Selective Extraction of REEs Thanks to One-Pot Silica Hybrid Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Synthesis and Characterizations

2.2. Extraction Experiments

2.3. Stripping

3. Results and Discussion

3.1. Materials Characterization

3.2. Extraction Properties

3.3. Mechanism of the Nd Extraction by SHM-4

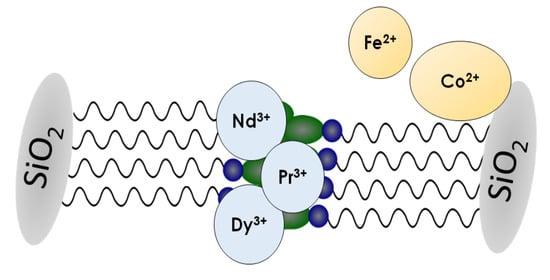

3.4. Extraction of Rare-Earth Elements (Nd, Pr, Dy) towards Competitive Elements

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Balaram, V. Rare earth elements: A review of applications, occurrence, exploration, analysis, recycling, and environmental impact. Geosci. Front. 2019, 10, 1285–1303. [Google Scholar] [CrossRef]

- Goodenough, K.M.; Wall, F.; Merriman, D. The rare earth elements: Demand, global resources, and challenges for resourcing future generations. Nat. Resour. Res. 2018, 27, 201–216. [Google Scholar] [CrossRef] [Green Version]

- European Commission. Critical Raw Materials Resilience: Charting a Path towards Greater Security and Sustainability; COM(2020) 474 Final; European Commission: Brussel, Belgium, 2020. [Google Scholar]

- U.S. Department of Energy. Critical Materials Strategy; U.S. Department of Energy: Washington, DC, USA, 2011.

- Kumari, A.; Panda, R.; Jha, M.K.; Kumar, J.R.; Lee, J.Y. Process development to recover rare earth metals from monazite mineral: A review. Min. Eng. 2015, 79, 102–115. [Google Scholar] [CrossRef]

- Sengupta, M. Environmental Impacts of Mining: Monitoring, Restoration, and Control; Routledge: New York, NY, USA, 2018. [Google Scholar]

- Li, X.Y.; Ge, J.P.; Chen, W.Q.; Wang, P. Scenarios of rare earth elements demand driven by automotive electrification in China: 2018–2030. Resour. Conserv. Recycl. 2019, 145, 322–331. [Google Scholar] [CrossRef]

- Yoon, H.S.; Kim, C.J.; Chung, K.W.; Kim, S.D.; Lee, J.Y.; Kumar, J.R. Solvent extraction, separation and recovery of dysprosium (Dy) and neodymium (Nd) from aqueous solutions: Waste recycling strategies for permanent magnet processing. Hydrometallurgy 2016, 165, 27–43. [Google Scholar] [CrossRef]

- Yang, Y.; Walton, A.; Sheridan, R.; Güth, K.; Gauß, R.; Gutfleisch, O.; Buchert, M.; Steenari, B.M.; Van Gerven, T.; Jones, P.T.; et al. REE recovery from end-of-life NdFeB permanent magnet scrap: A critical review. J. Sustain. Metall. 2017, 3, 122–149. [Google Scholar] [CrossRef]

- Du, X.; Graedel, T.E. Global rare earth in-use stocks in NdFeB permanent magnets. J. Ind. Ecol. 2011, 15, 836–843. [Google Scholar] [CrossRef]

- Lixandru, A.; Poenaru, I.; Güth, K.; Gauß, R.; Gutfleisch, O. A systematic study of HDDR processing conditions for the recycling of end-of-life Nd-Fe-B magnets. J. Alloys Compd. 2017, 724, 51–61. [Google Scholar] [CrossRef]

- Ogata, T.; Narita, H.; Tanaka, M. Immobilization of diglycol amic acid on silica gel for selective recovery of rare earth elements. Chem. Lett. 2014, 43, 1414–1416. [Google Scholar] [CrossRef]

- Ogata, T.; Narita, H.; Tanaka, M. Adsorption behavior of rare earth elements on silica gel modified with diglycol amic acid. Hydrometallurgy 2015, 152, 178–182. [Google Scholar] [CrossRef]

- Ogata, T.; Narita, H.; Tanaka, M. Adsorption mechanism of rare earth elements by adsorbents with diglycolamic acid ligands. Hydrometallurgy 2016, 163, 156–160. [Google Scholar] [CrossRef]

- Florek, J.; Chalifour, F.; Bilodeau, F.; Larivière, D.; Kleitz, F. Nanostructured hybrid materials for the selective recovery and enrichment of rare earth elements. Adv. Funct. Mater. 2014, 24, 2668–2676. [Google Scholar] [CrossRef]

- Juère, E.; Florek, J.; Larivière, D.; Kim, K.; Kleitz, F. Support effects in rare earth element separation using diglycolamide-functionalized mesoporous silica. New J. Chem. 2016, 40, 4325–4334. [Google Scholar] [CrossRef]

- Besnard, R.; Winkler, R.; Arrachart, G.; Cambedouzou, J.; Pellet-Rostaing, S. Ion extraction applications of bilayer-structured hybrid silicas. Mater. Chem. Front. 2018, 2, 1031–1039. [Google Scholar] [CrossRef]

- Shinozaki, T.; Ogata, T.; Kakinuma, R.; Narita, H.; Tokoro, C.; Tanaka, M. Preparation of polymeric adsorbents bearing diglycolamic acid ligands for rare earth elements. Ind. Eng. Chem. Res. 2018, 57, 11424–11430. [Google Scholar] [CrossRef]

- Arrambide, C.; Arrachart, G.; Berthalon, S.; Wehbie, M.; Pellet-Rostaing, S. Extraction and recovery of rare earths by chelating phenolic copolymers bearing diglycolamic acid or diglycolamide moieties. React. Funct. Polym. 2019, 142, 147–158. [Google Scholar] [CrossRef]

- Arrachart, G.; Karatchevtseva, I.; Cassidy, D.J.; Triani, G.; Bartlett, J.R.; Wong Chi Man, M. Synthesis and characterisation of carboxylate-terminated silica nanohybrid powders and thin films. J. Mater. Chem. 2008, 18, 3643–3649. [Google Scholar] [CrossRef]

- Zheng, X.D.; Wang, C.; Dai, J.D.; Shi, W.D.; Yan, Y.S. Design of mesoporous silica hybrid materials as sorbents for the selective recovery of rare earth metals. J. Mater. Chem. A 2015, 3, 10327–10335. [Google Scholar] [CrossRef]

- Hu, Y.M.; Florek, J.; Lariviere, D.; Fontaine, F.G.; Kleitz, F. Recent advances in the separation of rare earth elements using mesoporous hybrid materials. Chem. Rec. 2018, 18, 1261–1276. [Google Scholar] [CrossRef]

- Alauzun, J.; Mehdi, A.; Mouawia, R.; Reyé, C.; R.Corriu, J.P. Synthesis of new lamellar materials by self-assembly and coordination chemistry in the solids. J. Sol. Gel Sci. Technol. 2008, 46, 383–392. [Google Scholar] [CrossRef]

- Besnard, R.; Arrachart, G.; Cambedouzou, J.; Pellet-Rostaing, S. Tuning the nanostructure of highly functionalized silica using amphiphilic organosilanes: Curvature agent effects. Langmuir 2016, 32, 4624–4634. [Google Scholar] [CrossRef]

- Besnard, R.; Arrachart, G.; Cambedouzou, J.; Pellet-Rostaing, S. Tuning the morphology of functionalized silica using amphiphilic organosilanes. J. Sol. Gel Sci. Technol. 2017, 81, 452–467. [Google Scholar] [CrossRef]

- Winkler, R. Development of an “all in one“ approach for the synthesis of silica-based hybrid materials. Ph.D. Thesis, ICSM. University Montpellier, Montpellier, France, 2019. [Google Scholar]

- Winkler, R.; Pellet-Rostaing, S.; Arrachart, G. Improvement of organosilane synthesis through click chemistry. Tetrahedron Lett. 2020. [Google Scholar] [CrossRef]

- Besnard, R.; Cambedouzou, J.; Arrachart, G.; Diat, O.; Pellet-Rostaing, S. Self-assembly of condensable “bola-amphiphiles” in water/tetraethoxysilane mixtures for the elaboration of mesostructured hybrid materials. Langmuir 2013, 29, 10368–10375. [Google Scholar] [CrossRef] [PubMed]

- Besnard, R.; Arrachart, G.; Cambedouzou, J.; Pellet-Rostaing, S. Structural study of hybrid silica bilayers from “bola-amphiphile” organosilane precursors: Catalytic and thermal effects. RSC Adv. 2015, 5, 57521–57531. [Google Scholar] [CrossRef]

- Mattsson, S.; Dahlström, M.; Karlsson, S. A mild hydrolysis of esters mediated by lithium salts. Tetrahedron Lett. 2007, 48, 2497–2499. [Google Scholar] [CrossRef]

- Al-Oweini, R.; El-Rassy, H. Synthesis and characterization by FTIR spectroscopy of silica aerogels prepared using several Si(OR)4 and R″Si(OR′)3 precursors. J. Mol. Struct. 2009, 919, 140–145. [Google Scholar] [CrossRef]

- Creff, G.; Arrachart, G.; Hermet, P.; Wadepohl, H.; Almairac, R.; Maurin, D.; Sauvajol, J.L.; Carcel, C.; Moreau, J.J.E.; Dieudonné, P.; et al. Investigation on the vibrational and structural properties of a self-structured bridged silsesquioxane. Phys. Chem. Chem. Phys. 2012, 14, 5672–5679. [Google Scholar] [CrossRef]

- Arkles, B.; Larson, G. Silicon Compounds: Silanes & Silicones; Gelest: Morrisville, PA, USA, 2013. [Google Scholar]

- Rama Swami, K.; Kumaresan, R.; Nayak, P.K.; Venkatesan, K.A.; Antony, M.P. Extraction of Eu(III) in diglycolamide-organophosphorous acid and the interaction of binary solution with Eu(III) studied by FTIR spectroscopy. Vib. Spectrosc. 2017, 93, 1–11. [Google Scholar] [CrossRef]

- Kubelka, J.; Keiderling, T.A. Ab Initio calculation of amide carbonyl stretch vibrational frequencies in solution with modified basis Sets. 1. N-Methyl Acetamide. J. Phys. Chem. A 2001, 105, 10922–10928. [Google Scholar] [CrossRef]

- Wehbie, M.; Arrachart, G.; Arrambide Cruz, C.; Karamé, I.; Ghannam, L.; Pellet-Rostaing, S. Organization of diglycolamides on resorcinarene cavitand and its effect on the selective extraction and separation of HREEs. Sep. Purif. Technol. 2017, 187, 311–318. [Google Scholar] [CrossRef]

- Preston, J.S. Solvent extraction of metals by carboxylic acids. Hydrometallurgy 1985, 14, 171–188. [Google Scholar] [CrossRef]

- Moktli, B.; Poitrenaud, C. Medium effect on the separation factor in liquid-liquid extraction. Application to the separation of trtvalent lanthanide nitrates by tri-n-butylphosphate. Solvent Extr. Ion. Exch. 1997, 15, 455–481. [Google Scholar] [CrossRef]

- Wehbie, M.; Arrachart, G.; Karamé, I.; Ghannam, L.; Pellet-Rostaing, S. Triazole Diglycolamide Cavitand for lanthanide extraction. Sep. Purif. Technol. 2016, 169, 17–24. [Google Scholar] [CrossRef]

- Besnard, R.; Cambedouzou, J.; Arrachart, G.; Le Goff, X.F.; Pellet-Rostaing, S. Organosilica-metallic sandwich materials as precursors for palladium and platinum nanoparticle synthesis. RSC Adv. 2015, 5, 77619–77628. [Google Scholar] [CrossRef]

- Ansari, S.A.; Mohapatra, P.K. A review on solid phase extraction of actinides and lanthanides with amide based extractants. J. Chromatogr. A 2017, 1499, 1–20. [Google Scholar] [CrossRef]

- Ansari, S.A.; Pathak, P.; Mohapatra, P.K.; Manchanda, V.K. Chemistry of diglycolamides: Promising extractants for actinide partitioning. Chem. Rev. 2012, 112, 1751–1772. [Google Scholar] [CrossRef]

| [C] (g/L) | V (mL) | Ci (ppm) | Cf (ppm) | %Efficiency | |

|---|---|---|---|---|---|

| Extraction | 0.7 | 13.50 | 14.53 | 8.49 | 42% |

| Stripping | 6.04 | 4.98 | 82% |

| Elements | B | Co | Dy | Fe | Nd | Ni | Pr |

|---|---|---|---|---|---|---|---|

| w% | 1.1 | 1.6 | 1.3 | 67.2 | 24.5 | 0.6 | 3.7 |

| Concentration (ppm) | 11.32 | 15.45 | 12.35 | 641.6 | 218.7 | 3.05 | 34.34 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Winkler, R.; Pellet-Rostaing, S.; Arrachart, G. Selective Extraction of REEs Thanks to One-Pot Silica Hybrid Materials. Appl. Sci. 2020, 10, 7558. https://doi.org/10.3390/app10217558

Winkler R, Pellet-Rostaing S, Arrachart G. Selective Extraction of REEs Thanks to One-Pot Silica Hybrid Materials. Applied Sciences. 2020; 10(21):7558. https://doi.org/10.3390/app10217558

Chicago/Turabian StyleWinkler, Robert, Stéphane Pellet-Rostaing, and Guilhem Arrachart. 2020. "Selective Extraction of REEs Thanks to One-Pot Silica Hybrid Materials" Applied Sciences 10, no. 21: 7558. https://doi.org/10.3390/app10217558