Pollutant Emissions and Combustion Efficiency Assessment of Engines Using Biodiesel

Abstract

1. Introduction

- ○

- Sulfur dioxide (SO2) is a colorless gas that is mainly produced during the burning of fossil fuels containing sulfur. According to the 2014 emissions inventory [10], a high concentration of this contaminant can damage the lungs and generate infections, especially if it is in amounts greater than 1.5 ppm, and it may present with bronchial constriction and respiratory infections [11].

- ○

- In addition, nitrogen oxides (NOx) are generated in combustion processes by the reaction between atmospheric nitrogen and oxygen. The term nitrogen oxides generally refers to the sum of the concentrations of nitric oxide (NO) and either nitrogen dioxide or nitrous oxide (NO2) [12].

- ○

- Carbon monoxide (CO) is a tasteless, colorless, and odorless gas. In the atmosphere, it plays a minor role as a greenhouse gas because of its ability to absorb small amounts of infrared energy radiation [12].

- ○

- Finally, hydrocarbons (HC) means the collective concept of almost all chemical compounds of carbon and hydrogen. HC emissions are attributed to incomplete combustion of the air and fuel mixture due to a lack of oxygen. Partially oxidized hydrocarbons (e.g., aldehydes, ketones) smell unpleasant and form secondary products that, with the lasting action of specific concentrations, are also considered carcinogens [13].

2. Materials and Methods

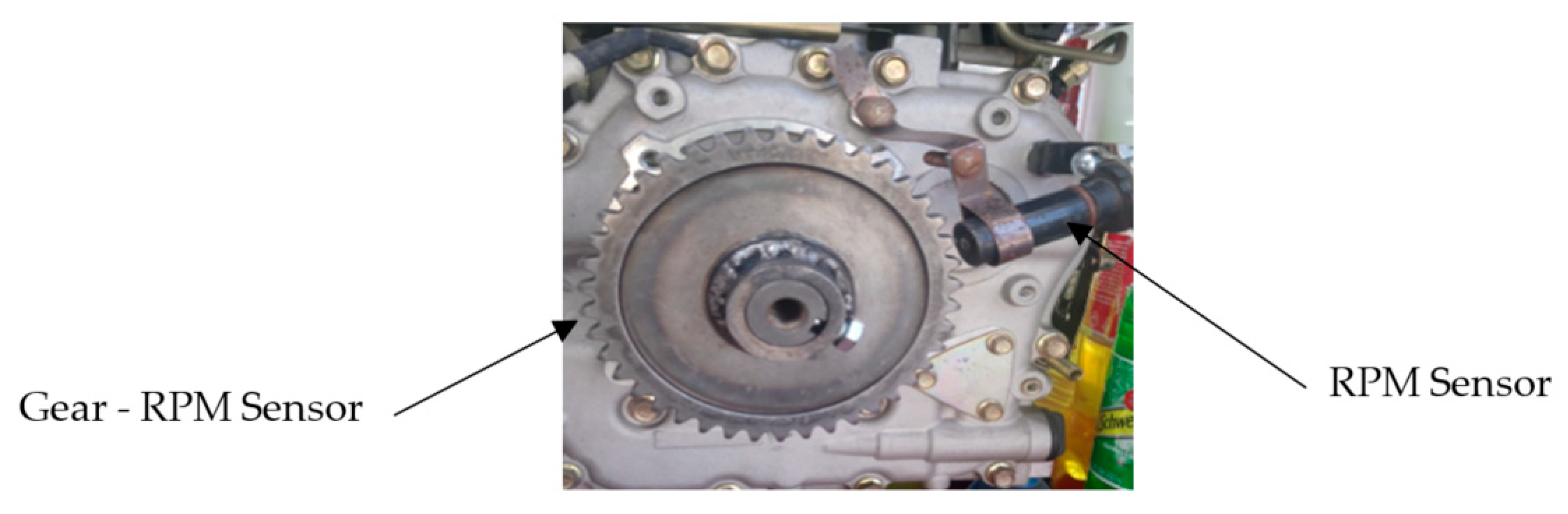

2.1. Equipment and Materials for Experimental Tests on a Low-Power Monocylinder Four-Stroke Engine

- Four-stroke low-power monocylindrical engine

- Electronic circuit

- Exhaust gas analyzer

2.2. Experimental Methodology Low-Power Monocylinder

- The mixtures B0, B10, B20, B30, B40, and B50 were produced to obtain greater accuracy.

- The mixture was poured into the diesel engine fuel tank.

- The engine was preheated with the corresponding blend, lasting 5 min, then, the regulation of fuel injection pressure and operating temperature were measured.

- The engine revolutions were adjusted at 2000 rpm (at this point, the maximum power and torque were obtained according to the engine’s peak performance).

- The gas probe was placed for 5 min in the exhaust pipe according to the manufacturer’s specifications, after which the ECA 450 equipment automatically gave the data.

- The experimental tests were performed with 5 min lapses in each measurement; then, measurements were made for each percentage of blending.

- At the end of each test, the fuel tank was purged to leave it clean for subsequent tests, and the amount of remaining blend was stored in containers.

2.3. Equipment and Materials for Experimental Tests in Electric Generator

- (A)

- Three-phase generator, with 30 kW Nominal/Closed/Manual Start. The technical characteristics are shown in Table 3 below.

- (B)

- Technical data of the exhaust gas analyzer: the BACHARACH® PCA 400 is an industrial-grade handheld emission and combustion analyzer. This analyzer measures combustion efficiency (%Eff), carbon monoxide (CO), and nitrogen oxide (NO), among others.

- (C)

- Fluke® 434 B multiphases (electrical network analyzer) is the perfect tool for advanced energy registration and monetization; identifying the areas of most significant energy waste of facilities, this analyzer measures voltage, current, frequency, harmonics, voltage fluctuations, and electrical power, among others.

2.4. Methodology for Experimental Tests in Electric Generator

2.5. Methodology for Combustion Product Volume Analysis

2.6. Methodology for Experimental Thermography Tests

- Blends preparation. Two types of blends were prepared: B5 and B10.

- Biodiesel load to the engine. One liter of fuel was entered into the engine tank for each blend (B5 and B10).

- Tank securing and engine starting. Once the necessary amount of fuel had been deposited, the tank was secured (hermetic seal) and the engine was started. A time of five minutes (warm-up period) was allocated to reach the operating temperature.

- Taking temperatures. During the period of operation, for five uninterrupted minutes and with an average opening of air intake, temperatures were taken with the Fluke ® thermal imager on all the engine profiles.

- Draining the fuel. After taking temperatures, the engine was switched off. The residual fuel was drained from the engine tank and stored in a beaker to verify the amount consumed. This process was repeated for each blend.

3. Results and Discussion

3.1. Characteristics of Biodiesel

3.2. Experimental Test Results with the Monocylindrical Engine

3.3. Experimental Test Results with Electric Generator

3.4. Results of Combustion Product Volume Analysis

3.5. Results of Experimental Thermography Tests

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bel, G.; Holst, M. Evaluation of the impact of Bus Rapid Transit on air pollution in Mexico City. Transp. Policy 2018, 63, 209–220. [Google Scholar] [CrossRef]

- World Bank. The World Bank Group. The Climate Change Knowledge Portal (CCKP). 2019. Available online: https://climateknowledgeportal.worldbank.org/country/mexico (accessed on 8 May 2020).

- Instituto Mexicano para la Competitividad. IMCO. Recuperado el 09 de Febrero de 2019. 2016. Available online: http://imco.org.mx/medio_ambiente/base-de-datos-global-urbana-de-la-contaminacion-del-aire-2016-via-oms/ (accessed on 17 July 2020).

- Jiang, X.Q.; Mei, X.D.; Feng, D. Air pollution and chronic airway diseases: What should 589 people know and do? J. Thorac. Dis. 2016, 8, E31–E40. [Google Scholar] [CrossRef] [PubMed]

- Hurtado Díaz, M. Instituto Nacional de Salud Pública. Recuperado el 10 de Febrero del 2019. febrero de 2015. Available online: http://www.inegi.org.mx/eventos/2015/Poblacion/doc/p-MagaliHurtado.pdf (accessed on 25 January 2020).

- Adaileh, W.M.; AlQdah, K.S. Performance of Diesel Engine Fuelled by a Biodiesel Extracted From A Waste Cocking Oil. Energy Procedia 2012, 18, 1317–1334. [Google Scholar] [CrossRef]

- Ganduglia, F. Manual de Biocombustibles. Instituto Interamericano de Cooperación para la Agricultura (IICA), ARPEL ICA-2009. ISBN13: 978-92-9248-121-6. 2009. Available online: http://repiica.iica.int/docs/B2223e/B2223e.pdf (accessed on 30 November 2020).

- Nayak, S.K.; Pattanaik, B.P. Experimental Investigation on Performance and Emission Characteristics of a Diesel Engine Fuelled with Mahua Biodiesel Using Additive. Energy Procedia 2014, 54, 569–579. [Google Scholar] [CrossRef]

- Wood, B.M.; Kirwan, K.; Maggs, S.; Meredith, J.; Coles, S.R. Study of combustion performance of biodiesel for potential application in motorsport. J. Clean. Prod. 2015, 93, 167–173. [Google Scholar] [CrossRef]

- Secretaría del Medio Ambiente de la Ciudad de México (SEDEMA). Calidad del aire en la Ciudad de México, informe 2016. Available online: http://www.aire.cdmx.gob.mx/descargas/publicaciones/flippingbook/informe-2016-calidad-del-aire-en-la-ciudad-de-mexico/mobile/informe_anual_calidad_aire_2016.pdf (accessed on 25 January 2020).

- Jacobson, M.Z.; Hoeve, J.E.T. Effects of Urban Surfaces and White Roofs on Global and Regional Climate. J. Clim. 2012, 25, 1028–1044. [Google Scholar] [CrossRef]

- Secretaría del Medio Ambiente de la Ciudad de México (SEDEMA). Calidad del aire en la Ciudad de México, informe 2015, Ciudad de Mèxico, Mèxico. Available online: http://www.aire.cdmx.gob.mx/descargas/publicaciones/flippingbook/informe_anual_calidad_aire_2015v3/files/downloads/Informe2015v3.pdf (accessed on 25 January 2020).

- Robert Bosch GmbH. Técnica de Gases de Escape para Motores de Gasolina; Bosch: Sttutgart, Germany, 2003. [Google Scholar]

- Mo, J.; Tang, C.; Li, J.; Guan, L.; Huang, Z. Experimental investigation on the effect of n-butanol blending on spray characteristics of soybean biodiesel in a common-rail fuel injection system. Fuel 2016, 182, 391–401. [Google Scholar] [CrossRef]

- Boudy, F.; Seers, P. Impact of physical properties of biodiesel on the injection process in a common-rail direct injection system. Energy Convers. Manag. 2009, 50, 2905–2912. [Google Scholar] [CrossRef]

- Kegl, B. Numerical analysis of injection characteristics using biodiesel fuel. Fuel 2006, 85, 2377–2387. [Google Scholar] [CrossRef]

- Yu, S.; Yin, B.; Jia, H.; Wen, S.; Li, X.; Yu, J. Theorical and experimental comparison of internal flow and spray characteristivs between diesel and biodieseil. Fuel 2017, 208, 20–29. [Google Scholar] [CrossRef]

- Shuai, S.; Abani, N.; Yoshikawa, T.; Reitz, R.D.; Park, S.W. Evaluation of the effects of injection timing and rate-shape on diesel low temperature combustion using advanced CFD modeling. Fuel 2009, 88, 1235–1244. [Google Scholar] [CrossRef]

- Ashok, B.; Lalvani, J.I.J.; Parthasarathy, M.; Annamalai, K. An assessment on performance, emission and combustion characteristics of single cylinder diesel engine powered by Cymbopogon flexuosus biofuel. Energy Convers. Manag. 2016, 117, 466–474. [Google Scholar] [CrossRef]

- Javed, S.; Baig, R.U.; Murthy, Y.V.V.S. Study on noise in a hydrogen dual-fulled zin- oxide nanopartice blended biodiesel engine and the development of an artificial neural network model. Energy 2018, 160, 774–782. [Google Scholar] [CrossRef]

- Guo, J.; Peltier, E.; Carter, R.E.; Krejci, A.J.; Stagg-Williams, S.M.; Depcik, C.D. Waste Cooking Oil Biodiesel Use in Two Off-Road Diesel Engines. ISRN Renew. Energy 2012, 2012, 1–10. [Google Scholar] [CrossRef]

- Karavalakis, G.; Tzirakis, E.; Mattheou, L.; Stournas, S.; Zannikos, F.; Karonis, D. The impact of using biodiesel/marine gas oil blends on exhaust emissions from a stationary diesel engine. J. Environ. Sci. Health Part A 2008, 43, 1663–1672. [Google Scholar] [CrossRef] [PubMed]

- Rosa, H.A.; Wazilewski, W.T.; Secco, D.; Chaves, L.I.; Veloso, G.; De Souza, S.N.M.; Da Silva, M.J.; Santos, R.F. Biodiesel produced from crambe oil in Brazil—A study of performance and emissions in a diesel cycle engine generator. Renew. Sustain. Energy Rev. 2014, 38, 651–655. [Google Scholar] [CrossRef]

- Valente, O.S.; Da Silva, M.J.; Pasa, V.M.; Belchior, C.R.P.; Sodré, J.R. Fuel consumption and emissions from a diesel power generator fuelled with castor oil and soybean biodiesel. Fuel 2010, 89, 3637–3642. [Google Scholar] [CrossRef]

- Lee, W.-J.; Liu, Y.-C.; Mwangi, F.K.; Chen, W.-H.; Lin, S.-L.; Fukushima, Y.; Liao, C.-N.; Wang, L.-C. Assessment of energy performance and air pollutant emissions in a diesel engine generator fueled with water-containing ethanol–biodiesel–diesel blend of fuels. Energy 2011, 36, 5591–5599. [Google Scholar] [CrossRef]

- Bayındır, H.; Işık, M.Z.; Argunhan, Z.; Yücel, H.L.; Aydın, H. Combustion, performance and emissions of a diesel power generator fueled with biodiesel-kerosene and biodiesel-kerosene-diesel blends. Energy 2017, 123, 241–251. [Google Scholar] [CrossRef]

- Santos, T.B.; Ferreira, V.P.; Torres, E.A.; M da Silva, J.; Ordoñez, J.C. Energy Analysis and Exhaust Emissions of a Stationary Engine Fueled with Diesel–Biodiesel Blends at Variable Loads; Springer: Berlin/Heidelberg, Germany, 2017; pp. 3237–3247. [Google Scholar]

- Domínguez, M.M.; De Antonio, A.J.R. Máquinas Térmicas; Editorial UNED: Madrid, Spain, 2014; pp. 35, 122–127. [Google Scholar]

- Prasad, R.; Bella, V. A Review on Diesel Soot Emission, its Effect and Control. Bull. Chem. React. Eng. Catal. 2011, 5, 69–86. [Google Scholar] [CrossRef]

- José, C.P.M.; Rosa, G.A.M.; Mariano, M.M.; Jesús, S.H. Química Aplicada a la Ingenieria; Editorial UNED: Madrid, Spain, 2015; pp. 561–562. [Google Scholar]

- Jarquin-López, G.; Polupan, G.; Sanchez-Flores, A.; Sanchez-Rivera, A.; Vasquez-Benitez, B. Cálculo de las Características Termodinámicas de los Productos de la Combustión del Gas Natural y del Combustóleo. In Proceedings of the Sexto Congreso Nacional de Ingeniería Electromecánica y de Sistemas, Ciudad de México, Mexico, 12–16 November 2001; pp. 308–313. [Google Scholar]

- Atabani, A.E.; Silitonga, A.; Badruddin, I.A.; Mahlia, T.; Masjuki, H.; Mekhilef, S. A comprehensive review on biodiesel as an alternative energy resource and its characteristics. Renew. Sustain. Energy Rev. 2012, 16, 2070–2093. [Google Scholar] [CrossRef]

- Aldhaidhawi, M.; Chiriac, R.; Badescu, V. Ignition delay, combustion and emission characteristics of Diesel engine fueled with rapeseed biodiesel—A literature review. Renew. Sustain. Energy Rev. 2017, 73, 178–186. [Google Scholar] [CrossRef]

- Can, Ö. Combustion characteristics, performance and exhaust emissions of a diesel engine fueled with a waste cooking oil biodiesel mixture. Energy Convers. Manag. 2014, 87, 676–686. [Google Scholar] [CrossRef]

- El-Seesy, A.I.; Abdel-Rahman, A.K.; Bady, M.; Ookawara, S. Performance, combustion, and emission characteristics of a diesel engine fueled by biodiesel-diesel mixtures with multi-walled carbon nanotubes additives. Energy Convers. Manag. 2017, 135, 373–393. [Google Scholar] [CrossRef]

- Miller, B.G. Clean Coal Engineering Technology; Chapter 7—Clean Coal Technologies for advanced Power Generation; Elsevier: Amsterdam, The Netherlands, 2011; pp. 251–300. [Google Scholar]

- Can, Ö.; Öztürk, E.; Yücesu, H.S. Combustion and exhaust emissions of canola biodiesel blends in a single cylinder DI diesel engine. Renew. Energy 2017, 109, 73–82. [Google Scholar] [CrossRef]

- Shameer, P.M.; Ramesh, K. Assessment on the consequences of injection timing and injection pressure on combustion characteristics of sustainable biodiesel fuelled engine. Renew. Sustain. Energy Rev. 2018, 81, 45–61. [Google Scholar] [CrossRef]

| Brand | Mpower |

|---|---|

| Model | 186FD |

| Type of motor | Diesel, mono cylinder, Vertical, four strokes |

| Maximum power | 9 HP/3600 RPM |

| Cylinder dimensions | 86 × 70 mm |

| Displacement | 406 mL |

| Compression | 19:1 |

| Maximum torque | 18.7 Nm/2880 RPM |

| Ignition system | Compression |

| Engine start | Electric and manual |

| Oil filter | Semidry type |

| Oil capacity | 1.65 Lt |

| Fuel tank capacity | 5.5 Lt |

| Fuel consumption | 280 g/kWh |

| Dimensions | 525 × 515 × 560 mm |

| Weight | 48.5 kg |

| MOTOR | |

|---|---|

| Engine Brand | Thunder® VANS |

| Engine Power | 67.00 HP |

| Displacement | 4100.00 cc |

| Ignition | Electric 24VCD 5 kW |

| Engine Type | Diesel |

| Engine strokes | 4 |

| Engine RPM | 1800 RPM |

| Fuel Tank Capacity | 150 L |

| Recommended Oil | SAE 15 W/40 (Included) |

| Oil Filter | Included |

| Oil Capacity | 11 L |

| Oil Sensor | Included |

| Maximum Power—Generator: | 33.3 kW |

| Nominal Power—Generator: | 30 kW |

| Voltage | 240/120 VCA |

| Properties | Diesel | Biodiesel |

|---|---|---|

| Norm | ASTM D975 | ASTM PS 121 |

| Kinetic viscosity at 40 °C | 1.3–4.1 | 1.9–6 |

| Specific gravity at 15.55 °C | 0.85 | 0.88 |

| Density (lb/gal) | 7.079 | 7.328 |

| Carbon % | 87 | 77 |

| Hydrógen % | 13 | 12 |

| Oxygen % | 0 | 11 |

| Sulfur % | 0.05 | 0.0024 |

| Flash point (°C) | 60–80 | 100–170 |

| Cetane number | −35 to –15 | −15 to 10 |

| Stoichiometric ratio (air/fuel) | 40–55 | 48–65 |

| Content (%) | B0 | B10 | B20 | B30 | B40 | B50 | B60 | B70 | B80 | B90 | B100 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | 87.00 | 86.00 | 85.00 | 84.00 | 83.00 | 82.00 | 81.00 | 80.00 | 79.00 | 78.00 | 77.00 |

| H | 13.00 | 12.90 | 12.80 | 12.70 | 12.60 | 12.50 | 12.40 | 12.30 | 12.20 | 12.10 | 12.00 |

| S | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| O | 0.00 | 1.10 | 2.20 | 3.30 | 4.40 | 5.50 | 6.60 | 7.70 | 8.80 | 9.90 | 11.00 |

| Total | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Elements | Description |

|---|---|

| IFOV (spatial resolution) with standard lenses | 1.31 mrad, D:S 753:1 |

| Detector resolution | 320 × 240 (76.800 píxels) |

| Super Resolution | Capture and combine quadruple data to create a 640 × 480 (307,200 pixels) image |

| MultiSharp™ approach | It focuses from near and far in the entire field of vision |

| Autofocus LaserSharp® | For uniformly focused images |

| Laser distance measurer | It calculates the distance to the target and offers correctly focused images on the screen, as well as the distances |

| Advanced manual focus | Yes |

| High resistance touch screen | 3.5-inch, 640 × 480 widescreen LCD |

| Rugged, ergonomic design suitable for one-handed use | Yes |

| Digital zoom | 2× and 4× |

| Test | Result | Methodology |

|---|---|---|

| Dynamic Viscosity mpa∙s @ 40 °C | 3.6499 | ASTM D7042 |

| Kinematic Viscosity mm2s @ 40 °C | 4.2063 | ASTM D7042 |

| Density g/cm3 @ 15 °C | 0.8865 | ASTM D4052 |

| Flashpoint °C | 150 | ASTM D93 |

| Acid number mg KOH/g | 0.424 | NMX-F-101-SCFI-2012 |

| Acid number % | 0.213 | NMX-F-101-SCFI-2012 |

| Calorific value MJ/kg | 39.8785 | ASTM D4809 |

| Oxidative stability (h) | 3.66 | ASTM D7525 |

| Cold filtered °C | −4 | ASTM D6371 |

| Combustion Product Volume (m3/kg) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| B0 | B10 | B20 | B30 | B40 | B50 | B60 | B70 | B80 | B90 | B100 | |

| VO | 11.18 | 11.03 | 10.88 | 10.72 | 10.57 | 10.42 | 10.27 | 10.12 | 9.96 | 9.81 | 9.66 |

| VO2 | 2.34 | 2.31 | 2.28 | 2.25 | 2.22 | 2.19 | 2.15 | 2.12 | 2.09 | 2.06 | 2.03 |

| VCO2 | 1.62 | 1.60 | 1.58 | 1.56 | 1.54 | 1.53 | 1.51 | 1.49 | 1.47 | 1.45 | 1.43 |

| VSO2 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| VN2 | 8.83 | 8.71 | 8.59 | 8.47 | 8.35 | 8.23 | 8.11 | 7.99 | 7.87 | 7.75 | 7.63 |

| VH2O | 1.62 | 1.61 | 1.60 | 1.58 | 1.57 | 1.56 | 1.54 | 1.53 | 1.51 | 1.50 | 1.49 |

| VRO2 | 1.62 | 1.60 | 1.58 | 1.56 | 1.54 | 1.53 | 1.51 | 1.49 | 1.47 | 1.45 | 1.43 |

| Blends | Minimum Temperature in Combustion Chamber | Maximum Temperature in Combustion Chamber |

|---|---|---|

| B5 | 174.12 °C | 174.37 °C |

| B10 | 175.35 °C | 175.60 °C |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paredes Rojas, J.C.; Torres San Miguel, C.R.; Vázquez Medina, R.; Leal Naranjo, J.A.; Ortiz Hernàndez, F.E.; Costa Castelló, R. Pollutant Emissions and Combustion Efficiency Assessment of Engines Using Biodiesel. Appl. Sci. 2020, 10, 8646. https://doi.org/10.3390/app10238646

Paredes Rojas JC, Torres San Miguel CR, Vázquez Medina R, Leal Naranjo JA, Ortiz Hernàndez FE, Costa Castelló R. Pollutant Emissions and Combustion Efficiency Assessment of Engines Using Biodiesel. Applied Sciences. 2020; 10(23):8646. https://doi.org/10.3390/app10238646

Chicago/Turabian StyleParedes Rojas, Juan Carlos, Christopher Rene Torres San Miguel, Rubén Vázquez Medina, José Alfredo Leal Naranjo, Fernando Elí Ortiz Hernàndez, and Ramón Costa Castelló. 2020. "Pollutant Emissions and Combustion Efficiency Assessment of Engines Using Biodiesel" Applied Sciences 10, no. 23: 8646. https://doi.org/10.3390/app10238646

APA StyleParedes Rojas, J. C., Torres San Miguel, C. R., Vázquez Medina, R., Leal Naranjo, J. A., Ortiz Hernàndez, F. E., & Costa Castelló, R. (2020). Pollutant Emissions and Combustion Efficiency Assessment of Engines Using Biodiesel. Applied Sciences, 10(23), 8646. https://doi.org/10.3390/app10238646