Laser and LED Hybrid Plant Lighting System Design Based on the Particle Swarm Algorithm

Abstract

:1. Introduction

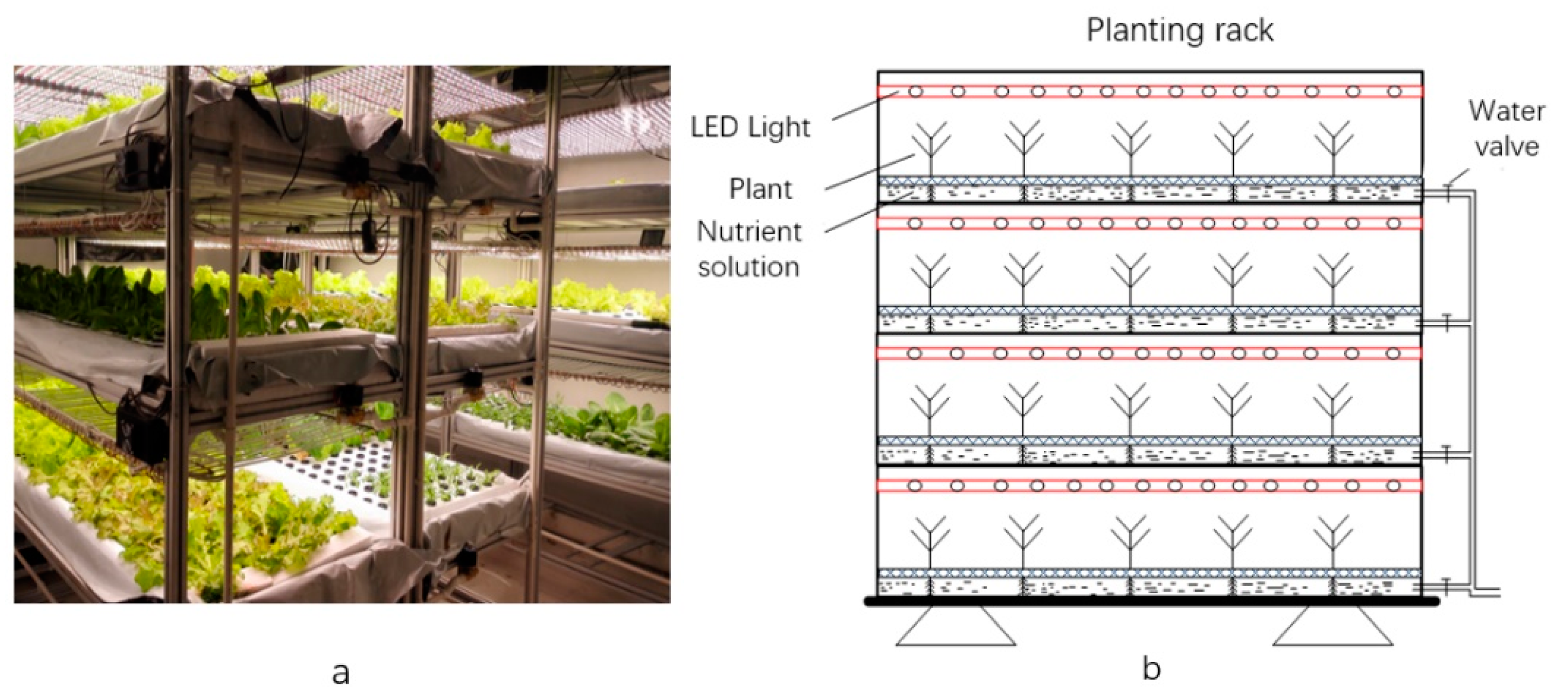

2. Materials and Methods

2.1. Light Source Mathematical Model

2.1.1. LED Mathematical Model under the Light Intensity System

2.1.2. LED Mathematical Model under Irradiance System

2.1.3. Laser Mathematical Model under Irradiance System

2.2. Algorithm Design

2.2.1. Evaluation Function Design

2.2.2. Algorithm Flow Design

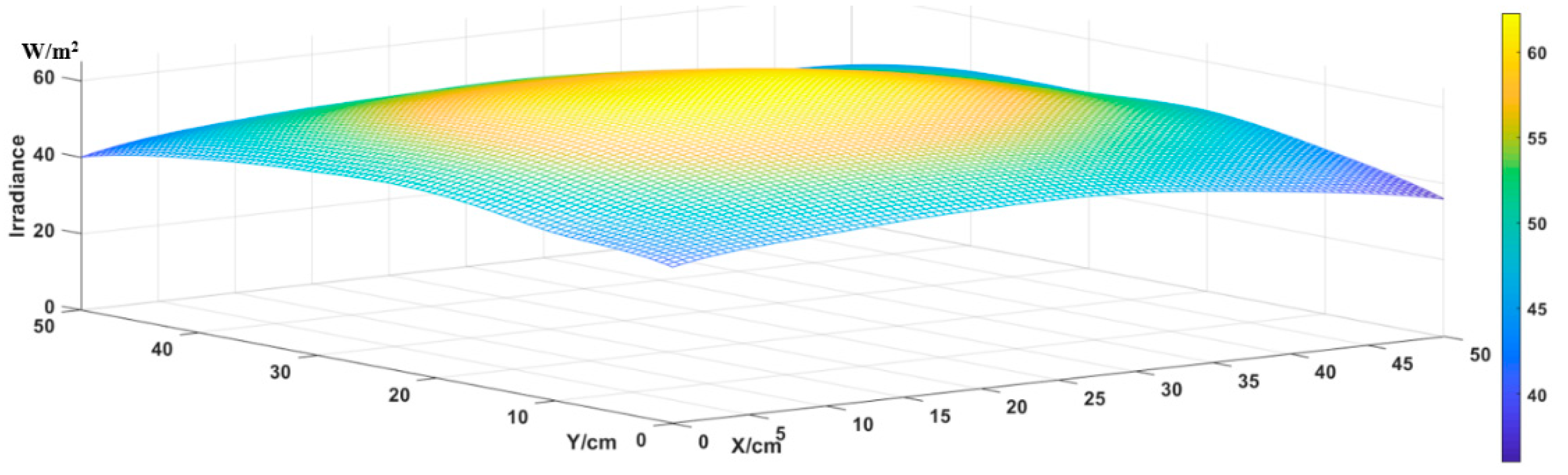

3. Simulation

3.1. Simulation Parameters

3.2. Simulation Procedure

- Use Equation (15) to construct the irradiance generated by a single laser placed at the light source plane point at the illumination plane point.

- Set the number of lasers to 10 and use the algorithm to generate 10 random position points. Enter and set the constraints of f and H, as well as the number of iterations.

- Referring to Figure 2, divide the illumination plane into 10,000 points, use Formula (16) to calculate the total irradiance of the 10 laser light source illumination planes, and use Formula (5) to calculate the variance.

- Use Formulas (17) and (18) to calculate the values of the f function and the H function, and verify whether the constraint conditions are met. If they are not, then the algorithm is iteratively updated according to Formulas (18) and (19) to update the light source position.

- When the number of iterations is reached, the final f function value is the output, which results in uniformity.

- Calculate the energy utilization rate (energy utilization rate=average irradiance received by the illumination plane, area of the illumination plane S, and the radiant power emitted by the light source).

3.3. Simulation Results

4. Experiment

5. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kitsinelis, S. Light Sources: Technologies and Applications; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Olle, M.; Viršile, A. The effects of light-emitting diode lighting on greenhouse plant growth and quality. Agric. Food Sci. 2013, 22, 223–234. [Google Scholar] [CrossRef]

- Darko, E.; Heydarizadeh, P.; Schoefs, B.; Sabzalian, M.R. Photosynthesis under artificial light: The shift in primary and secondary metabolism. Philos. Trans. R. Soc. B Biol. Sci. 2014, 369, 7. [Google Scholar] [CrossRef]

- Morrow, R.C. LED Lighting in Horticulture. Hortscience 2008, 43, 1947–1950. [Google Scholar] [CrossRef] [Green Version]

- Massa, G.D.; Kim, H.H.; Wheeler, R.M.; Mitchell, C.A. Plant Productivity in Response to LED Lighting. Hortscience 2008, 43, 1951–1956. [Google Scholar] [CrossRef]

- Singh, D.; Basu, C.; Meinhardt-Wollweber, M.; Roth, B. LEDs for energy efficient greenhouse lighting. Renew. Sust. Energy Rev. 2015, 49, 139–147. [Google Scholar] [CrossRef] [Green Version]

- Chen, J. The Effect of Different Light on the Quality and Yield of Coptis Chinensis; Northwest A&F University: Xianyang, China, 2011. [Google Scholar]

- Liu, S. Application of Artificial Light Source in Closed Plant Factory; Chinese Academy of Agricultural Sciences: Beijing, China, 2007. [Google Scholar]

- Xu, K.; Guo, Y.; Zhang, S.; Dai, W.; Fu, Q. The effect of different light qualities on the growth and development of Fengxiang strawberry. J. Fruit Sci. 2006, 23, 818–824. [Google Scholar]

- Xu, Y.; Anpo, M.; Fukuda, H.; Wada, T. Nature and Source of Light for Plant Factory. In Plant Factory Using Artificial Light; Elsevier: Amsterdam, The Netherlands, 2009; pp. 47–69. [Google Scholar]

- Williams, L. A light salad LED lighting applications in horticulture. Eng. Technol. 2018, 13, 50–53. [Google Scholar] [CrossRef]

- Huang, Q. Simulation Research and Design of LED Array Based on Uniform Illumination. Master’s Thesis, Huaqiao University, Xiamen, China, 2011. [Google Scholar]

- Hua, H.; Mao, X.; Tan, J.; Yu, X. Dynamic lighting design method based on LED array. Progress Laser Optoelectron. 2017, 54, 416–425. [Google Scholar]

- Su, Z.P.; Xue, D.L.; Ji, Z.C. Designing LED array for uniform illumination distribution by simulated annealing algorithm. Opt. Exp. 2012, 20, 843–855. [Google Scholar] [CrossRef]

- Tang, H.; Wen, S.; Fu, M.; He, G.; Zhang, H.; Liao, S.; Kang, L. LED plant lighting source design based on particle swarm algorithm under light quantum system. Acta Luminica 2019, 40, 340–348. [Google Scholar]

- Wei, X. Design and research of LED lighting control system for plant factories. J. Anhui Agric. Univ. 2010, 37, 806–810. [Google Scholar]

- Zhang, H.; Yang, Q.; Hu, J.; Fan, H.; Dai, J. Plant adaptive precision lighting system with controllable LED brightness. Trans. Chin. Soc. Agric. Eng. 2011, 27, 153–158. [Google Scholar]

- Zhao, Q. Research on LED Lighting System Used for Plant Growth Supplement Light. Master’s Thesis, Fudan University, Shanghai, China, 2012. [Google Scholar]

- Zhang, J.; Yang, J.; Hu, L.; Zhao, S.; Zhao, T.; Li, L. Design of LED light source for plant tissue culture based on single chip microcomputer. J. Hebei Agric. Univ. 2012, 35, 99–104. [Google Scholar]

- Durmus, D. Real-Time Sensing and Control of Integrative Horticultural Lighting Systems. Multidiscip. Sci. J. 2020, 3, 266–274. [Google Scholar] [CrossRef]

- Ooi, A.; Wong, A.; Ng, T.K.; Marondedze, C.; Gehring, C. Growth and development of Arabidopsis thaliana under single-wavelength. Nature 2016, 6, 2045–2322. [Google Scholar]

- Kühlbrandt, W.; Wang, D.N.; Fujiyoshi, Y. Atomic model of plant light-harvesting complex by electron crystallography. Nature 1994, 367, 614–621. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Bergmans, J.W.; Schenk, T.C.; Linnartz, J.P.; Rietman, R. Uniform illumination rendering using an array of LEDs: A signal processing perspective. IEEE Trans. Signal Process. 2009, 57, 1044–1057. [Google Scholar] [CrossRef] [Green Version]

- Whang, A.J.-W.; Chen, Y.-Y.; Teng, Y.-T. Designing uniform illuminance systems by surface-tailored lens and configurations of LED arrays. J. Disp. Technol. 2009, 5, 94–103. [Google Scholar] [CrossRef]

- Moreno, I.; Avendaño-Alejo, M.; Tzonchev, R.I. Designing light-emitting diode arrays for uniform near-field irradiance. Appl. Opt. 2006, 45, 2265–2272. [Google Scholar] [CrossRef] [PubMed]

- Zhenrong, Z.; Xiang, H.; Xu, L. Freeform surface lens for LED uniform illumination. Appl. Opt. 2009, 48, 6627–6634. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.; Zhu, D. Unit conversion between human eye photometry and plant photometry. Lamp Lighting 2007, 31, 34–36. [Google Scholar]

- Zhao, Z.; Ji, L.; Shen, Y.; Su, Z. Study on illumination uniformity of LED lighting system based on PSO particle swarm algorithm. Acta Luminica 2013, 34, 1677–1682. [Google Scholar]

- Wang, J. The Influence Mechanism of Different Light Intensity and Light Quality Ratios on the Photosynthetic Capacity of Lettuce under Red and Blue Light; Chinese Academy of Agricultural Sciences: Beijing, China, 2016. [Google Scholar]

| Parameter | Parameter Value |

|---|---|

| The maximum number of iterations | 500 |

| Laser population size Red LED population size Blue LED population size | 10 20 10 |

| Coefficient | 1.4 |

| Coefficient | 1.4 |

| Laser diffuser enlargement factor | 10 |

| Illumination plane size | 50 cm × 50 cm |

| Distance between laser and LED light source plane and light plane | 40 cm |

| Irradiance D at 40 cm on the LED optical axis Irradiance at 40 cm on the laser optical axis | 1 15 W |

| Laser and LED light intensity and irradiance conversion constant | 1 |

| Type of Light Source | Energy Utilization | Evenness | |

|---|---|---|---|

| Laser | 100% | 40% | |

| 85% | 80% | ||

| 82% | 86% | ||

| Blue LED | 90% | 70% | |

| 84% | 74% | ||

| 77% | 84% | ||

| Red LED | 90% | 70% | |

| 85% | 78% | ||

| 77% | 84% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.; Ma, J. Laser and LED Hybrid Plant Lighting System Design Based on the Particle Swarm Algorithm. Appl. Sci. 2020, 10, 7588. https://doi.org/10.3390/app10217588

Huang Y, Ma J. Laser and LED Hybrid Plant Lighting System Design Based on the Particle Swarm Algorithm. Applied Sciences. 2020; 10(21):7588. https://doi.org/10.3390/app10217588

Chicago/Turabian StyleHuang, Yongping, and Jianshe Ma. 2020. "Laser and LED Hybrid Plant Lighting System Design Based on the Particle Swarm Algorithm" Applied Sciences 10, no. 21: 7588. https://doi.org/10.3390/app10217588

APA StyleHuang, Y., & Ma, J. (2020). Laser and LED Hybrid Plant Lighting System Design Based on the Particle Swarm Algorithm. Applied Sciences, 10(21), 7588. https://doi.org/10.3390/app10217588