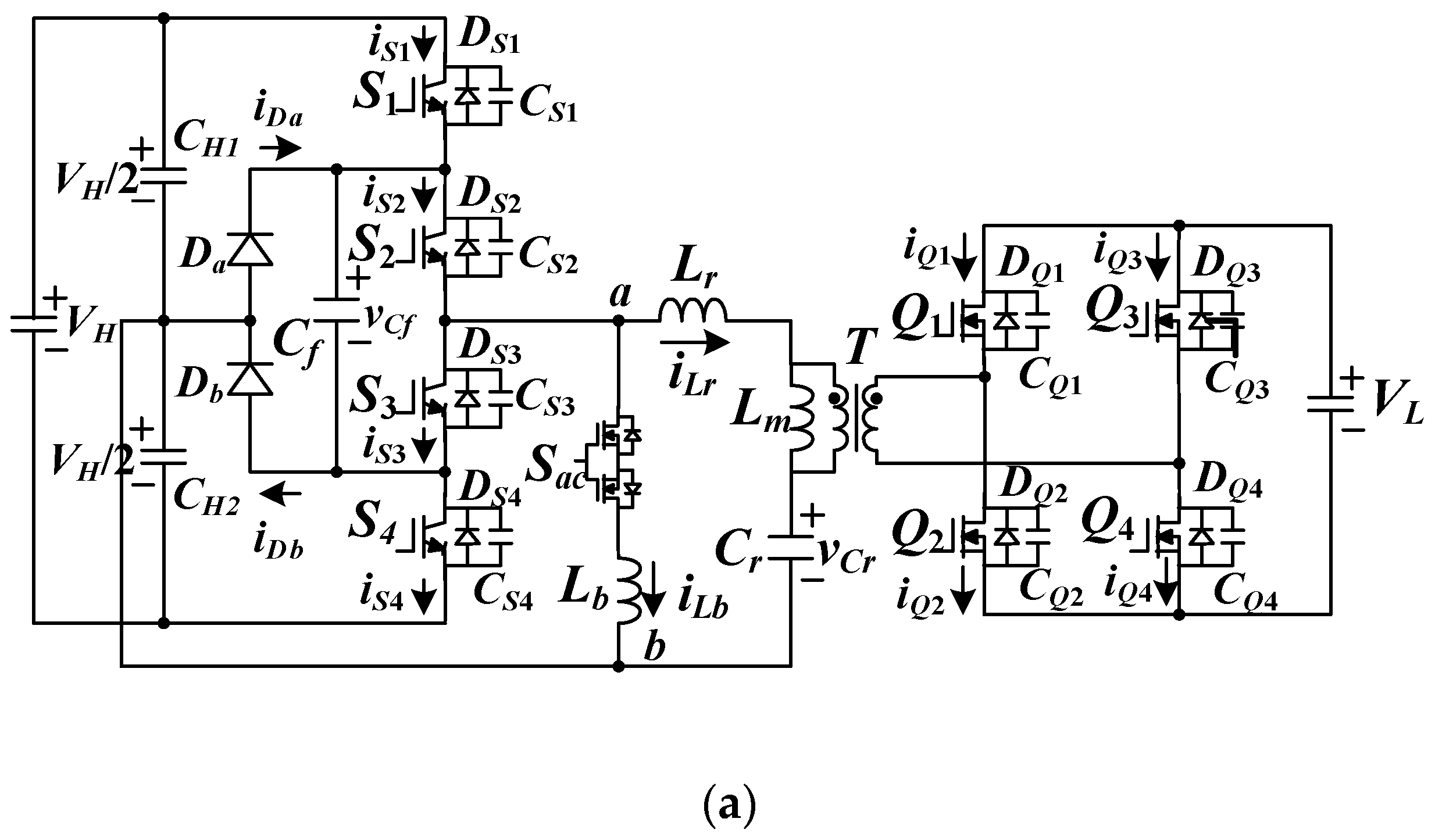

3. Circuit Operation

For forward power delivery, the electric power energy is transferred from

VH side to

VL side and

Sac is OFF.

S1~

S4 are controlled with PFM scheme. Due to PWM signals of

S1~

S4, there is a square wave with −

VH/2 or

VH/2 on the leg voltage

vab. However,

Q1~

Q4 are operated as the synchronous switches instead of the rectifier diodes in conventional full-bridge rectifier to reduce conduction loss. The equivalent resonant circuit and PWM waveforms for forward power delivery are provided in

Figure 2. To realize the ZVS operation of

S1~

S4, the input impedance of

LLC circuit must be inductive.

Figure 3 gives the corresponding equivalent circuits related to six operating steps in a switching period under

fr (resonant frequency) >

fsw (switching frequency). It is assumed that the

Lr represents the external series resonant inductance and the leakage inductance of transformer and

Cr represents the external series resonant capacitance and the parasitic capacitance on transformer winding turns. The output capacitances

CS1–

CS4 are assumed to be identical. In the same manner,

CQ1 = … =

CQ4. Since the current

iCf on

Cf is less than

iS1 and

iS2 in mode 1 and

iS3 and

iS4 in mode 4,

iCf is ignored in PWM waveforms. Therefore,

iS1 is equal to

iS2 in steps 1–3 and 6 and

iS3 is equal to

iS4 in steps 3–6.

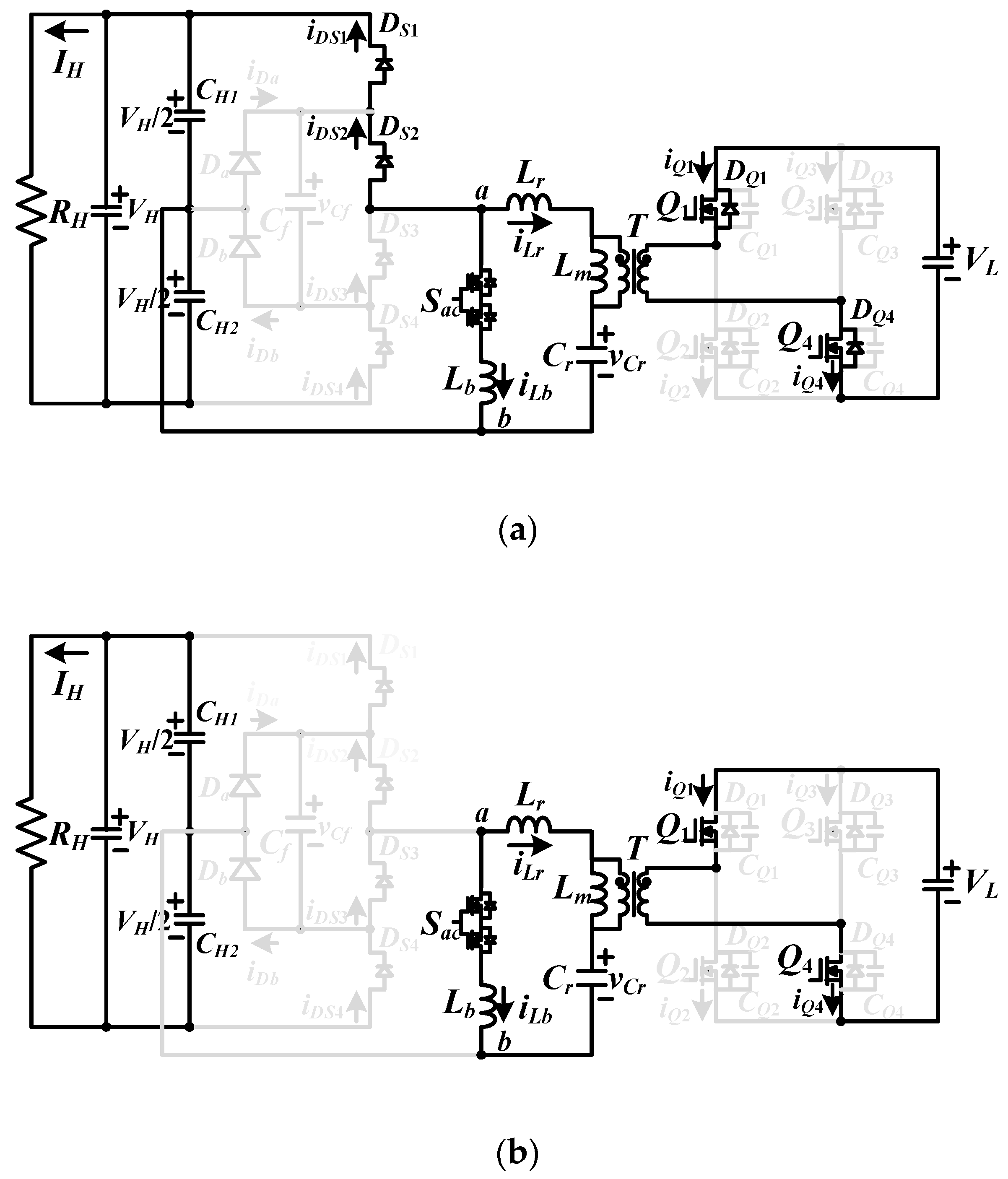

Step 1 (t0 ≤ t < t1): At t < t0, iLr < 0. Thus, iLr discharges CS1 and CS2 are discharged. At t0, vCS1 = vCS2 = 0. Thus, DS1 and DS2 are conducting due to iLr < 0. The ZVS operation of S1 and S2 can be achieved after time t0. If iLr < 0, Db is forward biased. The leg voltage vab = vCf = vCS3 = vCS4 = VH/2. Since iLr > iLm, Q1 and Q4 turn on to conduct the secondary-side current. When iLr increases and iLr > 0, Db becomes off. In this step, the magnetizing voltage vLm is equal to nVL, where n = np/ns is the transformer turns ratio, and iLm increases. The ripple current ΔiLm in step 1 is equal to nVLΔt01/Lm where Δt01 = t1 − t0. The resonant frequency in step 1 is .

Step 2 (t1≤t < t2): If fsw < fr, iQ1 and iQ4 will decrease to zero ampere at t1. Thus, Q1 and Q4 can turn off after time t1. In step 2, the leg voltage vab = VH/2 and Lr, Lm and Cr are resonant.

Step 3 (t2≤t < t3): At

t2,

S1 and

S2 turn off. The positive current

iLr(

t2) will charge

CS1 and

CS2. On the other hand,

CS3 and

CS4 are discharged in this step. The ZVS operation of

S3 and

S4 is expressed in Equation (1).

where

iLm,p is the peak current on

Lm and

CS =

CS1 = … =

CS4. The peak current

iLm,p is calculated from Equation (2).

The dead time

td between

S3 and

S1 (or

S4 and

S2) is approximately expressed in Equation (3).

Therefore, the maximum magnetizing inductance is derived in Equation (4).

Step 4 (t3≤t < t4): At t3, vCS3 = vCS4 = 0. Since iLr(t3) is positive, DS3 and DS4 are conducting. Power devices S3 and S4 can turn on after t3 under zero voltage condition. Since iLr(t3) > 0, Da is forward biased. The leg voltage vab = −VH/2 and vCf = vCS1 = vCS2 = VH/2. When iLr decreases and iLr < 0, Da becomes off. On the secondary side, iQ2(t3) < 0 and iQ3(t3) < 0. Therefore, Q2 and Q3 turn on to conduct the secondary-side current, the primary-side voltage vLm = −nVL and iLm decreases.

Step 5 (t4≤t < t5): The secondary-side switch currents iQ2 = iQ3 = 0 at t4. Then, Q2 and Q3 turn off. In this step, vab = −VH/2 and Lr, Lm and Cr are resonant.

Step 6 (t5≤t <Tsw+t0): At t5, S3 and S4 turn off. In this step, iLr(t5) < 0 and vCS1 and vCS2 decrease. The ZVS condition of S2 and S1 is the same as S4 and S3 in Equation (1). The step 6 is ended at time Tsw+t0.

The

LLC resonant circuit is controlled to achieve ZVS operation and the bidirectional power operation. The resonant circuit is based on the fundamental frequency analysis to achieve load voltage regulation. According to the switching status of power devices

S1~

S4 and

Q1~

Q4, the voltage values

VH/2 and −

VH/2 are observed on

vab, and the other voltage values

nVL and −

nVL are generated on the magnetizing inductor voltage

vLm.

Lr,

Cr, Lm and

Rac,L operate as a filter to suppress the high order harmonics. The root mean square (

rms) voltages at the fundamental frequency for input and output sides are

and

. Based on the power balance between the primary-side and the secondary-side of transformer, the primary-side load resistance is expressed as

. The transfer function

GH_L(

s) between the output and input sides in

Figure 2a is obtained as:

where

F = fsw/

fr,

,

K1 = Lm/

Lr and

. From the given input voltage

VH, the output voltage

VL and the circuit parameters

Lr,

Cr,

Lm and

RL, the switching frequency is obtained from Equation (6).

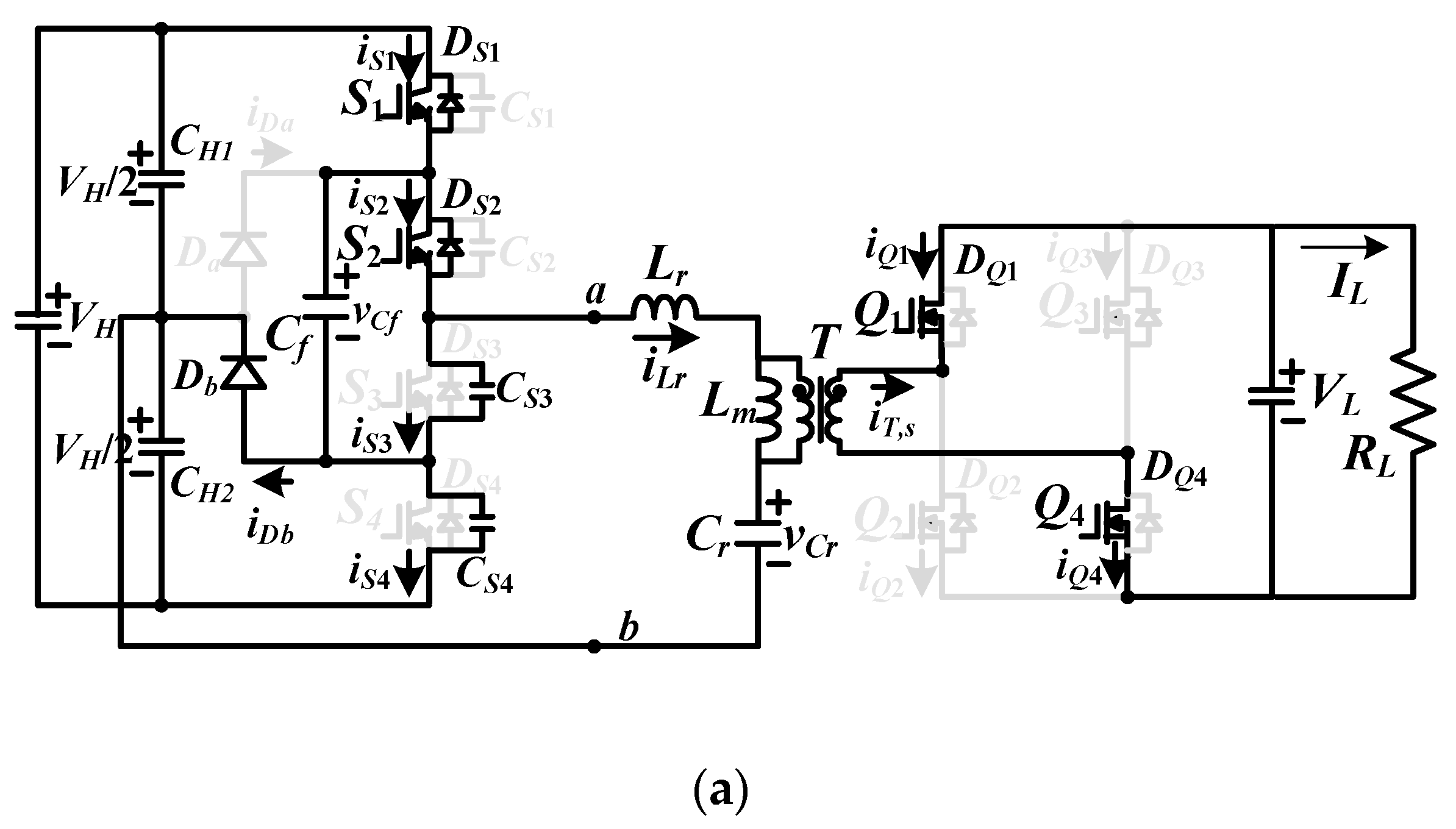

For reverse power flow shown in

Figure 1c, the developed converter transfers power from

VL terminal to

VH terminal.

Sac is turned on and

Lb,

Lr and

Cr are operated as a series resonant circuit to achieve voltage

VH regulation. Power devices

Q1~

Q4 are controlled with PFM scheme and

DS1~

DS4 work as a full-wave rectifier. When |

iLr|>

|iLb|,

DS1 and

DS2 or

DS3 and

DS4 are conducting. Since the

LLC resonant circuit by

Lr,

Cr and

Lb is operated at the inductive load, power devices

Q1~

Q4 are operated at the zero-voltage turn-on switching.

Figure 4a shows the ac equivalent resonant circuit at reverse power flow operation.

Lb and

Rac,H are the parallel inductance and ac equivalent resistance.

Figure 4b gives the main PWM waveforms and

Figure 5 demonstrates the corresponding equivalent circuits at the reverse power flow operation.

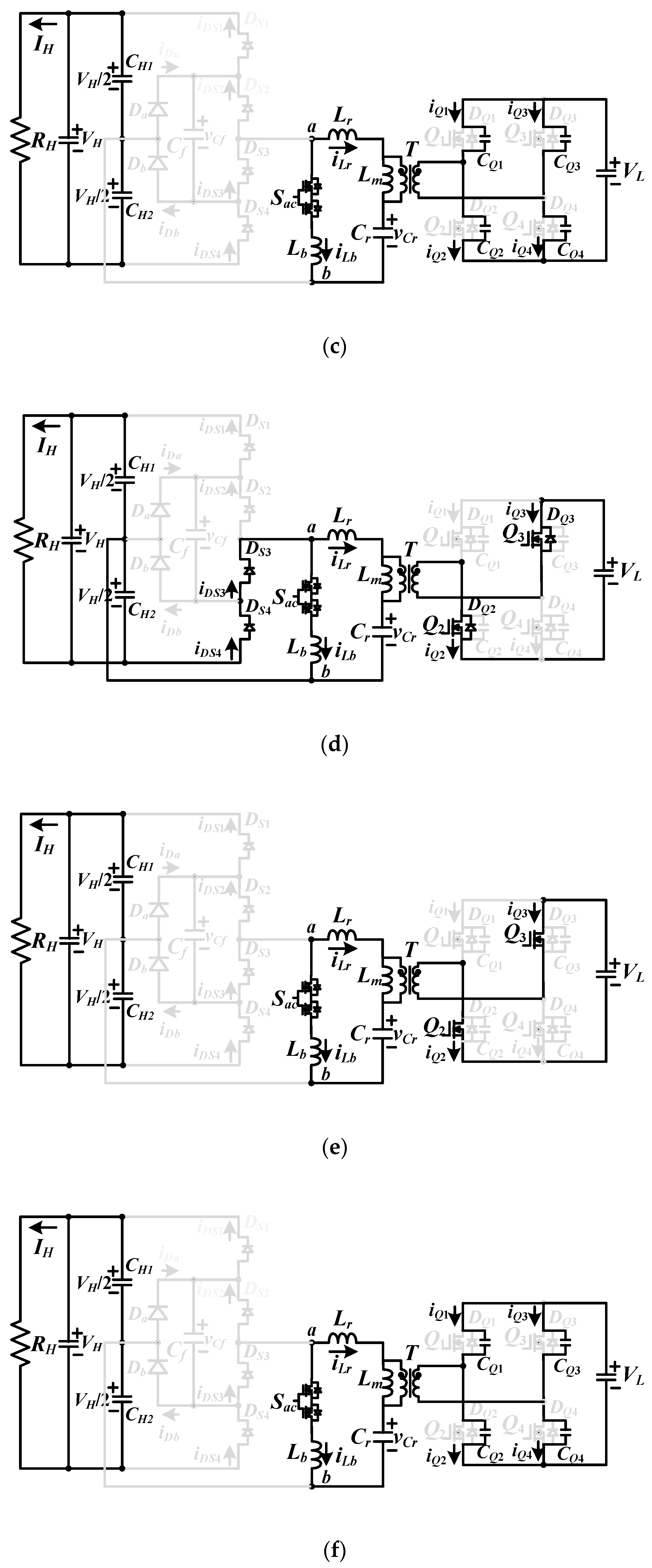

Step 1 (t0 ≤ t < t1): This step starts at t0 when vCQ4 = vCQ1 = 0. Then, the DQ4 and DQ1 conduct and vQ2,ds = vQ3,ds = VL. Due to DQ1 and DQ4 are conducting, vQ4,ds and vQ1,ds = 0 and Q1 and Q4 can turn on under zero voltage. Due to iLr(t0) + iLb(t0)<0, DS1 and DS2 are forward biased, CH1 is charged, vLm = nVL, vab = VH/2 and iLm and iLb both increase. Before switches Q1 and Q4 turn off, iDS1 and iDS2 will decrease to zero if fsw < .

Step 2 (t1≤t < t2): At time t1, iDS2 = iDS1 = 0 and DS2 and DS1 are off. Lr, Lb, and Cr are series resonant at frequency .

Step 3 (t2≤t < t3):Q4 and

Q1 turn off at

t2.

CQ2 and

CQ3 are discharged in step 3. The ZVS condition of

Q3 and

Q2 are obtained in Equation (7).

where

CQ =

CQ1 =..=

CQ4,

and

. At

t3, vCQ3(

t3) =

vCQ2(

t3) = 0. The time interval Δ

t23 is expressed in Equation (8).

where

td is dead time between

Q4 and

Q3 or

Q2 and

Q1.

Step 4 (t3≤t < t4): Step 4 starts at t3 when vCQ2 = vCQ3 = 0. Therefore, DQ3 and DQ2 conduct and Q3 and Q2 can turn on under zero voltage. In step 4, DS3 and DS4 conduct, vab = −VH/2, vLm = −nVL, and iLm and iLb both decrease.

Step 5 (t4≤t < t5):iDS3 = iDS4 = 0 at t4. In this step, Q2 and Q3 are still in the on state so that vLm = −nVL. Lb, Cr and Lr are series resonant.

Step 6 (t5≤t < Tsw+t0):Q2 and Q3 turn off at t5. Then, CQ1 and CQ4 are discharged and vCQ1 = vCQ4 = 0 at tsw + t0.

The proposed converter has the similar operation principle for both forward and reverse power operation. For the reverse power operation,

Q1~

Q4 are controlled as main power switches.

DS1~

DS4 are operated as diode rectifier to regulate voltage

VH. The resonant circuit including

Lb,

Lr and

Cr is operated as a filter to suppress high order harmonics. The input

rms voltage at fundamental frequency (

Figure 4a) is calculated as

and the ac equivalent resistance at high voltage side is

. The

rms voltage on

vab is expressed as

. Components

Rac,H,

Lb,

Lr and

Cr are resonant. The transfer function

GL_H(

s) and gain |

GL_H(

s)| are calculated in Equations (9) and (10), respectively.

where

F = fsw/

fr,

,

K2 = Lb/

Lr and

. From the given input voltage

VH, output voltage

VL and the circuit parameters

Lr,

Cr,

Lb and

RH, the switching frequency is obtained from Equation (10).

4. Circuit Parameters and Test Results

For forward power transfer, the input and output voltages are

VH = 750 V to 800 V and

VL = 48 V. The rated power is 1440 W (

vL = 48 V and

IL= 30 A). For reverse power transfer, the input and output voltages are

VL = 36 V to 52 V and

VH = 800 V. The transfer functions in Equations (6) and (10) for forward and backward power transfer operations are similar. Thus, the circuit parameters design operated at forward power flow is presented in this section. The dc voltage gain under

VH = 800 V input and

VL,max = 52 V output is designed to be unity. The transformer turns ratio is calculated in Equation (11).

In the prototype circuit, the selected primary and secondary turns are

nH = 48 and

nL = 6. Thus, the actual transformer turns ratio is

n =

nH/

nL = 8. With the adopted turns ratio, the actual maximum and minimum voltage gains at

VL,nom = 48 V condition are given in Equations (12) and (13).

The control parameters

K1 and

Q1 can be selected at full load

PL,full and minimum input voltage

VH,min conditions. To reduce circulating current, the inductor ratio

K1=10 is used in this prototype circuit. For

Q1 = 0.38 and

K1 = 10, it can obtain the peak gain of |

GH_L(s)| is 1.13. The ac equivalent resistance

Rac,L at the rated power is obtained in Equation (14).

The circuit parameters

and

under

fr = 100 kHz. The actual resonant inductance and capacitance are

Cr = 47 nF and

Lr = 54 µH and the magnetizing inductance

. The theoretical primary

rms current is calculated as:

The theoretical minimum switching frequency is obtained as

. The minimum switching frequency will result in the maximum

rms magnetizing current.

Therefore, the

rms resonant inductor current is obtained in Equation (17).

The flying capacitor

Cf is used to realize voltage balance of

CH1 and

CH2 so that

VCH1 =

VCH2 =

VH/2. The theoretical voltage stresses of power semiconductors can be calculated as

vS1,stress = .. = vS4,stress = VH,max/2

= 400 V and

vQ1,stress = .. = vQ4,stress = VL,max = 52 V. The switch currents approximate

and

. Power devices

S1~

S4 are implemented using IRG4PC40W with 600 V/20 A rating. Power switches

Q1~

Q4 are implemented using IRFB3307 with 75 V/150 A rating.

Sac is implemented using two G20N50C with 500 V/20 A rating. The parallel inductor

Lb is selected as 230 µH and

K2 =

Lb/

Lr = 4.25 under reverse power flow operation. The clamp diodes

Da and

Db are implemented with ultrafast recovery diodes HFA15TB60PBF with 600 V/15 A rating. The other circuit parameters used in the prototype are

CH1 =

CH2 = 330 µF/400 V,

Cf = 2.2 µF/630 V and

CL = 4400 µF/100 V. The parameters and specifications used in the laboratory prototype are given in

Table 1.

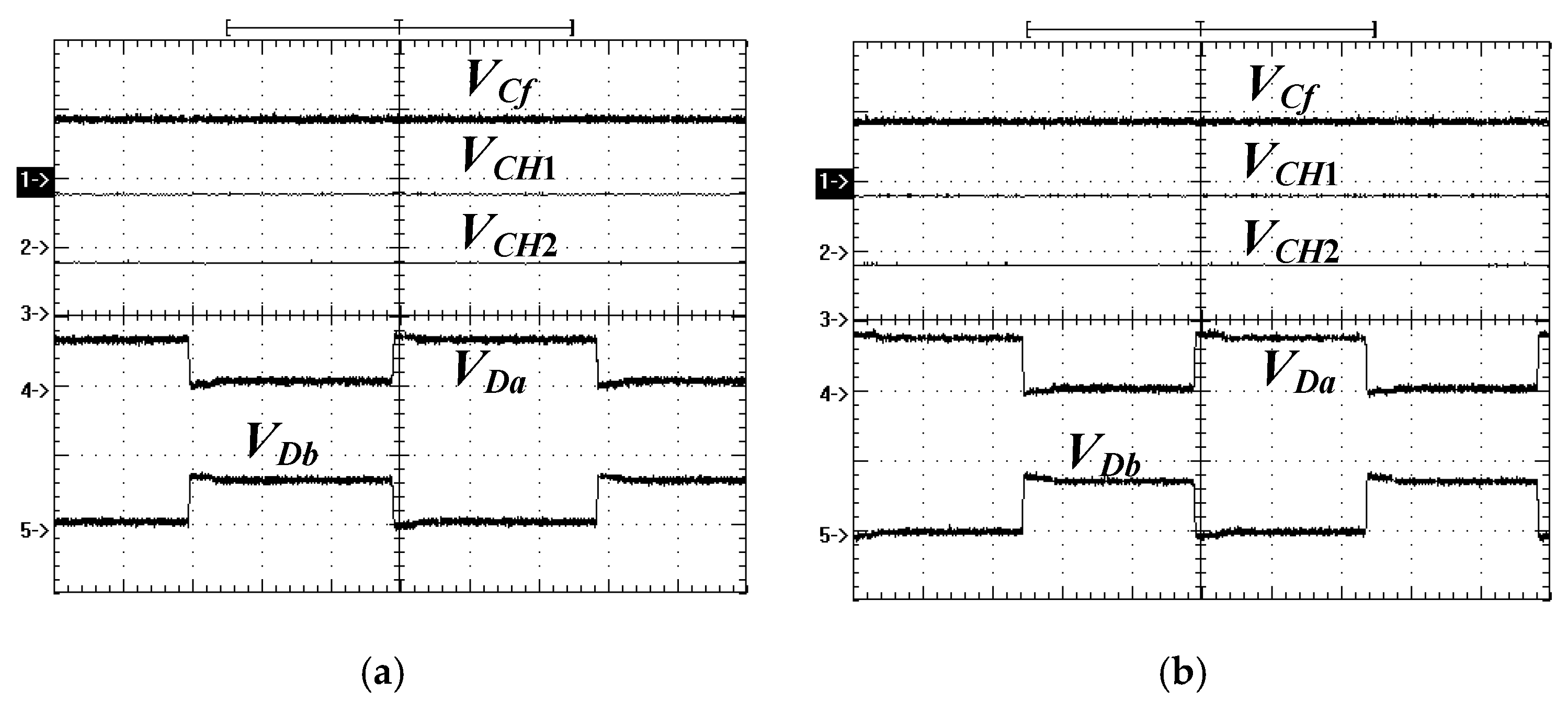

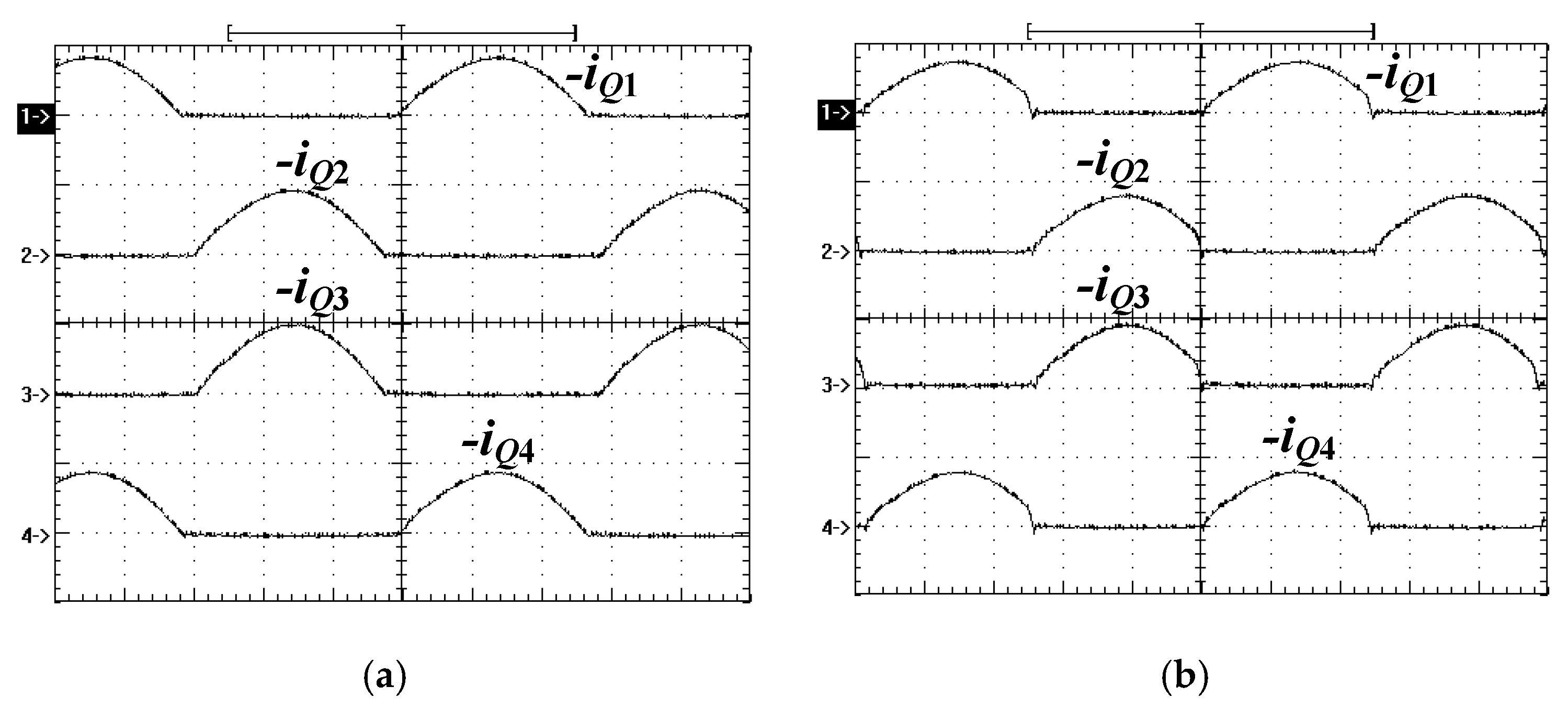

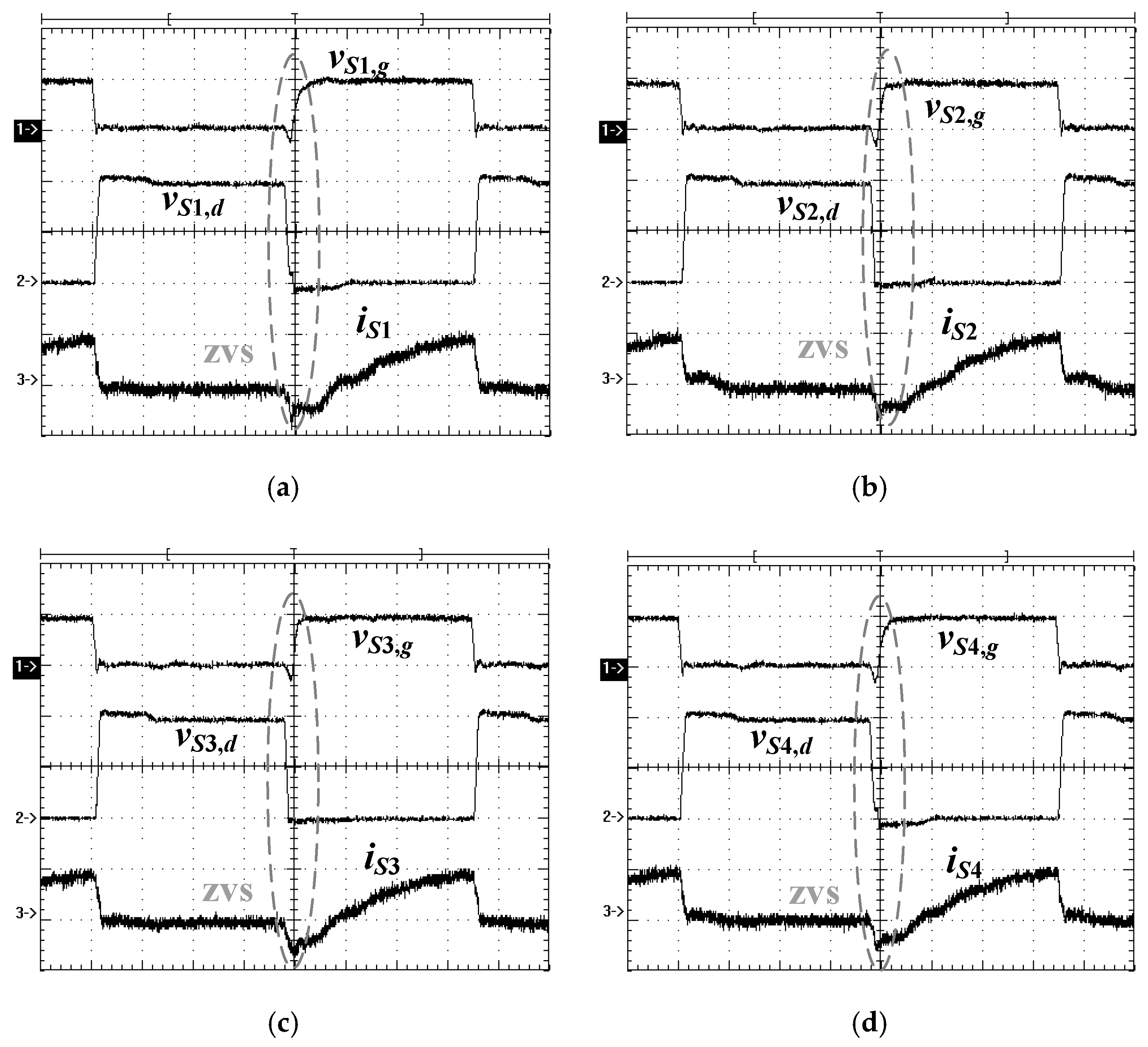

Figure 6,

Figure 7,

Figure 8,

Figure 9 and

Figure 10 provide the test results for forward power operation and

Figure 11,

Figure 12,

Figure 13 and

Figure 14 provide the measured waveforms for reverse power operation. The PWM signals of

S1–

S4 at 100% load are presented in

Figure 6.

S1 (

S3) and

S2 (

S4) have the same gate-to-source voltage signals. The converter at

VH = 750 V input has less switching frequency than

VH = 800 V input condition.

Figure 7 gives the experimental results of leg voltage

vab,

iLr and

vCr at 100% load. It can be seen that the measured waveforms

iLr and

vCr are almost the sinusoidal waves due to

fsw close to

fr for both 750 V and 800 V inputs.

Figure 8 shows the experimental results of

VCH1,

VCH2,

VCf,

VDa and

VDb. The dc voltage differences between

VCH1,

VCH2 and

VCf are about 5V.

Figure 9 demonstrates the switch currents of

Q1–Q4 at 100% load.

Figure 10 illustrates the PWM waveforms of

S1–

S4 at 20% load. It can observe that

S1–

S4 all turn on under ZVS at 20% load.

Figure 11 gives the PWM signals of

Q1~

Q4 under backward power operation and different input voltages. Power devices

Q1 (

Q2) and

Q4 (

Q3) have the same gate-to-source voltage signals.

Figure 12 illustrates the measured results of

iLr,

iLb and

vCr under for reverse power operation. The parallel inductor current

iLb is similar to the magnetizing current on conventional

LLC resonant converter to achieve voltage step-up capability.

Figure 13 shows the measured capacitor voltages

VCf,

VCH1 and

VCH2 on the high voltage side. These three voltages

VCH1,

VCH2 and

VCf are almost balanced with about 7 V voltage difference.

Figure 14 gives the measured PWM waveforms of

Q1~

Q4 under 20% load. It can observe that

Q1–

Q4 can turn on under zero voltage at 20% load. For forward power operation (buck mode), the measured circuit efficiencies are 89.7% at 20% load, 92.1% at 50% load and 91.8% at 100% load under 800 V input. For reverse power operation (boost mode), the measured circuit efficiencies are 86.3% at 20% load, 89.4% at 50% load and 88.9% at 100% load under 40 V input case.

Figure 15a gives the picture of the prototype circuit and the experimental setup is given in

Figure 15b.