Influence of Low-Pressure Plasma on the Surface Properties of CAD-CAM Leucite-Reinforced Feldspar and Resin Matrix Ceramics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Specimens Treatments

2.3. Surface Wettability

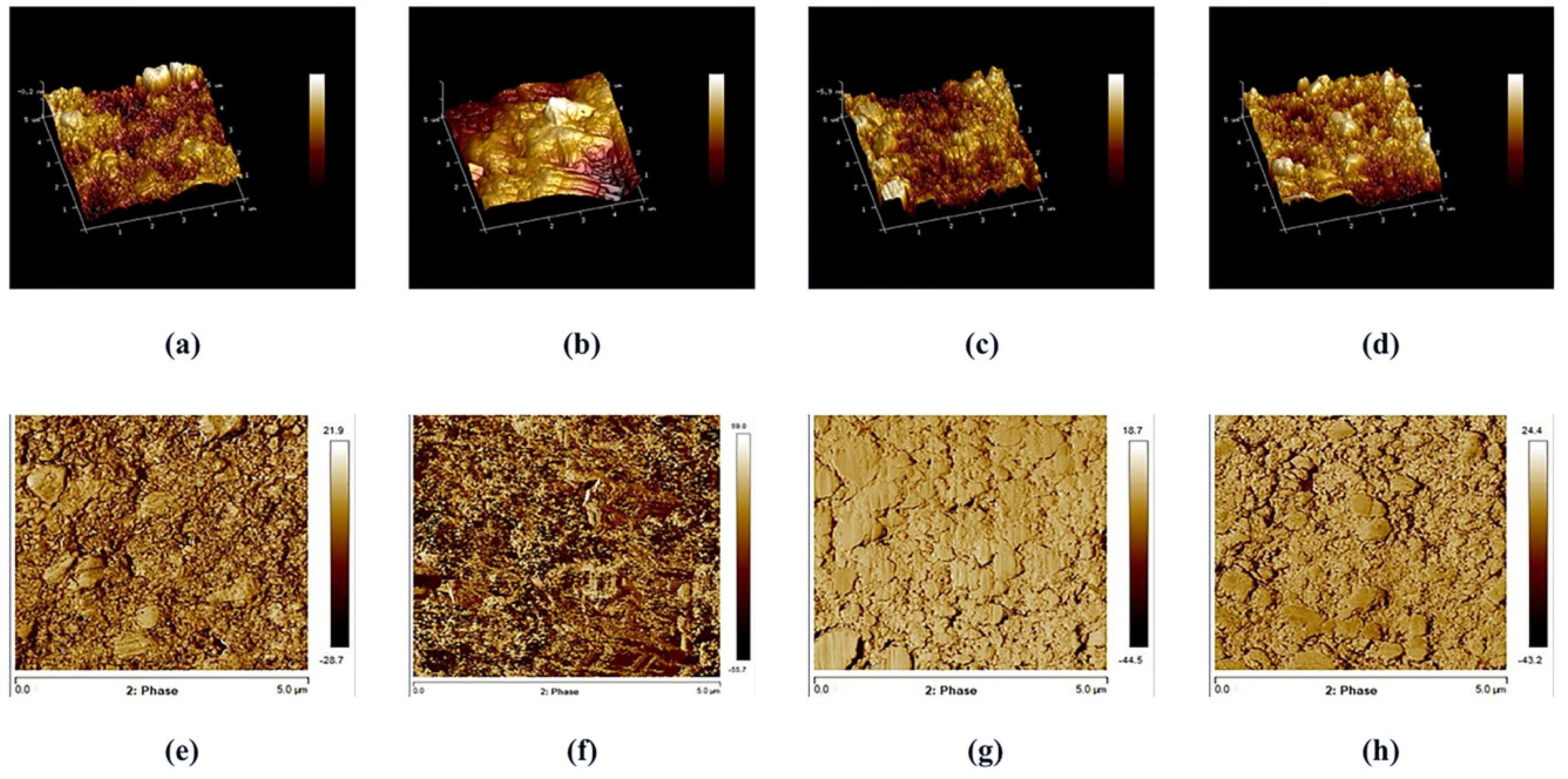

2.4. Surface Roughness

2.5. Data Processing

3. Results

4. Discussion

5. Conclusions

- Plasma treatment increases the wettability of the LIC group (22–38%) and RMC group (72–85%).

- Plasma treatments had little influence on surface roughness in both ceramic materials.

- When comparing the effectiveness of the plasma treatments between the two materials, the LIC group, in both plasma etching and plasma activation, obtained the lowest values of wettability and the highest values of roughness.

- Further studies are needed to evaluate the surface treatment of ceramic materials.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gracis, S.; Thompson, V.P.; Ferencz, J.L.; Silva, N.R.F.A.; Bonfante, E.A. A new classification system for all-ceramic and ceramic-like restorative materials. Int. J. Prosthodont. 2015, 28, 227–235. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pelaez, J.; G Cogolludo, P.; Serrano, B.; L Lozano, J.F.; Suarez, M.J. A four-year prospective clinical evaluation of zirconia and metal- ceramic posterior fixed dental prostheses. Int. J. Prosthodont. 2012, 25, 451–458. [Google Scholar] [PubMed]

- Freire, Y.; Gonzalo, E.; López Suárez, C.; Suárez, M.J. The marginal fit of CAD/CAM monolithic ceramic and metal-ceramic crowns. J. Prosthodont. 2019, 28, 299–304. [Google Scholar] [CrossRef] [PubMed]

- Fu, L.; Engqvist, H.; Xia, W. Glass-ceramics in dentistry: A review. Materials 2020, 13, 1049. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, J.E.; Kim, J.H.; Shim, J.S.; Roh, B.D.; Shin, Y. Effect of air-particle pressures on the surface topography and bond strengths of resin cement to the hybrid ceramics. Dent. Mater. J. 2017, 36, 454–460. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pelaez, J.; Cogolludo, P.G.; Serrano, B.; L Lozano, J.F.; Suarez, M.J. A prospective evaluation of zirconia posterior fixed dental prostheses: Three-year clinical results. J. Prosthet. Dent. 2012, 107, 373–379. [Google Scholar] [CrossRef]

- Şişmanoğlu, S.; Gürcan, A.T.; Yıldırım-Bilmez, Z.; Turunç-Oğuzman, R.; Gümüştaş, B. Effect of surface treatments and universal adhesive application on the microshear bond strength of CAD/CAM materials. J. Adv. Prosthodont. 2020, 12, 22–32. [Google Scholar] [CrossRef] [Green Version]

- Ruse, N.D.; Sadoun, M.J. Resin-composite blocks for dental CAD/CAM applications. J. Dent. Res. 2014, 93, 1232–1234. [Google Scholar] [CrossRef] [Green Version]

- Çelik, E.; Sahin, S.C.; Dede, D.Ö. Shear bond strength of nanohybrid composite to the resin matrix ceramics after different surface treatments. Photomed. Laser Surg. 2018, 36, 424–430. [Google Scholar] [CrossRef]

- Park, J.H.; Choi, Y.S. Microtensile bond strength and micromorphologic analysis of surface-treated resin nanoceramics. J. Adv. Prosthodont. 2016, 8, 275–284. [Google Scholar] [CrossRef] [Green Version]

- Cekic-Nagas, I.; Ergun, G.; Egilmez, F.; Vallittu, P.K.; Lassila, L.V. Micro-shear bond strength of different resin cements to ceramic/glass-polymer CAD-CAM block materials. J. Prosthodont. Res. 2016, 60, 265–273. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Burke, F.J.; Fleming, G.J.; Nathanson, D.; Marquis, P.M. Are adhesive technologies needed to support ceramics? An assessment of the current evidence. J. Adhes. Dent. 2002, 4, 7–22. [Google Scholar] [PubMed]

- Stawarczyk, B.; Beuer, F.; Ender, A.; Roos, M.; Edelhoff, D.; Wimmer, T. Influence of cementation and cement type on the fracture load testing methodology of anterior crowns made of different materials. Dent. Mater. J. 2013, 32, 888–895. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Blatz, M.B.; Vonderheide, M.; Bonejo, J. The effect of resin bonding on long-term success of high-strength ceramics. J. Dent. Res. 2018, 97, 132–139. [Google Scholar] [CrossRef] [PubMed]

- Maroulakos, G.; Thompson, G.A.; Kontogiorgos, E.D. Effect of cement type on the clinical performance and complications of zirconia and lithium disilicate tooth-supported crowns: A systematic review. J. Prosthet. Dent. 2019, 121, 754–765. [Google Scholar] [CrossRef] [PubMed]

- Emsermann, I.; Eggmann, F.; Krastl, G.; Weiger, R.; Amato, J. Influence of pretreatment methods on the adhesion of composite and polymer infiltrated ceramic CAD-CAM blocks. J. Adhes. Dent. 2019, 21, 433–443. [Google Scholar]

- Ustun, S.; Ayaz, E.A. Effect of different cement systems and aging on the bond strength of chairside CAD-CAM ceramics. J. Prosthet. Dent. 2020, 20, 1–9. [Google Scholar] [CrossRef]

- Zogheib, L.V.; Bona, A.D.; Kimpara, E.T.; McCabe, J.F. Effect of hydrofluoric acid etching duration on the roughness and flexural strength of a lithium disilicate-based glass ceramic. Braz. Dent. J. 2011, 22, 45–50. [Google Scholar] [CrossRef] [Green Version]

- Xiaoping, L.; Dongfeng, R.; Silikas, N. Effect of etching time and resin bond on the flexural strength of IPS e.max Press glass ceramic. Dent. Mater. 2014, 30, 330–336. [Google Scholar] [CrossRef]

- Veríssimo, A.H.; Moura, D.M.D.; Tribst, J.P.M.; Araújo, A.M.M.; Leite, F.P.P.; Souza, R.O.A.E. Effect of hydrofluoric acid concentration and etching time on resin-bond strength to different glass ceramics. Braz. Oral Res. 2019, 33, e041. [Google Scholar] [CrossRef] [Green Version]

- Moura, D.M.D.; Araújo, A.M.M.; Souza, K.B.; Veríssimo, A.H.; Tribst, J.P.M.; Souza, R.O.A.E. Hydrofluoric acid concentration, time and use of phosphoric acid on the bond strength of feldspathic ceramics. Braz. Oral Res. 2020, 34, e018. [Google Scholar] [CrossRef] [PubMed]

- Poitevin, A.; De Munck, J.; Van Ende, A.; Suyama, Y.; Mine, A.; Peumans, M. Bonding effectiveness of self-adhesive composites to dentin and enamel. Dent. Mater. 2013, 29, 221–230. [Google Scholar] [CrossRef] [PubMed]

- Özcan, M.; Bernasconi, M. Adhesion to zirconia used for dental restorations: A systematic review and meta-analysis. J. Adhes. Dent. 2015, 17, 7–26. [Google Scholar] [PubMed]

- Cho, B.H.; Han, G.J.; Oh, K.H.; Chung, S.N.; Chun, B.H. The effect of plasma polymer coating using atmospheric-pressure glow discharge on the shear bond strength of composite resin to ceramic. J. Mater. Sci. 2011, 46, 2755–2763. [Google Scholar] [CrossRef]

- Cha, S.; Park, Y.S. Plasma in dentistry. Clin. Plasma Med. 2014, 2, 4–10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Seker, E.; Kilicarslan, M.A.; Deniz, S.T.; Mumcu, E.; Ozkan, P. Effect of atmospheric plasma versus conventional surface treatments on the adhesion capability between self-adhesive resin cement and titanium surface. J. Adv. Prosthodont. 2015, 7, 249–256. [Google Scholar] [CrossRef]

- Koodaryan, R.; Hafezeqoran, A. Surface modification of dental polymers by plasma treatment: A review. Biomed. Pharmacol. J. 2016, 9, 317–321. [Google Scholar] [CrossRef]

- Seker, E.; Kilicarslan, M.A.; Polat, S.; Ozkir, E.; Pat, S. Non-thermal atmospheric plasma: Can it be taken as a common solution for the surface treatment of dental materials? Plasma Sci. Technol. 2016, 18, 417. [Google Scholar] [CrossRef] [Green Version]

- Han, G.J.; Chung, S.N.; Chun, B.H.; Kim, C.K.; Oh, K.H.; Cho, B.H. Effect of the applied power of atmospheric pressure plasma on the adhesion of composite resin to dental ceramic. J. Adhes. Dent. 2012, 14, 461–469. [Google Scholar]

- Canullo, L.; Micarelli, C.; Bettazzoni, L.; Koci, B.; Baldissara, P. Zirconia composite bonding after plasma of argon treatment. Int. J. Prosthodont. 2014, 27, 267–269. [Google Scholar] [CrossRef] [Green Version]

- Liu, T.; Hong, L.; Hottel, T.; Dong, X.; Yu, Q.; Chen, M. Non-thermal plasma enhanced bonding of resin cement to zirconia ceramic. Clin. Plasma Med. 2016, 4, 50–55. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bonitz, M.; Lopez, J.; Becker, K.H.; Thomsen, H. Complex Plasmas: Scientific Challenges and Technological Opportunities; Springer: Basel, Switzerland, 2014; pp. 455–485. [Google Scholar]

- Ramakrishnaiah, R.; Alkheraif, A.A.; Divakar, D.D.; Matinlinna, J.P.; Vallittu, P.K. The effect of hydrofluoric acid etching duration on the surface micromorphology, roughness, and wettability of dental ceramics. Int. J. Mol. Sci. 2016, 17, 822. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tabari, K.; Hosseinpour, S.; Mohammad-Rahimi, H. The impact of plasma treatment of Cercon® zirconia ceramics on adhesion to resin composite cements and surface properties. J. Lasers Med. Sci. 2017, 8, 56–61. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, D.S.; Ahn, J.J.; Bae, E.B.; Kim, G.C.; Jeong, C.M.; Huh, J.B.; Lee, S.H. Influence of non-thermal atmospheric pressure plasma treatment on shear bond strength between Y-TZP and self-adhesive resin cement. Materials 2019, 12, 3321. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lümkemann, N.; Eichberger, M.; Stawarczyk, B. Different surface modifications combined with universal adhesives: The impact on the bonding properties of zirconia to composite resin cement. Clin. Oral Investig. 2019, 23, 3941–3950. [Google Scholar] [CrossRef] [PubMed]

- Ahn, J.J.; Kim, D.S.; Bae, E.B.; Kim, G.C.; Jeong, C.M.; Huh, J.B.; Lee, S.H. Effect of non-thermal atmospheric pressure plasma (NTP) and zirconia primer treatment on shear bond strength between Y-TZP and resin cement. Materials 2020, 13, 3934. [Google Scholar] [CrossRef] [PubMed]

- Fornaini, C.; Poli, F.; Merigo, E.; Brulat-Bouchard, N.; El Gamal, A.; Rocca, J.P.; Selleri, S.; Cucinotta, A. Disilicate dental ceramic surface preparation by 1070 nm fiber laser: Thermal and ultrastructural analysis. Bioengineering 2018, 5, 10. [Google Scholar] [CrossRef] [Green Version]

- Prochnow, C.; Venturini, A.B.; Grasel, R.; Gundel, A.; Bottino, M.C.; Valandro, L.F. Adhesion to a lithium disilicate glass ceramic etched with hydrofluoric acid at distinct concentrations. Braz. Dent. J. 2018, 29, 492–499. [Google Scholar] [CrossRef]

- Farias, D.C.S.; Gonçalves, L.M.; Walter, R.; Chung, Y.; Blatz, M.B. Bond strengths of various resin cements to different ceramics. Braz. Oral Res. 2019, 33, e095. [Google Scholar] [CrossRef]

- Yoshida, F.; Tsujimoto, A.; Ishii, R.; Nojiri, K.; Takamizawa, T.; Miyazaki, M.; Latta, M.A. Influence of surface treatment of contaminated lithium disilicate and leucite glass ceramics on surface free energy and bond strength of universal adhesives. Dent. Mater. J. 2015, 34, 855–862. [Google Scholar] [CrossRef] [Green Version]

- Ishii, R.; Tsujimoto, A.; Takamizawa, T.; Tsubota, K.; Suzuki, T.; Shimamura, Y.; Miyazaki, M. Influence of surface treatment of contaminated zirconia on surface free energy and resin cement bonding. Dent. Mater. J. 2015, 34, 91–97. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lise, D.P.; Perdigão, J.; Van Ende, A.; Zidan, O.; Lopes, G.C. Microshear bond strength of resin cements to lithium disilicate substrates as a function of surface preparation. Oper. Dent. 2015, 40, 524–532. [Google Scholar] [CrossRef] [PubMed]

- Della Bona, A.; Borba, M.; Benetti, P.; Pecho, O.E.; Alessandretti, R.; Mosele, J.C.; Mores, R.T. Adhesion to dental ceramics. Curr. Oral Health Rep. 2014, 1, 232–238. [Google Scholar] [CrossRef] [Green Version]

- Bottino, M.A.; Snellaert, A.; Bergoli, C.D.; Özcan, M.; Bottino, M.C.; Valandro, L.F. Effect of ceramic etching protocols on resin bond strength to a feldspar ceramic. Oper. Dent. 2015, 40, 40–46. [Google Scholar] [CrossRef] [PubMed]

- Pashley, D.H.; Carvalho, R.M.; Sano, H.; Nakajima, M.; Yoshiyama, M.; Shono, Y.; Fernandes, C.A.; Tay, F. The microtensile bond test: A review. J Adhes Dent. 1999, 1, 299–309. [Google Scholar] [PubMed]

- Valverde, G.B.; Coelho, P.G.; Janal, M.N.; Lorenzoni, F.C.; Carvalho, R.M.; Thompson, V.P.; Weltemann, K.D.; Silva, N.R. Surface characterisation and bonding of Y-TZP following non-thermal plasma treatment. J. Dent. 2013, 41, 51–59. [Google Scholar] [CrossRef]

- Elias, A.B.; Simao, R.A.; Prado, M.; Cesar, P.F.; Botelho Dos Santos, G.; Moreira da Silva, E. Effect of different times of nonthermal argon plasma treatment on the microtensile bond strength of self-adhesive resin cement to yttria-stabilized tetragonal zirconia polycrystal ceramic. J. Prosthet. Dent. 2019, 121, 485–491. [Google Scholar] [CrossRef]

- Duzyol, M.; Sagsoz, O.; Polat Sagsoz, N.; Akgul, N.; Yildiz, M. The effect of surface treatments on the bond strength between CAD/CAM blocks and composite resin. J. Prosthodont. 2016, 25, 466–471. [Google Scholar] [CrossRef]

- Strasser, T.; Preis, V.; Behr, M.; Rosentritt, M. Roughness, surface energy, and superficial damages of CAD/CAM materials after surface treatment. Clin. Oral Investig. 2018, 22, 2787–2797. [Google Scholar] [CrossRef]

- Hallmann, L.; Ulmer, P.; Wille, S.; Polonskyi, O.; Köbel, S.; Trottenberg, T.; Bornholdt, S.; Haase, F.; Kersten, H.; Kern, M. Effect of surface treatments on the properties and morphological change of dental zirconia. J. Prosthet. Dent. 2016, 115, 341–349. [Google Scholar] [CrossRef]

- Bitencourt, S.B.; Dos Santos, D.M.; da Silva, E.V.F.; Barão, V.A.R.; Rangel, E.C.; da Cruz, N.C.; de Souza, G.M.; Goiato, M.C.; Pesqueira, A.A. Characterization of a new plasma-enhanced film to improve shear bond strength between zirconia and veneering ceramic. Mater. Sci. Eng. 2018, 92, 196–205. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Y.C.; Hsieh, J.P.; Chen, Y.C.; Kang, L.L.; Hwang, C.S.; Chuang, S.F. Promoting porcelain-zirconia bonding using different atmospheric pressure gas plasmas. Dent. Mater. 2018, 34, 1188–1198. [Google Scholar] [CrossRef] [PubMed]

- Pott, P.C.; Syvari, T.S.; Stiesch, M.; Eisenburger, M. Influence of nonthermal argon plasma on the shearbond strength between zirconia and different adhesives and luting composites after artificial aging. J. Adv. Prosthodont. 2018, 10, 308–314. [Google Scholar] [CrossRef] [PubMed]

- Park, C.; Yoo, S.H.; Park, S.W.; Yun, K.D.; Ji, M.K.; Shin, J.H.; Lim, H.P. The effect of plasma on shear bond strength between resin cement and colored zirconia. J. Adv. Prosthodont. 2017, 9, 118–123. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vechiato Filho, A.J.; dos Santos, D.M.; Goiato, M.C.; de Medeiros, R.A.; Moreno, A.; da Bonatto L, R. Surface characterization of lithium disilicate ceramic after nonthermal plasma treatment. J. Prosthet. Dent. 2014, 112, 1156–1163. [Google Scholar] [CrossRef] [PubMed]

- Dos Santos, D.M.; da Silva, E.V.F.; Vechiato-Filho, A.J.; Cesar, P.F.; Rangel, E.C.; da Cruz, N.C. Aging effect of atmospheric air on lithium disilicate ceramic after nonthermal plasma treatment. J. Prosthet. Dent. 2016, 115, 780–787. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kern, M. Resin bonding to oxide ceramics for dental restorations. J Adhes. Sci. Technol. 2009, 23, 1097–1111. [Google Scholar] [CrossRef]

- Su, N.; Yue, L.; Liao, Y.; Liu, W.; Zhang, H.; Li, X.; Wang, H.; Shen, J. The effect of various sandblasting conditions on surface changes of dental zirconia and shear bond strength between zirconia core and indirect composite resin. J. Adv. Prosthodont. 2015, 7, 214–223. [Google Scholar] [CrossRef] [Green Version]

- Okutan, Y.; Yucel, M.T.; Gezer, T.; Donmez, M.B. Effect of airborne particle abrasion and sintering order on the surface roughness and shear bond strength between Y-TZP ceramic and resin cement. Dent. Mater. J. 2019, 38, 241–249. [Google Scholar] [CrossRef] [Green Version]

- Śmielak, B.; Klimek, L.; Wojciechowski, R.; Bąkała, M. Effect of zirconia surface treatment on its wettability by liquid ceramics. J. Prosthet. Dent. 2019, 122, 410.e1–410.e6. [Google Scholar]

- Kasraei, S.; Atefat, M.; Beheshti, M.; Safavi, N.; Mojtahedi, M.; Rezaei-Soufi, L. Effect of surface treatment with CO2 laser on bond strength between cement resin and zirconia. J. Lasers Med. Sci. 2014, 5, 115–120. [Google Scholar] [PubMed]

- Popa, D.; Bordea, I.-R.; Burde, A.V.; Crişan, B.; Câmpian, R.S.; Constantiniuc, M. Surface modification of zirconia after laser irradiation. Optoelectron. Adv. Mat. 2016, 10, 785–788. [Google Scholar]

| Material | Type | Main Composition | Manufacturer |

|---|---|---|---|

| Cerasmart | Resin matrix ceramic | Resin Matrix (29%): Bis MEPP, Urethanedimethacrylate and Dimethacrylate monomer Filler (71%): Silica particles and Barium Borosilicate | GC Corp. Tokyo, Japan |

| Initial LRF | Leucite-reinforced feldspar ceramic | Glass matrix with silicon dioxide, sodium oxide and aluminum oxide | GC Corp. Tokyo, Japan |

| Group | Surface Treatment |

|---|---|

| Cerasmart Control (RMC-C)) | No Surface Treatment |

| Cerasmart Gold Standard (RMC-SB) | Sandblasting 50 µm Alumina at 1.5 bar, at 10 mm for 20 s |

| Cerasmart Plasma Activation (RCM-O2) | Plasma 100% Oxygen, 0.25–0.30 mbar, 40 kHz and 1000 W, for 5 min |

| Cerasmart Plasma Etching (RMC-Ar) | Plasma 100% Argon, 0.25–0.30 mbar, 40 kHz and 1000 W, for 60 min |

| Initial LRF Block Control (LIC-C) | No Surface Treatment |

| Initial LRF Block Gold Standard (LIC-HF) | Etching 9.6% Hydrofluoric Acid, for 60 s |

| Initial LRF Block Plasma Activation (LIC-O2) | Plasma 100% Oxygen, 0.25–0.30 mbar, 40 kHz and 1000 W, for 5 min |

| Initial LRF Block Plasma Etching (LIC-Ar) | Plasma 100% Argon, 0.25–0.30 mbar, 40 kHz and 1000 W, for 60 min |

| Instrument/Material | Type | Features/Composition | Manufacturer |

|---|---|---|---|

| PICO PCCE | Low-pressure plasma system | Direct current plasma system. Rectangular chamber (8 l) and PC control. Low-frequency plasma generator: 40 kHz, 1000 W. Rectangular electrode inside the chamber | Diener Electronic GmbH, Ebhausen, Germany |

| Porcelain Etch Gel | Etching gel | 9.6% Hydrofluoric Acid | Pulpdent, Watertown, MA, USA. |

| Aluminum Oxide | Aluminum Oxide | 50 µm Aluminum Oxide | Danville, San Ramon, CA, USA. |

| Variable | LIC-C | LIC-HF | LIC-O2 | LIC-Ar |

|---|---|---|---|---|

| Wettability | 42.04 (17.59) | 15.51 (5.36) | 32.89 (6.55) | 26.01 (2.92) |

| Roughness | 104.68 (43.23) | 496.17 (93.83) | 166.58 (26.14) | 157.71 (61.96) |

| Variable | RMC-C | RMC-SB | RMC-O2 | RMC-Ar |

|---|---|---|---|---|

| Wettability | 85.91 (3.76) | 108.11 (4.22) | 23.85 (4.94) | 12.82 (2.72) |

| Roughness | 62.25 (20.99) | 157.17 (28.27) | 81.78 (24.26) | 80.82 (30.57) |

| Variable | Material, Mean (SD) | Mann–Whitney U Test | ||

|---|---|---|---|---|

| LIC | RMC | Value | p-Value | |

| Wettability | 32.89 (6.55) | 23.85 (4.94) | 2.89 ** | 0.003 |

| Roughness | 166.58 (26.14) | 81.78 (24.26) | 4.10 ** | 0.000 |

| Variable | Material Mean (SD) | Mann Whitney U Test | ||

|---|---|---|---|---|

| LIC | RMC | Value | p-Value | |

| Wettability | 26.01 (2.92) | 12.82 (2.72) | 4.16 ** | 0.000 |

| Roughness | 157.71 (61.96) | 80.82 (30.57) | 3.29 ** | 0.000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sevilla, P.; Lopez-Suarez, C.; Pelaez, J.; Tobar, C.; Rodriguez-Alonso, V.; Suarez, M.J. Influence of Low-Pressure Plasma on the Surface Properties of CAD-CAM Leucite-Reinforced Feldspar and Resin Matrix Ceramics. Appl. Sci. 2020, 10, 8856. https://doi.org/10.3390/app10248856

Sevilla P, Lopez-Suarez C, Pelaez J, Tobar C, Rodriguez-Alonso V, Suarez MJ. Influence of Low-Pressure Plasma on the Surface Properties of CAD-CAM Leucite-Reinforced Feldspar and Resin Matrix Ceramics. Applied Sciences. 2020; 10(24):8856. https://doi.org/10.3390/app10248856

Chicago/Turabian StyleSevilla, Pablo, Carlos Lopez-Suarez, Jesús Pelaez, Celia Tobar, Veronica Rodriguez-Alonso, and María J. Suarez. 2020. "Influence of Low-Pressure Plasma on the Surface Properties of CAD-CAM Leucite-Reinforced Feldspar and Resin Matrix Ceramics" Applied Sciences 10, no. 24: 8856. https://doi.org/10.3390/app10248856

APA StyleSevilla, P., Lopez-Suarez, C., Pelaez, J., Tobar, C., Rodriguez-Alonso, V., & Suarez, M. J. (2020). Influence of Low-Pressure Plasma on the Surface Properties of CAD-CAM Leucite-Reinforced Feldspar and Resin Matrix Ceramics. Applied Sciences, 10(24), 8856. https://doi.org/10.3390/app10248856