1. Introduction

The performance of mechanical and routine tasks, as well as the speeding-up of processes in which precision cannot be overlooked, are just two of the most outstanding features that have made industrial robots the most preferred tool for increasing productivity and reducing operational costs.

For a robot to perform a specific movement, a control device that ensures the completion of this movement is essential. Despite the utmost importance of control in manipulator robots, control is still an issue that poses several practical and theoretical challenges to the field, due to the complex dynamic of these robots and the need to achieve highly precise trajectory-tracking in the case of high-speed movements with variable loads [

1,

2].

Manipulator robots are multivariable and non-linear dynamic systems. Therefore, obtaining mathematical models that both represent them and in which classic or modern control laws are satisfactorily applicable is difficult, as it is necessary to know the exact masses, inertias, and lengths of each link, as well as other characteristic parameters. Also, these robots face a series of uncertainties inherent to their practical application, such as internal friction or external disturbances. To solve such inconveniences, several control strategies have been proposed, among which the Proportional-Integral-Derivative (PID) method is widely accepted and extensively used in industrial robots. The success of this method is attributed to its simple structure and robust performance in a wide range of operating conditions. Furthermore, these controllers can minimize the steady-state error of a manipulator robot, but they are sensitive to the variation of parameters and uncertainties of the latter [

3,

4,

5].

Conventional control techniques such as PID, adaptive control, and sliding mode control, among others, depend largely on precise mathematical modelling. These approaches may be adapted to robots operated in environments without uncertainty and with models that are exactly known; thus, the absence of an accurate analytical model makes it difficult to design an adequate controller [

6,

7]. Nevertheless, operations in non-structured environments, where there always will be some degree of uncertainty, require robots to carry out tasks that are more complex [

8,

9].

Fuzzy control is a control technique that belongs to the expert systems and that allows for controlling dynamic systems without any mathematical model. This characteristic makes fuzzy control suitable for complex processes that are difficult to model analytically, either because of the incomplete knowledge of the procedure or the unfeasibility of identifying the experimental model due to the unquantifiability of the process inputs and outputs. Thus, this technique may be understood as a mean that enables the conversion of a linguistic control strategy, which is based on the knowledge of an operator, into an automatic control strategy [

10].

A controller based on fuzzy logic delivers fast and precise dynamic responses, allows for analyzing information through a true-and-false scale, and is generally robust, and tolerant to imprecisions and noise in the input data, among other characteristics. The logic programming of fuzzy controllers is governed by rules whose order is arbitrary and can be modified in number and type of membership function [

11,

12].

Since its creation, fuzzy logic has been widely adopted by researchers to develop controllers for a wide variety of systems in different fields. Some examples of these controllers are: the intelligent medication dispenser, which is based on the analysis of the data flow from a patient’s body temperature [

13]; a robust fuzzy algorithm to analyze asthma data [

14]; the use of terms and linguistic expressions to capture the human way of reasoning at different accuracy levels [

15]; clustering algorithm for wireless sensor networks with five input parameters (energy, centrality, distance to base station, number of hops and node density), which is fault tolerant [

16]; selection and tuning of control law parameters to pilot an Unmanned Aerial Vehicle (UAV) [

17]; stabilization of an inverted pendulum on a car [

18]; general scheme for controlling non-linear, uncertain and chaotic MIMO systems [

19,

20]; adaptation of a classic PID controller through an expert system based on fuzzy rules [

21]; control of uncertain strict-feedback non-linear systems, with asymmetric output restrictions that vary over time in the presence of input saturation [

22]; type-1 fuzzy logic-based controller for push recovery by humanoids [

23]; Adaptive Neuro Fuzzy Inference System (ANFIS) controller for navigation of single as well as multiple mobile robots in highly cluttered environments [

24], etc.

In robotics, control system algorithms based on fuzzy logic are usually calculated using information related to position and speed, which is obtained by sensors located in each of the robot joints (encoders, tachometers, etc.) [

25]. The main scientific advances that employ position and speed,

i.e., error and first derivative of the error with respect to time, as linguistic variables of a control system based on fuzzy logic are: (1) Hybrid control systems, comprising force/motion, force/position and fuzzy-PID; (2) Fuzzy adaptive control with obstacle avoidance and dynamic uncertainty; (3) Fuzzy adaptive control for efficient surfing of mobile robots, whose main contribution is following trajectories and avoiding obstacles; (4) Fractional order fuzzy controllers; (5) Adaptive fractional order PID controller; (6) Adaptive control methods based on PID architectures to control highly non-linear industrial processes, even under conditions of parameter variability, noise and instabilities [

1,

7,

26,

27,

28,

29,

30,

31,

32,

33,

34,

35,

36].

2. Controllers

According to [

37], there are several types of Fuzzy Logic Controllers (FLC) that can be built, among which the most known are FLC-PD, FLC-PI, and FLC-PID. Depending on the type of controller, the following inputs may be used: error

, error change

, and/or sum of errors

.

FLC-P: The equation for a conventional proportional (P) fuzzy controller is given by:

where

represents the proportional gain coefficient and

the control output. The rules for a P-type FLC are built based on the following formulation: If

is

then

is

, where

and

,

,

represent linguistic variables.

FLC-PD: A Proportional-Differential (PD) FLC can be developed by using error and error change model, as shown in the following equation:

where

and

represent the coefficients of proportional and differential gains, and

corresponds to control output. The rules for a PD-type FLC are formulated as follows: If

is

and

is

then

is

, where

,

and

are linguistic variables and

,

and

.

FLC-PI: A conventional Proportional Integral controller is described as:

where

and

are the proportional and integral gains coefficient, and

is the control output. This controller is built based on the following rules: If

is

and

is

then

is

, where

,

and

are linguistic variables. This type of FLC has a good performance and reduces error in stationary state, but causes degraded rise time and settling time. These undesirable characteristics are generated by the operation of the controller’s integral, although this integrator is introduced just to overcome the issue of errors in stationary state.

FLC similar to PID: An additional option that allows for obtaining better performance in terms of rise time, settling time, overshoot and error in stationary state is to develop a PID, which is described by the following equation:

The FLC-PID has the following rules: If is and is and is then is , where , , and .

In general, a two-term PD fuzzy controller is not able to eliminate error in stationary state, whereas a two-term PI-fuzzy controller is. However, the latter has a slower response due to the integral term in the control variable.

To meet the design criteria, including fast rise time, minimum overshoot, shorter settling time, and error at stationary status equal to zero, an additional option may be developed: a PID-type FLC. PID fuzzy controllers are four-dimensional (three inputs and one output) systems, whose control law is based on the error , error change , and error integral or sum Nevertheless, this FLC supports a long processing time that results in an excessively slow response, which is not suitable for applications that need a quick response, for example, the control of joint trajectory of the 2-DoF manipulator robot addressed in this study.

Several authors have proposed different approaches to overcome the problems above, such as decomposing PID FLC into a fuzzy PD connected in parallel to various types of fuzzy gains, fuzzy integrators, integral fuzzy controller, deterministic fuzzy controller; fuzzy PD with gain control in stationary state; fuzzy PD with integral action control; fuzzy PD with fuzzy integral gain controller; fuzzy PD and PI combined, and fuzzy PD and I combined. All these configurations and their corresponding schemes are shown in [

37].

None of these approaches include the error second derivative , nor are other applications with these characteristics found in the literature. This characteristic allows for obtaining representative improvements when assessing the results from joint trajectory tracking in manipulator robots (results were validated based on the calculation of performance indexes), and comparing them with results from conventional fuzzy and PID controllers. It must be noted that adding the error second derivative to the proposed fuzzy controller makes this study original and therefore a contribution to the manipulator robot’s control.

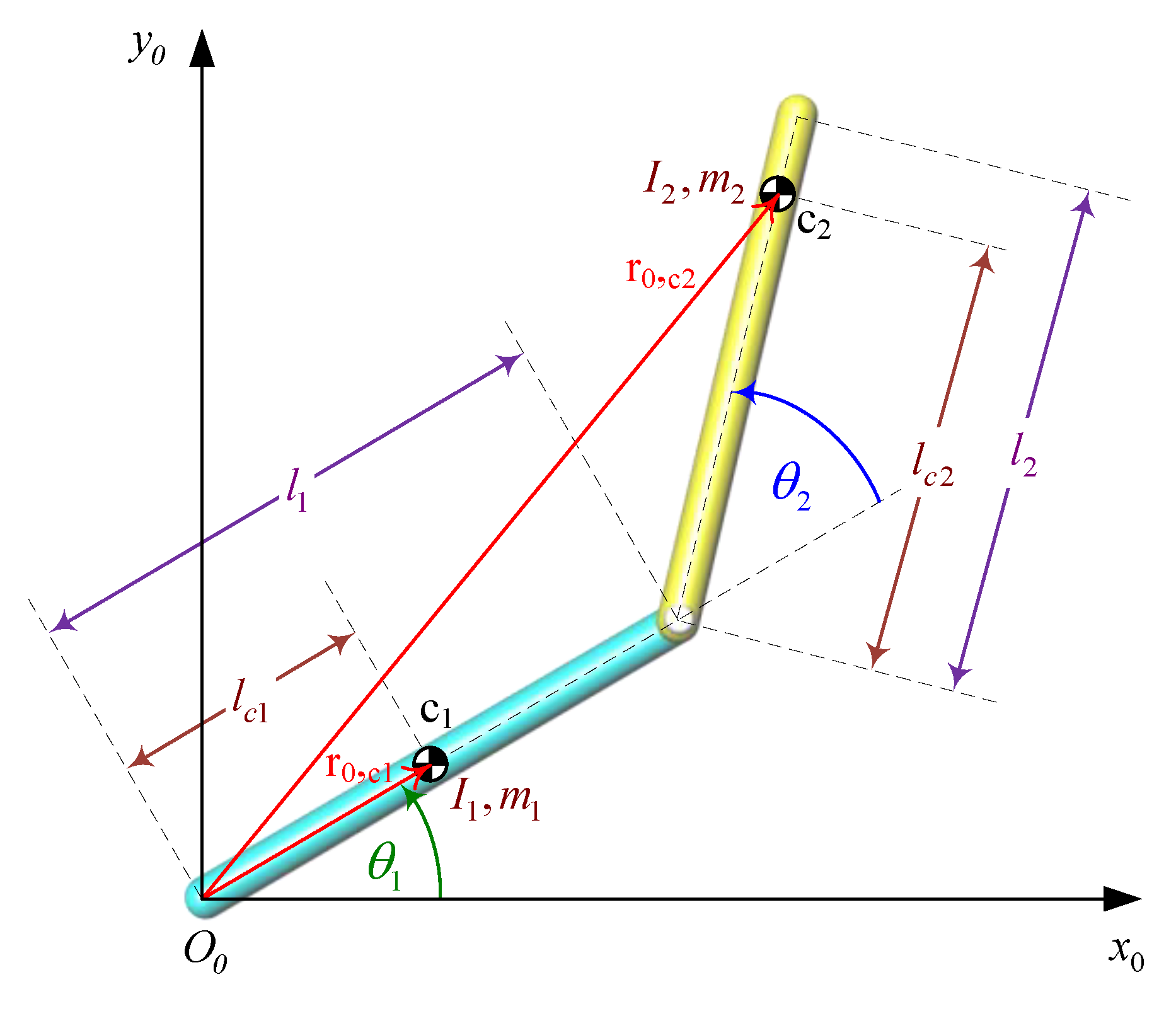

The new scheme we propose is applied to the control of the joint trajectory tracking of a 2-DoF planar robot, for which a complete simulation environment is developed using the software MatLab/Simulink®. Finally, a performance assessment is presented, which consists of a comparison between the fuzzy controller and a classic PID controller (the classic PID controller is only used for comparison).

5. Fuzzy Logic Controller Design

The block diagram shown in

Figure 4 represents the general structure of a fuzzy logic controller. This controller has three main components: 1. Fuzzification block, in charge of the transformation of each input element into membership degrees for the linguistic terms of the fuzzy sets, each of which has a membership function associated with its elements, indicating to what extent the element is part of the set; 2. Inference engine, which along with the knowledge base makes decisions −based on the membership degree of the input data from the fuzzy sets− and delivers output fuzzy sets that are calculated using the rules of the controller; 3. Defuzzification block that transforms fuzzy values −obtained from the inference− into values that are useful for the process to be controlled.

The output for each fuzzy controller is governed by the defuzzification process and its rule base. The defuzzification process transforms the fuzzy sets into exact values that feed the plant and depend on two Fuzzy Inference Systems (FIS). These systems are applied to achieve appropriate control actions based on assigning two rules: Mamdani and Takagi-Sugeno (TS) [

18]. The main difference between the two methods lies in the consequence of fuzzy rules. Mamdani inference systems use fuzzy sets, while TS systems employ linear functions of input variables as a consequence of the rule [

40,

41]. The rule structure of the Mamdani-type FIS is expressed as follows: IF x

1 is A

1 and x

2 is A

2 and ... and x

n is A

n THEN y is B, where x

i (i = 1, 2 ... n) are input variables and y is the output variable; A

1 ... A

n and B (linguistic terms) are used to define the distribution of the membership function of fuzzy subsets corresponding to the input and output variables [

41]. The crisp output of a Mamdani FIS is obtained when applying one of the following defuzzification methods [

40,

42].

Mass center, area or centroid: This technique takes the output distribution and finds its mass center to obtain a crisp number through the following equation:

where

is the center of mass and

is the membership in class

c at value

.

Maximum value mean: This technique takes the output distribution and finds the mean of its maximum values to obtain a crisp number through the following equation:

where

is the mean of maximum values,

is the point at which the membership function reaches its maximum, and

is the number of times the output distribution reaches the maximum level. This work uses a Mamdani FIS with the max-min composition rule and the centroid method.

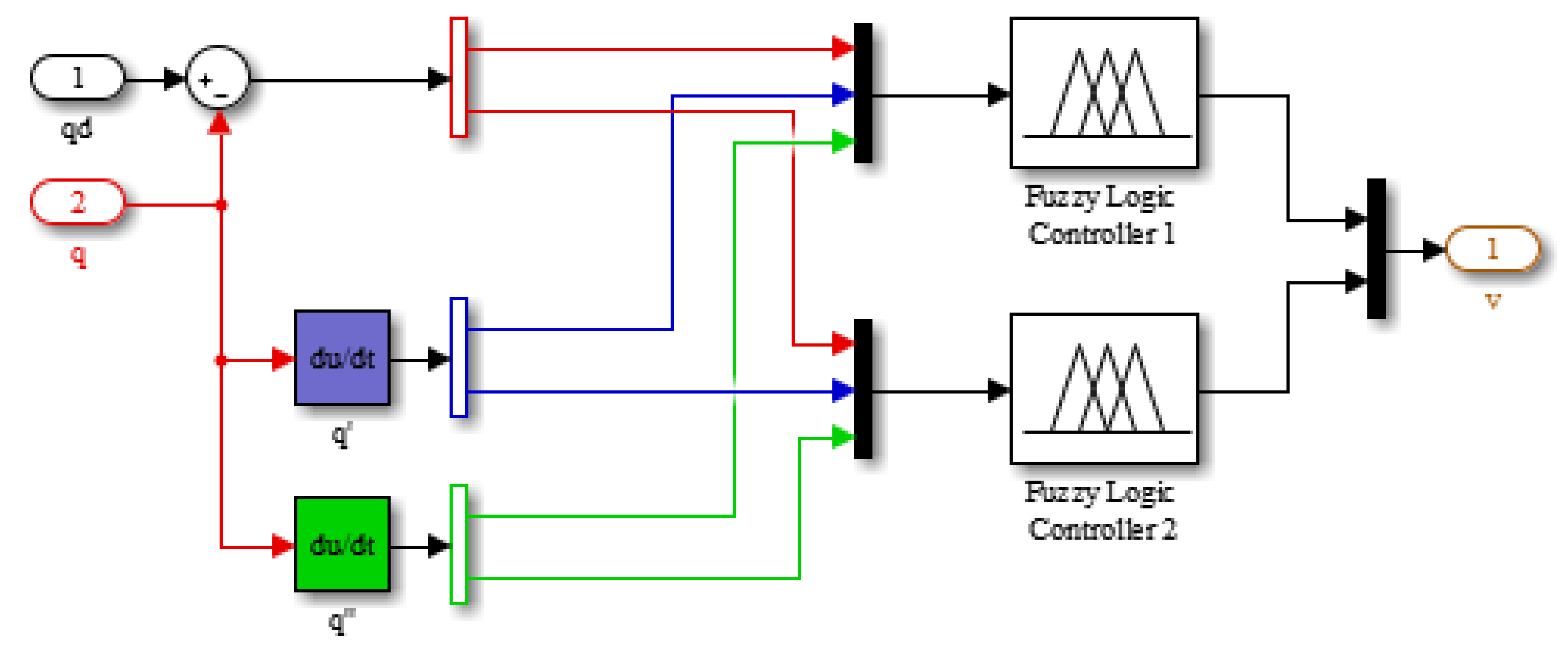

The control scheme designed for this scenario and simulated in Simulink

® is shown in

Figure 5. It includes two fuzzy logic controllers, one for each joint of the manipulator robot. In addition, each fuzzy block receives three fuzzy inputs. The first input corresponds to position and represents the difference between the desired position qd and the real position q. The following input corresponds to speed q’ (first derivative of position with respect to time) and the last one represents q’’ acceleration (second derivative of position with respect to time). Additionally, each block has only one fuzzy output that represents the voltage received by the actuator. The magnitude of this voltage generates the torque force necessary for moving the respective joint.

The universes of each fuzzy variable are determined through the analysis of the simulations conducted with a test trajectory. However, the universe of the variable “position” (expressed in radians) is the maximum joint movement of each joint, while the universes of the variables speed, acceleration and voltage are defined based on the technical specifications of the actuators used.

Table 2 and

Table 3 show the characteristics of the variables of each controller. In these tables the terms NB, NS, Z, PS and PB correspond to Negative Big, Negative Small, Zero, Positive Small and Positive Big, respectively. On the other hand, LVF, LF, S, RF and RVF represent Left Very Fast, Left Fast, Slow, Right Fast, Right Very Fast, accordingly; N, Z and P correspond to Negative, Zero and Positive, and LB, LS, Z, RS and RB to Left Big, Left Small, Zero, Right Small and Right Big.

Fuzzy rules express the previous knowledge on the relation between antecedents and consequents (input and output fuzzy sets). The rule base can be stored as a Fuzzy Associative Memory (FAM). FAMs are matrices that represent the consequence of each rule defined for each two-input combination [

37,

40].

Theoretically, the number of rules necessary for gathering all the possible input combinations for a three-term fuzzy controller is obtained by:

, where

,

and

are the number of linguistic terms of the three input variables. Specifically, if

, then the number of rules would be: R = 5 × 5 × 5 = 125. In practical applications, the design and implementation of a fuzzy controller with such a big number of rules is a tedious task that also requires substantial space in memory and long processing time [

37].

Therefore, we propose two FAMs for this controller, each with two different inputs, but with the same output (the voltage that enters the actuators). FAM 1 and FAM 2 combine speed and position inputs, while FAM 3 combines position and acceleration inputs. Both FAMs are shown in

Table 4 and

Table 5, respectively.

After different tests and result analysis, 12 out of the 15 possible combinations for FAM 3 were suppressed because they did not improve trajectory tracking under any conditions. For this reason, in

Table 6 most of the elements present in FAM 3 are represented by the letter

x, which corresponds to the value of excluded consequents.

The rule base shown in

Table 7 is built based on the combination of the results yielded by FAM 1 and FAM 3, and this procedure is also applied to obtain the rule base presented in

Table 8 yielded by FAM 2 and FAM 3.

The membership functions selected for the position, speed, acceleration and voltage of the Fuzzy Logic Controller 1 are shown in

Figure 6. Additionally, the 28 resulting rules entered in the rule editor of the fuzzy logic toolbox are presented in

Table 7. Likewise, the membership functions chosen for the Fuzzy Logic Controller 2 are exposed in

Figure 7. In this case, there are also 28 rules depicted in

Table 8. Both membership functions and the rule base for each controller were built after several test simulations. These tests were carried out considering the slope changes in the position curves a priority. In this way, it was determined that by making the position and voltage sets more selective around zero, test trajectory tracking presented a performance with less tracking error for both joints.

Initially, the membership functions designed were the same for both joints. However, after the selectivity adjustments for the position and voltage sets around zero, the second joint deviated a bit more from the trajectory of the first one. This was solved by modifying the LS and RS voltage sets of the second joint, changing the soft shapes of those sets into triangular ones.

Finally, a flowchart representing the computing process for fuzzy control is shown in

Figure 8.

8. Conclusions

Several authors agree that the use of a controller based on fuzzy logic is a very good choice for controlling non-linear systems with mathematical models difficult to represent. This factor, along with the structure of these controllers and the possibility of selecting the membership functions as well as the ranges of the fuzzy sets to be used, yields a wide variety of results that allows for improving the performance of the system to be controlled.

In this work, we developed a fuzzy logic application for controlling the trajectory-tracking of the joints of a 2-DoF planar manipulator robot. The results of the three test trajectories have evidenced that the controllers developed satisfactorily meet the tracking control requirements. Nevertheless, the performance of the fuzzy logic controllers is visibly superior to the performance of the classic PID controller. The values of these indicators reveal that the three tested trajectories are less accurate with the PID controller. However, trajectory number three is much harder to follow, since the joints of the manipulator robot are forced to change the direction of their motion to 90° angles in very short time lapses.

The main contribution of this study was the incorporation of the acceleration fuzzy variable, which allowed for noticeably improving system response. In total, we worked with three variables: position, speed and acceleration, each of them with its respective membership functions and fuzzy sets.

The design and analyses of fuzzy controllers for manipulator robots are envisaged as future works. This should incorporate, in addition to the joint acceleration variable, the error integral variable with adaptive reset in order to improve the transient and stationary behavior in the presence of load disturbances in the second joint. Furthermore, the dynamic model of the manipulator robot could be improved by adding the Stribeck effect through modeling with a first-order non-linear differential equation.