A Haptic Feedback Actuator Suitable for the Soft Wearable Device

Abstract

:1. Introduction

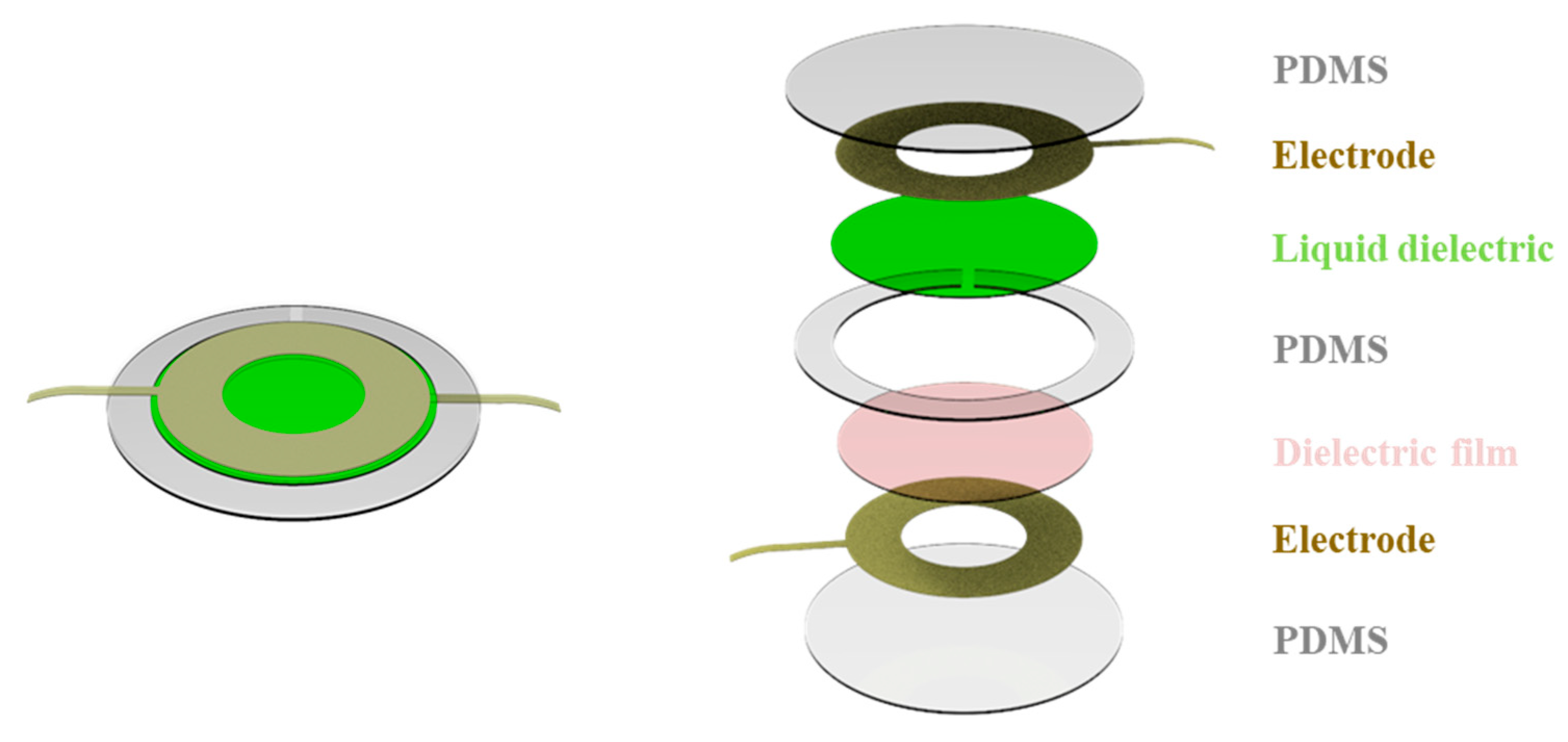

2. Design of Electro-Hydraulic Haptic Feedback Actuator

3. Materials and Methods

3.1. Fabrication

3.2. Test Methods

3.2.1. Output Displacement Measurement

3.2.2. Output Force Measurement

4. Results and Discussion

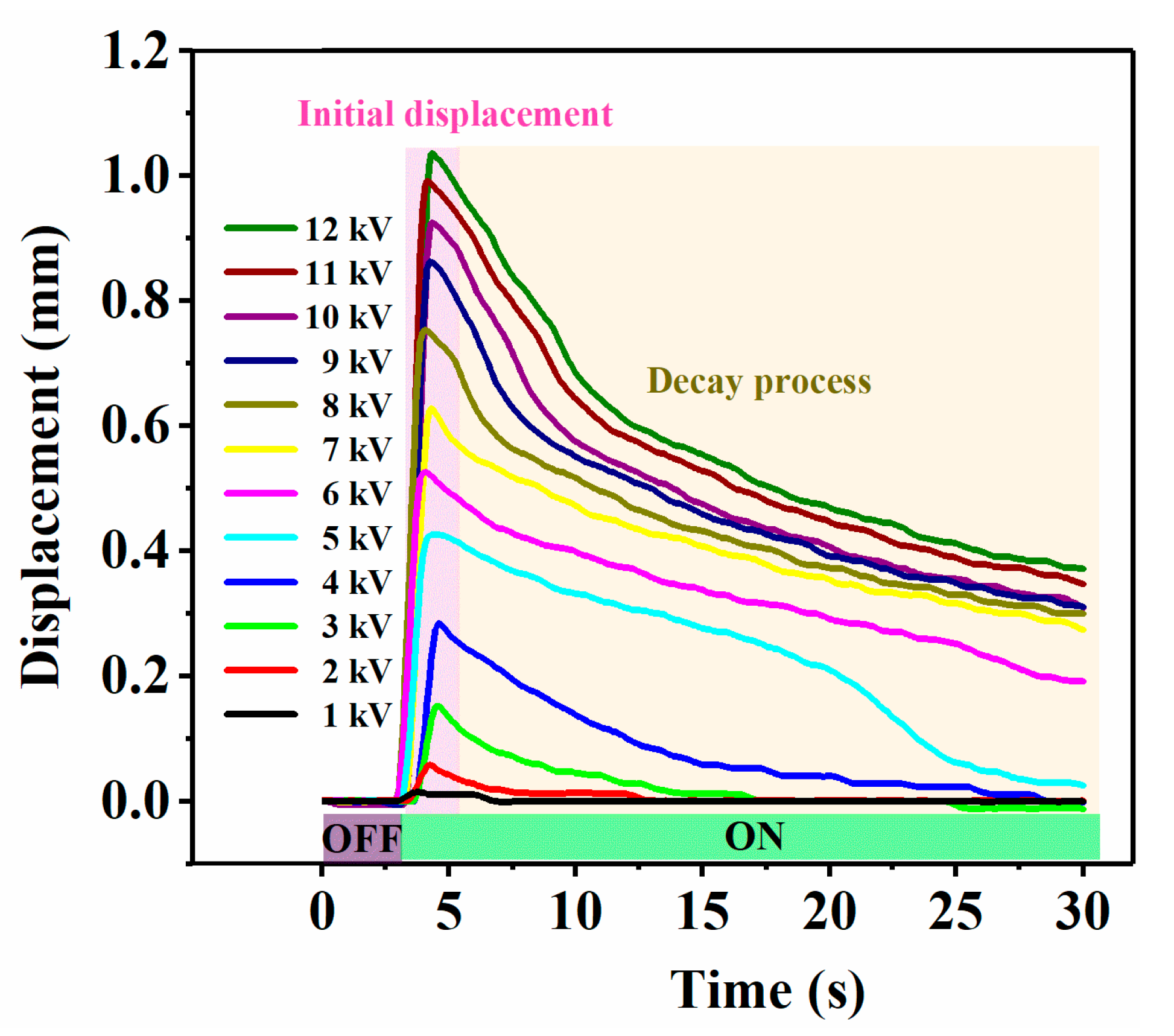

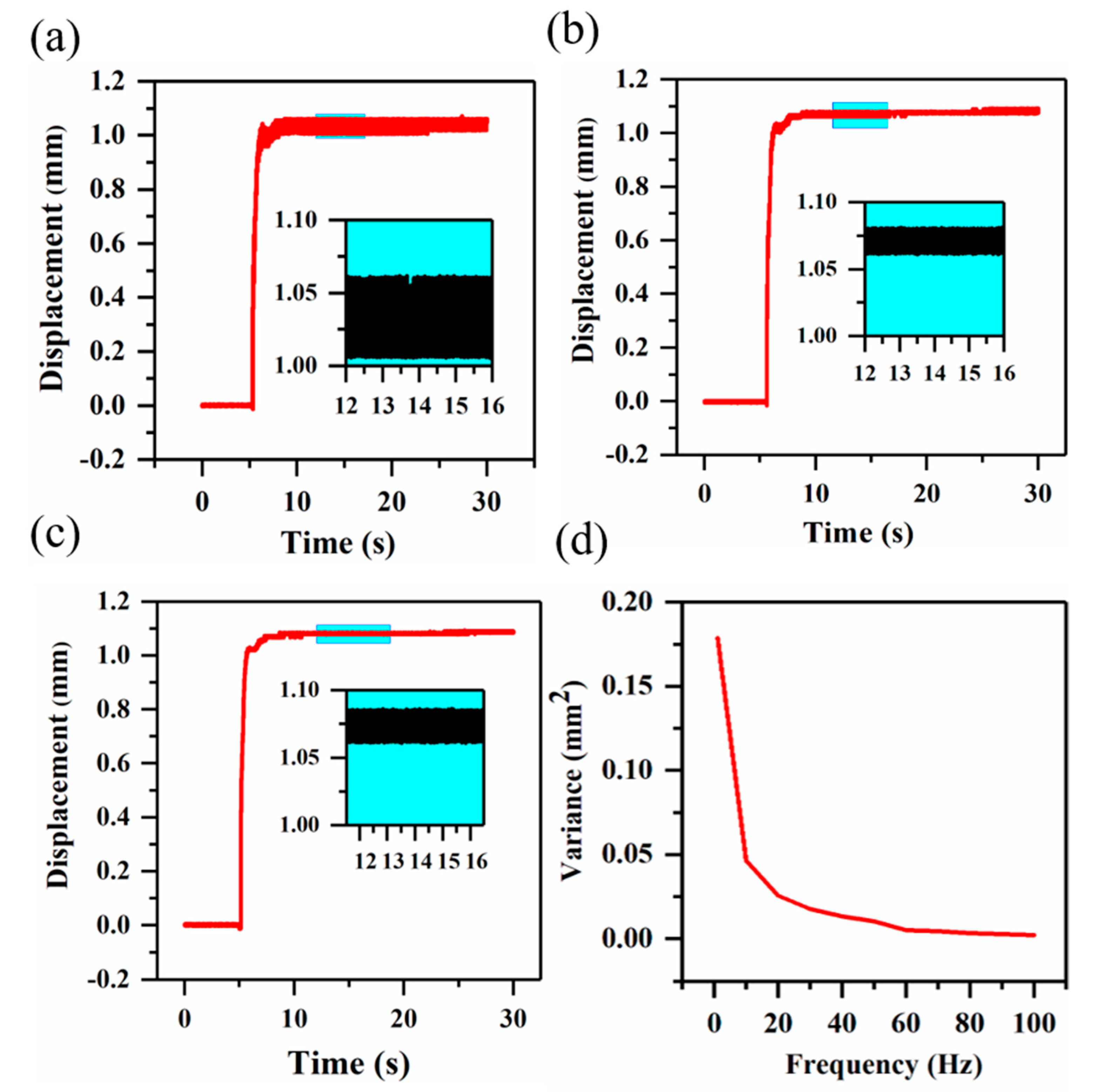

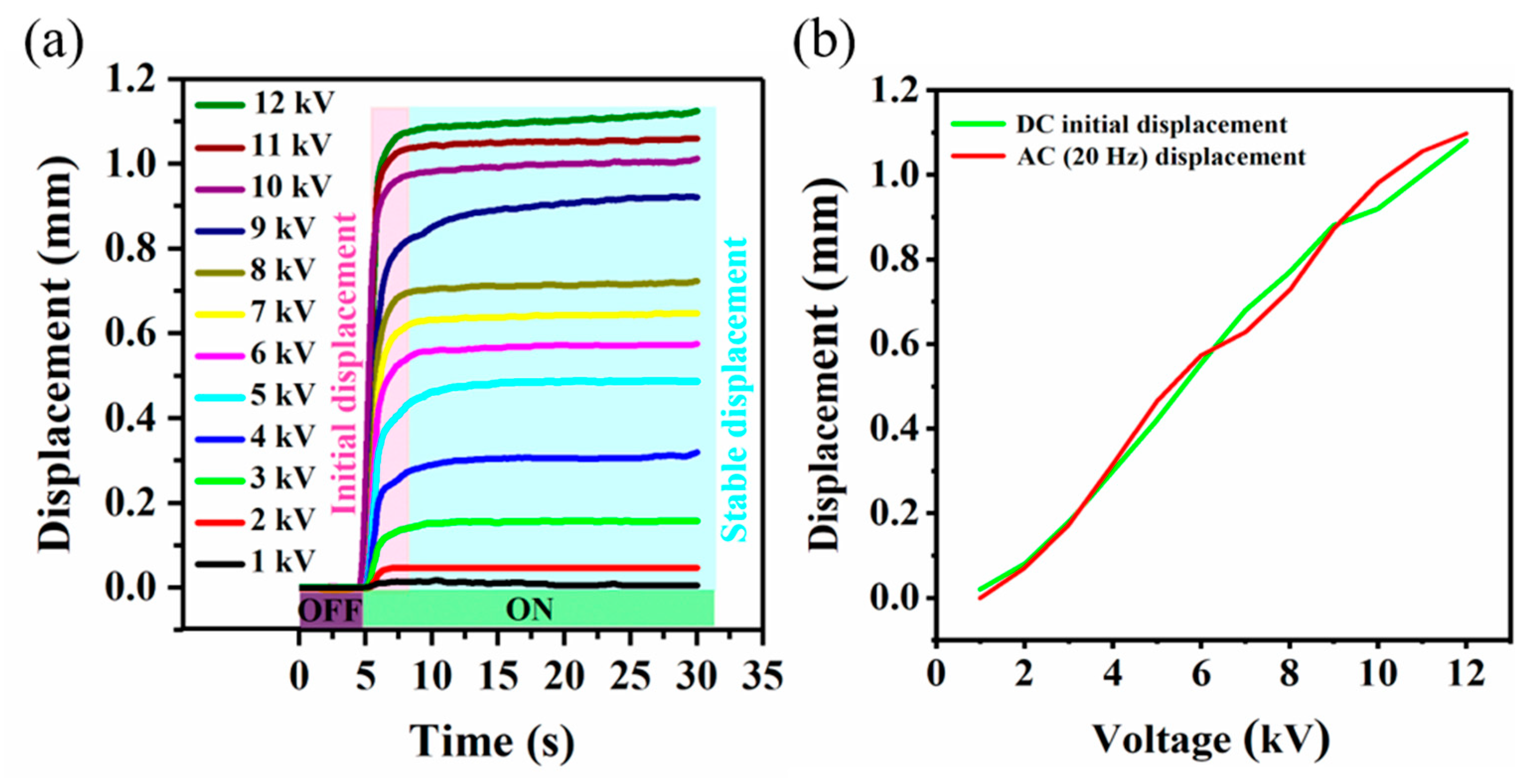

4.1. Output Performance of the Electro-Hydraulic Actuator

4.2. Haptic Feedback Teleoperation System Based on the Electro-Hydraulic Actuator

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Yu, X.; Xie, Z. Skin-integrated wireless haptic interfaces for virtual and augmented reality. Nature 2019, 575, 473–479. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Ranzani, T. Multi-fingered haptic palpation utilizing granular jamming stiffness feedback actuators. Smart Mater. Struct. 2014, 23, 095007. [Google Scholar] [CrossRef]

- Jung, H.-K.; Park, G. Structural impact detection with vibro-haptic interfaces. Smart Mater. Struct. 2016, 25, 075041. [Google Scholar] [CrossRef] [Green Version]

- Hwang, Y.-H.; Kang, S.-R. A robot-assisted cutting surgery of human-like tissues using a haptic master operated by magnetorheological clutches and brakes. Smart Mater. Struct. 2019, 28, 065016. [Google Scholar] [CrossRef]

- Choi, S.-H.; Kim, S. A new visual feedback-based magnetorheological haptic master for robot-assisted minimally invasive surgery. Smart Mater. Struct. 2015, 24, 065015. [Google Scholar] [CrossRef]

- Lee, H.-J.; Loh, K.J. Soft material actuation by atomization. Smart Mater. Struct. 2019, 28, 025030. [Google Scholar] [CrossRef]

- Sun, J.Y.; Keplinger, C. Ionic skin. Adv. Mater. 2015, 26, 7608–7614. [Google Scholar] [CrossRef]

- Martinez, R.V.; Branch, J.L. Robotic Tentacles with Three-Dimensional Mobility Based on Flexible Elastomers. Adv. Mater. 2013, 25, 205–212. [Google Scholar] [CrossRef] [PubMed]

- Miriyev, A.; Stack, K. Soft material for soft actuators. Nat. Commun. 2017, 8, 596. [Google Scholar] [CrossRef] [PubMed]

- Tsugawa, M.A.; Palmre, V. Slender tube-shaped and square rod-shaped IPMC actuators with integrated sensing for soft mechatronics. Nat. Commun. 2015, 50, 2781–2795. [Google Scholar] [CrossRef]

- Polygerinos, P.; Correll, N. Soft Robotics: Review of Fluid-Driven Intrinsically Soft Devices Manufacturing, Sensing, Control, and Applications in Human-Robot Interaction. Adv. Eng. Mater. 2017, 19, 1700016. [Google Scholar] [CrossRef]

- Yeo, J.C.; Yap, H.K. Flexible and Stretchable Strain Sensing Actuator for Wearable Soft Robotic Applications. Adv. Mater. Technol. 2016, 1, 1600018. [Google Scholar] [CrossRef]

- Saurabh, J.; Vikas, K. Soft robotic glove for kinesthetic haptic feedback in virtual reality environments. Electron. Imaging 2017, 3, 19–24. [Google Scholar]

- Chossat, J.B.; Chen, D.K.Y. Soft Wearable Skin-Stretch Device for Haptic Feedback Using Twisted and Coiled Polymer Actuators. IEEE Trans. Haptics 2019, 12, 521–532. [Google Scholar] [CrossRef]

- Kim, M.; Jeon, C. A Study on Immersion and Presence of a Portable Hand Haptic System for Immersive Virtual Reality. Sensors 2017, 17, 1141. [Google Scholar]

- Song, K.; Kim, S.H. Pneumatic actuator and flexible piezoelectric sensor for soft virtual reality glove system. Sci. Rep. 2019, 9, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Hou, S.; Wang, M. Photothermally Driven Refreshable Microactuators Based on Graphene Oxide Doped Paraffin. ACS Appl. Mater. Interfaces 2017, 9, 26476–26482. [Google Scholar] [CrossRef]

- Kwon, H.-J.; Lee, S.W. Braille dot display module with a PDMS membrane driven by a thermopneumatic actuator. Sens. Actuator A Phys. 2008, 154, 238–246. [Google Scholar] [CrossRef]

- Lee, H.S.; Phung, H. Design analysis and fabrication of arrayed tactile display based on dielectric elastomer actuator. Sens. Actuator A Phys. 2014, 205, 191–198. [Google Scholar] [CrossRef]

- Chakraborti, P.; Toprakci, H.A.K. A compact dielectric elastomer tubular actuator for refreshable Braille displays. Sens. Actuator A Phys. 2012, 179, 151–157. [Google Scholar] [CrossRef]

- Carpi, F.; Frediani, G. Hydrostatically Coupled Dielectric Elastomer Actuators. IEEE-Asme Mech. 2010, 15, 308–315. [Google Scholar] [CrossRef]

- Frediani, G.; Mazzei, D. Wearable wireless tactile display for virtual interactions with soft bodies. Front. Bioeng. Biotech. 2014, 2, 31. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Acome, E.; Mitchell, S.K. Hydraulically amplified self-healing electrostatic actuators with muscle-like performance. Science 2018, 359, 61–65. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kellaris, N.; Venkata, V.G. An analytical model for the design of Peano-HASEL actuators with drastically improved performance. Exterme Mech. Lett. 2019, 29, 100449. [Google Scholar] [CrossRef]

- Guo, W.; Wang, X. Plant oil and amino acid-derived elastomers with rapid room temperature self-healing ability. J. Mater. Chem. A 2019, 7, 21927–21933. [Google Scholar] [CrossRef]

- Nakamura, T.; Yamamoto, A. Modeling and control of electroadhesion force in DC voltage. Robomech. J. 2017, 4, 18. [Google Scholar] [CrossRef]

- Lee, S.-R.; Choi, S.-H. Design of a smart haptic system for repulsive force control under irregular manipulation environment. Smart Mater. Struct. 2014, 23, 125040. [Google Scholar] [CrossRef]

- Tzafestas, C.S. Whole-hand kinesthetic feedback and haptic perception in dextrous virtual manipulation. IEEE Trans. Syst. ManCybern. Part A Syst. Hum. 2003, 33, 100–113. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, J.; Cheng, X.; Wang, P.; Jiao, Z.; Yu, Y.; Yu, M.; Luo, B.; Yang, W. A Haptic Feedback Actuator Suitable for the Soft Wearable Device. Appl. Sci. 2020, 10, 8827. https://doi.org/10.3390/app10248827

Ma J, Cheng X, Wang P, Jiao Z, Yu Y, Yu M, Luo B, Yang W. A Haptic Feedback Actuator Suitable for the Soft Wearable Device. Applied Sciences. 2020; 10(24):8827. https://doi.org/10.3390/app10248827

Chicago/Turabian StyleMa, Jiaqi, Xiang Cheng, Pengfei Wang, Zhiwei Jiao, Yuan Yu, Meng Yu, Bin Luo, and Weimin Yang. 2020. "A Haptic Feedback Actuator Suitable for the Soft Wearable Device" Applied Sciences 10, no. 24: 8827. https://doi.org/10.3390/app10248827