A Review of Health Assessment Techniques for Distribution Transformers in Smart Distribution Grids

Abstract

1. Introduction

- -

- The paper provides a special review of modern monitoring distribution transformers methods. A number of methodologies are presented, evaluated and discussed. The advantages and disadvantages of using individual methods are presented.

- -

- The paper investigates different thoughts regarding the appropriate parameters for different online/real-time monitoring processes to evaluate the statement of distribution transformers.

- -

- A number of failure modes are also discussed in this paper.

2. Distribution Transformer Failure Modes

- -

- Core: The transformer’s core is made of silicon steel. This core is used to transmit the power from the primary to the secondary coils of the transformer through electromagnetic induction. The core fails due to DC magnetization or displacement of the core steel during the construction of the transformer. The lamination of the core can also peel off and increase losses and heat due to eddy-current.

- -

- Windings: Windings are the conductors wrapped around the core limb. A transformer consists of a primary winding and one or more secondary windings connected via an electromagnetic field. Windings generate magnetomotive force that is carried by the core to other windings for changing voltages. The most frequent fail in windings is due to short-circuits or transient over-voltages.

- -

- Tank: The tank is the physical protection for the transformer core and windings as well as is an oil container for cooling the transformer. The failure of the transformer tank can occur anywhere due to oil leakage, insulation material loses insulation function, dents… Oil leakage leads to flashover and transformer breakdown.

- -

- Insulation: The insulation between windings in transformers is usually provided by transformer oil. Oil contamination due to the oxidation processes and increasing size of the colloidal particles can generate conducting particles, raise the temperature inside the transformer and finally damage the oil insulation.

- -

- Bushings: are used to provide insulation while routing the winding terminals through the tank for connection with the power system. The main failure mode of the bushing is short-circuit. It may be due to material faults in the insulation or due to damage. The damage can occur due to sabotage, during shipping or airborne parts from other failed equipment. Damages, cracks in the porcelain and bad gaskets provide ingress of water inside the insulation of the bushing leading to its failure.

- -

- Tap changer: is used to regulate the output voltage of a transformer by changing the number of turns in one winding. For distribution transformers, tap-changer cannot be changed while the transformer is energized, it can only be changed after isolating the transformer from the circuit [11]. Therefore, the damage caused by a tap-changer fault rarely happens.

3. Transformer Health Assessment Techniques

- -

- Determine the most appropriate measurement techniques to employ for low cost, accurate, and in-situ health monitoring of distribution service transformers

- -

- Synthesize or create methods of determining transformer health from these measurements as well as contextual or environmental data as appropriate

- -

- Implement the system for field validation. Algorithms will be implemented locally and/or centrally (on a server) to measure and analyze the operational characteristics of distribution service transformers and provide an overall health index encompassing the pertinent failure and degradation modes

3.1. Health Index Calculation

- HI is the health index metric;

- SPi is the score of each assessment condition that is identified based on the measured data

- Smax is the maximum score of assessment condition

- WPi is the weight of each assessment condition;

- n is the number of the assessment condition.

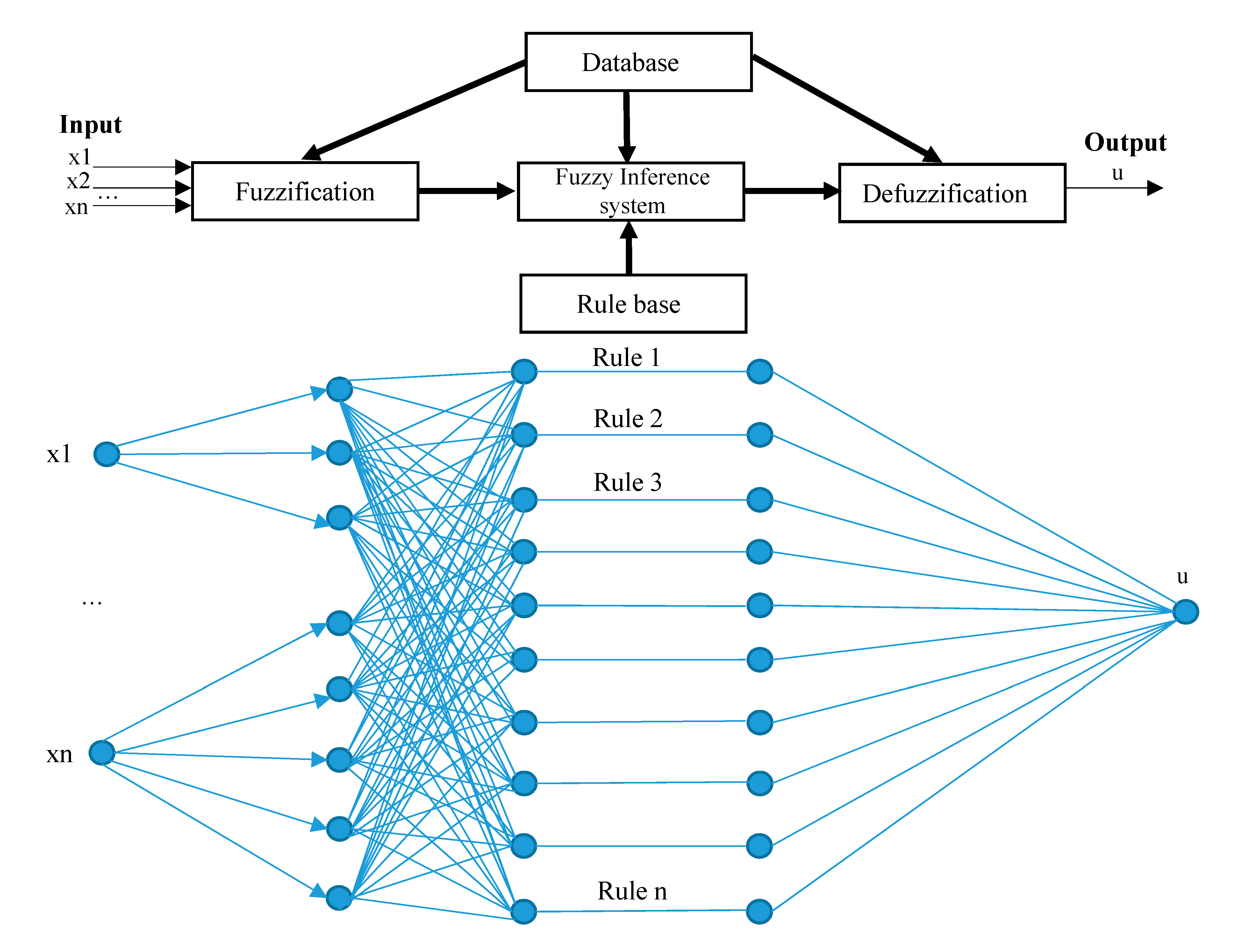

3.2. Fuzzy Logic

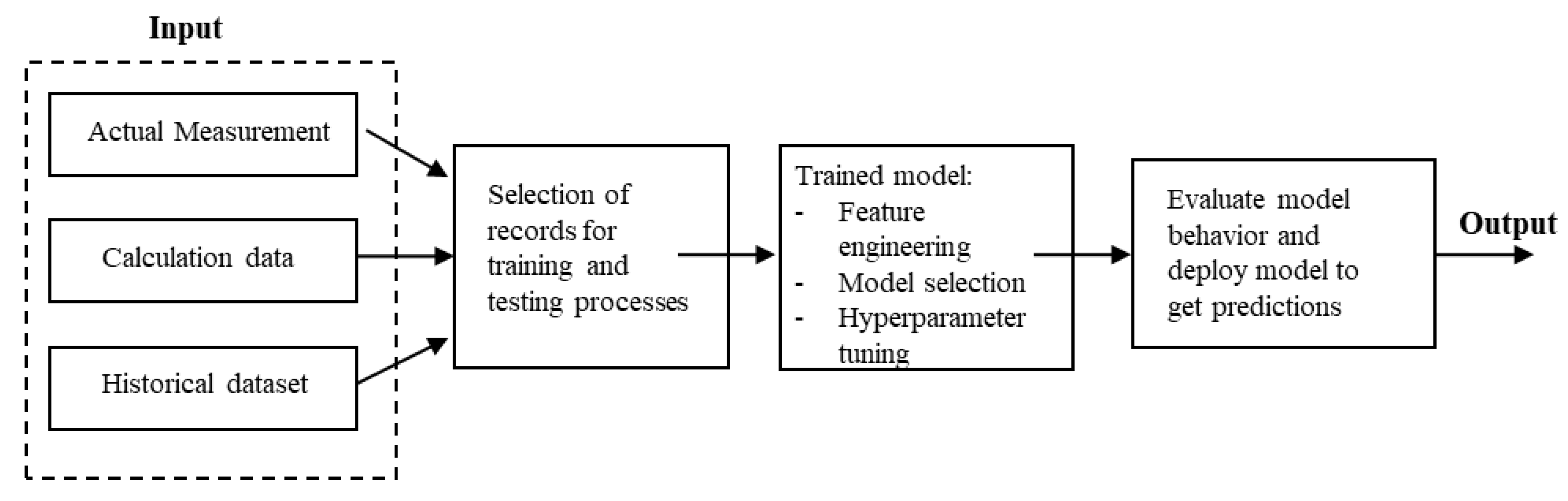

3.3. Machine Learning Algorithms

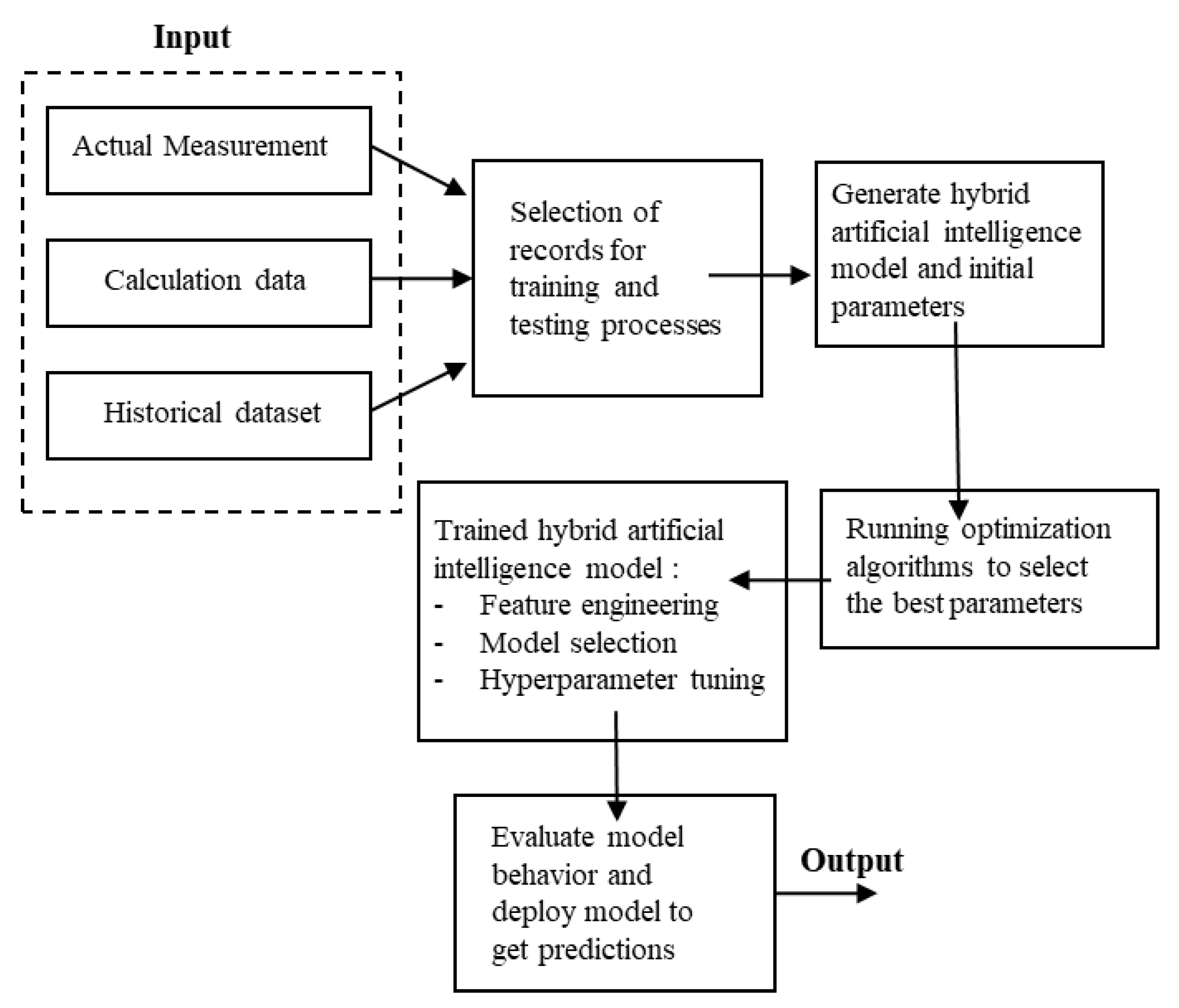

3.4. Hybrid Artificial Intelligence Approaches

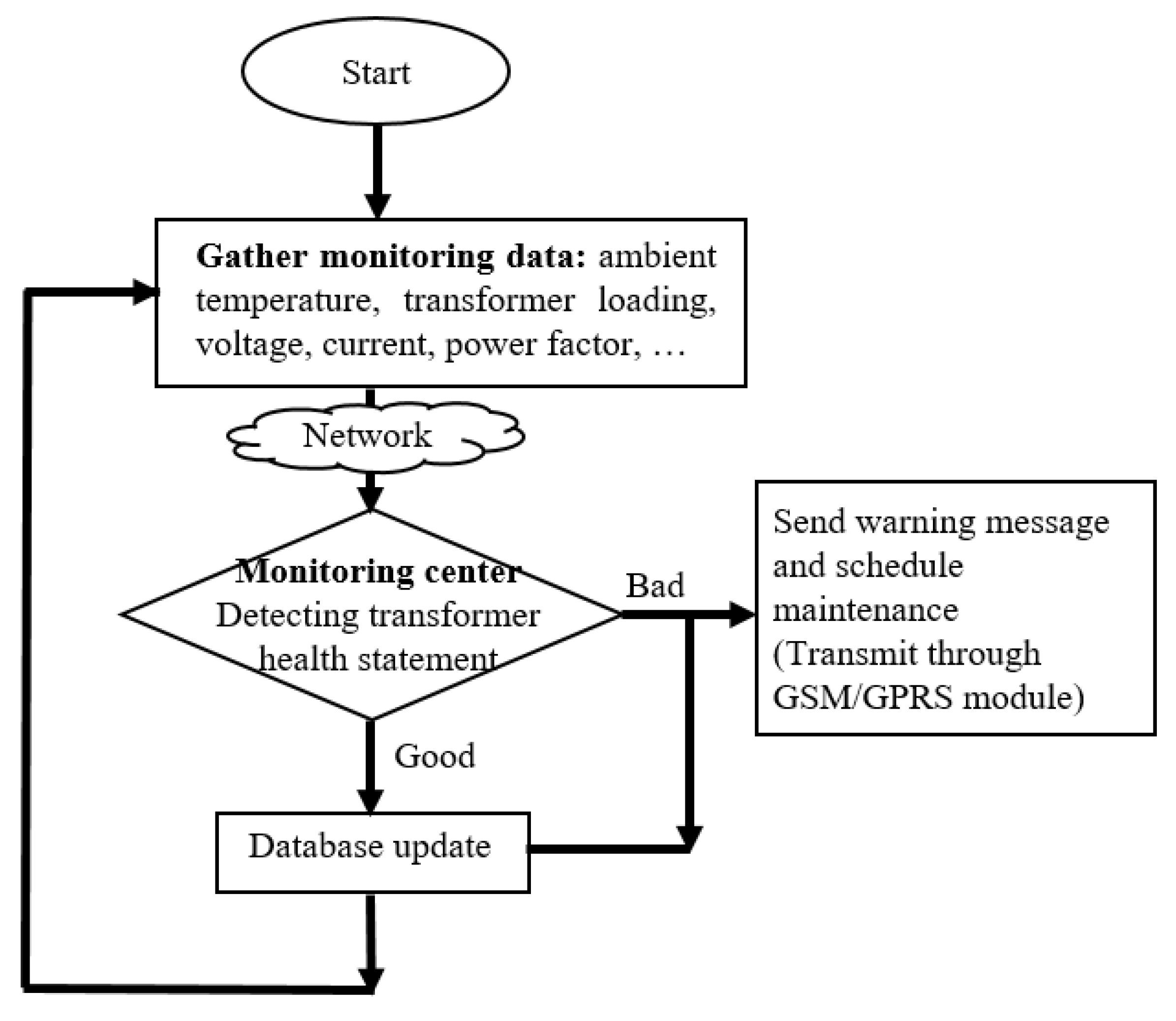

4. Advanced Technologies for Real-Time Monitoring Transformer Condition in a Smart Distribution Grid

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Agüero, J.R. Applications of smart grid technologies on power distribution systems. In Proceedings of the 2012 IEEE PES Innovative Smart Grid Technologies (ISGT), Washington, DC, USA, 16–20 January 2012; p. 1. [Google Scholar]

- Du, Z.; He, J.; Fang, R.; Wang, B. Diagnosis of smart distribution grid development. In Proceedings of the 2014 IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Hong Kong, China, 7–10 December 2014; pp. 1–4. [Google Scholar]

- Reclamation Bureau. Transformers: Basics, Maintenance, and Diagnostics; Reclamation Bureau: Denver, CO, USA, 2005.

- Murugan, R.; Ramasamy, R. Understanding the power transformer component failures for health index-based maintenance planning in electric utilities. Eng. Fail. Anal. 2019, 96, 274–288. [Google Scholar] [CrossRef]

- Rampersad, R.M.; Bahadoorsingh, S.; Sharma, C. Multifactorial Frameworks Modelling Linkages of Power Transformer Failure Modes. In Proceedings of the 2018 IEEE Electrical Insulation Conference (EIC), San Antonio, TX, USA, 17–20 June 2018; pp. 398–402. [Google Scholar]

- Haema, J.; Phadungthin, R. Development of condition evaluation for power transformer maintenance. In Proceedings of the 4th International Conference on Power Engineering, Energy and Electrical Drives, Istanbul, Turkey, 13–17 May 2013; pp. 620–623. [Google Scholar]

- Idrees, M.; Riaz, M.T.; Waleed, A.; Paracha, Z.J.; Raza, H.A.; Khan, M.A.; Hashmi, W.S. Fuzzy Logic Based Calculation and Analysis of Health Index for Power Transformer Installed in Grid Stations. In Proceedings of the 2019 International Symposium on Recent Advances in Electrical Engineering (RAEE), Islamabad, Pakistan, 28–29 August 2019; pp. 1–6. [Google Scholar]

- Technical Data 201-10 Single-Phase Overhead Transformers. Available online: http://www.aainy.com/pdf/cooper_single_phase_transformer.PDF (accessed on 10 September 2020).

- CSP Transformer. Available online: https://www.exportersindia.com/super-tech-forgings-group-of-companies/csp-transformer-3601409.htm (accessed on 10 September 2020).

- Tapan Kumar, S.; Prithwiraj, P. Smart Transformer Condition Monitoring and Diagnosis. In Transformer Ageing: Monitoring and Estimation Techniques; Wiley-IEEE Press: Piscataway, NJ, USA, 2017. [Google Scholar]

- Pitt, J. All You Need to Know About Tap Changers. Available online: https://www.azom.com/article.aspx?ArticleID=16582 (accessed on 10 September 2020).

- Jaiswal, G.C.; Tutakne, D.R.; Ballal, M.S.; Akhil Sai, P.K. Oil level assessment of Distribution Transformer by development of Capacitance Model. In Proceedings of the 2016 IEEE 6th International Conference on Power Systems (ICPS), New Delhi, India, 4–6 March 2016; pp. 1–5. [Google Scholar]

- Said, D.M.; Nor, K.M.; Majid, M.S. Analysis of distribution transformer losses and life expectancy using measured harmonic data. In Proceedings of the 14th International Conference on Harmonics and Quality of Power—ICHQP 2010, Bergamo, Italy, 26–29 September 2010; pp. 1–6. [Google Scholar]

- Taheri, S.; Vahedi, A.; Gholami, A.; Taheri, H. Estimation of hot spot temperature in distribution transformer considering core design using FEM. In Proceedings of the 2008 IEEE 2nd International Power and Energy Conference, Johor Bahru, Malaysia, 1–3 December 2008; pp. 1408–1413. [Google Scholar]

- Wang, L.; Wang, Q.; Qin, W.; Liao, T.; Yang, H.; Ma, G. Temperature Monitoring of Distribution Transformer Windings Based on Fiber Bragg Grating Array. In Proceedings of the 2019 2nd International Conference on Electrical Materials and Power Equipment (ICEMPE), Guangzhou, China, 7–10 April 2019; pp. 601–604. [Google Scholar]

- Dao, T.; Phung, B.T.; Blackburn, T. Effects of voltage harmonics on distribution transformer losses. In Proceedings of the 2015 IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Brisbane, QLD, Australia, 15–18 November 2015; pp. 1–5. [Google Scholar]

- Hadzhiev, I.; Yatchev, I.; Mechkov, E. Conjugate Heat Transfer Analysis Using 3D FEM Model of an Oil-immersed Distribution Transformer. In Proceedings of the 2018 International Conference on High Technology for Sustainable Development (HiTech), Sofia, Bulgaria, 11–14 June 2018; pp. 1–4. [Google Scholar]

- Zheng, Z.; Li, Z.; Gao, Y.; Yu, Q.Y.S. A New Inspection Method to Diagnose Winding Material and Capacity of Distribution Transformer based on Big Data. In Proceedings of the 2018 IEEE International Conference of Safety Produce Informatization (IICSPI), Chongqing, China, 10–12 December 2018; pp. 346–351. [Google Scholar]

- Arabul, A.Y.; Senol, I. Development of a hot-spot temperature calculation method for the loss of life estimation of an ONAN distribution transformer. Electr. Eng. 2018, 100, 1651–1659. [Google Scholar] [CrossRef]

- Sedighi, A.R.; Kafiri, A.; Sehhati, M.R.; Behdad, F. Life estimation of distribution transformers using thermography: A case study. Measurement 2020, 149, 106994. [Google Scholar] [CrossRef]

- Liu, Q.; Venkatasubramanian, R.; Matharage, S.; Wang, Z. Effect of Oil Regeneration on Improving Paper Conditions in a Distribution Transformer. Energies 2019, 12, 1665. [Google Scholar] [CrossRef]

- ANSI. American National Standard for Transformers—Standard for Overhead Type Distribution Transformers, 500 kVA and Smaller: High Voltage 34500 Volts and Below: Low Voltage, 7970/13800Y Volts and Below. In ANSI C57.12.20-1997; ANSI: New York, NY, USA, 2002; pp. 1–51. [Google Scholar]

- IEC Standard 60422:2013. Mineral Insulating Oils in Electrical Equipment—Supervision and Maintenance Guidance; IEC—Fluids for Electrotechnical Applications Technical Committee: Geneva, Switzerland, 2013. [Google Scholar]

- IEEE. IEEE Guide for Loading Mineral-Oil-Immersed Transformers—Corrigendum 1. In IEEE Std C57.91-1995/Cor 1-2002; IEEE: New York, NY, USA, 2003; pp. 1–16. [Google Scholar]

- IEEE Guide for Loading Mineral-Oil-Immersed Transformers and Step-Voltage Regulators. In IEEE Std C57.91-2011 (Revision of IEEE Std C57.91-1995); IEEE: New York, NY, USA, 2012; pp. 1–123.

- Zhou, Y.; Ma, L.; Yang, J.; Xia, C. Entropy Weight Health Index method of power transformer condition assessment. In Proceedings of the 2011 9th International Conference on Reliability, Maintainability and Safety, Guiyang, China, 12–15 June 2011; pp. 426–431. [Google Scholar]

- Jahromi, A.; Piercy, R.; Cress, S.; Service, J.; Fan, W. An approach to power transformer asset management using health index. IEEE Electr. Insul. Mag. 2009, 25, 20–34. [Google Scholar] [CrossRef]

- Arshad, M.; Islam, S.M.; Khaliq, A. Fuzzy logic approach in power transformers management and decision making. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 2343–2354. [Google Scholar] [CrossRef]

- Ahmed, M.R.; Geliel, M.A.; Khalil, A. Power transformer fault diagnosis using fuzzy logic technique based on dissolved gas analysis. In Proceedings of the 21st Mediterranean Conference on Control and Automation, Institute of Electrical and Electronics Engineers (IEEE), Chania, Greece, 25–28 June 2013; pp. 584–589. [Google Scholar]

- Davidenko, I.V.; Kuzina, T.S. Analysis of the modern methods of the power transformers health index calculation. In Proceedings of the 2017 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (EIConRus), St. Petersburg, Russia, 1–3 February 2017; pp. 1491–1495. [Google Scholar]

- Khalyasmaa, A.; Eroshenko, S.A.; Tashchilin, V.; Seguin, C.; Ehlinger, L.; Vibhute, R.R.; Atluri, S.R. Machine Learning Algorithms for Power Transformers Technical State Assessment. In Proceedings of the 2019 International Multi-Conference on Engineering, Computer and Information Sciences (SIBIRCON), Novosibirsk, Russia, 21–27 October 2019; pp. 601–606. [Google Scholar]

- Jaiswal, G.C.; Ballal, M.S.; Venikar, P.A.; Tutakne, D.R.; Suryawanshi, H.M. Genetic algorithm-based health index determination of distribution transformer. Int. Trans. Electr. Energy Syst. 2018, 28, e2529. [Google Scholar] [CrossRef]

- Ghazali, Y.Z.Y.; Talib, M.A.; Rosli, H.A. TNB Experience in Condition Assessment and Life Management of Distribution Power Transformers. In Proceedings of the CIRED 2009—20th International Conference and Exhibition on Electricity Distribution—Part 1, Prague, Czech Republic, 8–11 June 2009; paper n. 0686. pp. 1–4. [Google Scholar]

- Wattakapaiboon, W.; Pattanadech, N. The new developed Health Index for transformer condition assessment. In Proceedings of the 2016 International Conference on Condition Monitoring and Diagnosis (CMD), Xi’an, China, 25–28 September 2016; pp. 32–35. [Google Scholar]

- Management Association, Information Resources. Fuzzy Systems: Concepts, Methodologies, Tools, and Applications; IGI Global: Hershey, PA, USA, 2017. [Google Scholar]

- Saha, T.K. Review of modern diagnostic techniques for assessing insulation condition in aged transformers. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 903–917. [Google Scholar] [CrossRef]

- Aissaoui, A.G.; Tahour, A. Application of Fuzzy Logic in Control of Electrical Machines; IntechOpen Limited: London, UK, 2012. [Google Scholar]

- Rosero-Z, L.; Pavas, A.; Duran, I.C. Analysis of Maintenance in Transformers Based on a Fuzzy Logic Method. In Proceedings of the 2018 IEEE PES Transmission & Distribution Conference and Exhibition-Latin America (T&D-LA), Lima, Peru, 18–21 September 2018; pp. 1–5. [Google Scholar]

- Jaiswal, G.C.; Ballal, M.S.; Tutakne, D. Health index based condition monitoring of distribution transformer. In Proceedings of the 2016 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Trivandrum, India, 14–17 December 2016; pp. 1–5. [Google Scholar]

- Zhang, X.; Hanshan, L. Research on transformer fault diagnosis method and calculation model by using fuzzy data fusion in multi-sensor detection system. Optik 2019, 176, 716–723. [Google Scholar]

- Abu-Elanien, A.E.B.; Salama, M.M.A.; Ibrahim, M. Calculation of a Health Index for Oil-Immersed Transformers Rated Under 69 kV Using Fuzzy Logic. IEEE Trans. Power Deliv. 2012, 27, 2029–2036. [Google Scholar] [CrossRef]

- Jancarczyk, D.; Bernas, M.; Boczar, T. Distribution Transformer Parameters Detection Based on Low-Frequency Noise, Machine Learning Methods, and Evolutionary Algorithm. Sensors 2020, 20, 4332. [Google Scholar] [CrossRef] [PubMed]

- Alqudsi, A.; El-Hag, A.H. Application of Machine Learning in Transformer Health Index Prediction. Energies 2019, 12, 2694. [Google Scholar] [CrossRef]

- Du Toit, J. Enabling Predictive Maintenance using Semi-supervised Learning with Reg-D Transformer Data. IFAC Proc. Vol. 2014, 47, 6111–6116. [Google Scholar] [CrossRef]

- Jaiswal, G.C.; Ballal, M.S.; Tutakne, D.R. ANN based methodology for determination of distribution transformer health status. In Proceedings of the 2017 7th International Conference on Power Systems (ICPS), Pune, India, 21–23 December 2017; pp. 133–138. [Google Scholar]

- Abu-Elanien, A.E.B.; Salama, M.M.A.; Ibrahim, M. Determination of transformer health condition using artificial neural networks. In Proceedings of the 2011 International Symposium on Innovations in Intelligent Systems and Applications, Istanbul, Turkey, 15–18 June 2011; pp. 1–5. [Google Scholar]

- Leal, A.G.; Jardini, J.A.; Magrini, L.C.; Ahn, S.U. Distribution Transformer Losses Evaluation: A New Analytical Methodology and Artificial Neural Network Approach. IEEE Trans. Power Syst. 2009, 24, 705–712. [Google Scholar] [CrossRef]

- Farag, A.S.; Mohandes, M.; Al-Shaikh, A. Diagnosing failed distribution transformers using neural networks. IEEE Trans. Power Deliv. 2001, 16, 631–636. [Google Scholar] [CrossRef]

- Shil, P.; Anderson, T. Distribution Transformer Health Monitoring and Predictive Asset Maintenance. In Proceedings of the 2019 SAS Global Forum, Dallas, TX, USA, 28 April–1 May 2019; pp. 1–11. [Google Scholar]

- Chen, X.; Cui, H.; Luo, L. Fault Diagnosis of Transformer Based on Random Forest. In Proceedings of the 2011 Fourth International Conference on Intelligent Computation Technology and Automation, Shenzhen, China, 28–29 March 2011; pp. 132–134. [Google Scholar]

- Gholami, R.; Fakhari, N. Chapter 27—Support Vector Machine: Principles, Parameters, and Applications. In Handbook of Neural Computation; Samui, P., Sekhar, S., Balas, V.E., Eds.; Academic Press: Cambridge, MA, USA, 2017; pp. 515–535. [Google Scholar]

- Kari, T.; Gao, W.; Zhao, D.; Abiderexiti, K.; Mo, W.; Wang, Y.; Luan, L. Hybrid feature selection approach for power transformer fault diagnosis based on support vector machine and genetic algorithm. IET Gener. Transm. Distrib. 2018, 12, 5672–5680. [Google Scholar] [CrossRef]

- Fei, S.-W.; Zhang, X.-B. Fault diagnosis of power transformer based on support vector machine with genetic algorithm. Expert Syst. Appl. 2009, 36, 11352–11357. [Google Scholar] [CrossRef]

- Illias, H.A.; Chai, X.R.; Abu Bakar, A.H.; Mokhlis, H. Transformer Incipient Fault Prediction Using Combined Artificial Neural Network and Various Particle Swarm Optimisation Techniques. PLoS ONE 2015, 10, e0129363. [Google Scholar] [CrossRef]

- Sarajcev, P.; Jakus, D.; Vasilj, J.; Nikolic, M. Analysis of Transformer Health Index Using Bayesian Statistical Models. In Proceedings of the 2018 3rd International Conference on Smart and Sustainable Technologies (SpliTech), Split, Croatia, 26–29 June 2018; pp. 1–7. [Google Scholar]

- Hernanda, I.G.N.S.; Mulyana, A.; Asfani, D.A.; Negara, I.M.Y.; Fahmi, D. Application of health index method for transformer condition assessment. In Proceedings of the TENCON 2014—2014 IEEE Region 10 Conference, Bangkok, Thailand, 22–25 October 2014; pp. 1–6. [Google Scholar]

- Gorgan, B.; Notingher, P.; Badicu, L.-V.; Gabriel, T. Calculation of power transformers health indexes. Ann. Univ. Craiova Electr. Eng. Ser. 2010, 34, 13–18. [Google Scholar]

- Jardini, J.; Schmidt, H.; Tahan, C.M.; De Oliveira, C.C.; Ahn, S.U. Distribution transformer loss of life evaluation: A novel approach based on daily load profiles. IEEE Trans. Power Deliv. 2000, 15, 361–366. [Google Scholar] [CrossRef]

- Niu, J.; Su, J.; Yang, Y.; Cai, Y.; Liu, H. Distribution transformer failure rate prediction model based on multi-source information. In Proceedings of the 2016 International Conference on Condition Monitoring and Diagnosis (CMD), Xi’an, China, 25–28 September 2016; pp. 944–947. [Google Scholar]

- Yingyu, C.; Yubo, Z.; Youyuan, W.; Jian, F. State evaluation model of distribution transformer considering environmental factors and operation data. In Proceedings of the 2020 IEEE Electrical Insulation Conference (EIC), Knoxville, TN, USA, 22 June–3 July 2020; pp. 98–102. [Google Scholar]

- Sun, L. An Effective Health Index Calculation of 10 kV Distribution Transformer Using Fuzzy Set Theory and Nonlinear Fuzzy AHP, 1st ed.; Routledge: Abingdon, UK, 2020. [Google Scholar]

- Wang, N.; Zhao, F. An Assessment of the Condition of Distribution Network Equipment Based on Large Data Fuzzy Decision-Making. Energies 2020, 13, 197. [Google Scholar] [CrossRef]

- Arshad, M.R.; Islam, S. A Novel Fuzzy Logic Technique for Power Transformer Asset Management. In Proceedings of the Conference Record of the 2006 IEEE Industry Applications Conference Forty-First IAS Annual Meeting, Tampa, FL, USA, 8–12 October 2006; pp. 276–286. [Google Scholar]

- Roland, U.; Omorogiuwa, D. Artificial Neural Network Approach to Distribution Transformers Maintenance. Int. J. Sci. Res. Eng. Technol. 2015, 1, 62–70. [Google Scholar]

- Pylvanainen, J.K.; Nousiainen, K.; Verho, P. Studies to Utilize Loading Guides and ANN for Oil-Immersed Distribution Transformer Condition Monitoring. IEEE Trans. Power Deliv. 2006, 22, 201–207. [Google Scholar] [CrossRef]

- Tran, Q.T.; Davies, K.; Roose, L. Machine learning for assessing the service transformer health using an energy monitor device. IOSR J. Electr. Electron. Eng. 2020, 15, 1–6. [Google Scholar]

- Kartojo, I.H.; Wang, Y.-B.; Zhang, G.-J.; Suwarno. Partial Discharge Defect Recognition in Power Transformer using Random Forest. In Proceedings of the 2019 IEEE 20th International Conference on Dielectric Liquids (ICDL), Rome, Italy, 23–27 June 2019; pp. 1–4. [Google Scholar]

- Lu, J.; Wu, M. Condition assessment for power transformer based on improved particle swarm optimization and Support Vector Machine. In Proceedings of the 2010 5th International Conference on Critical Infrastructure (CRIS), Beijing, China, 20–22 September 2010; pp. 1–6. [Google Scholar]

- Tariku, A.; Bekele, G. Distribution Transformer Failure Study and Solution Proposal in Ethiopia. In Proceedings of the 2020 IEEE PES/IAS PowerAfrica, Nairobi, Kenya, 25–28 August 2020; pp. 1–5. [Google Scholar]

- Singh, J.; Singh, S.; Singh, A. Distribution transformer failure modes, effects and criticality analysis (FMECA). Eng. Fail. Anal. 2019, 99, 180–191. [Google Scholar] [CrossRef]

- Dong, M.; Nassif, A.B.; Li, B. A Data-Driven Residential Transformer Overloading Risk Assessment Method. IEEE Trans. Power Deliv. 2018, 34, 387–396. [Google Scholar] [CrossRef]

- Nebey, A.H. Automatic load sharing of distribution transformer for overload protection. BMC Res. Notes 2020, 13, 17. [Google Scholar] [CrossRef]

- Raghavan, A.; Kiesel, P.; Teepe, M.; Cheng, F.; Chen, Q.; Karin, T.; Jung, D.; Mostafavi, S.; Smith, M.; Stinson, R.; et al. Low-cost embedded optical sensing systems for distribution transformer monitoring. IEEE Trans. Power Deliv. 2020, 1. [Google Scholar] [CrossRef]

- Agah, S.M.; Abyaneh, H.A. Effect of Modeling Non-Normality and Stochastic Dependence of Variables on Distribution Transformer Loss of Life Inference. IEEE Trans. Power Deliv. 2012, 27, 1700–1709. [Google Scholar] [CrossRef]

- Ashkezari, A.D.; Ma, H.; Saha, T.K.; Ekanayake, C. Application of fuzzy support vector machine for determining the health index of the insulation system of in-service power transformers. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 965–973. [Google Scholar] [CrossRef]

- Nelson, A.; Jaiswal, G.; Ballal, M. Economical aspects of Remote Conditon Monitoring System for Distribution Transformer. In Proceedings of the 2014 International Conference on Power, Automation and Communication (INPAC), Amravati, India, 6–8 October 2014; pp. 45–49. [Google Scholar]

- Dileepkumar Reddy, Y.M. Real Time Transformer Health Monitoring System Using GSM Technology. Int. J. Res. 2018, 7, 3515–3518. [Google Scholar]

- Pawar, R.R.; Deosarkar, S.B. Health condition monitoring system for distribution transformer using Internet of Things (IoT). In Proceedings of the 2017 International Conference on Computing Methodologies and Communication (ICCMC), Erode, India, 18–19 July 2017; pp. 117–122. [Google Scholar]

- Rahman, S.; Dey, S.K.; Bhawmick, B.K.; Das, N.K. Design and implementation of real time transformer health monitoring system using GSM technology. In Proceedings of the 2017 International Conference on Electrical, Computer and Communication Engineering (ECCE), Cox’s Bazar, Bangladesh, 16–18 February 2017; pp. 258–261. [Google Scholar]

- Velhal, G.; Pujara, A.; Velhal, V.; Bakre, S.; Muralidhara, V. Smart Transformer using Advanced Metering Infrastructure (AMI) and Advance Sensor Infrastructure (ASI). IJIREEICE 2015, 3, 5–8. [Google Scholar] [CrossRef]

- Atkinson, G.; Thottan, M. Leveraging advanced metering infrastructure for distribution grid asset management. In Proceedings of the 2014 IEEE Conference on Computer Communications Workshops (INFOCOM WKSHPS), Toronto, ON, Canada, 27 April–2 May 2014; pp. 670–675. [Google Scholar]

- Candela, R.; Di Stefano, A.; Fiscelli, G.; Bononi, S.F.; De Rai, L.; Di Stefano, A. A novel partial discharge detection system based on wireless technology. In Proceedings of the AEIT Annual Conference 2013, Palermo, Italy, 3–5 October 2013; pp. 1–6. [Google Scholar]

- Madonia, A.; Vigni, V.L.; Sanseverino, E.R.; Romano, P.; Viola, F.; Candela, R. Remote voltage synchronization for wireless Partial Discharge diagnostics. In Proceedings of the 2016 IEEE International Conference on Dielectrics (ICD), Montpellier, France, 3–7 July 2016; pp. 947–950. [Google Scholar]

- Chen, N.; Ding, Y.; Sun, Q.; Sun, X.; Liu, L. Threshold decision-based online monitoring system for detection and location partial discharges in power transformers. In Proceedings of the IET International Communication Conference on Wireless Mobile & Computing (CCWMC 2009), Shanghai, China, 7–9 December 2009; pp. 444–447. [Google Scholar]

- Ballal, M.S.; Jaiswal, G.C.; Tutkane, D.R.; Venikar, P.A.; Mishra, M.K.; Suryawanshi, H.M. Online condition monitoring system for substation and service transformers. IET Electr. Power Appl. 2017, 11, 1187–1195. [Google Scholar] [CrossRef]

- Mariprasath, T.; Kirubakaran, V. A real time study on condition monitoring of distribution transformer using thermal imager. Infrared Phys. Technol. 2018, 90, 78–86. [Google Scholar] [CrossRef]

- Nelson, A.A.; Jaiswal, G.C.; Ballal, M.S.; Tutakne, D.R. Remote condition monitoring system for distribution transformer. In Proceedings of the 2014 21st International Conference on Telecommunications (ICT), Guwahati, India, 18–20 December 2014; pp. 1–5. [Google Scholar]

- Tran, Q.T.T.; Davies, K.; Roose, L.; Doan, B.V.; Nguyen, N.Q. Online distribution service transformer health assessment using real-time grid energy monitor. In Proceedings of the 2020 IEEE Kansas Power and Energy Conference (KPEC), Manhattan, KS, USA, 13–14 July 2020; pp. 1–6. [Google Scholar]

- Xie, C.; Zou, G.; Wang, H.; Jin, Y. A new condition assessment method for distribution transformers based on operation data and record text mining technique. In Proceedings of the 2016 China International Conference on Electricity Distribution (CICED), Xi’an, China, 10–13 August 2016; pp. 1–7. [Google Scholar]

- Wang, X.; Wu, K.; Xu, Y. Research on Transformer Fault Diagnosis based on Multi-source Information Fusion. Int. J. Control. Autom. 2014, 7, 197–208. [Google Scholar] [CrossRef]

- Newton-Evans Research Company. U.S. Market for Distribution Transformers Standing at $3 Billion, Based on Findings from Recent Newton-Evans Study. Available online: https://www.newton-evans.com/u-s-market-for-distribution-transformers-standing-at-3-billion-based-on-findings-from-recent-newton-evans-study/ (accessed on 10 September 2020).

| Component | Failure Category | Failure Mode | Frequency of Occurence | Operation Impact Level | |

|---|---|---|---|---|---|

| 1 | Insulation | Chemical/Mechanical | Water accumulation in the oil/paper | High | High |

| Chemical/Thermal | Aging of oil/paper | ||||

| Thermal | Thermal degradation of oil/paper | ||||

| 2 | Winding | Electrical/Mechanical | Short circuit between turns/strands | Medium | High |

| Short-circuit to ground | |||||

| Open circuit | |||||

| Magnetic/Mechanical | Conductor tilting, conductor bending, clamping system failure, axial instability, and lead deformation | ||||

| Winding bulk movement | |||||

| Buckling | |||||

| 3 | Bushing | Electrical/Mechanical | Short circuit within capacitance graded layers | Medium | High |

| Mechanical/Thermal | Bushing thermal expansion | ||||

| Mechanical | Bushing failure due to porcelain damage | ||||

| 4 | Tank | Mechanical/Thermal | Internal rupture | Low | Low |

| Leakage | |||||

| 5 | Core | Electrical/Mechanical | Multiple grounding | Low | Low |

| Ungrounded core | |||||

| Short circuit core laminations | |||||

| Mechanical/Thermal | Core deformation | ||||

| 6 | Other | Unknown causes | Operational errors, lack of maintenance, and protection system trips/failures | Low | N/A |

| Measurement Technique | Standard | Limit Level for Distribution Voltage Class | ||

|---|---|---|---|---|

| Normal | Suspect | Poor | ||

| Hot spot temperature (insulation class 150) | IEEE C57.91-1995, IEC 60076-7 | <95 °C | 95–105 °C | >105 °C |

| Power factor | IEC 60422 | ≤0.1% | 0.1–0.5% | >0.5% |

| Voltage harmonic distortion | IEEE 519-2014 | THD(Uf) ≤ 5% | 5% | >5% |

| Noise level (for transformer of power 50 kVA) | IEC 60076-10 (2001), IEEE C57.12.90 (2006) | 39–42 dB | 42–45 dB | >45 dB |

| Humidity (saturation percentage) | IEEE 62-1995 | 0–20% | 21–30% | >30% |

| Turns ratio | IEC 60076-3 2000, IEEE C57.12.90 | ≤0.1% | ≥0.2% to ≤0.5% | ≥0.5% |

| Winding resistance | IEC 60076-3 2000 | <1% | ≥ 1% to ≤4% | ≥5% |

| Core resistance | IEC 60076-3 2000 | ≥1000 MΩ | ≥100 MΩ | ≤10 MΩ |

| Short circuit impedance | IEC 60076-5 2000 | ≤1% | 1% ≤ 2% | ≥5% |

| Dissolved gas analysis | IEEE C57-104-2008 | 0–1920 | 1920–4630 | ≥4360 |

| CO2/CO ratio test | IEC 60599 1999 | ≥3–10 | ≤3 | ≥10 and above |

| Dielectric Strength | IEC 60422-2005 | ≥50 kV/mm | ≤50–40 kV/mm | ≤40 kV/mm |

| Interfacial tension | IEC 60422 | ≥28 dyne/cm | 28–22 dyne/cm | ≤22 dyne/cm |

| Frequency domain spectroscopy | IEC 60422 2005 | ≤2.2% (Dry) | ≥2.2 and ≤4.8% (Moderately wet) | ≥4.8% Extremely wet |

| Methods | Dependency on the Datasets | Dependency on the Weighted Parameters | Number of Samples Required | Accuracy | Complexity | Implement Cost | Computation Effort |

|---|---|---|---|---|---|---|---|

| Health index calculation [33,34,56,57,58,59,60] | √ | Small | Low | Low | High | High | |

| Fuzzy logic [38,39,40,41,61,62,63] | √ | Small | Low | Low | High | Low | |

| Artificial neural networks effort [45,46,64,65] | √ | Large | Good | Low | Low | Low | |

| Machine learning algorithms using Random Forest [66,67] | √ | Large | Good | Low | Low | Low | |

| GA based health index determination [32] | √ | Small | Good | High | High | High | |

| Combination of GA and support vector machine [52,53] | √ | Large | High | High | Low | High | |

| PSO and Support Vector Machine SVM [68] | √ | Large | High | High | Low | High |

| Method | Advantages | Disadvantages | |

|---|---|---|---|

| 1 | Health index calculation [33,34,56,57,58,59,60] |

|

|

| 2 | Fuzzy logic [38,39,40,41,61,62,63] |

|

|

| 3 | Artificial neural networks effort [45,46,64,65] |

|

|

| 4 | Machine learning algorithms using Random Forest [66,67] |

|

|

| 5 | Genetic algorithm (GA) based health index determination [32] |

|

|

| 6 | Combination of genetic algorithm (GA) and support vector machine (SVM) [52,53] |

|

|

| 7 | Particle swarm optimization (PSO) and Support Vector Machine SVM [68] |

|

|

| Monitoring Techniques | Monitoring Parameters | Advantage | Disadvantage | |

|---|---|---|---|---|

| 1 | Health condition monitoring using IoT (GSM/GPRS) [78,79] | 1. Current 2. Voltage 3. Oil level 4. Oil temperature | Reliable Low cost Time resolution: 1 min | Need to add sensors on transformers: Oil level indicator |

| 2 | Online condition monitoring system for substation and service transformer [85] | 1.Age 2. Loading history 3. Inspection and maintenance 4. Type of transformer 5. Location 6. Unbalanced voltage 7. Harmonic load current and power factor 8. Efficiency deviation due to internal fault 9. Winding temperature 10. Top oil temperature 11. Oil level | High accuracy Low cost: 2% of transformer cost (15 kVA three-phase) Time resolution: 30 min | Need to add sensors: Oil level indicator Energy meter |

| 3 | Studies to Utilize Loading Guides and ANN for Oil-Immersed Distribution Transformer Condition Monitoring [65] | 1. Three-phase loading values (current); 2. Ambient temperature; 3. Calculated top oil temperature 4. Calculated hot spot temperature | Reliable Low cost, only use Energy meter Time resolution (1 h) No need to add sensors | Further studies needed to improve the precision |

| 4 | A real time study on condition monitoring of distribution transformer using thermal imager [86] | 1. Thermal imager | High accuracy Time resolution (1 h) | High initial cost |

| 5 | Remote Condition Monitoring System using public network [87] | 1. Temperature 2. Oil level 3. Loading 4. Humming noise | Saving cost Easy to extend to the other monitoring parameters | The accuracy will have significant changes when some imbalance occurs in the mechanical forces |

| 6 | Online distribution service transformer health assessment using real-time grid energy monitor [88] | 1. Top oil temperature 2. Vibration 3. Transformer loading 4. Power factor | Reliable Low cost, only use Energy meter High time resolution (1 s) No need to add sensors | Further studies needed to improve the precision |

| 7 | Multi-source information analysis (statistical data, text mining) [89] | 1. Voltage deviation 2. Load rate 3. Unbalance factor 4. Harmonic voltage distortion | Higher accuracy Low cost, only use Energy meter Good time resolution (15 min) No need to add sensors | Need conventional test data (Unbalance and Harmonic distortion) |

| 8 | Transformer Fault Diagnosis based on Multi-source Information Fusion [90] | 1. DGA 2. SCADA real-time data 3. Special sensor real-time data 4. Related electrical test data 5. Operation and repair records | Very high accuracy Can predicting the location, type and property of transformer faults. | Need to use many parameters for information fusion methods that they match to each other for high accuracy and they need to use many types of historical transformer fault data. |

| 9 | Leveraging advanced metering infrastructure (AMI) [91] | 1. Transformer loading 2. Transformer Aging 3. Estimated Ambient temperature 4. Computed hottest temperature | Comfortable for utility to monitor and set up suitable asset management plans. Time resolution (1 h) | Need to install many of smart meters that be installed at customer locations for each of distribution transformers |

| 10 | Advanced Metering Infrastructure (AMI) [49] | 1. Customer Information System 2. Transformer loading 3. Weather data | Can collect the loading data of all areas. | Need to install many of smart meters at customer side Need to collect many information from customer side |

| 11 | Smart Transformer using Advanced MeteringInfrastructure (AMI) and Advance SensorInfrastructure (ASI) [80] | 1. DGA 2. Temperature 3. ambient temperature 4. Real-time loading 5. Electrical parameters | Comfortable for utility to monitor and set up suitable asset management plans. | Need to install many of smart meters that be installed at customer locations for each of distribution transformers |

| 12 | Wireless Partial Discharges diagnosis [84] | 1. Voltage pulses | Wireless Small physical dimension Portable High accuracy No sensors needed | Devoted to dielectric health only Further studies needed to improve the precision concerning noise |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tran, Q.T.; Davies, K.; Roose, L.; Wiriyakitikun, P.; Janjampop, J.; Riva Sanseverino, E.; Zizzo, G. A Review of Health Assessment Techniques for Distribution Transformers in Smart Distribution Grids. Appl. Sci. 2020, 10, 8115. https://doi.org/10.3390/app10228115

Tran QT, Davies K, Roose L, Wiriyakitikun P, Janjampop J, Riva Sanseverino E, Zizzo G. A Review of Health Assessment Techniques for Distribution Transformers in Smart Distribution Grids. Applied Sciences. 2020; 10(22):8115. https://doi.org/10.3390/app10228115

Chicago/Turabian StyleTran, Quynh T., Kevin Davies, Leon Roose, Puthawat Wiriyakitikun, Jaktupong Janjampop, Eleonora Riva Sanseverino, and Gaetano Zizzo. 2020. "A Review of Health Assessment Techniques for Distribution Transformers in Smart Distribution Grids" Applied Sciences 10, no. 22: 8115. https://doi.org/10.3390/app10228115

APA StyleTran, Q. T., Davies, K., Roose, L., Wiriyakitikun, P., Janjampop, J., Riva Sanseverino, E., & Zizzo, G. (2020). A Review of Health Assessment Techniques for Distribution Transformers in Smart Distribution Grids. Applied Sciences, 10(22), 8115. https://doi.org/10.3390/app10228115