Macro-Modelling Approach for the In-Plane Cyclic Response of Cold-Formed Steel Partition Walls

Abstract

1. Introduction

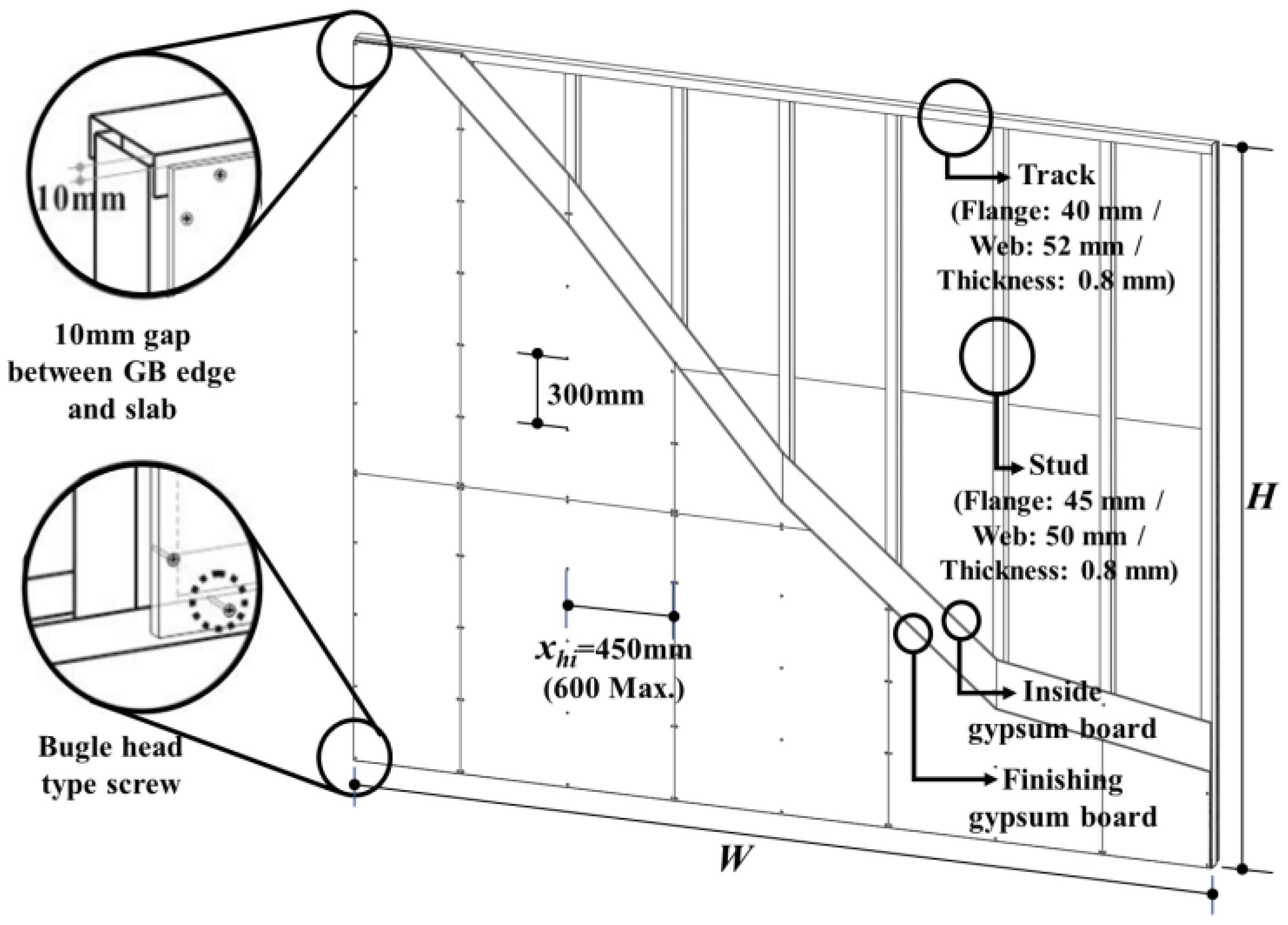

2. Damage Mechanism of CFS Partition Walls

2.1. General Construction Details of CFS Partition Walls

2.2. Typical Damage Mechanism of CFS Partition Walls under Lateral Loads

3. Development of the Proposed Analytical Model

3.1. In-Plane Displacements of CFS Partition Walls

3.2. Structural Characteristics of CFS Partition Walls

3.2.1. Screw Connections

3.2.2. Gypsum Boards

3.2.3. CFS Studs

3.3. Hysteresis Modelling of CFS Partition Walls

4. Validation of the Proposed Analytical Model

4.1. Overview of CFS Partition Wall Experiments and Their Analytical Models

4.2. Validation of the Proposed Analytical Model

4.2.1. Force–displacement Hysteretic Curves Assessment

4.2.2. Damage State Identification

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Filiatrault, A.; Uang, C.M.; Folz, B.; Christopoulos, C.; Gatto, K. Reconnaissance Report of Nisqually (Seattle-Olympia) 28 February 2001 Earthquake; Deptment of Structural Engineering, University of California: San Diego, CA, USA, 2001. [Google Scholar]

- Dhakal, R. Damage to non-structural components and contents in 2010 far-field earthquake. Bull. N. Z. Soc. Earthq. Eng. 2010, 43, 404–411. [Google Scholar]

- Baird, A.; Tasligedik, A.S.; Palermo, S.; Pampanin, S. Seismic performance of vertical non-structural components in the 22nd Februrary 2011 Christchurch earthquake. Earthq. Spectra 2014, 30, 401–425. [Google Scholar] [CrossRef]

- Taghavi, S.; Miranda, E. Response Assessment of Nonstructural Building Elements; Report No. PEER 2003/2005; Pacific Engineering Research Center: Berkeley, CA, USA, 2003. [Google Scholar]

- Peterman, K.D.; Nakata, N.; Schafer, B.W. Hysteretic characterization of cold-formed steel stud-to-sheathing connections. J. Constr. Steel Res. 2014, 101, 254–264. [Google Scholar] [CrossRef]

- Fiorino, L.; Iuorio, O.; Landolfo, R. Seismic analysis of sheathing-braced cold-formed steel structures. Eng. Struct. 2012, 34, 538–547. [Google Scholar] [CrossRef]

- Usefi, N.; Sharafi, P.; Ronagh, H. Numerical models for lateral behaviour analysis of cold-formed steel framed walls: State of the art, evaluation and challenges. Thin Walled Struct. 2019, 138, 252–285. [Google Scholar] [CrossRef]

- Xu, L.; Martinez, J. Strength and stiffness determination of shear wall panels in cold-formed steel framing. Thin Walled Struct. 2006, 44, 1084–1095. [Google Scholar] [CrossRef]

- Ye, J.; Wang, X. Piecewise Function Hysteretic Model for Cold-Formed Steel Shear Walls with Reinforced End Studs. Appl. Sci. 2017, 7, 94. [Google Scholar] [CrossRef]

- Paevere, P.J. Full-Scale Testing, Modelling and Analysis of Light-Frame Structures under Lateral Loading. Ph.D. Thesis, University of Melbourne, Melbourne, Australia, 2002. [Google Scholar]

- Nithyadharan, M.; Kalyanaraman, V. Modelling hysteretic behavior of cold-formed steel wall panels. Eng. Struct. 2013, 46, 643–652. [Google Scholar] [CrossRef]

- Retamales, R.; Davies, R.; Mosqueda, G.; Filiatrault, A. Experimental seismic fragility of cold-formed steel framed gypsum partition walls. ASCE J. Struct. Eng. 2013, 139, 1285–1293. [Google Scholar] [CrossRef]

- Lee, T.; Kato, M.; Matsumiya, T.; Suita, K.; Nakashima, M. Seismic performance evaluation of non-structural components: Drywall partitions. Earthq. Eng. Struct. Dyn. 2007, 36, 367–382. [Google Scholar] [CrossRef]

- Restrepo, J.I.; Lang, A.F. Study of loading protocol in light-gauge stud partition wall. Earthq. Spectra 2011, 27, 1169–1185. [Google Scholar] [CrossRef]

- Davies, D.; Retamales, R.; Mosqueda, G.; Filiatrault, A. Experimental Seismic Evaluation, Model Parameterization, and Effects of Cold-Formed Steel-Framed Gypsum Partition Walls on the Seismic Performance of an Essential Facility; Technical Report MCEER-11-0005; MCEER, University at Buffalo, State University of New York: Buffalo, NY, USA, 2011. [Google Scholar]

- Wood, R.L.; Hutchinson, C. Design-Oriented Model for Capturing the In-Plane Seismic Response of Partition Walls. J. Struct. Eng. 2014, 140, 04014023. [Google Scholar] [CrossRef]

- Rahmanishamsi, E.; Soroushian, S.; Maragakis, E.M. Analytical model for the in-plane seismic performance of cold-formed steel-framed gypsum partition walls. Earthq. Eng. Struct. Dyn. 2016, 45, 619–634. [Google Scholar] [CrossRef]

- Magliulo, G.; Petrone, C.; Capozzi, V.; Maddaloni, G.; Lopez, P.; Manfredi, G. Seismic performance evaluation of plasterboard partitions via shake table tests. Bull. Earthq. Eng. 2014, 12, 1657–1677. [Google Scholar] [CrossRef]

- Petrone, C.; Magliulo, G.; Manfredi, G. Shake table tests on standard and innovative temporary partition walls. Earthq. Eng. Struct. Dyn. 2017, 46, 1599–1624. [Google Scholar] [CrossRef]

- McCormick, J.; Matsuoka, Y.; Pan, P.; Nakashima, M. Evaluation of non-structural partition walls and suspended ceiling systems through a shake table study. In Proceedings of the Structures Congress, Vancouver, BC, Canada, 24–26 April 2008. [Google Scholar]

- Wang, X.; Pantoli, E.; Hutchinson, T.C.; Restrepo, J.I.; Wood, R.L.; Hoehler, M.S.; Grzesik, P.; Sesma, F.H. Seismic performance of cold-formed steel wall systems in a full-scale building. J. Struct. Eng. 2015, 141, 04015014. [Google Scholar] [CrossRef]

- Pantoli, E.; Chen, M.C.; Wang, X.; Astroza, R.; Ebrahimian, H.; Hutchinson, T.C.; Conte, J.P.; Restrepo, J.I.; Marin, C.; Walsh, K.D.; et al. Full-Scale Structural and Nonstructural Building System Performance during Earthquakes: Part II-NCS Damage States. Earthq. Spectra 2016, 32, 771–794. [Google Scholar] [CrossRef]

- Restrepo, J.I.; Bersofsky, A.M. Performance characteristics of light gage steel stud partition walls. Thin Walled Struct. 2011, 49, 317–324. [Google Scholar] [CrossRef]

- Petrone, C.; Magliulo, G.; Lopez, P.; Manfredi, G. Seismic fragility of plasterboard partitions via in-plane quasi-static tests. Earthq. Eng. Struct. Dyn. 2015, 44, 2589–2606. [Google Scholar] [CrossRef]

- Jenkins, C.; Soroushian, S.; Rahmanishamsi, E.; Maragakis, E.M. Experimental fragility analysis of cold-formed steel-framed partition wall systems. Thin Walled Struct. 2016, 103, 115–127. [Google Scholar] [CrossRef]

- Buonopane, S.G.; Tun, T.H.; Schafer, B.W. Fastener-based computational models for prediction of seismic behavior of CFS shear walls. In Proceedings of the 10th U.S. National Conference on Earthquake Engineering Frontiers of Earthquake Engineering, Anchorage, AL, USA, 21–25 July 2014. [Google Scholar]

- Choi, K.S.; Kim, H.J. Structural Behavior of Screw Connections between Cold-Formed Steel Studs and Gypsum Boards. In Proceedings of the 4th International Workshop on the Seismic Performance of Non-Structural Elements (SPONSE), Pavia, Italy, 22–23 May 2019. [Google Scholar]

- Movahednia, M.; Mirhosseini, S.M.; Zeighami, E. Numerical Evaluation of the Behavior of Steel Frames with Gypsum Board Infill Walls. Adv. Civil Eng. 2019, 2019, 6846139. [Google Scholar] [CrossRef]

- AISI. North American Standard for Cold-Formed Steel Framing-Wall Stud Design; American Iron and Steel Institute: Washington, DC, USA, 2012. [Google Scholar]

- ASCE. Seismic Evaluation and Retrofit of Existing Buildings: ASCE/SEI 41-17; American Society of Civil Engineers: Reston, VI, USA, 2017. [Google Scholar]

- Carr, A.J. User’s Manual of Ruaumoko, the Maori God of Volcanoes and Earthquakes; Department of Civil Engineering, University of Canterbury: Christchurch, New Zealand, 2009. [Google Scholar]

- FEMA. Interim Protocols for Determining Seismic Performance Characteristics of Structural and Nonstructural Components Through Laboratory Testing; Applied Technology Council: Redwood City, CA, USA, 2006. [Google Scholar]

- Ye, J.; Feng, R.; Chen, W.; Liu, W. Behavior of cold-formed steel wall stud with sheathing subjected to compression. J. Constr. Steel Res. 2016, 116, 79–91. [Google Scholar] [CrossRef]

- Pali, T.; Macillo, V.; Terracciano, M.T.; Bucciero, B.; Fiorino, L.; Landolfo, R. In-plane quasi-static cyclic tests of nonstructural lightweight steel drywall partitions for seismic performance evaluation. Earthq. Eng. Struct. Dyn. 2018, 47, 1566–1588. [Google Scholar] [CrossRef]

- Fiorino, L.; Bucciero, B.; Landolfo, R. Evaluation of seismic dynamic behaviour of drywall partitions, facades and ceilings through shake table testing. Eng. Struct. 2019, 180, 103–123. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, D.-H.; Kim, H.-J. Macro-Modelling Approach for the In-Plane Cyclic Response of Cold-Formed Steel Partition Walls. Appl. Sci. 2020, 10, 8163. https://doi.org/10.3390/app10228163

Shin D-H, Kim H-J. Macro-Modelling Approach for the In-Plane Cyclic Response of Cold-Formed Steel Partition Walls. Applied Sciences. 2020; 10(22):8163. https://doi.org/10.3390/app10228163

Chicago/Turabian StyleShin, Dong-Hyeon, and Hyung-Joon Kim. 2020. "Macro-Modelling Approach for the In-Plane Cyclic Response of Cold-Formed Steel Partition Walls" Applied Sciences 10, no. 22: 8163. https://doi.org/10.3390/app10228163

APA StyleShin, D.-H., & Kim, H.-J. (2020). Macro-Modelling Approach for the In-Plane Cyclic Response of Cold-Formed Steel Partition Walls. Applied Sciences, 10(22), 8163. https://doi.org/10.3390/app10228163