Effect of the Addition of Petrochemicals onto the Atomization and Ignition of the Coal-Water Slurry Prepared from the Wastes

Abstract

:1. Introduction

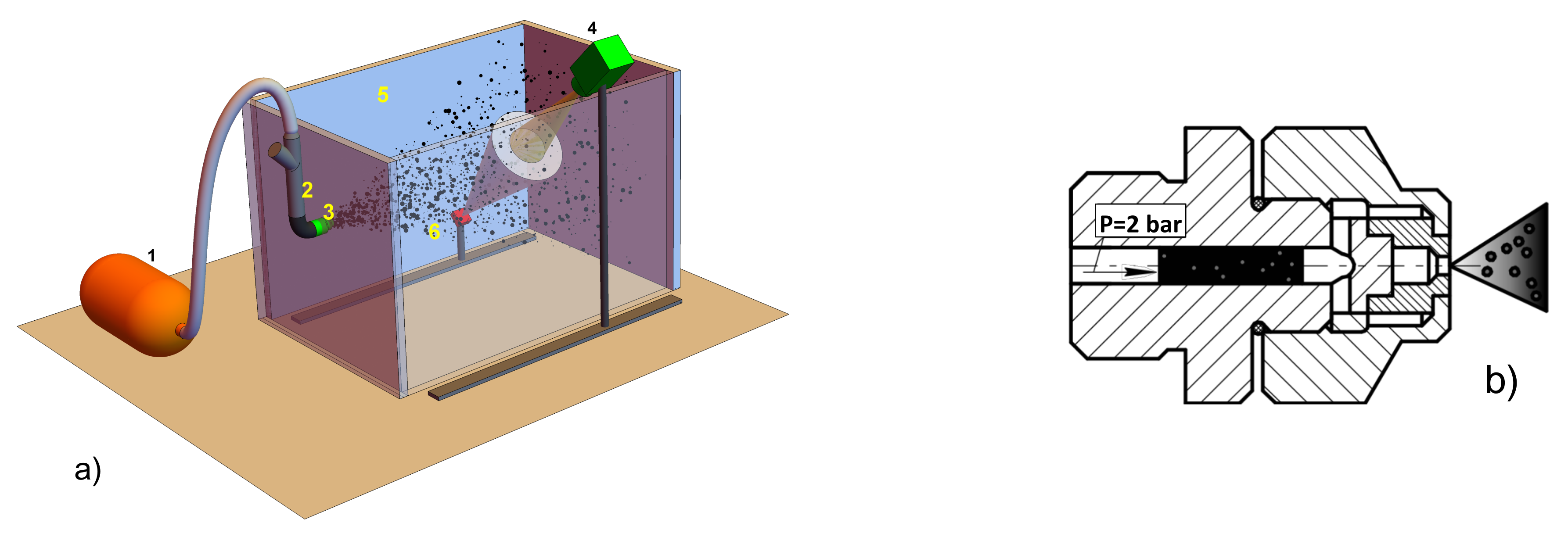

2. Materials and Methods

- The coal-water slurry (CWS) consisting of the filter cake of the low-caking coal from the South-East Siberian region and water (40 wt.%);

- The coal-water slurry consisting of the same filter cake and water (30 wt.%) with addition of the 10 wt.% of waste motor oil (CWSP).

3. Results and Discussion

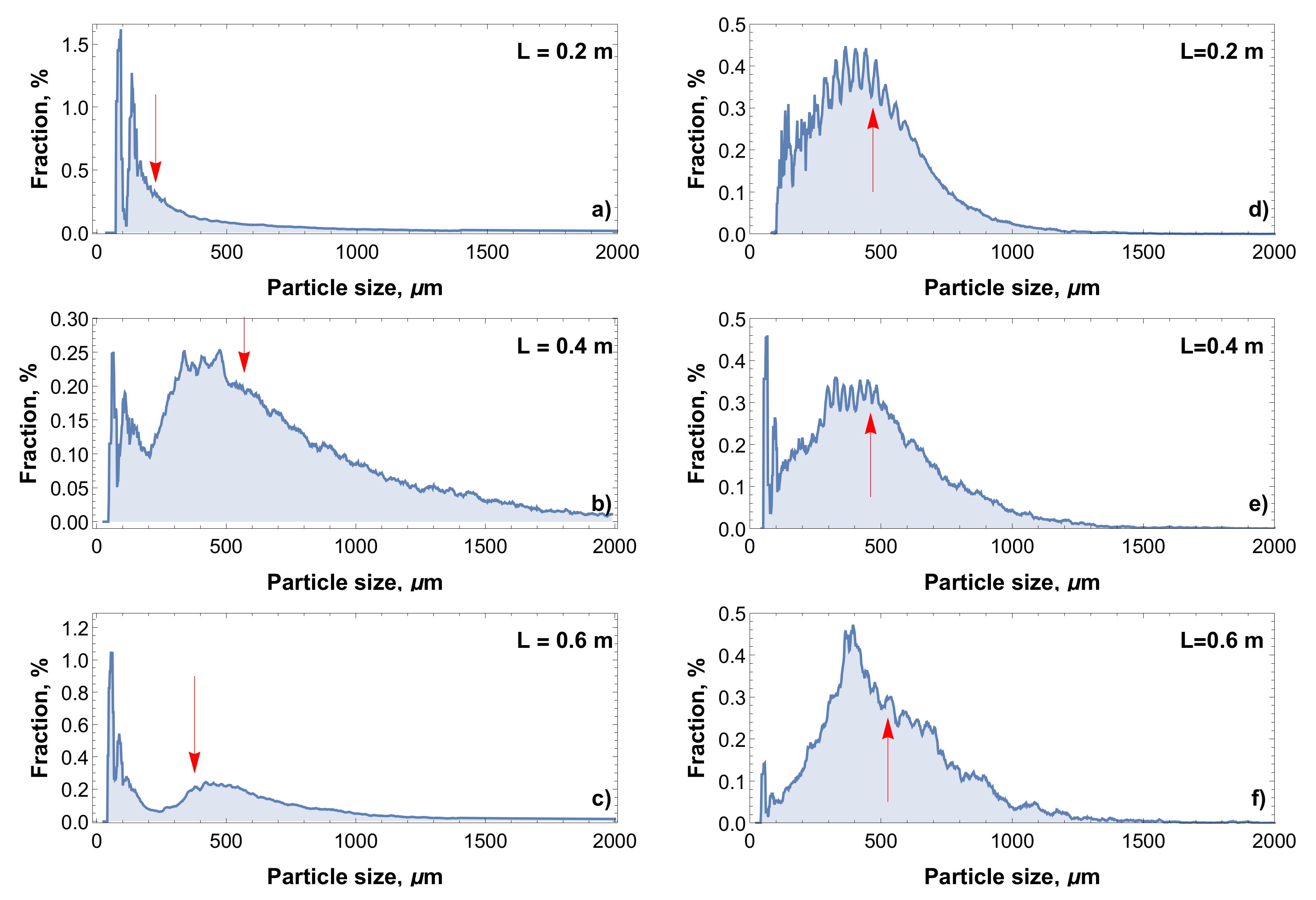

3.1. Size Distribution of the Fuel Aerosol

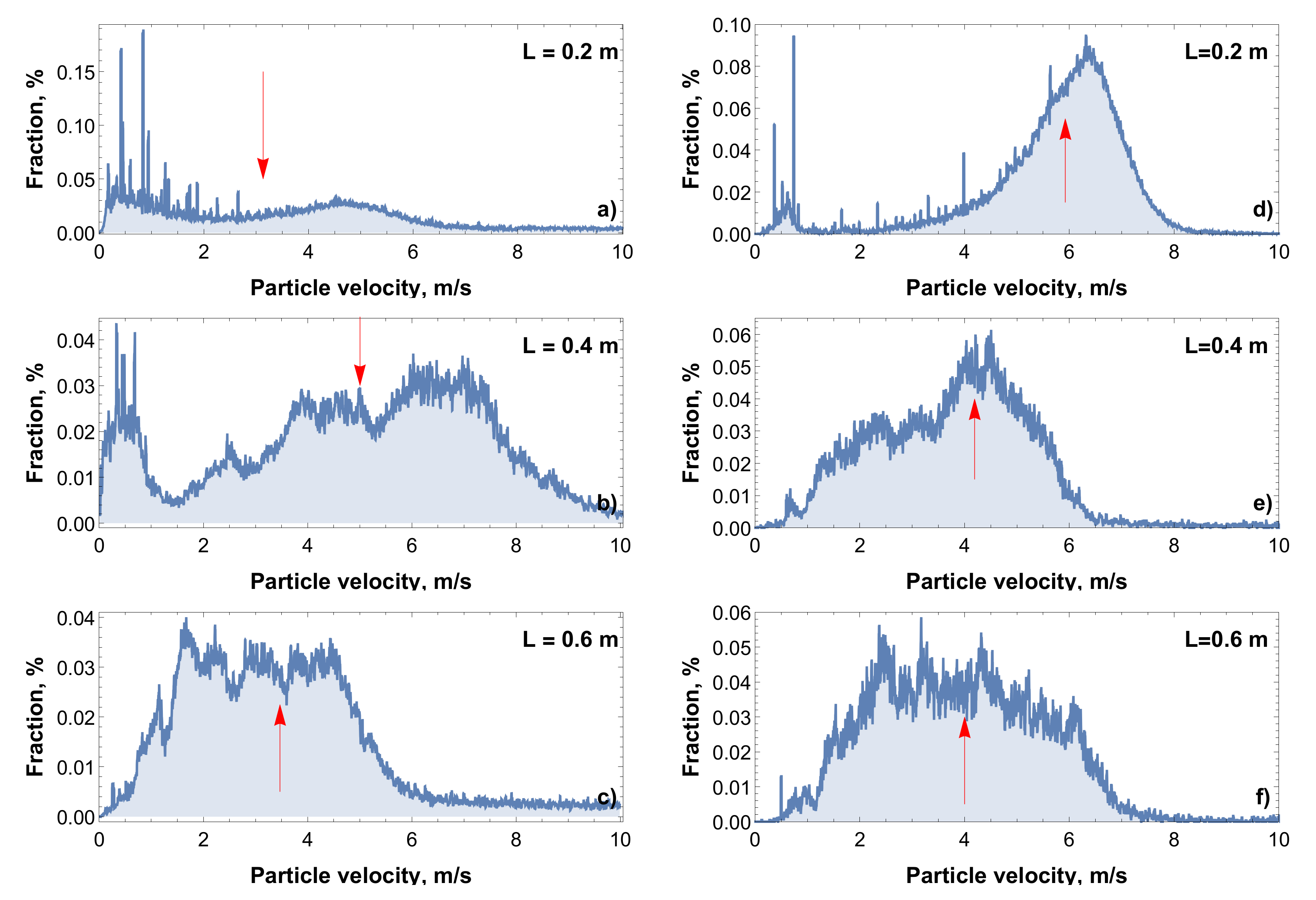

3.2. Velocity Distribution of the Fuel Aerosol

3.3. Effect of the Petrochemicals on the Slurry Atomization

4. Ignition and Combustion of the Aerosol Particles

4.1. Effect of Petrochemicals on the Ignition Delay Time

4.2. Temperature Dynamics of Aerosol Particles

5. Conclusions

- -

- it introduce much more uniform size and velocity distribution of fuel aerosol during the first meter of its propagation when main changes of parameters of aerosol occurs. The used nozzle produces in average 0.5 mm droplets that keep size very stable;

- -

- petrochemicals allows up to 27% faster ignition of the CWSP aerosol particles relatively to CWS particles of the same size;

- -

- the peak temperature of combustion of the CWSP aerosol is 3–5% higher than for similar droplets of CWS.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CWS | Coal-water slurry |

| CWSP | Coal-water slurry with petrochemicals |

| IDT | Ignition Delay Time |

| PAG | Polyalkylene glycol |

| PTV | Particle Tracking Velocimetry |

References

- BP Statistical Review of World Energy, 68th ed. 2019. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2019-full-report.pdf (accessed on 27 November 2020).

- Barati, M.; Esfahani, S.; Utigard, T.A. Energy recovery from high temperature slags. Energy 2011, 36, 5440–5449. [Google Scholar] [CrossRef]

- Kijo-Kleczkowska, A. Combustion of coal-water suspensions. Fuel 2011, 90, 865–877. [Google Scholar] [CrossRef]

- Essenhigh, R.H.; Misra, M.K.; Shaw, D.W. Ignition of coal particles: A review. Combust. Flame 1989, 77, 3–30. [Google Scholar] [CrossRef]

- Bogomolov, A.; Valiullin, T.; Vershinina, K.; Shevyrev, S.; Shlegel, N. Igniting Soaring Droplets of Promising Fuel Slurries. Energies 2019, 12, 208. [Google Scholar] [CrossRef] [Green Version]

- Zhu, M.; Zhang, Z.; Zhang, Y.; Liu, P.; Zhang, D. An experimental investigation into the ignition and combustion characteristics of single droplets of biochar water slurry fuels in air. Appl. Energy 2017, 185, 2160–2167. [Google Scholar] [CrossRef]

- Valiullin, T.R.; Vershinina, K.Y.; Glushkov, D.O.; Shevyrev, S.A. Droplet ignition of coal-water slurries prepared from typical coal- and oil-processing wastes. Coke Chem. 2017, 60, 211–218. [Google Scholar] [CrossRef]

- Nyashina, G.S.; Strizhak, P.A. The influence of liquid plant additives on the anthropogenic gas emissions from the combustion of coal-water slurries. Environ. Pollut. 2018, 242, 31–41. [Google Scholar] [CrossRef]

- Wilczyńska-Michalik, W.; Moryl, R.; Sobczyk, J.; Michalik, M. Composition of coal combustion by-products: The importance of combustion technology. Fuel Process. Technol. 2014, 124, 35–43. [Google Scholar] [CrossRef]

- Chernetskiy, M.; Vershinina, K.; Strizhak, P. Computational modeling of the combustion of coal water slurries containing petrochemicals. Fuel 2018, 220, 109–119. [Google Scholar] [CrossRef]

- Yuri, B.Z. Non-Equilibrium Evaporation and Condensation Processes: Analytical Solutions; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Mukherjee, A.; Pisupati, S.V. Effect of additives on interfacial interactions for viscosity reduction of carbonaceous solid-water slurries. Fuel 2016, 180, 50–58. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, H.-F.; Xu, J.-L.; Li, W.-F.; Cheng, W. Breakup and atomization of a round coal water slurry jet by an annular air jet. Chem. Eng. Sci. 2012, 78, 63–74. [Google Scholar] [CrossRef]

- Katrinak, K.A.; Rez, P.; Buseck, P.R. Structural variations in individual carbonaceous particles from an urban aerosol. Environ. Sci. Technol. 1992, 26, 1967–1976. [Google Scholar] [CrossRef]

- Zhang, Q.; Gong, Y.; Guo, Q.; Xue, Z.; Wang, F.; Yu, G. Experimental study of particle evolution characteristics in an opposed multi-burner gasifier. Chem. Eng. Sci. 2017, 162, 104–119. [Google Scholar] [CrossRef]

- Egorov, R.I.; Tkachenko, P.P.; Taburchinov, R.I.; Chulkov, A.O. The propagation and ignition of the finely dispersed coal-water aerosol. Fuel 2020, 263, 116767. [Google Scholar] [CrossRef]

- Andreussi, P.; Tognotti, L.; Graziadio, M.; de Michele, G. Atomization of coal-water fuels by a pneumatic nozzle: Characteristics of the spray. Aerosol Sci. Technol. 1990, 13, 35–46. [Google Scholar] [CrossRef] [Green Version]

- Piskunov, M.V.; Strizhak, P.A.; Shcherbinina, A.A. Intensive evaporation and boiling of a heterogeneous liquid droplet with an explosive disintegration in high-temperature gas area. Therm. Sci. 2016, 20, 541–553. [Google Scholar] [CrossRef]

- Xi, X.; Liu, H.; Cai, C.; Jia, M.; Ma, X. Analytical and experimental study on boiling vaporization and multi-mode breakup of binary fuel droplet. Int. J. Heat Mass Transf. 2021, 165, 120620. [Google Scholar] [CrossRef]

- Antonov, D.V.; Piskunov, M.V.; Strizhak, P.A. Explosive disintegration of two-component drops under intense conductive, convective, and radiant heating. Appl. Therm. Eng. 2019, 152, 409–419. [Google Scholar] [CrossRef]

- Fostiropoulos, S.; Strotos, G.; Nikolopoulos, N.; Gavaises, M. Numerical investigation of heavy fuel oil droplet breakup enhancement with water emulsions. Fuel 2020, 278, 118381. [Google Scholar] [CrossRef]

- Daviault, S.G.; Ramadan, O.B.; Matida, E.A.; Hughes, P.M.; Hughes, R. Atomization performance of petroleum coke and coal water slurries from a twin fluid atomizer. Fuel 2012, 98, 183–193. [Google Scholar] [CrossRef]

- Kim, H.; Kim, C.; Lim, H.; Song, J. Spray formation of a liquid carbon dioxide-water mixture at elevated pressures. Energies 2016, 9, 948. [Google Scholar] [CrossRef] [Green Version]

- Glushkov, D.O.; Syrodoy, S.V.; Zakharevich, A.V.; Strizhak, P.A. Ignition of promising coal-water slurry containing petrochemicals: Analysis ofkey aspects. Fuel Proc. Technol. 2016, 148, 224–235. [Google Scholar] [CrossRef]

- Egorov, R.I.; Antonov, D.V.; Valiullin, T.R.; Strizhak, P.A. The ignition dynamics of the water-filled fuel compositions. Fuel Proc. Technol. 2018, 174, 26–32. [Google Scholar] [CrossRef]

- Sullivan, M.V.; Wolfe, J.K.; Zisman, W.A. Flammability of the Higher Boiling Liquids and Their Mists. Ind. Eng. Chem. 1947, 39, 1607–1614. [Google Scholar] [CrossRef]

- Kovanda, K.P.; Latunski, M. Polyalkylene Glycol Hydraulic Fluids, 20 Years of Fire Resistance. In Fire Resistant Fluids; Sherman, J., Ed.; ASTM International: West Conshohocken, PA, USA, 2014; pp. 143–154. [Google Scholar]

- Ohmi, K.; Li, H.-Y. Particle-tracking velocimetry with new algorithms. Meas. Sci. Technol. 2000, 11, 603–616. [Google Scholar] [CrossRef]

- Feng, Y.; Goree, J.; Liu, B. Accurate particle position measurement from images. Rev. Sci. Instrum. 2007, 78, 053704. [Google Scholar] [CrossRef] [Green Version]

- Ortiz, M.; Gonzales, N.; Guzman, C.; Paiva, E.; Bello, E. Thermal Conductivity of Mixtures. Therm. Conduct. 1985, 18, 213–223. [Google Scholar]

- Sazhin, S.S. Advanced Models of Fuel Droplet Heating and Evaporation. Progr. Energy Comb. Sci. 2006, 32, 162–214. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taburchinov, R.I.; Belonogov, M.V.; Egorov, R.I. Effect of the Addition of Petrochemicals onto the Atomization and Ignition of the Coal-Water Slurry Prepared from the Wastes. Appl. Sci. 2020, 10, 8574. https://doi.org/10.3390/app10238574

Taburchinov RI, Belonogov MV, Egorov RI. Effect of the Addition of Petrochemicals onto the Atomization and Ignition of the Coal-Water Slurry Prepared from the Wastes. Applied Sciences. 2020; 10(23):8574. https://doi.org/10.3390/app10238574

Chicago/Turabian StyleTaburchinov, Roman I., Maxim V. Belonogov, and Roman I. Egorov. 2020. "Effect of the Addition of Petrochemicals onto the Atomization and Ignition of the Coal-Water Slurry Prepared from the Wastes" Applied Sciences 10, no. 23: 8574. https://doi.org/10.3390/app10238574