Figure 1.

Comparison of turbine total to static efficiency vs. blade-to-gas-speed ratio between a radial and axial turbine.

Figure 1.

Comparison of turbine total to static efficiency vs. blade-to-gas-speed ratio between a radial and axial turbine.

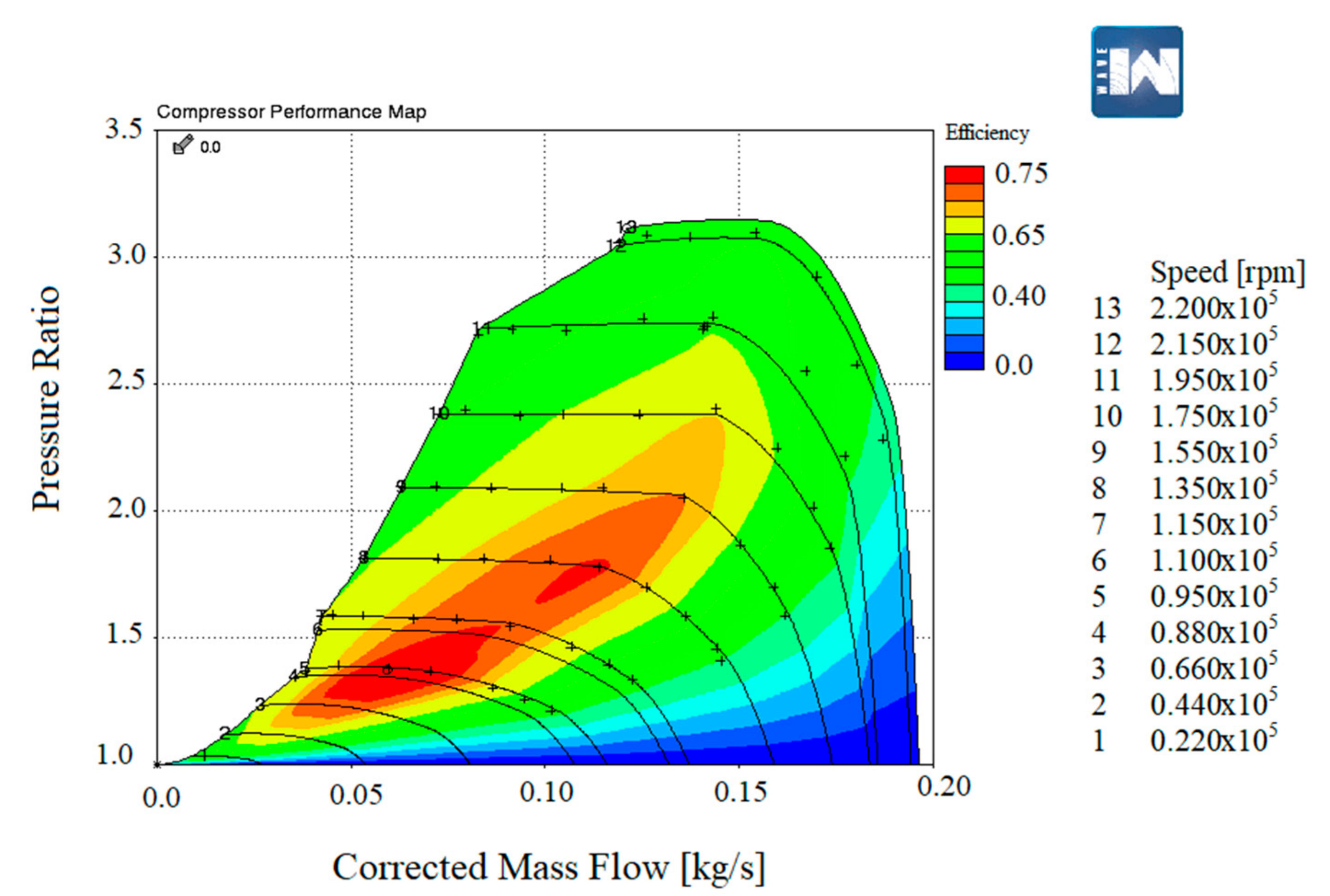

Figure 2.

Typical map of a compressor.

Figure 2.

Typical map of a compressor.

Figure 3.

SI Wiebe combustion model parameters.

Figure 3.

SI Wiebe combustion model parameters.

Figure 4.

Torque and power performance of Ford Eco Boost 1.6 L petrol engine at full load.

Figure 4.

Torque and power performance of Ford Eco Boost 1.6 L petrol engine at full load.

Figure 5.

BSFC (Brake-specific fuel consumption) of Ford Eco Boost 1.6 L petrol engine at full load.

Figure 5.

BSFC (Brake-specific fuel consumption) of Ford Eco Boost 1.6 L petrol engine at full load.

Figure 6.

Turbine Ricardo WAVE map.

Figure 6.

Turbine Ricardo WAVE map.

Figure 7.

Compressor dimensionless map.

Figure 7.

Compressor dimensionless map.

Figure 8.

Turbine map for different dimensionless speeds.

Figure 8.

Turbine map for different dimensionless speeds.

Figure 9.

Scaled compressor map.

Figure 9.

Scaled compressor map.

Figure 10.

Scaled turbine map.

Figure 10.

Scaled turbine map.

Figure 11.

Variation of engine torque during compressor speed sweep at different engine speeds.

Figure 11.

Variation of engine torque during compressor speed sweep at different engine speeds.

Figure 12.

Variation of engine power during compressor speed sweep at different engine speeds.

Figure 12.

Variation of engine power during compressor speed sweep at different engine speeds.

Figure 13.

Comparison between provided engine torque and Ricardo WAVE model.

Figure 13.

Comparison between provided engine torque and Ricardo WAVE model.

Figure 14.

Comparison between provided engine power and Ricardo WAVE model.

Figure 14.

Comparison between provided engine power and Ricardo WAVE model.

Figure 15.

Comparison between provided engine BSFC and Ricardo WAVE model.

Figure 15.

Comparison between provided engine BSFC and Ricardo WAVE model.

Figure 16.

Variation of engine air mass flow rate during compressor speed sweep at each engine speed.

Figure 16.

Variation of engine air mass flow rate during compressor speed sweep at each engine speed.

Figure 17.

Baseline engine torque at different engine speeds.

Figure 17.

Baseline engine torque at different engine speeds.

Figure 18.

Baseline engine brake power at different engine speeds.

Figure 18.

Baseline engine brake power at different engine speeds.

Figure 19.

Baseline engine BSFC at different engine speeds.

Figure 19.

Baseline engine BSFC at different engine speeds.

Figure 20.

Baseline engine carbon monoxide emissions at different engine loads.

Figure 20.

Baseline engine carbon monoxide emissions at different engine loads.

Figure 21.

Baseline engine NOx emissions at different engine loads.

Figure 21.

Baseline engine NOx emissions at different engine loads.

Figure 22.

Baseline engine uHC (Unburned Hydrocarbons) emissions at different engine loads.

Figure 22.

Baseline engine uHC (Unburned Hydrocarbons) emissions at different engine loads.

Figure 23.

Transient WAVE simulation component setup.

Figure 23.

Transient WAVE simulation component setup.

Figure 24.

Baseline time to reach maximum shaft speed at various engine speeds and loads.

Figure 24.

Baseline time to reach maximum shaft speed at various engine speeds and loads.

Figure 25.

Mass flow rate vs. pressure ratio plots at constant shaft speeds for axial turbine.

Figure 25.

Mass flow rate vs. pressure ratio plots at constant shaft speeds for axial turbine.

Figure 26.

Total to static efficiency vs. pressure ratio plots at constant shaft speeds for axial turbine.

Figure 26.

Total to static efficiency vs. pressure ratio plots at constant shaft speeds for axial turbine.

Figure 27.

Corrected mass flow rate vs. pressure ratio plots at constant shaft speeds at different rack positions for VNT (Variable Nozzle Turbine)

Figure 27.

Corrected mass flow rate vs. pressure ratio plots at constant shaft speeds at different rack positions for VNT (Variable Nozzle Turbine)

Figure 28.

Total to static efficiency vs. pressure ratio plots at constant shaft speeds at different rack positions for VNT.

Figure 28.

Total to static efficiency vs. pressure ratio plots at constant shaft speeds at different rack positions for VNT.

Figure 29.

Comparison of (a) engine brake torque, (b) engine brake power, (c) engine BSFC, (d) turbine power, and (e) turbine efficiency between radial and axial turbines at different engine operating conditions.

Figure 29.

Comparison of (a) engine brake torque, (b) engine brake power, (c) engine BSFC, (d) turbine power, and (e) turbine efficiency between radial and axial turbines at different engine operating conditions.

Figure 30.

Comparison of engine cylinder emissions between radial (a,c,e) and axial turbines (b,d,f) at different engine operating conditions.

Figure 30.

Comparison of engine cylinder emissions between radial (a,c,e) and axial turbines (b,d,f) at different engine operating conditions.

Figure 31.

Comparison between radial (left) and axial (right) turbines time to maximum shaft speed at different engine operating conditions.

Figure 31.

Comparison between radial (left) and axial (right) turbines time to maximum shaft speed at different engine operating conditions.

Figure 32.

Transient response profiles for turbocharger shaft speed and manifold pressure at engine speeds of 5000 rpm (a,b), 4000 rpm (c,d), and 3000 rpm (e,f) at 100% (left) and 60% (right) engine loads.

Figure 32.

Transient response profiles for turbocharger shaft speed and manifold pressure at engine speeds of 5000 rpm (a,b), 4000 rpm (c,d), and 3000 rpm (e,f) at 100% (left) and 60% (right) engine loads.

Figure 33.

(a) Optimized blade design and (b) 3D model of the axial turbine.

Figure 33.

(a) Optimized blade design and (b) 3D model of the axial turbine.

Table 1.

Reference conditions for conducting turbocharger maps.

Table 1.

Reference conditions for conducting turbocharger maps.

| Reference Condition | Compressor | Turbine |

|---|

| Pressure | 100 | 101.3 |

| Temperature | 298 | 288 |

Table 2.

Target conditions for turbocharger.

Table 2.

Target conditions for turbocharger.

| Parameter | Compressor Target | Turbine Target |

|---|

| Ttarg | 411 K | 1170 K |

| Ptarg | 2.14 bar | 2.65 bar |

| mtarg | 0.118 kg/s | 0.127 kg/s |

Table 3.

Results of scaling for different engine speed performances.

Table 3.

Results of scaling for different engine speed performances.

| Engine Speed | | |

|---|

| 1000 rpm | 0.05571 | 0.05186 |

| 3000 rpm | 0.05253 | 0.05258 |

| 5000 rpm | 0.04985 | 0.05298 |

| 6000 rpm | 0.04664 | 0.05308 |

Table 4.

Design point turbine boundary conditions generated in WAVE.

Table 4.

Design point turbine boundary conditions generated in WAVE.

| Condition | Value |

|---|

| Inlet total pressure (bar) | 2.65611 |

| Outlet static pressure (bar) | 1.30352 |

| Inlet total temperature (K) | 1168.55 |

| Outlet static temperature (K) | 1052.44 |

| Mass flow rate (kg/s) | 0.1272 |

Table 5.

Turbocharger speed map.

Table 5.

Turbocharger speed map.

| NTC (rpm) | Engine Speed (rpm) |

|---|

| Load | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 |

|---|

| 100% | 46,700 | 106,500 | 143,630 | 145,210 | 158,850 | 141,757 |

| 80% | 26,978 | 69536 | 112,308 | 111,906 | 121,476 | 111,412 |

| 60% | 5214 | 24751 | 63,182 | 64,313 | 69,697 | 66,690 |

| 40% | n/a | n/a | 13,395 | 21,609 | 31,429 | 32,202 |

Table 6.

Air mass flow rate at each engine speed and load.

Table 6.

Air mass flow rate at each engine speed and load.

| mae (kg/hr) | Engine Speed (rpm) |

|---|

| Load | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 |

|---|

| 100% | 57.9623 | 143.255 | 257.264 | 335.677 | 427.272 | 433.747 |

| 80% | 46.2953 | 113.751 | 207.029 | 269.308 | 342.331 | 347.253 |

| 60% | 34.8423 | 85.4361 | 153.386 | 202.144 | 256.701 | 259.625 |

| 40% | n/a | n/a | 102.079 | 132.553 | 167.475 | 171.063 |

Table 7.

Number of cycles required to complete a 3-s transient simulation for each engine speed.

Table 7.

Number of cycles required to complete a 3-s transient simulation for each engine speed.

| Engine Speed (rpm) | Number of Cycles |

|---|

| 1000 | 25 |

| 2000 | 50 |

| 3000 | 75 |

| 4000 | 100 |

| 5000 | 125 |

| 6000 | 150 |

Table 8.

Experimentally obtained mass moment of inertia for GT1548 turbocharger.

Table 8.

Experimentally obtained mass moment of inertia for GT1548 turbocharger.

| Turbocharger | Turbine | Compressor |

|---|

| Moment of Inertia (kg/m2) | Moment of Inertia (kg/m2) | Moment of Inertia (kg/m2) |

| 5.54 × 10−6 | 4.72 × 10−6 | 8.22 × 10−7 |

Table 9.

Results of inertia testing of GT1548 turbocharger.

Table 9.

Results of inertia testing of GT1548 turbocharger.

| Parameter | GT 1548 Turbocharger | GT1548 Scaled Turbocharger | Scale Factor |

|---|

| Compressor diameter | 0.048 m | 0.04902 m | 1.02125 |

| Turbine diameter | 0.0412 m | 0.05343 m | 1.29684 |

| Compressor inertia | 8.22 × 10−7 kg m2 | 9.13 × 10−7 kg m2 | (1.02125)5 |

| Turbine inertia | 4.72 × 10−6 kg m2 | 1.73 × 10−5 kg m2 | (1.29684)5 |

| Turbocharger inertia | 5.54 × 10−6 kg m2 | 1.82 × 10−5 kg m2 | n/a |

Table 10.

Turbocharger shaft speed based on engine model operating conditions for map generation.

Table 10.

Turbocharger shaft speed based on engine model operating conditions for map generation.

| Engine Speed (rpm) | Load (%) | Turbocharger Speed (rpm) |

|---|

| 5000 | 100 | 158,850 |

| 3000 | 100 | 143,360 |

| 5000 | 80 | 121,476 |

| 2000 | 100 | 106,500 |

| 2000 | 80 | 69,536 |

| 1000 | 100 | 46,700 |

| 1000 | 80 | 26,978 |

Table 11.

Comparison of baseline radial, axial turbine, and optimised axial turbine design.

Table 11.

Comparison of baseline radial, axial turbine, and optimised axial turbine design.

| | Radial Turbine | Axial Turbine (Initial Design) | Axial Turbine (Optimized Design) |

|---|

| Mass (g) | 226.76 | 112.93 | 85.41 |

| Mass moment of inertia (kg/m2) | 1.82 × 10−5 | 1.59 × 10−5 | 1.16 × 10−5 |

| Safety Factor | NA | 2.38 | 2.16 |