Abstract

The remarkable developments in renewable energy at the global scale have paved the way for a sustainable future and cleaner environment. As a fundamental element of this renewable energy revolution, wind energy has received tremendous attention worldwide. In order to harness maximal energy from a wind farm, one crucial decision is the selection of a turbine that is most compatible with the geographical and topographical characteristics of the location under consideration. This selection mechanism ideally considers multiple conflicting decision criteria—i.e., an improvement in one criterion negatively impacts one or more other criteria. Therefore, a tradeoff solution is desired in which the selection criteria are simultaneously optimized to the best achievable limits. Considering the above observations, this paper proposes a TOPSIS (the technique for order of preference by similarity to ideal solution)-based wind turbine selection approach. The problem is modeled as a multi-criteria decision problem while considering hub height, wind speed, percentages of zero and rated output, and annual energy production as the decision criteria. A case study is shown for data collected from two potential sites in northern and north-western Saudi Arabia. Fifteen turbines with rated capacities ranging from 1.5 to 3 MW from various manufacturers were evaluated. Results indicate that the TOPSIS approach was effective in identifying the best turbines for each site. Furthermore, the proposed approach helped in identifying the similarities in the behavior of turbines for the two sites. A comparison of the TOPSIS approach with other multi-criteria decision-making techniques proved the robustness of the method.

1. Introduction

The need for energy has been a fundamental requirement for mankind. From the stone age to the present era, human beings have used energy in various forms [1]. The requirement for energy has especially become vital for survival of mankind in present times due to immense industrial developments and technology-infused lifestyles. For the past one hundred years, fossil fuels have catered to the energy requirements of the world. However, the use of these fossil fuels came with a price in terms of environmental deterioration. Furthermore, the extraction and refining of these fossil fuels is a highly expensive process. In addition, the fluctuating oil prices create uncertainty in the world economy.

The above issues have led to the development of renewable energy systems which can harness energy from renewable sources. Among these sources, wind energy has become an attractive choice around the globe for generating clean, cheap, and commercially viable power [2]. In comparison with traditional fossil fuels, another appeal of utilizing wind energy is the less complex deployment of wind turbines; plus, they require far lesser operational and maintenance costs [3]. Furthermore, wind is not restricted by national borders and therefore cannot be controlled by countries, as is the case with fossil fuels and other traditional sources of energy. The long operational age of 20 to 25 years of wind turbines also makes the utilization of wind energy an attractive choice [3].

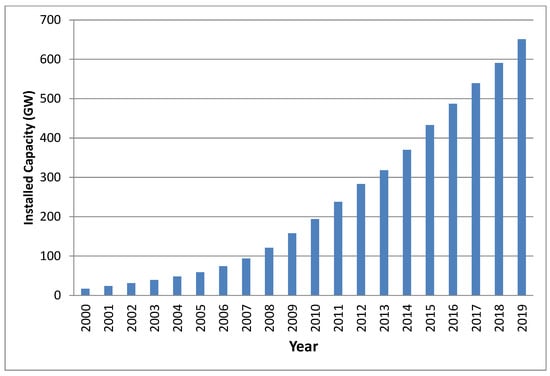

The importance of wind energy for sustainable growth comes from the recent trends in wind energy usage. Statistics indicate that the generation of wind energy has seen almost exponential growth over the past two decades, as illustrated in Figure 1. The figure shows that global wind energy generation has increased from almost 17 GW in the year 2000 to over 651 GW in 2019 worldwide [4]. According to a recent report by the Global Wind Energy Council [4], an onshore capacity of 60.4 GW was added worldwide in 2019, indicating an increase of 19% compared to 2018. China still leads the world, with a total of 230 GW of onshore installed capacity [4]. They are followed by the US, which had total onshore installations of over 100 GW in 2019 [4]. Other countries with new installations in the top five are India (2.4 GW), Spain (2.3 GW), and Sweden (1.6 GW) [4]. Many other countries around the globe are striving to add more wind energy to their national grids [4].

Figure 1.

Growth of wind energy installed capacity: 2000–2019.

In order to design an efficient wind farm that would generate the maximum possible energy, a crucial decision is to select the turbine type that is most suitable to the geographic and topographic conditions of the site. This decision problem is formally referred to as the turbine selection problem. Over the years, the turbine selection problem has received notable attention from researchers [5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30]. Like many computational and engineering problems, the turbine selection problem has two main elements—the problem model and the computational model. From an engineering point of view, a good problem model should reflect the real environment as much as possible, so that the model can be used in practical and commercial applications. From the computational science perspective, the algorithm that is used to solve an engineering problem should not only fully integrate with the problem model, but should be computationally efficient as well. As discussed in Section 3, many of the studies proposed an efficient problem model, but the computational model was not effective. In other studies, the case was the opposite. Therefore, there is a need to have an approach that provides both an effective problem model and computational efficiency.

As far as the problem model is concerned, the turbine selection problem should ideally be modeled as a multi-criteria decision-making (MCDM) problem, where several decision factors should be considered in the turbine selection process, for a more realistic and practical problem design. For example, the fluctuations in the wind speed negatively affect the amount of energy generated, and therefore, the selection of a turbine should consider the wind speed as a decision factor. Furthermore, the variations in wind speed depend on several factors, such as geographical location, climate, topography, and turbine hub height. While the first three factors depend on the natural conditions of the location and cannot be changed, the turbine height is a user controlled variable. This turbine height is directly related to the wind speed, which in turn affects several other factors, such as percentage of zero output, percentage of rated output, and annual energy production. Percentage of zero output refers to the percentage of time for which a turbine does not produce any energy. Likewise, percentage of rated output refers to the percentage of time during which a turbine produces maximal energy. The annual energy production refers to the total energy produced by a turbine over a period of one year. Studies have shown that the hub height (the height of tower on which a turbine is installed) is crucial for the amount of energy generated from a turbine [21,31]. The reason is that wind speed is different at different heights, and more wind is available at higher altitudes, thereby resulting in higher energy yields [31]. However, hub height cannot go beyond a certain limit due to technical, financial, structural, and operational issues. Studies indicate that increasing the hub height just by 10 m results in an overall cost increment by of around USD 120,000 [21]. Therefore, it is not possible to optimize hub height, wind speed, percentages of zero power and rated power, and annual energy output at the same time due to the conflict among them. Accordingly, the problem model desires an approach which can effectively provide a balance between the aforesaid factors. This balance can be achieved by utilizing multi-criteria decision-making (MCDM) techniques.

Over the years, several MCDM techniques have been proposed in the literature. One such technique is the technique for order of preference by similarity to ideal solution, commonly known as TOPSIS. The approach has been successfully applied to a number of MCDM problems in several disciplines. In addition, the TOPSIS approach provides a simple yet effective mechanism to deal with multiple criteria, in addition to being computationally efficient. These observations motivated the use of the TOPSIS technique for the wind turbine selection problem that is modeled as an MCDM problem in this paper. The paper demonstrates the application of the proposed novel method based on TOPSIS for data sets from Saudi Arabia. However, this method can be used comfortably with any data set from anywhere. Thus, the proposed method is not localized, but rather applied to a local problem. A detailed discussion on the novelty of the method, based on the published work, has been given in Section 3.

The rest of this paper is organized as follows. Section 2 provides the status of previous research and current status of the turbine selection problem. This is followed by a discussion on the motivations and contributions of the proposed work in Section 3. The methodology of the study is discussed in Section 4. Application of the TOPSIS method to the underlying problem is discussed in Section 5. Section 6 provides the results and discussion of the TOPSIS method, organized in three subsections. Furthermore, comparison of the TOPSIS method with other MCDM techniques is provided in Section 7. Finally, conclusions are provided in Section 8.

2. Literature Review

As mentioned in Section 1, the turbine selection problem is concerned with both the problem model and the computational model. Accordingly, the literature review on the turbine selection problem in the following paragraphs is organized considering the problem and computational models. A summary of reviewed literature is also provided in Table 1.

Table 1.

Summary of reviewed literature.

Sarja and Halonen [5] carried out interviews with wind energy experts and identified product reliability and availability, production volume, cost, and maintenance management as the important factors for turbine selection. The main drawback of the study was that modeling of the problem was not provided which would be used to make the selection decisions. Perkin et al. [6] identified rotor diameter, generator size, hub height, pitch angle range, and rotations per minute (RPM) range as the decision criteria. A genetic algorithm (GA)-based approach was developed. The major concern of the study was the computational complexity arising from the use of GA. Nemes and Munteanu [7] used system reliability indices to compare nine different wind turbine types. Chowdhury et al. [8] used energy production capacity as the only criterion for decision making, and utilized a particle swarm optimization (PSO) algorithm to solve the problem. Only one turbine type was considered in the optimization process. Furthermore the use of PSO was not an appropriate decision since the algorithm has a high time complexity.

Firuzabad and Dobakhshari [9] used turbine reliability as the only selection criterion, based on which a probabilistic model was developed while assuming five turbine types in the selection pool. Bencherif et al. [10] adopted an approach based on Weibull distribution but considered capacity factor as the only decision criterion. They studied the proposed approach using 24 turbine types. Montoya et al. [11] adapted GA and used two decision criteria which were power output and deviation in daily power output. Chowdhury et al. [12] considered 121 varieties of turbines while using cost of energy as the decision criterion, but a limitation was the complexity of the algorithm they proposed. Bekele and Ramayya [13] considered blade design as the decision factor and used GA to optimize the blade shape according to site specifications. A major limitation of the study was that their approach was to design a completely new turbine for each specific site, rather than using existing turbines from different manufacturers. Helgason [14] used minimum cost of energy as the decision criterion and applied their proposed approach to study various sites in Iceland while assuming 47 different turbine types. Dong et al. [15] adapted several nature-inspired algorithms, namely, GA, PSO, and differential evolution (DE) for turbine selection while using matching index, turbine cost index, and the integrated matching index for selection. Shirgholami et al. [16] identified over 30 decision criteria for turbine selection, but also identified that only a subset of these criteria could be used in the selection process. The selection of these criteria was done based on the characteristics of the potential site. They used an AHP-based approach. Bagočius et al. [17] proposed a turbine selection strategy based on WASPAS method for offshore wind farms while considering five selection criteria. These criteria were nominal power of the wind turbine, maximum power generated in the area, the amount of energy per year generated in the area, investments, and emissions. However, only four turbine types were considered. Khan and Rehman [18,19] proposed the use of fuzzy logic for turbine selection while considering hub height, zero output percentage, and rated output as the decision criteria. They also proposed an enhanced two-tier selection approach [20] based on fuzzy logic. Furthermore, goal programming and weighted sum (also known as weighted linear combination, weighted aggregation, and simple additive weighting) approaches for turbine selection were also proposed by them [21,22,23]. All their studies considered a few sites in Saudi Arabia, while considering turbines types with small to medium rated powers. Şağbanşua and Balo [24] used the AHP approach for selection of turbines from different manufacturers while considering technical, economic, environmental, and customer related factors. However, they considered only 1.5 MW turbines. Furthermore, no comparison with other techniques was made. Shateranlou and PourHossein [25] proposed a blade element momentum (BEM) method combined with multi-objective optimization algorithms to select the best turbine. Using their proposed approach, they extracted the power curve for a specific site, and then selected the turbine that fits this power curve. They used turbine blade radius, tip speed ratio, blade sectional radius width (chord) and twisting angle distribution, turbine tower height, and blade airfoil standard as the decision criteria. Dinmohammadi and Shafiee [26] proposed a hybrid AHP–TOPSIS-based multi-criteria model for the selection of turbines with different structures. They considered bottom fixed, floating, vertical-axis, horizontal-axis, gearbox-operated, and gearless wind turbines. Hammad and Batarseh [27] proposed a method similar to that of Shateranlou and PourHossein, but using the mapping of Weibull probability functions. They mapped the Weibull probability functions of several sites with the power curve of various turbines, and then chose the best turbine that showed the highest compatibility with the characteristics of that specific site. Jakubowski et. al. [28] used an approach very similar to Hammad and Batarseh by mapping the Weibull probability distribution of wind conditions in a site in Poland to the power curves of various turbines. Sedaghat et. al. [29] used the levelized cost of electricity, capacity factor, and normalized annual energy production as the decision criteria through generation of Pareto front to select the best turbine. Beskese et al. [30] proposed a hybrid AHP–TOPSIS approach for wind turbine evaluation for a potential site in Turkey. The model was developed using qualitative and quantitative data.

3. Contributions of the Proposed Work

The literature review in the previous section discussed relevant studies. Accordingly, certain limitations in those studies can be identified with respect to the problem models and the computational methods. As far as the problem models are concerned, several studies used simple decision models, or used selection criteria for which the required data are difficult to obtain. For example, single selection criteria were used in several studies [7,8,9,10,12,13,14], which made the models rather unrealistic. Furthermore, in studies where multi-criteria models were used, the decision criteria used in the underlying decision models were complex since the data for the decision criteria were difficult to obtain [5,7,9,15,16,17,25,30]. Examples of such criteria are product reliability and availability, maintenance management, system reliability indices, matching index, turbine cost index, the integrated matching index, emissions, turbine blade radius, tip speed ratio, blade sectional radius width (chord) and twisting angle distribution, and blade airfoil standard.

With regard to the computational methods, the majority of studies used complex algorithms. For example, non-deterministic algorithms such as GA, PSO, DE, and Pareto frontier approach were used in several studies [6,8,11,13,15,29]. The aforementioned algorithms have limitations with regard to their computational efficiency; in comparison with a deterministic algorithm (such as TOPSIS), they take a notable amount of time to generate the best solution. Similarly, methods such as the analytical hierarchy process (AHP), fuzzy logic, the weighted sum method, and goal programming have been used in several studies [16,18,19,20,21,23,24,24]. While the computational efficiencies of those methods are better than those of non-deterministic algorithms, other limitations can be observed. A practical limitation of AHP is that a high number of alternatives implies a large number of comparisons [32]. In fuzzy logic, the selection of an appropriate fuzzy operator is a challenge, as different fuzzy operators may give different results [21]. In goal programming, identifying the target (ideal solutions) is a difficult task, since incorrect targets may result in inefficient solutions [33]. A major concern with the weighted sum method is that a small change in weights may result in big changes in the criteria’s importance and significantly different weights may produce nearly similar decisions [34].

The TOPSIS method, on the other hand, does not suffer from most of the above concerns. The TOPSIS approach is a computationally efficient method. The method is simple and able to consider a non limited number of alternatives—a limitation of the AHP method [35]. The method has been effectively used to solve a number of decision problems. Furthermore, the TOPSIS method does not require involvement of the decision-maker for defining upper and/or lower limits of criteria, as is required in fuzzy logic, goal programming, or the weighted sum method. Noting these characteristics, the key contributions of the work proposed herein are enumerated as follows:

- A TOPSIS-based approach is proposed for the turbine selection problem. To the best of our knowledge, this study is the first attempt to solve the turbine selection problem using the TOPSIS method.

- A multi-criteria decision approach is employed using important and relevant criteria. These criteria include hub height, wind speed, percentage of zero power, percentage of rated power, and annual energy production. The importance of these criteria is endorsed by several previous studies [18,21,29,36,37]. Furthermore, the approach is robust and scalable, and can be easily extended to accommodate more selection criteria.

- As opposed to many previous studies, the proposed method was tested on real data collected from two potential sites in Saudi Arabia, namely, Turaif and Wejh. However, the approach is generic and is broadly applicable to any real site around the globe.

- To demonstrate the impact and diversity of the TOPSIS approach in different scenarios, a comparative analysis on the performance of the proposed TOPSIS approach is provided with regard to the two diverse potential sites. Both sites have different topographic and climatic conditions.

- Comparison of the TOPSIS approach is done with three other MCDM techniques that were employed for turbine selection problem in previous studies [18,19,20,21,22,23]. These techniques include the weighted sum method, fuzzy logic, and goal programming. The comparison aims at analyzing the trends of a turbine type for the two sites when TOPSIS is used and when all four techniques are used in an aggregated manner.

4. Methodology

A quantitative model is adopted in the research and is based on an empirical study. The important decision criteria have been identified by the literature. These criteria are hub height, wind speed, percentage of zero power, percentage of rated power, and annual energy production. These criteria were used to develop the TOPSIS-based turbine selection model. Six decision criteria were considered in the model. The measurements were taken with a step size of 10 m for hub height. Using the input data for the five decision criteria, the ideal limits were identified, which were used as inputs in the TOPSIS module. The output of the TOPSIS module gives the relative ranking of each solution. This procedure was repeated for each turbine at a later stage to identify the best turbine.

The above approach was implemented using a program in C++ language. For each turbine, site specific data were fed as input to the program which generates several solutions. The best (optimal) solution is also identified by the program based on the strategy discussed in Section 5. The site-specific information focuses on data for wind turbines in the range of 1500 to 3075 kW. Empirical analysis was carried out, providing comparisons of different types of turbines for the two sites. Based on the outcomes of the analysis, interpretations and recommendations were made.

5. Application of the TOPSIS Method for Turbine Selection

TOPSIS (technique for order preference by similarity to an ideal solution) [38] is an MCDM technique that selects the best solution from a pool of solutions. The primary concept of the method is that the chosen solution should be the closest to the positive ideal solution and the farthest from the negative ideal solution [39]. The method is simple and computationally efficient. The procedure of TOPSIS consists of a series of steps [39] listed below:

- Calculate the normalized decision matrix. The calculation of the normalized value is done as

- Calculate the weighted normalized decision matrix. The calculation of weighted normalized value is done aswhere is the weight of the criterion, and

- Determine the ideal solutions (both positive and negative):where I is associated with benefit criteria, and J is associated with cost criteria.

- Calculate the separation measures, using the n-dimensional Euclidean distance. The separation of each solution from the positive ideal solution is given asSimilarly, the separation from the negative ideal solution is given as

- Calculate the relative closeness to the ideal solution. The relative closeness of the solution with respect to is defined asNote that since and , then

- Rank the preference order. The solution with the highest value of is the best solution.

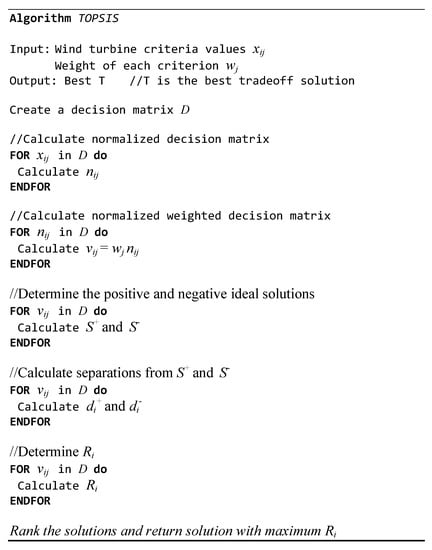

Figure 2 illustrates the pseudo code of the TOPSIS method. In order to apply the TOPSIS method to the multi-criteria turbine selection problem, several requirements need to be fulfilled. The first and foremost requirement is to identify the decision criteria. In this work, five decision criteria are assumed. These are hub height, wind speed, zero output percentage, rated output percentage, and annual energy production. Note that while five criteria are assumed, the proposed TOPSIS approach is scalable and can be extended to as many criteria as required without the loss of generality. The second requirement is to assign weights to each of the five criteria to calculate the weighted normalized decision matrix. A simple weighting assignment is to treat all criteria equally, thereby resulting in a weight of 0.2 for each criterion. The third requirement stipulates the need of satisfying the incommensurability, which is inherently dealt with by the TOPSIS approach. Incommensurability refers to situation where different decision criteria have different units and magnitudes.

Figure 2.

Pseudo code of the TOPSIS method.

6. Results and Discussion

Empirical research was carried out; real data were collected from two potential and geographically diverse sites in Saudi Arabia. These two sites are Turaif and Wejh. The former is located in the northern part of Saudi Arabia, while the latter is in the north-western part of the country. Turaif is at a height of 827 meters above sea level, while Wejh is located at a height of 24 meters above sea level. The measurements for wind speed were taken at hub heights ranging from 50 to 140 m. The speed of wind was interpolated or estimated at an interval size of 10 meters using local wind shear exponent. The data for the study were collected over a period of 39 years, from 2 January 1980 to 31 December 2018 and are comprised of hourly average values [40]. Necessary information relevant to this study was extracted from the collected data. Moreover, 15 different turbines from various manufacturers were considered. The rated capacities of the turbines were between 1.5 and 3 MW. Table 2 provides specifications of these turbines.

Table 2.

Specifications of turbines used in the study.

The TOPSIS analysis was carried out using the input data. Results were divided into three sets of analysis. In the first set, data for a specific turbine were selected and TOPSIS analysis was performed to identify the best balance between hub height (HH), wind speed (WS), percentage of zero output (ZP), percentage of rated output (RP), and annual energy production (AEP). This procedure was repeated for all turbines and the best tradeoff solution was found for each turbine. In the second analysis, the best solutions for each turbine from the first phase were mutually compared, and the best turbine among all turbines was identified. In the third analysis, results from the two sites were compared and analyzed to observe any specific trends. Details of these analysis are provided in the following sections.

6.1. TOPSIS Analysis for Identification of Best Tradeoff

In this phase, data collected from the two sites were analyzed and the best tradeoff solution for each turbine was identified using the TOPSIS method for each site. Table A1, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8, Table A9, Table A10, Table A11, Table A12, Table A13, Table A14 and Table A15 given in Appendix A show the results for the 15 turbines for the two sites. The measurements for the decision criteria were taken at different hub heights. The best balance for each site is marked in boldface. As an example, consider Table A1. The first decision criterion, the hub height, is given in column 1. This criterion is common for both sites. Then, the values of other decision criteria are mentioned in columns 2–5 for Turaif and columns 9–12 for Wejh. The values of the output, , are given in column 8 for Turaif and column 15 for Wejh. The higher the value of , the betterthe selection. As an example, consider Table A1, where the maximum for Turaif is 0.429. Similarly, in the same table, the maximum value of for Wejh is 0.656. Both choices indicate the best selection for the respective sites.

As far as Turaif is concerned, results in Table A1, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8, Table A9, Table A10, Table A11, Table A12, Table A13, Table A14 and Table A15 indicate that the best tradeoff between the decision criteria was found at the hub height of 130 or 140 m, identified by the corresponding values. There is one exception of turbine type Acciona AW 70/1500 Class I, for which the best tradeoff was found at 60 m. Similar trends are found with regard to Wejh; the best tradeoffs were found mainly at 140 m, with Dongfang DF110-2500 standing best at 130 m. Furthermore, there are instances where decisions at 130 and 140 meters were the same. Such instances are Dewind D92 and Doosan WinDS 3000 for Turaif, and Windtec FC 3000-130 for Wejh. In this scenario, it is the role of the decision-maker to pick any of the two solutions.

6.2. TOPSIS Analysis for Identification of Best Turbine

In order to identify the best turbine for each of the two sites, Table 3 and Table 4 consolidate the best results from Table A1, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8, Table A9, Table A10, Table A11, Table A12, Table A13, Table A14 and Table A15. The best results were identified by the maximum values which are indicated in the last columns of Table 3 and Table 4. It is observed from these tables that the best turbine for both sites was Enercon E-82 E4/3000, since the maximum value (marked in boldface) for both sites is associated with this turbine. Furthermore, the second best turbine for both sites is Alstom ECO 100/2000 Class I. As far as the worst turbines are concerned, results indicate that Acciona AW 70/1500 Class I was the worst performer for Turaif, while Dongfang DF110-2500 was the worst turbine for Wejh.

Table 3.

Best tradeoff for each turbine for Turaif. The best turbine among all is marked with an asterisk.

Table 4.

Best tradeoff for each turbine for Wejh. The best turbine among all is marked with an asterisk.

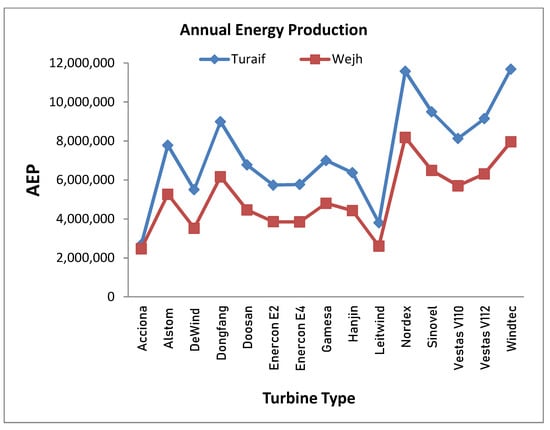

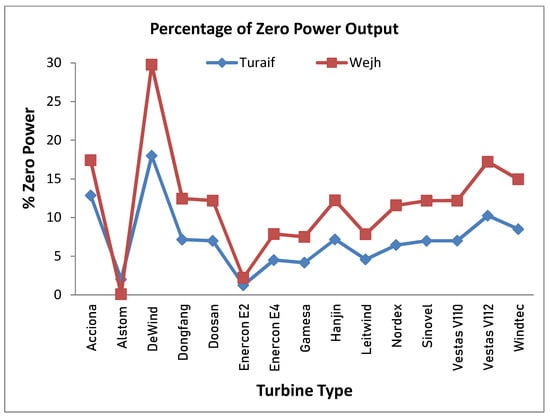

6.3. Comparison between Turaif and Wejh

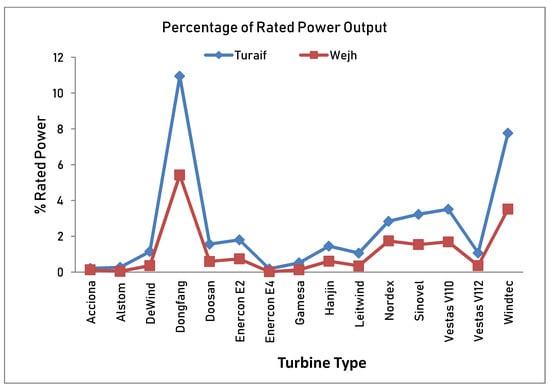

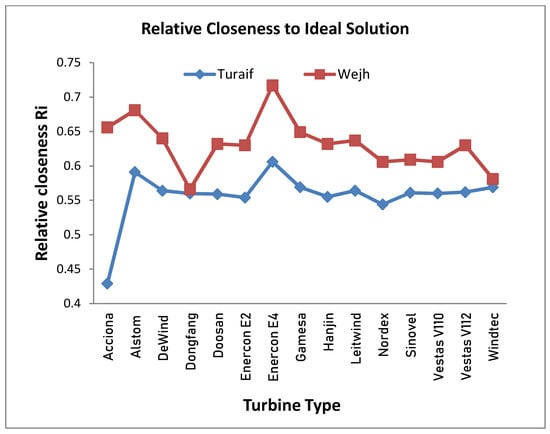

A mutual comparison was also performed to observe the commonalities and differences between the results for the two sites. As mentioned earlier, both sites have topographic and geographic differences, with the main ones being differences in terms of the height above sea level, and longitude and latitude. Figure 3, Figure 4, Figure 5 and Figure 6 shows the plots for the 15 turbines for various attributes. Some interesting facts are observed from these figures. In Figure 3, the annual energy production for each turbine for the two sites is shown. It can be seen from this figure that the energy production of the turbines relative to each other is the same for both sites; the only difference is that the energy production for Turaif is shifted upwards. For example, Windtec FC 3000-130 shows the maximum production for Turaif among all turbines, while Acciona AW 70/1500 Class I shows the worst production. Other turbines show production in different ranges. The same observation can ve made for Wejh; Windtec FC 3000-130 is the best performer and Acciona AW 70/1500 Class I is the worst, with other turbines showing the same pattern as that of Turaif, but with lower production levels. Similar trends were observed with regard to percentage of zero power output and percentage of rated power output in Figure 4 and Figure 5 respectively, where the relative trends between turbines have the same patterns for the two sites, but shifted by a certain scale. The results make sense since Turaif is at much higher altitude than Wejh, which results in more energy absorption by turbines by the former. However, the relative performances of different turbines are the same for both sites, which indicates that a turbine would exhibit the same level of relative performance when compared with the same turbine but at a different location. This further indicates that if the relative performances of turbines can be studied and analyzed for any given site, the same relative performances and behaviors may be predicted for any other site. These observations are further strengthened by the plots given in Figure 6 which show the relative closeness to an ideal solution for each turbine. Again, the trends pertaining to different turbines are generally similar for the two sites, except the up-shift trends for Turaif.

Figure 3.

Comparison of annual energy production (AEP) for different turbines for Turaif and Wejh.

Figure 4.

Comparison of ZPO for different turbines for Turaif and Wejh.

Figure 5.

Comparison of RPO for different turbines for Turaif and Wejh.

Figure 6.

Comparison of for different turbines for Turaif and Wejh.

7. Comparison with Other Multi-Criteria Decision-Making Techniques

This section provides a comparative analysis of the proposed TOPSIS approach with other techniques. The section first provides a primer on some MCDM techniques previously applied to the turbine selection problem. This is followed by empirical analysis and comparisons of TOPSIS and other techniques in the context of the two sites.

7.1. Brief Discussion of Other MCDM Techniques

Some previous studies employed other MCDM techniques for the turbine selection problem. These techniques include the weighted sum method (WSM) [22], fuzzy logic (FL) [18,19,20], and goal programming (GP) [21,23]. This study adapted the approaches presented in the above studies according to the model presented in Section 5 consisting of five selection criteria. A brief discussion of the aforementioned three methods in the context of the turbine selection problem is presented below for the sake of comprehensiveness. Detailed discussion can be found in the references mentioned above.

The weighted sum method has been widely applied to MCDM problems, since it is simple and time efficient [41]. The basic approach of WSM is the aggregation of criteria to form an overall decision function. A precondition of the aggregation is that the decision criteria are normalized so as to overcome the incommensurability issue. Once the criteria are normalized, weights are assigned to each decision criterion as per the aspirations of the decision-maker. Following this, the weighted normalized criteria are aggregated using an aggregation function, which generates the output in the form of a scalar value. A necessary requirement is that the sum of all weights should not exceed 1.

The weighted sum approach using the five turbine selection criteria requires that upper limit for each criterion is defined. These upper limits are required for the purpose of normalization of criteria. Note that in the context of turbine selection problem, the weighted sum approach deals with the problem as a maximization problem. That is, the interest is in finding the turbines where hub height and zero percentage are minimized, while wind speed, rated percentage, and annual energy production are maximized. Accordingly, the following equation is used for the decision.

In the above equation, W(t) defines the weighted sum of turbine t. Each fraction in Equation (1) represents the normalized value of a selection criterion. The higher the value of W(t), the better the turbine. Furthermore, in order to be consistent with the weights in the TOPSIS approach, in Equation (8).

The application of fuzzy logic to wind turbine selection problem requires that the five selection criteria are aggregated to form an overall decision function. This decision function is first formulated as a rule, which is then transformed into a mathematical function. For the turbine selection problem, the following fuzzy rule can be formulated.

Rule 1: IF a turbine has low hub height, high wind speed, low zero output percentage, high rated output percentage, and high annual energy production, then it is a good turbine.

In the above rule, the terms “low hub height”, “high wind speed”, “low zero output percentage”, “high rated output percentage”, “high annual energy production”, and “good turbines” are linguistic variables, each of which defines a fuzzy subset of solutions. For example, high wind speed is the fuzzy subset of solutions of high wind speeds. For each fuzzy subset, a membership function is defined. The membership function returns a value in the interval [0, 1]. This value signifies the degree of satisfaction with the decision criterion under consideration [20]. Rule 1 can be mathematically represented using the fuzzy arithmetic mean operator [42] as follows:

where is the membership function for good turbine. Similarly, , , , , and are the membership functions for hub height, wind speed, zero output percentage, rated output percentage, and annual energy production, respectively. The solution for the nearest to 1 is declared as the best solution. For details on the approach about formation of the above membership functions, interested readers are referred to Khan and Rehman [18,19,20].

Similar to weighted sum and fuzzy logic, goal programming is another MCDM technique that has been used for the turbine selection problem. In goal programming, target/ideal values are set by the decision-maker, and the objective is to reach the target value in the decision-making process. The absolute difference (deviation) between the target value and actual achieved value is measured. This is done for all decision criteria. Finally, all deviations are added. This is done for alternatives (solutions), and the alternative that results in the minimum deviation is declared as the best solution. As far as turbine selection problem is concerned, the method has been applied in previous studies [21,23]. Accordingly, the goal programming formulation for the problem model in this study can be done as follows:

In the above equation, Dev(t) refers to the collective deviation of all criteria. represents the ideal value of criterion x. refers to the actual achieved value of criterion x of the solution which results in the minimum value for Equation (10), recorded as the best solution found.

7.2. Comparative Results

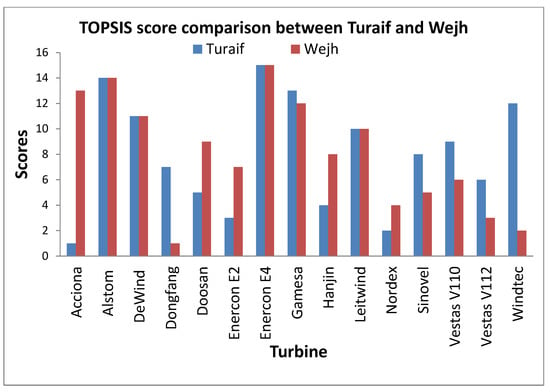

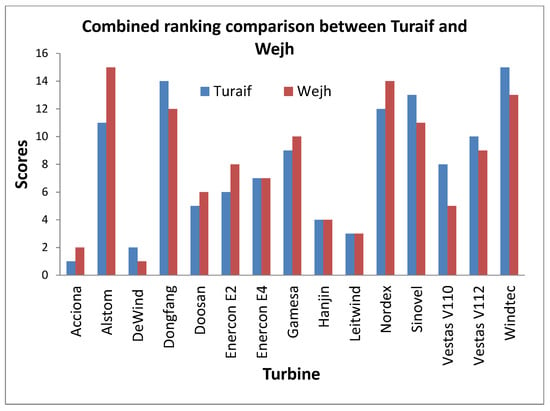

The comparison of the TOPSIS approach with the aforementioned techniques was done in the context of the consolidated results presented in Table 3 and Table 4 for Turaif and Wejh. The objective of the analysis was to investigate whether the trends obtained using the TOPSIS approach match with the trends observed using the combined effect of all MCDM approaches. For this purpose, an approach similar to the ranking approach proposed by Lee et al. [43] was adopted in this study and works as follows. Each turbine in Table 3 and Table 4 was evaluated with regard to the three methods. Then, based on the outcome of each method, scores were assigned to each turbine. Note that there were 15 turbines. Therefore, the best turbine was given maximum 15 points which was the highest score. Then, the second best turbine was given 14 points and so on. The worst turbine scored 1 point. In order to understand the approach, consider the results in Table 5. For TOPSIS, the value of for each turbine is given. Next to this value, the score is given with respect to the standing of the turbine. The same approach was used for the other methods, as shown in the table. The second to last column of the table shows the total score obtained by adding the individual scores from each method. The higher the total score, the higher the ranking. The same approach was followed for the turbines for Wejh, as shown in Table 6.

Table 5.

The scores in terms of different methods for Turaif.

Table 6.

The scores in terms of different methods for Turaif.

In order to be consistent, the limits and the weights used for different methods were the same. More specifically, the TOPSIS approach described in Section 5 used the positive ideal values and negative ideal values extracted from the input data for all turbines. The same input data were used to define the upper limits in weighted sum method, the upper and lower limits in fuzzy logic, and the ideal values in goal programming. Furthermore, since five decision criteria were considered, equal weights (i.e., 0.2) were assumed for each criterion in TOPSIS and WSM. For FL and GP, the structure of the decision function automatically assumes equal preference for each objective, as is obvious from Equations (9) and (10).

It is obvious from Table 5 and Table 6 that different MCDM methods produced different results. This trend is somewhat common in comparative studies in the domain of MCDM [43,44]. However, as stated in Section 1, the objective of this comparison was to investigate the trends of the two sites when TOPSIS was used versus the trends when the combined effect of all MCDM methods was analyzed. The reason for studying the combined effect was inspired by the study of Lee et al. [43], who chose the best alternative by aggregating the rankings obtained using different methods. In order to address the aforementioned objective, the combined scores in Table 5 and Table 6 were scaled to a level of 1–15. This was done to be consistent with the 1–15 score level for the TOPSIS approach. The last columns of Table 5 and Table 6 show the scaled scores for Turaif and Wejh respectively. In order to further elaborate the comparative trends, Figure 7 and Figure 8 show the scores for each turbine for the two sites using the TOPSIS and combined MCDM approaches, respectively. As observed in Figure 7, six turbine types show higher ranks for Turaif when compared with their ranks with Wejh, while five turbine types show lower ranks for Turaif. For four turbine types, both Turaif and Wejh show equal rankings. Note that the notion of ranking is different from scores here. Ranking is simply reflecting the relative superiority of the same turbine type when used for the two sites, irrespective of the scores the turbine obtained for the two sites. In the same fashion, the relative ranking for all turbine types is plotted in Figure 8, where it can be observed that six turbine types had better ranks for Turaif, and for the same number had lower ranks for Turaif; three turbine types had equal ranks. For clear understanding, these rankings are summarized in Table 7. It is obvious from the table that out of 15 turbine types, the trends for 11 turbine types were the same when Turaif and Wejh were compared using the TOPSIS method and all four methods combined. This shows the robustness of the TOPSIS method.

Figure 7.

Comparison of scores for different turbines for Turaif and Wejh using TOPSIS.

Figure 8.

Comparison of scores for different turbines for Turaif and Wejh using all methods combined.

Table 7.

Comparative rankings using TOPSIS and combined methods combined.

8. Conclusions

Wind energy is gradually becoming a major part of today’s energy generation systems worldwide, since it promises to provide sustainable and environmental-friendly energy for the future. Maximum energy harnessing from a wind farm is not possible unless the farm has been designed efficiently. One essential part of efficient wind farm development is the selection of best turbine type that matches the requirements of that wind farm site. This selection process is governed by consideration of multiple, realistic decision criteria that may be diverse in their nature. Such a selection process demands that a simple and computationally efficient multi-criteria selection technique is employed that would effectively incorporate the requirements of these different selection criteria in the decision process. The TOPSIS method adapted in this paper effectively addresses the requirements of a multi-criteria turbine selection problem, whereby five different yet important selection criteria were considered. These criteria are hub height, wind speed, percentage of zero output, percentage of rated output, and annual energy production. The TOPSIS approach was applied to turbine selection for two potential sites located in the northern and north-western parts of Saudi Arabia and used realistic data collected over a period of 39 years. The results indicated that the TOPSIS approach produced results that identified the best turbines for the each site, thereby enabling the decision makers to choose from a variety of commercially available turbines. A comparative analysis of the two sites indicated that the relative behaviors of the turbines were very similar for the two sites. A further comparison with other MCDM techniques such as the weighted sum method, fuzzy logic, and goal programming indicated that TOPSIS was a robust approach as far as the turbine selection problem with respect to the two sites is concerned.

Our future work will be directed towards further assessment of the TOPSIS approach with more diverse test scenarios. This should potentially include different terrain types, bigger data sets with more turbines, and a variety of potential sites.

Author Contributions

Conceptualization, S.R. and S.A.K.; methodology, S.A.K. and S.R.; software, S.R. and S.A.K. and L.M.A.; validation, S.R., S.A.K., and L.M.A.; formal analysis, S.A.K.; investigation, S.R. and S.A.K.; resources, S.R. and L.M.A.; data curation, S.R.; writing—original draft preparation, S.R., S.A.K., and L.M.A.; supervision, S.R.; project administration, S.R.; funding acquisition, S.R. and L.M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Deanship of Research at King Fahd University of Petroleum and Minerals under grant number SB181015.

Acknowledgments

The authors extend their appreciation to the Deanship of Research at King Fahd University of Petroleum and Minerals for funding this work through research grant number SB181015.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| normalized value of criteria | |

| weighted normalized value of criteria | |

| weight of criterion j | |

| ideal positive solution | |

| ideal negative solution | |

| separation from positive ideal solution | |

| separation from negative ideal solution | |

| relative closeness of solution w.r.t. | |

| Weighted sum of turbine t | |

| Membership function for turbine t | |

| Membership function for hub height | |

| Membership function for wind speed | |

| Membership function for percentage of zero output | |

| Membership function for percentage of rated output | |

| Membership function for annual energy production | |

| Dev(t) | Collective deviation for all criteria for turbine t |

| Ideal value of criterion x | |

| Actual achieved value of criterion x | |

| Multi-criteria decision-making | |

| Technique for Order of Preference by Similarity to Ideal Solution | |

| Genetic Algorithms | |

| Particle Swarm Optimization | |

| Analytical Hierarchy Process | |

| Weighted aggregated sum product assessment | |

| Hub height (in meters) | |

| Wind speed (in m/s) | |

| Percentage of zero output | |

| Percentage of rated output | |

| Annual energy production (in kWh/yr) | |

| Maximum Hub height (in meters) | |

| Maximum Wind speed (in m/s) | |

| Maximum Percentage of zero output | |

| Maximum Percentage of rated output | |

| Maximum Annual energy production (in kWh/yr) | |

| Fuzzy logic | |

| Weighted sum method | |

| Goal programming | |

| Acciona | Acciona AW70/1500 Class I |

| Alstom | Alstom ECO 100/2000 Class I |

| DeWind | DeWind D92 |

| Dongfang | Dongfang DF110-2500 |

| Doosan | Doosan WinDS 3000 |

| EnerconE2 | Enercon E-82E2/2000 |

| EnerconE4 | Enercon E-82E4/3000 |

| Gamesa | Gamesa G97-2.0MW |

| Hanjin | Hanjin HJWT2000-93 |

| Leiwtwind | Leitwind LTW70-2000 |

| Nordex | Nordex N131/3000 |

| Sinovel | Sinovel SL3000/115 |

| Vestas112 | Vestas V112-3.0MW |

| Vestas110 | Vestas V110-2.0MW |

| Windtec | Windtec FC3000-130 |

Appendix A

Table A1.

TOPSIS analysis for turbine Acciona AW 70/1500 Class I. The best choice for each site is marked with an asterisk.

Table A1.

TOPSIS analysis for turbine Acciona AW 70/1500 Class I. The best choice for each site is marked with an asterisk.

| HH | Turaif | Wejh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (m) | WS | ZP | RP | AEP | WS | ZP | RP | AEP | ||

| 50 | 6.08 | 13.56 | 0.16 | 2,511,427 | 0.427 | 4.99 | 22.90 | 0.01 | 1,631,379 | 0.344 |

| 60 | 6.24 | 12.87 | 0.21 | 2,696,078 | 0.429 * | 5.11 | 21.80 | 0.02 | 1,761,383 | 0.343 |

| 70 | 6.37 | 12.33 | 0.26 | 2,859,608 | 0.428 | 5.23 | 20.94 | 0.03 | 1,877,239 | 0.350 |

| 80 | 6.49 | 11.88 | 0.31 | 3,006,741 | 0.423 | 5.33 | 20.23 | 0.04 | 1,982,126 | 0.369 |

| 90 | 6.6 | 11.51 | 0.36 | 3,140,724 | 0.409 | 5.41 | 19.60 | 0.05 | 2,078,069 | 0.400 |

| 100 | 6.7 | 11.17 | 0.41 | 3,263,976 | 0.386 | 5.49 | 19.06 | 0.06 | 2,166,765 | 0.440 |

| 110 | 6.79 | 10.87 | 0.46 | 3,378,100 | 0.352 | 5.57 | 18.56 | 0.08 | 2,249,234 | 0.539 |

| 120 | 6.87 | 10.61 | 0.51 | 3,484,564 | 0.314 | 5.64 | 18.15 | 0.09 | 2,326,365 | 0.572 |

| 130 | 6.95 | 10.38 | 0.56 | 3,584,210 | 0.282 | 5.70 | 17.77 | 0.11 | 2,398,928 | 0.631 |

| 140 | 7.02 | 10.17 | 0.62 | 3,678,128 | 0.265 | 5.76 | 17.41 | 0.13 | 2,467,511 | 0.656 * |

Table A2.

TOPSIS analysis for turbine Alstom ECO 100/2000 Class I. The best choice for each site is marked with an asterisk.

Table A2.

TOPSIS analysis for turbine Alstom ECO 100/2000 Class I. The best choice for each site is marked with an asterisk.

| HH | Turaif | Wejh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (m) | WS | ZP | RP | AEP | WS | ZP | RP | AEP | ||

| 50 | 6.08 | 2.66 | 0.06 | 5,311,341 | 0.409 | 4.99 | 0.12 | 0.00 | 3,485,619 | 0.319 |

| 60 | 6.24 | 2.53 | 0.08 | 5,704,562 | 0.411 | 5.11 | 0.12 | 0.00 | 3,762,654 | 0.295 |

| 70 | 6.37 | 2.42 | 0.10 | 6,052,657 | 0.418 | 5.23 | 0.12 | 0.01 | 4,009,747 | 0.368 |

| 80 | 6.49 | 2.34 | 0.13 | 6,365,770 | 0.456 | 5.33 | 0.11 | 0.01 | 4,233,309 | 0.350 |

| 90 | 6.60 | 2.26 | 0.15 | 6,650,370 | 0.483 | 5.41 | 0.11 | 0.01 | 4,437,715 | 0.330 |

| 100 | 6.70 | 2.19 | 0.17 | 6,911,742 | 0.512 | 5.49 | 0.11 | 0.02 | 4,626,457 | 0.496 |

| 110 | 6.79 | 2.14 | 0.19 | 7,153,358 | 0.537 | 5.57 | 0.11 | 0.02 | 4,801,919 | 0.480 |

| 120 | 6.87 | 2.08 | 0.21 | 7,378,063 | 0.555 | 5.64 | 0.10 | 0.03 | 4,966,023 | 0.635 |

| 130 | 6.95 | 2.04 | 0.24 | 7,588,310 | 0.580 | 5.70 | 0.10 | 0.03 | 5,120,199 | 0.613 |

| 140 | 7.02 | 2.00 | 0.27 | 7,785,749 | 0.591 * | 5.76 | 0.10 | 0.04 | 5,265,803 | 0.681* |

Table A3.

TOPSIS analysis for turbine DeWind D92. The best choice for each site is marked with an asterisk.

Table A3.

TOPSIS analysis for turbine DeWind D92. The best choice for each site is marked with an asterisk.

| HH | Turaif | Wejh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (m) | WS | ZP | RP | AEP | WS | ZP | RP | AEP | ||

| 50 | 6.08 | 23.90 | 0.33 | 3,554,286 | 0.436 | 4.99 | 38.21 | 0.04 | 2,163,993 | 0.360 |

| 60 | 6.24 | 22.70 | 0.42 | 3,868,633 | 0.442 | 5.11 | 36.60 | 0.07 | 2,375,710 | 0.362 |

| 70 | 6.37 | 21.76 | 0.51 | 4,145,965 | 0.454 | 5.23 | 35.30 | 0.09 | 2,564,732 | 0.361 |

| 80 | 6.49 | 20.97 | 0.60 | 4,394,194 | 0.474 | 5.33 | 34.19 | 0.12 | 2,735,843 | 0.382 |

| 90 | 6.60 | 20.31 | 0.69 | 4,618,874 | 0.499 | 5.41 | 33.19 | 0.15 | 2,892,282 | 0.416 |

| 100 | 6.70 | 19.72 | 0.78 | 4,824,184 | 0.524 | 5.49 | 32.35 | 0.19 | 3,036,566 | 0.479 |

| 110 | 6.79 | 19.21 | 0.87 | 5,012,960 | 0.545 | 5.57 | 31.59 | 0.23 | 3,170,538 | 0.542 |

| 120 | 6.87 | 18.77 | 0.97 | 5,187,854 | 0.561 | 5.64 | 30.93 | 0.27 | 3,295,595 | 0.591 |

| 130 | 6.95 | 18.37 | 1.06 | 5,350,521 | 0.564 * | 5.70 | 30.31 | 0.32 | 3,412,988 | 0.632 |

| 140 | 7.02 | 17.99 | 1.15 | 5,502,655 | 0.564 * | 5.76 | 29.77 | 0.36 | 3,523,561 | 0.640 * |

Table A4.

TOPSIS analysis for turbine Dongfang DF110-2500. The best choice for each site is marked with an asterisk.

Table A4.

TOPSIS analysis for turbine Dongfang DF110-2500. The best choice for each site is marked with an asterisk.

| HH | Turaif | Wejh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (m) | WS | ZP | RP | AEP | WS | ZP | RP | AEP | ||

| 50 | 6.08 | 9.39 | 3.34 | 6,519,861 | 0.442 | 4.99 | 16.13 | 1.59 | 4,346,507 | 0.438 |

| 60 | 6.24 | 8.93 | 4.23 | 6,965,871 | 0.446 | 5.11 | 15.34 | 2.09 | 4,664,726 | 0.446 |

| 70 | 6.37 | 8.55 | 5.23 | 7,355,533 | 0.459 | 5.23 | 14.73 | 2.59 | 4,945,179 | 0.460 |

| 80 | 6.49 | 8.22 | 6.24 | 7,700,508 | 0.481 | 5.33 | 14.21 | 3.10 | 5,195,996 | 0.485 |

| 90 | 6.60 | 7.96 | 7.24 | 8,009,363 | 0.508 | 5.41 | 13.76 | 3.58 | 5,423,059 | 0.511 |

| 100 | 6.70 | 7.71 | 8.21 | 8,288,809 | 0.534 | 5.49 | 13.37 | 4.05 | 5,630,576 | 0.537 |

| 110 | 6.79 | 7.51 | 9.14 | 8,543,449 | 0.551 | 5.57 | 13.03 | 4.52 | 5,821,956 | 0.555 |

| 120 | 6.87 | 7.32 | 10.06 | 8,777,304 | 0.559 | 5.64 | 12.71 | 4.98 | 5,999,156 | 0.564 |

| 130 | 6.95 | 7.16 | 10.94 | 8,993,076 | 0.560 * | 5.70 | 12.45 | 5.43 | 6,164,460 | 0.566 * |

| 140 | 7.02 | 7.00 | 11.82 | 9,193,307 | 0.558 | 5.76 | 12.19 | 5.84 | 6,319,248 | 0.562 |

Table A5.

TOPSIS analysis for turbine Doosan WinDS3000. The best choice for each site is marked with an asterisk.

Table A5.

TOPSIS analysis for turbine Doosan WinDS3000. The best choice for each site is marked with an asterisk.

| HH | Turaif | Wejh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (m) | WS | ZP | RP | AEP | WS | ZP | RP | AEP | ||

| 50 | 6.08 | 9.40 | 0.47 | 4,369,087 | 0.441 | 4.99 | 16.13 | 0.08 | 2,865,384 | 0.368 |

| 60 | 6.24 | 8.93 | 0.59 | 4,729,954 | 0.447 | 5.11 | 15.34 | 0.12 | 3,103,645 | 0.365 |

| 70 | 6.37 | 8.56 | 0.71 | 5,057,001 | 0.458 | 5.23 | 14.74 | 0.16 | 3,319,926 | 0.367 |

| 80 | 6.49 | 8.23 | 0.84 | 5,356,886 | 0.480 | 5.33 | 14.21 | 0.21 | 3,518,405 | 0.387 |

| 90 | 6.60 | 7.96 | 0.96 | 5,634,306 | 0.504 | 5.41 | 13.76 | 0.27 | 3,702,388 | 0.431 |

| 100 | 6.70 | 7.72 | 1.08 | 5,892,609 | 0.528 | 5.49 | 13.38 | 0.33 | 3,874,142 | 0.486 |

| 110 | 6.79 | 7.51 | 1.19 | 6,134,469 | 0.542 | 5.57 | 13.04 | 0.38 | 4,035,330 | 0.528 |

| 120 | 6.87 | 7.32 | 1.32 | 6,361,797 | 0.556 | 5.64 | 12.71 | 0.45 | 4,187,367 | 0.582 |

| 130 | 6.95 | 7.16 | 1.44 | 6,576,412 | 0.559 * | 5.70 | 12.46 | 0.53 | 4,331,374 | 0.621 |

| 140 | 7.02 | 7.00 | 1.56 | 6,779,562 | 0.559 * | 5.76 | 12.20 | 0.60 | 4,468,187 | 0.632 * |

Table A6.

TOPSIS analysis for turbine Enercon E-82 E2/2000. The best choice for each site is marked with an asterisk.

Table A6.

TOPSIS analysis for turbine Enercon E-82 E2/2000. The best choice for each site is marked with an asterisk.

| HH | Turaif | Wejh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (m) | WS | ZP | RP | AEP | WS | ZP | RP | AEP | ||

| 50 | 6.08 | 1.67 | 0.55 | 3,908,583 | 0.446 | 4.99 | 2.99 | 0.10 | 2,563,184 | 0.370 |

| 60 | 6.24 | 1.59 | 0.69 | 4,201,630 | 0.452 | 5.11 | 2.83 | 0.15 | 2,765,474 | 0.368 |

| 70 | 6.37 | 1.53 | 0.83 | 4,460,943 | 0.463 | 5.23 | 2.71 | 0.20 | 2,945,786 | 0.370 |

| 80 | 6.49 | 1.47 | 0.96 | 4,693,399 | 0.477 | 5.33 | 2.61 | 0.27 | 3,108,770 | 0.397 |

| 90 | 6.60 | 1.43 | 1.10 | 4,904,445 | 0.499 | 5.41 | 2.53 | 0.33 | 3,257,746 | 0.429 |

| 100 | 6.70 | 1.39 | 1.22 | 5,097,631 | 0.514 | 5.49 | 2.45 | 0.40 | 3,395,056 | 0.479 |

| 110 | 6.79 | 1.35 | 1.37 | 5,275,713 | 0.537 | 5.57 | 2.37 | 0.48 | 3,522,579 | 0.538 |

| 120 | 6.87 | 1.31 | 1.50 | 5,440,956 | 0.545 | 5.64 | 2.31 | 0.57 | 3,641,713 | 0.592 |

| 130 | 6.95 | 1.28 | 1.64 | 5,595,181 | 0.550 | 5.70 | 2.26 | 0.65 | 3,753,511 | 0.617 |

| 140 | 7.02 | 1.26 | 1.80 | 5,739,430 | 0.554 * | 5.76 | 2.22 | 0.74 | 3,858,955 | 0.630 * |

Table A7.

TOPSIS analysis for turbine Enercon E-82 E4/3000. The best choice for each site is marked with an asterisk.

Table A7.

TOPSIS analysis for turbine Enercon E-82 E4/3000. The best choice for each site is marked with an asterisk.

| HH | Turaif | Wejh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (m) | WS | ZP | RP | AEP | WS | ZP | RP | AEP | ||

| 50 | 6.08 | 6.03 | 0.03 | 3,874,862 | 0.394 | 4.99 | 10.52 | 0.00 | 2,530,963 | 0.283 |

| 60 | 6.24 | 5.73 | 0.05 | 4,169,620 | 0.407 | 5.11 | 10.02 | 0.00 | 2,732,520 | 0.262 |

| 70 | 6.37 | 5.50 | 0.06 | 4,432,370 | 0.408 | 5.23 | 9.59 | 0.00 | 2,913,226 | 0.241 |

| 80 | 6.49 | 5.31 | 0.08 | 4,670,072 | 0.447 | 5.33 | 9.23 | 0.00 | 3,077,518 | 0.221 |

| 90 | 6.60 | 5.13 | 0.10 | 4,887,685 | 0.501 | 5.41 | 8.95 | 0.00 | 3,228,599 | 0.202 |

| 100 | 6.70 | 4.98 | 0.11 | 5,088,723 | 0.518 | 5.49 | 8.68 | 0.01 | 3,368,719 | 0.499 |

| 110 | 6.79 | 4.84 | 0.13 | 5,275,628 | 0.569 | 5.57 | 8.45 | 0.01 | 3,499,526 | 0.489 |

| 120 | 6.87 | 4.72 | 0.15 | 5,450,443 | 0.602 | 5.64 | 8.23 | 0.01 | 3,622,458 | 0.479 |

| 130 | 6.95 | 4.61 | 0.16 | 5,614,841 | 0.597 | 5.70 | 8.05 | 0.01 | 3,738,398 | 0.469 |

| 140 | 7.02 | 4.51 | 0.18 | 5,769,935 | 0.606 * | 5.76 | 7.88 | 0.02 | 3,848,353 | 0.717 * |

Table A8.

TOPSIS analysis for turbine Gamesa G97-2.0 MW. The best choice for each site is marked with an asterisk.

Table A8.

TOPSIS analysis for turbine Gamesa G97-2.0 MW. The best choice for each site is marked with an asterisk.

| HH | Turaif | Wejh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (m) | WS | ZP | RP | AEP | WS | ZP | RP | AEP | ||

| 50 | 6.08 | 5.58 | 0.14 | 4,971,160 | 0.431 | 4.99 | 10.03 | 0.01 | 3,287,488 | 0.351 |

| 60 | 6.24 | 5.30 | 0.17 | 5,311,123 | 0.428 | 5.11 | 9.54 | 0.02 | 3,532,671 | 0.349 |

| 70 | 6.37 | 5.07 | 0.21 | 5,606,868 | 0.435 | 5.23 | 9.12 | 0.03 | 3,748,451 | 0.356 |

| 80 | 6.49 | 4.88 | 0.26 | 5,868,372 | 0.462 | 5.33 | 8.80 | 0.04 | 3,941,565 | 0.374 |

| 90 | 6.60 | 4.72 | 0.30 | 6,102,752 | 0.485 | 5.41 | 8.50 | 0.05 | 4,116,268 | 0.403 |

| 100 | 6.70 | 4.57 | 0.34 | 6,314,648 | 0.511 | 5.49 | 8.25 | 0.07 | 4,275,954 | 0.499 |

| 110 | 6.79 | 4.45 | 0.38 | 6,508,118 | 0.533 | 5.57 | 8.04 | 0.08 | 4,423,102 | 0.537 |

| 120 | 6.87 | 4.34 | 0.43 | 6,685,633 | 0.558 | 5.64 | 7.84 | 0.10 | 4,559,555 | 0.613 |

| 130 | 6.95 | 4.25 | 0.47 | 6,849,496 | 0.563 | 5.70 | 7.65 | 0.11 | 4,686,655 | 0.625 |

| 140 | 7.02 | 4.17 | 0.52 | 7,001,725 | 0.569 * | 5.76 | 7.51 | 0.13 | 4,805,785 | 0.649 * |

Table A9.

TOPSIS analysis for turbine Hanjin HJWT2000-93. The best choice for each site is marked with an asterisk.

Table A9.

TOPSIS analysis for turbine Hanjin HJWT2000-93. The best choice for each site is marked with an asterisk.

| HH | Turaif | Wejh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (m) | WS | ZP | RP | AEP | WS | ZP | RP | AEP | ||

| 50 | 6.08 | 9.42 | 0.47 | 4,552,426 | 0.448 | 4.99 | 16.17 | 0.08 | 2,982,459 | 0.368 |

| 60 | 6.24 | 8.95 | 0.59 | 4,876,812 | 0.453 | 5.11 | 15.39 | 0.12 | 3,213,212 | 0.364 |

| 70 | 6.37 | 8.58 | 0.72 | 5,161,005 | 0.467 | 5.23 | 14.78 | 0.16 | 3,417,237 | 0.365 |

| 80 | 6.49 | 8.25 | 0.84 | 5,413,711 | 0.484 | 5.33 | 14.25 | 0.21 | 3,600,277 | 0.384 |

| 90 | 6.60 | 7.98 | 0.96 | 5,641,045 | 0.505 | 5.41 | 13.8 | 0.27 | 3,766,569 | 0.426 |

| 100 | 6.70 | 7.74 | 1.09 | 5,847,676 | 0.530 | 5.49 | 13.41 | 0.33 | 3,919,029 | 0.480 |

| 110 | 6.79 | 7.53 | 1.20 | 6,037,218 | 0.542 | 5.57 | 13.07 | 0.39 | 4,059,755 | 0.532 |

| 120 | 6.87 | 7.34 | 1.33 | 6,211,605 | 0.553 | 5.64 | 12.75 | 0.46 | 4,190,603 | 0.584 |

| 130 | 6.95 | 7.18 | 1.45 | 6,373,608 | 0.555 * | 5.70 | 12.49 | 0.53 | 4,312,877 | 0.615 |

| 140 | 7.02 | 7.03 | 1.56 | 6,524,469 | 0.552 | 5.76 | 12.23 | 0.61 | 4,427,608 | 0.632 * |

Table A10.

TOPSIS analysis for turbine Leitwind LTW70-2000. The best choice for each site is marked with an asterisk.

Table A10.

TOPSIS analysis for turbine Leitwind LTW70-2000. The best choice for each site is marked with an asterisk.

| HH | Turaif | Wejh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (m) | WS | ZP | RP | AEP | WS | ZP | RP | AEP | ||

| 50 | 6.08 | 6.01 | 0.33 | 2,590,458 | 0.439 | 4.99 | 10.49 | 0.04 | 1,695,636 | 0.363 |

| 60 | 6.24 | 5.72 | 0.42 | 2,791,523 | 0.445 | 5.11 | 9.99 | 0.07 | 1,831,760 | 0.365 |

| 70 | 6.37 | 5.49 | 0.51 | 2,972,116 | 0.456 | 5.23 | 9.57 | 0.09 | 1,954,550 | 0.365 |

| 80 | 6.49 | 5.29 | 0.59 | 3,136,781 | 0.469 | 5.33 | 9.20 | 0.12 | 2,066,902 | 0.387 |

| 90 | 6.60 | 5.11 | 0.69 | 3,288,471 | 0.500 | 5.41 | 8.91 | 0.15 | 2,170,740 | 0.423 |

| 100 | 6.70 | 4.96 | 0.78 | 3,429,386 | 0.525 | 5.49 | 8.65 | 0.18 | 2,267,467 | 0.467 |

| 110 | 6.79 | 4.82 | 0.87 | 3,561,223 | 0.545 | 5.57 | 8.42 | 0.22 | 2,358,216 | 0.532 |

| 120 | 6.87 | 4.71 | 0.96 | 3,685,270 | 0.557 | 5.64 | 8.20 | 0.27 | 2,443,829 | 0.601 |

| 130 | 6.95 | 4.59 | 1.06 | 3,802,472 | 0.564 * | 5.70 | 8.02 | 0.31 | 2,524,915 | 0.628 |

| 140 | 7.02 | 4.50 | 1.14 | 3,913,676 | 0.561 | 5.76 | 7.86 | 0.35 | 2,602,009 | 0.637 * |

Table A11.

TOPSIS analysis for turbine Nordex N131/3000. The best choice for each site is marked with an asterisk.

Table A11.

TOPSIS analysis for turbine Nordex N131/3000. The best choice for each site is marked with an asterisk.

| HH | Turaif | Wejh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (m) | WS | ZP | RP | AEP | WS | ZP | RP | AEP | ||

| 50 | 6.08 | 8.62 | 0.92 | 8,504,922 | 0.456 | 4.99 | 15.32 | 0.31 | 5,760,853 | 0.394 |

| 60 | 6.24 | 8.19 | 1.12 | 9,031,649 | 0.460 | 5.11 | 14.61 | 0.43 | 6,160,035 | 0.391 |

| 70 | 6.37 | 7.84 | 1.33 | 9,485,898 | 0.468 | 5.23 | 14 | 0.57 | 6,509,001 | 0.400 |

| 80 | 6.49 | 7.54 | 1.52 | 9,884,089 | 0.477 | 5.33 | 13.51 | 0.73 | 6,818,982 | 0.425 |

| 90 | 6.60 | 7.30 | 1.73 | 10,238,104 | 0.493 | 5.41 | 13.09 | 0.88 | 7,097,942 | 0.459 |

| 100 | 6.70 | 7.08 | 1.93 | 10,556,804 | 0.508 | 5.49 | 12.7 | 1.04 | 7,351,799 | 0.503 |

| 110 | 6.79 | 6.90 | 2.14 | 10,845,975 | 0.522 | 5.57 | 12.37 | 1.2 | 7,584,389 | 0.544 |

| 120 | 6.87 | 6.73 | 2.37 | 11,109,818 | 0.535 | 5.64 | 12.08 | 1.38 | 7,799,305 | 0.580 |

| 130 | 6.95 | 6.57 | 2.59 | 11,352,896 | 0.540 | 5.70 | 11.82 | 1.55 | 7,998,834 | 0.598 |

| 140 | 7.02 | 6.45 | 2.84 | 11,578,293 | 0.544 * | 5.76 | 11.58 | 1.74 | 8,185,010 | 0.606 * |

Table A12.

TOPSIS analysis for turbine Sinovel SL3000/115. The best choice for each site is marked with an asterisk.

Table A12.

TOPSIS analysis for turbine Sinovel SL3000/115. The best choice for each site is marked with an asterisk.

| HH | Turaif | Wejh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (m) | WS | ZP | RP | AEP | WS | ZP | RP | AEP | ||

| 50 | 6.08 | 9.39 | 0.96 | 6,632,186 | 0.439 | 4.99 | 16.12 | 0.27 | 4,418,179 | 0.391 |

| 60 | 6.24 | 8.92 | 1.18 | 7,095,683 | 0.441 | 5.11 | 15.33 | 0.38 | 4,746,076 | 0.390 |

| 70 | 6.37 | 8.55 | 1.40 | 7,503,843 | 0.446 | 5.23 | 14.73 | 0.50 | 5,037,027 | 0.398 |

| 80 | 6.49 | 8.22 | 1.62 | 7,868,771 | 0.457 | 5.33 | 14.20 | 0.64 | 5,298,941 | 0.423 |

| 90 | 6.60 | 7.95 | 1.87 | 8,199,107 | 0.478 | 5.41 | 13.75 | 0.77 | 5,537,503 | 0.456 |

| 100 | 6.70 | 7.71 | 2.11 | 8,500,607 | 0.501 | 5.49 | 13.36 | 0.91 | 5,756,929 | 0.500 |

| 110 | 6.79 | 7.51 | 2.37 | 8,777,953 | 0.524 | 5.57 | 13.02 | 1.06 | 5,959,892 | 0.546 |

| 120 | 6.87 | 7.32 | 2.64 | 9,034,599 | 0.543 | 5.64 | 12.70 | 1.22 | 6,149,030 | 0.582 |

| 130 | 6.95 | 7.15 | 2.93 | 9,273,298 | 0.555 | 5.70 | 12.45 | 1.38 | 6,325,976 | 0.602 |

| 140 | 7.02 | 7.00 | 3.23 | 9,496,276 | 0.561 * | 5.76 | 12.19 | 1.54 | 6,492,396 | 0.609 * |

Table A13.

TOPSIS analysis for turbine Vestas V110. The best choice for each site is marked with an asterisk.

Table A13.

TOPSIS analysis for turbine Vestas V110. The best choice for each site is marked with an asterisk.

| HH | Turaif | Wejh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (m) | WS | ZP | RP | AEP | WS | ZP | RP | AEP | ||

| 50 | 6.08 | 9.40 | 1.03 | 6,004,721 | 0.440 | 4.99 | 16.13 | 0.3 | 4,029,225 | 0.394 |

| 60 | 6.24 | 8.93 | 1.26 | 6,376,031 | 0.440 | 5.11 | 15.34 | 0.42 | 4,306,757 | 0.393 |

| 70 | 6.37 | 8.56 | 1.49 | 6,694,271 | 0.443 | 5.23 | 14.74 | 0.57 | 4,548,616 | 0.405 |

| 80 | 6.49 | 8.23 | 1.75 | 6,971,803 | 0.456 | 5.33 | 14.22 | 0.71 | 4,763,187 | 0.426 |

| 90 | 6.60 | 7.96 | 2.00 | 7,217,285 | 0.472 | 5.41 | 13.77 | 0.85 | 4,955,901 | 0.458 |

| 100 | 6.70 | 7.72 | 2.27 | 7,436,972 | 0.496 | 5.49 | 13.38 | 1.01 | 5,130,901 | 0.503 |

| 110 | 6.79 | 7.52 | 2.55 | 7,635,472 | 0.519 | 5.57 | 13.04 | 1.17 | 5,291,203 | 0.546 |

| 120 | 6.87 | 7.32 | 2.85 | 7,816,086 | 0.539 | 5.64 | 12.71 | 1.35 | 5,438,905 | 0.583 |

| 130 | 6.95 | 7.16 | 3.18 | 7,981,536 | 0.554 | 5.70 | 12.46 | 1.51 | 5,575,759 | 0.598 |

| 140 | 7.02 | 7.01 | 3.51 | 8,133,928 | 0.560 * | 5.76 | 12.2 | 1.69 | 5,703,519 | 0.606 * |

Table A14.

TOPSIS analysis for turbine Vestas V112. The best choice for each site is marked with an asterisk.

Table A14.

TOPSIS analysis for turbine Vestas V112. The best choice for each site is marked with an asterisk.

| HH | Turaif | Wejh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (m) | WS | ZP | RP | AEP | WS | ZP | RP | AEP | ||

| 50 | 6.08 | 13.40 | 0.33 | 6,424,320 | 0.439 | 4.99 | 22.64 | 0.05 | 4,200,601 | 0.370 |

| 60 | 6.24 | 12.72 | 0.43 | 6,901,962 | 0.448 | 5.11 | 21.56 | 0.07 | 4,533,556 | 0.363 |

| 70 | 6.37 | 12.19 | 0.51 | 7,323,283 | 0.455 | 5.23 | 20.73 | 0.09 | 4,829,414 | 0.359 |

| 80 | 6.49 | 11.76 | 0.60 | 7,700,227 | 0.472 | 5.33 | 20.01 | 0.12 | 5,096,189 | 0.375 |

| 90 | 6.60 | 11.38 | 0.70 | 8,041,682 | 0.501 | 5.41 | 19.39 | 0.16 | 5,339,421 | 0.425 |

| 100 | 6.70 | 11.04 | 0.79 | 8,353,468 | 0.525 | 5.49 | 18.84 | 0.19 | 5,563,363 | 0.467 |

| 110 | 6.79 | 10.74 | 0.88 | 8,640,153 | 0.544 | 5.57 | 18.36 | 0.23 | 5,770,720 | 0.529 |

| 120 | 6.87 | 10.49 | 0.97 | 8,905,399 | 0.555 | 5.64 | 17.95 | 0.27 | 5,964,065 | 0.579 |

| 130 | 6.95 | 10.25 | 1.07 | 9,152,209 | 0.562 * | 5.70 | 17.57 | 0.32 | 6,145,047 | 0.621 |

| 140 | 7.02 | 10.05 | 1.16 | 9,382,609 | 0.561 | 5.76 | 17.22 | 0.36 | 6,315,349 | 0.630 * |

Table A15.

TOPSIS analysis for turbine Windtec FC 3000-130. The best choice for each site is marked with an asterisk.

Table A15.

TOPSIS analysis for turbine Windtec FC 3000-130. The best choice for each site is marked with an asterisk.

| HH | Turaif | Wejh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (m) | WS | ZP | RP | AEP | WS | ZP | RP | AEP | ||

| 50 | 6.08 | 11.36 | 2.05 | 8,508,531 | 0.431 | 4.99 | 19.35 | 0.88 | 5,709,133 | 0.419 |

| 60 | 6.24 | 10.77 | 2.56 | 9,054,678 | 0.430 | 5.11 | 18.41 | 1.18 | 6,108,825 | 0.422 |

| 70 | 6.37 | 10.32 | 3.14 | 9,525,854 | 0.437 | 5.23 | 17.68 | 1.49 | 6,458,727 | 0.432 |

| 80 | 6.49 | 9.94 | 3.75 | 9,939,049 | 0.453 | 5.33 | 17.05 | 1.82 | 6,770,263 | 0.454 |

| 90 | 6.60 | 9.62 | 4.36 | 10,306,589 | 0.476 | 5.41 | 16.51 | 2.16 | 7,051,016 | 0.487 |

| 100 | 6.70 | 9.34 | 5.06 | 10,636,346 | 0.510 | 5.49 | 16.04 | 2.50 | 7,306,586 | 0.523 |

| 110 | 6.79 | 9.10 | 5.75 | 10,935,505 | 0.540 | 5.57 | 15.61 | 2.84 | 7,541,109 | 0.554 |

| 120 | 6.87 | 8.88 | 6.43 | 11,208,357 | 0.559 | 5.64 | 15.26 | 3.19 | 7,757,882 | 0.574 |

| 130 | 6.95 | 8.69 | 7.11 | 11,458,985 | 0.568 | 5.70 | 14.95 | 3.52 | 7,959,208 | 0.581 * |

| 140 | 7.02 | 8.51 | 7.77 | 11,690,264 | 0.569 * | 5.76 | 14.66 | 3.84 | 8,147,224 | 0.581 * |

References

- Taylor, M.J. Energy for the world’s kitchens: Biomass for survival in the past, present and future. In Handbook on the Geographies of Energy; Edward Elgar Publishing: Cheltenham, UK, 2017. [Google Scholar]

- Baseer, M.A.; Meyer, J.P.; Rehman, S.; Alam, M.M.; Al-Hadhrami, L.M.; Lashin, A. Performance evaluation of cup-anemometers and wind speed characteristics analysis. Renew. Energy 2016, 86, 733–744. [Google Scholar] [CrossRef]

- Rehman, S.; Ali, S.S.; Khan, S.A. Wind farm layout design using cuckoo search algorithms. Appl. Artif. Intell. 2016, 30, 899–922. [Google Scholar]

- Global Wind Report 2019 (by GWEC). Available online: https://gwec.net/global-wind-report-2019/ (accessed on 11 October 2020).

- Sarja, J.; Halonen, V. Wind turbine selection criteria: A customer perspective. J. Energy Power Eng. 2013, 7, 1795. [Google Scholar]

- Perkin, S.; Garrett, D.; Jensson, P. Optimal wind turbine selection methodology: A case-study for Búrfell, Iceland. Renew. Energy 2015, 75, 165–172. [Google Scholar] [CrossRef]

- Nemes, C.; Munteanu, F. Optimal selection of wind turbine for a specific area. In Proceedings of the 2010 12th International Conference on Optimization of Electrical and Electronic Equipment, Basov, Romania, 20–22 May 2010; pp. 1224–1229. [Google Scholar]

- Chowdhury, S.; Zhang, J.; Messac, A.; Castillo, L. Optimizing the arrangement and the selection of turbines for wind farms subject to varying wind conditions. Renew. Energy 2013, 52, 273–282. [Google Scholar] [CrossRef]

- Fotuhi-Firuzabad, M.; Dobakhshari, A.S. Reliability-based selection of wind turbines for large-scale wind Farms. World Acad. Sci. Eng. Technol. 2009, 49, 734–740. [Google Scholar]

- Bencherif, M.; Brahmi, B.N.; Chikhaoui, A. Optimum selection of wind turbines. Sci. J. Energy Eng. 2014, 2, 36. [Google Scholar] [CrossRef]

- Montoya, F.G.; Manzano-Agugliaro, F.; López-Márquez, S.; Hernández-Escobedo, Q.; Gil, C. Wind turbine selection for wind farm layout using multi-objective evolutionary algorithms. Expert Syst. Appl. 2014, 41, 6585–6595. [Google Scholar] [CrossRef]

- Chowdhury, S.; Mehmani, A.; Zhang, J.; Messac, A. Market suitability and performance tradeoffs offered by commercial wind turbines across differing wind regimes. Energies 2016, 9, 352. [Google Scholar] [CrossRef]

- Bekele, A.; Ramayya, A. Site specific design optimization of horizontal axis wind turbine based on minimum cost of energy for Adama I wind farm. Int. J. Eng. Res. Technol. 2013, 2, 862–870. [Google Scholar]

- Helgason, K. Selecting Optimum Location and Type of Wind Turbines in Iceland. Master’s Thesis, School of Science and Engineering Reykjavík University, Reykjavik, Iceland, 2012. [Google Scholar]

- Dong, Y.; Wang, J.; Jiang, H.; Shi, X. Intelligent optimized wind resource assessment and wind turbines selection in Huitengxile of Inner Mongolia, China. Appl. Energy 2013, 109, 239–253. [Google Scholar] [CrossRef]

- Shirgholami, Z.; Zangeneh, S.N.; Bortolini, M. Decision system to support the practitioners in the wind farm design: A case study for Iran mainland. Sustain. Energy Technol. Assess. 2016, 16, 1–10. [Google Scholar] [CrossRef]

- Bagočius, V.; Zavadskas, E.K.; Turskis, Z. Multi-person selection of the best wind turbine based on the multi-criteria integrated additive-multiplicative utility function. J. Civ. Eng. Manag. 2014, 20, 590–599. [Google Scholar] [CrossRef]

- Khan, S.A.; Rehman, S. On the use of unified and-or fuzzy aggregation operator for multi-criteria decision making in wind farm design process using wind turbines in 500 kW–750 kW range. In Proceedings of the 2012 IEEE International Conference on Fuzzy Systems, Brisbane, Australia, 10–15 June 2012; pp. 1–6. [Google Scholar]

- Khan, S.A.; Rehman, S. On the use of Werners Fuzzy Aggregation Operator for Multi-Criteria Decision making in wind Farm Design Process using Wind Turbines in 1000kW-1200kW Range. In Proceedings of the International Clean Energy Conference, Lleida, Spain, 16–18 May 2012; pp. 16–18. [Google Scholar]

- Rehman, S.; Khan, S.A. Fuzzy Logic Based Multi-Criteria Wind Turbine Selection Strategy—A Case Study of Qassim, Saudi Arabia. Energies 2016, 9, 872. [Google Scholar] [CrossRef]

- Rehman, S.; Khan, S.A. Goal Programming-Based Two-Tier Multi-Criteria Decision-Making Approach for Wind Turbine Selection. Appl. Artif. Intell. 2019, 33, 27–53. [Google Scholar] [CrossRef]

- Rehman, S.; Khan, S.A. Multi-criteria wind turbine selection using weighted sum approach. Int. J. Adv. Comput. Sci. Appl. 2017, 8, 128–132. [Google Scholar] [CrossRef]

- Rehman, S.; Khan, S.A. Application of Fuzzy Goal Programming to Wind Turbine Selection with Multiple Criteria? A Study of Three Potential Sites in Saudi Arabia. In Proceedings of the 2017 6th IIAI International Congress on Advanced Applied Informatics (IIAI-AAI), Hamamatsu, Japan, 9–13 July 2017; pp. 853–857. [Google Scholar]

- Şağbanşua, L.; Balo, F. Multi-criteria decision making for 1.5 MW wind turbine selection. Procedia Comput. Sci. 2017, 111, 413–419. [Google Scholar] [CrossRef]

- Shateranlou, H.R.; PourHossein, K. Optimal wind turbine selection by BEM method and heuristic multi-objective optimization algorithms: A case-study for Tabriz-East Azerbaijan. In Proceedings of the 2016 21st Conference on Electrical Power Distribution Networks Conference (EPDC), Karaj, Iran, 26–27 April 2016; pp. 11–18. [Google Scholar]

- Dinmohammadi, A.; Shafiee, M. Determination of the most suitable technology transfer strategy for wind turbines using an integrated AHP-TOPSIS decision model. Energies 2017, 10, 642. [Google Scholar] [CrossRef]

- Hammad, M.; Batarseh, L. Innovative wind turbine selection method using modified Weibull probability function. J. Archit. Eng. Tech. 2015, 4, 2. [Google Scholar]

- Jakubowski, M.; Mech, L.; Wolniewicz, K. A methodology of wind turbines selection for the given wind conditions. J. Mech. Energy Eng. 2017, 1, 171–178. [Google Scholar]

- Sedaghat, A.; Alkhatib, F.; Eilaghi, A.; Sabati, M.; Borvayeh, L.; Mostafaeipour, A. A new strategy for wind turbine selection using optimization based on rated wind speed. Energy Procedia 2019, 160, 582–589. [Google Scholar] [CrossRef]

- Beskese, A.; Camci, A.; Temur, G.T.; Erturk, E. Wind turbine evaluation using the hesitant fuzzy AHP-TOPSIS method with a case in Turkey. J. Intell. Fuzzy Syst. 2020, 38, 997–1011. [Google Scholar] [CrossRef]

- Khan, S.A.; Rehman, S. Iterative non-deterministic algorithms in on-shore wind farm design: A brief survey. Renew. Sustain. Energy Rev. 2013, 19, 370–384. [Google Scholar] [CrossRef]

- Ishizaka, A.; Pearman, C.; Nemery, P. AHPSort: An AHP-based method for sorting problems. Int. J. Prod. Res. 2012, 50, 4767–4784. [Google Scholar] [CrossRef]

- Khan, S.A. Design and Analysis of Evolutionary and Swarm Intelligence Techniques for Topology Design of Distributed Local Area Networks. Ph.D. Thesis, University of Pretoria, Pretoria, South Africa, 2009. [Google Scholar]

- Miettinen, K. Some methods for nonlinear multi-objective optimization. In Proceedings of the International Conference on Evolutionary Multi-Criterion Optimization, Zurich, Switzerland, 7–9 March 2001; pp. 1–20. [Google Scholar]

- Junior, F.R.; Osiro, L.; Carpinetti, L.C. A comparison between Fuzzy AHP and Fuzzy TOPSIS methods to supplier selection. Appl. Soft Comput. 2014, 21, 194–209. [Google Scholar] [CrossRef]

- Lee, J.; Kim, H.; Kang, Y.; Kim, J. Determining the Optimized Hub Height of Wind Turbine Using the Wind Resource Map of South Korea. Energies 2019, 12, 2949. [Google Scholar] [CrossRef]

- Ding, Y. Chapter 6: Production Efficiency Analysis and Power Curve, Data Science for Wind Energy; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Hwang, C.; Yoon, K. Methods for multiple attribute decision making. In Multiple Attribute Decision Making; Springer: Berlin/Heidelberg, Germany, 1981; pp. 58–191. [Google Scholar]

- Jahanshahloo, G.R.; Lotfi, F.H.; Izadikhah, M. Extension of the TOPSIS method for decision-making problems with fuzzy data. Appl. Math. Comput. 2006, 181, 1544–1551. [Google Scholar] [CrossRef]

- Specifications: Windtec FC 3000-130Global Modeling & Assimilation Office, National Aeronautics and Space Administration, NASA. 2020. Available online: https://gmao.gsfc.nasa.gov/reanalysis/MERRA-2/data_access/ (accessed on 17 February 2020).

- Coello, C.A.C. A comprehensive survey of evolutionary-based multiobjective optimization techniques. Knowl. Inf. Syst. 1999, 1, 269–308. [Google Scholar] [CrossRef]

- Gao, L.S. The fuzzy arithmetic mean. Fuzzy Sets Syst. 1999, 107, 335–348. [Google Scholar] [CrossRef]

- Lee, H.C.; Chang, C.T. Comparative analysis of MCDM methods for ranking renewable energy sources in Taiwan. Renew. Sustain. Energy Rev. 2018, 92, 883–896. [Google Scholar] [CrossRef]

- Dhiman, H.S.; Deb, D. Fuzzy TOPSIS and fuzzy COPRAS based multi-criteria decision making for hybrid wind farms. Energy 2020, 117755. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).