Investigation on the Hump Behavior of Gate-Normal Nanowire Tunnel Field-Effect Transistors (NWTFETs)

Abstract

:1. Introduction

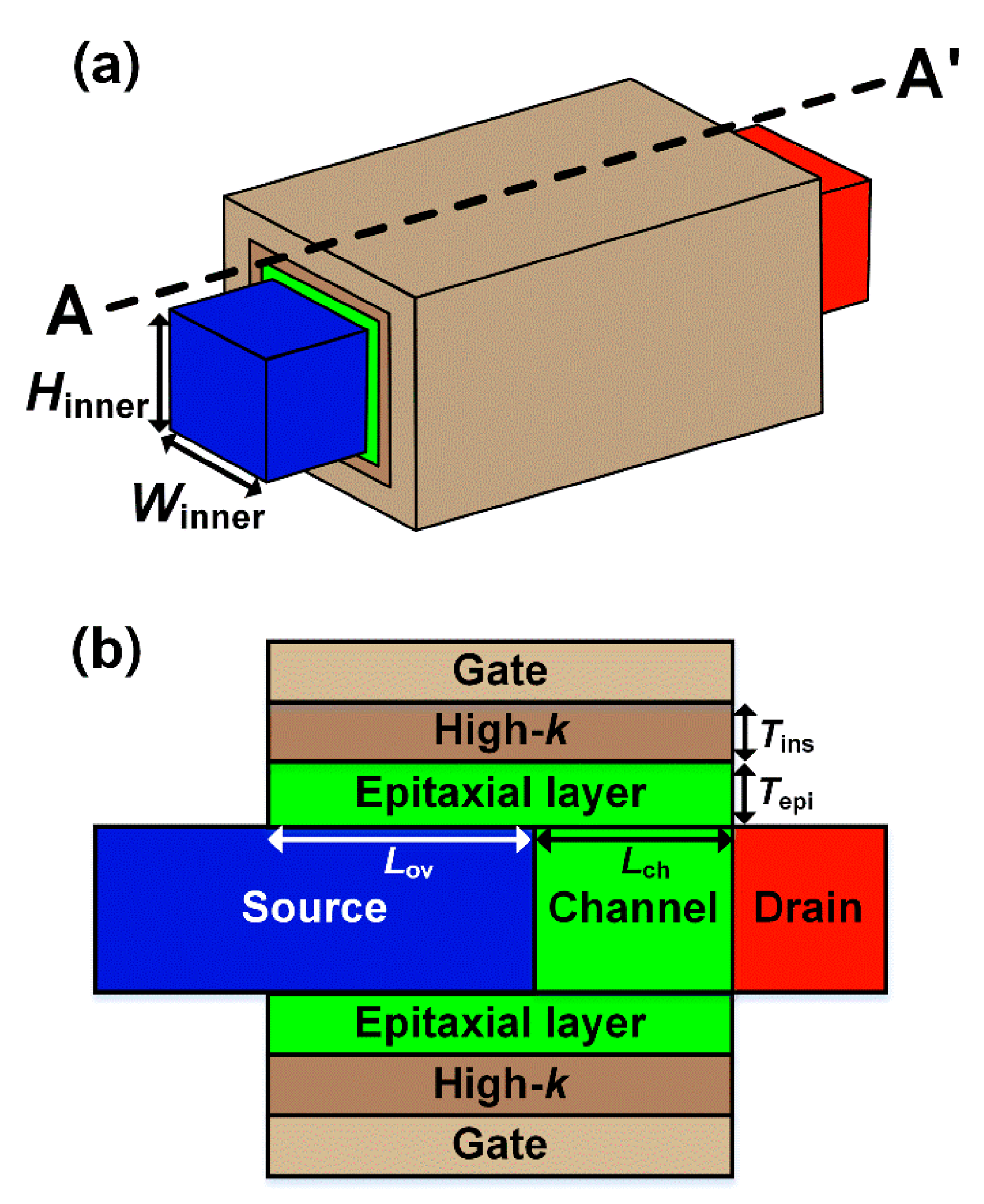

2. Device Structure and Simulation Methodology

3. Simulation Results and Discussion

3.1. Analysis of Hump Behavior of Gate-Normal NWTFETs

3.2. Hump Suppression by Rounding NW Corners and Reducing Gate Insulator Thickness

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bangsaruntip, S.; Cohen, G.M.; Majunmdar, A.; Sleight, J.W. Universality of short-channel effects in undoped-body silicon nanowire MOSFETs. IEEE Electron Device Lett. 2010, 31, 903–905. [Google Scholar] [CrossRef]

- Ionescu, A.M.; Riel, H. Tunnel field-effect transistors as energy-efficient electronic switches. Nature 2011, 479, 329–337. [Google Scholar] [CrossRef] [PubMed]

- Seabaugh, A.C.; Zhang, Q. Low-Voltage Tunnel Transistors for Beyond CMOS Logic. Proc. IEEE 2010, 98, 2095–2110. [Google Scholar] [CrossRef]

- Choi, W.Y.; Park, B.G.; Lee, J.D.; Liu, T.J.K. Tunneling Field-Effect Transistors (TFETs) with Subthreshold Swing (SS) Less Than 60 mV/dec. IEEE Electron Device Lett. 2007, 28, 743–745. [Google Scholar] [CrossRef]

- Knoch, J.; Appenzeller, J. Modeling of high-performance p-type Ⅲ-Ⅴ heterojunction tunnel FETs. IEEE Electron Dev. Lett. 2010, 31, 305–307. [Google Scholar] [CrossRef]

- Choi, W.Y.; Lee, W. Hetero-Gate-Dielectric Tunneling Field-Effect Transistors. IEEE Electron Dev. Lett. 2010, 57, 2317–2319. [Google Scholar] [CrossRef]

- Beneventi, G.B.; Gnani, E.; Gnudi, A.; Reggiani, S.; Baccarani, G. Dual-metal-gate InAs tunnel FET with enhanced turn-on steepness and high ON-current. IEEE Electron Dev. Lett. 2014, 61, 776–784. [Google Scholar] [CrossRef]

- Hsu, W.; Mantey, J.; Register, L.F.; Banerjee, S.K. Strained-Si/strained-Ge type-Ⅱ staggered heterojunction gate-normal-tunneling field-effect transistor. Appl. Phys. Lett. 2013, 103, 093501. [Google Scholar] [CrossRef]

- Hsu, W.; Mantey, J.; Register, L.F.; Banerjee, S.K. On the Electrostatic Control of Gate-Normal Tunneling Field-Effect Transistors. IEEE Electron Dev. Lett. 2015, 62, 2292–2299. [Google Scholar] [CrossRef]

- Shih, C.H.; Chie, N.D. Design and modeling of line-tunneling field-effect transistors using low-bandgap semiconductors. IEEE Electron Dev. Lett. 2014, 61, 1904–1913. [Google Scholar] [CrossRef]

- Wang, P.Y.; Tsui, B.Y. Epitaxial tunnel layer structure for P-channel tunnel FET improvement. IEEE Electron Dev. Lett. 2013, 60, 4098–4104. [Google Scholar] [CrossRef]

- Gandhi, R.; Chen, Z.; Singh, N.; Banerjee, K.; Lee, S. Vertical Si-nanowire n-type tunneling FETs with low subthreshold swing (≤ 50mV/decade) at room temperature. IEEE Electron Dev. Lett. 2011, 32, 437–439. [Google Scholar] [CrossRef]

- Smith, J.T.; Sandow, C.; Das, S.; Minamisawa, R.A.; Mantl, S.; Appenzeller, J. Silicon nanowire tunneling field-effect transistor arrays: Improving subthreshold performance using excimer laser annealing. IEEE Electron Dev. Lett. 2011, 58, 1822–1829. [Google Scholar] [CrossRef]

- Tran, D.P.; Pham, T.T.T.; Wolfrum, B.; Offenhausser, A.; Thierry, B. Cmos-compatible silicon nanowire field-effect transistor biosensor: Technology development toward commercialization. Materials 2018, 11, 785. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, M.; Koo, J.; Chung, E.A.; Jeong, D.Y.; Koo, Y.S.; Kim, S. Silicon nanowire-based tunneling field-effect transistors on flexible plastic substrates. Nanotechnology 2009, 20, 455201–455206. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.N.; Jung, S.W.; Kim, W.H.; Lee, M.H.; Shin, K.S.; Seong, W.K. Well controlled assembly of silicon nanowires by nanowire transfer method. Nanotechnology 2007, 18, 445302. [Google Scholar] [CrossRef]

- Lee, W.; Choi, W.Y. Quantitative analysis of hump effects of Gate-All-Around Metal-Oxide-Semiconductor Field-Effect Transistors. JJAP 2010, 49, 04DC11. [Google Scholar] [CrossRef]

- Kim, H.W.; Sun, M.C.; Kim, S.W.; Park, B.G. Hump Phenomenon in Transfer Characteristics of Double-Gated Thin-Body Tunneling Field-Effect Transistor (TFET) with Gate/Source Overlap. In Proceedings of the IEEE 5th International Nanoelectronics Conference (INEC), Singapore, 2–4 January 2013; pp. 364–366. [Google Scholar]

- Kim, S.W.; Choi, W.Y. Hump effects of germanium/silicon heterojunction tunnel field-effect transistors. IEEE Electron Dev. Lett. 2016, 63, 2583–2588. [Google Scholar] [CrossRef]

- Lee, S.H.; Park, J.U.; Kim, G.; Jee, D.W.; Kim, J.H.; Kim, S.W. Rigorous Study on Hump Phenomena in Surrounding Channel Nanowire (SCNW) Tunnel Field-Effect Transistor (TFET). Appl. Sci. 2020, 10, 3596. [Google Scholar] [CrossRef]

- Kwon, Y.S.; Lee, S.H.; Kim, Y.; Kim, G.; Kim, J.H.; Kim, S.W. Surrounding Channel Nanowire Tunnel Field-Effect Transistor with Dual Gate to Reduce a Hump Phenomenon. J. Nanosci. 2020, 20, 4182–4187. [Google Scholar]

- Lee, C.W.; Yun, S.R.N.; Yu, C.G.; Park, J.T.; Colinge, J.P. Device design guidelines for nano-scale MuGFETs. Solid State Electron. 2007, 51, 505–510. [Google Scholar] [CrossRef]

- Song, J.Y.; Choi, W.Y.; Park, J.H.; Lee, J.D.; Park, B.G. Design optimization of gate-all-around (GAA) MOSFETs. IEEE T Nanotechnol. 2006, 5, 186–191. [Google Scholar] [CrossRef]

- Ruiz, F.J.G.; Godoy, A.; Gamiz, F.; Sampedro, C.; Donetti, L. A comprehensive study of the corner effects in pi-gate SOI MOSFETs including quantum effects. IEEE Electron Dev. Lett. 2007, 54, 3369–3377. [Google Scholar] [CrossRef]

- Fossum, J.G.; Yang, J.W.; Trivedi, V.P. Suppression of corner effects in triple-gate MOSFETs. IEEE Electron Device Lett. 2003, 24, 745–747. [Google Scholar] [CrossRef]

- Synopsys. User Manual; Version L-2016.03, Synopsys TCAD Sentaurus; Synopsys: San Jose, CA, USA, 2016.

- Kao, K.H.; Verhulst, A.S.; Vandenberghe, W.G.; Sorée, B.; Groeseneken, G.; De Meyer, K. Direct and indirect band-to-band tunneling in germanium-based TFETs. IEEE Electron Dev. Lett. 2012, 59, 292–301. [Google Scholar] [CrossRef]

- Kim, S.W.; Choi, W.Y.; Sun, M.C.; Kim, H.W.; Park, B.G. Design guideline of Si-based L-Shaped Tunneling Field-Effect Transistors. JJAP 2012, 51, 06FE03-1–06FE03–5. [Google Scholar]

- Liu, L.; Liang, R.; Zhao, L.; Wang, J.; Xu, J. Influence of corner effect on performance of three-dimensional tunnel field-effect transistor. JJAP 2014, 53, 064304. [Google Scholar] [CrossRef]

- Tseng, P.H.; Hwu, J.G. Convex corner induced capacitance-voltage response from depletion to deep depletion in non-planar substrate metal-oxide-semiconductor capacitors with ultra thin oxide. Thin Solid Films. 2014, 556, 317–321. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Lch | 20 nm |

| Lov | 40 nm |

| Winner, Hinner | 20 nm |

| Tins | 2 nm |

| Tepi | 2 nm |

| NS | 1 × 1020 cm−3 (p-type) |

| ND | 1 × 1020 cm−3 (n-type) |

| Nch, Nepi | Intrinsic |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, M.W.; Choi, W.Y. Investigation on the Hump Behavior of Gate-Normal Nanowire Tunnel Field-Effect Transistors (NWTFETs). Appl. Sci. 2020, 10, 8880. https://doi.org/10.3390/app10248880

Kang MW, Choi WY. Investigation on the Hump Behavior of Gate-Normal Nanowire Tunnel Field-Effect Transistors (NWTFETs). Applied Sciences. 2020; 10(24):8880. https://doi.org/10.3390/app10248880

Chicago/Turabian StyleKang, Min Woo, and Woo Young Choi. 2020. "Investigation on the Hump Behavior of Gate-Normal Nanowire Tunnel Field-Effect Transistors (NWTFETs)" Applied Sciences 10, no. 24: 8880. https://doi.org/10.3390/app10248880