WEC and the acceleration limits along the direction d;

- Given the acceleration limits, using (7) it is possible to evaluate the maximum and minimum value of the actuator torque corresponding to the acceleration limits;

- If the torque limits are not respected, the acceleration limits are reduced to fulfill the constraints. This step is iterative and is not completed until the torque constraints are respected.

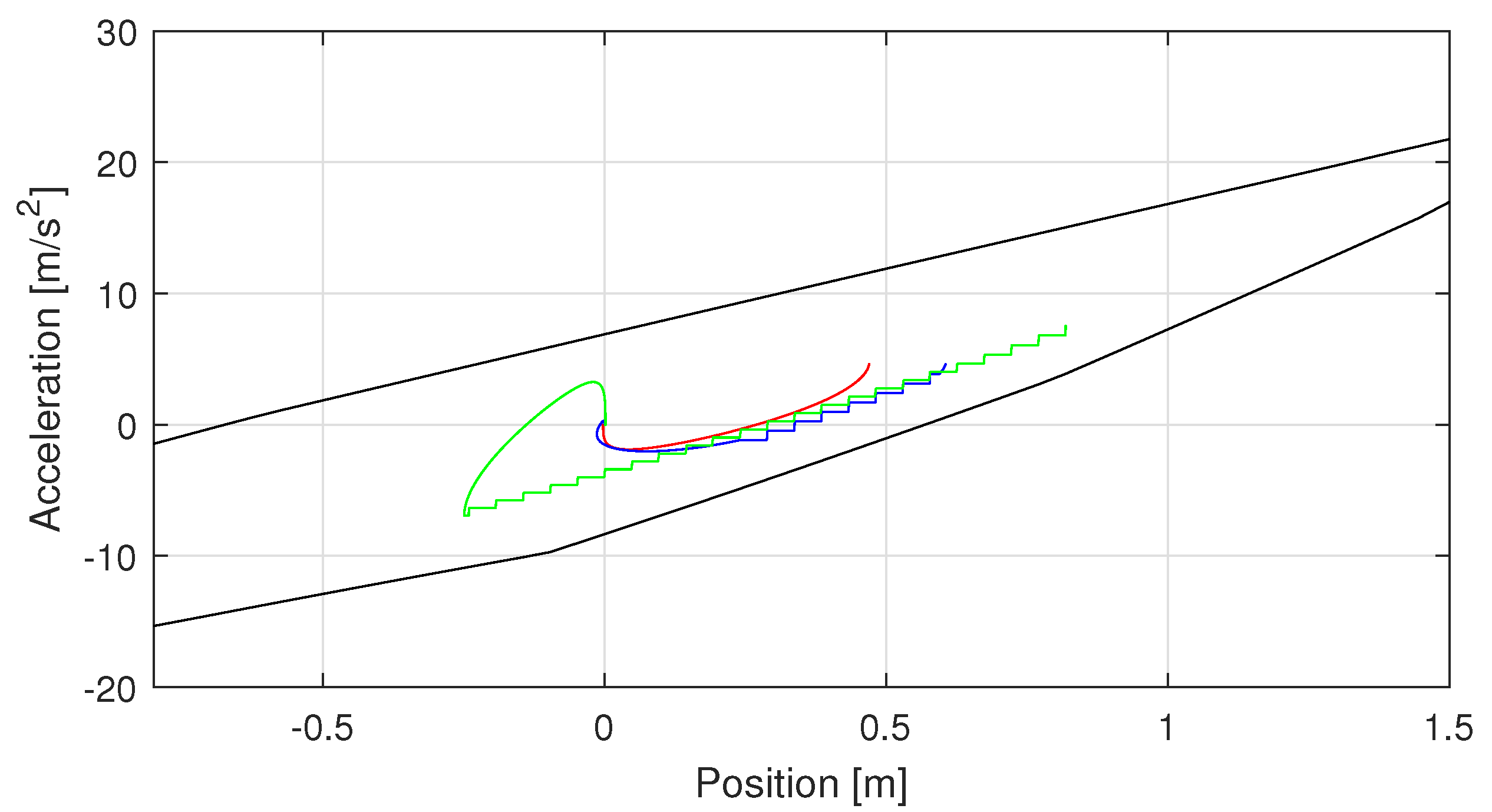

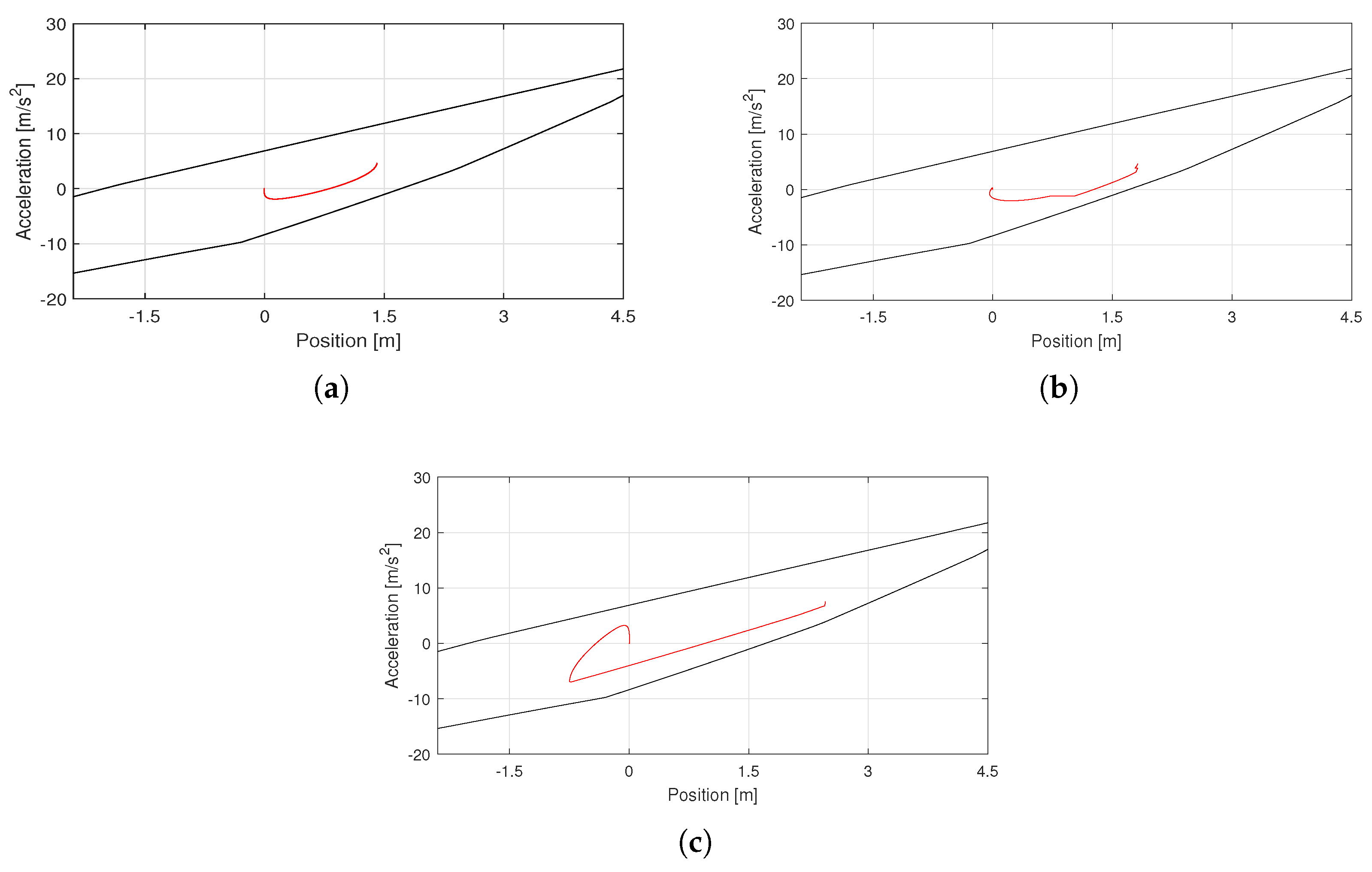

3.3. Motion Planning

- The acceleration limits are respected and the trajectory is feasible and does not require any changes;

- The trajectory must be modified to respect the acceleration limits, but the end-effector stops at the SP;

- The trajectory must be modified to respect the acceleration limits and the end-effector goes beyond the SP and has to return.

- Trajectory stopping at the SP:As the acceleration exceeds the limits, the value of acceleration adopted is set equal to the minimum limit in that position, instead of the one obtained from the polynomial motion law. While keeping the acceleration equal to the minimum value, it is possible to reach a point P along d that allows the end-effector to reach and stop at the SP if the acceleration is set as constant and equal to the minimum acceleration limit in that point. P can be identified since the position, speed and acceleration values are known. However, keeping a constant acceleration from P to SP means an abrupt change in the acceleration in P, which is not feasible. Therefore, a new polynomial law is defined starting from P to the SP, constraining the initial and final values of the position, speed and acceleration; the required time for this section can be estimated as the time needed to stop with constant acceleration. Moreover, this last section is also feasible, since it follows a constant acceleration motion law, which, in turn, is feasible.

- Trajectory beyond the SP:For greater distances from the SP, after setting the acceleration value equal to the limit, it is not possible to identify a point P that allows the end-effector to stop at the SP with a constant acceleration. It is preferable to decrease the acceleration value, i.e., setting it equal to the minimum limit for each position, until the end-effector stops. Then, similarly to the initial situation, it is possible to design a fifth-degree polynomial motion law that stops the end-effector in the SP. Due to its definition, this second motion law does not assure to keep the acceleration value lower than the maximum acceleration limit, thus it is possible to identify again the three cases presented above. However, since the end-effector is nearer to the SP after this first trajectory, it is less likely that the required acceleration does not respect the acceleration limits.

4. Strategy Simulation

4.1. Simulation Model

4.2. Simulation Results

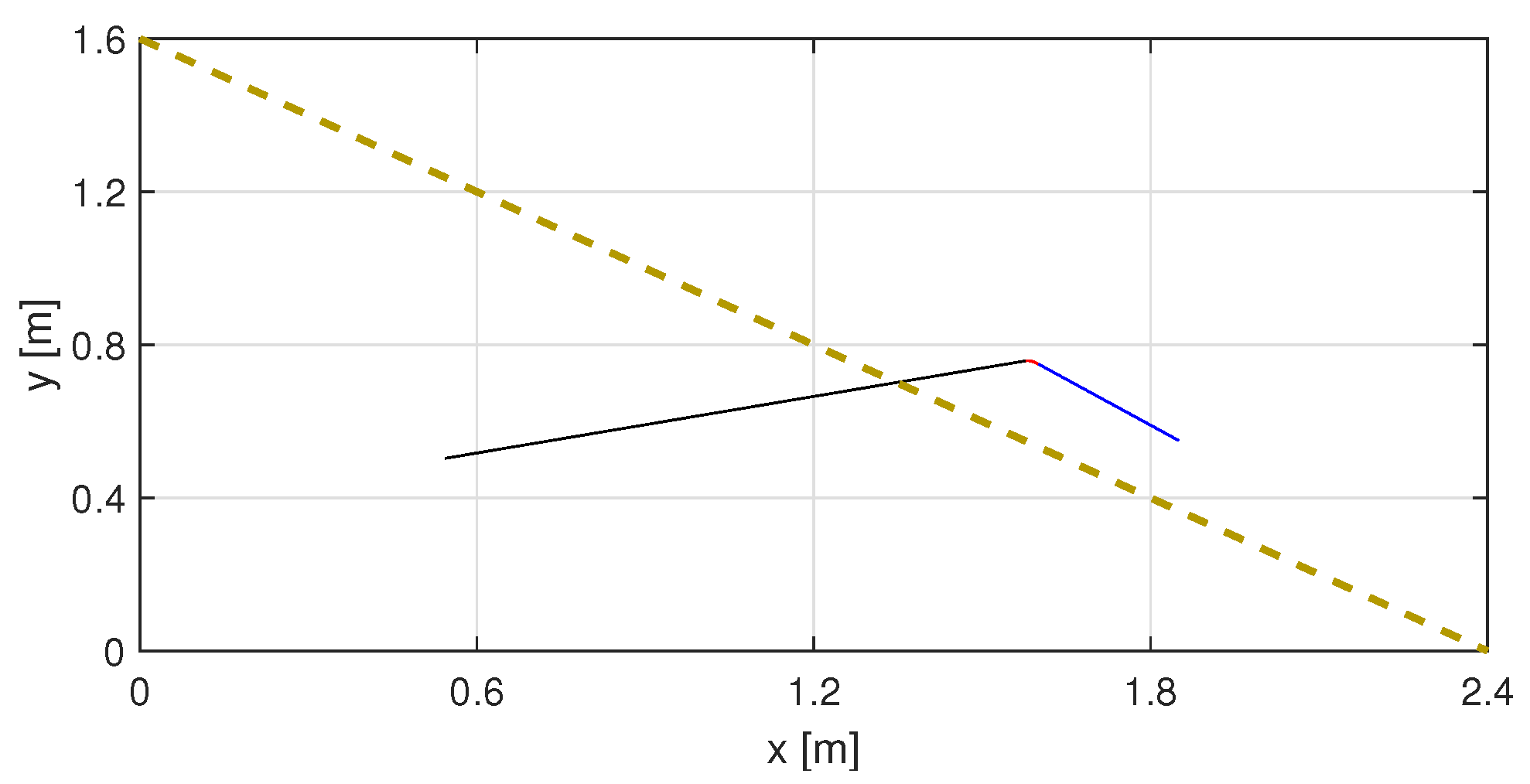

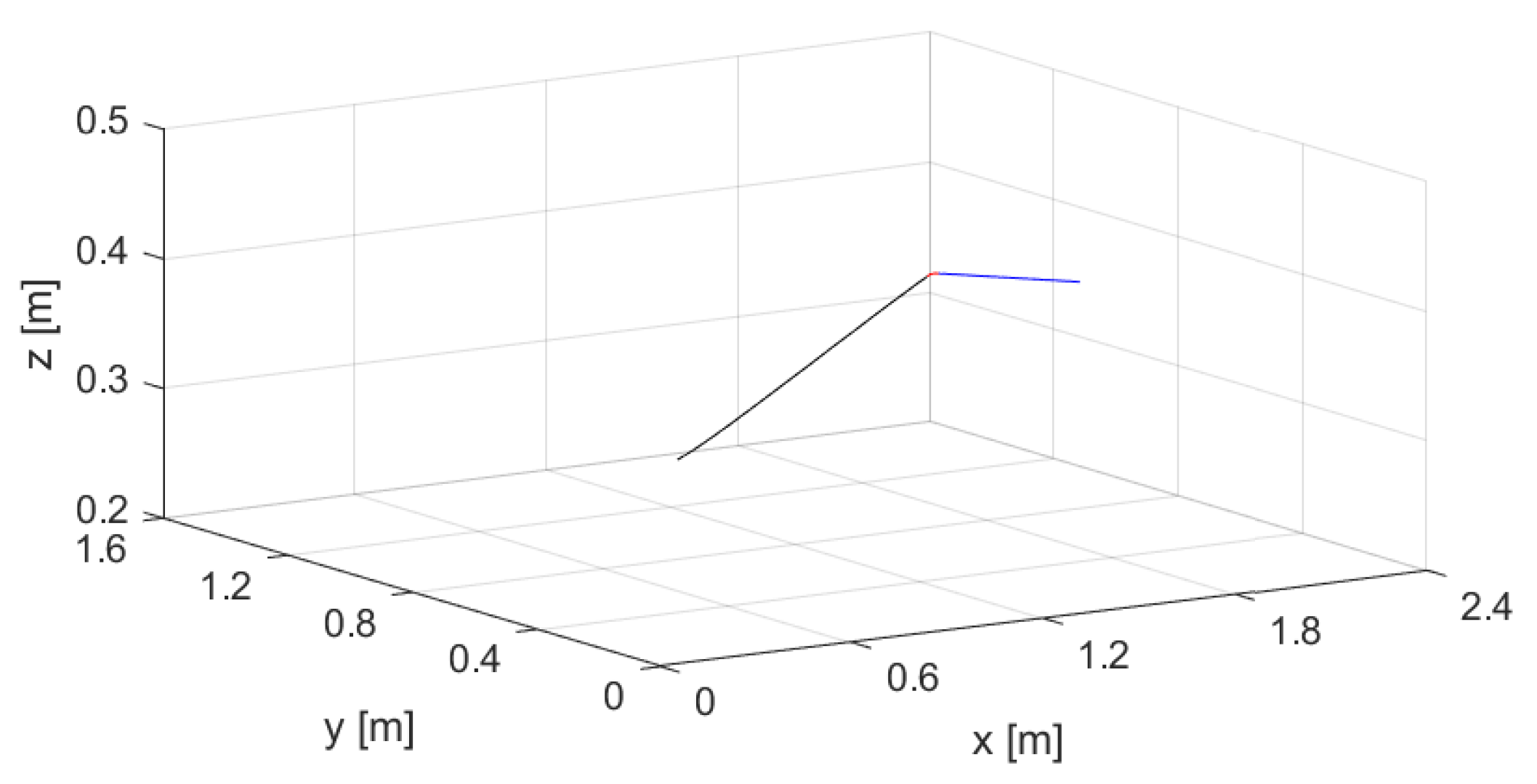

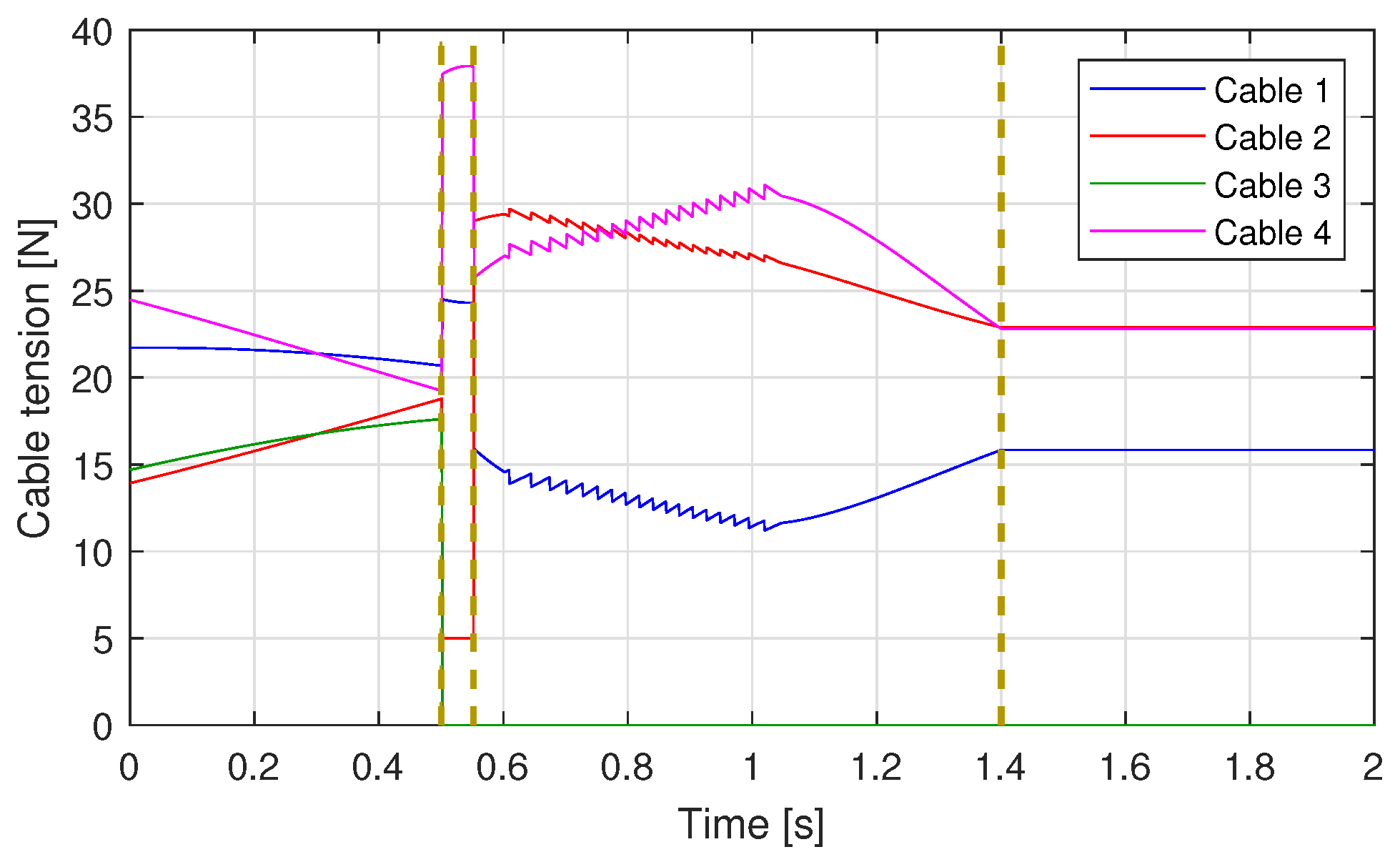

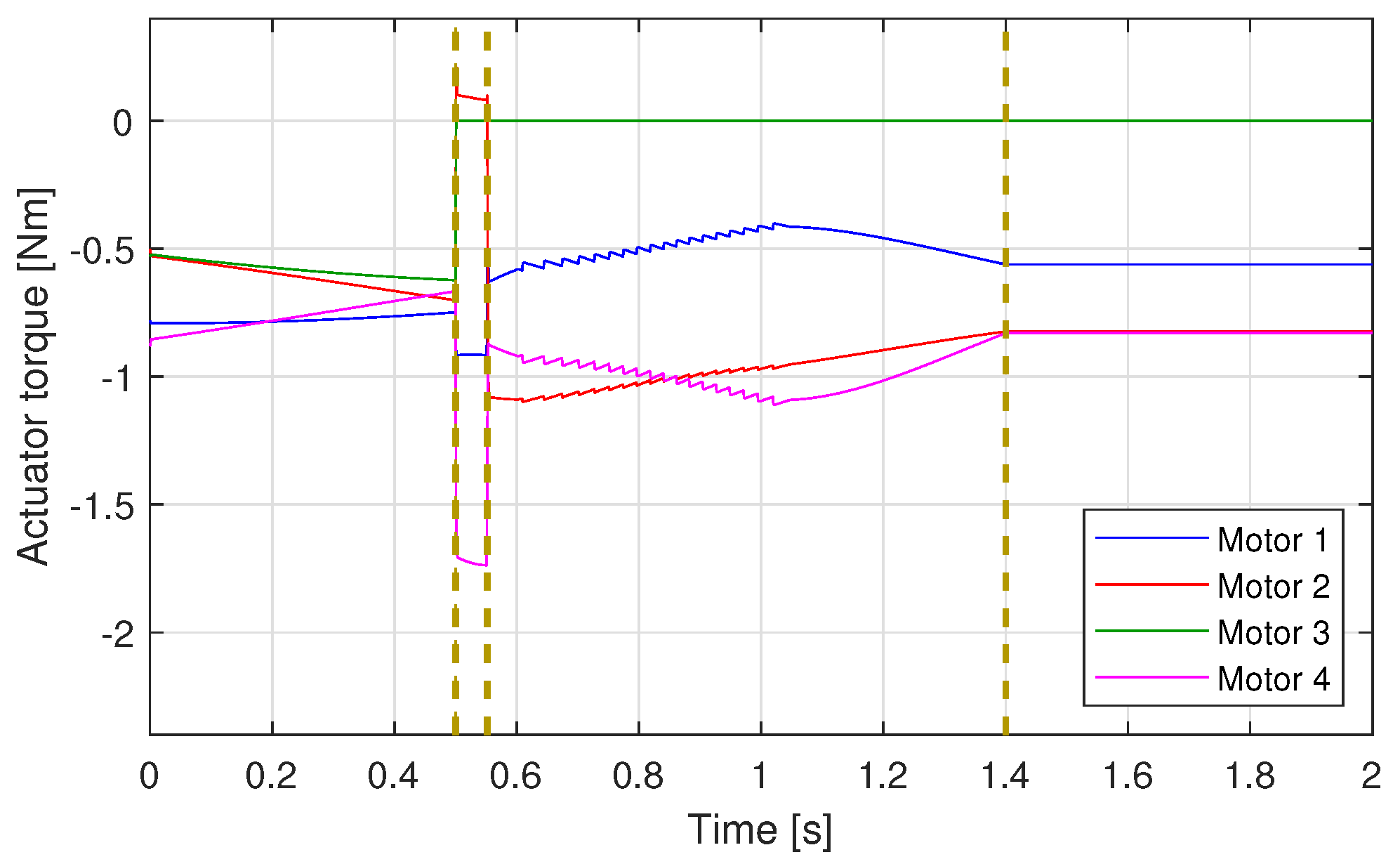

4.2.1. Motion Planning

4.2.2. Robot Behaviour

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Merlet, J.P. Parallel Robots; Springer Science & Business Media: New York, NY, USA, 2006; Volume 128. [Google Scholar]

- Bostelman, R.; Albus, J.; Dagalakis, N.; Jacoff, A.; Gross, J. Applications of the NIST RoboCrane. In Proceedings of the 5th International Symposium on Robotics and Manufacturing, Maui, HI, USA, 25–27 April 1994. [Google Scholar]

- Rosati, G.; Gallina, P.; Rossi, A.; Masiero, S. Wire-based robots for upper-limb rehabilitation. Int. J. Assist. Robot. Mechatronics 2006, 7, 3–10. [Google Scholar]

- Cone, L.L. Skycam-an aerial robotic camera system. Byte 1985, 10, 122. [Google Scholar]

- Ghaffar, A.; Hassan, M. Failure analysis of cable based parallel manipulators. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Aedermannsdorf, Switzerland, 2015; Volume 736, pp. 203–210. [Google Scholar]

- Bosscher, P.; Ebert-Uphoff, I. Wrench-based analysis of cable-driven robots. In Proceedings of the IEEE International Conference on Robotics and Automation, New Orleans, LA, USA, 26 April–1 May 2004; pp. 4950–4955. [Google Scholar]

- Notash, L. Failure recovery for wrench capability of wire-actuated parallel manipulators. Robotica 2012, 30, 941–950. [Google Scholar] [CrossRef]

- Boumann, R.; Bruckmann, T. Development of Emergency Strategies for Cable-Driven Parallel Robots after a Cable Break. In Proceedings of the International Conference on Cable-Driven Parallel Robots, Krakow, Poland, 30 June–4 July 2019; pp. 269–280. [Google Scholar]

- Berti, A.; Gouttefarde, M.; Carricato, M. Dynamic recovery of cable-suspended parallel robots after a cable failure. In Advances in Robot Kinematics 2016; Springer: Champaign, IL, USA, 2018; pp. 331–339. [Google Scholar]

- Riechel, A.T.; Ebert-Uphoff, I. Force-feasible workspace analysis for underconstrained, point-mass cable robots. In Proceedings of the IEEE International Conference on Robotics and Automation, New Orleans, LA, USA, 26 April–1 May 2004; pp. 4956–4962. [Google Scholar]

- Boschetti, G.; Passarini, C.; Trevisani, A. A recovery strategy for cable driven robots in case of cable failure. Int. J. Mech. Control 2017, 18, 41–48. [Google Scholar]

- Boschetti, G.; Trevisani, A. Cable robot performance evaluation by wrench exertion capability. Robotics 2018, 7, 15. [Google Scholar] [CrossRef]

- Lorenz, M.; Brinker, J.; Prause, I.; Corves, B. Power manipulability analysis of redundantly actuated parallel kinematic manipulators with different types of actuators. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 2129–2136. [Google Scholar]

- Boschetti, G. A Novel Kinematic Directional Index for Industrial Serial Manipulators. Appl. Sci. 2020, 10, 5953. [Google Scholar] [CrossRef]

- Boschetti, G.; Passarini, C.; Trevisani, A.; Zanotto, D. A fast algorithm for wrench exertion capability computation. In Cable-Driven Parallel Robots; Springer: Champaign, IL, USA, 2018; pp. 292–303. [Google Scholar]

- Carricato, M.; Abbasnejad, G. Direct geometrico-static analysis of under-constrained cable-driven parallel robots with 4 cables. In Cable-Driven Parallel Robots; Springer: Berlin/Heidelberg, Germany, 2013; pp. 269–285. [Google Scholar]

- Zhang, N.; Shang, W. Dynamic trajectory planning of a 3-DOF under-constrained cable-driven parallel robot. Mech. Mach. Theory 2016, 98, 21–35. [Google Scholar] [CrossRef]

- Pott, A.; Mütherich, H.; Kraus, W.; Schmidt, V.; Miermeister, P.; Verl, A. IPAnema: A family of cable-driven parallel robots for industrial applications. In Cable-Driven Parallel Robots; Springer: Berlin/Heidelberg, Germany, 2013; pp. 119–134. [Google Scholar]

| Parameter | Value | Unit |

|---|---|---|

| m | ||

| 1.6 | m | |

| h | 1 | m |

| m | 3 | kg |

| 5 × 10 | kg m | |

| b | 1.6 × 10 | - |

| 2 | Nm | |

| −2 | Nm | |

| 50 | N | |

| 5 | N |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boschetti, G.; Minto, R.; Trevisani, A. Improving a Cable Robot Recovery Strategy by Actuator Dynamics. Appl. Sci. 2020, 10, 7362. https://doi.org/10.3390/app10207362

Boschetti G, Minto R, Trevisani A. Improving a Cable Robot Recovery Strategy by Actuator Dynamics. Applied Sciences. 2020; 10(20):7362. https://doi.org/10.3390/app10207362

Chicago/Turabian StyleBoschetti, Giovanni, Riccardo Minto, and Alberto Trevisani. 2020. "Improving a Cable Robot Recovery Strategy by Actuator Dynamics" Applied Sciences 10, no. 20: 7362. https://doi.org/10.3390/app10207362

APA StyleBoschetti, G., Minto, R., & Trevisani, A. (2020). Improving a Cable Robot Recovery Strategy by Actuator Dynamics. Applied Sciences, 10(20), 7362. https://doi.org/10.3390/app10207362